Introduction: Navigating the Global Market for how to make leather bracelets

Navigating the intricate landscape of the leather accessories market can be challenging for B2B buyers, particularly when it comes to sourcing high-quality leather bracelets. As the demand for unique, handcrafted accessories grows globally, understanding the various methods to create leather bracelets is essential for suppliers looking to meet customer expectations. This guide covers a spectrum of techniques, including beaded, braided, and cuff-style leather bracelets, offering insights into materials, tools, and creative applications.

Moreover, we delve into critical aspects such as supplier vetting processes, cost considerations, and market trends that influence purchasing decisions across different regions, including Africa, South America, the Middle East, and Europe, with a particular focus on Germany and Saudi Arabia. By providing a comprehensive overview of the leather bracelet-making process, this guide empowers international buyers to make informed decisions that enhance their product offerings.

Whether you are a retailer seeking to diversify your catalog or a manufacturer aiming to optimize production methods, understanding the nuances of leather bracelet creation will equip you with the knowledge to capitalize on emerging opportunities. Embrace the craftsmanship and creativity inherent in leatherworking to elevate your business in a competitive marketplace.

Table Of Contents

- Top 1 How To Make Leather Bracelets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make leather bracelets

- Understanding how to make leather bracelets Types and Variations

- Key Industrial Applications of how to make leather bracelets

- 3 Common User Pain Points for ‘how to make leather bracelets’ & Their Solutions

- Strategic Material Selection Guide for how to make leather bracelets

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather bracelets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather bracelets’

- Comprehensive Cost and Pricing Analysis for how to make leather bracelets Sourcing

- Alternatives Analysis: Comparing how to make leather bracelets With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make leather bracelets

- Navigating Market Dynamics and Sourcing Trends in the how to make leather bracelets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather bracelets

- Strategic Sourcing Conclusion and Outlook for how to make leather bracelets

- Important Disclaimer & Terms of Use

Understanding how to make leather bracelets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stamped Leather Bracelet | Customizable with messages or designs; often enhanced with patina | Personalized gifts, promotional items | Pros: High customization; emotional appeal. Cons: Labor-intensive production. |

| Beaded Leather Bracelet | Incorporates beads with leather strands; often colorful and playful | Fashion accessories, artisanal markets | Pros: Versatile design options; popular among diverse demographics. Cons: Requires additional materials (beads). |

| Braided Leather Bracelet | Features woven leather strips; can be simple or intricate | Fashion retail, handmade markets | Pros: Strong visual appeal; durable design. Cons: Complexity may increase production time. |

| Leather Cuff Bracelet | Wider leather band, often adorned with studs or rivets | Fashion-forward brands, statement pieces | Pros: Bold statement accessory; attracts attention. Cons: May not appeal to minimalist markets. |

| Friendship Leather Bracelet | Often made with multiple strands; symbolizes connection | Gifts, social events, promotional giveaways | Pros: Emotional significance; suitable for bulk orders. Cons: May require more intricate designs for mass production. |

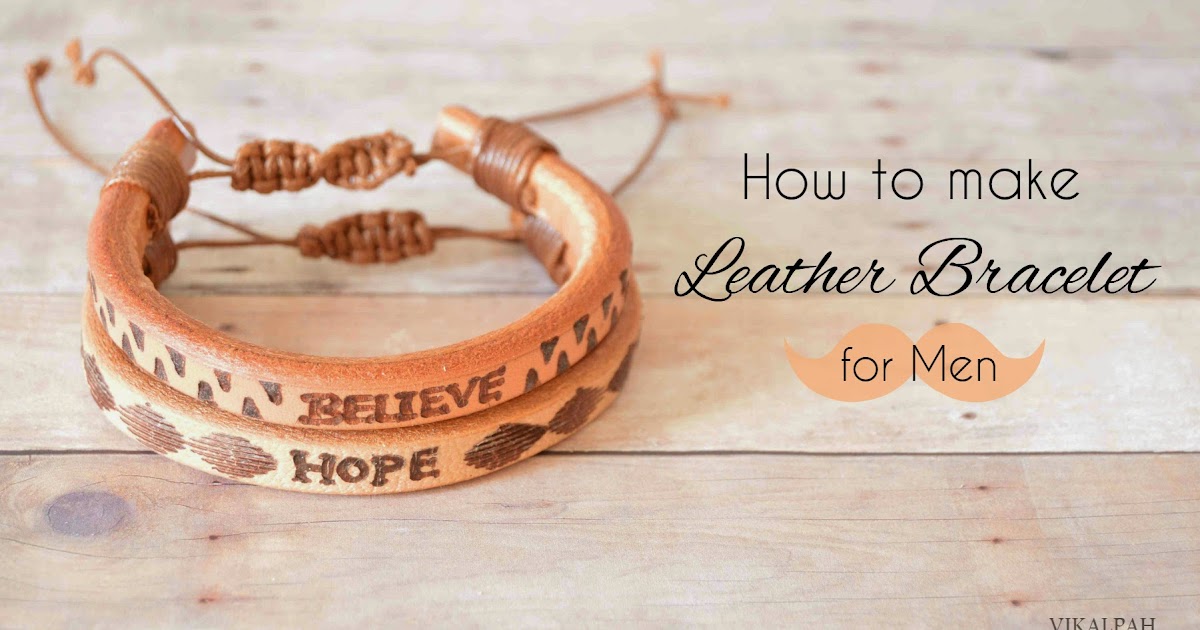

What are the Characteristics and Suitability of Stamped Leather Bracelets for B2B Buyers?

