Introduction: Navigating the Global Market for pu leather material meaning

In today’s global marketplace, understanding the nuances of PU leather material meaning is crucial for B2B buyers looking to source high-quality, sustainable materials. With a growing demand for affordable yet stylish alternatives to genuine leather, many businesses face the challenge of navigating a complex landscape filled with varying quality, durability, and environmental considerations. This guide delves into the essential aspects of PU leather, including its composition, applications across different industries, and the implications of sourcing this synthetic material.

International buyers from Africa, South America, the Middle East, and Europe, particularly in markets like Brazil and Saudi Arabia, will find value in this comprehensive exploration. We will cover the types of PU leather available, effective supplier vetting strategies, cost implications, and the environmental impact associated with its production. By equipping decision-makers with in-depth knowledge and actionable insights, this guide empowers businesses to make informed purchasing choices that align with both their operational needs and sustainability goals.

As the demand for eco-friendly products rises, understanding PU leather’s role in the marketplace becomes increasingly significant. With this guide, navigate the complexities of sourcing PU leather to enhance your product offerings while addressing consumer preferences for both quality and environmental responsibility.

Table Of Contents

- Top 4 Pu Leather Material Meaning Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pu leather material meaning

- Understanding pu leather material meaning Types and Variations

- Key Industrial Applications of pu leather material meaning

- 3 Common User Pain Points for ‘pu leather material meaning’ & Their Solutions

- Strategic Material Selection Guide for pu leather material meaning

- In-depth Look: Manufacturing Processes and Quality Assurance for pu leather material meaning

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu leather material meaning’

- Comprehensive Cost and Pricing Analysis for pu leather material meaning Sourcing

- Alternatives Analysis: Comparing pu leather material meaning With Other Solutions

- Essential Technical Properties and Trade Terminology for pu leather material meaning

- Navigating Market Dynamics and Sourcing Trends in the pu leather material meaning Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pu leather material meaning

- Strategic Sourcing Conclusion and Outlook for pu leather material meaning

- Important Disclaimer & Terms of Use

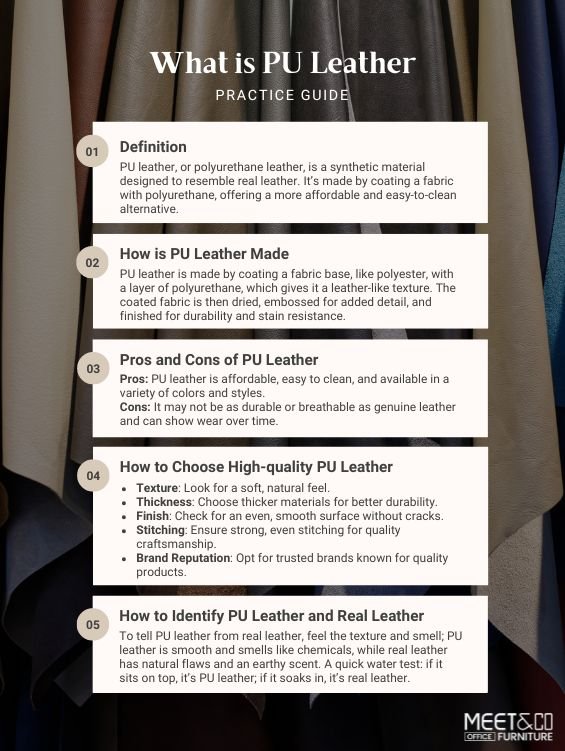

Understanding pu leather material meaning Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PU Leather | Cost-effective, basic texture, non-breathable | Fashion accessories, furniture | Pros: Affordable, easy to clean. Cons: Short lifespan, prone to wear and tear. |

| Microfiber PU Leather | Soft texture, high durability, water-resistant | Automotive upholstery, high-end bags | Pros: Durable, stain-resistant. Cons: Higher cost than standard PU. |

| Coated PU Leather | Enhanced finish, various textures, protective coating | Footwear, handbags, wallets | Pros: Aesthetic appeal, customizable. Cons: Potential for chemical exposure. |

| Eco-Friendly PU Leather | Made with sustainable practices, reduced VOCs | Eco-conscious fashion brands, furniture | Pros: Environmentally friendly, non-toxic. Cons: May have a higher price point. |

| Textured PU Leather | Embossed patterns, varied finishes, design versatility | Fashion items, interior design | Pros: Unique designs, visually appealing. Cons: Can be less durable than smoother finishes. |

What are the Characteristics and Suitability of Standard PU Leather?

Standard PU leather is a widely recognized synthetic material that mimics the look of genuine leather at a lower cost. It features a basic texture and is primarily used in fashion accessories and furniture. While it is easy to clean and maintain, the lifespan is relatively short, often lasting only 6 to 24 months. B2B buyers should consider its affordability and low maintenance needs but remain cautious about its durability, as it is prone to cracking and peeling over time.

How Does Microfiber PU Leather Stand Out in Durability?

Microfiber PU leather is known for its soft texture and high durability, making it suitable for applications in automotive upholstery and premium bags. This variant offers water resistance and is less likely to show wear compared to standard PU leather. B2B buyers looking for long-lasting products may find microfiber PU leather to be a viable option, despite its higher cost. The investment is often justified by its longevity and overall performance in high-use environments.

