Catalog

Material Insight: Faux Stretch Leather

B2B Product Guide: Faux Stretch Leather

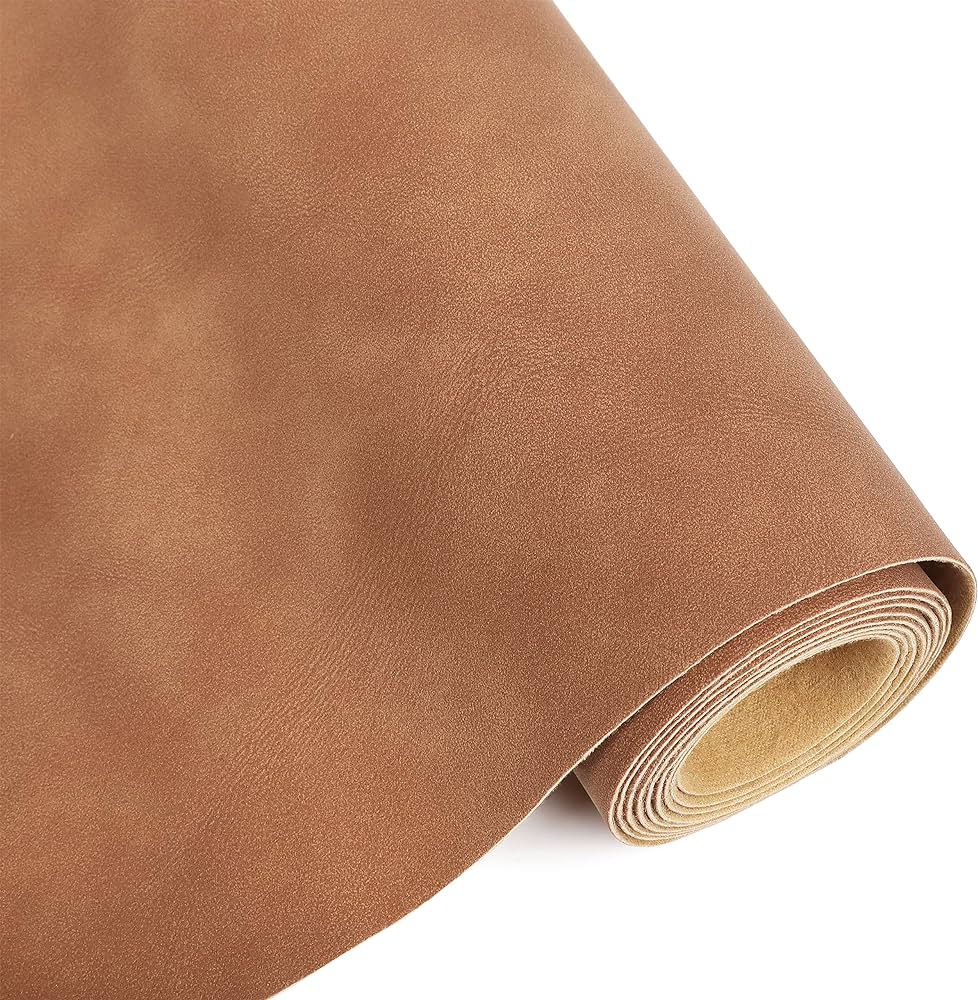

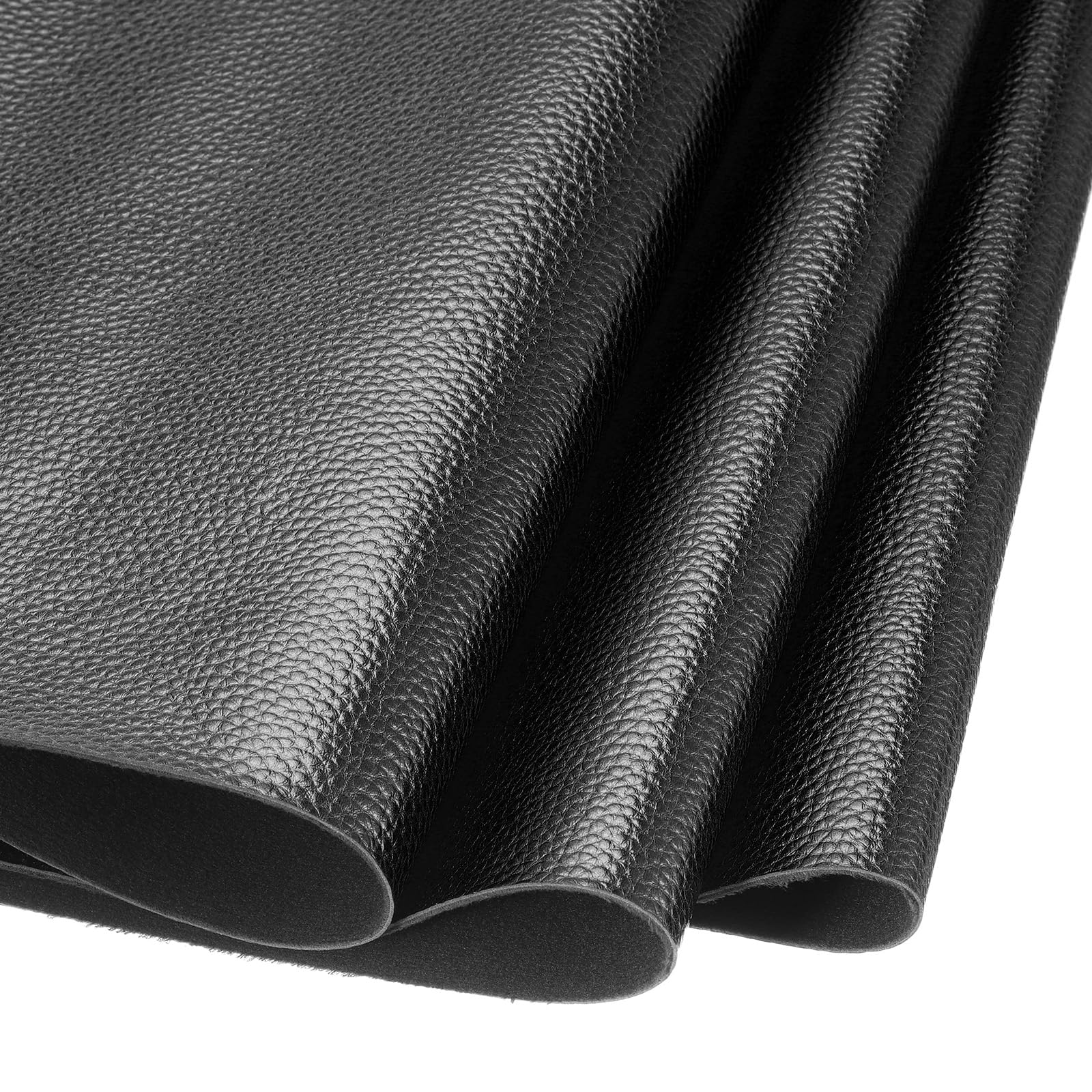

Faux stretch leather has emerged as a high-performance alternative to traditional leather in a wide range of applications, including upholstery, automotive interiors, apparel, and footwear. Engineered for flexibility, durability, and aesthetic versatility, this advanced synthetic material combines the luxurious look and feel of genuine leather with enhanced functional benefits such as elasticity, consistent thickness, and improved process efficiency. Unlike natural leather, faux stretch leather offers uniform quality across batches, making it ideal for high-volume manufacturing where precision and repeatability are critical.

Why is Faux Leather the Best Choice for This Application?

Faux stretch leather outperforms traditional materials in several key areas:

- Superior Elasticity and Recovery: Designed with built-in stretch, it conforms comfortably to complex shapes and repeated movement, making it ideal for form-fitting furniture, automotive seating, and performance apparel.

- Consistent Quality and Availability: Unlike natural leather, which varies in grain, thickness, and yield, faux stretch leather delivers uniform performance and appearance, reducing waste and improving production efficiency.

- Cost-Effective at Scale: With stable raw material sourcing and streamlined production, it offers predictable pricing and lower total cost of ownership for large-scale B2B operations.