Stamped leather bracelets are unique in their ability to convey personal messages, making them ideal for personalized gifts or promotional items. The customization aspect allows businesses to create products that resonate with their clientele. For B2B buyers, sourcing stamped leather bracelets can lead to higher customer satisfaction and loyalty, especially when targeting markets that value emotional connections and meaningful gifts. However, the labor-intensive production process may require careful consideration of pricing and lead times.

How Do Beaded Leather Bracelets Stand Out in the Market?

Beaded leather bracelets combine the texture of leather with the vibrant colors of beads, appealing to a wide demographic. They are particularly suitable for fashion accessories and artisanal markets, where unique and personalized items are sought after. B2B buyers should consider the sourcing of both leather and beads, as well as the potential for customization. While they offer versatility in design, the necessity for additional materials can complicate inventory management.

What Advantages Do Braided Leather Bracelets Offer to Retailers?

Braided leather bracelets are characterized by their woven design, which can range from simple to intricate patterns. This type of bracelet is particularly appealing in fashion retail and handmade markets. B2B buyers can leverage the strong visual appeal and durability of braided bracelets to attract customers looking for high-quality accessories. However, the complexity of production may lead to longer lead times, necessitating a balance between demand and supply capabilities.

Why Are Leather Cuff Bracelets Popular Among Fashion Brands?

Leather cuff bracelets are wider and often adorned with decorative elements like studs or rivets, making them a bold fashion statement. They are particularly popular among brands that target fashion-forward consumers. B2B buyers should consider the appeal of such statement pieces in their product lines, especially in markets that favor distinctive accessories. However, this style may not resonate with minimalist consumers, which could limit its market reach.

How Can Friendship Leather Bracelets Be Used in Promotional Strategies?

Friendship leather bracelets often consist of multiple strands, symbolizing connection and unity. They are ideal for gifts, social events, or promotional giveaways, making them a versatile option for B2B buyers. The emotional significance of these bracelets can enhance marketing strategies, especially in campaigns aimed at fostering community and connection. However, the intricacy involved in their design may require careful planning for mass production and inventory management.

Key Industrial Applications of how to make leather bracelets

| Industry/Sector | Specific Application of how to make leather bracelets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Customizable leather bracelets for fashion lines | Enhances brand identity with unique, personalized products | Sourcing quality leather, customization capabilities, design trends |

| Corporate Gifting | Leather bracelets as corporate gifts | Strengthens client relationships through thoughtful gifts | Bulk order options, branding capabilities, lead times |

| Artisan Crafts | Leather bracelet workshops for skill development | Engages local communities and promotes craftsmanship | Availability of training materials, instructor expertise, local demand |

| Promotional Products | Leather bracelets for event giveaways | Increases brand visibility at events through practical items | Cost of materials, design options, production timelines |

| Retail & E-commerce | Selling DIY leather bracelet kits | Expands product offerings and attracts DIY enthusiasts | Supply chain logistics, kit assembly requirements, pricing strategies |

How Can the Fashion & Accessories Industry Utilize Leather Bracelets?

In the fashion and accessories sector, leather bracelets serve as customizable items that can be tailored to reflect brand identity. Fashion brands can offer unique designs that resonate with their target audience, enhancing customer loyalty and driving sales. For international buyers, considerations include sourcing high-quality leather that meets ethical standards and aligns with current design trends. This ensures that the end product not only looks appealing but also satisfies consumer demand for sustainability.

What Role Do Leather Bracelets Play in Corporate Gifting?

Leather bracelets are increasingly popular as corporate gifts, allowing companies to forge stronger relationships with clients and employees. By offering personalized bracelets, businesses can convey appreciation and foster loyalty. International B2B buyers must consider bulk ordering options and the ability to brand these items with logos or messages. Additionally, lead times for production are crucial, especially for businesses operating on tight schedules or planning events.

How Can Artisan Crafts Benefit from Leather Bracelet Workshops?

Artisan crafts can leverage leather bracelet-making workshops as a means to engage local communities and promote craftsmanship. These workshops not only provide participants with hands-on experience but also help preserve traditional crafting techniques. For international buyers, key considerations include the availability of training materials and the expertise of instructors. Understanding local demand for such workshops can also inform the business model, ensuring sustainability and profitability.

How Can Promotional Products Incorporate Leather Bracelets?

Promotional products often include practical items that enhance brand visibility at events. Leather bracelets make excellent giveaways, as they are both stylish and functional. International buyers should focus on the cost of materials and design options that can be customized for specific events. Additionally, production timelines are critical to ensure that promotional items are delivered on time for marketing campaigns or corporate events.

What Opportunities Exist for Retail & E-commerce with DIY Leather Bracelet Kits?

The rise of DIY culture presents a unique opportunity for retail and e-commerce businesses to sell DIY leather bracelet kits. These kits attract enthusiasts looking to create personalized accessories, thus expanding product offerings. Buyers in this sector should consider supply chain logistics for sourcing materials and the requirements for kit assembly. Competitive pricing strategies will also be essential to attract a wider audience and ensure successful sales.

