Introduction: Navigating the Global Market for leather maker near me

In today’s global marketplace, sourcing high-quality leather makers can be a daunting task for international B2B buyers. Whether you are seeking a reliable supplier for bespoke leather products or looking to scale your operations with premium materials, finding a “leather maker near me” is often easier said than done. This guide addresses the complexities of sourcing leather makers by providing a comprehensive overview of the different types of leather products, applications across various industries, and essential supplier vetting criteria.

Understanding the nuances of the leather market is crucial for making informed purchasing decisions. This guide will delve into the diverse range of leather types, from full-grain to corrected-grain, and their respective uses in fashion, furniture, and accessories. Additionally, we will explore the economic factors influencing pricing and how to evaluate potential suppliers effectively.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Brazil and Vietnam—this resource aims to empower you with actionable insights. By leveraging the knowledge provided, you can confidently navigate the complexities of the leather supply chain, ensuring that your sourcing decisions align with your business goals and quality standards.

Table Of Contents

- Top 7 Leather Maker Near Me Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather maker near me

- Understanding leather maker near me Types and Variations

- Key Industrial Applications of leather maker near me

- 3 Common User Pain Points for ‘leather maker near me’ & Their Solutions

- Strategic Material Selection Guide for leather maker near me

- In-depth Look: Manufacturing Processes and Quality Assurance for leather maker near me

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather maker near me’

- Comprehensive Cost and Pricing Analysis for leather maker near me Sourcing

- Alternatives Analysis: Comparing leather maker near me With Other Solutions

- Essential Technical Properties and Trade Terminology for leather maker near me

- Navigating Market Dynamics and Sourcing Trends in the leather maker near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather maker near me

- Strategic Sourcing Conclusion and Outlook for leather maker near me

- Important Disclaimer & Terms of Use

Understanding leather maker near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Leather Makers | Tailored products, unique designs, artisan craftsmanship | High-end retail, bespoke goods | Pros: Unique offerings, personalized service. Cons: Higher cost, longer lead times. |

| Mass Production Leather Manufacturers | Standardized products, economies of scale, rapid turnaround | Bulk supply, commercial goods | Pros: Cost-effective, consistent quality. Cons: Limited customization, less personal touch. |

| Specialty Leather Artisans | Focus on niche markets, sustainable practices, premium materials | Luxury goods, artisan markets | Pros: High quality, eco-friendly options. Cons: Higher prices, limited availability. |

| Leather Goods Wholesalers | Wide range of products, competitive pricing, established supply chains | Retail distribution, e-commerce | Pros: Variety, bulk discounts. Cons: May lack product exclusivity, potential quality variance. |

| Leather Tool Suppliers | Tools and supplies for leather crafting, educational resources | DIY projects, small businesses | Pros: Comprehensive resources, support for crafters. Cons: Not a direct product supplier, niche focus. |

What Characteristics Define Custom Leather Makers?

Custom leather makers are distinguished by their ability to create tailored products that meet specific client requirements. They often utilize traditional craftsmanship techniques, resulting in unique designs that reflect the buyer’s personal style. For B2B buyers, this type of maker is ideal for high-end retail and bespoke goods, where exclusivity is key. However, the trade-off often includes higher costs and longer lead times, making it crucial for businesses to plan their orders accordingly.

How Do Mass Production Leather Manufacturers Operate?

Mass production leather manufacturers focus on creating standardized products that can be produced quickly and efficiently. They leverage economies of scale to offer competitive pricing, making them suitable for businesses needing bulk supply for commercial goods. While these manufacturers provide consistent quality, buyers may find limited customization options. This model is best suited for companies looking to stock a wide range of products without significant investment in unique designs.

What Makes Specialty Leather Artisans Unique?

Specialty leather artisans concentrate on niche markets, often emphasizing sustainable practices and premium materials. Their products are typically handcrafted, reflecting a commitment to quality and craftsmanship that appeals to luxury goods markets. B2B buyers in this segment can expect high-quality, eco-friendly options, though they may come at a premium price. Businesses should consider the artisan’s reputation and product availability when sourcing from this type of maker.

What Are the Benefits of Working with Leather Goods Wholesalers?

Leather goods wholesalers offer a wide range of products at competitive prices, making them a go-to source for retail distribution and e-commerce businesses. They often have established supply chains that facilitate timely deliveries, which can be beneficial for maintaining stock levels. However, buyers should be aware that while wholesalers provide variety and bulk discounts, the products may lack exclusivity, and quality can vary between batches.

Why Should You Consider Leather Tool Suppliers?

Leather tool suppliers cater to the crafting community by providing essential tools and supplies for leatherwork. They often offer educational resources, tutorials, and support for small businesses and DIY projects. While these suppliers may not provide finished leather goods, they are invaluable for businesses involved in leather crafting. Buyers should evaluate the range of tools available and consider how these resources can enhance their own product offerings.