Illustrative image related to pu leather material meaning

What are the Benefits of Coated PU Leather for Aesthetics?

Coated PU leather features an enhanced finish with various textures and a protective coating, making it ideal for footwear, handbags, and wallets. Its customizable nature allows brands to offer unique designs that appeal to consumers. However, potential buyers should be aware of the possible presence of harmful chemicals during production. While it offers aesthetic appeal, B2B buyers must balance these benefits against the implications of chemical exposure.

Why Consider Eco-Friendly PU Leather for Sustainable Practices?

Eco-friendly PU leather is produced using sustainable practices and aims to reduce the presence of volatile organic compounds (VOCs). This type of PU leather is increasingly popular among eco-conscious fashion brands and furniture manufacturers. Although it may come at a higher price point, the benefits of being environmentally friendly and non-toxic can resonate well with consumers. B2B buyers focused on sustainability should prioritize this option to align with modern market demands.

What Makes Textured PU Leather a Unique Choice?

Textured PU leather is characterized by its embossed patterns and varied finishes, providing a design versatility that appeals to fashion items and interior design applications. While it can enhance visual appeal, this type may not be as durable as smoother finishes. B2B buyers should weigh the creative possibilities against the material’s potential limitations in longevity, particularly for high-traffic applications.

Key Industrial Applications of pu leather material meaning

| Industry/Sector | Specific Application of pu leather material meaning | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Production of jackets, handbags, and footwear | Cost-effective alternative to genuine leather, appealing to a broader market | Ensure compliance with international safety standards; assess durability and aesthetic quality |

| Automotive | Interior upholstery and seat covers | Lightweight, moisture-resistant, and easy to maintain | Evaluate resistance to wear and tear; consider sourcing from eco-friendly manufacturers |

| Furniture & Home Decor | Upholstery for sofas and chairs | Versatile design options, affordability, and ease of cleaning | Focus on sourcing materials with low VOC emissions; assess long-term durability |

| Sports Equipment | Production of sports bags and gear | Lightweight, flexible, and resistant to environmental factors | Ensure compliance with sports industry regulations; assess performance under high-stress conditions |

| Electronics | Protective cases for devices | Provides a premium look and feel while being cost-effective | Look for suppliers that offer customizable options; check for compatibility with various devices |

How is PU Leather Material Used in the Fashion & Apparel Industry?

In the fashion and apparel industry, PU leather is predominantly utilized in the production of jackets, handbags, and footwear. Its ability to mimic the appearance of genuine leather at a lower cost makes it an attractive option for brands targeting budget-conscious consumers. Additionally, PU leather is lightweight and versatile, allowing designers to create a wide range of styles. For international B2B buyers, it is critical to ensure compliance with safety standards and to assess the durability and aesthetic quality of the materials sourced.

What Role Does PU Leather Play in Automotive Interiors?

In the automotive sector, PU leather is commonly used for interior upholstery and seat covers. The material’s lightweight nature contributes to improved fuel efficiency, while its moisture resistance makes it suitable for various climates. B2B buyers in this field should focus on evaluating the resistance of PU leather to wear and tear, as well as ensuring that suppliers adhere to eco-friendly manufacturing practices. This is especially relevant for buyers in regions where sustainability is becoming increasingly important.

Illustrative image related to pu leather material meaning

How is PU Leather Beneficial in Furniture & Home Decor?

PU leather is widely used in upholstery for sofas and chairs within the furniture and home decor industry. Its versatility allows for a range of design options, making it appealing to consumers looking for stylish yet affordable furnishings. The ease of cleaning PU leather also enhances its attractiveness to both manufacturers and end-users. When sourcing materials, buyers should prioritize options with low VOC emissions and assess the long-term durability of the PU leather to ensure customer satisfaction.

What Are the Applications of PU Leather in Sports Equipment?

In the realm of sports equipment, PU leather is utilized for the production of sports bags and gear. The material’s lightweight and flexible properties make it ideal for active use, while its resistance to various environmental factors enhances the longevity of the products. B2B buyers in this sector must ensure that the materials comply with industry regulations and assess their performance under high-stress conditions, particularly for equipment used in competitive sports.

How is PU Leather Used for Electronics Protection?

PU leather is also employed in the production of protective cases for electronic devices, offering a premium look and feel at a cost-effective price point. This application appeals to both manufacturers and consumers who desire stylish yet functional accessories. Buyers should look for suppliers that provide customizable options to meet specific device requirements, while also ensuring compatibility with a variety of electronics to cater to diverse market needs.

3 Common User Pain Points for ‘pu leather material meaning’ & Their Solutions

Scenario 1: Misunderstanding PU Leather’s Durability

The Problem: B2B buyers often assume that PU leather, marketed as a cost-effective alternative to genuine leather, will provide similar durability. However, many find themselves facing unexpected challenges. For instance, a furniture manufacturer might purchase PU leather for upholstery, only to discover that the material cracks and peels after a short period of use. This not only leads to dissatisfaction among customers but also incurs additional costs for replacements and repairs, negatively impacting the brand’s reputation.

