Introduction: Navigating the Global Market for custom design leather jackets

In today’s competitive fashion landscape, sourcing custom design leather jackets poses a unique challenge for international B2B buyers. As businesses strive to differentiate themselves through unique offerings, understanding the nuances of this market becomes essential. This comprehensive guide delves into the multifaceted world of custom leather jackets, exploring various types, applications, and the critical process of supplier vetting. By addressing key factors such as cost, quality assurance, and design flexibility, this resource equips buyers from regions like Africa, South America, the Middle East, and Europe—countries such as Vietnam and Nigeria—with the insights needed to make informed purchasing decisions.

Navigating the global market for custom leather jackets can be daunting due to the vast array of options and potential pitfalls in quality and service. This guide aims to demystify the process, offering actionable strategies to identify reliable suppliers and assess product quality. Whether you are a fashion retailer seeking to expand your collection or a designer looking to bring a bespoke vision to life, understanding the intricacies of sourcing is paramount. By leveraging the knowledge provided herein, buyers can confidently engage with suppliers, ensuring that their investments yield high-quality, ethically produced leather jackets that resonate with their brand values and customer expectations.

Table Of Contents

- Top 4 Custom Design Leather Jackets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom design leather jackets

- Understanding custom design leather jackets Types and Variations

- Key Industrial Applications of custom design leather jackets

- 3 Common User Pain Points for ‘custom design leather jackets’ & Their Solutions

- Strategic Material Selection Guide for custom design leather jackets

- In-depth Look: Manufacturing Processes and Quality Assurance for custom design leather jackets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom design leather jackets’

- Comprehensive Cost and Pricing Analysis for custom design leather jackets Sourcing

- Alternatives Analysis: Comparing custom design leather jackets With Other Solutions

- Essential Technical Properties and Trade Terminology for custom design leather jackets

- Navigating Market Dynamics and Sourcing Trends in the custom design leather jackets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom design leather jackets

- Strategic Sourcing Conclusion and Outlook for custom design leather jackets

- Important Disclaimer & Terms of Use

Understanding custom design leather jackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Biker Jacket | Asymmetrical front zipper, wide lapels, and pockets | Fashion retailers, motorcycle gear shops | Pros: Timeless style, durable. Cons: May not suit all body types. |

| Bomber Jacket | Ribbed cuffs and hem, fitted silhouette | Fashion brands, military surplus stores | Pros: Versatile, stylish. Cons: Limited customization options. |

| Café Racer Jacket | Tailored fit, minimalistic design, often with patches | Custom apparel companies, niche retailers | Pros: Trendy, customizable. Cons: May lack insulation for colder climates. |

| Aviator Jacket | Soft leather, shearling lining, and a rugged look | Outdoor gear retailers, fashion boutiques | Pros: Warmth and comfort, unique style. Cons: Higher price point. |

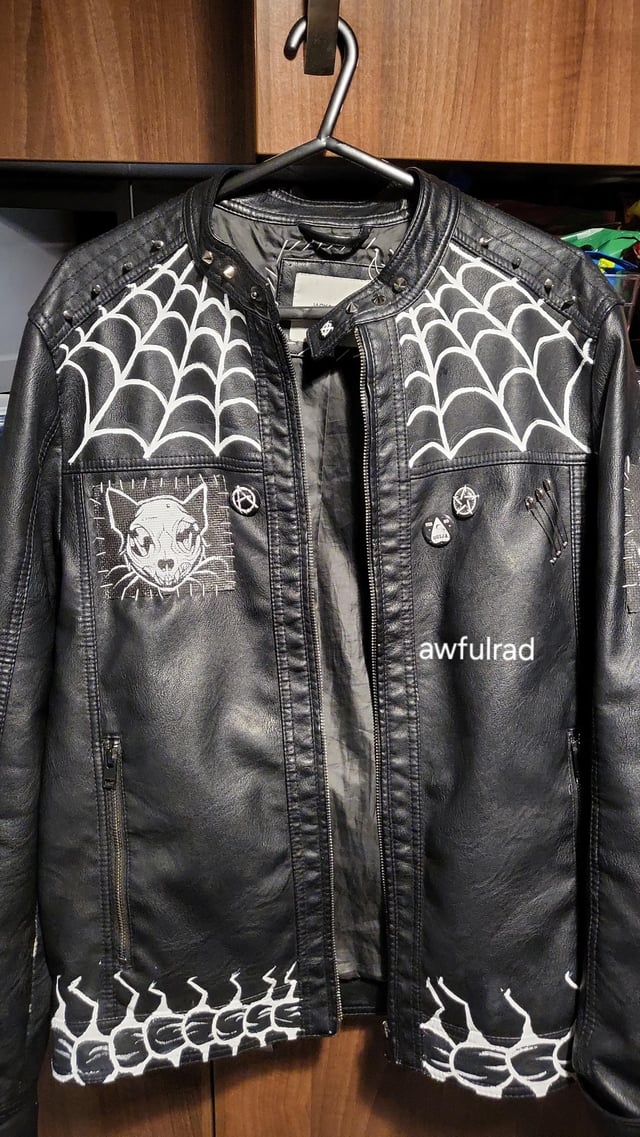

| Custom Embroidered Jacket | Personalized designs, logos, and graphics | Corporate branding, promotional events | Pros: Strong brand identity, unique. Cons: Longer production time. |

What Are the Characteristics of Classic Biker Jackets?

Classic biker jackets are defined by their asymmetrical front zipper, wide lapels, and multiple pockets. This style is often made from durable leather, providing both protection and style for motorcycle enthusiasts. In the B2B space, these jackets are popular among fashion retailers and motorcycle gear shops that cater to a rugged, adventurous clientele. When purchasing, businesses should consider the fit options and the potential for customization to meet varying customer preferences.

