Introduction: Navigating the Global Market for faux leather fabric for clothing

In today’s competitive landscape, sourcing faux leather fabric for clothing can be a daunting task for international B2B buyers. With the rise of ethical consumerism and the increasing demand for sustainable fashion, navigating the complexities of this market has never been more critical. Faux leather, a versatile and cost-effective alternative to genuine leather, offers a unique blend of aesthetic appeal and practicality, making it an ideal choice for various applications, from stylish apparel to durable upholstery. However, the challenge lies in finding reliable suppliers who can deliver quality materials that meet diverse regional standards and consumer preferences.

This comprehensive guide aims to demystify the global market for faux leather fabric by providing actionable insights on the types of fabrics available, their applications, and the key factors to consider when vetting suppliers. We will explore the cost dynamics, market trends, and innovative uses of faux leather, equipping buyers from Africa, South America, the Middle East, and Europe—such as Brazil and Germany—with the knowledge they need to make informed purchasing decisions. By highlighting best practices in sourcing, this guide serves as an essential resource for businesses looking to enhance their product offerings while adhering to ethical and environmental standards. Prepare to navigate the faux leather landscape with confidence and clarity.

Table Of Contents

- Top 7 Faux Leather Fabric For Clothing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faux leather fabric for clothing

- Understanding faux leather fabric for clothing Types and Variations

- Key Industrial Applications of faux leather fabric for clothing

- 3 Common User Pain Points for ‘faux leather fabric for clothing’ & Their Solutions

- Strategic Material Selection Guide for faux leather fabric for clothing

- In-depth Look: Manufacturing Processes and Quality Assurance for faux leather fabric for clothing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather fabric for clothing’

- Comprehensive Cost and Pricing Analysis for faux leather fabric for clothing Sourcing

- Alternatives Analysis: Comparing faux leather fabric for clothing With Other Solutions

- Essential Technical Properties and Trade Terminology for faux leather fabric for clothing

- Navigating Market Dynamics and Sourcing Trends in the faux leather fabric for clothing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faux leather fabric for clothing

- Strategic Sourcing Conclusion and Outlook for faux leather fabric for clothing

- Important Disclaimer & Terms of Use

Understanding faux leather fabric for clothing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Faux Leather | High durability, waterproof, and flexible | Upholstery, fashion items, accessories | Pros: Cost-effective, easy to maintain. Cons: Less breathable than other materials. |

| PU Faux Leather | Softer texture, more environmentally friendly | High-end fashion, jackets, bags | Pros: Feels like real leather, versatile. Cons: Can be less durable in extreme conditions. |

| Veganistisch leer | Made from natural materials like cork or pineapple | Eco-friendly fashion, sustainable brands | Pros: Biodegradable, unique aesthetics. Cons: May have limited color options. |

| Embossed Faux Leather | Textured surface mimicking animal skins | Fashion apparel, luxury items | Pros: High-end appearance, unique designs. Cons: Can be more expensive due to processing. |

| Stretch Faux Leather | Elasticity for form-fitting garments | Activewear, fitted clothing | Pros: Comfortable, allows for movement. Cons: May require special care to maintain elasticity. |

What Are the Characteristics of PVC Faux Leather?

PVC (polyvinyl chloride) faux leather is recognized for its exceptional durability and flexibility. It is waterproof, making it suitable for both indoor and outdoor applications, including upholstery and fashion items. B2B buyers should consider PVC for its cost-effectiveness and ease of maintenance, as it resists stains and is simple to clean. However, its low breathability may be a downside for clothing items intended for warmer climates.

How Does PU Faux Leather Compare to Other Types?

PU (polyurethane) faux leather offers a softer texture and a more environmentally friendly profile compared to PVC. Its high-end feel makes it popular for fashion items, jackets, and bags. B2B buyers should note that while PU can mimic the look of genuine leather effectively, it may not perform as well in extreme conditions. Its versatility in applications and aesthetic appeal often justify the investment despite potential durability concerns.

What Makes Vegan Leather a Sustainable Choice?

Vegan leather is a term that encompasses various materials made from natural resources, such as cork or pineapple fibers. This type of faux leather appeals to eco-conscious brands and consumers, aligning with the growing demand for sustainable products. B2B purchasers should focus on the unique aesthetics and biodegradable properties of vegan leather. However, it may offer limited color options and require careful sourcing to ensure quality.