Illustrative image related to pu leather material meaning

The Solution: To mitigate this issue, B2B buyers should conduct thorough research before sourcing PU leather. Look for suppliers who provide detailed information about the material’s expected lifespan and performance under various conditions. Request samples to evaluate the texture and resilience firsthand. Moreover, consider asking for certifications that indicate the material’s durability, such as tests for abrasion resistance and UV stability. By prioritizing quality over price, buyers can ensure that the PU leather they select meets the demands of their end-use applications, ultimately leading to greater customer satisfaction.

Scenario 2: Navigating Toxicity Concerns in PU Leather Products

The Problem: With increasing awareness of environmental and health issues, B2B buyers are often concerned about the potential toxicity of PU leather. A buyer sourcing materials for fashion accessories might encounter reports that some PU leather products contain harmful volatile organic compounds (VOCs) and other toxic chemicals, raising concerns about safety for both workers and consumers. This can lead to hesitation in making purchasing decisions, as buyers worry about legal liabilities and negative public perception.

The Solution: Buyers should proactively seek out suppliers who are transparent about their manufacturing processes and the materials used in their PU leather products. Request documentation that demonstrates compliance with safety standards, such as REACH or OEKO-TEX certifications, which indicate that the product has been tested for harmful substances. Additionally, consider forming partnerships with manufacturers who prioritize eco-friendly practices, such as using water-based adhesives and low-VOC coatings. By aligning with responsible suppliers, B2B buyers can confidently source PU leather that meets safety regulations and resonates with environmentally-conscious consumers.

Scenario 3: Misleading Marketing and Product Specifications

The Problem: B2B buyers often encounter misleading marketing claims that can create confusion regarding the actual quality and characteristics of PU leather. For example, a buyer looking to source materials for bags may come across terms like “genuine leather” or “leather-like,” leading them to mistakenly believe they are purchasing high-quality materials. This misrepresentation can result in poor purchasing decisions and damaged client relationships when the final product does not meet expectations.

The Solution: To navigate this challenge, buyers must develop a clear understanding of the terminology used in the industry. Familiarize yourself with the differences between PU leather, genuine leather, and other synthetic materials. Engage in direct communication with suppliers to clarify product specifications and demand detailed descriptions of the material’s composition and performance features. Establishing a checklist that outlines essential criteria—such as the type of backing material used, the thickness of the PU layer, and expected wear resistance—can help buyers make informed decisions. By being proactive and asking the right questions, B2B buyers can avoid pitfalls associated with misleading marketing and ensure they procure products that align with their quality standards.

Strategic Material Selection Guide for pu leather material meaning

What Are the Key Materials Used in PU Leather Production?

When considering PU leather for various applications, understanding the materials involved is crucial for B2B buyers. The primary components of PU leather include polyurethane, fabric backing, and additives that enhance its properties. Below, we analyze these materials in detail, focusing on their properties, advantages, disadvantages, and implications for international buyers.

1. Polyurethane (PU)

Key Properties:

Polyurethane is a versatile polymer known for its flexibility and durability. It can withstand a wide range of temperatures, typically from -30°C to 80°C, making it suitable for various climates. Additionally, PU exhibits good resistance to abrasion and moisture, although it is not entirely waterproof.

Pros & Cons:

The main advantage of polyurethane is its ability to mimic the look and feel of genuine leather at a lower cost. However, its durability is often questioned; it can crack and peel over time, especially with heavy use. Manufacturing PU leather involves complex processes, including coating and embossing, which can increase production time.

Impact on Application:

PU is commonly used in fashion items, upholstery, and accessories, where aesthetic appeal is crucial. However, its limited lifespan compared to genuine leather can affect long-term value.

Illustrative image related to pu leather material meaning

Considerations for International Buyers:

Buyers in regions like Africa and South America should be aware of local regulations regarding chemical safety, as some PU products may contain volatile organic compounds (VOCs). Compliance with standards such as ASTM or DIN is essential for ensuring product safety and quality.

2. Fabric Backing

Key Properties:

The fabric backing, usually made from polyester or cotton, provides structural support to PU leather. It enhances the material’s tensile strength and contributes to its overall flexibility.

Pros & Cons:

Fabric backing improves the comfort and wearability of PU leather products. However, the quality of the backing material can vary significantly, affecting the final product’s durability and appearance. Low-quality fabric may lead to premature wear and tear.

Impact on Application:

The choice of backing material can influence the end product’s suitability for specific applications, such as clothing versus upholstery. High-quality backing is essential for items that require more durability, like furniture.

Considerations for International Buyers:

Buyers should ensure that the fabric backing complies with local textile regulations. For instance, in Europe, standards such as OEKO-TEX® can assure buyers of the fabric’s safety and environmental impact.

Illustrative image related to pu leather material meaning

3. Additives and Coatings

Key Properties:

Additives such as flame retardants, UV stabilizers, and antimicrobial agents are often incorporated into PU leather to enhance its performance. These additives can improve the material’s resistance to environmental factors and prolong its lifespan.

Pros & Cons:

While additives can significantly enhance the functionality of PU leather, they may also introduce potential health risks. Some additives can be harmful, leading to concerns about toxicity and environmental impact.

Impact on Application:

The inclusion of specific additives can make PU leather suitable for specialized applications, such as automotive interiors or medical supplies, where safety and durability are paramount.

