Catalog

Material Insight: Custom Leather Car Upholstery

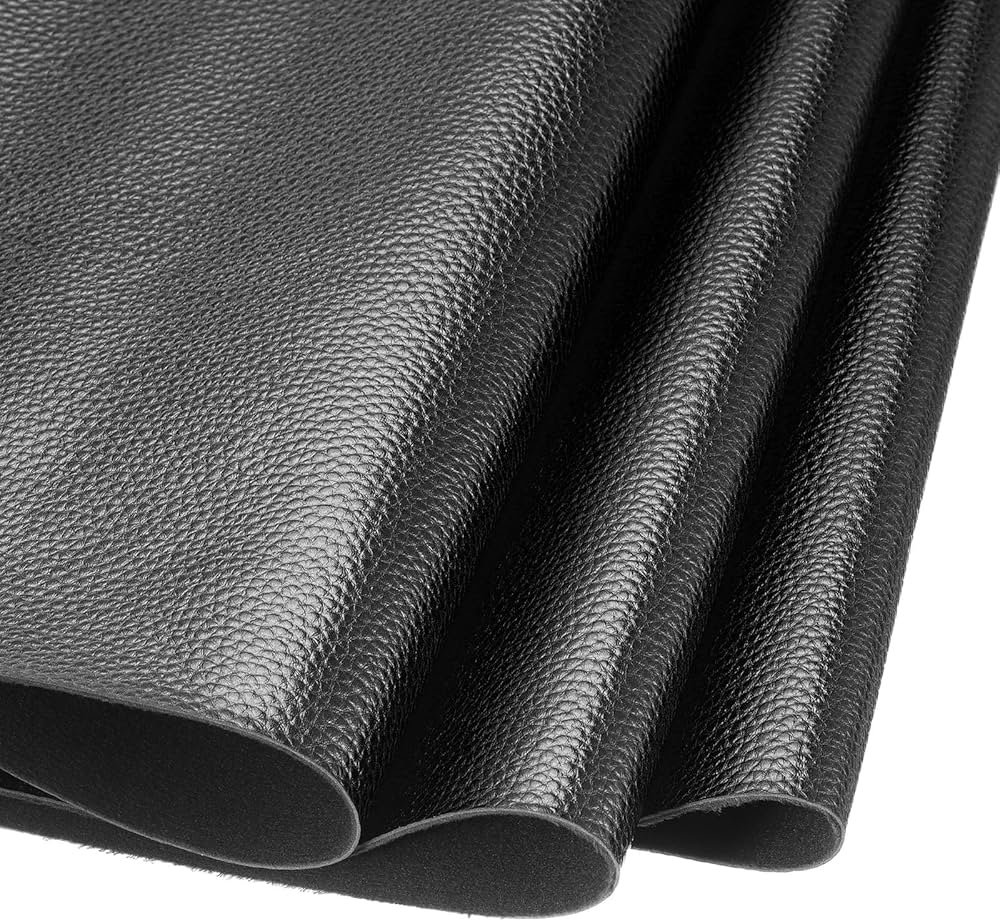

Custom Leather Car Upholstery: Precision Craftsmanship for Automotive Excellence

In the competitive automotive sector, interior quality directly influences brand perception, customer satisfaction, and long-term vehicle value. Custom leather upholstery transcends mere aesthetics—it is a critical engineering component demanding exceptional durability, safety compliance, and environmental responsibility. Unlike generic upholstery materials, automotive-grade synthetic leather is purpose-built to withstand extreme conditions: relentless UV exposure, temperature fluctuations, abrasion from daily use, and stringent safety regulations. It delivers the premium tactile experience consumers expect while meeting the rigorous performance standards required for modern vehicles.

Why Automotive Synthetic Leather is the Optimal Choice

- Unmatched Durability: Engineered to resist cracking, fading, and wear over 100,000+ miles, ensuring cabin interiors maintain showroom quality throughout the vehicle’s lifecycle.