Key Industrial Applications of leather maker near me

| Industry/Sector | Specific Application of leather maker near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom leather garments and accessories | High-quality, bespoke products that enhance brand identity | Craftsmanship, material sourcing, and ethical production |

| Automotive | Leather upholstery for vehicles | Enhanced aesthetics and comfort, increasing resale value | Durability, color matching, and compliance with safety standards |

| Furniture | Leather for high-end furniture upholstery | Luxurious appearance and improved customer satisfaction | Material quality, stain resistance, and customization options |

| Sporting Goods | Leather goods for sports equipment | Increased durability and performance in demanding conditions | Weight, flexibility, and specific performance requirements |

| E-commerce | Leather products for online retail | Expands product range, appealing to diverse consumer bases | Reliable supply chain, shipping logistics, and return policies |

How is Leather Used in the Fashion and Apparel Industry?

Leather makers play a crucial role in the fashion and apparel industry by providing custom leather garments and accessories. These products range from jackets to handbags, allowing brands to offer high-quality, bespoke items that enhance their identity. International B2B buyers, particularly from Africa and Europe, often seek unique textures and finishes that reflect local trends. Key considerations include the craftsmanship involved, the sourcing of sustainable materials, and adherence to ethical production practices to meet consumer expectations.

What is the Role of Leather in the Automotive Sector?

In the automotive industry, leather makers supply premium upholstery materials that significantly enhance vehicle aesthetics and comfort. High-quality leather not only elevates the interior design but also contributes to the vehicle’s resale value. Buyers from regions like South America and the Middle East must consider factors such as durability, color matching to existing interiors, and compliance with safety standards. This ensures that the leather meets the rigorous demands of automotive environments.

How is Leather Utilized in Furniture Manufacturing?

Leather is extensively used in the furniture sector, particularly for high-end upholstery. It offers a luxurious appearance and is often associated with durability, making it a preferred choice for premium furniture lines. For international buyers, especially in Europe, sourcing considerations include material quality, stain resistance, and customization options to fit specific design themes. Ensuring that the leather can withstand everyday use while maintaining its aesthetic appeal is vital for customer satisfaction.

What are the Applications of Leather in Sporting Goods?

The sporting goods industry benefits from leather makers by providing durable leather for equipment such as gloves, balls, and protective gear. The use of leather in these products enhances durability and performance, crucial for athletes in demanding conditions. B2B buyers need to focus on aspects like weight, flexibility, and specific performance requirements to ensure the products meet the needs of their target market. Sourcing high-quality leather that can withstand rigorous use is essential for maintaining brand reputation.

How Does E-commerce Leverage Leather Products?

In the e-commerce landscape, leather makers provide a diverse range of products, from wallets to belts, allowing retailers to expand their offerings and cater to various consumer preferences. This diversification can attract a broader customer base, particularly in emerging markets. Buyers must ensure a reliable supply chain, efficient shipping logistics, and favorable return policies to enhance customer satisfaction and foster repeat business. Establishing strong relationships with local leather makers can also ensure timely fulfillment of orders and adherence to quality standards.

3 Common User Pain Points for ‘leather maker near me’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather for Unique Projects

The Problem: B2B buyers often struggle to find a reliable leather maker who can provide high-quality leather that meets specific project requirements. This challenge is particularly acute for businesses in industries such as fashion, automotive, or furniture, where the quality and type of leather can significantly impact the end product. Buyers may encounter issues such as inconsistent quality, limited options, or suppliers who do not understand their unique specifications, leading to delays and increased costs.

The Solution: To effectively source high-quality leather, buyers should start by conducting thorough research on local leather makers. Utilize industry directories, trade shows, and online platforms to identify potential suppliers. Once a shortlist is created, initiate direct communication to discuss specific project requirements, including leather grades, finishes, and sourcing sustainability. It’s advisable to request samples before placing bulk orders to ensure the materials meet your quality standards. Establishing a clear set of specifications and maintaining open lines of communication with the maker can foster a strong partnership that meets your ongoing needs.

Scenario 2: Managing Lead Times and Delivery Expectations

The Problem: Timely delivery of leather products is crucial for B2B buyers, especially those working on tight deadlines for product launches or client projects. Delays in production or shipping can lead to missed deadlines, which can have cascading effects on supply chains and customer satisfaction. Often, buyers find that the lead times provided by local leather makers are longer than expected, or they may lack transparency about potential delays.

The Solution: To manage lead times effectively, buyers should establish clear timelines and expectations from the outset. When engaging with a leather maker, inquire about their production capacity and typical lead times for various products. It is also beneficial to build a buffer into your project timelines to accommodate unforeseen delays. Regularly check in with the supplier during the production process for updates, and consider implementing a tracking system for shipments. Establishing a proactive communication strategy can help mitigate delays and keep all stakeholders informed.

Scenario 3: Customization Challenges in Leather Products

The Problem: Many B2B buyers require customized leather products tailored to their specific branding or functional needs. However, navigating the customization process with local leather makers can be fraught with challenges. Buyers may face limitations in terms of design capabilities, color matching, or the availability of materials that fit their brand aesthetic. This can lead to frustration and suboptimal product outcomes.