How Do Bomber Jackets Stand Out?

Bomber jackets feature ribbed cuffs and hem, creating a fitted silhouette that appeals to a broad audience. Their versatility allows them to be marketed across various sectors, including fashion brands and military surplus stores. B2B buyers should evaluate the availability of materials and color options, as well as the potential for branding through embroidery or patches, making them suitable for promotional purposes.

What Defines Café Racer Jackets?

Café racer jackets are known for their tailored fit and minimalistic design, often adorned with patches that reflect personal style. These jackets are particularly suited for custom apparel companies and niche retailers that focus on unique, stylish pieces. Buyers in the B2B sector should prioritize manufacturers that offer extensive customization options, ensuring that the end product resonates with their target market while maintaining quality.

What Are the Features of Aviator Jackets?

Aviator jackets are typically crafted from soft leather and lined with shearling, providing both warmth and a rugged aesthetic. They are ideal for outdoor gear retailers and fashion boutiques that want to offer a blend of functionality and style. When sourcing aviator jackets, B2B buyers should consider the quality of materials and the craftsmanship involved, as these factors significantly impact the jacket’s durability and appeal.

Why Choose Custom Embroidered Jackets?

Custom embroidered jackets allow businesses to showcase their unique designs, logos, and graphics, making them an excellent choice for corporate branding and promotional events. These jackets not only serve as fashionable outerwear but also strengthen brand identity among consumers. B2B buyers should be mindful of production timelines and the minimum order quantities when sourcing these items, as customization can extend lead times compared to off-the-shelf options.

Key Industrial Applications of custom design leather jackets

| Industry/Sector | Specific Application of custom design leather jackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Exclusive branded collections for high-end markets | Differentiates brand offerings, attracts affluent customers | Quality of leather, craftsmanship, and customization options |

| Film and Entertainment | Replicas of iconic movie jackets for merchandise | Enhances fan engagement and boosts merchandise sales | Licensing agreements, design accuracy, and production timelines |

| Automotive Industry | Custom jackets for automotive brands and events | Strengthens brand identity and loyalty among enthusiasts | Material durability, branding options, and fit for promotional events |

| Corporate Branding | Branded jackets for employee uniforms or giveaways | Promotes brand visibility and employee morale | Customization capabilities, bulk order discounts, and lead times |

| Sports Teams | Custom jackets for team merchandise and fan apparel | Fosters team spirit and fan loyalty | Fabric quality, design flexibility, and order fulfillment processes |

How Are Custom Design Leather Jackets Used in the Fashion Retail Sector?

In the fashion retail sector, custom design leather jackets serve as exclusive pieces that elevate a brand’s collection. Retailers can offer bespoke jackets that cater to niche markets, attracting customers looking for unique fashion statements. This customization allows brands to differentiate themselves from competitors, appealing to affluent clientele who value exclusivity and craftsmanship. For international buyers, ensuring high-quality leather, precise craftsmanship, and a variety of customization options are crucial factors in sourcing.

What Role Do Custom Leather Jackets Play in Film and Entertainment?

In the film and entertainment industry, custom leather jackets are often created as replicas of iconic styles worn by characters in movies or shows. These jackets serve as merchandise, enhancing fan engagement and driving additional revenue through sales. Buyers in this sector must consider licensing agreements to ensure compliance and design accuracy to meet audience expectations. Timely production is also essential, particularly for promotional events or product launches.

How Are Custom Jackets Beneficial for the Automotive Industry?

The automotive industry utilizes custom leather jackets as promotional items during events or as part of branded merchandise. These jackets reinforce brand identity and foster loyalty among enthusiasts, making them effective marketing tools. When sourcing for this application, businesses should prioritize the durability of materials, the ability to incorporate brand logos, and the fit of the jackets for promotional activities. Customization options can also enhance appeal to a diverse clientele.

Illustrative image related to custom design leather jackets

Why Do Corporations Use Custom Design Leather Jackets for Branding?

Corporations often use custom leather jackets as part of employee uniforms or promotional giveaways. These jackets not only promote brand visibility but also enhance employee morale by providing stylish and professional attire. For B2B buyers in this sector, it’s essential to consider customization capabilities, potential bulk order discounts, and lead times to ensure timely delivery for events or campaigns. Quality and comfort are also key factors to maintain a positive brand image.

How Do Sports Teams Leverage Custom Leather Jackets for Merchandise?

Sports teams frequently offer custom leather jackets as part of their merchandise, appealing to fans looking to showcase their team spirit. These jackets can be designed with team logos and colors, fostering loyalty among supporters. Buyers in this sector should focus on fabric quality, design flexibility, and efficient order fulfillment processes to meet demand during peak seasons. Ensuring that the jackets are stylish and comfortable can significantly enhance fan engagement and sales.

3 Common User Pain Points for ‘custom design leather jackets’ & Their Solutions

Scenario 1: Sizing Issues with Custom Leather Jackets

The Problem: A common challenge faced by B2B buyers, particularly in regions with diverse body types, is ensuring that custom leather jackets fit well across different sizes. Miscommunication regarding sizing specifications can lead to significant dissatisfaction, delays in production, and increased costs due to returns and alterations. Buyers may worry that their clients will not receive jackets that cater to specific size requirements, especially if they are sourcing for a niche market with unique body dimensions.