- Sustainability Advantage: Free from the environmental burdens of animal farming and heavy tanning processes, high-quality faux stretch leather supports eco-conscious manufacturing and ESG goals.

- Design Flexibility: Available in a wide range of colors, textures, and finishes, it enables rapid customization to meet brand-specific requirements without long lead times.

At WINIW, we have over 20 years of specialized experience in developing premium synthetic leather solutions for global B2B clients. As an innovator in microfiber and PU-based materials, we combine advanced coating technologies, sustainable practices, and rigorous quality control to deliver faux stretch leather that meets the highest industry standards. Our products are engineered for durability, comfort, and environmental responsibility—making WINIW a trusted partner for forward-thinking manufacturers seeking reliable, scalable, and eco-friendly materials.

Technical Performance & Standards

WINIW Faux Stretch Leather: Technical Product Guide for B2B Applications

WINIW Faux Stretch Leather delivers a premium, high-performance alternative to genuine leather, engineered specifically for demanding commercial and industrial applications. Designed to overcome the cost volatility, inconsistency, and ethical concerns of animal hides, our solution provides manufacturers with a reliable, eco-conscious material that meets rigorous performance standards without compromising on aesthetics or functionality. Below are the core technical advantages driving adoption across furniture, automotive, and fashion sectors.

Key Technical Advantages

- Cost-Effective Performance: Eliminates price fluctuations inherent in genuine leather supply chains. Our consistent production process reduces material waste by up to 30% during cutting due to uniform grain and absence of natural defects, directly lowering per-unit manufacturing costs.

- Enhanced Durability: Features a proprietary polyurethane (PU) topcoat bonded to a high-tenacity polyester knit backing, achieving 50,000+ double rubs (Martindale test) and 150% tensile strength retention after 10,000 stretch cycles. Resists cracking, peeling, and UV degradation for extended product lifecycles.

- Precision Color Customization: Leverages digital color matching (Pantone®/RAL) with batch-to-batch color consistency (ΔE < 0.5). Offers rapid turnaround for custom color development (2–3 weeks) and seamless scalability from prototypes to mass production without minimum order constraints.

- REACH & Eco-Compliance: Fully compliant with EU REACH Regulation (SVHC-free) and Prop 65. Utilizes water-based, solvent-free coating systems, eliminating DMF, APEOs, and heavy metals. Contributes to LEED and BREEAM points for sustainable interior projects.

- Certified Quality Assurance: Manufactured under ISO 9001-certified processes ensuring stringent control over thickness tolerance (±0.1mm), colorfastness (Grade 4–5 for light/rub/water), and dimensional stability (< 2% shrinkage at 70°C).

Technical Specifications Comparison

| Property | WINIW Faux Stretch Leather | Industry Standard PU Leather |

|---|---|---|

| Thickness Range | 0.6mm – 1.2mm | 0.8mm – 1.5mm |

| Tensile Strength | ≥ 25 N/mm² | 18 – 22 N/mm² |

| Elongation at Break | 180% – 220% | 120% – 160% |

| Martindale Abrasion | 50,000+ cycles (no wear) | 20,000 – 30,000 cycles |

| Colorfastness (Light) | ISO 105-B02: Grade 7–8 | Grade 5–6 |

| REACH Compliance | Fully compliant (SVHC-free) | Varies by supplier |

| Production Lead Time | 15–20 days (custom orders) | 30–45 days |

WINIW Faux Stretch Leather empowers B2B partners to achieve design flexibility, supply chain resilience, and uncompromised sustainability. Our ISO 9001-certified production ensures every meter meets exacting performance criteria while supporting circular economy goals through end-of-life recyclability programs. Request a technical datasheet or sample swatch kit to validate performance against your specific application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Faux Stretch Leather vs. Real Leather

When selecting materials for upholstery, apparel, or accessories, manufacturers and designers must balance performance, cost, and sustainability. Two commonly compared materials are faux stretch leather and real leather. Each offers distinct advantages depending on application, target market, and environmental goals.

