Introduction: Navigating the Global Market for how to make a leather wallet

In the competitive landscape of leather goods, understanding how to make a leather wallet can pose a significant challenge for international B2B buyers. Whether you are sourcing high-quality leather for bespoke designs or looking for sustainable production methods, navigating the complexities of materials, craftsmanship, and supplier reliability is crucial. This comprehensive guide delves into various wallet types, applications, and the essential tools and techniques needed to create a premium leather wallet, providing insights that cater specifically to businesses in Africa, South America, the Middle East, and Europe, including Nigeria and Vietnam.

The guide will explore the diverse materials available, from vegetable-tanned leather to exotic hides, and offer strategies for vetting suppliers to ensure quality and ethical practices. Buyers will gain insights into cost considerations, production timelines, and market trends that can impact purchasing decisions. By equipping B2B buyers with the knowledge and resources necessary to make informed choices, this guide empowers businesses to enhance their product offerings and meet the evolving demands of their customers. As you navigate the global market for leather wallets, this resource serves as a valuable tool for achieving success in your procurement strategy.

Table Of Contents

- Top 4 How To Make A Leather Wallet Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather wallet

- Understanding how to make a leather wallet Types and Variations

- Key Industrial Applications of how to make a leather wallet

- 3 Common User Pain Points for ‘how to make a leather wallet’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather wallet

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather wallet

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather wallet’

- Comprehensive Cost and Pricing Analysis for how to make a leather wallet Sourcing

- Alternatives Analysis: Comparing how to make a leather wallet With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather wallet

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather wallet Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather wallet

- Strategic Sourcing Conclusion and Outlook for how to make a leather wallet

- Important Disclaimer & Terms of Use

Understanding how to make a leather wallet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bi-Fold Wallet | Two main sections for cash and cards; simple design | Retail, promotional giveaways | Pros: Cost-effective, easy to produce. Cons: May lack uniqueness. |

| Tri-Fold Wallet | Three sections for cards and cash; compact design | Corporate gifts, branding | Pros: More storage, versatile. Cons: Bulkier than bi-fold. |

| Cardholder Wallet | Minimalist design; focuses on card slots | High-end retail, luxury brands | Pros: Sleek, modern appeal. Cons: Limited cash storage. |

| Travel Wallet | Larger size; includes passport and travel essentials | Travel agencies, tourism companies | Pros: Multi-functional, caters to travelers. Cons: Higher production costs. |

| RFID Blocking Wallet | Incorporates RFID-blocking technology for security | Security-focused brands | Pros: High demand for security features. Cons: Potentially higher price point. |

What Are the Key Characteristics of a Bi-Fold Wallet?

The bi-fold wallet is characterized by its straightforward design, which typically features two main compartments for cash and cards. This type is popular among consumers who prefer simplicity and ease of use. In a B2B context, bi-fold wallets are often produced in bulk for retail or as promotional items, making them a cost-effective choice for businesses looking to offer branded merchandise. While they are economical, buyers should be aware that the simplicity may not appeal to consumers seeking unique or high-end designs.

How Does a Tri-Fold Wallet Stand Out?

The tri-fold wallet expands on the bi-fold design by incorporating a third section, allowing for additional storage for cards and cash. This design is particularly appealing to corporate buyers looking for gifts that provide functionality and style. While tri-fold wallets offer versatility, they can be bulkier than their bi-fold counterparts. Buyers should consider the target market’s preferences for compactness versus storage capacity when making purchasing decisions.

Why Choose a Cardholder Wallet for Luxury Branding?

Cardholder wallets are designed with minimalism in mind, featuring primarily card slots and often lacking a cash compartment. This type appeals to a modern audience that values sleek aesthetics and practicality. B2B buyers in high-end retail or luxury branding may find cardholder wallets an excellent fit for their product lines. However, the limited storage for cash could deter some consumers, making it essential for buyers to understand their market’s needs.

What Benefits Does a Travel Wallet Offer to Businesses?

Travel wallets are larger and designed to accommodate not only cash and cards but also passports and travel documents. This functionality makes them ideal for businesses in the travel and tourism sectors, where offering multi-purpose products can enhance customer experience. While they provide excellent utility, the larger size may lead to increased production costs and complexity in design. Businesses should weigh these factors against potential consumer demand for travel-related products.

How Does RFID Blocking Technology Enhance Wallet Security?

RFID blocking wallets incorporate technology that protects against electronic theft, making them increasingly popular among consumers concerned about security. B2B buyers focusing on security-conscious markets may find these wallets particularly appealing. While the demand for RFID features can justify a higher price point, businesses must ensure that the added costs align with their target audience’s willingness to pay for enhanced security features.

Key Industrial Applications of how to make a leather wallet

| Industry/Sector | Specific Application of how to make a leather wallet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Custom leather wallets for retail | Unique product offering enhances brand identity and customer loyalty | Sourcing high-quality leather and skilled artisans for production |

| Gift & Promotional Items | Personalized leather wallets for corporate gifts | Strengthens client relationships and brand visibility | Need for customization options and reliable delivery timelines |

| E-commerce & Online Retail | DIY leather wallet kits for hobbyists | Attracts niche market segment and increases sales volume | Consider packaging and instructional clarity for international buyers |

| Luxury Goods | High-end, bespoke leather wallets | Appeals to affluent customers seeking exclusivity | Ensuring premium leather quality and craftsmanship standards |

| Educational Institutions | Leatherworking workshops teaching wallet making | Provides hands-on skills development and community engagement | Requirement for materials and tools that meet educational budgets |

How Can the Fashion & Accessories Sector Benefit from Leather Wallet Production?

