Introduction: Navigating the Global Market for custom made leather wristbands

In the evolving landscape of global commerce, sourcing custom made leather wristbands presents unique challenges for international B2B buyers. Whether you are in Brazil, Saudi Arabia, or anywhere in between, the quest for high-quality, personalized wristbands that align with your brand’s identity and consumer expectations can be daunting. This guide aims to demystify the process by providing actionable insights into the diverse types of leather wristbands available, their various applications across different industries, and effective strategies for vetting suppliers.

Understanding the nuances of material quality, design options, and pricing structures is crucial for making informed purchasing decisions. As you navigate this market, you’ll discover how to assess the craftsmanship of potential suppliers, ensuring that your investment not only meets your business needs but also resonates with your target audience. From promotional giveaways to fashion accessories, leather wristbands serve as versatile tools for branding and customer engagement.

By equipping yourself with the knowledge from this comprehensive guide, you will be empowered to make strategic choices that enhance your brand’s visibility and credibility in the competitive global marketplace. Whether you aim to enhance your product line or create custom promotional items, this resource will serve as a valuable companion in your journey toward successful sourcing.

Table Of Contents

- Top 7 Custom Made Leather Wristbands Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom made leather wristbands

- Understanding custom made leather wristbands Types and Variations

- Key Industrial Applications of custom made leather wristbands

- 3 Common User Pain Points for ‘custom made leather wristbands’ & Their Solutions

- Strategic Material Selection Guide for custom made leather wristbands

- In-depth Look: Manufacturing Processes and Quality Assurance for custom made leather wristbands

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom made leather wristbands’

- Comprehensive Cost and Pricing Analysis for custom made leather wristbands Sourcing

- Alternatives Analysis: Comparing custom made leather wristbands With Other Solutions

- Essential Technical Properties and Trade Terminology for custom made leather wristbands

- Navigating Market Dynamics and Sourcing Trends in the custom made leather wristbands Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom made leather wristbands

- Strategic Sourcing Conclusion and Outlook for custom made leather wristbands

- Important Disclaimer & Terms of Use

Understanding custom made leather wristbands Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Personalized Leather Bracelets | Customizable with names or messages; various leather colors | Gifts, promotional items, brand merchandise | Pros: Unique branding, personal touch. Cons: Longer production time for customization. |

| Medical ID Leather Bracelets | Includes medical alert features; durable leather construction | Healthcare, personal safety products | Pros: Essential for safety, easily identifiable. Cons: Limited design options. |

| Braided Leather Wristbands | Textured design; often available in multiple colors | Fashion accessories, event giveaways | Pros: Stylish and trendy, appeals to younger demographics. Cons: May require more maintenance. |

| Buckle Leather Bracelets | Classic design with buckle closure; adjustable sizes | Corporate gifts, employee recognition | Pros: Durable, timeless style. Cons: Potentially less customizable. |

| Vintage European Leather Bracelets | Intricate designs; premium leather quality | High-end fashion, luxury branding | Pros: Unique aesthetic, appeals to luxury markets. Cons: Higher cost, longer lead times. |

What Are the Characteristics of Personalized Leather Bracelets?

Personalized leather bracelets are tailored to include names, initials, or special messages, making them ideal for corporate gifting and promotional items. They come in various colors and styles, allowing businesses to align the product with their branding. When considering B2B purchases, buyers should assess the customization options available and the minimum order quantities, as personalized items often require a longer lead time.

How Do Medical ID Leather Bracelets Enhance Safety?

Medical ID leather bracelets serve a crucial role in personal safety by displaying essential medical information. Constructed from durable leather, these bracelets are designed for daily wear and can be customized to include medical alerts. B2B buyers in the healthcare sector should focus on the quality of the materials and the clarity of the engraving to ensure effectiveness in emergencies.

What Makes Braided Leather Wristbands a Fashion Statement?

Braided leather wristbands are popular for their stylish and modern appearance, often appealing to younger consumers. These bracelets can be produced in various colors and patterns, making them suitable for fashion accessories or event giveaways. Buyers should consider the target demographic and market trends when selecting braided wristbands, as their design can significantly influence consumer interest.

Illustrative image related to custom made leather wristbands

Why Choose Buckle Leather Bracelets for Corporate Gifts?

Buckle leather bracelets offer a classic look with adjustable sizes, making them versatile for various wrist sizes. Their timeless design makes them suitable for corporate gifts and employee recognition programs. When purchasing, buyers should evaluate the quality of the leather and the buckle mechanism, as these factors impact durability and overall presentation.

What Are the Benefits of Vintage European Leather Bracelets?

Vintage European leather bracelets are characterized by their intricate designs and high-quality leather, appealing to the luxury market. These bracelets can serve as unique fashion statements or high-end promotional items. Buyers should be aware of the higher costs associated with these products and the potential for longer lead times, which can affect inventory planning and marketing strategies.

Key Industrial Applications of custom made leather wristbands

| Industry/Sector | Specific Application of custom made leather wristbands | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Accessories | Branding and promotional giveaways | Enhances brand visibility and customer loyalty | Quality of leather, customization options, lead times, and minimum order quantities. |

| Healthcare | Medical ID wristbands | Provides essential medical information for emergencies | Compliance with health regulations, durability, and comfort for wearers. |

| Events and Festivals | Event entry wristbands | Streamlines guest access and enhances event experience | Customization for branding, security features, and production speed. |

| Corporate Gifting | Employee recognition awards | Strengthens employee morale and brand identity | Personalization options, bulk pricing, and delivery timelines. |

| Tourism and Hospitality | Souvenir wristbands | Increases customer engagement and promotes local culture | Design uniqueness, material quality, and cost-effectiveness. |

How are Custom Made Leather Wristbands Used in Fashion and Accessories?