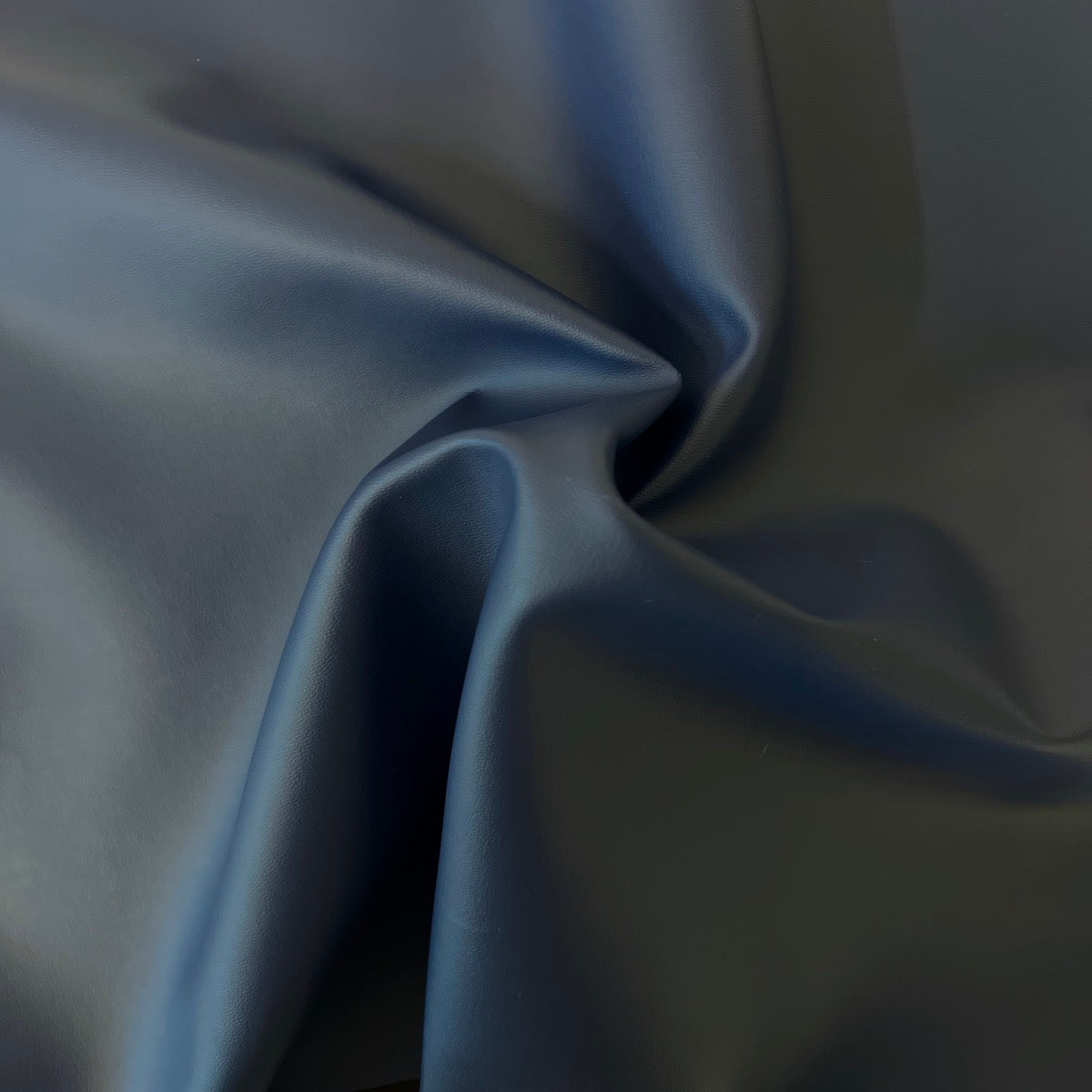

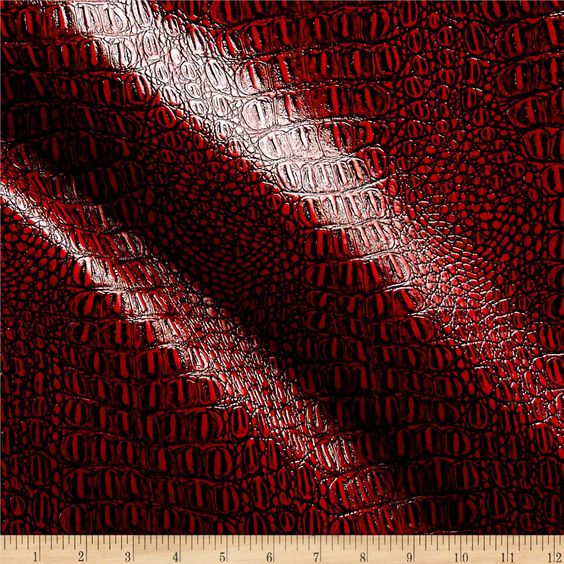

Illustrative image related to faux leather fabric for clothing

Why is Embossed Faux Leather Popular in Fashion?

Embossed faux leather features textured surfaces that replicate the appearance of animal skins, making it a sought-after choice for luxury fashion items. This type of faux leather allows for unique designs and high-end aesthetics, attracting brands looking to differentiate their products. B2B buyers should consider the cost implications of embossed faux leather, as its processing can lead to higher prices, but the potential for premium branding can justify the expense.

What Are the Benefits of Stretch Faux Leather in Activewear?

Stretch faux leather is designed with elasticity, making it ideal for form-fitting garments such as activewear. This material provides comfort and freedom of movement, appealing to manufacturers targeting the fitness and fashion markets. B2B buyers should be aware that while stretch faux leather enhances wearability, it may require special care to maintain its elasticity over time. This consideration is crucial for brands focused on durability and performance in their offerings.

Key Industrial Applications of faux leather fabric for clothing

| Industry/Sector | Specific Application of faux leather fabric for clothing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Jackets and Coats | Offers a stylish alternative to real leather at lower costs, appealing to eco-conscious consumers. | Assess durability, color variety, and ethical production standards. |

| Automotive | Upholstery and Seat Covers | Enhances interior aesthetics while providing easy maintenance and resistance to wear and tear. | Evaluate fire resistance, easy cleaning properties, and color matching with vehicle interiors. |

| Sports & Outdoor Gear | Protective Gear and Apparel | Provides durability and weather resistance, essential for outdoor activities and sports. | Consider breathability, flexibility, and moisture-wicking capabilities. |

| Home Decor | Cushions and Decorative Accents | Adds luxury appeal and is easy to clean, ideal for residential and commercial spaces. | Look for stain resistance, color options, and texture to match interior design themes. |

| Footwear | Boots and Casual Shoes | Combines comfort and style, with lower production costs than genuine leather. | Focus on flexibility, abrasion resistance, and compliance with footwear safety standards. |

How is Faux Leather Fabric Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, faux leather is predominantly utilized for making stylish jackets and coats. Its ability to mimic the luxurious appearance of genuine leather while being more affordable attracts a diverse consumer base, especially those prioritizing ethical fashion. Buyers should look for durable options that can withstand wear and tear, as well as a wide range of colors and textures to cater to different fashion trends. Ensuring that the sourcing aligns with sustainable practices can also enhance brand reputation in various markets, particularly in Europe.

Illustrative image related to faux leather fabric for clothing

What Role Does Faux Leather Play in Automotive Applications?