3 Common User Pain Points for ‘how to make leather bracelets’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Leather Materials

The Problem: B2B buyers often struggle to find reliable suppliers for high-quality leather materials needed to make durable and appealing bracelets. With numerous options available, differentiating between genuine leather and synthetic alternatives can be challenging. Additionally, buyers may face issues with inconsistent quality across batches, leading to frustration and potential loss of revenue due to defective products.

The Solution: To overcome this challenge, B2B buyers should establish partnerships with reputable suppliers who specialize in leather products. Conduct thorough research to identify suppliers with positive reviews and a solid track record in the industry. Request samples before making bulk purchases to evaluate the quality of the leather firsthand. Consider sourcing leather from regions known for their craftsmanship, such as Italy or Argentina, where tanning processes yield superior materials. Building a long-term relationship with a trusted supplier can also ensure more consistent quality over time, reducing the risk of product returns and enhancing customer satisfaction.

Illustrative image related to how to make leather bracelets

Scenario 2: Mastering the Techniques for Bracelet Making

The Problem: Many buyers lack the skills or knowledge needed to effectively craft leather bracelets, leading to a reliance on outsourced labor or pre-made products. This can result in increased costs and a lack of unique, customizable options for their clientele. Additionally, the learning curve associated with different techniques, such as braiding, stamping, or adding embellishments, can be steep, creating further barriers to entry for new artisans.

The Solution: Investing in comprehensive training programs or workshops can significantly enhance the skills of your workforce. Look for online courses or local classes led by experienced leather artisans who can provide hands-on instruction. For those unable to attend workshops, consider utilizing instructional videos and resources available through platforms like Creativebug or YouTube. Additionally, collaborating with skilled artisans for mentorship opportunities can facilitate knowledge transfer and foster innovation within your business. By developing in-house expertise, you can create distinctive leather bracelets that resonate with your target market while improving overall production efficiency.

Scenario 3: Challenges in Marketing Custom Leather Bracelets

The Problem: B2B buyers often face difficulties in effectively marketing their custom leather bracelets. With increasing competition in the jewelry market, distinguishing their products and reaching the right audience can be daunting. Buyers may also struggle with defining their brand identity and communicating the unique selling points of their leather bracelets, leading to lower sales and diminished brand loyalty.

The Solution: To enhance marketing efforts, buyers should develop a clear brand strategy that highlights the unique aspects of their leather bracelets, such as craftsmanship, materials, and customization options. Utilize social media platforms like Instagram and Pinterest to showcase visually appealing images of the products and the bracelet-making process. Engaging storytelling can also be a powerful tool; share the inspiration behind each design to connect with potential customers on a personal level. Additionally, consider collaborating with influencers or local artisans to expand reach and credibility. Implementing targeted online advertising can further enhance visibility and drive traffic to your business, ultimately leading to increased sales and brand recognition in the competitive jewelry market.

Strategic Material Selection Guide for how to make leather bracelets

What Are the Key Materials for Making Leather Bracelets?

When selecting materials for leather bracelets, it’s essential to consider the properties, advantages, and limitations of each option. Here, we will analyze four common materials used in the production of leather bracelets: genuine leather, synthetic leather, suede, and leather cord. Each material presents unique characteristics that can influence the final product’s performance and marketability.

Illustrative image related to how to make leather bracelets

How Does Genuine Leather Perform in Bracelet Manufacturing?

Genuine leather, derived from animal hides, is renowned for its durability and aesthetic appeal. It possesses excellent tensile strength, making it resistant to tearing and wear. Additionally, genuine leather has a natural breathability that allows for comfort when worn. However, it can be sensitive to moisture and temperature changes, which may lead to degradation over time if not properly cared for.

Pros: Genuine leather is highly durable, has a luxurious feel, and can be dyed or embossed for customization.

Cons: It typically comes at a higher cost and may require additional treatments to enhance water resistance.

Impact on Application: Genuine leather is suitable for high-end markets, particularly in Europe and the Middle East, where craftsmanship is highly valued.

International Considerations: Buyers should ensure compliance with animal welfare regulations and sustainability standards, especially in regions like Germany where eco-friendly practices are emphasized.

What Advantages Does Synthetic Leather Offer for Bracelet Production?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), serves as a cost-effective alternative to genuine leather. It is resistant to moisture and UV rays, making it suitable for outdoor use. Synthetic leather can also be produced in a wide variety of colors and textures, allowing for creative flexibility.

Pros: Lower cost, easy maintenance, and a wide range of design options.

Cons: Generally less durable than genuine leather and may not have the same luxurious feel.

Impact on Application: Ideal for budget-friendly products targeting younger consumers or casual markets.

International Considerations: Compliance with chemical safety standards (e.g., REACH in Europe) is crucial, as synthetic materials can sometimes contain harmful substances.

Illustrative image related to how to make leather bracelets

How Does Suede Compare as a Material for Leather Bracelets?

Suede, a type of leather with a napped finish, offers a soft texture that is appealing for fashion accessories. It is lightweight and provides a unique aesthetic, making it popular for trendy bracelet designs. However, suede is more susceptible to stains and moisture damage compared to other leather types.