In the fashion industry, custom made leather wristbands serve as a powerful branding tool. Companies often use these wristbands as promotional giveaways during events or as part of merchandise collections. They not only enhance brand visibility but also foster customer loyalty by creating a tangible connection with the brand. For international buyers, sourcing high-quality leather that meets regional fashion trends and ensuring customization options are essential to meet diverse consumer preferences.

What Role Do Custom Made Leather Wristbands Play in Healthcare?

In healthcare, custom made leather wristbands are frequently utilized as medical ID bracelets. They provide critical information regarding allergies, medical conditions, or emergency contacts, which can be lifesaving during urgent situations. The wristbands must comply with health regulations and be made from durable yet comfortable materials for patients. Buyers in this sector should prioritize sourcing from suppliers who can guarantee quality and compliance, especially in regions with stringent health standards.

Illustrative image related to custom made leather wristbands

How Do Custom Made Leather Wristbands Enhance Events and Festivals?

For events and festivals, custom made leather wristbands are an effective means of controlling access and enhancing the overall experience for attendees. These wristbands can be tailored to reflect the event’s branding, offering a unique keepsake for participants. Buyers should consider sourcing options that allow for quick turnaround times and security features, such as unique designs or tamper-proof materials, to ensure a seamless event experience.

Why Are Custom Made Leather Wristbands Important for Corporate Gifting?

In the corporate sector, custom made leather wristbands are often used as awards for employee recognition. These wristbands serve as a tangible acknowledgment of achievements, fostering a sense of belonging and motivation within the workforce. Businesses looking to source these wristbands should focus on personalization options that reflect their brand identity, as well as competitive pricing for bulk orders to maximize cost-effectiveness.

How Can Custom Made Leather Wristbands Benefit Tourism and Hospitality?

In the tourism and hospitality industry, custom made leather wristbands function as memorable souvenirs for tourists. They can encapsulate local culture or serve as a reminder of a unique experience, thereby enhancing customer engagement. Buyers should consider the distinctiveness of designs and the quality of materials when sourcing these wristbands, ensuring they resonate with international visitors while remaining cost-effective for mass production.

3 Common User Pain Points for ‘custom made leather wristbands’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality and Authenticity of Materials

The Problem: B2B buyers often grapple with the challenge of ensuring that the custom made leather wristbands they order are crafted from high-quality, genuine leather. Many suppliers may provide misleading information or substitute genuine leather with synthetic alternatives, which can compromise the product’s durability and appeal. This issue is particularly critical for businesses in industries such as fashion and promotional products, where brand reputation hinges on the quality of materials used. Additionally, the risk of receiving subpar products can lead to financial losses and damage customer trust.

Illustrative image related to custom made leather wristbands

The Solution: To mitigate this problem, buyers should prioritize sourcing suppliers who are transparent about their materials and production processes. Requesting samples before placing bulk orders can provide a tangible assurance of quality. It is advisable to establish relationships with suppliers who have certifications or verifiable credentials that confirm their use of genuine leather. Additionally, consider implementing a standardized quality control process that includes inspections upon delivery to ensure compliance with the agreed specifications. This proactive approach not only safeguards your investment but also reinforces your commitment to delivering high-quality products to your customers.

Scenario 2: Challenges with Customization Options and Design Limitations

The Problem: Customization is a significant selling point for leather wristbands, but many B2B buyers encounter limitations in design options from suppliers. This can range from restricted color choices to a lack of flexibility in engraving or embossing capabilities. For businesses that aim to create unique branding experiences or personalized gifts, these restrictions can hinder their ability to meet customer expectations and differentiate themselves in a competitive market.

The Solution: To overcome these challenges, buyers should seek out manufacturers who specialize in bespoke leather products and offer extensive customization options. Communicate your specific needs regarding colors, sizes, and personalization features early in the negotiation process. Consider collaborating with suppliers who utilize advanced technology, such as laser engraving or digital printing, which allows for greater design flexibility. Furthermore, developing a clear design brief and engaging in open dialogue with suppliers can help align expectations and foster innovation in product offerings. This collaborative approach can lead to unique wristbands that effectively represent your brand and satisfy customer demands.

Scenario 3: Logistics and Timeliness in Delivery

The Problem: Timely delivery of custom made leather wristbands is crucial for B2B buyers, especially when tied to promotional events or product launches. Delays in production or shipping can lead to missed deadlines, which may result in lost sales opportunities and damaged business relationships. Additionally, varying lead times from different suppliers can complicate planning and inventory management.

The Solution: To address logistics challenges, buyers should conduct thorough research on potential suppliers’ production capabilities and shipping reliability. Establishing clear timelines and expectations upfront during the ordering process is essential. It may also be beneficial to implement a phased ordering strategy, allowing for smaller initial orders to test the supplier’s reliability and quality before committing to larger quantities. Consider leveraging local suppliers to reduce shipping times and costs. Additionally, maintaining open lines of communication with suppliers throughout the production process can help preemptively address any potential delays. By taking these steps, buyers can ensure a smoother procurement process and improve their ability to meet market demands efficiently.