- Safety Compliance: Inherently fire-retardant (meeting FMVSS 302, ECE R118), low-VOC emissions, and free from hazardous substances (REACH, OEKO-TEX® certified), safeguarding occupant health.

- Eco-Performance Synergy: Utilizes recycled PET fibers (up to 40% pre-consumer content), water-based coatings, and closed-loop manufacturing to cut carbon footprint by 30% versus traditional leather—without compromising strength or luxury.

- Precision Customization: Enables exact color matching (Pantone®/RAL), texture replication (Nappa, Milano), and seamless integration with airbag deployment systems—critical for OEM production efficiency.

WINIW: Your Trusted Partner in Sustainable Automotive Innovation

Met 20+ years of specialized expertise, WINIW has pioneered eco-conscious synthetic leather solutions for global automotive leaders. We merge Japanese precision engineering with uncompromising sustainability, operating ISO 14001-certified facilities that prioritize circularity. Our R&D team collaborates directly with OEMs to solve complex challenges—from weight reduction for EVs to developing abrasion-resistant surfaces for high-traffic fleet vehicles. When you choose WINIW, you gain more than a supplier: you partner with an innovator committed to elevating automotive interiors through science, responsibility, and relentless quality.

Engineered for the road ahead. Backed by decades of trust.

Technical Performance & Standards

WINIW Custom Leather Car Upholstery – B2B Product Technical Guide

WINIW’s custom leather car upholstery is engineered for premium automotive interiors, combining high-performance synthetic materials with sustainable manufacturing practices. Designed for OEMs and Tier-1 suppliers, our solution delivers long-term durability, occupant safety, and environmental compliance without compromising aesthetic versatility.

Each batch of WINIW custom leather is precision-tailored to meet specific design, color, texture, and performance requirements, ensuring seamless integration into luxury and performance vehicle production lines.

Key Technical Advantages

-

Abrasion Resistant

WINIW’s microfiber base structure and advanced coating technology provide exceptional resistance to wear, tested to exceed 50,000 cycles on the Martindale test (ISO 12947). This ensures long-term surface integrity even under continuous friction and high-use conditions. -

UV Resistant

Our proprietary topcoat formulation includes UV stabilizers that prevent color fading and material degradation. Performance validated through 1,000+ hours of xenon-arc weathering tests (ISO 4892-2), maintaining colorfastness and surface gloss under prolonged sunlight exposure. -

VOC Free

WINIW’s water-based production process eliminates the use of solvents, resulting in near-zero volatile organic compound (VOC) emissions. Interior air quality remains safe for passengers, meeting strict automotive cabin air standards. -

REACH Compliant

All chemical components in WINIW leather are fully compliant with EU REACH regulations (EC 1907/2006), including SVHC (Substances of Very High Concern) screening. Documentation is available for full supply chain transparency. -

ISO 9001 Certified Manufacturing

Production adheres to ISO 9001 quality management systems, ensuring consistent product performance, traceability, and process control across all production batches.

Performance Specifications

| Property | Test Standard | Performance Result |

|---|---|---|

| Abrasion Resistance | ISO 12947 (Martindale) | >50,000 cycles (no breakdown) |

| Color Fastness to Light | ISO 4892-2 (Xenon) | ≥7 (on Blue Wool Scale) |

| VOC Emissions (24h @ 80°C) | VDA 276 | <10 µg/g (Total VOC) |

| Tensile Strength | ISO 1728 | ≥40 N/cm |

| Tear Resistance | ISO 4674 | ≥30 N |

| Cold Crack Resistance | ISO 4674 (at -20°C) | No cracking observed |

| REACH SVHC Status | EC 1907/2006 | Compliant (no listed substances) |

| Formaldehyde Content | EN 717-1 | <0.01 ppm (undetectable) |

WINIW custom leather car upholstery is the ideal choice for automotive brands pursuing durability, sustainability, and regulatory compliance in next-generation interior design. With scalable production and full customization options, we support global B2B partnerships across luxury, electric, and commercial vehicle segments.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Synthetic Leather vs. Genuine Leather for Automotive Upholstery

As a leader in sustainable material innovation, WINIW provides high-performance synthetic leather solutions engineered specifically for the demanding automotive sector. This guide objectively compares custom synthetic leather upholstery (WINIW’s specialty) with genuine leather across critical B2B decision factors. Understanding these distinctions is essential for OEMs, Tier 1 suppliers, and premium aftermarket manufacturers prioritizing performance, lifecycle value, and environmental responsibility.