Pros: Soft texture, lightweight, and visually appealing for fashion-forward designs.

Cons: Less durable and more challenging to clean than other leather types.

Impact on Application: Best suited for fashion markets that prioritize style over longevity.

International Considerations: Buyers should be aware of the care requirements for suede, especially in humid climates prevalent in parts of Africa and South America.

What Role Does Leather Cord Play in Bracelet Making?

Leather cord is a versatile material often used in beaded or braided bracelet designs. It is typically thinner than strips of leather, allowing for intricate designs and layering. Leather cord is easy to work with, making it a popular choice for DIY projects.

Pros: Flexible, easy to manipulate, and suitable for various bracelet styles.

Cons: May lack the durability of thicker leather options and can fray over time.

Impact on Application: Ideal for casual, handmade, or artisanal markets.

International Considerations: Ensure that the leather cord meets local regulations regarding animal products, especially in regions with strict import laws.

Summary Table of Material Selection for Leather Bracelets

| Materiaal | Typical Use Case for how to make leather bracelets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end, luxury bracelets | Durable and luxurious feel | Higher cost and moisture sensitivity | Hoog |

| Synthetic Leather | Budget-friendly, casual bracelets | Cost-effective and versatile | Less durable and less premium feel | Low |

| Suède | Fashion-forward, trendy bracelets | Soft and visually appealing | Susceptible to stains and moisture | Medium |

| Leather Cord | DIY, beaded, or braided bracelets | Flexible and easy to work with | Less durable and can fray | Low |

This strategic material selection guide provides critical insights for B2B buyers looking to source materials for leather bracelet production, enabling informed decisions that align with market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather bracelets

What Are the Main Stages in the Manufacturing Process of Leather Bracelets?

The manufacturing process for leather bracelets involves several key stages, each critical for ensuring the final product meets quality standards and customer expectations. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step is sourcing high-quality leather, which can vary in thickness, texture, and finish. Leather is often categorized into types such as full-grain, top-grain, and suede, each offering unique characteristics. After selecting the appropriate leather, it undergoes a conditioning process to enhance its flexibility and durability. This may include treatments with oils or waxes to improve water resistance and texture.

-

Forming: Once the leather is prepared, it is cut into strips or shapes as per the bracelet design. This requires precision tools like rotary cutters or die-cutting machines. Techniques such as stamping or embossing may be applied at this stage to add decorative elements. For instance, using steel stamps, manufacturers can imprint designs or messages onto the leather, creating customized products that appeal to specific market segments.

-

Assembly: In this stage, the cut leather pieces are assembled into the final bracelet form. This may involve stitching, gluing, or riveting components together. High-quality stitching techniques, such as saddle stitching, are preferred for their strength and durability. Additionally, hardware elements like clasps, buttons, or beads are added during assembly, which may require additional tools like rivet setters or pliers.

-

Finishing: The final stage focuses on enhancing the bracelet’s aesthetics and durability. This may involve applying finishes like dyes, paints, or protective coatings. For example, a patina effect can be added using craft paints to create a unique look. Quality checks are essential at this stage to ensure that the color and finish meet the desired specifications.

How Is Quality Assurance Implemented in Leather Bracelet Manufacturing?

Quality assurance (QA) is vital for maintaining product standards and ensuring customer satisfaction in the leather bracelet manufacturing process. Adhering to international standards such as ISO 9001 is essential for establishing a robust QA framework.

-

International Standards Compliance: ISO 9001 provides guidelines for quality management systems, emphasizing continuous improvement and customer focus. Manufacturers should ensure that their processes are aligned with these standards to enhance product reliability and customer trust.

-

Industry-Specific Certifications: Depending on the target market, additional certifications may be required. For example, in Europe, the CE marking may be necessary for certain leather goods, indicating compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: To ensure product quality throughout the manufacturing process, several checkpoints are established:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival. Leather quality should be assessed for consistency in color, texture, and thickness.

– In-Process Quality Control (IPQC): During production, random samples should be tested for adherence to specifications, including stitching integrity and component fit.

– Final Quality Control (FQC): Once production is complete, a final inspection is conducted to ensure the finished products meet all quality standards, including aesthetic aspects like color and finish.

What Common Testing Methods Are Used in Leather Bracelet Production?

Testing methods play a crucial role in ensuring that leather bracelets meet quality and safety standards. Common testing methods include:

-

Physical Testing: This involves assessing the leather’s strength, flexibility, and durability. Tests may include tensile strength tests to measure how much force the leather can withstand before breaking.

-

Chemical Testing: This ensures that the leather is free from harmful substances, particularly important for products that come into contact with skin. Testing for chemicals like azo dyes or heavy metals is essential for compliance with safety regulations.

-

Wear and Tear Testing: Simulating the conditions under which the bracelet will be used helps evaluate its longevity. This may involve bending, stretching, and exposing the leather to various environmental conditions to assess wear resistance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess a supplier’s manufacturing practices, quality control systems, and adherence to international standards. During an audit, buyers should look for documentation of quality processes, employee training records, and compliance with safety standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s quality metrics, including defect rates and corrective actions taken. This transparency is vital for building trust and understanding a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing process and product quality. These inspections typically include verifying compliance with industry standards, conducting random sampling, and providing detailed reports on findings.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control.