The Solution: To overcome customization challenges, it is essential to engage in a collaborative design process with your leather maker. Start by providing detailed design briefs that include sketches, color swatches, and examples of existing products that resonate with your vision. Utilize digital tools for design visualization, if available, to ensure that both parties are aligned on expectations. Additionally, request a prototype or mock-up before finalizing the order. This approach not only helps in achieving the desired outcome but also fosters a stronger partnership with the leather maker, ensuring they understand your brand’s unique requirements and can deliver accordingly.

Strategic Material Selection Guide for leather maker near me

What Are the Key Materials Used by Leather Makers?

When selecting materials for leather crafting, understanding their properties and suitability for various applications is crucial for international B2B buyers. Here, we analyze four common materials used in leather making: full-grain leather, top-grain leather, suede, and synthetic leather. Each material has unique characteristics that can significantly impact product performance and marketability.

How Does Full-Grain Leather Perform in Leather Making?

Full-grain leather is considered the highest quality leather available. It retains the natural grain and texture of the hide, providing exceptional durability and breathability. This material is highly resistant to wear and develops a unique patina over time, enhancing its aesthetic appeal. However, full-grain leather can be more expensive due to its sourcing and processing requirements.

From a B2B perspective, full-grain leather is ideal for high-end products such as luxury handbags, belts, and wallets. Buyers should ensure compliance with international standards like ASTM for leather quality and durability. Additionally, the sourcing of full-grain leather may vary by region, impacting lead times and costs.

What Are the Benefits and Drawbacks of Top-Grain Leather?

Top-grain leather is the second-highest quality leather, created by sanding down the surface of full-grain leather to remove imperfections. It offers a more uniform appearance and is slightly more affordable than full-grain leather. While it is durable and resistant to stains, it does not develop the same rich patina over time.

Top-grain leather is suitable for a variety of products, including furniture, bags, and clothing. International buyers should be aware of the finishing processes used, as these can affect the leather’s breathability and longevity. Compliance with environmental standards is also essential, especially in regions with strict regulations.

How Does Suede Compare to Other Leather Types?

Suede is made from the underside of the hide, giving it a soft texture and a unique look. It is less durable than full-grain or top-grain leather and is more susceptible to stains and water damage. However, suede is popular for fashion items and accessories due to its luxurious feel and aesthetic appeal.

For B2B buyers, suede is often used in the production of shoes, jackets, and handbags. It is essential to consider the care and maintenance requirements when marketing suede products, as they may not be suitable for all climates. Additionally, buyers should ensure that suede complies with local regulations regarding animal welfare and environmental impact.

What Role Does Synthetic Leather Play in the Market?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is an alternative to traditional leather. It is typically more affordable and easier to clean, making it a popular choice for budget-conscious consumers. While synthetic leather can mimic the appearance of real leather, it lacks the breathability and durability of natural leather.

For international B2B buyers, synthetic leather is commonly used in automotive interiors, upholstery, and fashion accessories. It is crucial to verify that synthetic leather products meet international standards for durability and safety, such as those set by JIS or DIN. Additionally, buyers should consider the environmental impact of synthetic materials, especially in regions with growing sustainability initiatives.

Summary of Material Properties for Leather Making

| Materiaal | Typical Use Case for leather maker near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury handbags, belts, wallets | Exceptional durability and patina | Higher cost | Hoog |

| Top-Grain Leather | Furniture, bags, clothing | Uniform appearance, stain-resistant | Less patina development | Medium |

| Suède | Shoes, jackets, handbags | Soft texture and aesthetic appeal | Less durable, stain-prone | Medium |

| Synthetic Leather | Automotive interiors, upholstery, fashion | Cost-effective and easy to clean | Lacks breathability and durability | Low |

This strategic material selection guide provides valuable insights for international B2B buyers in the leather industry, helping them make informed decisions based on material properties, applications, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather maker near me

What Are the Main Stages in the Manufacturing Process of Leather Goods?

The manufacturing process of leather goods typically encompasses several critical stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw leather, which can include full-grain, top-grain, or corrected-grain leather. The leather is then conditioned and treated to enhance its durability and flexibility. Tanning, which can be vegetable-based or chrome-based, is a crucial step that preserves the leather and gives it distinct characteristics. Proper material preparation ensures that the leather maintains its integrity throughout the manufacturing process.

-

Forming: During this phase, the prepared leather is cut into specific shapes and sizes according to product designs. Techniques such as die-cutting or manual cutting are employed to achieve precision. This stage often requires the use of templates or patterns to ensure consistency across production batches. B2B buyers should inquire about the technology and tools used during this stage, as they can significantly affect the final product’s quality.

-

Assembly: The assembly stage involves stitching and joining various leather components. Skilled artisans may use both traditional hand-stitching techniques and modern sewing machines, depending on the product type. Quality stitching is essential for both aesthetics and durability. It’s important for buyers to verify the stitching techniques and materials used, as these factors contribute to the overall strength and lifespan of the leather goods.