Strategic Material Selection Guide for custom made leather wristbands

When selecting materials for custom-made leather wristbands, it is essential to consider the properties, advantages, disadvantages, and specific market needs. This analysis will cover four common materials used in the manufacturing of leather wristbands: genuine leather, synthetic leather, suede, and leatherette. Each material presents unique characteristics that influence their suitability for different applications and markets.

What Are the Key Properties of Genuine Leather for Custom Wristbands?

Genuine leather is a natural material known for its durability and aesthetic appeal. It typically has excellent temperature resistance, allowing it to maintain its integrity in various climates. Genuine leather is also breathable, which enhances comfort when worn for extended periods. However, it can be susceptible to moisture, which may lead to degradation if not properly treated.

Illustrative image related to custom made leather wristbands

Pros and Cons: The primary advantage of genuine leather is its longevity and luxurious feel, making it suitable for high-end products. However, it comes with a higher cost and requires more complex manufacturing processes, including tanning and finishing. Additionally, genuine leather may not be the best choice in humid environments unless treated for water resistance.

Impact on Application: Genuine leather is compatible with various media, including engraving and dyeing, which can enhance branding opportunities. However, its susceptibility to water may limit its use in wet conditions.

How Does Synthetic Leather Compare in Terms of Performance and Cost?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers an alternative to genuine leather that is more resistant to water and stains. It can withstand various temperature conditions, although extreme heat may cause it to degrade over time.

Pros and Cons: The main advantage of synthetic leather is its lower cost and ease of maintenance. It is also more versatile in terms of color and texture options. However, synthetic materials may not provide the same level of durability or luxurious feel as genuine leather, which could affect brand perception.

Impact on Application: Synthetic leather is suitable for applications where moisture resistance is crucial, such as outdoor events. However, it may not be as appealing for high-end markets that favor natural materials.

What Are the Unique Characteristics of Suede for Wristbands?

Suede, a type of leather with a napped finish, offers a soft texture and a unique aesthetic. It is generally less durable than full-grain leather but provides a distinct look that can appeal to fashion-forward consumers. Suede can be sensitive to moisture and stains, which can limit its application in certain environments.

Pros and Cons: The softness and luxurious appearance of suede are significant advantages, making it ideal for fashion accessories. However, its susceptibility to staining and wear can be a drawback, especially in regions with high humidity or dust.

Impact on Application: Suede wristbands can be customized through embossing or stitching, enhancing their appeal. However, buyers in regions with harsher climates may need to consider the material’s limitations regarding durability and maintenance.

Illustrative image related to custom made leather wristbands

What Role Does Leatherette Play in Custom Wristband Manufacturing?

Leatherette, a synthetic alternative to leather, is designed to mimic the look and feel of genuine leather while offering greater durability against wear and tear. It is often more affordable and easier to clean, making it a practical choice for mass production.

Pros and Cons: The key advantage of leatherette is its affordability and ease of maintenance. However, it may lack the authenticity and premium feel of genuine leather, which can affect its desirability in high-end markets.

Impact on Application: Leatherette is suitable for promotional items and bulk orders, especially in markets where cost is a significant factor. However, it may not align with the preferences of consumers seeking luxury or artisanal products.

Summary Table of Material Selection for Custom Made Leather Wristbands

| Materiaal | Typical Use Case for custom made leather wristbands | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end fashion accessories | Durability and luxurious feel | Higher cost and moisture sensitivity | Hoog |

| Synthetic Leather | Budget-friendly promotional items | Cost-effective and water-resistant | Less durable and may lack premium feel | Low |

| Suède | Fashion-forward accessories | Soft texture and unique aesthetic | Susceptible to stains and wear | Medium |

| Leatherette | Mass-produced items and promotional products | Affordable and easy to maintain | Lacks authenticity and premium feel | Low |

This strategic material selection guide provides B2B buyers with insights into the various materials available for custom-made leather wristbands, allowing them to make informed decisions based on their market needs and consumer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom made leather wristbands

What Are the Key Stages in the Manufacturing Process of Custom Made Leather Wristbands?

The manufacturing process for custom made leather wristbands involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these stages can empower B2B buyers to make informed decisions when selecting suppliers.

1. Material Preparation

The first step in the manufacturing process is the preparation of raw materials. High-quality leather is sourced, often categorized based on its type (e.g., full-grain, top-grain, or genuine leather) and thickness. The choice of leather significantly influences the wristband’s durability and aesthetic appeal.

In addition to leather, other materials such as buckles, snaps, or stainless steel components may be sourced. These materials must adhere to specific quality standards to ensure they complement the leather and enhance the wristband’s overall look and functionality.

2. Forming the Wristband

Once the materials are prepared, the next stage involves cutting and forming the leather into the desired shape. This process may utilize various cutting techniques, including die-cutting for precision or hand-cutting for more intricate designs.

During this stage, manufacturers may also apply techniques such as embossing or debossing to create patterns or logos on the leather. These embellishments not only enhance the aesthetic value of the wristbands but also allow for personalization, which is a significant selling point for custom-made products.

3. Assembly of Components

After forming, the individual components of the wristband are assembled. This step typically involves stitching or gluing the leather pieces together, as well as attaching any additional elements such as clasps or decorative charms.

