When I choose a pvc football manufacturer for my soccer business, I always focus on three essentials: proven quality, transparent processes, and a strong industry reputation. I start by listing my business needs, such as order volume, customization options, budget, and sustainability goals. I recommend aiming for long-term value and reliable partnerships instead of just chasing the lowest price.

- Proven quality ensures durability.

- Transparent processes build trust.

- Industry reputation reflects consistency.

Key Takeaways

- Identify your business needs before choosing a PVC football manufacturer. Consider order volume, customization, budget, and sustainability goals.

- Evaluate manufacturers based on material quality and performance standards. Look for certifications like ISO 9001 and FIFA Quality to ensure reliability.

- Request samples to test the feel and durability of soccer balls. This hands-on approach helps you make informed decisions before placing a large order.

- Communicate clearly with manufacturers. Prompt responses and detailed information build trust and help avoid misunderstandings.

- Watch for red flags like inconsistent quality and poor communication. These signs can indicate potential issues with the manufacturer.

Define Your Needs for PVC Soccer Balls

Before I approach any manufacturer, I clarify my business requirements for pvc soccer balls. This step helps me avoid costly mistakes and ensures I select the right partner for my soccer business.

Order Volume & MOQ

I always start by estimating my order volume. Manufacturers set minimum order quantities (MOQ) for pvc soccer balls, which directly impacts pricing. When I commit to larger orders, I benefit from lower per-unit costs. Established manufacturers prefer bulk orders because they improve production efficiency and offer better quality assurance. Smaller orders often come with higher prices and fewer options, so I weigh my needs carefully.

Customization Options

Customization is essential for branding and meeting specific soccer league requirements. I consider how much customization I need, such as logos, colors, or special designs. Customizing pvc soccer balls can extend lead times, sometimes up to 90 days, due to extra design and production steps. Costs also vary based on the level of customization and order size. I always ask about setup fees and production timelines before finalizing my order.

Budget & Pricing

Budget planning is critical. I analyze the pricing structure for pvc soccer balls by looking at several factors:

- Production costs depend on the materials used.

- Advanced features or smart technology increase prices.

- Well-known brands charge more for their soccer products.

- Market demand can push prices higher.

I compare quotes from different manufacturers and check for hidden costs, such as shipping or customization fees.

Delivery Timelines

Reliable delivery timelines keep my soccer business running smoothly. I ask manufacturers for clear estimates and track record on delivering pvc soccer balls. Custom orders usually take longer, so I plan ahead to avoid delays during peak soccer seasons.

Sustainability Goals

Sustainability matters to me and my customers. I look for manufacturers who use eco-friendly materials, like recycled plastics or natural fibers, in their pvc soccer balls. Regulatory changes now require greener practices, so I choose partners who meet these standards. This approach aligns with my values and meets growing consumer demand for sustainable soccer products.

Tip: I create a simple table to compare manufacturers on MOQ, customization, pricing, delivery, and sustainability. This helps me make informed decisions and select the best pvc soccer balls for my business.

| Criteria | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| MOQ | 500 | 1000 | 200 |

| Customization | Yes | Yes | Limited |

| Pricing | Moderate | Low | Hoog |

| Delivery | 60 days | 90 days | 45 days |

| Sustainability | Yes | No | Yes |

Evaluating PVC Football Manufacturer Quality

When I evaluate a pvc football manufacturer, I always start with a deep dive into the materials and construction methods. The right material selection and strict quality standards make all the difference in soccer ball performance and durability. Here’s how I break down the process:

Material Selection (PVC, PU, Synthetic Leather)

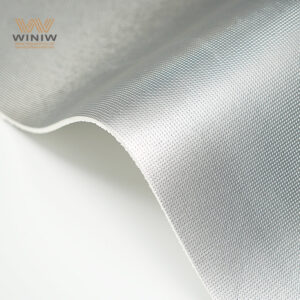

I always pay close attention to the material used in soccer ball construction. The choice of material impacts both durability and performance. When I compare soccer ball materials, I look at three main options: pvc, polyurethane (PU), and synthetic leather.