Faux leather is extensively used in automotive upholstery, including seat covers and interior linings. Its resistance to wear, easy maintenance, and aesthetic appeal make it a favored choice among automotive manufacturers and suppliers. Buyers should prioritize materials that meet fire safety regulations and can withstand varying climate conditions, especially in regions like the Middle East where temperatures can soar. Additionally, color matching with existing vehicle designs is crucial for maintaining brand consistency.

How is Faux Leather Fabric Beneficial for Sports & Outdoor Gear?

In the sports and outdoor gear industry, faux leather is utilized for protective gear and apparel, providing a blend of durability and weather resistance. This fabric’s ability to repel moisture and withstand abrasions makes it ideal for outdoor activities. Buyers should consider sourcing options that offer breathability and flexibility to enhance user comfort during physical activities. Furthermore, adherence to international safety standards is essential, especially when exporting to markets in Africa and South America.

Why Choose Faux Leather for Home Decor?

Faux leather is increasingly popular in home decor, particularly for cushions and decorative accents. Its easy-to-clean nature and luxurious look contribute to a sophisticated interior ambiance, appealing to both residential and commercial buyers. When sourcing, it is important to evaluate the fabric’s stain resistance and available color options to ensure compatibility with various design themes. This versatility allows businesses to cater to diverse customer preferences across different regions, including Europe and South America.

Illustrative image related to faux leather fabric for clothing

What Advantages Does Faux Leather Offer in Footwear Production?

In the footwear industry, faux leather is commonly used for boots and casual shoes, providing a comfortable and stylish alternative to genuine leather. Its lower production costs and wide range of design possibilities make it an attractive option for manufacturers. Buyers should focus on sourcing materials that are flexible and abrasion-resistant to ensure product longevity. Compliance with footwear safety standards is also a critical consideration, particularly in international markets where regulations may vary significantly.

3 Common User Pain Points for ‘faux leather fabric for clothing’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Faux Leather Sourcing

The Problem: B2B buyers often face the challenge of sourcing high-quality faux leather that meets specific standards for durability and aesthetic appeal. With a wide range of suppliers, it can be difficult to distinguish between premium materials and inferior alternatives. This inconsistency can lead to unsatisfactory product performance, customer complaints, and financial losses, particularly in markets where brand reputation hinges on quality.

The Solution: To mitigate quality concerns, buyers should establish a thorough vetting process for suppliers. This includes requesting samples of faux leather fabrics and conducting comparative analyses based on criteria such as texture, flexibility, and durability. Additionally, buyers should inquire about the manufacturing process, including the types of materials used (e.g., PVC versus polyurethane) and their environmental impact. Engaging in partnerships with suppliers who provide transparency and certifications can also enhance trust. Regular quality audits and establishing clear return policies will further safeguard against sourcing subpar materials.

Scenario 2: Addressing the Challenges of Color Consistency in Faux Leather

The Problem: Color inconsistency is a prevalent issue when purchasing faux leather fabric, especially when ordering large quantities from different batches or suppliers. Variations in dye lots can lead to mismatched shades, which can be particularly problematic for fashion brands that require uniformity across their clothing lines. This inconsistency can affect product lines, leading to customer dissatisfaction and potential revenue loss.

The Solution: To combat color inconsistency, B2B buyers should prioritize suppliers who guarantee color matching and consistency across batches. Implementing a color standardization process can help as well. Buyers can request Pantone color references or lab-dip approvals before placing large orders to ensure that the shades align with their expectations. It’s also beneficial to maintain a record of all color specifications and communicate these clearly with suppliers to prevent misunderstandings. Establishing a reliable inventory system that tracks orders and batches can help buyers manage potential discrepancies effectively.

Illustrative image related to faux leather fabric for clothing

Scenario 3: Overcoming Durability and Performance Issues in Faux Leather Products

The Problem: Durability is a critical concern for B2B buyers of faux leather, particularly in high-wear applications like jackets, bags, and upholstery. Buyers may find that some faux leather products do not hold up as expected over time, leading to issues like cracking, peeling, or fading. This not only affects customer satisfaction but also increases return rates and replacement costs, impacting overall profitability.

The Solution: To enhance the durability of faux leather products, buyers should focus on sourcing materials specifically designed for resilience. This includes looking for fabrics with high tensile strength and abrasion resistance ratings. When selecting faux leather, opting for products that are treated with protective coatings can also improve longevity. Buyers should invest in comprehensive testing, such as wear and tear trials, to assess how different materials perform under real-world conditions. Collaborating closely with manufacturers to understand the intended use and environmental factors can further ensure that the right faux leather is selected for each application, ultimately leading to more reliable and durable products.

Strategic Material Selection Guide for faux leather fabric for clothing

What Are the Key Materials Used in Faux Leather Fabric for Clothing?

Faux leather fabrics are primarily made from synthetic materials designed to mimic the aesthetic and tactile qualities of genuine leather. Understanding the various materials available for faux leather can help international B2B buyers make informed decisions based on performance, cost, and application suitability.

What Are the Properties of PVC Faux Leather?

Polyvinyl Chloride (PVC) is one of the most common materials used in faux leather production. Known for its durability and resistance to moisture, PVC faux leather is ideal for a wide range of applications, including jackets, bags, and upholstery. It can withstand various environmental conditions, making it suitable for both indoor and outdoor use.

Illustrative image related to faux leather fabric for clothing

Pros: PVC is relatively inexpensive, easy to clean, and available in a wide array of colors and textures. Its waterproof nature makes it a popular choice for products exposed to moisture.

Cons: However, PVC has lower breathability compared to other materials, which can lead to discomfort in warmer climates. Additionally, its production process may involve harmful chemicals, raising environmental concerns.

Impact on Application: PVC faux leather is compatible with various media, including screen printing and embroidery, making it versatile for branding and customization.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local regulations regarding the use of PVC, as some countries have stringent environmental standards. Compliance with ASTM standards is also crucial for ensuring product quality.