Illustrative image related to custom design leather jackets

The Solution: To alleviate sizing concerns, buyers should implement a comprehensive measurement guide when placing orders. This guide should include detailed instructions on how to take accurate body measurements, supplemented by visuals to clarify each step. Additionally, partnering with manufacturers that offer a virtual fitting solution or a sample jacket program can help buyers ensure the perfect fit before mass production. By prioritizing clear communication and offering size consultations, B2B buyers can enhance customer satisfaction and minimize the risk of returns.

Scenario 2: Concerns Over Material Quality and Durability

The Problem: Buyers often grapple with uncertainty regarding the quality of materials used in custom leather jackets. In an industry plagued by cheap imitations and unethical sourcing practices, it can be challenging to ensure that products meet both aesthetic and durability standards. This concern is particularly pronounced for buyers aiming to represent their brand’s reputation and sustainability commitments in the market, as poor-quality materials can lead to customer complaints and potential damage to their brand image.

The Solution: To address material quality concerns, B2B buyers should conduct thorough research on potential suppliers, focusing on those that provide transparency regarding their sourcing practices. Requesting samples of different leather types allows buyers to evaluate the texture, weight, and overall feel of the materials. Additionally, establishing relationships with suppliers that prioritize ethical manufacturing and use full-grain leather can assure buyers of the durability and quality of the jackets. Regular quality audits and feedback loops with suppliers can also help maintain consistent standards over time.

Scenario 3: Limited Customization Options for Branding

The Problem: For many B2B buyers, the ability to customize leather jackets to reflect their brand identity is essential. However, they often find that some manufacturers offer limited options for customization, such as color choices, embroidery, or design elements. This can frustrate buyers who seek to differentiate their products in a competitive market, as a lack of unique branding opportunities can hinder their ability to attract and retain customers.

The Solution: To overcome this limitation, buyers should seek out suppliers that emphasize bespoke services and a wide range of customization options. Engaging in consultations with manufacturers can clarify the scope of customization available, including the ability to incorporate logos, unique color palettes, and personalized design features. Additionally, buyers can leverage digital design tools provided by manufacturers to visualize their concepts before finalizing orders. By collaborating closely with suppliers and maintaining open lines of communication, buyers can create tailored products that resonate with their target audience and enhance brand recognition.

Illustrative image related to custom design leather jackets

Strategic Material Selection Guide for custom design leather jackets

What Are the Key Materials for Custom Design Leather Jackets?

When selecting materials for custom design leather jackets, it is crucial for B2B buyers to understand the properties, advantages, and limitations of each option. This knowledge enables informed decisions that align with market demands and customer preferences across diverse regions, including Africa, South America, the Middle East, and Europe.

How Does Full Grain Leather Compare to Other Materials?

Full grain leather is the highest quality leather available, known for its durability and natural appearance. It retains the hide’s original texture, making each jacket unique. Key properties include excellent breathability and resistance to wear and tear, which enhances the jacket’s longevity.

Pros: Full grain leather is highly durable and develops a beautiful patina over time, making it suitable for high-end fashion markets. It is also relatively easy to maintain with proper care.

Cons: The cost of full grain leather is on the higher end, which may not align with budget constraints for some buyers. Additionally, manufacturing complexity can increase due to the need for skilled labor to handle the material properly.

Illustrative image related to custom design leather jackets

Impact on Application: Full grain leather jackets are ideal for premium markets and can withstand various environmental conditions, making them suitable for diverse climates.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local climate conditions, as full grain leather performs well in both warm and cooler climates. Compliance with international standards such as ASTM for leather quality may also be necessary.

What Are the Benefits of Top Grain Leather?

Top grain leather is slightly less durable than full grain but offers a more uniform appearance due to its sanding and finishing process. It is still robust and provides a good balance between quality and cost.

Pros: This material is easier to work with during the manufacturing process, allowing for a wider variety of styles and designs. It is also less expensive than full grain leather, making it attractive for mid-range markets.

Cons: Top grain leather may not develop the same rich patina as full grain leather, potentially affecting its long-term appeal.

Impact on Application: Top grain leather is suitable for fashion-forward designs and can cater to a broader audience, particularly in regions with a growing middle class.

Considerations for International Buyers: Buyers should be aware of the varying perceptions of leather quality in different markets. Compliance with local standards and consumer expectations is crucial for successful sales.

Why Choose Suede for Custom Leather Jackets?

Suede, made from the underside of the animal hide, offers a soft and luxurious texture. It is lightweight and provides a unique aesthetic that appeals to fashion-conscious consumers.

Illustrative image related to custom design leather jackets

Pros: Suede is highly versatile and can be dyed in various colors, making it ideal for trendy designs. Its lightweight nature also enhances comfort.

Cons: However, suede is less durable than other leather types and is more susceptible to stains and water damage, which may limit its use in certain climates.

Impact on Application: Suede jackets are best suited for casual and stylish applications, particularly in urban markets where fashion trends change rapidly.

Considerations for International Buyers: Buyers should consider the climate and potential for moisture exposure when selecting suede. Ensuring that the material meets local quality standards is also important.

What Role Does Faux Leather Play in Custom Design Jackets?

Faux leather, or synthetic leather, is an alternative to traditional leather that appeals to environmentally conscious consumers. It can mimic the appearance of real leather while being more affordable.

Pros: Faux leather is generally less expensive and easier to clean, making it suitable for a wide range of applications. It also appeals to consumers looking for cruelty-free options.

Illustrative image related to custom design leather jackets

Cons: While it is durable, faux leather may not offer the same level of breathability or long-term durability as natural leather, which can affect its marketability.

Impact on Application: Faux leather jackets can cater to budget-conscious consumers and those seeking trendy styles without the ethical concerns associated with animal products.

Considerations for International Buyers: Buyers should ensure compliance with environmental regulations and standards for synthetic materials in their respective markets.

