Introduction: Navigating the Global Market for oil on leather

In the competitive landscape of leather goods, one of the most pressing challenges faced by international B2B buyers is sourcing high-quality oil on leather products that meet stringent market demands. Understanding the nuances of leather care and maintenance, particularly regarding oil treatments, is essential for preserving the integrity and aesthetics of leather goods. This guide provides a comprehensive exploration of oil on leather, covering various types, applications, and the pivotal role of oil in enhancing leather’s durability and appearance.

Buyers will gain insights into the different types of leather oils available, their specific applications across various industries, and best practices for supplier vetting to ensure quality and compliance. Additionally, we delve into cost considerations, offering strategies for negotiating favorable terms while maintaining product excellence.

Designed specifically for B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—this guide empowers stakeholders to make informed purchasing decisions. By addressing common challenges and providing actionable solutions, we aim to enhance your procurement process, ensuring that your leather products not only meet but exceed customer expectations in a global market.

Table Of Contents

- Top 4 Oil On Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for oil on leather

- Understanding oil on leather Types and Variations

- Key Industrial Applications of oil on leather

- 3 Common User Pain Points for ‘oil on leather’ & Their Solutions

- Strategic Material Selection Guide for oil on leather

- In-depth Look: Manufacturing Processes and Quality Assurance for oil on leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘oil on leather’

- Comprehensive Cost and Pricing Analysis for oil on leather Sourcing

- Alternatives Analysis: Comparing oil on leather With Other Solutions

- Essential Technical Properties and Trade Terminology for oil on leather

- Navigating Market Dynamics and Sourcing Trends in the oil on leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of oil on leather

- Strategic Sourcing Conclusion and Outlook for oil on leather

- Important Disclaimer & Terms of Use

Understanding oil on leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mineral Oil | Derived from petroleum, offers water resistance. | Footwear, upholstery, and bags. | Pros: Effective for conditioning; Cons: Can darken leather. |

| Neatsfoot Oil | Natural oil from cattle, penetrates deeply. | High-end leather goods, saddlery. | Pros: Excellent for softening; Cons: Can become sticky if over-applied. |

| Coconut Oil | Plant-based, with antibacterial properties. | Fashion accessories, garments. | Pros: Eco-friendly; Cons: May leave a residue if not absorbed. |

| Leather Cream | Contains waxes and oils for surface protection. | Luxury handbags, belts, and shoes. | Pros: Enhances shine; Cons: Requires regular reapplication. |

| Synthetic Leather Oil | Specifically designed for PU and synthetic leathers. | Automotive upholstery, furniture. | Pros: Safe for synthetics; Cons: Limited effectiveness on natural leather. |

What Are the Key Characteristics of Mineral Oil for Leather?

Mineral oil is a widely used conditioning agent derived from petroleum. It is known for its water-resistant properties, making it suitable for items exposed to moisture, such as footwear and upholstery. B2B buyers should consider its effectiveness in maintaining leather’s suppleness, but they should also be aware that it can darken the leather’s appearance. For businesses dealing in leather goods, understanding the balance between conditioning and potential discoloration is crucial.

How Does Neatsfoot Oil Benefit High-End Leather Goods?

Neatsfoot oil is derived from the rendered fat of cattle and is favored for its ability to penetrate deeply into leather, restoring its natural oils. It is particularly popular among manufacturers of high-end leather goods and saddlery. While it effectively softens and revitalizes leather, over-application can lead to a sticky residue. B2B buyers should weigh the need for deep conditioning against the potential for maintenance challenges when opting for this oil.

Why Choose Coconut Oil for Fashion Accessories?

Coconut oil is a natural, plant-based option known for its antibacterial properties, making it a popular choice for fashion accessories and garments. Its eco-friendly nature appeals to businesses aiming for sustainable practices. However, buyers must consider that coconut oil may leave a residue if not properly absorbed, which could affect the aesthetic of the leather. Understanding the balance between sustainability and product presentation is vital for B2B buyers.

What Advantages Does Leather Cream Offer for Luxury Handbags?

Leather cream combines waxes and oils to provide a protective layer while enhancing the shine of leather products. This product is particularly advantageous for luxury handbags and belts, where appearance is paramount. While it offers excellent surface protection, B2B buyers should note that it requires regular reapplication to maintain its effectiveness. Businesses must factor in the ongoing maintenance costs associated with using leather cream in their product care routines.