Manufacturers often employ specialized machinery to ensure consistency and durability in stitching, which is crucial for the longevity of the wristband. Quality stitching techniques, such as saddle stitching, may be used to provide additional strength.

4. Finishing Touches

The final stage in the manufacturing process is finishing. This includes polishing, dyeing, and applying protective coatings to enhance the leather’s appearance and protect it from wear and tear.

Finishing techniques may also involve the application of water-resistant treatments or the use of natural oils and waxes to maintain the leather’s suppleness. The finishing process is essential for creating a product that not only looks good but also stands the test of time.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that the final products meet both international standards and customer expectations. For B2B buyers, understanding the QA processes can provide confidence in their supplier selection.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a critical role in the quality assurance of custom made leather wristbands. ISO 9001 sets the framework for a quality management system that focuses on consistent quality and customer satisfaction.

Illustrative image related to custom made leather wristbands

Other relevant standards may include CE marking for safety compliance in Europe and industry-specific certifications such as API for products used in oil and gas. Compliance with these standards indicates that manufacturers adhere to best practices and are committed to maintaining high-quality production.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps identify defects early. This may include checking stitching consistency, leather quality, and assembly integrity.

-

Final Quality Control (FQC): Before the products are packaged and shipped, they undergo a final inspection to ensure they meet quality standards and customer specifications.

What Common Testing Methods Are Used in Quality Assurance?

Several testing methods are employed to ensure the quality of custom made leather wristbands:

-

Tensile Strength Testing: This assesses the durability of the leather and stitching, ensuring that the wristbands can withstand everyday wear.

-

Colorfastness Testing: This ensures that the dye used in the leather does not fade when exposed to light or moisture, maintaining the product’s appearance over time.

-

Water Resistance Testing: Particularly for wristbands intended for outdoor use, testing for water resistance can help determine their suitability for various environments.

How Can B2B Buyers Verify Supplier Quality Control Measures?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following methods for verification:

Illustrative image related to custom made leather wristbands

What Role Do Audits and Reports Play in Supplier Verification?

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request documentation of any internal or external audits, including findings and corrective actions taken.

Additionally, suppliers should be able to provide quality assurance reports that detail their compliance with relevant standards and any testing results for their products.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These inspections can occur at various stages of production, providing B2B buyers with assurance that their orders meet the expected quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider:

-

Cultural Differences: Understanding the cultural context of manufacturing practices can enhance communication with suppliers, helping to align expectations.

-

Import Regulations: Buyers must be aware of their country’s import regulations and ensure that suppliers comply with all necessary documentation and standards.

-

Logistical Considerations: International shipping can introduce variables that affect product quality. Buyers should discuss packaging and handling procedures with suppliers to mitigate risks during transit.

In summary, understanding the manufacturing processes and quality assurance measures for custom made leather wristbands is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can ensure they source high-quality products that meet their business needs.

Illustrative image related to custom made leather wristbands

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom made leather wristbands’

Inleiding

Sourcing custom made leather wristbands requires careful planning and strategic decision-making. This guide provides a step-by-step checklist designed to help B2B buyers navigate the procurement process effectively, ensuring they find reliable suppliers who can meet their specific needs. By following these steps, you will not only save time but also enhance the quality of your sourcing decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the specifications for the wristbands you need. This includes material type (genuine leather vs. synthetic), design elements (braided, embossed, etc.), size variations, and any customization options such as engraving or colors.

– Consider the target market: Ensure that the specifications align with the preferences and expectations of your intended audience, particularly if you’re targeting diverse regions such as Africa or Europe.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in custom leather wristbands. Utilize online platforms, trade shows, and industry networks to gather a comprehensive list of candidates.

– Look for reputable companies: Focus on suppliers with positive reviews, a solid track record, and experience in serving similar markets.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each supplier to ensure they can fulfill your requirements. This includes examining their production capacity, quality control measures, and design flexibility.

– Request samples: Evaluate the quality of their products through samples to ensure that they meet your standards before placing a larger order.

Step 4: Verify Supplier Certifications

It is crucial to verify that suppliers hold relevant certifications that demonstrate their adherence to industry standards and ethical practices. This may include certifications for quality management (ISO), environmental management, and fair labor practices.

– Ask for documentation: Request copies of certifications and any compliance reports to verify their credibility.

Illustrative image related to custom made leather wristbands

Step 5: Discuss Pricing and Terms

Initiate discussions about pricing, minimum order quantities, and payment terms. Understanding the financial implications early on will help you avoid unexpected costs and ensure the project remains within budget.

– Negotiate terms: Be prepared to negotiate, especially for bulk orders, and inquire about any potential discounts or incentives for long-term partnerships.

Step 6: Check References and Reviews

Before finalizing your decision, contact references provided by the supplier to gain insights into their reliability and service quality. Reviews from other B2B clients can provide valuable perspectives on the supplier’s performance.

– Evaluate feedback: Pay attention to comments regarding lead times, product quality, and customer support to gauge how well the supplier meets client expectations.

Step 7: Finalize Contracts and Agreements

Once you have chosen a supplier, ensure that all terms are clearly outlined in a formal contract. This should include delivery timelines, quality standards, payment terms, and any penalties for non-compliance.

– Protect your interests: A well-drafted contract helps mitigate risks and ensures accountability on both sides throughout the sourcing process.

By following this practical checklist, B2B buyers can confidently navigate the procurement of custom made leather wristbands, ensuring they partner with reliable suppliers who can meet their specific requirements.