-

Cultural and Regulatory Differences: Understanding the cultural context and regulatory environment of the supplier’s country is crucial. Different regions may have varying standards for quality and safety, necessitating thorough research and adaptation to local practices.

-

Logistical Considerations: Shipping and logistics can impact product quality. Buyers should ensure that suppliers follow best practices for packaging and transport to prevent damage during transit.

-

Communication Barriers: Language differences can complicate quality assurance efforts. Establishing clear communication channels and possibly utilizing local intermediaries can help mitigate misunderstandings and ensure that quality expectations are clearly articulated.

In conclusion, the manufacturing processes and quality assurance measures for leather bracelets are multifaceted and require careful attention to detail. By understanding these processes and implementing robust quality control measures, B2B buyers can ensure they source high-quality leather products that meet their customers’ demands.

Illustrative image related to how to make leather bracelets

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather bracelets’

Inleiding

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring materials and equipment necessary for making leather bracelets. With the growing demand for handmade leather goods in markets across Africa, South America, the Middle East, and Europe, this guide will help streamline your sourcing process, ensuring you acquire quality materials and tools for successful production.

Step 1: Identify Your Target Market

Understanding your target audience is crucial for determining the types of leather bracelets to produce. Research market trends and preferences in your specific regions—such as Africa or Europe—where handmade leather products are gaining traction. This insight will guide your design choices and help you select materials that resonate with your customers.

Step 2: Define Your Technical Specifications

Establish clear technical specifications for the leather bracelets you wish to create. Consider factors such as leather thickness, color, and finish, as well as additional components like beads or clasps. These details will help you communicate effectively with suppliers and ensure you receive materials that meet your production needs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have experience in the leather goods market and can provide high-quality materials consistently.

- Check Certifications: Ensure that suppliers adhere to industry standards, such as environmental and labor regulations, which can affect the sustainability and ethical sourcing of materials.

- Assess Production Capabilities: Confirm that potential suppliers can meet your volume requirements and timelines.

Step 4: Source Quality Leather Materials

Select high-quality leather that fits your design specifications. Look for suppliers that offer a variety of leather types, such as vegetable-tanned or chrome-tanned options, which can affect durability and aesthetics.

- Request Samples: Always request leather samples to evaluate texture, color, and quality before making bulk purchases.

- Consider Local Sources: Investigate local tanneries or suppliers, which may offer unique regional materials and support local economies.

Step 5: Secure Necessary Tools and Equipment

Compile a list of essential tools required for crafting leather bracelets, such as cutting tools, stamps, and finishing products. Ensure that these tools are compatible with your production methods.

- Invest in Quality Tools: High-quality tools can enhance the craftsmanship of your bracelets, leading to better product outcomes.

- Consider Bulk Orders: If you plan to scale production, consider ordering tools in bulk to reduce costs.

Step 6: Establish a Reliable Supply Chain

Formulate a dependable supply chain strategy to ensure consistent access to materials and tools. Establish agreements with multiple suppliers to mitigate risks associated with delays or shortages.

Illustrative image related to how to make leather bracelets

- Plan for Inventory Management: Implement a system to track inventory levels and reordering processes to avoid production interruptions.

- Build Strong Relationships: Foster good relationships with suppliers to facilitate better communication and support.

Step 7: Test and Iterate Your Designs

Before launching your leather bracelets to the market, conduct thorough testing of your designs. Gather feedback from potential customers and make necessary adjustments to improve product quality and appeal.

- Run Small Batch Trials: Produce small batches for testing to minimize risk and gather valuable insights.

- Incorporate Feedback: Use customer feedback to refine your designs, ensuring they meet market expectations and preferences.

By following these steps, B2B buyers can effectively source the materials and tools needed to create high-quality leather bracelets that cater to diverse international markets.

Comprehensive Cost and Pricing Analysis for how to make leather bracelets Sourcing

What Are the Key Cost Components for Sourcing Leather Bracelets?

When sourcing leather bracelets, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of leather can vary significantly based on quality, thickness, and type (e.g., genuine leather vs. synthetic). Additional materials such as beads, clasps, and decorative elements also contribute to the overall material cost. For example, high-quality vegetable-tanned leather may command a higher price but offers better durability and aesthetic appeal.

-

Labor: Labor costs include wages for skilled artisans and workers involved in the crafting process. This can vary widely depending on the region; for instance, labor costs in Europe may be higher than in South America or Africa. Skilled labor is essential for ensuring high-quality craftsmanship, which can impact the final price of the product.

-

Manufacturing Overhead: This encompasses expenses related to the facility, utilities, and equipment used in production. Overhead costs can differ based on the location of the manufacturer and their operational efficiencies.

-

Tooling: Initial setup costs for tools and machinery required for leather bracelet production must be considered. These costs can be amortized over the production run, impacting pricing for larger orders.

-

Quality Control (QC): Ensuring that the leather bracelets meet specific standards can incur additional costs. Investing in QC processes helps prevent defects and returns, which can be particularly important for maintaining brand reputation in international markets.

-

Logistics: Shipping costs, customs duties, and insurance are critical factors, especially for international transactions. Understanding Incoterms (International Commercial Terms) is vital, as they define the responsibilities of buyers and sellers regarding shipping and delivery.