Illustrative image related to oil on leather

How Does Synthetic Leather Oil Differ in Application?

Synthetic leather oil is specifically formulated for PU and synthetic leathers commonly used in automotive upholstery and furniture. This oil ensures compatibility and effectiveness without damaging the material. While it provides a safe conditioning option for synthetics, its effectiveness on natural leather is limited. B2B buyers should consider the specific materials they work with when choosing this type of oil, ensuring they select the right product for their needs.

Key Industrial Applications of oil on leather

| Industry/Sector | Specific Application of oil on leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear | Leather conditioning and waterproofing | Extends product lifespan and enhances appearance | Sourcing high-quality oils that are non-toxic and effective for leather types used in footwear. |

| Automotive | Leather seat treatment and maintenance | Improves durability and comfort, enhances resale value | Compliance with environmental regulations, availability of bulk quantities, and compatibility with various leather types. |

| Fashion and Accessories | Leather handbag and apparel care | Maintains aesthetic appeal and prolongs product life | Sourcing oils that are safe for diverse leather finishes and have minimal impact on color and texture. |

| Furniture | Leather upholstery protection and restoration | Increases longevity and preserves luxury appeal | Need for oils that are suitable for large-scale applications and can be easily applied without professional help. |

| Equestrian Equipment | Saddle and tack maintenance | Enhances performance and longevity of gear | Availability of specialized oils that cater to the unique requirements of equestrian leather products. |

How Is Oil Used in the Footwear Industry for Leather Conditioning?

In the footwear industry, oil is commonly used to condition and waterproof leather. This application is crucial as it not only extends the life of shoes but also enhances their visual appeal. Buyers in this sector must consider sourcing oils that are non-toxic and compatible with various leather types, ensuring they do not alter the color or texture adversely. Additionally, suppliers should provide oils that are easy to apply and have proven efficacy in protecting against moisture and wear.

What Role Does Oil Play in Automotive Leather Maintenance?

For the automotive industry, oil is essential for treating and maintaining leather seats. This application improves the durability and comfort of leather interiors while significantly enhancing the vehicle’s resale value. International buyers should focus on sourcing oils that comply with environmental regulations and are effective in bulk applications. It’s also important that these oils are compatible with different types of automotive leather, ensuring consistent quality and performance across various vehicle models.

How Is Oil Utilized in Fashion and Accessories for Leather Care?

In the fashion and accessories sector, oil is used for the care and maintenance of leather handbags, jackets, and other apparel. This application helps maintain the aesthetic appeal of products while prolonging their lifespan. Buyers in this industry should prioritize sourcing oils that are safe for various leather finishes and do not compromise the integrity of colors and textures. The ability to provide oils that are easy to apply and effective in restoring shine is also a significant consideration for B2B buyers.

Why Is Oil Important for Furniture Leather Protection?

The furniture industry benefits from oil applications for protecting and restoring leather upholstery. This use is vital for increasing the longevity of high-end furniture pieces and preserving their luxury appeal. Buyers should look for oils that can be applied easily, ideally without professional intervention, and that offer bulk purchasing options to meet the demands of large-scale furniture manufacturers. Additionally, sourcing oils that are non-toxic and environmentally friendly can be a significant selling point.

How Does Oil Support Equestrian Equipment Maintenance?

Oil plays a critical role in maintaining saddles and tack in the equestrian industry. It enhances the performance and longevity of leather gear, which is essential for both riders and horses. Buyers should seek specialized oils that cater specifically to equestrian leather, ensuring they meet the unique requirements of this sector. Considerations include sourcing oils that provide deep conditioning, are easy to apply, and help prevent damage from moisture and dirt.

3 Common User Pain Points for ‘oil on leather’ & Their Solutions

Scenario 1: Managing Oil Stains on High-Value Leather Goods

The Problem: B2B buyers in industries such as fashion or luxury retail often face the challenge of maintaining the pristine condition of high-value leather products. An oil stain can not only tarnish the appearance but also significantly decrease the item’s resale value. The fear of losing significant investment due to oil spills from oils, lotions, or even food can be daunting. Buyers may feel overwhelmed by the multitude of cleaning products available, unsure which methods are safe for their specific leather types.