Illustrative image related to pu leather material meaning

Considerations for International Buyers:

Buyers must be vigilant about the chemical composition of PU leather, particularly in regions with strict environmental regulations, such as the EU. Compliance with REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is crucial for market entry.

Summary Table of PU Leather Materials

| Material | Typical Use Case for pu leather material meaning | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Fashion items, upholstery, accessories | Mimics genuine leather at a lower cost | Prone to cracking and peeling | Medium |

| Fabric Backing | Clothing, furniture, bags | Enhances comfort and flexibility | Quality varies, affecting durability | Low |

| Additives and Coatings | Automotive interiors, medical supplies | Improves performance and longevity | Potential toxicity and environmental concerns | Medium |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding PU leather materials. Understanding the properties, advantages, and limitations of each component will facilitate better procurement strategies and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pu leather material meaning

What Are the Key Stages in the Manufacturing Process of PU Leather?

The manufacturing process of PU leather involves several critical stages that ensure the final product meets the aesthetic and functional requirements of various applications. Understanding these stages can help B2B buyers make informed decisions when sourcing materials.

Material Preparation: What Goes Into PU Leather?

The first step in the production of PU leather is the preparation of the base material. Typically, this involves a woven fabric, such as polyester or nylon, that provides the structural integrity of the product. The chosen fabric is treated to enhance its durability and flexibility. The next phase involves the creation of the polyurethane layer. This polymer is synthesized through a chemical reaction between diisocyanates and polyols, resulting in a versatile material that can mimic the look and feel of genuine leather.

How Is PU Leather Formed?

Once the base material is prepared, the next stage is forming the PU leather. This typically involves applying a layer of liquid polyurethane onto the fabric substrate. The coating process can be done using various techniques, including:

Illustrative image related to pu leather material meaning

- Roll Coating: A method where a roller applies the polyurethane evenly across the fabric.

- Spray Coating: This involves spraying the polyurethane to create a textured finish.

- Foam Coating: A thicker layer is applied for added cushioning.

After coating, the material is embossed with patterns that resemble natural leather textures, enhancing its visual appeal.

What Are the Finishing Techniques Used in PU Leather Production?

The finishing stage is crucial for adding durability and aesthetics to PU leather. This may include treatments that make the material resistant to water, stains, and UV light. Common finishing techniques include:

- Heat Setting: This process involves applying heat to stabilize the polyurethane layer and enhance adhesion to the backing fabric.

- Surface Treatments: Additional chemical coatings may be applied to improve scratch resistance or provide a matte or glossy finish.

Finishing not only affects the material’s performance but also its marketability, making it essential for suppliers to invest in high-quality finishing processes.

What Quality Assurance Standards Are Relevant for PU Leather?

Quality assurance (QA) is critical in the production of PU leather to ensure safety, durability, and compliance with international standards. B2B buyers should be aware of various QA protocols that manufacturers must follow.

Which International Standards Should B2B Buyers Consider?

One of the most recognized international quality management standards is ISO 9001, which focuses on maintaining consistent quality in products and services. Compliance with ISO 9001 indicates that the manufacturer has implemented a quality management system (QMS) that adheres to global best practices.

In addition to ISO certifications, industry-specific standards like CE marking for products sold in Europe and API (American Petroleum Institute) certifications for products related to petroleum can also be relevant. These certifications ensure that the materials used are safe and meet regulatory requirements.

What Are the Key Quality Control Checkpoints in PU Leather Production?

Quality control (QC) is integrated into multiple stages of the PU leather manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials before production begins. Checks may include verifying the quality of the base fabric and the consistency of the polyurethane mixture.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to ensure that each step meets established quality standards. This may involve monitoring the coating thickness and texture consistency.

-

Final Quality Control (FQC): Once the PU leather is produced, a final inspection is conducted before shipment. This includes visual inspections for defects and testing for physical properties such as tear strength and color fastness.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing PU leather, B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing processes and quality control measures. This firsthand experience can help identify potential risks in the supply chain.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can offer transparency into a supplier’s QC practices. These reports should outline testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can perform inspections at various stages of production, ensuring that standards are met.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must navigate unique challenges when sourcing PU leather. Here are some key considerations:

-

Cultural and Regulatory Differences: Understanding the specific regulatory requirements in different regions is crucial. For instance, certain countries may have stricter regulations regarding the use of chemicals in manufacturing, impacting the choice of suppliers.

-

Logistical Challenges: International shipping can introduce delays that affect product quality. Buyers should consider how suppliers manage logistics and whether they have contingency plans for quality assurance during transit.

-

Language Barriers: Clear communication is essential for ensuring quality expectations are met. Buyers should establish a common language or use translation services to facilitate discussions with suppliers.

By understanding the manufacturing processes and quality assurance practices related to PU leather, B2B buyers can make informed sourcing decisions that align with their business needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu leather material meaning’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure PU leather material. As an alternative to genuine leather, PU leather offers various advantages, including cost-effectiveness and aesthetic appeal. However, understanding the nuances of this synthetic material is crucial for making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, outline your specific requirements for PU leather. Consider factors such as thickness, texture, color, and intended applications (e.g., upholstery, fashion accessories). Clearly defined specifications will help streamline communication with suppliers and ensure that the material meets your quality standards.