-

Finishing: This final stage adds the aesthetic and functional aspects to the leather products. Finishing processes can include dyeing, polishing, embossing, or applying protective coatings. Each of these processes can significantly impact the look and feel of the leather, as well as its resistance to wear and tear. B2B buyers should consider the types of finishes applied and whether they align with their brand standards and customer expectations.

How Do Quality Assurance Practices Ensure Leather Product Integrity?

Quality assurance (QA) is a vital aspect of the leather manufacturing process, ensuring that products meet both international standards and customer expectations.

-

International Standards: Many leather manufacturers adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. This certification indicates that a manufacturer consistently meets customer and regulatory requirements, which is particularly important for international B2B buyers. Additionally, specific industry standards, such as CE marking for safety and API standards for oil and gas applications, may also apply depending on the end-use of the leather products.

-

Quality Control Checkpoints: Effective QA includes multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checks are conducted to monitor the production process, ensuring that each step is performed according to established guidelines.

– Final Quality Control (FQC): Before shipping, a thorough inspection is carried out on finished products to verify that they meet quality standards and specifications. This includes checking for defects, ensuring proper finishing, and confirming that all components are in place. -

Testing Methods for Leather Goods: Common testing methods include abrasion resistance tests, tensile strength tests, and water resistance assessments. These tests help verify the durability and functionality of leather products. B2B buyers should ask suppliers about the specific testing methods they utilize and the results to ensure the products will perform as expected in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to mitigating risks associated with product quality. Here are some strategies to consider:

-

Audits: Conducting supplier audits can provide insights into the manufacturing process and quality assurance practices. These audits can be performed by the buyer’s quality assurance team or outsourced to third-party auditing firms. Audits assess adherence to industry standards and identify areas for improvement.

-

Quality Reports: Requesting quality reports from suppliers can help buyers understand the supplier’s quality performance over time. These reports often include data on defect rates, test results, and compliance with international standards. Regular reports demonstrate a commitment to quality and transparency.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and quality assurance processes. These inspections can be scheduled at various points in the production cycle, from material sourcing to final product shipment.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, may encounter specific quality control nuances:

-

Cultural Differences: Understanding cultural differences in business practices can be crucial. Buyers should be aware of local manufacturing norms and expectations, which may influence quality assurance processes.

-

Regulatory Compliance: Different countries may have varying regulatory requirements for leather products. It is essential for buyers to ensure that their suppliers comply with the regulations applicable to their target markets, including safety standards and environmental regulations.

-

Language Barriers: Language differences can pose challenges in communication regarding quality specifications and standards. B2B buyers should consider having bilingual representatives or translators during negotiations and inspections to ensure clarity in expectations.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when selecting leather makers. This knowledge not only aids in supplier evaluation but also helps establish long-term partnerships based on quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather maker near me’

In the competitive landscape of leather goods, sourcing the right leather maker can significantly impact your product quality and business success. This guide outlines a practical step-by-step checklist tailored for B2B buyers seeking local leather manufacturers. By following these steps, you can ensure that you select a reliable and skilled partner for your leather production needs.

Step 1: Identify Your Project Requirements

Before reaching out to potential leather makers, clearly define what you need. This includes the type of leather products you want to produce, specifications such as size, style, and functionality. Detailing these requirements helps narrow down the search to those manufacturers capable of meeting your expectations.

- Product Types: Are you looking for handbags, wallets, or custom leather items?

- Quality Standards: Specify the quality of leather (e.g., full-grain, top-grain) to ensure alignment with your brand.

Step 2: Research Local Leather Makers

Utilize online directories and platforms to compile a list of leather makers in your vicinity. Look for companies that specialize in your product type and have a strong reputation. This foundational research is vital to identify potential suppliers who can fulfill your requirements.

- Directories: Consider using B2B platforms like Alibaba, ThomasNet, or local trade associations.

- Reviews and Ratings: Check online reviews and testimonials to gauge past client experiences.

Step 3: Evaluate Potential Suppliers

Before committing to a partnership, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This step ensures that you’re not just relying on their marketing but have tangible proof of their capabilities.

- Company Background: Investigate their history, expertise, and any specializations in leather craftsmanship.

- Client References: Contact past clients to learn about their experiences and satisfaction with the supplier’s products and services.

Step 4: Assess Production Capabilities

Understanding the supplier’s production capacity and capabilities is essential. Inquire about their manufacturing processes, lead times, and the technology they use. This information helps you determine if they can meet your volume needs and timelines.

- Technology and Equipment: Ensure they have modern machinery that can handle your specific requirements.

- Scalability: Discuss their ability to scale production up or down based on your fluctuating demand.

Step 5: Verify Quality Control Measures

Quality control is paramount in leather production. Ask potential suppliers about their quality assurance processes, including inspections and testing methods. A robust quality control system minimizes defects and ensures product consistency.

- Inspection Protocols: Inquire about the frequency and methods of quality checks during production.

- Certifications: Look for relevant industry certifications that reflect their commitment to quality standards.