Summary Table of Material Properties

| Materiaal | Typical Use Case for custom design leather jackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end fashion jackets | Exceptional durability and unique patina | Higher cost and manufacturing complexity | Hoog |

| Top Grain Leather | Mid-range fashion jackets | Good balance of quality and cost | Less patina development compared to full grain | Medium |

| Suède | Casual, trendy jackets | Soft texture and versatile color options | Less durable and susceptible to stains | Medium |

| Kunstleer | Budget-friendly and ethical fashion jackets | Cost-effective and easy to maintain | May lack breathability and long-term durability | Low |

This strategic material selection guide provides valuable insights for B2B buyers in the custom design leather jacket market, enabling them to make informed decisions that cater to their target audience’s needs and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom design leather jackets

What Are the Main Stages of Manufacturing Custom Design Leather Jackets?

The manufacturing process for custom design leather jackets involves a meticulous series of stages that ensure high-quality outcomes tailored to individual specifications. Understanding these stages is crucial for B2B buyers looking for reliable suppliers.

Illustrative image related to custom design leather jackets

Material Preparation: How Are Leather and Components Selected?

The first step in the manufacturing process is material preparation. Suppliers typically source high-grade leather from reputable tanneries. Full-grain leather is often preferred due to its durability and natural look. Buyers should inquire about the types of leather available and whether they can inspect samples before placing bulk orders.

In addition to leather, other components such as linings, zippers, and hardware must be selected. Quality suppliers offer a variety of options, allowing buyers to customize every aspect of the jacket. This stage also includes the preparation of design specifications, where buyers can submit sketches or images to guide the production.

Forming: What Techniques Are Used to Shape the Leather?

Once the materials are prepared, the next stage is forming. This involves cutting the leather according to the specified designs. Advanced techniques like laser cutting may be employed for precision and efficiency, ensuring that each piece aligns perfectly with the design.

Artisans often use specialized tools to create patterns and shapes that reflect the buyer’s requirements. This stage is critical, as any errors in cutting can lead to significant material waste and affect the overall quality of the finished product.

Assembly: How Are Custom Jackets Constructed?

The assembly stage is where the jacket begins to take shape. Skilled craftsmen sew the cut leather pieces together using heavy-duty stitching techniques that enhance durability. Depending on the design, various sewing methods, including double stitching and topstitching, may be utilized to add strength and aesthetic appeal.

In custom manufacturing, each jacket is typically made one at a time, allowing for greater attention to detail. This contrasts with mass production, where speed often compromises quality. Buyers should inquire about the number of craftsmen involved in the process and their experience levels to ensure that skilled hands are creating their products.

Finishing: What Final Touches Are Applied?

The finishing stage involves several processes that enhance both the appearance and functionality of the leather jacket. This may include applying protective coatings, conditioning the leather, and adding embellishments such as embroidery or patches. Quality finishes not only improve the jacket’s look but also increase its longevity.

Buyers should discuss finishing options with suppliers to ensure that the final product aligns with their brand image. Additionally, it’s beneficial to ask about the drying and curing processes used, as these can significantly impact the jacket’s feel and durability.

What Quality Assurance Processes Are in Place for Custom Leather Jackets?

Quality assurance (QA) is paramount in the manufacturing of custom leather jackets, particularly for B2B buyers who require consistency and reliability. Various international standards and industry-specific certifications help ensure that products meet quality expectations.

Illustrative image related to custom design leather jackets

Which International Standards Should Buyers Be Aware Of?

ISO 9001 is one of the most recognized quality management standards globally. It focuses on maintaining consistent quality through effective processes and continual improvement. Suppliers adhering to ISO 9001 demonstrate a commitment to quality, which can significantly reduce the risk of defects in the final product.

In addition to ISO standards, buyers should also look for industry-specific certifications, such as CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards. Suppliers with such certifications provide an additional layer of assurance regarding product quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. Suppliers should verify the quality of leather and components before production begins.

-

In-Process Quality Control (IPQC): During the assembly phase, QC inspectors monitor the production process to catch any defects early. This can include checking stitching quality and ensuring that dimensions match specifications.

-

Final Quality Control (FQC): Once the jackets are completed, a final inspection is conducted to ensure that they meet all design and quality criteria before shipping. This may include testing zippers, verifying measurements, and checking for any cosmetic defects.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, ensuring that suppliers maintain stringent QC practices is critical. Here are some strategies to verify these measures:

What Should Buyers Look for in Supplier Audits and Reports?

Requesting and reviewing supplier audits can provide valuable insights into their QC processes. Buyers should look for detailed reports that outline the methods used for quality assurance, including any certifications obtained and the frequency of audits conducted.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can add an additional layer of security. These independent inspectors can evaluate the manufacturing process and product quality against established standards, ensuring that the supplier adheres to agreed-upon specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

When sourcing from suppliers in regions like Africa, South America, the Middle East, and Europe, it’s essential to understand the local manufacturing practices and regulations. Different countries may have varying standards for leather quality and environmental practices. Buyers should educate themselves on these differences to ensure compliance and quality.

Illustrative image related to custom design leather jackets

Furthermore, cultural factors may influence communication styles and negotiation tactics. Building strong relationships with suppliers and maintaining open lines of communication can facilitate smoother transactions and enhance quality assurance.

Conclusion: Ensuring Quality in Custom Leather Jacket Manufacturing

Navigating the complexities of manufacturing and quality assurance for custom design leather jackets requires diligence and a keen understanding of the processes involved. By familiarizing themselves with the manufacturing stages, quality control measures, and supplier verification strategies, B2B buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom design leather jackets’

To assist B2B buyers in procuring custom design leather jackets, this guide outlines a practical checklist. Each step is designed to ensure that you select the right suppliers and achieve the desired quality and specifications for your products.