In the fashion and accessories industry, the ability to create custom leather wallets allows brands to differentiate themselves in a competitive market. By offering unique designs, companies can enhance their brand identity and cultivate customer loyalty. International buyers, especially from regions like Africa and Europe, must prioritize sourcing high-quality leather and skilled artisans who can execute intricate designs while maintaining consistent quality standards.

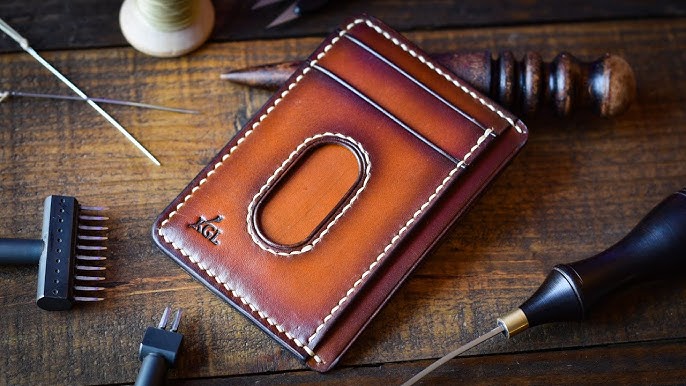

Illustrative image related to how to make a leather wallet

What Role Do Personalized Leather Wallets Play in Corporate Gifting?

Personalized leather wallets serve as excellent corporate gifts, allowing businesses to strengthen client relationships and enhance brand visibility. By providing customized options, companies can leave a lasting impression on clients and partners. For international B2B buyers, it’s crucial to ensure that customization options are available, along with reliable delivery timelines to meet promotional deadlines, especially in fast-paced markets across South America and the Middle East.

How Can E-commerce Platforms Leverage DIY Leather Wallet Kits?

E-commerce businesses can tap into the growing DIY trend by offering leather wallet kits that cater to hobbyists and craft enthusiasts. These kits not only attract niche market segments but can also significantly boost sales volume. When sourcing these kits, online retailers should focus on clear packaging and instructional materials, ensuring they cater to international buyers, particularly in emerging markets like Vietnam, where interest in DIY crafts is on the rise.

Why Are High-End Bespoke Leather Wallets Important in Luxury Markets?

In the luxury goods sector, bespoke leather wallets represent exclusivity and superior craftsmanship, appealing to affluent customers. These products can command premium prices, making them lucrative for businesses. International buyers in this market must ensure that they source only the finest leather and adhere to strict craftsmanship standards to meet the expectations of discerning customers across Europe and the Middle East.

How Do Educational Institutions Benefit from Leatherworking Workshops?

Educational institutions can offer leatherworking workshops that teach participants how to make wallets, providing hands-on skills development and fostering community engagement. These workshops can enhance the institution’s reputation and attract more students. When sourcing materials and tools for these workshops, it’s essential to consider budget constraints while ensuring quality, especially in regions with limited access to premium supplies.

Illustrative image related to how to make a leather wallet

3 Common User Pain Points for ‘how to make a leather wallet’ & Their Solutions

Scenario 1: Navigating Material Sourcing Challenges in Leather Wallet Production

The Problem: Many B2B buyers, especially those in emerging markets, face significant hurdles in sourcing high-quality leather suitable for wallet manufacturing. The variety of leather types—such as vegetable-tanned versus chrome-tanned—can be confusing. Buyers may struggle to find reliable suppliers that can provide consistent quality, leading to production delays and increased costs. Additionally, the lack of local suppliers can result in extended lead times and complications with international shipping, impacting the overall production timeline.

The Solution: To effectively source leather, buyers should establish partnerships with reputable tanneries that specialize in high-quality leather suitable for wallets. Engaging in trade shows or leather expos can help buyers meet suppliers face-to-face, fostering relationships that ensure reliable quality and service. It’s also advisable to request samples of different leather types and test them for durability, texture, and color retention before making bulk purchases. Creating a detailed specification sheet that outlines the desired leather characteristics will also streamline the sourcing process and ensure alignment with supplier capabilities. By prioritizing quality over cost and developing long-term relationships with trusted suppliers, businesses can mitigate sourcing issues and enhance their product offerings.

Scenario 2: Overcoming Skill Gaps in Leather Wallet Craftsmanship

The Problem: A common challenge for B2B buyers in the leather goods industry is the skill gap in craftsmanship. Many manufacturers may lack the necessary skills for intricate leatherworking techniques required to create high-quality wallets. This can lead to poor product quality, increased waste, and ultimately dissatisfied customers. As the demand for unique and high-end leather wallets rises, the inability to meet these expectations can hinder a company’s growth and reputation.