-

Margin: The profit margin varies by supplier and market demand. High-quality products may allow for a larger margin, while competitive pricing may be necessary to secure larger orders or enter new markets.

How Do Price Influencers Affect Leather Bracelet Sourcing?

Several factors influence pricing in the leather bracelet market, which can significantly impact B2B sourcing strategies:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, so it’s advisable to negotiate MOQs that align with your demand projections.

-

Specifications and Customization: Custom designs or specific material requests can increase costs. Buyers should clearly communicate their requirements to avoid unexpected price increases.

-

Quality and Certifications: Products certified for quality or eco-friendliness may carry a premium price. Buyers should assess whether these certifications are necessary for their target market.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may command higher prices due to their quality assurance processes and brand recognition.

What Are the Best Negotiation Tips for B2B Buyers Sourcing Leather Bracelets?

Effective negotiation can lead to significant cost savings for international B2B buyers. Here are some strategies:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with maintenance, durability, and potential returns. A higher upfront cost may be justified if the product lasts longer.

-

Leverage Competitive Quotes: Gather multiple quotes from different suppliers to create leverage during negotiations. This can help you secure better pricing or terms.

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and terms in the long run. Consider regular communication and prompt payments as part of relationship-building efforts.

-

Be Aware of Pricing Nuances: International buyers should account for currency fluctuations, tariffs, and local market conditions that may affect pricing. Understanding these nuances can provide additional leverage during negotiations.

Conclusion

Navigating the cost and pricing landscape for leather bracelets requires a comprehensive understanding of various factors. By analyzing cost components and being aware of price influencers, B2B buyers can make informed decisions that align with their business objectives. It’s crucial to engage in effective negotiation tactics to secure the best possible deals, ensuring a profitable and sustainable sourcing strategy.

Alternatives Analysis: Comparing how to make leather bracelets With Other Solutions

Understanding Alternatives to Making Leather Bracelets

When considering the production of leather bracelets, it is essential to evaluate alternative methods that can achieve similar results. The market offers various techniques that can cater to different business needs, whether for cost-effectiveness, efficiency, or unique design requirements. This analysis will compare the traditional method of making leather bracelets with other viable alternatives, providing a comprehensive understanding for B2B buyers.

| Comparison Aspect | How To Make Leather Bracelets | Alternative 1: Beaded Bracelets | Alternative 2: Silicone Bracelets |

|---|---|---|---|

| Performance | High durability and aesthetic appeal; customizable designs | Good durability; can be colorful and lightweight | Flexible and waterproof; suitable for various applications |

| Cost | Moderate initial investment for materials and tools | Low to moderate; beads and string are inexpensive | Low; silicone is cost-effective and widely available |

| Ease of Implementation | Requires some skill and tools; a learning curve exists | Easy; minimal tools needed, suitable for beginners | Very easy; no tools required, can be mass-produced |

| Maintenance | Requires occasional cleaning and care | Low maintenance; easy to clean | Very low maintenance; resistant to wear |

| Best Use Case | Crafting unique, personalized jewelry for niche markets | Fashion accessories or DIY projects for casual wear | Promotional items, events, or giveaways due to their affordability |

What Are the Advantages and Disadvantages of Making Beaded Bracelets?

Beaded bracelets present a compelling alternative to leather bracelets. They are relatively easy to create, requiring minimal tools, such as string and beads. This makes them accessible for hobbyists and small businesses looking to enter the jewelry market without significant upfront costs. However, while beaded bracelets can be colorful and appealing, they may lack the durability and premium feel that leather offers. Additionally, the design options can be limited compared to the bespoke potential of leatherwork, which might not satisfy high-end clientele.

How Do Silicone Bracelets Compare to Leather Bracelets?

Silicone bracelets are another alternative that offers unique advantages, particularly for promotional uses. They are incredibly cost-effective, making them ideal for bulk orders, and are available in a wide range of colors and styles. Their flexibility and waterproof nature allow them to be worn in various settings without concern for damage. On the downside, silicone lacks the aesthetic appeal and craftsmanship associated with leather, which may deter buyers looking for luxury items. Furthermore, their disposable nature could be seen as a negative aspect in terms of sustainability, particularly for environmentally conscious markets.

Making the Right Choice for Your Business

In conclusion, selecting the appropriate method for bracelet production hinges on your target market and business goals. If the aim is to create high-quality, personalized jewelry, traditional leather bracelet making may be the best choice despite its higher initial investment and required skill level. On the other hand, if cost-effectiveness and ease of production are paramount, beaded or silicone alternatives could be more advantageous. By understanding the strengths and limitations of each option, B2B buyers can make informed decisions that align with their operational objectives and customer preferences.

Essential Technical Properties and Trade Terminology for how to make leather bracelets

What Are the Key Technical Properties of Leather for Bracelet Making?

When sourcing materials for leather bracelet production, understanding specific technical properties is crucial for ensuring quality and meeting customer expectations. Here are some essential specifications:

1. Material Grade

The grade of leather refers to its quality and characteristics, which can vary from full-grain to corrected grain. Full-grain leather is the highest quality, retaining the natural grain and imperfections, making it more durable and aesthetically appealing. For B2B buyers, selecting the right grade is vital as it influences the product’s longevity, appearance, and ultimately customer satisfaction.