Step 2: Research Supplier Credentials

Conduct thorough research on potential suppliers. Look for certifications that demonstrate compliance with international standards, such as ISO certifications or environmental sustainability credentials. These certifications can indicate a supplier’s commitment to quality and ethical practices, reducing the risk of toxic materials and ensuring environmentally friendly production.

Illustrative image related to pu leather material meaning

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This information will provide insights into the supplier’s reliability, production capabilities, and customer service. Don’t just rely on their website; engage in direct conversations to gauge their responsiveness and expertise.

Step 4: Request Samples for Testing

Always request samples of PU leather before placing a bulk order. Evaluate the samples based on tactile qualities, durability, and visual appeal. Testing the material under real-world conditions will help you assess its performance in your specific applications, ensuring it meets your expectations.

Step 5: Assess Environmental Impact

Understand the environmental implications of the PU leather you intend to source. Inquire about the manufacturing processes, including the use of volatile organic compounds (VOCs) and other chemicals. Suppliers should provide transparency regarding their practices, as choosing environmentally friendly options can enhance your brand’s sustainability profile.

Illustrative image related to pu leather material meaning

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Ensure that all agreements are documented in a contract to avoid misunderstandings later. Discuss the possibility of long-term partnerships or volume discounts, as these can provide additional value.

Step 7: Plan for Quality Assurance

Establish a quality assurance process to monitor the received PU leather. Define inspection criteria and methods for checking the material upon arrival. This step is vital to ensure that the product meets your technical specifications and quality standards, reducing the risk of costly returns or rework.

By following this checklist, B2B buyers can confidently navigate the sourcing process for PU leather, ensuring they select high-quality materials that align with their business needs and ethical standards.

Illustrative image related to pu leather material meaning

Comprehensive Cost and Pricing Analysis for pu leather material meaning Sourcing

What Are the Key Cost Components in PU Leather Sourcing?

When sourcing PU leather, understanding the cost structure is essential for B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The base material for PU leather is polyurethane, which is combined with a backing fabric. The quality and type of these materials significantly influence the price. Higher-grade polyurethanes and specialized backing fabrics can lead to increased costs.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as those in South America or parts of Africa, the production costs may be more economical. However, quality control and skilled labor are vital for ensuring product durability and aesthetic appeal.

-

Manufacturing Overhead: This includes expenses related to the production facility, equipment maintenance, utilities, and other fixed costs associated with running a manufacturing operation. Efficient production processes can reduce overhead costs, impacting the final price.

-

Tooling: Tooling refers to the investment in molds and equipment necessary for manufacturing PU leather products. Custom tooling for unique designs can significantly increase initial costs, but these costs can be amortized over larger production runs.

-

Quality Control (QC): Ensuring that the PU leather meets specified standards is crucial. QC processes may involve testing for durability, toxicity, and environmental compliance, all of which can add to the overall cost.

-

Logistics: Shipping and handling costs can vary widely based on the distance from the supplier to the buyer, as well as the chosen shipping method. For international buyers, understanding Incoterms is vital for managing logistics costs effectively.

-

Margin: Suppliers will typically add a markup to cover their costs and generate profit. This margin can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect PU Leather Sourcing?

Several factors can influence the pricing of PU leather beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom designs or specific performance characteristics can elevate costs. Buyers must weigh the benefits of customization against their budget constraints.

-

Material Quality and Certifications: PU leather that meets international quality standards or has certifications (e.g., eco-friendly materials) may command higher prices. Buyers should assess whether the added cost aligns with their market positioning.

-

Supplier Factors: Established suppliers with a reputation for quality and reliability may charge premium prices. However, they may also provide better service and faster delivery times, which can justify the higher cost.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can significantly impact the final price. Buyers must understand their responsibilities regarding shipping, customs clearance, and insurance to avoid unexpected costs.

What Are Effective Buyer Tips for Negotiating PU Leather Prices?

To navigate the complexities of PU leather pricing effectively, international B2B buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and MOQs. Leverage your position as a buyer to secure favorable conditions.

-

Focus on Total Cost of Ownership (TCO): Look beyond the initial price. Consider durability, maintenance, and potential replacement costs when assessing the overall value of PU leather products.

-

Research Market Trends: Stay informed about market dynamics, including changes in material costs and demand fluctuations. This knowledge can empower buyers during negotiations.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Engaging with multiple suppliers can provide insights into competitive pricing and help identify the best value.

-

Understand Regional Variances: Pricing structures can differ significantly between regions. Buyers from Africa, South America, the Middle East, and Europe should account for local economic factors that may influence costs.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on specific supplier negotiations, market conditions, and individual buyer circumstances. Always conduct thorough research and engage with suppliers to obtain accurate and up-to-date pricing information.