Illustrative image related to custom made leather wristbands

Comprehensive Cost and Pricing Analysis for custom made leather wristbands Sourcing

What Are the Key Cost Components in Custom Made Leather Wristbands?

When sourcing custom made leather wristbands, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of leather significantly impacts costs. Genuine leather is typically more expensive than synthetic options. Additional materials like stainless steel for buckles or clasps can also influence pricing.

-

Labor: Skilled craftsmanship is crucial, especially for bespoke designs. Labor costs can vary based on the complexity of the wristband, the skill level of the artisans, and the region where production takes place.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance in the production facility. Efficient operations can help lower these expenses.

-

Tooling: Initial costs for molds or dies used in the manufacturing process can be substantial, particularly for unique designs. These costs are often amortized over production runs.

-

Quality Control (QC): Ensuring that each wristband meets quality standards requires investment in QC processes, which may include inspections and testing.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and the volume of the order. Understanding these variables is crucial for calculating total expenses.

-

Margin: Suppliers typically add a profit margin on top of their costs. This can vary significantly based on market demand and competition.

How Do Price Influencers Affect Custom Made Leather Wristbands?

Several factors can influence the pricing of custom made leather wristbands:

-

Volume/MOQ: Many suppliers offer tiered pricing based on order volume. Larger orders often result in lower per-unit costs, which can lead to significant savings.

-

Specifications and Customization: Unique designs or specific features, such as engraving or special stitching, can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (like eco-friendly leather) can drive up costs. It’s essential to balance quality with budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more for their products due to their experience and quality assurance processes.

-

Incoterms: Understanding the shipping terms (like FOB, CIF, etc.) is critical. These terms dictate who pays for shipping and insurance, impacting the total cost.

What Buyer Tips Can Help Negotiate Better Prices?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following strategies for negotiating better prices:

-

Research and Compare: Gather quotes from multiple suppliers to understand the market rate. This information can provide leverage during negotiations.

-

Negotiate Terms: Don’t just focus on price; negotiate payment terms, delivery schedules, and after-sales support. Flexible terms can lead to overall cost savings.

-

Focus on Total Cost of Ownership (TCO): Consider all costs associated with the wristbands, including maintenance and potential returns. A slightly higher initial price might lead to lower TCO if the product is of better quality.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, import tariffs, and local regulations that can affect pricing. Building relationships with suppliers can also help mitigate these risks.

-

Utilize Local Partnerships: Engaging local agents or distributors who understand the market can provide valuable insights and help navigate cultural nuances in negotiation.

Conclusion

Understanding the comprehensive cost structure and pricing influencers for custom made leather wristbands is vital for B2B buyers. By effectively negotiating and considering all cost components, businesses can optimize their purchasing strategies and achieve better value. Always remember that prices can vary significantly based on the factors mentioned, and it’s advisable to treat indicative prices as a starting point for negotiation.

Alternatives Analysis: Comparing custom made leather wristbands With Other Solutions

Exploring Viable Alternatives to Custom Made Leather Wristbands

In the world of promotional items and fashion accessories, custom made leather wristbands stand out for their quality, personalization, and durability. However, various alternatives exist that can achieve similar branding and aesthetic goals. This section will compare custom made leather wristbands against two prominent alternatives: silicone wristbands and fabric wristbands. By evaluating these options, B2B buyers can make informed decisions that align with their marketing strategies and budget considerations.

| Comparison Aspect | Custom Made Leather Wristbands | Silicone Wristbands | Fabric Wristbands |

|---|---|---|---|

| Performance | High durability and premium feel | Flexible and water-resistant | Moderate durability, comfortable |

| Cost | Higher initial investment (typically $10-$30) | Low cost (usually $1-$5) | Moderate cost ($2-$10) |

| Ease of Implementation | Custom design and production may take longer | Quick production and delivery | Moderate lead times, depending on design |

| Maintenance | Requires care to maintain appearance | Low maintenance, easy to clean | Machine washable, moderate upkeep |

| Best Use Case | Premium branding, special events | Mass giveaways, casual promotions | Events requiring comfort, fashion-focused campaigns |

In-depth Analysis of Alternatives

Silicone Wristbands

Silicone wristbands have gained immense popularity due to their affordability and versatility. They are lightweight, flexible, and available in a wide range of colors. Ideal for mass giveaways, they serve as effective promotional tools for events, fundraisers, and awareness campaigns. However, their lower perceived value compared to leather may not resonate with brands aiming for a luxury image. Additionally, while silicone is water-resistant, it may not offer the same level of durability as leather in terms of wear and tear.

Fabric Wristbands

Fabric wristbands, often used for events like concerts and festivals, provide a comfortable fit and can be customized with vibrant designs. They are suitable for temporary use and can be machine washed, making them practical for various occasions. However, their durability is moderate, and they may not convey the same level of prestige as leather wristbands. Fabric options can also be more prone to fraying or fading over time, which could impact their effectiveness as a branding tool.

How Should B2B Buyers Choose the Right Solution?

When selecting the right wristband solution, B2B buyers should consider their target audience, branding goals, and budget constraints. Custom made leather wristbands are an excellent choice for brands looking to make a lasting impression with premium quality and personalization. On the other hand, if the objective is to maximize reach with cost-effective giveaways, silicone wristbands may be more appropriate. For events where comfort and casual branding are paramount, fabric wristbands offer a practical solution.