Illustrative image related to faux leather fabric for clothing

How Does PU Faux Leather Compare?

Polyurethane (PU) is another widely used material in faux leather production. It offers a more natural feel and appearance compared to PVC, closely resembling genuine leather. PU is often chosen for high-end fashion items due to its aesthetic appeal and flexibility.

Pros: PU faux leather is softer, more breathable, and more environmentally friendly than PVC. It is also resistant to cracking and peeling, enhancing its longevity.

Cons: The primary drawback of PU is its higher cost relative to PVC. Additionally, it may not be as resistant to water, limiting its use in certain applications.

Impact on Application: PU is ideal for fashion items such as skirts, jackets, and trousers, where a luxurious look and feel are essential.

Considerations for International Buyers: European buyers, particularly from Germany, may prefer PU due to its eco-friendliness and adherence to stringent EU regulations. Buyers should verify compliance with DIN standards for textile safety.

Illustrative image related to faux leather fabric for clothing

What Are the Benefits of Using Vegan Leather?

Vegan leather, often made from a blend of materials such as cork, apple peels, or recycled plastics, is gaining popularity among environmentally conscious consumers. This material is designed to be cruelty-free while still providing the look and feel of leather.

Pros: Vegan leather is highly sustainable and can be produced with minimal environmental impact. It also offers a unique aesthetic that appeals to niche markets.

Cons: The production process can be complex, leading to higher manufacturing costs. Additionally, the durability of vegan leather can vary significantly based on the materials used.

Impact on Application: Vegan leather is suitable for fashion-forward items and accessories, appealing to consumers looking for sustainable options.

Illustrative image related to faux leather fabric for clothing

Considerations for International Buyers: Buyers in the Middle East and Europe may find a growing demand for vegan leather products, aligning with consumer trends towards sustainability. Compliance with JIS standards may also be relevant for specific applications.

Summary Table of Faux Leather Materials

| Materiaal | Typical Use Case for faux leather fabric for clothing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Jackets, bags, upholstery | Durable and waterproof | Low breathability | Low |

| PU | Fashion items, jackets, trousers | Soft, breathable, and eco-friendly | Higher cost | Med |

| Veganistisch leer | Sustainable fashion items, accessories | Highly sustainable and unique aesthetic | Variable durability | Hoog |

This guide provides a comprehensive overview of the key materials used in faux leather fabric for clothing, enabling B2B buyers to make informed decisions based on their specific needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for faux leather fabric for clothing

What Are the Main Stages in the Manufacturing Process of Faux Leather Fabric for Clothing?

The production of faux leather fabric involves several key stages, each critical to ensuring the material’s quality and durability. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to faux leather fabric for clothing

How is Material Prepared for Faux Leather Fabric?

The manufacturing process begins with material preparation, which typically involves selecting the base material. Faux leather is primarily produced from PVC (polyvinyl chloride) or PU (polyurethane), which are both synthetic polymers. In some eco-friendly variations, vegetable oils may be used. The chosen material undergoes a compounding process where additives are mixed in to enhance properties like flexibility, durability, and color. This stage also includes the creation of a substrate, which acts as the foundation for the faux leather, providing structural integrity.

What Techniques Are Used in the Forming Stage?

Once the materials are prepared, the next stage is forming. This can involve a variety of techniques, such as coating, lamination, or extrusion. In the coating process, a layer of synthetic material is applied to the substrate, often using techniques like knife-over-roll or gravure printing. Lamination involves bonding layers of material to create a thicker, more durable fabric. Extrusion, on the other hand, allows for continuous production where the faux leather is formed into sheets that can be cut into desired shapes.

How is the Assembly of Faux Leather Fabric Executed?

Following the forming stage, the assembly process involves cutting and stitching the fabric into specific patterns or designs intended for clothing. This may include creating panels for jackets, skirts, or pants. Precision in this stage is crucial, as the quality of stitching and cutting directly affects the final product’s look and feel. Automated cutting machines and sewing technologies are often utilized to enhance efficiency and ensure consistency in production.

What Finishing Techniques Enhance Faux Leather Fabric Quality?

The finishing stage is where faux leather is treated to enhance its appearance and performance. Techniques such as embossing, dyeing, and applying protective coatings are commonly employed. Embossing adds texture and can mimic the grain of genuine leather, while dyeing allows for a wide range of colors. Protective coatings can improve water resistance and durability, making the fabric suitable for various applications, including outdoor wear.

What Quality Assurance Measures Are in Place for Faux Leather Fabric?

Quality assurance (QA) is paramount in the faux leather manufacturing process, ensuring that the final product meets international standards and client expectations.

What Are the Relevant International Standards for Quality Assurance?

Many manufacturers adhere to international quality standards, such as ISO 9001, which focuses on quality management systems. This certification ensures that processes are in place to consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking in Europe or API for certain applications may also apply, particularly for faux leather used in automotive or industrial contexts.

What QC Checkpoints Are Commonly Implemented?

Quality control (QC) is integrated throughout the manufacturing process, with critical checkpoints established at various stages. Incoming Quality Control (IQC) checks raw materials for conformity to specifications before production begins. In-Process Quality Control (IPQC) monitors production processes to ensure that they adhere to established standards. Finally, Final Quality Control (FQC) assesses the finished products for defects and compliance with specifications before shipping.

Which Testing Methods Are Common for Faux Leather Fabric?

Common testing methods for faux leather include tensile strength tests, colorfastness assessments, and abrasion resistance tests. These evaluations help ensure that the fabric can withstand the wear and tear associated with clothing while maintaining its aesthetic qualities. Other tests may include water resistance and flammability assessments, depending on the intended use of the fabric.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability and compliance.

What Auditing and Reporting Practices Should Buyers Consider?