Illustrative image related to pu leather material meaning

Alternatives Analysis: Comparing pu leather material meaning With Other Solutions

In the competitive landscape of materials for manufacturing and design, PU leather has emerged as a popular option due to its affordability and versatility. However, as sustainability and durability become more significant considerations for B2B buyers, it’s crucial to explore alternative materials that can offer enhanced performance, lower environmental impact, and longer lifespan. This section provides a comparative analysis of PU leather against two notable alternatives: vegetable-tanned leather and recycled polyester fabric.

| Comparison Aspect | PU Leather Material Meaning | Vegetable-Tanned Leather | Recycled Polyester Fabric |

|---|---|---|---|

| Performance | Moderate durability; prone to cracking and peeling over time | High durability; develops a unique patina | Good durability; resistant to wear and tear |

| Cost | Low initial cost; frequent replacements needed | Higher upfront cost; cost-effective over time due to longevity | Moderate cost; varies based on sourcing and quality |

| Ease of Implementation | Widely available; easy to source | Requires skilled craftsmanship; less accessible | Relatively easy to source; growing market availability |

| Maintenance | Minimal maintenance; wipe clean | Requires occasional conditioning; more care needed | Low maintenance; easy to clean |

| Best Use Case | Fast fashion, low-cost items | Luxury goods, high-end accessories | Eco-friendly products, activewear |

What Are the Benefits and Drawbacks of Vegetable-Tanned Leather?

Vegetable-tanned leather stands out for its durability and aesthetic appeal. This material is tanned using natural plant-based tannins, resulting in a product that not only lasts longer but also ages beautifully, gaining character over time. While the initial cost is higher than PU leather, the longevity of vegetable-tanned leather often makes it a more economical choice in the long run. However, it requires more maintenance and is not as readily available, which could pose challenges for businesses with high-volume demands.

How Does Recycled Polyester Fabric Compare to PU Leather?

Recycled polyester fabric is an innovative alternative that emphasizes sustainability. Made from post-consumer plastic bottles and other recycled materials, it offers good durability and resistance to wear, making it suitable for various applications, including outdoor gear and activewear. Its environmental benefits, such as reducing plastic waste, are significant selling points. However, the performance may not match the luxurious feel of leather, and sourcing high-quality recycled polyester can sometimes be challenging, affecting consistency in production.

How Can B2B Buyers Choose the Right Material for Their Needs?

When selecting a material for production, B2B buyers should consider several factors, including the intended use of the product, target market, and budget. If the focus is on sustainability and long-term investment, vegetable-tanned leather may be the superior choice despite its higher initial cost. On the other hand, for businesses aiming for affordability and rapid production, PU leather may suffice, provided they are aware of its limitations in durability and environmental impact. Recycled polyester fabric serves as a compelling option for those looking to align with eco-friendly practices while maintaining a balance between cost and performance. Ultimately, the best solution will depend on the specific needs and values of the business, emphasizing the importance of thorough research and consideration before making a decision.

Illustrative image related to pu leather material meaning

Essential Technical Properties and Trade Terminology for pu leather material meaning

What Are the Key Technical Properties of PU Leather Material?

1. Material Composition

PU leather is primarily made from polyurethane, a synthetic polymer derived from a chemical reaction between diisocyanates and polyols. The polyurethane layer is applied to a backing material, usually fabric, which provides structure and support. Understanding the material composition is crucial for B2B buyers as it influences the product’s durability, feel, and overall performance in various applications, from fashion to upholstery.

2. Thickness

The thickness of PU leather can vary, typically ranging from 0.5mm to 1.5mm. This specification is vital for manufacturers and designers as it impacts the material’s flexibility, durability, and application suitability. Thicker PU leather may be more durable but can also be less pliable, affecting how it drapes or conforms to shapes in finished products.

3. Abrasion Resistance

Abrasion resistance measures how well a material withstands wear and tear from friction. For PU leather, this property is essential in assessing its longevity, especially in high-use applications like furniture or fashion accessories. A higher abrasion resistance rating indicates a longer-lasting product, making it a key consideration for B2B buyers focused on quality and customer satisfaction.

4. Water Resistance

PU leather is often marketed as water-resistant, making it suitable for various environments. However, the degree of water resistance can vary based on the manufacturing process and any additional treatments applied. B2B buyers should evaluate this property to ensure the material meets the specific needs of their target market, particularly in regions with high humidity or rainfall.

5. Chemical Resistance

Chemical resistance refers to the material’s ability to withstand exposure to various substances without degrading. This is particularly important for PU leather used in automotive or industrial applications, where exposure to oils, solvents, and cleaning agents is common. Understanding this property helps B2B buyers select the right material for their products to avoid premature failure.

Illustrative image related to pu leather material meaning

6. VOC Emissions

Volatile Organic Compounds (VOCs) are chemicals released during the manufacturing process that can have health and environmental impacts. For B2B buyers, being aware of VOC emissions is critical, especially in markets with strict regulations on material safety and environmental standards. This property is increasingly influencing purchasing decisions as consumers and businesses become more environmentally conscious.

What Are the Common Trade Terms Associated with PU Leather?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products or components that are sold by another company under its brand name. In the context of PU leather, buyers may work with OEMs to develop customized products that meet specific requirements, enhancing brand identity and market presence.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and cash flow. A high MOQ may require larger upfront investments, while a lower MOQ can facilitate smaller, more manageable orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. B2B buyers often use RFQs when seeking competitive pricing for PU leather products, enabling informed decision-making and better negotiation outcomes.

Illustrative image related to pu leather material meaning

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers navigate logistics and costs effectively when importing PU leather materials from different regions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for planning production schedules and ensuring timely delivery to customers, especially in industries with strict timelines.