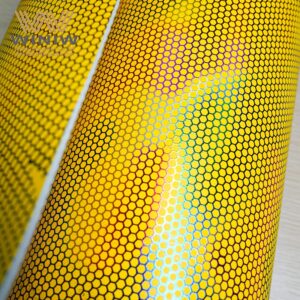

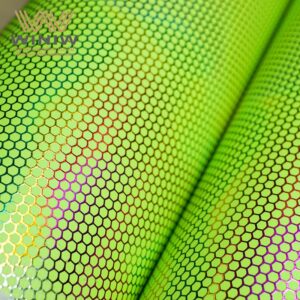

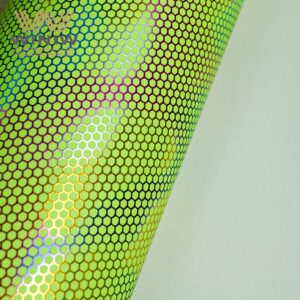

- PVC: This material offers the best value for training and recreational soccer balls. The advantages of pvc construction include water resistance, easy cleaning, and affordability. I find pvc balls last longer in rough conditions, making them ideal for schools and community leagues.

- PU: Polyurethane provides a softer touch and better ball control. I recommend PU for players who want a high-performance material for matches. However, PU balls can wear out faster on hard surfaces.

- Synthetic Leather: This advanced material combines the benefits of both pvc and PU. Professional match balls often use synthetic leather for superior feel and consistent flight.

When I compare soccer ball materials, I always ask manufacturers for a detailed material comparison. I want to know how materials impact performance and durability. The right choice depends on the intended use—training, matches, or professional play.

Note: Always request a sample to test the feel and bounce. This helps you understand how materials impact performance before placing a large order.

Performance Standards

Performance is non-negotiable for me. I expect every pvc football manufacturer to meet strict performance standards. These standards cover shape retention, air retention, bounce, and flight stability. I check if the soccer balls pass FIFA or IMS tests, especially for professional match balls.

I also look for consistency in performance across batches. A high-quality soccer ball should deliver the same experience every time. I ask manufacturers about their testing protocols and how they ensure each ball meets the required performance benchmarks.

- Shape retention: The ball should keep its round shape after repeated kicks.

- Air retention: The bladder and valve must prevent leaks.

- Bounce: The ball should rebound within a specific range.

- Flight: The construction and materials must support stable flight.

I believe that advanced materials and precise construction techniques lead to better performance and longer durability.

Manufacturing Certifications

Certifications give me confidence in a manufacturer’s commitment to quality. I always check if the pvc football manufacturer holds ISO 9001 or similar certifications. These standards prove that the company follows strict quality management systems.

For soccer balls used in official matches, I look for FIFA Quality Pro or IMS certifications. These labels guarantee that the ball meets international performance and safety standards. I also ask about compliance with environmental regulations, especially if I have sustainability goals.

Tip: Certifications are not just paperwork. They show that the manufacturer invests in quality processes and advanced materials.

Quality Control

Quality control is the backbone of any reliable pvc football manufacturer. I want to see clear quality control procedures at every stage of production. This includes raw material inspection, in-process checks, and final product testing.

I ask manufacturers to share their quality control checklist. I want to know how they handle defects, how often they test for performance, and what steps they take to ensure consistent durability. For professional match balls, I expect even stricter controls and more frequent testing.

A strong quality control system reduces the risk of receiving defective soccer balls. It also ensures that every batch meets my expectations for performance and durability.

Here’s a quick checklist I use when evaluating a manufacturer’s quality control:

| Quality Control Step | What I Look For |

|---|---|

| Raw Material Inspection | Consistent material quality |

| In-Process Checks | Regular testing during construction |

| Final Product Testing | Performance and durability tests |

| Defect Handling | Clear process for managing rejects |

| Batch Consistency | Uniform quality across all soccer balls |

By focusing on material selection, performance standards, certifications, and quality control, I make sure I choose a pvc football manufacturer who delivers the best value and reliability. I never compromise on quality because it directly affects my reputation and customer satisfaction.

Assessing Reliability & Support

Reputation & Experience

When I select a pvc football manufacturer, I always research their reputation in the soccer industry. I look for companies with years of experience producing soccer balls. A long history often means the manufacturer understands the demands of soccer clubs and retailers. I check online reviews and industry awards. I also ask other soccer professionals about their experiences. Reliable manufacturers usually have strong relationships with soccer organizations and maintain high standards for product maintenance.