Step 1: Define Your Design Specifications

Before you begin sourcing, clearly outline the design specifications for your custom leather jackets. This includes style (biker, bomber, etc.), materials (type of leather, lining), and additional features (zippers, pockets, custom embroidery). A well-defined specification will help streamline communication with suppliers and ensure that your vision is accurately conveyed.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom leather jackets. Look for manufacturers with a strong track record in quality and customer service. Utilize trade platforms, industry forums, and social media to gather insights and reviews about potential partners.

Illustrative image related to custom design leather jackets

- Check References: Ask for client testimonials or case studies, particularly from businesses in your region or industry.

- Evaluate Online Presence: A well-maintained website and active social media accounts often indicate a professional and engaged supplier.

Step 3: Verify Quality Assurance Processes

Quality assurance is critical in the leather industry due to the variability in material quality. Ensure that potential suppliers have robust quality control measures in place.

- Request Samples: Ask for samples of previous work to assess the quality of craftsmanship and materials used.

- Inquire About Certifications: Look for suppliers who adhere to international quality standards, such as ISO certifications, which indicate a commitment to quality.

Step 4: Assess Customization Capabilities

Customization is a key selling point for leather jackets, so it’s essential to evaluate the supplier’s ability to meet your specific design needs.

- Design Flexibility: Confirm that the supplier can accommodate various design elements, such as custom logos, graphics, and unique sizing options.

- Consultation Services: Suppliers who offer design consultations can provide valuable insights and help refine your jacket designs.

Step 5: Understand Pricing Structures

Discuss pricing in detail to ensure that it aligns with your budget while also reflecting the quality of the product. Be wary of suppliers that offer significantly lower prices, as this may indicate compromises in quality.

- Request Detailed Quotes: Obtain itemized quotes that outline costs for materials, labor, and any additional customization.

- Negotiate Terms: Explore options for bulk purchasing discounts or favorable payment terms to maximize your investment.

Step 6: Review Shipping and Delivery Policies

Logistics can significantly impact your procurement process. Understand the supplier’s shipping policies, including lead times and costs, to avoid unexpected delays.

- International Shipping Capabilities: Ensure the supplier can handle international shipping, particularly if you are sourcing from different regions.

- Return and Alteration Policies: Familiarize yourself with their return and alteration policies, as these can be crucial if the final product does not meet expectations.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear lines of communication with your supplier to facilitate feedback and ensure that all details are understood.

Illustrative image related to custom design leather jackets

- Designate Points of Contact: Assign specific contacts from both your team and the supplier to streamline communication.

- Use Collaborative Tools: Consider using project management or design collaboration tools to keep track of progress and share ideas efficiently.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing custom design leather jackets and ensure a successful procurement process that meets their business needs.

Comprehensive Cost and Pricing Analysis for custom design leather jackets Sourcing

What Are the Key Cost Components for Custom Design Leather Jackets?

When sourcing custom design leather jackets, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of leather significantly impacts costs. Full grain leather, known for its durability and quality, often commands higher prices than lower-grade options. Additionally, custom fabrics, linings, and embellishments (like embroidery or hardware) will add to the overall material costs.

-

Labor: Skilled craftsmanship is crucial in producing high-quality leather jackets. Labor costs can vary based on the location of production, with artisans in countries with higher wage standards typically charging more. Customization and bespoke services require additional labor, which should be factored into the pricing.

-

Manufacturing Overhead: This includes costs associated with the facilities, utilities, and equipment used in production. Custom designs may require specialized tools or setups, increasing overhead costs.

-

Tooling: Customization often necessitates unique patterns or molds, adding to the initial tooling costs. These costs can be amortized over larger orders, making it more cost-effective for bulk purchases.

-

Quality Control (QC): Ensuring that each jacket meets quality standards is vital. QC processes may incur additional costs, particularly for custom orders where specifications must be meticulously followed.

-

Logistics: Shipping costs can vary significantly based on the destination and chosen shipping method. Buyers should be aware of potential tariffs and duties, especially for international shipments.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market standard can help buyers negotiate better terms.

How Do Price Influencers Affect Custom Leather Jacket Sourcing?

Several factors influence the pricing of custom leather jackets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually benefit from bulk pricing, while lower quantities may incur higher per-unit costs.

-

Specifications and Customization: The more intricate the design and specifications, the higher the cost. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Materials and Quality Certifications: High-quality materials and certifications (like eco-friendly or ethical sourcing) can raise prices but may be worth the investment for brand reputation and customer satisfaction.

-

Supplier Factors: Supplier reputation, location, and production capabilities can significantly affect costs. Established suppliers may offer better pricing due to economies of scale.

-

Incoterms: The agreed terms of shipping can influence total costs. Understanding responsibilities for shipping, insurance, and tariffs can help in calculating the overall expense.

What Are Effective Buyer Tips for Negotiating Costs?

-

Negotiate Wisely: Leverage your volume needs to negotiate better terms. Suppliers may offer discounts for larger orders or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, potential alterations, and shipping costs. A higher upfront investment may lead to lower long-term costs.

-

Understand Pricing Nuances for International Transactions: For buyers in Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, import duties, and local regulations that could affect pricing.

-

Seek Transparency: Inquire about the breakdown of costs and the reasons behind pricing. This can aid in understanding where savings can be made or where investments are necessary.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms over time. Long-term partnerships often yield favorable outcomes for both parties.