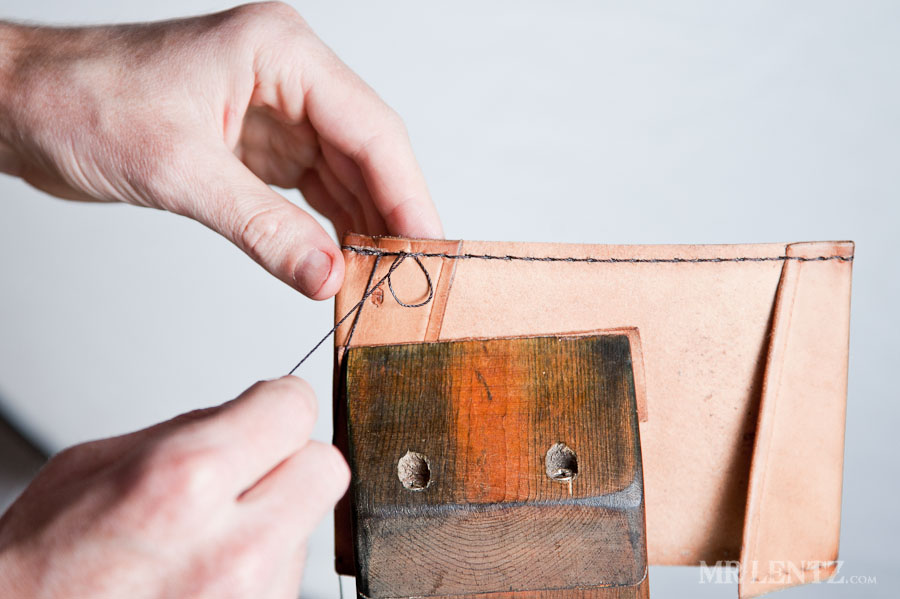

The Solution: To bridge the skill gap, businesses should invest in training programs for their workforce. Collaborating with experienced leather craftsmen to conduct workshops can provide employees with hands-on experience and knowledge about essential techniques, such as saddle stitching, edge finishing, and dyeing. Additionally, utilizing online resources, tutorials, and instructional videos can supplement this training. Implementing a mentorship program where seasoned craftsmen guide less experienced workers can further enhance skill development. By prioritizing skill enhancement, companies can improve product quality, reduce waste, and ultimately create a more satisfied customer base.

Illustrative image related to how to make a leather wallet

Scenario 3: Managing Production Timelines in Leather Wallet Manufacturing

The Problem: Many businesses in the leather wallet sector struggle with managing production timelines effectively. Delays can occur due to various factors, including material shortages, labor inefficiencies, and unexpected demand spikes. These delays not only impact customer satisfaction but can also lead to financial losses and damage to the brand’s reputation.

The Solution: To manage production timelines effectively, businesses should implement a robust production planning strategy that incorporates demand forecasting, inventory management, and lean manufacturing principles. Utilizing software tools that provide real-time data on inventory levels and production schedules can help streamline operations. Additionally, establishing a buffer stock of essential materials can mitigate the risks associated with supply chain disruptions. Regularly reviewing production processes and workflows to identify bottlenecks will also improve efficiency. By adopting a proactive approach to production planning and embracing flexibility in operations, companies can better meet customer demands and maintain a competitive edge in the market.

Strategic Material Selection Guide for how to make a leather wallet

What Are the Key Materials for Making a Leather Wallet?

When producing leather wallets, selecting the right materials is crucial for ensuring product quality, durability, and market competitiveness. Below are analyses of four common materials used in leather wallet production, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is made using natural tannins from plants, which makes it biodegradable and environmentally friendly. It typically has a weight of 3-4 oz, providing a good balance between flexibility and sturdiness.

Illustrative image related to how to make a leather wallet

Pros & Cons: This type of leather is known for its durability and ability to develop a rich patina over time. However, it can be more expensive than chrome-tanned leather and may require more care to maintain its appearance.

Impact on Application: Vegetable-tanned leather is ideal for wallets that require a classic aesthetic and longevity. Its compatibility with dyes and finishes allows for creative customization.

Considerations for International B2B Buyers: Buyers should ensure compliance with environmental regulations regarding tanning processes, especially in regions like Europe where strict standards are enforced. Familiarity with ASTM standards for leather quality can also be beneficial.

2. Chrome-Tanned Leather

Key Properties: Chrome-tanned leather is treated with chromium salts, resulting in a softer and more pliable material. It is less prone to water damage and can withstand various environmental conditions.

Illustrative image related to how to make a leather wallet

Pros & Cons: The primary advantage of chrome-tanned leather is its cost-effectiveness and faster tanning process. However, it may not be as durable as vegetable-tanned leather and can have a less appealing aesthetic for high-end products.

Impact on Application: This material is suitable for mass-produced wallets where cost and speed of production are priorities. It can handle moisture better, making it suitable for everyday use.

Considerations for International B2B Buyers: Buyers should be aware of potential health regulations regarding chromium levels in leather, particularly in regions with stringent safety standards. Understanding JIS standards can also help ensure compliance.

3. Suede Leather

Key Properties: Suede is made from the underside of the animal hide, giving it a soft, velvety texture. It is lightweight and has a unique aesthetic appeal.

Pros & Cons: Suede wallets can offer a luxurious feel and are often favored for fashion-forward designs. However, they are less durable than full-grain leather and can be more challenging to clean and maintain.

Illustrative image related to how to make a leather wallet

Impact on Application: Suede is suitable for wallets targeting a fashion-conscious demographic. Its aesthetic appeal can enhance brand perception, but it may not be ideal for everyday use.

Considerations for International B2B Buyers: Buyers should consider the market demand for suede products and ensure that they can source high-quality suede that meets local standards. Compliance with environmental regulations related to animal welfare is also important.

4. Synthetic Leather (PU or PVC)

Key Properties: Synthetic leather, made from polyurethane (PU) or polyvinyl chloride (PVC), mimics the appearance of real leather while being more affordable and easier to clean.