Step 6: Request Samples

Before finalizing your choice, request samples of their work. Evaluating samples allows you to assess the quality of materials, craftsmanship, and overall product aesthetics. This step is critical for ensuring that the supplier’s output aligns with your brand’s standards.

- Sample Request: Specify what products or materials you want samples of to make a well-informed decision.

- Evaluation Criteria: Check for consistency, durability, and finishing quality in the samples received.

Step 7: Negotiate Terms and Build Relationships

Once you have selected a supplier, engage in negotiations to establish mutually beneficial terms. Discuss pricing, payment terms, delivery schedules, and any customization options. Building a solid relationship with your supplier fosters long-term cooperation and reliability.

- Contracts: Draft clear agreements that outline expectations, responsibilities, and timelines.

- Communication: Establish open lines of communication to facilitate smooth transactions and address any potential issues promptly.

By following these steps, B2B buyers can effectively source a reliable leather maker that meets their specific needs, ensuring high-quality products and successful partnerships.

Comprehensive Cost and Pricing Analysis for leather maker near me Sourcing

What Are the Key Cost Components for Sourcing Leather Goods?

When sourcing leather products, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality of leather significantly affects pricing. Full-grain leather, for instance, commands a premium due to its durability and aesthetic appeal. Additionally, sourcing from reputable tanneries with certifications (like ISO or environmental compliance) can impact costs.

-

Labor: Skilled artisans are essential in leather crafting, especially for high-quality products. Labor costs vary by region; countries with lower labor costs may provide competitive pricing, but this could come at the expense of craftsmanship quality.

-

Manufacturing Overhead: This includes the costs associated with running the production facility, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead, ultimately affecting the final product price.

-

Tooling: Specialized tools and equipment, including dies and molds for specific designs, contribute to the initial setup costs. While these are one-time expenses, they can be significant, particularly for custom orders.

-

Quality Control (QC): Ensuring that products meet quality standards involves inspection and testing. This step is crucial to maintain brand reputation and prevent costly returns or replacements.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and volume. International shipping may also incur customs duties, which should be factored into the overall cost.

-

Margin: Suppliers will add a markup to cover their costs and generate profit. Understanding the typical margins in the leather industry can help buyers identify reasonable pricing.

How Do Price Influencers Impact Sourcing Leather Products?

Several factors can influence the pricing of leather goods, which are crucial for B2B buyers to consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for businesses looking to stock inventory.

-

Specifications and Customization: Customized products generally come at a higher price due to the additional labor and materials involved. Buyers should clearly outline their specifications to avoid unexpected costs.

-

Materials: The choice of leather type and finishing processes can significantly affect pricing. Exotic leathers or specialized finishes will raise costs compared to standard offerings.

-

Quality and Certifications: Products that come with quality certifications may demand higher prices, but they often justify the cost through durability and customer satisfaction.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers may charge more but often provide better quality assurance and customer service.

-

Incoterms: Understanding international shipping terms is critical for pricing. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of products.

What Are the Best Buyer Tips for Cost-Efficient Leather Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Wisely: Use your understanding of the cost components and pricing influencers to negotiate effectively. Don’t hesitate to ask for discounts on larger orders or adjustments for long-term contracts.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with the product, including maintenance and potential replacement.

-

Research Supplier Options: Explore multiple suppliers to compare pricing, quality, and service. Look for suppliers with a solid track record and positive customer feedback.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions, labor costs, and material availability. Understanding these nuances can help you make more informed decisions.

-

Stay Informed on Market Trends: Regularly review market trends in leather goods to anticipate changes in pricing. Factors such as global demand, supply chain disruptions, and economic shifts can all impact costs.

Conclusion: Understanding the Cost Landscape for Leather Sourcing

Navigating the complexities of leather sourcing requires a comprehensive understanding of cost structures and pricing influencers. By leveraging this knowledge, B2B buyers can make informed decisions that lead to better value and quality in their leather products. Always remember that indicative prices can vary significantly based on the specifics of each order, so thorough research and negotiation are key to successful sourcing.

Alternatives Analysis: Comparing leather maker near me With Other Solutions

Understanding Alternatives for Leather Production

When sourcing leather products, B2B buyers often seek options that not only meet their quality requirements but also align with their operational needs. While finding a local leather maker can provide customized solutions and high-quality craftsmanship, it’s essential to consider other viable alternatives that may offer different advantages. This section compares ‘leather maker near me’ with other solutions, providing insights to help international buyers make informed decisions.

| Comparison Aspect | Leather Maker Near Me | Alternative 1: Online Leather Suppliers | Alternative 2: Mass-Production Factories |

|---|---|---|---|

| Performance | High quality, artisanal craftsmanship | Variable quality, often good | Consistent quality, but may lack uniqueness |

| Cost | Higher due to custom work | Moderate; varies by supplier | Lower due to economies of scale |

| Ease of Implementation | Requires direct engagement | Easy ordering online | Straightforward, bulk ordering process |

| Maintenance | Custom care instructions provided | Standard care instructions | Limited support, generic instructions |

| Best Use Case | Unique, customized projects | Standardized products, bulk needs | Large-scale production, cost-sensitive projects |

What Are the Pros and Cons of Using Online Leather Suppliers?