Conclusion

Sourcing custom design leather jackets requires a thorough understanding of cost components and pricing influencers. By leveraging negotiation tactics and considering the Total Cost of Ownership, international B2B buyers can make informed decisions that align with their budget and quality expectations. Always approach sourcing with a clear understanding of the complexities involved to maximize value in your purchases.

Alternatives Analysis: Comparing custom design leather jackets With Other Solutions

When considering the purchase of leather jackets, B2B buyers often explore various options to ensure they receive the best value for their investment. Custom design leather jackets stand out as a unique solution, but it is crucial to compare them against other viable alternatives. This analysis will provide insights into how custom leather jackets stack up against ready-to-wear leather jackets and synthetic leather options, helping buyers make informed decisions.

| Comparison Aspect | Custom Design Leather Jackets | Ready-to-Wear Leather Jackets | Synthetic Leather Jackets |

|---|---|---|---|

| Performance | Tailored fit, high durability | Variable fit, moderate durability | Good appearance, less durability |

| Cost | Higher price point ($398+) | Moderate price point ($150-$500) | Lower price point ($50-$150) |

| Ease of Implementation | Requires measurement process | Immediate availability | Immediate availability |

| Maintenance | Moderate (care required) | Moderate (care required) | Low (easy to clean) |

| Best Use Case | Unique, personalized fashion | Standard styles for resale | Budget-friendly, casual wear |

How Does the Performance of Custom Design Leather Jackets Compare to Alternatives?

Custom design leather jackets are crafted to fit individual body measurements, ensuring an exceptional fit and longevity. They typically utilize high-quality full-grain leather, which is more durable than the materials used in many ready-to-wear options. In contrast, ready-to-wear leather jackets may vary in fit and quality, potentially leading to issues with comfort and wear over time. Synthetic leather jackets, while visually appealing, often lack the durability and authentic feel of genuine leather.

What is the Cost Difference Between Custom and Alternative Leather Jackets?

Custom leather jackets usually come at a premium price, starting around $398. This investment reflects the craftsmanship and personalized service involved in their creation. Ready-to-wear leather jackets can range from $150 to $500, making them more accessible for businesses looking for bulk orders. Synthetic leather jackets represent the most budget-friendly option, typically costing between $50 and $150, which can be appealing for businesses with tight budgets but may sacrifice quality.

How Easy is it to Implement Each Solution?

Custom design leather jackets require a more involved purchasing process, including sending measurements and potentially multiple fittings. This can be time-consuming, but it ensures a perfect fit. Ready-to-wear jackets are immediately available for purchase, making them convenient for businesses that need quick solutions. Synthetic leather jackets also offer immediate availability and are easy to source, making them a practical choice for businesses needing mass quantities without extensive customization.

What Maintenance is Required for Custom Leather Jackets Compared to Alternatives?

Both custom and ready-to-wear leather jackets require moderate maintenance, including proper cleaning and conditioning to maintain their appearance. In contrast, synthetic leather jackets are easier to maintain, requiring little more than a wipe-down to keep them looking good. This ease of care can be a significant factor for businesses looking for low-maintenance options.

Illustrative image related to custom design leather jackets

How Can B2B Buyers Choose the Right Leather Jacket Solution for Their Needs?

In conclusion, selecting the right leather jacket solution hinges on understanding the specific requirements of your business. If quality, durability, and personalization are top priorities, custom design leather jackets are the optimal choice despite their higher cost. For businesses seeking cost-effective solutions without much customization, ready-to-wear jackets present a balanced option. Meanwhile, synthetic leather jackets may appeal to budget-conscious buyers who prioritize immediate availability and ease of maintenance. Evaluating these factors will ensure that B2B buyers make informed choices that align with their brand and operational needs.

Essential Technical Properties and Trade Terminology for custom design leather jackets

What Are the Key Technical Properties of Custom Design Leather Jackets?

When sourcing custom design leather jackets, understanding critical technical properties is essential for making informed purchasing decisions. Here are some key specifications that B2B buyers should consider:

1. Material Grade: What Is Full Grain Leather?

Full grain leather is the highest quality leather available, made from the top layer of the hide, which retains the natural grain. This type of leather is known for its durability, breathability, and ability to develop a rich patina over time. For buyers, selecting full grain leather ensures that the jackets will not only look luxurious but will also stand the test of time, making them a worthy investment.

2. Custom Fit Tolerance: Why Is Accurate Sizing Important?

Custom fit tolerance refers to the allowable variation in measurements when producing a jacket tailored to individual specifications. For B2B buyers, ensuring a tight tolerance means the final product will fit the end user perfectly, reducing the need for costly alterations or returns. Accurate sizing enhances customer satisfaction and fosters brand loyalty.

Illustrative image related to custom design leather jackets

3. Lining Material: How Does It Affect Comfort and Insulation?

The choice of lining material is critical for comfort and insulation. Common options include cotton, polyester, or satin, each offering different benefits. A well-chosen lining enhances the wearability of the jacket, making it suitable for various climates and activities. Buyers should prioritize lining options that complement the intended use of the jackets, ensuring versatility and comfort.

4. Hardware Quality: What Role Do Zippers and Fasteners Play?

The quality of hardware, such as zippers and buttons, can significantly impact the overall look and functionality of a leather jacket. High-quality hardware, like YKK zippers, ensures durability and ease of use. For B2B buyers, specifying premium hardware not only elevates the perceived value of the product but also reduces the likelihood of repairs and customer dissatisfaction.

5. Finish Type: How Does It Influence Aesthetic Appeal?

The finish type applied to leather jackets can vary from matte to glossy, and can even include treatments for water resistance or protection against wear. Different finishes can cater to diverse consumer preferences and market trends. Buyers should consider finish types that align with their target audience, enhancing the jacket’s marketability.