Client References

I request client references before making any commitment. Speaking directly with other soccer business owners gives me valuable insights. I ask about order accuracy, delivery reliability, and product maintenance. I want to know if the manufacturer responds quickly to issues and supports soccer teams with replacement balls or repairs. Honest feedback from current clients helps me avoid costly mistakes and ensures my soccer business receives consistent support.

Tip: I create a list of questions for references, focusing on soccer ball quality, order fulfillment, and maintenance support.

After-Sales Service

After-sales service plays a critical role in my decision. I expect the manufacturer to offer clear maintenance instructions for soccer balls. I ask if they provide repair kits or replacement parts. Good after-sales service includes fast responses to warranty claims and guidance on proper soccer ball maintenance. I prefer manufacturers who offer training materials for soccer coaches and players. This support helps extend the life of every soccer ball and keeps my business running smoothly.

| After-Sales Service | What I Expect |

|---|---|

| Maintenance Guides | Clear instructions provided |

| Repair Kits | Available for purchase |

| Warranty Support | Fast claim processing |

| Training Materials | For soccer coaches/players |

Communication Responsiveness

Effective communication matters to me. I test how quickly the manufacturer replies to my soccer inquiries. I want clear answers about order status, maintenance procedures, and technical details. Responsive communication builds trust and helps me solve soccer ball issues before they affect my business. I prefer manufacturers who assign a dedicated contact person for ongoing support and maintenance questions.

Note: I always keep records of my communication with the manufacturer. This helps me track soccer ball orders and maintenance requests efficiently.

Comparing Pricing & Value

Price Structure

When I compare price structures between manufacturers, I always look beyond the initial quote. I ask for a detailed breakdown of costs for each soccer ball. This includes the base price, customization fees, and charges for premium materials. Some manufacturers offer tiered pricing based on order volume. I find that larger orders often reduce the per-unit cost, especially for pvc soccer balls. I also check if the price includes packaging and shipping. A transparent price structure helps me plan my budget and avoid surprises.

| Price Component | What I Check |

|---|---|

| Base Ball Cost | Standard pvc soccer ball |

| Customization Fees | Logos, colors, designs |

| Premium Materials | PU, synthetic leather |

| Packaging | Included or extra |

| Shipping | Domestic or international |

Hidden Costs

Hidden costs can disrupt my soccer business. I always ask manufacturers to clarify any extra charges. Common hidden costs include rush order fees, sample charges, and import duties. Some companies add costs for special materials or expedited shipping. I review contracts carefully to spot these fees. I also ask about warranty coverage and replacement policies. By identifying hidden costs early, I protect my profit margins and avoid unexpected expenses.

Tip: I create a checklist of possible hidden costs before signing any agreement with a pvc soccer ball manufacturer.

- Rush order fees

- Sample charges

- Import duties

- Premium materials surcharges

- Expedited shipping

Value-Added Services

Value-added services set top manufacturers apart. I look for companies that offer design support, packaging customization, and logistics assistance. Some manufacturers provide soccer ball maintenance guides or training materials for coaches. These services improve the overall value of my order. I also appreciate after-sales support, such as warranty claims and replacement parts. When a manufacturer invests in value-added services, I know they care about long-term partnerships and customer satisfaction.

Note: I always ask about available value-added services when comparing manufacturers. These extras can make a big difference in the success of my soccer business.

Making the Right Choice

Shortlisting Manufacturers

I always begin making the right choice by narrowing my list of potential partners. I compare each pvc football manufacturer based on their track record, product range, and ability to meet my soccer business needs. I use a table to score each company on materials quality, customization, and delivery reliability. This process helps me focus on those who consistently deliver high-quality soccer balls and understand the importance of durable materials.

| Criteria | Manufacturer X | Manufacturer Y | Manufacturer Z |

|---|---|---|---|

| Materials | Excellent | Good | Excellent |

| Customization | Yes | Limited | Yes |

| Delivery | On Time | Delayed | On Time |

Requesting Samples

Before I select the perfect ball for my soccer program, I always request samples. I test each sample for feel, bounce, and durability. I check the stitching, the quality of the pvc, and the consistency of the materials. I also ask my team to use the balls in real soccer drills. This hands-on approach reveals how the materials perform under pressure. I keep notes on air retention and surface grip, which are critical for soccer training and matches.