Buyers should conduct regular audits of potential suppliers to assess their manufacturing practices and quality management systems. This can include reviewing documentation related to ISO certifications, quality control reports, and production processes. Requesting samples for independent testing can also provide insight into the fabric’s performance and adherence to quality standards.

Illustrative image related to faux leather fabric for clothing

How Do Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further enhance confidence in a supplier’s quality control measures. These independent organizations can perform on-site audits, evaluate production processes, and conduct product testing, providing an unbiased assessment of the supplier’s capabilities.

What Are the Nuances of Quality Control for International B2B Transactions?

When engaging in international transactions, particularly with suppliers from different regions, it’s important to consider the nuances of quality control. Language barriers, cultural differences, and varying regulatory standards can impact communication and compliance. Buyers should be proactive in establishing clear expectations regarding quality standards and ensure that suppliers are equipped to meet these requirements.

How Can Buyers Navigate Quality Certification Differences?

Understanding the differences in quality certifications across regions is essential. For instance, while ISO standards are widely recognized, certain regions may have unique certifications that are not universally accepted. Buyers should familiarize themselves with the specific requirements of their target markets and ensure that their suppliers can meet these standards.

By comprehensively understanding the manufacturing processes and quality assurance measures associated with faux leather fabric, B2B buyers can make informed decisions, ensuring they source high-quality materials that align with their brand values and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather fabric for clothing’

The following guide is designed to assist B2B buyers in sourcing faux leather fabric for clothing. This checklist provides clear, actionable steps to ensure that you procure high-quality materials that meet your business needs and standards.

Illustrative image related to faux leather fabric for clothing

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is critical for ensuring that the faux leather fabric meets your project requirements. Consider factors such as thickness, texture, and finish. Additionally, decide whether you need specific properties like waterproofing or UV resistance, which can impact the durability and appearance of the final product.

Step 2: Research Potential Suppliers

A thorough market analysis will help you identify reliable suppliers. Look for manufacturers with a strong reputation in the faux leather market, especially those known for high-quality materials. Utilize trade directories, industry forums, and recommendations from peers to compile a list of potential partners.

- Key considerations:

- Review online ratings and testimonials.

- Check for any industry-specific certifications or awards.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that your chosen suppliers hold relevant certifications. Certifications can indicate compliance with international standards for quality and safety, which is crucial when sourcing materials for clothing. Look for certifications related to sustainability, such as OEKO-TEX or GOTS, especially if your target market values eco-friendly products.

Step 4: Request Samples

Always request samples before placing a bulk order. Assess the quality of the faux leather fabric firsthand to ensure it aligns with your expectations. Pay attention to aspects such as texture, flexibility, and color accuracy. This step can prevent costly mistakes and ensure that the material will meet the design requirements of your clothing line.

Illustrative image related to faux leather fabric for clothing

Step 5: Negotiate Pricing and Terms

Once you are satisfied with the samples, engage in discussions about pricing and payment terms. Understanding the cost structure is vital for maintaining your profit margins. Be prepared to negotiate based on order volume, delivery times, and payment conditions. Ensure that all terms are documented to avoid misunderstandings later.

Step 6: Confirm Production Capabilities

Verify that the supplier can handle your required production volume and timeline. Discuss their capacity to meet deadlines, especially if you have specific launch dates for your clothing line. Understanding their production processes can also provide insights into potential bottlenecks and quality control measures.

Step 7: Establish a Communication Plan

Effective communication is essential for a successful partnership. Set clear expectations regarding response times and updates throughout the sourcing process. Regular check-ins can help address any issues promptly and keep the project on track, ensuring that both parties are aligned on goals and timelines.

By following this checklist, B2B buyers can navigate the complexities of sourcing faux leather fabric for clothing more efficiently, leading to successful procurement outcomes and enhanced product offerings.

Comprehensive Cost and Pricing Analysis for faux leather fabric for clothing Sourcing

What Are the Key Cost Components in Faux Leather Fabric Sourcing?

When evaluating the cost structure of faux leather fabric for clothing, several components must be considered:

Illustrative image related to faux leather fabric for clothing

-

Materials: The primary material for faux leather includes PVC or PU, with prices varying based on quality and sourcing. Higher-grade materials, such as those with additional features like water resistance or UV protection, can increase costs.

-

Labor: Labor costs involve the workforce required for cutting, sewing, and finishing the fabric. These costs can fluctuate significantly based on the production location, with countries like China often offering lower labor costs compared to Europe.

-

Manufacturing Overhead: This encompasses factory costs, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, affecting the overall price of the fabric.

-

Tooling: Initial setup costs for specialized machinery or molds for custom designs can be significant. This cost can be amortized over larger production runs, making it essential to consider volume when sourcing.

-

Quality Control (QC): Implementing stringent QC measures is crucial for maintaining fabric quality. While this adds to the overall cost, it can prevent costly reworks and returns.

-

Logistics: Shipping and handling play a pivotal role, especially for international buyers. Factors such as distance, shipping method, and tariffs can significantly impact the total cost.

-

Margin: Suppliers typically include a profit margin based on the perceived value of their product and market demand. This margin can vary based on competition and exclusivity of the fabric.

How Do Price Influencers Affect Faux Leather Fabric Costs?

Multiple factors can influence the pricing of faux leather fabric, particularly for international B2B buyers:

-

Volume/MOQ: Suppliers often set a minimum order quantity (MOQ). Higher volumes can lead to price breaks, making it more cost-effective per unit.

-

Specifications and Customization: Customized fabrics or unique specifications (like embossed patterns or specific color matches) can incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials: The choice of materials impacts pricing. For instance, eco-friendly or high-performance fabrics generally command a premium.

-

Quality and Certifications: Fabrics that meet specific industry standards or certifications (e.g., eco-labels) may come at a higher price due to the rigorous testing and compliance involved.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their reliability and service quality.