Illustrative image related to custom design leather jackets

What Are Common Trade Terminology Terms in the Custom Leather Jacket Industry?

Understanding industry jargon is vital for effective communication with suppliers and manufacturers. Here are some common terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer): What Does It Mean for Custom Jackets?

OEM refers to companies that produce goods based on specifications provided by another company. In the context of custom leather jackets, an OEM can create jackets according to a buyer’s unique design and branding. This allows businesses to offer distinctive products without investing heavily in manufacturing infrastructure.

2. MOQ (Minimum Order Quantity): Why Is It Significant?

MOQ is the minimum number of units a supplier is willing to produce or sell in a single order. For B2B buyers, understanding MOQ is crucial for budgeting and inventory management. Negotiating a favorable MOQ can help optimize costs while ensuring adequate stock levels.

3. RFQ (Request for Quotation): How Does It Facilitate Cost Transparency?

An RFQ is a document sent to suppliers to request pricing for specific products or services. By submitting an RFQ for custom leather jackets, buyers can obtain detailed quotes that help them compare costs and make informed purchasing decisions. This process fosters transparency and aids in supplier selection.

Illustrative image related to custom design leather jackets

4. Incoterms: What Are They and Why Do They Matter?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade, including shipping, risk, and insurance obligations. Familiarity with Incoterms helps B2B buyers understand their liabilities and rights during the shipping process, leading to smoother transactions and less risk of disputes.

In conclusion, grasping both the essential technical properties and trade terminology surrounding custom design leather jackets equips B2B buyers with the knowledge needed to make strategic decisions. By focusing on quality materials and understanding industry jargon, buyers can enhance their sourcing strategies and ultimately achieve better business outcomes.

Navigating Market Dynamics and Sourcing Trends in the custom design leather jackets Sector

What Are the Current Market Dynamics and Key Trends in the Custom Design Leather Jackets Sector?

The global custom design leather jackets market is witnessing significant growth, driven by increasing consumer demand for personalized fashion and the rise of e-commerce platforms. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking bespoke leather products that reflect individual styles and cultural nuances. Notably, technology advancements such as virtual fitting apps and online design consultations are reshaping the purchasing experience, allowing buyers to customize products with ease.

Emerging trends include the integration of sustainable practices in the production process, with buyers showing preference for suppliers that prioritize ethical sourcing and eco-friendly materials. The market is also influenced by a growing interest in vintage and retro designs, prompting manufacturers to blend traditional craftsmanship with modern aesthetics. As international trade agreements evolve, buyers can benefit from reduced tariffs, making sourcing from regions with favorable trade relations more cost-effective.

Illustrative image related to custom design leather jackets

Additionally, the rise of social media marketing and influencer collaborations is driving brand visibility, encouraging B2B buyers to align with manufacturers that leverage these platforms effectively. Understanding these dynamics is essential for international buyers aiming to capitalize on the lucrative custom leather jacket market.

How Is Sustainability and Ethical Sourcing Impacting the Custom Design Leather Jackets Sector?

Sustainability and ethical sourcing have become paramount in the custom design leather jackets sector, as consumers increasingly demand transparency in supply chains. The environmental impact of leather production is significant, leading to a push for more responsible practices. International B2B buyers are now more inclined to partner with manufacturers that utilize eco-friendly tanning processes, which minimize chemical usage and water consumption.

Moreover, the use of leather as a byproduct of the meat industry is gaining traction, as it positions leather as a sustainable material rather than a primary commodity. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for suppliers aiming to demonstrate their commitment to ethical practices. These certifications not only enhance brand reputation but also assure buyers of compliance with environmental regulations.

By prioritizing suppliers that adhere to ethical standards, B2B buyers can not only meet consumer demand for sustainable products but also contribute to a more responsible fashion industry. This shift towards sustainability is not just a trend but a critical factor influencing purchasing decisions in the global market.

What Is the Evolution of the Custom Design Leather Jackets Market?

The custom design leather jackets market has evolved significantly over the past few decades, transitioning from traditional craftsmanship to a more personalized approach driven by technological advancements. Initially, leather jackets were primarily mass-produced, catering to standardized sizes and styles. However, with the advent of e-commerce and digital design tools, consumers now have the opportunity to create unique, tailored jackets that reflect their individual preferences.

This evolution has been marked by a resurgence of interest in artisanal craftsmanship, where skilled artisans focus on quality and detail, allowing for customization in fit, design, and materials. The increasing availability of high-quality leather from sustainable sources has further facilitated this shift, enabling buyers to choose from a variety of options without compromising on ethical standards.

As the market continues to adapt to consumer demands for individuality and sustainability, the focus on custom design leather jackets is expected to grow, offering lucrative opportunities for B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of custom design leather jackets

-

How do I ensure the quality of custom design leather jackets from suppliers?

To ensure quality, start by vetting potential suppliers thoroughly. Request samples of their leather and craftsmanship to evaluate the materials and stitching quality. Look for certifications or standards that indicate ethical sourcing and manufacturing practices. Additionally, check reviews and testimonials from other businesses to gauge reliability. Establish clear quality assurance criteria, including specifications for leather grades and construction methods, and ensure these are communicated in your purchase agreements. -

What is the minimum order quantity (MOQ) for custom leather jackets?

MOQs can vary widely among manufacturers, typically ranging from 10 to 50 units per design. Some suppliers may offer flexibility for smaller orders, especially for startups or new brands. It’s essential to communicate your needs upfront and inquire about the possibility of lower MOQs. Be aware that lower MOQs may result in higher per-unit costs, so factor this into your pricing strategy when sourcing. -

What customization options are available for B2B buyers of leather jackets?