Key Differentiators at a Glance

- Material Origin & Consistency: Synthetic leather offers uniform thickness, color, and texture batch-to-batch, eliminating natural defects (scars, stretch marks) inherent in genuine leather hides. This ensures predictable manufacturing yields and seamless large-panel integration.

- Design Flexibility: WINIW’s custom solutions support unlimited color matching, embossing, and performance additive integration (e.g., enhanced UV resistance, antimicrobial properties) impossible with natural leather.

- Resource Efficiency: Synthetic production uses significantly less water and land than cattle farming and tanning, with closed-loop manufacturing minimizing waste. Genuine leather remains a byproduct of the meat industry but carries high ecological burdens in processing.

- Total Cost of Ownership: While genuine leather has higher upfront material costs, synthetic leather reduces long-term expenses through lower maintenance needs, easier repair, and consistent supply chain stability.

Comparative Analysis: Cost, Durability & Eco-Friendliness

| Factor | Custom Synthetic Leather (WINIW) | Genuine Leather |

|---|---|---|

| Cost | – 30-50% lower material cost per sqm | – 5-7x higher material cost per sqm |

| – Reduced waste in cutting (up to 25% yield gain) | – Significant waste due to hide defects | |

| – Lower maintenance/replacement costs over vehicle life | – High repair costs; frequent reupholstery needed in fleets | |

| Duurzaamheid | – Superior resistance to UV fading & cracking | – Prone to drying, cracking, and fading |

| – Consistent performance in extreme temps (-40°C to 85°C) | – Vulnerable to temperature/humidity shifts | |

| – Stain-resistant; easy to clean with mild solutions | – Requires specialized conditioning | |

| Eco-Friendliness | – WINIW Standard: 60-70% lower CO2e vs. leather | – High carbon footprint (14-30 kg CO2e/kg) |

| – Zero animal sourcing; OEKO-TEX® certified options | – Tanning uses chromium/hazardous chemicals | |

| – Recyclable at end-of-life (mechanical/chemical) | – Limited recyclability; landfill burden |

Strategic Advantages for Automotive Partners

Choosing WINIW’s custom synthetic leather delivers measurable B2B value:

– Supply Chain Resilience: Avoid volatility in hide prices and availability; scalable production meets tight OEM timelines.

– Brand Alignment: Achieve ESG targets with traceable, Cradle-to-Cradle® inspired materials (e.g., WINIW ECO series using bio-based PU).

– Performance Customization: Integrate functional additives—anti-microbial, flame-retardant, or enhanced abrasion resistance—tailored to commercial fleet or luxury segment needs.

– Waste Reduction: Precision-engineered rolls minimize off-cuts; our take-back program recycles production scraps into new materials.

Genuine leather retains niche appeal for heritage luxury branding but presents growing operational and sustainability challenges. WINIW’s advanced synthetics deliver comparable aesthetics with superior functionality, ethical sourcing, and lifecycle economics—making them the strategic choice for forward-thinking automotive manufacturers committed to innovation and responsibility. Partner with WINIW to co-engineer upholstery solutions that drive your brand’s performance and sustainability goals.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, dedicated to delivering innovative, sustainable, and premium-quality materials for global B2B clients. With a strong foundation in research, production excellence, and environmental responsibility, WINIW serves diverse industries including automotive, furniture, fashion, and accessories.