6. Certification

Certification refers to the verification of a product’s compliance with specific standards, such as environmental regulations or material safety. For PU leather, certifications can enhance marketability and consumer trust, making it an important consideration for buyers focused on quality and sustainability.

Illustrative image related to pu leather material meaning

Navigating Market Dynamics and Sourcing Trends in the pu leather material meaning Sector

What Are the Current Market Dynamics and Key Trends Affecting PU Leather Sourcing?

The PU leather market is experiencing dynamic shifts driven by several global factors. One significant driver is the increasing demand for sustainable and affordable alternatives to genuine leather. As consumers and businesses alike seek eco-friendly options, PU leather has become a favored choice due to its lower cost and versatility in applications ranging from fashion to furniture. Additionally, the rise of e-commerce is reshaping the sourcing landscape, enabling B2B buyers from Africa, South America, the Middle East, and Europe to access a wider array of suppliers.

Technological advancements are also playing a crucial role in this sector. Innovations in manufacturing processes are leading to higher-quality PU leather products that closely mimic the look and feel of genuine leather. This trend is particularly relevant for international buyers who prioritize both aesthetics and functionality in their purchases. Furthermore, digital platforms are enhancing supply chain transparency, allowing buyers to better evaluate the quality and sustainability credentials of PU leather products.

Emerging markets, particularly in Brazil and Saudi Arabia, are witnessing a surge in demand for PU leather due to rising disposable incomes and changing consumer preferences. As the market continues to evolve, buyers must stay informed about these trends to make strategic sourcing decisions that align with their business goals.

How Does Sustainability and Ethical Sourcing Impact PU Leather in B2B Markets?

Sustainability has become a pivotal concern in the PU leather sector, compelling businesses to rethink their sourcing strategies. The environmental impact of PU leather production is significant, primarily due to its petroleum-based composition and the presence of volatile organic compounds (VOCs). As awareness of these issues grows, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices.

Ethical sourcing is not just a trend; it’s becoming a requirement for many businesses. Buyers are now seeking out suppliers who can provide transparency in their manufacturing processes and who adhere to strict environmental standards. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® can serve as indicators of a supplier’s commitment to sustainability.

Moreover, many companies are exploring alternatives to traditional PU leather, including plant-based or recycled materials that minimize ecological footprints. These innovations not only satisfy consumer demands for sustainability but also align with global regulatory trends aimed at reducing plastic waste. For B2B buyers, investing in ethically sourced PU leather can enhance brand reputation and customer loyalty, making it a strategic business decision.

What Is the Historical Context of PU Leather Development Relevant for B2B Buyers?

Understanding the historical evolution of PU leather provides valuable context for B2B buyers. Introduced in the mid-20th century, PU leather emerged from the broader development of synthetic materials. Initially designed for industrial applications, it gradually found its way into consumer markets as manufacturers sought affordable alternatives to genuine leather.

The production process for PU leather involves coating a backing material with polyurethane, allowing for mass production and a consistent aesthetic appeal. However, this rapid production often comes at the expense of quality and environmental impact. As buyers navigate the current landscape, recognizing the historical context of PU leather can help them make informed decisions about product quality, supplier practices, and the long-term implications of their sourcing choices.

By integrating this knowledge into their procurement strategies, B2B buyers can better align their sourcing with market demands and sustainability goals, ultimately enhancing their competitive edge in a rapidly changing marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of pu leather material meaning

-

How do I determine the quality of PU leather when sourcing?

To assess the quality of PU leather, request product samples from potential suppliers. Examine the texture, flexibility, and overall feel; high-quality PU leather should mimic genuine leather closely. Additionally, inquire about the manufacturing process, including the types of chemicals used and any certifications related to safety and environmental impact. Checking for compliance with international standards, such as REACH or RoHS, can further ensure the product’s quality and safety. -

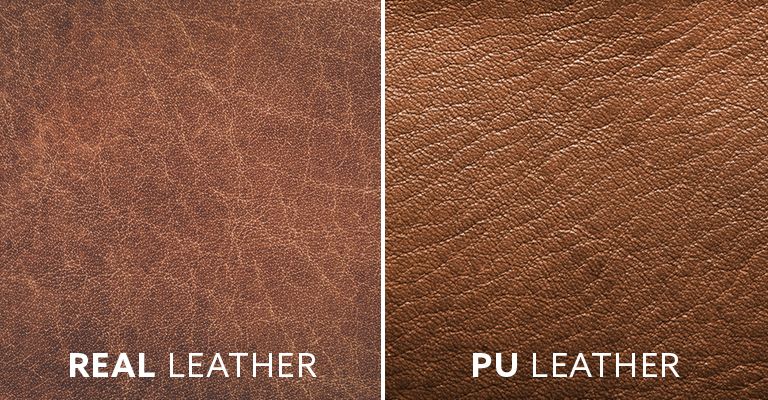

What are the key differences between PU leather and genuine leather?

PU leather is a synthetic alternative made from polyurethane, while genuine leather comes from animal hides. The primary differences lie in durability, maintenance, and environmental impact. PU leather typically lasts between 1-2 years and may crack or peel, while genuine leather can last decades and develops a unique patina over time. Additionally, PU leather is often less expensive but can contain harmful chemicals, making genuine leather a more sustainable option for long-term investments. -

What customization options are available for PU leather products?