The Solution: To effectively manage oil stains, it is crucial to implement a proactive cleaning strategy. First, always keep a specialized leather cleaning kit on hand, which should include saddle soap, leather conditioner, and absorbent powders such as cornstarch or baby powder. When an oil spill occurs, act quickly: blot the stain gently with a dry cloth to absorb excess oil, avoiding any rubbing that could spread the stain. Follow up by sprinkling cornstarch on the area and allowing it to sit for at least 15 minutes to absorb the oil. Afterward, gently brush off the powder. This method ensures that the leather retains its integrity while effectively removing the stain. Regular conditioning of leather products can also help protect against future stains by maintaining the material’s natural oils and preventing it from drying out.

Scenario 2: Preventing Oil Damage in Leather Upholstery

The Problem: Businesses that use leather upholstery in office environments or hospitality settings may encounter oil stains from food spills or body oils. These stains can lead to unsightly marks, causing embarrassment for clients and guests. Additionally, the cleaning process can be time-consuming and may require professional intervention, disrupting business operations.

The Solution: To prevent oil damage, it is essential to apply a high-quality leather protector immediately after installation. This creates a barrier against spills and stains. In the event of an oil stain, a quick response is critical. Use a mixture of mild soap and warm water to blot the area, followed by a specialized leather cleaner designed for your upholstery type. Be sure to test any product on an inconspicuous area first. After cleaning, apply a leather conditioner to restore moisture and flexibility, which helps in prolonging the life of the upholstery. Training staff on immediate spill management can significantly reduce the risk of permanent damage, ensuring the leather remains in top condition.

Illustrative image related to oil on leather

Scenario 3: Addressing Oil Absorption Issues in Leather Manufacturing

The Problem: B2B buyers involved in leather manufacturing often face challenges related to oil absorption during the tanning process. Excessive oil absorption can lead to inconsistent product quality, which affects the final product’s appearance and performance. This inconsistency can lead to costly returns and damage a brand’s reputation.

The Solution: To mitigate oil absorption issues, manufacturers should focus on selecting the right type of leather and implementing a controlled tanning process. Opt for vegetable-tanned leather, known for its natural resistance to oil, or synthetic alternatives that offer durability without excessive absorption. Additionally, incorporating a consistent oiling regimen post-tanning can help manage the leather’s porosity. Regular testing of leather samples for oil absorption before full-scale production can identify potential issues early, allowing for adjustments in the tanning or finishing processes. Establishing quality control measures that focus on oil resistance can also enhance overall product quality, ensuring that the final output meets market standards and customer expectations.

Strategic Material Selection Guide for oil on leather

When it comes to addressing oil on leather, the choice of materials for cleaning and protecting leather goods is crucial. Various materials exhibit different properties that can significantly influence their effectiveness in oil stain management. Here, we analyze four common materials used in this context: saddle soap, baking soda, cornstarch, and leather conditioner.

What Are the Key Properties of Saddle Soap in Oil Removal from Leather?

Saddle soap is a traditional cleaning agent specifically designed for leather. Its key properties include a gentle cleansing action that effectively removes dirt and oil without damaging the leather’s surface. Saddle soap is typically pH-balanced and contains natural oils, which help maintain the leather’s suppleness while cleaning.

Pros: Saddle soap is widely available and relatively inexpensive, making it a cost-effective solution for both individual consumers and businesses. It is easy to apply and does not require specialized equipment.

Cons: While effective for light to moderate oil stains, saddle soap may not perform well on heavy or deeply embedded stains. Additionally, it may require multiple applications to achieve the desired results.

Impact on Application: Saddle soap is particularly suitable for use on finished leather surfaces, but care should be taken with suede or nubuck, as it can alter their texture.

How Does Baking Soda Function as an Oil Absorbent for Leather?

Baking soda is a versatile household item known for its absorbent properties. When applied to oil stains, it acts by absorbing excess oil, which can help prevent the stain from setting in.

Pros: It is an inexpensive and readily available material that poses minimal risk of damaging the leather. Baking soda is also non-toxic, making it safe for use in various environments.

Cons: The effectiveness of baking soda can diminish with time, as it may not fully remove older or more stubborn stains. It may also leave a residue that requires additional cleaning.