Illustrative image related to how to make a leather wallet

Pros & Cons: The main advantage is its low cost and versatility in design. However, synthetic leather may not provide the same level of durability or breathability as natural leather.

Impact on Application: Synthetic leather is suitable for budget-friendly wallets and can appeal to environmentally conscious consumers when made from recycled materials.

Considerations for International B2B Buyers: Buyers should verify the quality and sustainability of synthetic leather options, particularly in markets where eco-friendly products are in demand. Understanding compliance with international standards for synthetic materials is essential.

Summary of Material Selection for Leather Wallets

| Material | Typical Use Case for how to make a leather wallet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end, classic wallets | Durable and develops a rich patina | Higher cost and requires maintenance | High |

| Chrome-Tanned Leather | Mass-produced wallets | Cost-effective and moisture-resistant | Less durable and aesthetic appeal may vary | Medium |

| Suede Leather | Fashion-forward wallets | Luxurious feel and unique aesthetics | Less durable and harder to maintain | Medium |

| Synthetic Leather | Budget-friendly wallets | Affordable and easy to clean | May lack durability and breathability | Low |

This strategic material selection guide provides B2B buyers with essential insights into the various materials available for leather wallet production, enabling informed decision-making based on their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather wallet

What Are the Key Stages in the Manufacturing Process of Leather Wallets?

The manufacturing process of leather wallets is a meticulous journey that involves several stages, each critical to ensuring a high-quality final product. Understanding these stages can help B2B buyers identify quality suppliers and ensure they are making sound purchasing decisions.

Illustrative image related to how to make a leather wallet

Material Preparation: How Is Leather Selected and Treated?

The first step in manufacturing leather wallets is selecting the right type of leather. Common choices include vegetable-tanned leather, chrome-tanned leather, and exotic leathers. Each type has its unique properties, affecting durability, texture, and cost. Once the leather is selected, it undergoes preparation, which may include conditioning and dyeing to enhance its aesthetic appeal and longevity.

After preparation, the leather is cut into specific patterns based on wallet designs. Accurate cutting is essential as it affects the wallet’s overall structure and functionality. Manufacturers may use precision cutting tools, such as die-cutting machines, to ensure uniformity and minimize waste.

Forming: What Techniques Are Used to Shape the Leather?

Once the leather pieces are cut, they proceed to the forming stage. This involves shaping the leather into the desired wallet structure. Techniques such as folding, molding, and stitching are employed. For wallets, edge burnishing is particularly important, as it enhances the product’s appearance and durability. This process involves smoothing and polishing the edges of the leather to prevent fraying and provide a finished look.

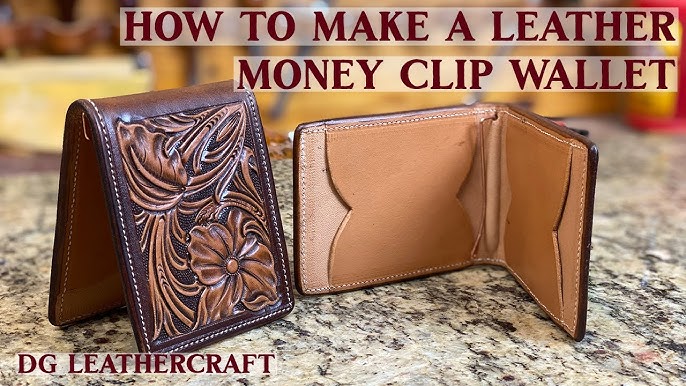

Additionally, manufacturers may use techniques such as heat embossing or debossing to add branding or decorative elements to the wallet. These techniques require specialized equipment and skilled craftsmanship to ensure precision and quality.

Illustrative image related to how to make a leather wallet

Assembly: How Are Wallet Components Joined Together?

The assembly stage involves combining the various leather components into a complete wallet. This process typically includes stitching, gluing, or riveting components together. Skilled artisans may use hand-stitching techniques, such as saddle stitching, which not only provides a sturdy seam but also adds to the wallet’s aesthetic appeal.

Quality control during assembly is crucial. Manufacturers often employ quality checkpoints, ensuring that each component meets the required standards before proceeding to the next stage. Any defects identified during this phase can be corrected before the wallet moves on to finishing.

Finishing: What Processes Enhance the Wallet’s Appearance and Durability?

Finishing processes are vital in providing the leather wallet with its final appearance and functional qualities. This stage may include applying protective coatings, additional dyeing, or polishing to enhance the leather’s natural beauty. Manufacturers may also apply wax or oil treatments to improve water resistance and longevity.

Quality assurance during the finishing stage is essential. Any inconsistencies in color or texture can affect customer satisfaction. Therefore, a final inspection is typically performed to ensure that the wallet meets the established quality standards before packaging and distribution.

How Is Quality Assurance Implemented in Leather Wallet Manufacturing?

Quality assurance (QA) is a systematic process that ensures the final product meets predetermined standards and specifications. For B2B buyers, understanding these QA processes can provide insights into supplier reliability and product quality.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to international quality standards, such as ISO 9001, which focuses on quality management systems and continuous improvement. Compliance with these standards demonstrates a commitment to quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE marking for European markets and API standards for specific product quality can also be essential. Understanding these standards can help B2B buyers make informed decisions when selecting suppliers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

Illustrative image related to how to make a leather wallet

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Ensuring that the leather and other materials meet quality specifications is crucial for the entire production process.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are performed to monitor the quality of the processes and components. This may include checking stitching quality, material alignment, and adherence to design specifications.