Customization options for PU leather products can vary significantly by supplier. Common options include color selection, texture finishes, embossing, and specific dimensions tailored to your needs. When sourcing, communicate your requirements clearly to the supplier and inquire about minimum order quantities (MOQs) for custom orders. This ensures that your products align with your brand identity and customer preferences. -

What is the typical minimum order quantity (MOQ) for PU leather?

Minimum order quantities for PU leather can vary widely among suppliers, typically ranging from 100 to 1,000 units. Factors influencing MOQ include the type of product, customization options, and the supplier’s production capabilities. It’s essential to discuss your needs upfront, as some suppliers may offer flexibility based on your long-term partnership potential or order frequency. -

What payment terms should I expect when sourcing PU leather?

Payment terms can vary by supplier and region but often include options such as a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may also offer letter of credit or payment upon delivery. Always negotiate clear terms that protect your interests, and consider using escrow services for larger transactions to ensure both parties meet their obligations. -

How do I ensure quality assurance (QA) for my PU leather orders?

To ensure quality assurance, establish clear specifications and standards with your supplier before production begins. Request regular updates and, if possible, conduct on-site inspections during the manufacturing process. Many suppliers will also provide a pre-shipment inspection report, which can help verify that the products meet your quality standards. Additionally, consider implementing a return policy for defective goods. -

What logistics considerations should I keep in mind when importing PU leather?

When importing PU leather, consider shipping methods, customs regulations, and potential tariffs or duties that may apply. Ensure your supplier provides all necessary documentation, such as certificates of origin and compliance. Choosing a reliable freight forwarder familiar with your destination’s import regulations can facilitate smooth logistics. Additionally, factor in lead times for production and shipping to align with your inventory needs. -

Are there environmental concerns associated with PU leather production?

Yes, PU leather production can raise environmental concerns due to the use of synthetic materials and potentially harmful chemicals. Many PU leather products may contain volatile organic compounds (VOCs) that can affect air quality. To mitigate these concerns, seek suppliers who adhere to eco-friendly practices and certifications. Additionally, consider sustainable alternatives, such as vegetable-tanned leather, which may offer a lower environmental impact.

Top 4 Pu Leather Material Meaning Manufacturers & Suppliers List

1. Manuel Dreesmann – Fiona Bag

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: What is PU leather – and why you should avoid! Skip to content Worldwide Free Shipping Over 100€ Manuel-dreesmann Open navigation menu New New Fiona bag Tote Bag With Zipper The Fiona Bag The perfect shoulder bag Tote bag with zipper Carry your belongings safely Bags Bags Tote Bags Shoulder Bags Crossbody Bags Handbags Clutches Pouches & Belt Bags Backpacks The Croissant Bag Discover our bestselle…

2. Prestige Leather Care – PU Leather Cleaning Solutions

Domain: prestigeleathercare.co.uk

Registered: 2015 (10 years)

Introduction: PU leather, or polyurethane leather, is an artificial type of leather made from thermoplastic polymers. It is also known by various names including bicast leather, split leather, reconstituted leather, bonded leather, and corrected grain leather. PU leather can be cleaned using a suitable leather cleaner and a leather cleaning brush. It is considered vegan only if it is 100% PU; otherwise, it may …

3. HowStuffWorks – PU Leather Guide

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: PU (Polyurethane) leather is an artificial leather made from polyurethane, a type of plastic. It is 100% vegan, with no animal skin involved. There are two types of PU leather: full-synthetic (totally vegan) and semi-synthetic (which has a natural leather base). PU leather is water-resistant, easy to clean, and available in a wide variety of colors, making it suitable for upholstery and fashion it…

4. Senreve – PU Leather Products

Domain: senreve.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as polyurethane leather, is a synthetic material made from a base layer of fabric coated with a layer of polyurethane. It is designed to mimic the look and feel of genuine leather while being more affordable and easier to maintain. PU leather is often used in various products such as bags, shoes, and furniture. It is water-resistant, durable, and available in a variety of co…

Strategic Sourcing Conclusion and Outlook for pu leather material meaning

The landscape of PU leather sourcing presents both challenges and opportunities for international buyers. Understanding the material’s composition, potential toxicity, and environmental impact is crucial for making informed purchasing decisions. While PU leather offers an affordable alternative to genuine leather, its durability and sustainability are often questionable, leading to increased long-term costs and environmental concerns.

Illustrative image related to pu leather material meaning

Strategic sourcing becomes essential in this context, allowing businesses to prioritize suppliers who adhere to ethical practices and provide transparency in their manufacturing processes. By opting for high-quality alternatives, such as vegetable-tanned leather, companies can enhance product longevity, reduce environmental footprints, and foster a commitment to sustainability that resonates with today’s conscientious consumers.

As you navigate the complexities of sourcing PU leather, consider the broader implications of your choices. Investing in sustainable materials not only supports responsible production but also positions your brand as a leader in ethical business practices. Embrace this opportunity to forge partnerships that align with your values and contribute positively to global supply chains. Together, let’s shape a future where quality and sustainability go hand in hand.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to pu leather material meaning

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.