B2B buyers can typically customize leather jackets in various ways, including selecting leather types, colors, and finishes. Additional options may include custom embroidery, logos, and personalized features like zippers and hardware. Discuss your design ideas with the supplier, and request a design consultation to explore all available options. Ensure that the supplier can accommodate your specific requirements and that they have experience in executing complex customizations. -

What payment terms should I expect when sourcing custom leather jackets?

Payment terms often depend on the supplier’s policies and your negotiation. Common arrangements include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipping. Some suppliers may offer net terms, allowing payment after delivery, especially for established buyers. It’s important to clarify payment methods accepted (e.g., bank transfer, PayPal) and any additional fees related to currency conversion or international transactions. -

How can I manage logistics and shipping for international orders of leather jackets?

Effective logistics management is crucial for international orders. Discuss shipping options with your supplier, including express and standard delivery methods. Consider using freight forwarders to streamline the process and manage customs clearance. Be aware of import duties and taxes that may apply in your country, and ensure that your supplier provides the necessary documentation for smooth customs processing. Tracking options should also be discussed to monitor shipment progress. -

What are the common challenges in sourcing custom leather jackets internationally?

Sourcing internationally can present challenges such as language barriers, time zone differences, and varying quality standards. Additionally, navigating customs regulations and potential delays in shipping can complicate the process. To mitigate these challenges, establish clear communication with your supplier, use a reliable logistics partner, and be prepared for potential cultural differences in business practices. Building a strong relationship with your supplier can also help address issues more effectively. -

How do I evaluate the supplier’s ability to meet my design specifications?

To assess a supplier’s capability to meet your design specifications, review their portfolio of previous work and request references from other B2B clients. Evaluate their design process, including how they handle custom requests and revisions. A reputable supplier should have a clear process for prototyping, allowing you to approve designs before full production. Additionally, inquire about their turnaround times and production capacity to ensure they can meet your demand. -

What quality assurance measures should I implement when sourcing leather jackets?

Implementing quality assurance measures is essential to ensure the final product meets your standards. Establish a clear set of specifications for materials, craftsmanship, and finishing. Consider conducting factory audits and requesting pre-shipment inspections to verify that products meet agreed-upon quality levels. Develop a return policy for defective items and ensure your supplier understands the importance of adhering to quality standards to maintain your brand’s reputation.

Top 4 Custom Design Leather Jackets Manufacturers & Suppliers List

1. Lusso Leather – Custom Leather Jackets

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Product Name: Custom Leather Jackets

Regular Price: $502.00

Sale Price: $398.00

Shipping: Free shipping on all jackets

Return Policy: 30 days for returns/alterations

Sizes Available: XSmall, Small, Medium, Large, XLarge, XXL, Custom Size, Custom Plus Size

Custom Plus Size Price: $481.00

Customization Options: Select from a variety of fabrics and leathers, custom embroidery, sublimation printing, l…

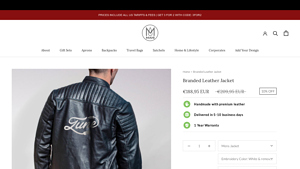

2. Mahileather – Branded Leather Jacket

Domain: mahileather.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Branded Leather Jacket”, “price”: “$215.46”, “original_price”: “$239.40”, “discount”: “10% OFF”, “material”: “premium leather”, “shipping”: “Free Worldwide Shipping”, “warranty”: “1 Year Warranty”, “returns”: “30 day returns”, “available_sizes”: [“Small”, “Medium”, “Large”], “available_colors”: [“White”, “Grey”, “Black”, “Navy Suede”, “Grey Suede”], “branding_options”: [“remove M…

3. Custom Leather Jackets – Premium Quality Tailoring

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom-made leather jacket, high-quality material and craftsmanship, fit to measure, custom design, premium/luxury quality, price range $1000-$2000, preference for vendors in Europe, long expertise required.

4. Himel Bros. – Bespoke Leather Jackets

Domain: himelbros.com

Registered: 2010 (15 years)

Introduction: Bespoke Leather Jackets from Himel Bros. – 12 weeks from order finalization for production and shipping. Allow 1-2 weeks for measurements & design details. Price range: $2,950.00 to $3,150.00. Models include: The Heron A-1 Custom, The Canuck Custom, The Kensington Custom, The Wolverine Custom, The Ross Mk. 1 Custom, The Frobisher Custom, The Lady Kensington Custom, The Ross Mk. 1 Shinki Suede, The…

Strategic Sourcing Conclusion and Outlook for custom design leather jackets

In summary, the strategic sourcing of custom design leather jackets presents a unique opportunity for B2B buyers to capitalize on a growing market that values individuality, craftsmanship, and quality. By leveraging relationships with manufacturers who emphasize ethical practices and high-grade materials, businesses can secure products that not only meet the demands of discerning customers but also align with sustainable principles.

Key takeaways include the importance of understanding regional market preferences, ensuring transparent supply chains, and fostering strong partnerships with suppliers who offer customization options. This approach not only enhances customer satisfaction but also positions your brand as a leader in the bespoke leather jacket segment.

As we look to the future, the demand for personalized fashion solutions is set to increase, particularly across diverse markets in Africa, South America, the Middle East, and Europe. Now is the time for international buyers to engage with innovative manufacturers, embrace digital design tools, and invest in high-quality leather products. By doing so, you will not only meet the evolving needs of your customers but also drive sustainable growth in your business. Take the next step towards transforming your product offerings with custom design leather jackets that resonate with your target audience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.