Ultimately, the decision should align with the company’s overall marketing strategy and the message they wish to convey through their promotional items. By weighing the pros and cons of each option, buyers can ensure they choose the most effective wristband solution for their specific needs.

Essential Technical Properties and Trade Terminology for custom made leather wristbands

What Are the Key Technical Properties of Custom Made Leather Wristbands?

When sourcing custom made leather wristbands, understanding the technical properties is essential for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

Illustrative image related to custom made leather wristbands

-

Material Grade:

The quality of leather is classified into various grades, such as full-grain, top-grain, genuine leather, and bonded leather. Full-grain leather, for instance, is the highest quality, retaining the natural grain and durability. Higher-grade materials ensure longevity, making them ideal for high-end markets. Choosing the right material grade can significantly impact customer satisfaction and brand reputation. -

Thickness (Gauge):

The thickness of leather is measured in millimeters or ounces. Common thicknesses for wristbands range from 1.0 to 2.5 mm. A thicker leather provides greater durability and resistance to wear, while thinner leather offers flexibility and comfort. Understanding the appropriate thickness is crucial for aligning product offerings with target market expectations. -

Tolerances:

Tolerance refers to the allowable variation in dimensions during the manufacturing process. For wristbands, tolerances can affect fit and comfort. For example, if a wristband is designed to fit a wrist size of 7 inches, a tolerance of ±0.25 inches ensures that the product remains comfortable for the user. Establishing clear tolerances is vital for maintaining quality control and ensuring customer satisfaction. -

Closure Mechanism:

Different types of closures, such as snap, buckle, or magnetic, can be used in wristbands. The choice of closure affects both functionality and aesthetic appeal. B2B buyers should consider which closure type best suits their customer preferences and the intended use of the wristband, whether for casual wear, fashion statements, or functional use. -

Customization Options:

Customization capabilities, including engraving, color variations, and design patterns, are essential for differentiating products in a competitive market. Understanding the extent of customization that a manufacturer can provide is crucial for meeting specific client needs and enhancing brand identity. -

Finish and Treatment:

Leather can undergo various treatments such as dyeing, waxing, or oiling, which can affect its appearance and durability. A proper finish not only enhances the aesthetic appeal but also protects the leather from environmental damage. Buyers should inquire about the types of finishes available and their implications for product longevity.

What Are Common Trade Terms in Custom Made Leather Wristbands?

Familiarity with industry jargon is critical for effective communication and negotiation in B2B transactions. Here are several common terms that buyers should know:

-

OEM (Original Equipment Manufacturer):

This term refers to a company that produces goods that are marketed by another company under its own brand. For B2B buyers, partnering with an OEM can lead to cost-effective production while maintaining brand integrity. -

MOQ (Minimum Order Quantity):

MOQ defines the smallest quantity of product that a supplier is willing to sell. Understanding MOQ is vital for budget management and inventory planning, especially for companies looking to test market demand without overcommitting. -

RFQ (Request for Quotation):

An RFQ is a formal document sent to suppliers requesting a price quote for specific products or services. It helps B2B buyers compare costs and terms from multiple suppliers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms):

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations. -

Lead Time:

Lead time refers to the amount of time between placing an order and receiving the product. In the custom leather wristband market, understanding lead times is crucial for inventory management and meeting customer demand. -

Sample Policy:

This term refers to the supplier’s guidelines regarding the provision of product samples. Knowing a supplier’s sample policy can help buyers assess quality and make informed purchasing decisions before committing to larger orders.

By understanding these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and ensure successful transactions in the custom made leather wristband market.

Navigating Market Dynamics and Sourcing Trends in the custom made leather wristbands Sector

What Are the Current Market Dynamics and Key Trends Influencing Custom Made Leather Wristbands?

The custom made leather wristbands market is witnessing significant growth, driven by increasing consumer demand for personalized and unique accessories. This trend is particularly prominent among younger demographics who seek to express individuality through customized products. In addition, the rise of e-commerce platforms has made it easier for international B2B buyers to source these products directly from manufacturers, leading to a more competitive pricing landscape.

Emerging technologies, such as 3D printing and digital design tools, are transforming the manufacturing process, allowing for greater customization options and quicker turnaround times. B2B buyers in regions like Africa, South America, the Middle East, and Europe are increasingly leveraging these technologies to enhance their product offerings. Moreover, the integration of artificial intelligence in inventory management and customer service is streamlining operations, providing a more efficient sourcing experience.

The market is also influenced by changing fashion trends, where leather wristbands are not only seen as accessories but also as fashion statements that can be worn across various occasions. This versatility appeals to diverse consumer segments, from casual wearers to those looking for elegant, statement pieces. For international buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with current consumer preferences.

Illustrative image related to custom made leather wristbands

How Is Sustainability and Ethical Sourcing Shaping the Custom Made Leather Wristbands Market?

Sustainability has become a cornerstone in the sourcing of custom made leather wristbands, as both consumers and businesses prioritize ethical practices. The environmental impact of leather production is under scrutiny, prompting manufacturers to adopt more sustainable practices. Buyers are increasingly seeking suppliers who can demonstrate responsible sourcing of leather, including the use of vegetable-tanned leather, which minimizes harmful chemicals in the tanning process.