Online leather suppliers offer a convenient alternative for businesses looking to purchase leather materials or products without the need for local sourcing. These suppliers often have a wide range of options available, from different leather types to various pre-made goods.

Pros: They provide an extensive selection and often competitive pricing. The ease of ordering from anywhere makes them an attractive option for businesses without local leather artisans.

Cons: However, the quality can vary significantly between suppliers, and there is less opportunity for customization. Buyers must also rely on product descriptions and reviews, which may not always be accurate.

How Do Mass-Production Factories Compare to Local Leather Makers?

Mass-production factories represent a different approach to leather goods manufacturing. They typically produce items in large quantities, benefiting from economies of scale that allow them to offer lower prices.

Pros: The main advantage is cost efficiency, making them suitable for businesses needing high volumes of standardized products. Delivery times can also be more predictable due to established manufacturing processes.

Cons: The downside is a lack of uniqueness and personalized service. Products may lack the artisanal quality that comes from local makers, and customization options are usually limited. Additionally, quality control can be an issue, as the focus is often on quantity over craftsmanship.

How Can B2B Buyers Choose the Right Leather Solution?

Selecting the right leather sourcing solution depends largely on the specific needs of your business. If your focus is on unique, high-quality items that require customization, engaging with a local leather maker may be the best route. Conversely, if your business model demands standardized products at a lower price point, exploring online leather suppliers or mass-production factories may be more appropriate.

Ultimately, understanding the trade-offs between quality, cost, and service will empower B2B buyers to make choices that align with their operational goals and market expectations.

Essential Technical Properties and Trade Terminology for leather maker near me

What Are the Key Technical Properties of Leather for B2B Buyers?

When sourcing leather products, understanding the essential technical properties can significantly influence quality, durability, and cost. Here are some critical specifications to consider:

-

Material Grade

Leather is categorized into various grades, such as full-grain, top-grain, and corrected grain. Full-grain leather, known for its durability and breathability, retains the original surface, while top-grain is sanded and treated for a more uniform appearance. Understanding these grades helps buyers determine the product’s longevity and suitability for their specific needs. -

Thickness

Measured in millimeters or ounces, leather thickness affects its strength and application. Thicker leather is generally more durable and better suited for heavy-duty items like belts and bags, whereas thinner leather is often used for garments. Buyers must align thickness with the intended use to ensure product performance. -

Finish Type

The finish applied to leather can vary widely, including aniline, semi-aniline, and pigmented finishes. Aniline leather is dyed with transparent dyes and retains its natural look, while pigmented leather has a more uniform appearance and is more resistant to wear. Knowing the finish type is crucial for assessing aesthetic qualities and maintenance requirements. -

Tensile Strength

This property measures how much force leather can withstand before breaking. A higher tensile strength indicates a more robust material, which is essential for products subjected to stress, like luggage or automotive upholstery. Buyers should consider tensile strength when evaluating the longevity and reliability of leather goods. -

Water Resistance

While most leather has some level of water resistance, specific treatments can enhance this property. Water-resistant leather is vital for items exposed to moisture, such as outdoor gear or footwear. Understanding the level of water resistance can help buyers make informed decisions based on environmental conditions. -

Colorfastness

This property refers to how well leather retains its color when exposed to light or washing. High colorfastness is crucial for products like handbags and apparel that experience regular exposure to sunlight. Buyers should inquire about colorfastness ratings to ensure the longevity of aesthetic appeal.

What Are Common Trade Terms in the Leather Industry?

Navigating the leather market requires familiarity with specific jargon. Here are some common terms that every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, OEMs often create custom leather goods for brands that want to offer unique products under their label. -

MOQ (Minimum Order Quantity)

This is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers as it can affect inventory costs and supply chain management. Negotiating MOQs can lead to cost savings, especially for bulk orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotations on specific products or services. It helps buyers compare pricing and terms from different suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risk transfer, and delivery obligations. -

Lead Time

This refers to the time taken from placing an order until it is delivered. Understanding lead times is critical for effective inventory management and ensuring timely product availability for end customers. -

Grain

The term “grain” refers to the surface texture of leather. Different grains (e.g., pebbled, smooth) can influence the product’s appearance and tactile qualities. Buyers should consider grain types when selecting leather for various applications.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing leather products, ensuring they meet their quality and business needs effectively.

Navigating Market Dynamics and Sourcing Trends in the leather maker near me Sector

What are the Current Market Dynamics and Sourcing Trends in the Leather Sector?

The leather industry is witnessing significant evolution, driven by global demand for quality and sustainability. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking partnerships with local leather makers to meet the growing consumer preference for authentic, handcrafted products. This trend is supported by the rise of e-commerce platforms that facilitate direct sourcing, enabling buyers to connect with artisans and manufacturers without intermediaries. Moreover, technological advancements are reshaping the landscape, with innovations in leather production processes, such as digital cutting and 3D modeling, enhancing efficiency and reducing waste.