-

Final Quality Control (FQC): Once the wallets are finished, a final inspection is conducted to assess the overall quality, including aesthetics, functionality, and packaging. This step is vital for ensuring that the products meet customer expectations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the QC processes of potential suppliers. Here are several actionable strategies:

-

Supplier Audits: Conducting audits of a supplier’s manufacturing facility can provide valuable insights into their quality control practices. This includes reviewing their adherence to international standards and their internal QC processes.

-

Quality Reports: Requesting detailed quality reports from suppliers can help assess their compliance with quality standards. These reports should outline the results of IQC, IPQC, and FQC checks, providing transparency into their operations.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality practices. This can be particularly beneficial for B2B buyers who may not have the resources to conduct their audits.

What Are the Unique QC and Certification Considerations for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential. Variability in local standards and regulations can impact compliance and quality assurance processes.

Buyers should be aware of the specific requirements for their target markets. For example, European buyers may prioritize CE certification, while buyers in regions with less stringent regulations might focus more on cost and lead time. Establishing clear communication with suppliers about these requirements can help avoid potential pitfalls.

Illustrative image related to how to make a leather wallet

In conclusion, understanding the manufacturing processes and quality assurance measures involved in leather wallet production is crucial for B2B buyers. By focusing on these elements, buyers can ensure they select reliable suppliers who deliver high-quality products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather wallet’

Introduction

This guide provides a comprehensive checklist for B2B buyers aiming to source materials and tools for making leather wallets. By following these steps, buyers can ensure they procure high-quality products that meet their specific requirements while also streamlining the manufacturing process.

Step 1: Define Your Technical Specifications

Establish clear specifications for the leather wallet you intend to produce. This includes dimensions, design features (such as the number of card slots), and the type of leather (e.g., vegetable-tanned or chrome-tanned).

– Detail Your Design Needs: Consider patterns that align with your brand identity and customer preferences.

– Specify Material Quality: Determine the weight and durability of leather needed for everyday use.

Step 2: Identify Reliable Suppliers

Research potential suppliers who specialize in leather and leather goods. Look for companies with a strong reputation in the industry and positive feedback from previous clients.

– Evaluate Supplier Experience: Choose suppliers who have been in the market for several years and have experience with similar products.

– Check Geographic Compatibility: Consider sourcing from suppliers in regions known for leather production, such as Italy or South America, to benefit from quality craftsmanship.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Assess Product Samples: Ask for samples of leather and finished wallets to evaluate quality.

– Verify Certifications: Ensure suppliers adhere to industry standards, such as environmental certifications for leather tanning processes.

Step 4: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms regarding pricing, payment schedules, and delivery timelines. This step is vital to ensuring the financial viability of your project.

– Consider Bulk Discounts: Inquire about pricing structures for large orders, which can significantly reduce costs.

– Clarify Payment Terms: Establish clear payment terms to avoid any misunderstandings that could disrupt production.

Step 5: Confirm Supply Chain Logistics

Understanding logistics is essential for timely delivery and inventory management. Ensure that your chosen supplier has a reliable logistics plan in place.

– Evaluate Shipping Options: Assess shipping methods and lead times based on your operational needs.

– Plan for Customs and Duties: Be aware of potential customs regulations and duties that may affect costs and delivery times.

Step 6: Monitor Quality Control Processes

Implement quality control measures to ensure that the leather and finished wallets meet your specifications. This step is crucial for maintaining product consistency and customer satisfaction.

– Establish Inspection Protocols: Define how and when inspections will occur, whether at the supplier’s facility or upon arrival.

– Request Quality Assurance Reports: Ask suppliers for documentation proving that their products meet your quality standards.

Step 7: Build Long-term Relationships

Foster relationships with your suppliers to encourage collaboration and improve communication. Strong partnerships can lead to better pricing, priority service, and innovation in product development.

– Engage in Regular Communication: Maintain open lines of communication to discuss any issues or opportunities for improvement.

– Consider Joint Development Projects: Explore possibilities for co-developing new products or designs that can benefit both parties.

By following this structured approach, B2B buyers can effectively source materials and tools for crafting high-quality leather wallets that meet market demands and enhance brand reputation.

Comprehensive Cost and Pricing Analysis for how to make a leather wallet Sourcing

What Are the Key Cost Components for Sourcing Leather Wallets?

When sourcing leather wallets, understanding the comprehensive cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of leather significantly impacts costs. Vegetable-tanned leather, typically weighing between 3-4 oz, is a popular choice due to its durability and aesthetic appeal. Prices can vary based on the source and quality of leather, ranging from $5 to $15 per square foot. Additionally, other materials like waxed thread, adhesives, and finishing oils contribute to the total material cost.

-

Labor: Labor costs depend on the region and skill level required for leather craftsmanship. In regions like Africa or South America, labor costs may be lower, but the expertise in leatherwork can vary. Skilled artisans can demand higher wages, impacting the overall production cost.

-

Manufacturing Overhead: This includes expenses related to the factory’s operational costs, such as utilities, rent, and equipment maintenance. Efficient production processes can minimize overhead, but inefficiencies can lead to increased costs.

-

Tooling: Initial investment in tools (e.g., diamond chisels, stitching ponies) can be significant, especially for small-scale producers. However, these costs can be amortized over time with increased production volumes.