2. Thickness (Gauge)

Leather thickness is typically measured in millimeters (mm) or ounces (oz). For bracelets, a thickness of 1mm to 2mm is common, balancing flexibility and durability. Understanding the thickness is important for manufacturers as it affects the bracelet’s comfort, style, and the techniques used for crafting.

3. Tolerance

Tolerance refers to the allowable variation in dimensions during manufacturing. For leather bracelets, precise tolerances ensure that components fit together correctly, preventing issues during assembly. This is particularly important for B2B buyers who require consistent quality across large orders.

4. Finish Type

The finish of leather can significantly affect its appearance and feel. Common finishes include aniline, semi-aniline, and pigmented. Each type has different characteristics in terms of color retention, water resistance, and tactile quality. B2B buyers need to specify the desired finish to align with branding and product requirements.

5. Patina Development

Patina refers to the natural aging process of leather, which can enhance its appearance over time. Understanding how different leather types develop patina can be a selling point for products aimed at consumers who appreciate the aesthetic of aged materials. Buyers should consider this property when selecting leather to create unique, long-lasting pieces.

6. Water Resistance

Water resistance is an important property for leather products, particularly for outdoor or everyday wear items. Buyers should inquire about the treatments used to enhance water resistance, as it impacts the product’s usability and durability in various environments.

What Common Trade Terminology Should B2B Buyers Know in Leather Bracelet Manufacturing?

Familiarity with industry terminology is crucial for effective communication and negotiation in the leather bracelet market. Here are some key terms:

Illustrative image related to how to make leather bracelets

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are sold under another brand’s name. In the leather bracelet industry, buyers may engage with OEMs to create custom designs or variations of existing products, making it essential for manufacturers to understand their capabilities and limitations.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum quantity of units that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers as it affects inventory management, cost efficiency, and the feasibility of launching new products. Buyers should negotiate MOQs that align with their production schedules and market demand.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. B2B buyers should use RFQs to compare offers from different suppliers, ensuring they receive competitive pricing and favorable terms.

Illustrative image related to how to make leather bracelets

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, insurance, and customs clearance, minimizing risks in cross-border transactions.

5. Lead Time

Lead time is the duration from placing an order to receiving the goods. In the leather bracelet market, understanding lead times is essential for inventory planning and meeting customer demands. Buyers should communicate their timelines clearly to suppliers to ensure timely delivery.

6. Customization

Customization refers to the ability to modify existing products to meet specific buyer requirements, such as size, color, or design features. This term is crucial for B2B buyers who wish to differentiate their offerings in a competitive market.

Understanding these properties and terms will empower B2B buyers to make informed decisions, ensuring that their leather bracelet products meet market demands and maintain high quality.

Navigating Market Dynamics and Sourcing Trends in the how to make leather bracelets Sector

What Are the Current Market Dynamics and Key Trends in the Leather Bracelet Sector?

The leather bracelet market is experiencing a resurgence driven by a growing consumer preference for personalized and handmade products. As international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, seek unique offerings, the demand for leather bracelets that can be customized with names, messages, or symbols is on the rise. This trend is fueled by the increasing popularity of DIY crafting and artisanal products, with platforms like Creativebug and wikiHow providing resources for both consumers and businesses to learn about leather crafting techniques.

Additionally, advancements in technology are influencing sourcing trends. E-commerce platforms and social media are facilitating direct connections between manufacturers and buyers, allowing for more streamlined supply chains. Businesses are increasingly leveraging digital marketplaces to showcase their products, expand their reach, and engage with customers. This shift is particularly significant in regions like Europe and the Middle East, where digital adoption is high, and consumers are increasingly shopping online for handmade goods.

Moreover, sustainability is becoming a pivotal factor in purchasing decisions. Buyers are now more informed about the environmental impact of their purchases and are seeking suppliers who prioritize ethical practices. The market is moving towards innovative leather alternatives, such as vegetable-tanned leather, which aligns with eco-friendly values, and this trend is likely to grow as more consumers demand sustainable options.

How Is Sustainability and Ethical Sourcing Affecting the Leather Bracelet Market?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the leather bracelet market. The environmental impact of traditional leather production, which often involves harmful chemicals and processes, has led to an increased demand for environmentally friendly materials. Buyers are now looking for suppliers who utilize sustainable practices, such as vegetable tanning or sourcing leather from responsible farms that adhere to ethical animal treatment standards.

Moreover, certifications play a significant role in validating the sustainability claims of suppliers. Certifications such as the Leather Working Group (LWG) or Global Organic Textile Standard (GOTS) provide assurance to B2B buyers that the materials they are sourcing are environmentally friendly and ethically produced. As consumers become more conscious of their purchasing decisions, buyers who prioritize these certifications will have a competitive advantage in the market.

The shift towards sustainability also encourages innovation in the industry. Companies are exploring alternative materials, such as synthetic leathers made from recycled plastics or plant-based materials, which not only reduce environmental impact but also cater to the growing vegan market. This evolution presents significant opportunities for B2B buyers to differentiate their offerings and meet the demands of socially responsible consumers.

What Is the Historical Context of Leather Bracelets That Influences Current Trends?

The history of leather bracelets dates back thousands of years, with early examples found in various cultures, from ancient Egypt to indigenous tribes around the world. Initially used for practical purposes, such as securing garments or as protective gear, leather bracelets have evolved into fashion statements and symbols of personal expression.