Emerging trends include the customization of leather products, where buyers are looking for bespoke solutions tailored to their specific market needs. This shift is particularly relevant in sectors like fashion and automotive, where unique designs and high-quality materials are paramount. Additionally, the integration of digital tools in inventory management and supply chain logistics is becoming more prevalent, allowing for better tracking and forecasting, which is essential for maintaining competitive advantage in a fast-paced market.

How Does Sustainability Influence Sourcing Decisions in the Leather Industry?

Sustainability has become a critical factor in sourcing decisions for B2B buyers in the leather sector. The environmental impact of traditional leather production, which often involves harmful chemicals and unsustainable practices, has prompted a shift towards more ethical sourcing methods. Buyers are increasingly looking for suppliers who adhere to sustainable practices, including waste reduction, water conservation, and the use of eco-friendly tanning processes.

Furthermore, certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are gaining traction. These certifications assure buyers that the leather they are sourcing is produced in an environmentally responsible manner. As consumers across the globe become more aware of sustainability issues, B2B buyers must align their sourcing strategies with these values to meet market demand and enhance brand reputation.

What is the Historical Context Behind Modern Leather Sourcing Practices?

Historically, leather has been a symbol of quality and durability, dating back thousands of years. Ancient civilizations utilized leather for clothing, armor, and various tools, establishing its importance in human culture. As the industrial revolution progressed, leather production evolved with mechanization, leading to mass production techniques that made leather goods more accessible. However, this also resulted in environmental challenges due to the increased use of chemicals and less attention to sustainable practices.

In recent decades, the leather industry has experienced a resurgence in artisanal craftsmanship, particularly as consumers seek unique, high-quality products. This evolution has paved the way for modern sourcing practices that prioritize ethical considerations, sustainability, and the integration of technology in production processes. Today’s B2B buyers are not only looking for quality but also for suppliers who can demonstrate a commitment to sustainable practices, reflecting a broader societal shift towards responsible consumption.

Frequently Asked Questions (FAQs) for B2B Buyers of leather maker near me

1. How do I find a reliable leather maker near me for B2B sourcing?

To find a reliable leather maker, begin by researching local directories and online platforms specific to your region. Attend industry trade shows and exhibitions, where you can meet manufacturers face-to-face and assess their capabilities. Additionally, leverage platforms like LinkedIn to connect with industry professionals and ask for recommendations. Always request samples of their work and verify their certifications to ensure quality standards are met.

2. What should I consider when vetting a leather supplier for my business?

When vetting a leather supplier, assess their production capacity, lead times, and quality control processes. Review customer testimonials and case studies to gauge their reliability and service levels. It’s also essential to inquire about their sourcing methods for raw materials to ensure they align with your ethical standards. Consider conducting an on-site visit to observe their operations firsthand, if feasible, to ensure they meet your quality requirements.

3. What are the typical minimum order quantities (MOQs) for leather products?

Minimum order quantities can vary significantly based on the leather maker and the specific product. Generally, MOQs can range from 50 to several hundred units, depending on the complexity of the item and the supplier’s production capabilities. Discussing your specific needs with the supplier can sometimes lead to flexibility in MOQs, especially for new partnerships or sample orders.

4. How can I customize leather products to meet my brand’s needs?

Customization options typically include selecting leather types, colors, and finishes, as well as adding logos or specific design features. Communicate your vision clearly to the supplier, providing them with sketches or samples if possible. Many leather makers offer prototyping services, allowing you to review a sample before full-scale production. Ensure you discuss timelines for customization to align with your product launch plans.

5. What payment terms are commonly offered by leather manufacturers?

Payment terms can vary by supplier but often include options like advance payment, net 30, or net 60 days. Some suppliers may require a deposit before starting production, especially for custom orders. It’s crucial to negotiate terms that work for your cash flow while ensuring the supplier has adequate security. Always clarify the payment methods accepted, such as bank transfers, letters of credit, or online payment platforms.

6. How do I ensure quality assurance in leather goods production?

To ensure quality assurance, establish clear quality standards and communicate them to your supplier. Request detailed specifications for materials and processes, and consider implementing periodic quality checks during production. Many suppliers will provide inspection reports or allow third-party inspections to verify compliance with your standards. Building a collaborative relationship with your supplier can also enhance accountability in quality control.

7. What logistics considerations should I keep in mind when sourcing leather products internationally?

When sourcing leather products internationally, consider shipping methods, customs regulations, and import duties that may apply. Evaluate the supplier’s ability to handle logistics efficiently, including their experience with exporting goods to your region. Establish a clear timeline for delivery and discuss options for tracking shipments. It’s also beneficial to have contingency plans in place for potential delays or issues during transit.