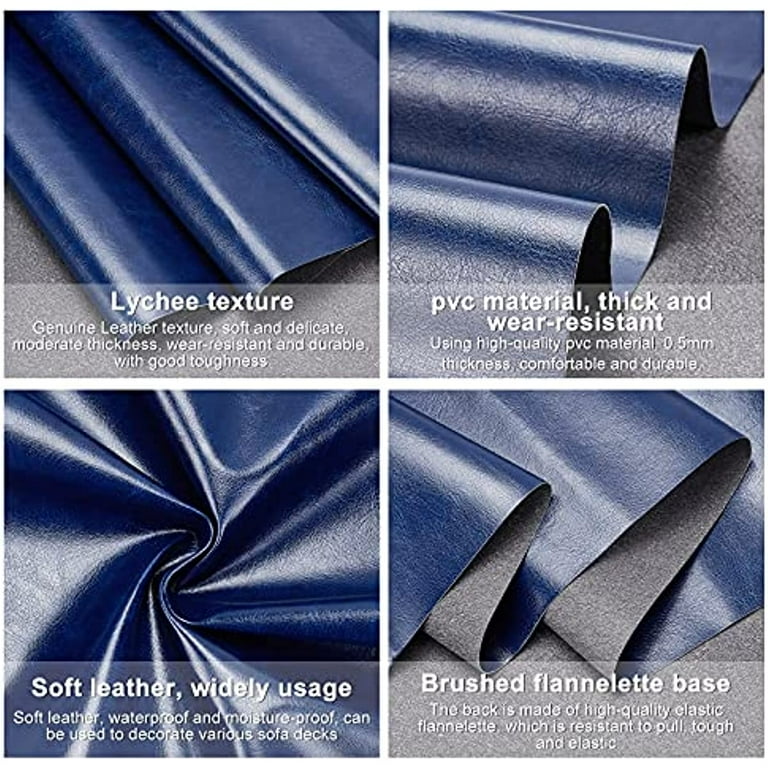

Faux stretch leather—often made from polyurethane (PU) with added elastane or spandex—delivers flexibility, consistent texture, and design versatility. It is engineered to mimic the look and feel of real leather while offering enhanced stretch and ease of maintenance. Real leather, derived from animal hides, is valued for its natural grain, breathability, and long-term aging characteristics. However, it involves higher costs and environmental considerations.

Below is a comparative analysis of the two materials across key business-relevant metrics:

| Criteria | Faux Stretch Leather | Real Leather |

|---|---|---|

| Cost | Lower upfront cost; scalable production | Higher cost due to sourcing and processing |

| Duurzaamheid | Resistant to fading and staining; may show wear over time with heavy use | Highly durable; develops patina with age; susceptible to moisture damage |

| Eco-Friendliness | PU-based versions have improved; recyclable options available; lower carbon footprint in production | High environmental impact from tanning and livestock; biodegradable but resource-intensive |

Key Differences and Business Considerations:

- Faux stretch leather supports consistent batch production, reducing waste and streamlining manufacturing.

- Real leather offers premium tactile qualities and is often preferred in luxury markets, though supply chain transparency is increasingly scrutinized.

- Faux stretch leather is ideal for performance-driven applications such as activewear, automotive interiors, and modern furniture requiring flexibility.

- Real leather requires specialized care and conditioning, impacting long-term maintenance costs for end users.

- From a sustainability perspective, advanced faux leathers like those developed by WINIW utilize eco-conscious processes and reduced solvent use, aligning with circular economy goals.

For B2B partners focused on innovation, scalability, and environmental responsibility, high-performance faux stretch leather presents a competitive alternative to traditional leather—without compromising on aesthetics or functionality.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a leading manufacturer of premium synthetic leather, engineered to meet the stringent demands of global brands in furniture, automotive, fashion, and technical applications. Our vertically integrated manufacturing ecosystem, built on scale, innovation, and uncompromising quality, ensures reliable partnership for volume-driven B2B clients.

Core Manufacturing Strengths

- 100,000 sqm Advanced Production Hub: Our state-of-the-art facility in China integrates coating, finishing, and inspection under one roof, enabling end-to-end process control and rapid scaling for orders exceeding 500,000 linear meters monthly.