-

Quality Control (QC): Ensuring high-quality products requires investment in QC processes, which can add 5-10% to production costs. This is critical for maintaining brand reputation, especially in international markets where quality standards vary.

-

Logistics: Shipping costs, influenced by Incoterms, distance, and volume, can add substantially to the final price. Buyers should consider the total logistics cost, including customs duties, which can vary significantly based on the destination country.

-

Margin: Finally, manufacturers will add a profit margin, often ranging from 20% to 50%, depending on the market demand and competition.

How Do Price Influencers Affect Leather Wallet Sourcing?

Various factors influence pricing in the leather wallet market, which buyers should consider to make informed purchasing decisions.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Bulk orders often lead to reduced per-unit costs, making it beneficial for businesses to negotiate higher volumes with suppliers.

-

Specifications and Customization: Customized wallets with specific features or designs can incur additional costs. Buyers should be clear about their requirements and understand how these specifications influence the final price.

-

Materials and Quality Certifications: The use of premium materials and certifications (like eco-friendly or sustainable sourcing) can increase costs. Buyers should assess whether these certifications add value to their brand and justify the higher price.

-

Supplier Factors: The reliability and reputation of suppliers play a critical role. Established suppliers may charge a premium for their experience and reliability, while newer players may offer lower prices to attract business.

-

Incoterms: Understanding the implications of different Incoterms is essential for cost management. Terms like FOB (Free on Board) can shift logistics costs and risks, impacting the overall price structure.

What Tips Can Buyers Use to Negotiate Better Prices?

B2B buyers can adopt several strategies to enhance cost-efficiency and negotiate favorable terms when sourcing leather wallets:

-

Negotiation: Approach suppliers with a clear understanding of the market and be prepared to negotiate terms based on volume and long-term partnerships. Suppliers may be more flexible with pricing for larger or repeat orders.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, customs, and potential quality issues. A higher upfront cost might be justified by lower TCO if the product has better durability and requires fewer replacements.

-

Pricing Nuances for International Buyers: Be aware of regional economic factors that can influence pricing, such as currency fluctuations and import tariffs. This knowledge can provide leverage during negotiations.

-

Supplier Diversification: Establish relationships with multiple suppliers to foster competition and obtain better prices. This can also mitigate risks associated with supply chain disruptions.

By understanding these cost components, price influencers, and effective negotiation strategies, B2B buyers can make informed decisions that align with their business objectives and enhance profitability in the leather wallet market.

Alternatives Analysis: Comparing how to make a leather wallet With Other Solutions

Understanding Alternative Solutions for Wallet Production

In the competitive landscape of leather goods manufacturing, understanding various methods to create a leather wallet is crucial for B2B buyers. This analysis will provide insights into traditional leather crafting alongside modern alternatives, allowing businesses to make informed decisions based on performance, cost, ease of implementation, and maintenance.

Comparison Table

| Comparison Aspect | How To Make A Leather Wallet | Alternative 1: Fabric Wallet Production | Alternative 2: RFID-blocking Wallet Technology |

|---|---|---|---|

| Performance | High durability and aesthetic appeal | Moderate durability; varies by fabric type | High security; offers anti-theft features |

| Cost | Moderate; requires investment in tools and materials | Generally lower; fabric is less expensive | Higher initial cost due to technology integration |

| Ease of Implementation | Requires skill and time; crafting process can be complex | Easier; sewing machines can speed up production | Moderate; requires technology setup and training |

| Maintenance | Requires regular conditioning and care | Low maintenance; fabrics are often washable | Low maintenance; durable materials used |

| Best Use Case | High-end markets; artisanal products | Budget-friendly options for everyday use | Security-focused markets; tech-savvy consumers |

Pros and Cons of Each Alternative

Fabric Wallet Production

Fabric wallets present a cost-effective alternative to leather wallets. They are often easier to produce, requiring less skill and specialized tools. For businesses targeting budget-conscious consumers, fabric wallets can be a lucrative option, especially when considering the variety of colors and patterns available. However, their durability may not match that of leather, making them less suitable for luxury markets.

RFID-blocking Wallet Technology

RFID-blocking wallets integrate technology to protect against electronic theft, appealing to a growing market concerned about security. This option is ideal for tech-savvy consumers who prioritize safety in their everyday transactions. While the initial investment may be higher due to the technology involved, the potential for premium pricing can offset this. The main drawback is the need for additional training and knowledge about the technology, which may complicate the production process.

Conclusion: Choosing the Right Solution for Wallet Production

When selecting the most appropriate method for wallet production, B2B buyers must carefully consider their target market, production capabilities, and budget constraints. For businesses aiming to produce high-end, durable products, the traditional leather wallet remains an excellent choice. However, for those looking to tap into budget-conscious or security-focused demographics, exploring fabric wallets or RFID-blocking technology may yield better returns. Ultimately, understanding the unique advantages and limitations of each approach will empower buyers to make strategic decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for how to make a leather wallet

What Are the Key Technical Properties in Leather Wallet Production?