8. How can I maintain a long-term relationship with my leather supplier?

Maintaining a long-term relationship with your leather supplier involves regular communication, feedback, and collaboration. Schedule periodic reviews to discuss performance and address any concerns promptly. Consider placing repeat orders or expanding your product range with them to strengthen the partnership. Additionally, showing appreciation for their efforts, such as recognizing their contributions to your success, can foster goodwill and loyalty.

Top 7 Leather Maker Near Me Manufacturers & Suppliers List

1. Yelp – Best Custom Leather Goods

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Custom Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

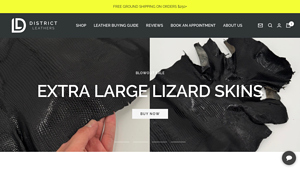

2. District Leathers – Key Products

Domain: districtleathers.com

Registered: 2016 (9 years)

Introduction: Key product details include a variety of leather types such as Upholstery Leather, Lamb & Calf Leather, Cow Leather, Goat & Sheep Leather, Shearlings & Fur, Pig Leather, Horse Leather, Kangaroo, Deer & Bison, Transparent Leather, Vegetable Tanned, Stretch Leather, Suede/Nubuck, Vegan Leather, Metallic Leather, Distressed Leather, Woven Leather, Hair-On Leathers, Leaf Leather, Alligator & Crocodile…

3. Makers Leather Supply – Hermann Oak Tooling Side

Domain: makersleathersupply.com

Registered: 2012 (13 years)

Introduction: {“products”:[{“name”:”Hermann Oak – Branded Natural Tooling & Carving Side”,”price”:”$225.00″,”reviews”:”11 reviews”},{“name”:”Maker’s Breezy Clutch Purse/Wallet Acrylic Template Set”,”price”:”$34.95″,”reviews”:”4 reviews”},{“name”:”Maker’s Contact Cement”,”price”:”$32.95″,”reviews”:”26 reviews”},{“name”:”Maker’s Indelible Leather Marker – Precision Dye & Edge Finishing Pen”,”price”:”$6.95″,”revie…

4. Daniel’s Leather – 3-in-1 Fox Coat

Domain: dl-nyc.com

Registered: 2018 (7 years)

Introduction: Home – Daniel’s Leather offers a variety of high-quality leather and fur products for men, women, and kids. Key products include: 3-in-1 Fox Coat ($2,999), Reversed Trucker Shearling ($999), 4 in 1 Fox Fur Coat with Removable Hood, Sleeves, and Body ($3,999), and Suede Jean Jacket ($399). The site features collections from brands like Pelle-Pelle, Avirex, and Jeff Hamilton, all priced around $1,05…

5. District Leather – Leather Goods

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Dedicated leather shops in NYC, specifically in the Fashion District, include District Leather, Impact, and Global. Pacific Trimming is recommended for buckles and Riri zippers. Talas in Williamsburg specializes in goat and stingray leathers, primarily for bookbinding. Vegtan leather is available but may require specific inquiry as most leathers sold are upholstery/chrome.

6. Custom Leather Creations – Personalized Patterned Leather Name Belt

Domain: customleathercreations.com

Registered: 2002 (23 years)

Introduction: Hudson Valley’s top leather shop crafting custom belts, wallets & more. Products include: Personalized Patterned Leather Name Belt (from $45.00), Classic Leather Belt ($32.00), Personalized Leather Name Bracelet ($15.00), Animals of the Wild Patterned Leather Belt ($40.00), Occupation Leather Belt (from $36.00), Personalized Leather Dog Collar ($25.00), Personalized Classic Leather Name Belt (from…

7. The Local Branch – Authentic American Leather Goods

Domain: thelocalbranch.co

Registered: 2013 (12 years)

Introduction: The Local Branch offers a variety of authentic American made leather goods, including:

1. **Leather/Canvas Goods**:

– USA Handmade Leather Bags

– USA Handcrafted Wallets

– USA Handcrafted Belts & Accessories

– USA Handcrafted Backpacks & Briefcases

– USA Handcrafted Leather Home Goods

– USA Handmade One of a Kind Leather Goods

2. **Apparel**:

– USA Made/Printed Apparel

– …

Strategic Sourcing Conclusion and Outlook for leather maker near me

In the dynamic landscape of the leather industry, strategic sourcing emerges as a crucial element for international B2B buyers. By prioritizing partnerships with local leather makers, companies can tap into high-quality materials while supporting sustainable practices. This approach not only enhances supply chain resilience but also fosters innovation and responsiveness to market demands.

Key takeaways include the importance of identifying reliable suppliers that align with your business values and quality standards. Engaging with leather makers who prioritize craftsmanship and sustainability can lead to superior products that resonate with consumers. Moreover, leveraging digital platforms for sourcing can streamline procurement processes, allowing for efficient order management and timely delivery.

As we look to the future, the potential for growth in the leather market remains robust, particularly in emerging economies across Africa, South America, the Middle East, and Europe. International buyers are encouraged to explore local artisans and manufacturers to build meaningful relationships that can drive business success. Embrace the opportunity to enhance your product offerings by collaborating with skilled leather makers near you. Your next strategic sourcing decision could redefine your brand’s footprint in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.