Tip: I recommend testing samples in different weather conditions to see how the materials respond.

Negotiating Terms

Once I find a manufacturer who meets my standards, I move to negotiating terms. I discuss pricing, payment schedules, and delivery timelines. I make sure the contract covers materials specifications and quality guarantees. I ask for clear terms on returns and replacements if the soccer balls do not meet expectations. I always clarify who covers shipping costs and how warranty claims work.

Placing a Trial Order

I never commit to a large order without a trial. I place a small order to evaluate the manufacturer’s consistency and service. I track how quickly they deliver and whether the soccer balls match the approved samples. I inspect the materials and test the balls in real soccer games. This step confirms I am making the right choice for my business and ensures I work with a reliable partner who values quality.

Making the right choice requires careful evaluation at every step. By focusing on materials, testing samples, and negotiating clear terms, I set my soccer business up for long-term success.

Red Flags in PVC Manufacturer Selection

When I evaluate a pvc football manufacturer, I watch for warning signs that could jeopardize my business. Spotting these red flags early helps me avoid costly mistakes and ensures I work with reliable partners.

Inconsistent Quality

I notice inconsistent quality when soccer balls from the same batch show differences in stitching, material thickness, or bounce. This issue signals poor production control and a lack of attention to detail. I always inspect samples from multiple batches. If I see variations, I question the manufacturer’s commitment to durability and long-term performance. Consistency matters because my customers expect every ball to meet the same standards.

Tip: I keep a simple checklist to track quality issues. If I find more than one defect in a batch, I reconsider my supplier.

Poor Communication

Clear communication builds trust. I avoid manufacturers who respond slowly or provide vague answers. When I ask about pvc specifications or delivery timelines, I expect prompt and detailed replies. Poor communication often leads to misunderstandings, missed deadlines, and frustration. I prefer working with companies that assign a dedicated contact person and keep me updated throughout the order process.

| Communication Issue | Impact on My Business |

|---|---|

| Slow replies | Delays in order planning |

| Vague information | Unclear expectations |

| No contact person | Difficult problem solving |

Lack of Certifications

Certifications prove a manufacturer meets industry standards. I always ask for documentation like ISO 9001 or FIFA Quality marks. If a manufacturer cannot provide these, I see it as a major red flag. Lack of certifications suggests they may not follow strict quality or safety protocols. I want assurance that every pvc soccer ball I order meets recognized benchmarks for performance and safety.

Note: I request copies of certifications before placing any order. This step protects my business and my reputation.

I follow a clear process when I select a pvc football manufacturer. I focus on material quality, reliability, and sustainability. I always test samples to check durability and longevity. I ask direct questions about maintenance and longevity. I use these steps:

- Review manufacturer credentials for soccer ball production.

- Test samples for durability and longevity.

- Confirm support for maintenance and longevity.

- Watch for red flags in quality and communication.

I rely on this checklist to ensure every soccer ball delivers the longevity my customers expect.

FAQ

What is the typical minimum order quantity (MOQ) for PVC footballs?

I usually see MOQs start at 200 to 500 pieces. Some manufacturers offer lower MOQs for new clients or sample orders. I always confirm the MOQ before starting negotiations.

How do I ensure the PVC footballs meet my quality standards?

I request samples and test them for durability, bounce, and air retention. I also ask for certifications and review the manufacturer’s quality control checklist. This process helps me avoid surprises.

Can I customize the design and logo on my PVC footballs?

Yes, I often customize colors, logos, and patterns. I provide my artwork to the manufacturer and confirm design proofs before production. Customization may increase lead time and cost.

How long does production and delivery usually take?

Production and delivery usually take 45 to 90 days, depending on order size and customization. I always ask for a clear timeline and track progress to avoid delays.

What should I do if I receive defective footballs?

I contact the manufacturer immediately with photos and details. Most reputable companies offer replacements or refunds for defective products. I keep records of all communication for reference.