In recent decades, the resurgence of handmade and artisanal products has reignited interest in leather crafting, particularly in the jewelry sector. The rise of the DIY movement has empowered individuals to create their own leather accessories, leading to a burgeoning market for leather crafting supplies and tutorials. This historical context underscores the enduring appeal of leather bracelets as versatile items that blend tradition with modern creativity.

For B2B buyers, understanding this evolution is essential as it highlights the potential for storytelling in marketing leather products. Leveraging the rich history of leather crafting can resonate with consumers looking for authenticity and connection to the past, ultimately enhancing the value proposition of leather bracelets in the contemporary marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather bracelets

-

How do I choose the right leather supplier for making bracelets?

Selecting the right leather supplier involves assessing their product quality, certifications, and reliability. Look for suppliers who offer various leather types suitable for bracelets, such as vegetable-tanned or chrome-tanned leather. Evaluate their production capacity to meet your demand and ensure they can provide samples for quality checks. It’s also beneficial to check reviews from other B2B buyers and inquire about their experience in the leather goods market, particularly in your target regions. -

What is the best leather type for crafting durable bracelets?

For crafting durable leather bracelets, vegetable-tanned leather is highly recommended due to its natural properties and ability to age beautifully. It offers a strong yet flexible texture, making it ideal for various designs, from simple bands to intricate stamped pieces. Chrome-tanned leather is another option, known for its softness and vibrant colors but may not be as eco-friendly. Consider the end use and customer preferences when selecting the leather type. -

What customization options should I consider for leather bracelets?

Customization options for leather bracelets can include stamping, dyeing, and adding embellishments like beads or metal studs. You can also offer personalized engravings with names or meaningful phrases to enhance customer appeal. Discuss with your supplier about their capabilities in customization, including minimum order quantities (MOQs) for personalized items. Providing unique designs can help differentiate your products in the competitive market. -

What are typical minimum order quantities (MOQs) for leather bracelets?

Minimum order quantities (MOQs) for leather bracelets can vary widely among suppliers, typically ranging from 50 to 500 units per design. Factors influencing MOQs include the complexity of the design, customization options, and the supplier’s production capacity. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are starting small or testing new designs in different markets. -

What payment terms are standard in B2B leather supply transactions?

Standard payment terms in B2B leather supply transactions often include a deposit (usually 30-50%) upfront, with the balance due before shipment. Some suppliers may offer credit terms for established businesses, allowing payment within 30 to 60 days after delivery. Always clarify payment methods accepted, such as bank transfers or letters of credit, and ensure that terms are documented in your purchase agreement to avoid disputes. -

How do I ensure quality assurance for leather bracelets?

To ensure quality assurance for leather bracelets, establish clear quality standards with your supplier before production. Request samples to evaluate leather quality, stitching, and overall craftsmanship. Implement regular inspections during the manufacturing process, especially for large orders. Additionally, consider third-party quality control services to provide objective assessments and ensure that the final products meet your specifications. -

What logistics considerations should I keep in mind when importing leather bracelets?

When importing leather bracelets, consider shipping methods, customs regulations, and import duties specific to your country. Choose a reliable logistics partner experienced in handling leather goods to navigate potential challenges, such as temperature sensitivity and packaging requirements. Additionally, ensure that your supplier provides all necessary documentation for customs clearance, including invoices and certificates of origin, to avoid delays. -

What are the trends in leather bracelet designs that I should be aware of?

Current trends in leather bracelet designs include eco-friendly materials, minimalist styles, and personalized options. Many consumers are looking for unique, handcrafted pieces that reflect their individuality. Incorporating elements like mixed materials (e.g., combining leather with metals or beads) and adjustable designs can also appeal to a broader audience. Stay updated on market trends through industry reports and social media platforms to align your product offerings with consumer preferences.

Top 1 How To Make Leather Bracelets Manufacturers & Suppliers List

1. Reddit – Handmade Leather Bracelet

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: First leather bracelet made by user, inspired by a simple drawing. Used Olive and Tobacco pueblo leather for a natural color combination. Features a big closing ring for security. The process involved measuring multiple times and drawing a low-fi prototype, similar to UX design methods.

Strategic Sourcing Conclusion and Outlook for how to make leather bracelets

In conclusion, the art of making leather bracelets offers significant opportunities for B2B buyers seeking to diversify their product offerings. By leveraging strategic sourcing, businesses can access high-quality materials and innovative techniques that enhance craftsmanship and appeal to a broad audience. Key takeaways include the importance of selecting suitable leather types, understanding various bracelet-making techniques, and incorporating personalized elements to attract customers.

Illustrative image related to how to make leather bracelets

International buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia, are well-positioned to capitalize on the growing demand for unique, handcrafted accessories. As consumer preferences shift towards personalized and sustainable products, investing in artisanal leather goods can set your brand apart in a competitive market.

Embrace this opportunity to elevate your product line by sourcing premium leather and engaging in creative design practices. By doing so, you not only meet customer expectations but also foster long-term relationships with suppliers who share your commitment to quality and innovation. Start your journey today to transform your offerings and resonate with discerning consumers globally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to make leather bracelets

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.