When entering the leather wallet manufacturing sector, understanding the essential technical properties is crucial for ensuring product quality, customer satisfaction, and compliance with industry standards. Here are some critical specifications that B2B buyers should consider:

Illustrative image related to how to make a leather wallet

-

Material Grade

The quality of leather significantly influences the durability and aesthetics of the wallet. Vegetable-tanned leather is commonly preferred for its eco-friendliness and ability to develop a unique patina over time. The grade of leather can impact the wallet’s market value, making it vital for buyers to specify their requirements clearly. -

Thickness (Oz Weight)

Leather thickness is measured in ounces, typically ranging from 1 to 8 ounces for wallets. A 3-4 oz weight is standard for wallets, offering a balance between durability and flexibility. Buyers must consider the end-use of the wallet—thicker leather provides more durability but may compromise flexibility, affecting usability. -

Stitching Tolerance

Stitching tolerance refers to the precision with which stitching holes are punched and threads are sewn. A tighter tolerance leads to stronger seams and a more professional finish. For B2B buyers, understanding stitching tolerance is critical, as it directly impacts the wallet’s longevity and aesthetic appeal. -

Finish Type

The finish of the leather affects its appearance and resistance to wear and moisture. Common finishes include aniline, semi-aniline, and pigment-dyed. Each type has its advantages and trade-offs regarding color richness, durability, and maintenance requirements. Buyers should specify their preferred finish to meet customer expectations. -

Edge Treatment

The edges of leather wallets can be left raw, painted, or burnished. Proper edge treatment enhances the wallet’s visual appeal and prevents fraying, contributing to overall durability. B2B buyers should inquire about edge treatment options to ensure that the final product aligns with their branding and quality standards.

What Are Common Trade Terminology Terms in Leather Wallet Manufacturing?

In the leather wallet industry, understanding trade terminology is essential for effective communication and decision-making. Here are some common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce goods based on specifications provided by another company. For leather wallet buyers, working with an OEM can ensure that the final product meets specific design and quality standards without investing in production infrastructure. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for B2B buyers, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their sales forecasts to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products. For leather wallets, issuing an RFQ helps buyers gather competitive pricing and clarify terms, enabling informed purchasing decisions. It is an essential step in sourcing suppliers effectively. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms used in international trade, defining the responsibilities of buyers and sellers. Familiarity with Incoterms is vital for B2B buyers in the leather wallet sector to understand shipping costs, risk management, and delivery obligations. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the finished product. In the leather wallet industry, lead times can vary based on production capacity and material availability. Buyers must account for lead times in their planning to ensure timely product delivery to customers.

By familiarizing themselves with these essential properties and terms, B2B buyers can navigate the leather wallet manufacturing landscape more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather wallet Sector

What Are the Key Market Dynamics and Sourcing Trends in the Leather Wallet Sector?

The leather wallet sector is experiencing significant growth driven by a combination of consumer preferences for quality and craftsmanship, alongside a rising demand for unique, personalized products. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can offer both traditional and innovative designs. The rise of e-commerce platforms has also facilitated easier access to global markets, enabling buyers to source materials and finished products directly from manufacturers.

Illustrative image related to how to make a leather wallet

Emerging technologies are reshaping the leather goods landscape, with advancements in leather tanning processes and digital design tools enhancing product quality and customization options. For instance, artificial intelligence is being used to predict trends and consumer preferences, allowing suppliers to adapt their offerings accordingly. Additionally, the integration of automated manufacturing techniques is streamlining production, reducing lead times and costs, which is particularly beneficial for international buyers looking for competitive pricing.

Current trends indicate a growing preference for multifunctional wallets that combine utility with style, as consumers seek products that cater to their fast-paced lifestyles. B2B buyers should also be aware of the increasing popularity of minimalist designs, which are not only aesthetically appealing but also align with the modern consumer’s desire for simplicity and practicality.

How Is Sustainability Influencing Sourcing Practices in the Leather Wallet Industry?

Sustainability has become a crucial consideration in the leather wallet sector, prompting B2B buyers to prioritize ethical sourcing practices. The environmental impact of traditional leather production, including water usage, chemical pollution, and deforestation, has led to a demand for more sustainable materials and processes. Buyers are increasingly seeking suppliers who use vegetable-tanned leather, a more eco-friendly alternative that reduces harmful chemical usage and promotes responsible sourcing.

The importance of ethical supply chains cannot be overstated, as consumers are becoming more conscious of the origins of their products. B2B buyers should look for suppliers who are transparent about their sourcing practices and who adhere to fair labor standards. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) can help buyers identify manufacturers committed to sustainable practices.

Additionally, the use of recycled materials and innovative alternatives, such as lab-grown leather or synthetic options made from sustainable sources, is gaining traction. These materials not only meet consumer demand for eco-friendly products but also provide manufacturers with a competitive edge in a crowded marketplace.

Illustrative image related to how to make a leather wallet

What Is the Historical Context of Leather Wallet Production That Influences Today’s B2B Landscape?

The history of leather wallet production dates back centuries, with leather being one of the first materials used for crafting durable goods. Historically, leather was sourced from various animals and processed using traditional tanning methods, which were labor-intensive and often harmful to the environment. As the industrial revolution introduced mechanization, the leather industry saw significant advancements in production efficiency and scalability.

In recent decades, the leather goods market has evolved, with a shift towards artisanal craftsmanship and bespoke designs. This evolution reflects a broader consumer trend favoring quality over quantity, prompting B2B buyers to seek suppliers who can deliver unique, high-quality products. The resurgence of traditional leatherworking techniques, combined with modern technology, has enabled manufacturers to cater to diverse markets while maintaining the authenticity and appeal of handcrafted goods.

Understanding this historical context can provide B2B buyers with insights into current market dynamics, helping them to navigate sourcing challenges and identify opportunities for collaboration with suppliers that prioritize quality, sustainability, and ethical practices.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather wallet

-

How do I ensure the quality of leather when sourcing materials for wallet production?