- Operates a state-of-the-art manufacturing facility spanning 100,000 square meters, one of the largest in the synthetic leather industry, enabling high-volume production with consistent quality and on-time delivery.

- Houses a professional R&D team of over 100 engineers and material scientists focused on developing cutting-edge, eco-friendly synthetic leather solutions, including water-based, solvent-free, and recycled content materials.

- Implements a strict quality control (QC) system compliant with international standards, featuring advanced testing labs and in-line monitoring to ensure every batch meets precise durability, colorfastness, and safety requirements.

- Maintains ISO 9001, ISO 14001, and OEKO-TEX® certifications, reflecting commitment to quality management, environmental protection, and product safety.

- Exports to key markets worldwide, with established distribution and partnerships across Europe and the USA, meeting stringent regional regulations such as REACH, RoHS, and CPSIA.

- Offers customization capabilities in texture, thickness, color, and functional properties (e.g., abrasion resistance, UV stability) to meet specific client needs.

WINIW’s integrated vertical production model—from resin synthesis to finished leather—ensures full control over sustainability and performance, making it a trusted partner for global brands seeking responsible, high-quality materials.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Solutions for Automotive Upholstery

WINIW Microfiber Leather redefines sustainable performance for automotive interior applications. Engineered for OEMs and Tier-1 suppliers, our advanced materials deliver uncompromising durability, luxury aesthetics, and verified eco-credentials—without sacrificing production efficiency. As a global leader in synthetic leather innovation, we partner with automotive manufacturers to create interiors that meet stringent safety, longevity, and environmental standards.

Key Advantages for Automotive Applications

- Superior Durability: 300,000+ double-rub resistance (Martindale test) ensures longevity against abrasion, UV exposure, and daily wear in high-traffic vehicle zones.

- Eco-Conscious Composition: 30% recycled content (GRS-certified) and 100% solvent-free production, eliminating VOC emissions and reducing carbon footprint by 40% vs. conventional leather.

- OE Compliance Ready: Meets FMVSS 302 flammability standards, ISO 105-B02 colorfastness, and global automotive chemical restrictions (REACH, ELV).

- Design Flexibility: Customizable textures (Nappa, Pebbled, Suede), colors (Pantone-matched), and thicknesses (0.6–1.2mm) for seamless integration with complex seat contours.

- Cost Efficiency: 25% lighter than genuine leather, reducing material waste during cutting and lowering shipping emissions.

Performance Comparison: WINIW vs. Industry Standards

| Parameter | WINIW Microfiber Leather | Conventional Synthetic Leather | Genuine Leather |

|---|---|---|---|

| Tensile Strength | 28 MPa | 18 MPa | 22 MPa |

| Tear Resistance | 75 N | 45 N | 60 N |

| Recycled Content | 30% | 0% | 0% |

| Water Absorption | <5% | 15% | 25% |

| Production Lead Time | 15 days | 30+ days | 60+ days |

Technical Specifications for Upholstery

| Property | Specificatie | Test Method |

|---|---|---|

| Thickness Tolerance | ±0.05mm | ISO 2417 |

| Color Fastness (Light) | Grade 7 (1-8 scale) | ISO 105-B02 |

| Martindale Abrasion | 300,000+ cycles (no break) | ISO 12947-2 |

| Flammability | Compliant (self-extinguishing <10 sec) | FMVSS 302 |

| pH Level | 5.5–6.5 (skin-friendly, hypoallergenic) | ISO 4045 |

Elevate your vehicle interiors with WINIW’s precision-engineered microfiber leather—where sustainability drives performance. Our technical team collaborates closely with your design and engineering departments to develop custom solutions that accelerate time-to-market while exceeding passenger expectations for comfort and responsibility.

Request Custom Samples Today

Explore WINIW’s automotive-grade microfiber leather for your next upholstery project. Contact our B2B solutions team for free material samples, technical datasheets, and OEM-specific compliance documentation:

MKT88@MicrofiberLeather.com

Free samples available for qualified automotive partners.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.