-

Incoterms: The chosen Incoterms can affect cost structures. Different terms dictate who bears responsibility for shipping, insurance, and tariffs, impacting the final cost to the buyer.

What Tips Should Buyers Consider for Cost-Efficiency in Sourcing Faux Leather?

-

Negotiate: Always engage in price negotiations with suppliers. Understanding the cost components can give buyers leverage to negotiate better terms.

-

Assess Total Cost of Ownership (TCO): Beyond initial purchase costs, consider long-term factors such as durability, maintenance, and potential waste. A cheaper fabric may not be the best choice if it requires frequent replacement.

-

Understand Pricing Nuances for International Buyers: Different markets may have varying pricing strategies influenced by local demand and economic conditions. For instance, buyers from Africa may face different logistics costs compared to those from Europe. Understanding local market conditions can aid in effective negotiations.

-

Stay Informed About Market Trends: Keeping abreast of market trends, such as shifts toward sustainable materials, can help buyers anticipate price changes and align their sourcing strategies accordingly.

Disclaimer on Pricing

Prices for faux leather fabric can vary widely based on the factors outlined above. It is advisable for buyers to request quotes from multiple suppliers and consider all cost components to make informed purchasing decisions.

Alternatives Analysis: Comparing faux leather fabric for clothing With Other Solutions

Understanding Alternatives to Faux Leather Fabric for Clothing

In the realm of clothing materials, faux leather fabric has emerged as a popular choice due to its aesthetic appeal and ethical considerations. However, B2B buyers should also consider alternative options that may better suit their specific needs, whether that be in terms of cost, performance, or maintenance. This analysis will compare faux leather fabric with two viable alternatives: genuine leather and faux suede, allowing buyers to make informed decisions.

| Comparison Aspect | Faux Leather Fabric For Clothing | Genuine Leather | Faux Suede |

|---|---|---|---|

| Performance | Good durability, water-resistant | High durability, excellent breathability | Moderate durability, soft texture |

| Cost | Generally low to moderate | Hoog | Low to moderate |

| Ease of Implementation | Easy to source and work with | Requires specialized handling | Easy to work with |

| Maintenance | Easy to clean, stain-resistant | Requires regular conditioning | Easy to clean, less stain-resistant |

| Best Use Case | Fashionable apparel, upholstery | Luxury items, durable goods | Casual clothing, accessories |

Pros and Cons of Genuine Leather

Genuine leather is often viewed as the premium choice for high-end apparel and accessories. Its significant advantages include exceptional durability and breathability, making it ideal for items that require a long lifespan, such as luxury handbags and shoes. However, the higher cost of genuine leather can be a barrier for many businesses, especially in price-sensitive markets. Additionally, the maintenance requirements, including conditioning to prevent drying and cracking, can deter some buyers. For brands focused on sustainability, the ethical implications of animal sourcing may also pose a concern.

Exploring Faux Suede as an Alternative

Faux suede is another alternative that offers a soft, matte texture akin to real suede, making it appealing for casual clothing and accessories. This material is typically more affordable than both faux leather and genuine leather, allowing brands to maintain a stylish appearance without a hefty price tag. However, faux suede is generally less durable than faux leather and may not hold up as well in high-wear situations. While it is relatively easy to clean, it is more prone to stains compared to faux leather, which can affect its longevity in clothing applications.

Illustrative image related to faux leather fabric for clothing

Making the Right Choice for Your B2B Needs

In selecting the right material for clothing production, B2B buyers must consider various factors, including their target market, product positioning, and ethical considerations. Faux leather fabric stands out for its balance of affordability and aesthetic appeal, making it suitable for a range of applications from fashion to upholstery. Meanwhile, genuine leather may be more appropriate for luxury brands willing to invest in quality and longevity. On the other hand, faux suede offers a budget-friendly option for casual wear but may compromise on durability.

Ultimately, the decision should align with the brand’s identity, customer expectations, and operational capabilities. By weighing the pros and cons of each alternative, buyers can ensure they select the most appropriate solution that meets their business objectives and resonates with their target audience.

Essential Technical Properties and Trade Terminology for faux leather fabric for clothing

What Are the Key Technical Properties of Faux Leather Fabric for Clothing?

Faux leather, a synthetic alternative to genuine leather, is characterized by several important technical properties that impact its usability in clothing and fashion. Understanding these properties is crucial for B2B buyers looking to source quality materials for their apparel lines.

Illustrative image related to faux leather fabric for clothing

1. Material Composition

Faux leather is primarily composed of either PVC (polyvinyl chloride) or PU (polyurethane). PVC offers durability and is often more cost-effective, while PU mimics the texture of genuine leather more closely and is considered more environmentally friendly. Knowing the composition helps buyers assess durability, maintenance, and potential environmental impact.

2. Weight and Thickness

The weight of faux leather typically ranges from 200 to 600 grams per square meter (gsm), and thickness can vary from 0.5 mm to 2 mm. These specifications influence the fabric’s drape, feel, and application in different clothing items. Heavier weights are suitable for outerwear, while lighter weights can be used for linings and detailed designs.

3. Abrasion Resistance

Abrasion resistance is a measure of how well the material withstands wear and tear. This property is critical for clothing items that experience frequent movement, such as jackets or pants. Fabrics with higher abrasion resistance ratings ensure longevity and maintain aesthetic appeal over time, reducing replacement costs for manufacturers.

4. Water Resistance

Faux leather is generally water-resistant, making it a practical choice for outerwear. The level of water resistance can vary based on the material composition and coating processes. This property is particularly important for B2B buyers targeting markets in regions with varying climates, ensuring that the end product meets consumer expectations for functionality.

5. Colorfastness

Colorfastness refers to the ability of the fabric to retain its color after exposure to washing, sunlight, and other environmental factors. High colorfastness is essential for maintaining the visual appeal of clothing over time. Buyers should seek materials that have been tested for colorfastness to ensure quality and customer satisfaction.