Furthermore, ethical supply chains are becoming a competitive differentiator in the B2B landscape. Companies that can showcase their commitment to fair labor practices and environmental stewardship are likely to attract more business, especially from conscious consumers. Certifications such as the Leather Working Group (LWG) provide buyers with assurance that their suppliers adhere to strict environmental and ethical standards.

In addition, the demand for ‘green’ materials is on the rise, with many manufacturers exploring alternatives to traditional leather, such as recycled leather or synthetic options made from eco-friendly materials. This shift not only addresses environmental concerns but also caters to a growing segment of consumers who prefer cruelty-free products. B2B buyers should prioritize partnerships with suppliers who align with these sustainability goals to enhance their brand reputation and meet consumer expectations.

What Is the Historical Context of Custom Made Leather Wristbands in the B2B Sector?

The evolution of custom made leather wristbands can be traced back to ancient civilizations, where leather was primarily used for functional purposes such as protection and utility. Over time, leather craftsmanship evolved into an art form, with intricate designs symbolizing status and identity. The modern iteration of leather wristbands began to gain popularity in the late 20th century as fashion trends shifted towards more personalized and unique accessories.

In the B2B context, the advent of globalization and advancements in manufacturing technologies have made it feasible for businesses to offer customized products at scale. The rise of online marketplaces has further democratized access to these products, allowing international buyers to source directly from artisans and manufacturers worldwide. This historical perspective underscores the potential for growth in the custom made leather wristbands sector, as contemporary consumers continue to seek products that reflect their personal style and values.

By understanding these market dynamics, sustainability considerations, and historical context, B2B buyers can navigate the complex landscape of custom made leather wristbands with confidence, making informed decisions that align with both consumer trends and ethical practices.

Frequently Asked Questions (FAQs) for B2B Buyers of custom made leather wristbands

-

How do I ensure the quality of custom made leather wristbands before placing a bulk order?

To ensure the quality of custom made leather wristbands, request samples from potential suppliers. Evaluate the leather’s texture, durability, and overall craftsmanship. Additionally, inquire about the tanning process, as this can affect the leather’s longevity and appearance. Look for certifications that guarantee quality standards, and consider conducting a factory visit if possible. Establish clear quality assurance protocols, including inspections at various production stages, to safeguard against defects in your bulk order. -

What is the best way to customize leather wristbands for my brand?

The best way to customize leather wristbands for your brand is to collaborate closely with your supplier during the design phase. Provide clear specifications regarding colors, materials, sizes, and branding elements like logos or engravings. Utilize design software or prototypes to visualize your concepts. Discuss minimum order quantities (MOQs) for custom designs to avoid unnecessary costs. Finally, ensure that the supplier can meet your branding needs within your timeline to maintain consistency across your product line. -

What are the minimum order quantities (MOQs) for custom leather wristbands?

Minimum order quantities for custom leather wristbands typically vary by supplier, often ranging from 100 to 1,000 pieces. Factors influencing MOQs include the complexity of the design, materials used, and the supplier’s production capabilities. It’s advisable to discuss your specific needs with potential suppliers and negotiate MOQs if necessary. Smaller businesses may seek suppliers open to lower MOQs or consider combining orders with other businesses to meet the required quantities. -

What payment terms should I expect when ordering custom leather wristbands from international suppliers?

Payment terms for custom leather wristbands can vary widely among international suppliers. Common practices include a 30-50% deposit upfront, with the balance due before shipment. Some suppliers may offer letters of credit or payment upon delivery. Be sure to clarify payment methods, such as bank transfers or online payment platforms, and confirm any potential additional fees for international transactions. It’s essential to establish clear payment terms in the contract to avoid disputes later. -

How can I vet suppliers for custom leather wristbands effectively?

To effectively vet suppliers for custom leather wristbands, start by researching their reputation and customer reviews. Request references from other B2B clients who have worked with them. Evaluate their certifications and compliance with international quality standards. Assess their production capabilities by reviewing their portfolio and asking for samples. Additionally, consider visiting their facilities or using third-party inspection services to ensure they meet your quality and ethical standards. -

What are the logistics considerations for importing custom leather wristbands?

Logistics considerations for importing custom leather wristbands include shipping methods, customs clearance, and delivery timelines. Choose between air or sea freight based on your budget and urgency. Understand the import regulations and tariffs that apply to leather products in your country to avoid unexpected costs. Coordinate with your supplier to ensure proper documentation, such as invoices and certificates of origin, is in place for smooth customs processing. Establish a reliable logistics partner to facilitate timely delivery. -

What quality assurance measures should I implement for custom leather wristbands?

Implementing quality assurance measures for custom leather wristbands involves setting up inspection checkpoints throughout the production process. This includes reviewing raw materials, assessing production techniques, and conducting final inspections before shipment. Consider using third-party quality control services for unbiased evaluations. Establish clear quality standards and communicate them to your supplier, ensuring they understand your expectations. Document all inspections and quality assessments to maintain accountability. -

How do I handle disputes with suppliers regarding custom leather wristbands?

Handling disputes with suppliers requires a structured approach. Start by communicating your concerns clearly and professionally, referencing specific contractual agreements. Document all correspondence and evidence related to the dispute. If a resolution cannot be reached through discussion, consider mediation or arbitration as alternative dispute resolution methods. Escalate to legal action only as a last resort. Maintaining a professional relationship is crucial, as disputes are often part of business; therefore, focus on finding a mutually beneficial solution.