To ensure quality leather, establish relationships with reputable suppliers who provide samples for inspection. Request certifications that verify the leather’s origin, tanning process, and any chemical treatments. Conduct thorough quality checks upon receipt, looking for consistent color, texture, and absence of defects. Additionally, consider visiting suppliers’ facilities if feasible, to assess their production practices and quality control measures firsthand. -

What is the best type of leather for making durable wallets?

Vegetable-tanned leather is often considered the best choice for durable wallets due to its strength and ability to develop a rich patina over time. This type of leather is eco-friendly and ages beautifully, making it ideal for high-quality wallets that appeal to consumers. Other options include chrome-tanned leather for a softer feel or full-grain leather for premium quality. Evaluate your target market’s preferences when selecting the leather type. -

How can I customize leather wallets for my brand?

Customization options include embossing or debossing your logo, selecting specific colors, and choosing unique stitching styles. Collaborate with your supplier early in the design process to explore available customization techniques and their associated costs. Consider minimum order quantities (MOQs) for customized designs, as these may differ from standard wallet options. Providing a unique product can enhance brand recognition and customer loyalty. -

What are the typical minimum order quantities (MOQs) for leather wallets?

MOQs can vary significantly based on the supplier and the complexity of the wallet design. For standard models, MOQs may range from 50 to 200 units, while custom designs could require larger orders. Always clarify MOQs with potential suppliers during your initial discussions to ensure they align with your business needs. This will help you plan inventory and manage cash flow effectively. -

What payment terms should I expect when sourcing leather wallets internationally?

Payment terms in international trade often include options like advance payment, letter of credit, or payment upon delivery. Common practices involve a deposit (usually 30-50%) before production, with the balance due upon completion or prior to shipping. Negotiate terms that provide security for both parties and ensure they are clearly outlined in your purchase agreement to avoid misunderstandings. -

How do I vet suppliers for leather wallet production?

To vet suppliers, start by researching their reputation in the industry through online reviews and references. Request samples of their products to assess quality firsthand. Additionally, inquire about their production capabilities, lead times, and compliance with international labor and environmental standards. Consider using third-party audits to verify the supplier’s credentials and practices, especially for larger orders. -

What logistics considerations should I be aware of when importing leather wallets?

Logistics considerations include shipping methods, customs clearance, and potential tariffs or duties on imported goods. Choose a reliable freight forwarder who understands the complexities of international shipping and can assist with documentation. Be aware of shipping timelines, as delays can impact your inventory levels. Additionally, factor in warehousing needs and distribution channels in your target market. -

How can I ensure compliance with international regulations when sourcing leather wallets?

Compliance with international regulations requires thorough research on both export and import laws in your country and the supplier’s country. Familiarize yourself with regulations regarding leather goods, including safety standards and environmental regulations. Collaborate with your suppliers to ensure their practices align with these regulations and maintain proper documentation for all shipments to facilitate smooth customs processes.

Top 4 How To Make A Leather Wallet Manufacturers & Suppliers List

1. Instructables – Leather Wallet Tutorial

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Make a Leather Wallet tutorial by jessyratfink includes: 3-4 oz weight vegetable tanned leather, wallet patterns (3 styles: straight pockets, slanted pockets), diamond chisel set, sewing awl, waxed thread, stitching pony (optional), stitching groover, jojoba or leather-friendly oil, x-acto knife, ruler, rubber mallet, spray bottle, gum tragacanth, edge slicker, leather cement, cardboard, clamps, p…

2. Reddit – Beginner’s Leather Wallet

3. Leatherworker.net – Wallet Making Mastery

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Professional wallet making tutorial book by Danne, posted on February 4, 2022. The book is priced at $150. It aims to teach skills related to wallet making, potentially revealing unique techniques not covered in free resources. The discussion includes skepticism about the value of the book compared to free online content.

4. Weaver Leather Supply – Wallet and Cardholder Leathercrafting Kit

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Wallet and Cardholder Leathercrafting Kit, Natural – Regular price $31.75; Wallet and Cardholder Leathercrafting Kit, Brown – Regular price $31.75; Chuck’s Pick Stitch Groover – Regular price $37.50; 1/8” Flat Chisel Set (4pc) – Regular price $33.00; #4 Heavy-Duty Scratch Awl 3-1/2″ – Regular price $8.10; Rawhide Mallet – Regular price From $85.00; Stitching Horse – Regular price $390.00; Magnetic…

Strategic Sourcing Conclusion and Outlook for how to make a leather wallet

In conclusion, mastering the art of leather wallet production is not just about craftsmanship; it’s a strategic sourcing opportunity that can enhance your supply chain and profitability. By selecting high-quality materials, such as vegetable-tanned leather, and employing efficient techniques, businesses can ensure durability and customer satisfaction. The importance of having the right tools and a well-structured production process cannot be overstated, as they directly influence product quality and operational efficiency.

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, engaging in strategic sourcing can lead to significant competitive advantages. By fostering relationships with reliable suppliers and leveraging local craftsmanship, businesses can meet the unique preferences of diverse markets while optimizing costs.

As we look to the future, consider how you can integrate sustainable practices and innovative designs into your leather wallet offerings. This will not only appeal to eco-conscious consumers but also position your brand as a leader in the market. Embrace this opportunity to elevate your sourcing strategy and drive your business forward in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.