6. Flexibility and Stretchability

Faux leather can exhibit varying degrees of flexibility and stretchability, which influence comfort and fit. Fabrics designed with added stretch can enhance wearability, particularly in form-fitting garments. Understanding these characteristics allows buyers to select materials that align with their design intentions.

What Are Common Trade Terms Used in the Faux Leather Industry?

Navigating the faux leather market requires familiarity with specific trade terminology. Here are some essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are marketed by another company under its own brand name. In the context of faux leather, it denotes manufacturers who create materials that other brands use in their products. Understanding OEM relationships can help buyers identify reliable suppliers and establish partnerships.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is critical for budgeting and inventory planning, as it determines how much product a buyer must purchase at one time. Knowing the MOQ can help businesses manage cash flow and stock levels effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes detailed specifications for the desired products. Utilizing RFQs can streamline the procurement process, ensuring that buyers receive competitive pricing and clear terms from potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, which are vital for effective supply chain management.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the faux leather industry, understanding lead times is crucial for planning production schedules and ensuring timely market entry. Buyers should communicate lead time expectations clearly to avoid disruptions.

6. B2B (Business to Business)

B2B refers to transactions conducted between businesses, as opposed to transactions between businesses and individual consumers (B2C). This distinction is important for understanding market dynamics, marketing strategies, and customer relationship management within the faux leather supply chain.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing faux leather fabric, enhancing their competitive edge in the apparel market.

Illustrative image related to faux leather fabric for clothing

Navigating Market Dynamics and Sourcing Trends in the faux leather fabric for clothing Sector

What Are the Current Market Dynamics and Key Trends in the Faux Leather Fabric for Clothing Sector?

The faux leather fabric market is witnessing robust growth, driven by an increasing demand for sustainable and ethically produced materials across various global regions, particularly in Africa, South America, the Middle East, and Europe. Key drivers include the rising consumer awareness regarding animal welfare, leading to a shift towards vegan alternatives, as well as the durability and low maintenance requirements of faux leather compared to genuine leather. Furthermore, the increasing adoption of advanced manufacturing technologies, including digital printing and automated cutting, is enhancing the customization capabilities and efficiency of faux leather production, making it an attractive option for B2B buyers.

Emerging trends indicate a growing inclination towards multifunctional fabrics that offer features such as water resistance and UV protection, catering to diverse applications from fashion to upholstery. Additionally, the rise of e-commerce platforms has transformed the sourcing landscape, enabling international buyers to access a wider range of suppliers and products, often at competitive prices. As countries like Brazil and Germany strengthen their manufacturing capabilities, buyers should focus on leveraging local suppliers to mitigate shipping costs and lead times, while also exploring collaborations with innovative designers to tap into niche markets.

How Is Sustainability Influencing Sourcing Trends for Faux Leather Fabric?

Sustainability has become a cornerstone of sourcing strategies within the faux leather fabric sector. The environmental impact of traditional leather production, which involves significant water usage and chemical pollution, has prompted a shift towards eco-friendly alternatives. Buyers are increasingly prioritizing materials that are not only cruelty-free but also produced with a reduced ecological footprint. This includes sourcing faux leather made from recycled plastics or plant-based materials, which can significantly lower carbon emissions compared to conventional synthetic options.

Ethical sourcing is also gaining traction, with B2B buyers encouraged to establish transparent supply chains that adhere to fair labor practices. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By investing in such materials, businesses can enhance their brand reputation and appeal to a growing demographic of environmentally conscious consumers.

What Is the Brief Evolution and History of Faux Leather Fabric in the B2B Context?

The evolution of faux leather fabric can be traced back to the early 20th century when it was first developed as an alternative to genuine leather. Originally made from materials like PVC, faux leather has undergone significant advancements in terms of quality and aesthetics, allowing it to closely mimic the look and feel of real leather. By the 1970s, with the rise of synthetic fibers, faux leather gained popularity not only in fashion but also in upholstery, automotive, and accessories.

In recent years, technological innovations have led to the development of high-performance faux leather options that offer enhanced durability and a wider range of colors and textures. This evolution has positioned faux leather as a viable choice for B2B buyers looking to balance quality with ethical considerations, making it an essential component in the modern fabric marketplace. As the industry continues to evolve, staying informed about trends and innovations will be crucial for international buyers seeking to capitalize on this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of faux leather fabric for clothing

1. How do I choose the right faux leather fabric for my clothing line?

When selecting faux leather fabric, consider factors such as the desired texture, weight, and finish. Different types of faux leather, like PU or PVC, offer varying levels of durability and flexibility. Evaluate the specific applications of the fabric—whether for jackets, pants, or skirts—to determine the most suitable option. Additionally, request samples to assess quality and feel before making a bulk purchase. Lastly, consider sourcing from suppliers who offer a variety of colors and patterns to align with your brand’s aesthetic.

Illustrative image related to faux leather fabric for clothing

2. What are the advantages of using faux leather over genuine leather for clothing?

Faux leather provides several benefits, including cost-effectiveness, animal-friendliness, and ease of maintenance. It mimics the look and feel of genuine leather while being more resistant to stains and easier to clean. Faux leather is also available in a wider range of colors and finishes, allowing for greater design flexibility. Furthermore, it tends to be lighter and more water-resistant, making it ideal for various clothing applications, especially in regions with diverse climates.

3. What is the minimum order quantity (MOQ) for faux leather fabric?

The MOQ for faux leather fabric varies by supplier and can range from as low as 50 yards to over 500 yards. It’s important to communicate your specific needs with potential suppliers, as many are willing to negotiate MOQs, especially for first-time buyers or larger contracts. Always confirm the MOQ before placing an order to ensure it aligns with your production requirements. Additionally, inquire if the supplier offers sample orders to test the fabric quality before committing to larger quantities.