Top 7 Custom Made Leather Wristbands Manufacturers & Suppliers List

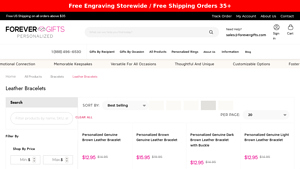

1. Forever Gifts – Personalized Genuine Brown Leather Bracelet

Domain: forevergifts.com

Registered: 1998 (27 years)

Introduction: Handcrafted Leather Bracelets for Men & Women. Free US Shipping on orders above $35. Personalized options available. Various styles include: 1) Personalized Genuine Brown Leather Bracelet – $12.95 (RRP: $15.95), made of soft brown leather, 0.5 inch width, snap closure, adjustable length 7-9 inches. 2) Personalized Braided Genuine Leather ID Bracelet – $15.95 (RRP: $19.95), features brown leather a…

2. Forjd Leather – Personalized Leather Business Card Holder

Domain: forjdleather.com

Registered: 2016 (9 years)

Introduction: [{‘name’: ‘Personalized Leather Business Card Holder’, ‘price’: ‘$33.00’}, {‘name’: ‘Genuine leather bracelet’, ‘price’: ‘$42.00’}, {‘name’: ‘Personalized leather bracelet’, ‘price’: ‘$42.00’}, {‘name’: ‘Leather Cuff Bracelet’, ‘price’: ‘$42.00’}, {‘name’: ‘Leather biker cuff’, ‘price’: ‘$42.50’}, {‘name’: ‘Richardson 112 Hat’, ‘price’: ‘$33.00’}, {‘name’: ‘Leather Wallet Pattern SVG format’, ‘pri…

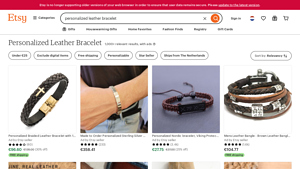

3. Etsy – Personalized Leather Bracelets

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Personalized Leather Bracelets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

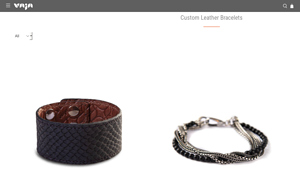

4. Vaja Cases – Custom Leather Bracelets

Domain: vajacases.com

Registered: 2000 (25 years)

Introduction: Custom Leather Bracelets include various styles and options such as:

– Tribe Leather Wristband – $89.00 (Ships in 1 Week!)

– Salerno Bracelet in Sterling Silver – $229.00

– Catania Bracelet Onix & Sterling Silver – $199.00

– Dubai – Sterling Silver Bangle Bracelet – $335.00

– Athens – Volcanic rock and Silver bracelet – from $280.00 (Sale Price: $330.00)

– Beijing – Adjustable Silver and Sil…

5. Swanky Badger – Personalized Men’s Leather Bracelet

Domain: swankybadger.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Personalized Mens Leather Bracelet”, “price_range”: “$29.99 – $59.98”, “material”: “Genuine Leather”, “size”: “6.25 x 0.5 inches”, “features”: “One Size Fits All”, “customer_rating”: “4.9”, “number_of_reviews”: 89, “giving_back”: “A portion of every sale goes to Children’s Hospitals.”}

6. Leathersmith Designs – Custom Leather Bracelets

Domain: leathersmithdesigns.com

Registered: 2000 (25 years)

Introduction: Custom leather bracelets and personalized wristbands made from genuine cowhide. Options for personalization include initials or names imprinted into the leather, with debossed lettering available in natural undyed color or dyed to match the leather. Etched monogramming can be handpainted in a color of choice. Christian bracelets feature various imprints such as crosses, doves, praying hands, Chris…

7. Old School Leather – Handmade Wristbands

Domain: oldschoolleather.com

Registered: 2002 (23 years)

Introduction: Handmade leather wristbands available in various colors, styles, and widths. Options include plain, tooled, and personalized designs. Free personalization available for names or initials. Popular among kids and adults for fashion and trade. Sizing guide provided. Key products include: Black Leather Bling Wristbands (1.5 Inch Wide, $22.00), Blue Flowers Handmade Leather Wristband (3/4″, $16.00), Ce…

Strategic Sourcing Conclusion and Outlook for custom made leather wristbands

What Are the Key Takeaways for B2B Buyers in Custom Made Leather Wristbands?

In summary, strategic sourcing of custom made leather wristbands offers international B2B buyers a unique opportunity to enhance their product offerings while ensuring quality and cost-efficiency. By leveraging relationships with reputable suppliers, businesses can access a diverse range of designs, materials, and personalization options that cater to varying market demands across regions like Africa, South America, the Middle East, and Europe.

Investing in high-quality leather wristbands not only enhances brand image but also meets the growing consumer preference for personalized and handcrafted products. The ability to provide custom options can significantly differentiate your business in a competitive landscape. As trends evolve, being proactive in sourcing can ensure that you remain at the forefront of market demands.

How Can B2B Buyers Position Themselves for Future Success?

Looking ahead, it is essential for B2B buyers to stay informed about market trends and supplier capabilities. Engage with manufacturers that prioritize sustainability and craftsmanship to align with consumer values. Consider establishing long-term partnerships that foster innovation and adaptability in your product lines.

Now is the time to explore the potential of custom made leather wristbands in your business strategy. Seize this opportunity to enhance your offerings and drive growth in your markets.

Illustrative image related to custom made leather wristbands

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.