- Dedicated R&D Team: 50+ material scientists and engineers continuously innovate within our ISO 17025-certified lab, developing eco-conscious solutions (e.g., water-based PU, recycled PET substrates) and custom formulations for performance, durability, and regulatory compliance.

- Strict Quality Control Protocol: Every meter undergoes 12+ automated and manual checkpoints, from raw material screening to final roll inspection. This ensures zero-defect shipment rates exceeding 99.8% for global clients.

Global Compliance & Sustainability

WINIW products consistently meet the highest international standards for safety and environmental responsibility, critical for entry into regulated markets:

| Region | Key Compliance Frameworks | WINIW Certification Highlights |

|---|---|---|

| Europe | REACH, OEKO-TEX® STANDARD 100 | Phthalate-free, heavy metal compliant (EN 71-3) |

| USA | CPSIA, CA Prop 65 | Formaldehyde-free, lead-safe (<90ppm) |

| Global | ISO 14001, ZDHC MRSL Level 3 | LEED-certified facility, 30%+ recycled content options |

Our commitment to eco-efficiency extends beyond compliance: closed-loop water systems reduce consumption by 40%, and bio-based PU innovations lower carbon footprint by 25% versus conventional synthetics. WINIW delivers not just material, but documented chain-of-custody traceability and audit-ready sustainability reporting for seamless integration into your ESG programs.

Partner with WINIW for scalable supply, innovation agility, and risk-mitigated sourcing—where industrial capacity meets environmental stewardship.

Contact Us for Samples

B2B Product Guide: WINIW™ Faux Stretch Leather

WINIW specializes in high-performance, eco-friendly synthetic leather solutions designed for demanding applications across fashion, footwear, automotive, and upholstery industries. Our Faux Stretch Leather line combines superior elasticity, durability, and aesthetic versatility—offering a sustainable alternative to traditional leather without compromising on quality or performance.

Engineered with advanced microfiber technology, WINIW Faux Stretch Leather delivers consistent thickness, excellent tensile strength, and outstanding recovery after elongation. Ideal for form-fitting designs and dynamic applications, this material supports modern manufacturing needs while aligning with global sustainability goals.

Key Features

- High elasticity with excellent recovery (up to 150% stretch recovery depending on substrate)

- Soft hand feel with a natural leather-like drape and appearance

- Breathable, lightweight construction suitable for performance wear and seating

- Superior color fastness and abrasion resistance (tested to ISO 11640 and Martindale standards)

- Eco-conscious production: free from phthalates, AZO dyes, and heavy metals

- Available in custom thicknesses (0.6mm–1.2mm), widths (up to 1.83m), and finishes (matte, glossy, embossed)

Recommended Applications

- Stretchable footwear uppers and linings

- Athletic and activewear apparel

- Upholstered furniture with curved or contoured frames

- Automotive interior trim and armrests

- Bags and accessories requiring flexibility and resilience

Technical Specifications (Typical Values)

| Property | Test Method | Value |

|---|---|---|

| Thickness | ISO 2418 | 0.8 mm ±0.1 |

| Tensile Strength (MD) | ISO 13934-1 | ≥ 90 N/5cm |

| Elongation at Break (MD) | ISO 13934-1 | ≥ 180% |

| Martindale Abrasion | ISO 12947 | ≥ 30,000 cycles |

| Color Fastness to Rubbing | ISO 105-X12 | Grade 4–5 (wet/dry) |

| PH Value | ISO 4045 | 4.0–7.5 |

All products comply with REACH, RoHS, and OEKO-TEX® STANDARD 100 requirements.

Why Choose WINIW Faux Stretch Leather?

- Custom development support for color, texture, and performance

- Scalable production with short lead times and global shipping

- Environmentally responsible: recyclable backings and low-VOC emissions

- Consistent batch-to-batch quality for reliable manufacturing output

Free samples are available for qualified B2B partners to evaluate performance and suitability for your specific application.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your product line with stretchable, sustainable innovation—choose WINIW Faux Stretch Leather.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.