4. How can I ensure the quality of faux leather fabric when sourcing internationally?

To ensure quality, start by vetting suppliers through reviews, certifications, and previous client testimonials. Request fabric samples to evaluate texture, durability, and color accuracy. Establish clear quality assurance standards and consider visiting the manufacturing site if feasible. Additionally, negotiating terms for third-party quality inspections before shipment can help mitigate risks. Always have a clear return policy in case the delivered product does not meet the agreed-upon specifications.

5. What payment terms should I expect when sourcing faux leather fabric?

Payment terms can vary significantly based on the supplier and your negotiation skills. Common terms include a 30% deposit upfront with the remaining balance due upon delivery or a letter of credit for larger orders. It’s advisable to clarify all payment options and conditions before finalizing the order. Additionally, consider using secure payment methods that provide buyer protection to safeguard your investment, especially when dealing with international suppliers.

6. How do I handle shipping and logistics for faux leather fabric?

When managing shipping and logistics, first confirm the supplier’s shipping capabilities, including options for air or sea freight. Determine the estimated delivery times and associated costs, factoring in customs duties and taxes for international shipments. It’s beneficial to work with a reliable freight forwarder who can assist with documentation and ensure compliance with local regulations. Additionally, consider insurance for your shipment to protect against loss or damage during transit.

7. Can I customize faux leather fabric for my clothing designs?

Yes, many suppliers offer customization options for faux leather fabric, including bespoke colors, finishes, and textures. Discuss your specific design requirements with the supplier to see if they can accommodate your needs. Customization may involve higher MOQs and longer lead times, so plan accordingly. Always request a sample of the customized fabric to ensure it meets your expectations before placing a full order.

8. What are the environmental considerations when sourcing faux leather?

Sourcing faux leather can have varying environmental impacts depending on the materials used in production. Opt for suppliers that utilize eco-friendly processes or biodegradable materials, such as those made from plant-based sources. Understanding the manufacturing practices of your supplier is crucial; inquire about their sustainability certifications and initiatives. By choosing environmentally responsible suppliers, you can align your clothing line with ethical consumer expectations and reduce your ecological footprint.

Illustrative image related to faux leather fabric for clothing

Top 7 Faux Leather Fabric For Clothing Manufacturers & Suppliers List

1. Mood Fabrics – Faux Leather Fabric

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: Faux Leather Fabric by the Yard | Ethical Alternative

2. Sewport – Faux Leather Solutions

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: Faux leather, also known as synthetic leather, is a petroleum-based alternative to genuine leather. It is soft to the touch, water-resistant, and highly resistant to stains, making it easy to clean. While less durable than real leather, it is resistant to abrasions and cuts, ideal for upholstery in homes with children or pets. Faux leather can be produced in various colors, including unconventiona…

3. Denver Fabrics – Faux Leather and Vinyl Collection

Domain: denverfabrics.com

Registered: 1998 (27 years)

Introduction: Faux Leather and Vinyl collection includes 47 products. Key offerings include:

– Metallic Silver Solid Stretch Faux Leather Home Decorating Fabric – $10.00

– Pale Blue Famous Maker Solid Recycled Leather and Polyurethane Blend Fabric – $12.00

– Gray Famous Maker Solid Recycled Leather and Polyurethane Blend Fabric – $12.00

– Purple Famous Maker Solid Recycled Leather and Polyurethane Blend Fabric …

4. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes 66 products available in various colors and textures. Colors include Beige, Black, Blue, Brown, Green, Grey, Navy, Orange, Pink, Purple, Red, Teal, White, and Yellow. Textures available are Alligator, Basket Weave, Crocodile, Legacy, Limited Edition, Lite, Ostrich, Pebble, Rugged, and Shimmer. The fabric is sold by quarter yard and is a vegan alter…

5. Kiki Textiles – Faux Leather Fabric

Domain: kikitextiles.com

Registered: 2021 (4 years)

Introduction: Faux leather (pleather) fabric by the yard available in various colors and styles. Key features include:

– Ethical and animal-friendly alternative to genuine leather.

– Advanced technology for realistic texture, sheen, and durability.

– Suitable for fashion (jackets, handbags, clothing), upholstery (furniture), and accessories (wallets, belts, shoes).

– Easy to clean and resistant to wear and tear…

6. Fabric Wholesale Direct – Faux Leather Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: Faux Leather Fabric By The Yard, Free Shipping On Orders $99+, Available in various colors and patterns, Suitable for multiple applications including apparel, upholstery, and home decor.

7. Online Fabric Store – Vinyl & Leather Fabrics

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: Vinyl & Leather fabrics available for various applications including apparel, décor, and utility. Features include options like flame retardant, water repellent, and extra wide. Available in multiple colors such as black, white, ivory, tan, and various shades. Material compositions include 100% vinyl, blends with polyvinyl, and other fabric types. Suitable for projects requiring durability and sty…

Strategic Sourcing Conclusion and Outlook for faux leather fabric for clothing

In conclusion, the strategic sourcing of faux leather fabric presents a significant opportunity for B2B buyers across diverse markets, particularly in Africa, South America, the Middle East, and Europe. As demand for sustainable and ethical fashion continues to rise, faux leather offers a compelling alternative to traditional leather, combining aesthetic appeal with practical benefits such as durability, ease of maintenance, and water resistance.

Key takeaways include the importance of selecting suppliers who prioritize quality and ethical manufacturing practices. Buyers should also leverage the variety of colors, textures, and finishes available to create unique products that cater to their target demographics.

Looking ahead, the faux leather market is poised for growth, driven by increasing consumer awareness and innovation in fabric technology. By adopting a strategic sourcing approach, international buyers can capitalize on these trends, ensuring they remain competitive in an evolving industry. We encourage you to explore partnerships with reliable manufacturers and to invest in faux leather solutions that align with your business goals and sustainability initiatives. Together, we can shape a more responsible and stylish future in fashion.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to faux leather fabric for clothing

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.