Impact on Application: Baking soda is best used for fresh oil stains and is particularly effective on porous leather types. It is less effective on finished surfaces where oil has penetrated deeply.

What Role Does Cornstarch Play in Oil Stain Removal from Leather?

Cornstarch functions similarly to baking soda in that it absorbs oil from leather. It is often recommended for treating oil stains due to its fine texture, which allows it to penetrate the leather’s surface.

Pros: Cornstarch is inexpensive and easy to use, requiring no special tools or knowledge. It is also safe for most leather types and does not contain harsh chemicals.

Cons: Like baking soda, cornstarch may not completely remove older or set-in stains. It can also require multiple applications for optimal results.

Impact on Application: Cornstarch is particularly effective on suede and nubuck leather, where its absorbent properties can help lift oil without damaging the material.

Illustrative image related to oil on leather

How Does Leather Conditioner Contribute to Oil Management?

Leather conditioner is designed to maintain the suppleness and appearance of leather. While it is not a direct cleaning agent, it can help protect against oil stains by creating a barrier on the leather’s surface.

Pros: Regular use of leather conditioner can prolong the life of leather products and enhance their appearance. It is also easy to apply and can be integrated into routine maintenance.

Cons: Leather conditioners may not remove existing oil stains and are more preventive than corrective. Some formulations can be costly, depending on the brand and quality.

Impact on Application: Leather conditioners are essential for all leather types but should be used with caution on suede, as they can alter its texture.

Summary Table of Material Selection for Oil on Leather

| Materiaal | Typical Use Case for oil on leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Saddle Soap | Cleaning light to moderate oil stains | Gentle on leather, pH-balanced | May require multiple applications | Low |

| Baking Soda | Absorbing fresh oil stains | Non-toxic, readily available | Less effective on old stains | Low |

| Cornstarch | Absorbing oil from suede/nubuck | Safe for most leather types | May leave residue, not for deep stains | Low |

| Leather Conditioner | Preventive maintenance | Prolongs leather life, easy to apply | Not effective for existing stains | Medium to High |

This guide provides valuable insights for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, by highlighting the properties, advantages, and limitations of each material in managing oil on leather. Understanding these factors can aid in making informed purchasing decisions that align with local market needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for oil on leather

What Are the Key Stages in the Manufacturing Process for Oil on Leather?

The manufacturing process for oil on leather involves several critical stages, each requiring precision and expertise to ensure a high-quality final product. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The first step involves selecting high-quality leather, which is typically sourced from reputable tanneries. The leather must undergo a thorough inspection to ensure it meets specific quality standards, including thickness, texture, and color uniformity. After selection, the leather is treated with oils that enhance its durability and aesthetic appeal. This oiling process not only nourishes the leather but also improves its resistance to water and stains. -

Forming:

During this stage, the prepared leather is cut into specific shapes and sizes according to the product design. Advanced cutting techniques, such as die-cutting or laser cutting, are often employed to achieve precision. This ensures that each piece fits seamlessly into the final product, whether it be bags, shoes, or upholstery. -

Assembly:

The assembly process typically involves stitching or bonding the cut leather pieces together. Skilled artisans or automated sewing machines are used to ensure strong seams that withstand wear and tear. In products like bags, additional components such as zippers, buckles, and linings are integrated at this stage. -

Finishing:

The final stage focuses on enhancing the visual appeal and protective qualities of the leather. This may involve applying additional oils, creams, or finishes that provide a sheen and further moisture resistance. Quality assurance checks are performed to ensure that the finished products meet aesthetic and functional requirements.

How Is Quality Control Implemented in the Production of Oil on Leather?

Quality control (QC) is an essential aspect of the manufacturing process for oil on leather, ensuring that products meet industry standards and customer expectations. Here are the primary components of QC in this sector:

Illustrative image related to oil on leather

-

International Standards:

Adhering to international standards such as ISO 9001 ensures that manufacturing processes are efficient and products are consistently of high quality. ISO 9001 focuses on quality management systems and emphasizes continuous improvement, which is crucial for maintaining competitive advantage in the global market. -

Industry-Specific Standards:

In addition to ISO standards, various industry-specific certifications, such as CE marking for products sold in Europe and API standards for oil-related products, may also be relevant. These standards often address safety, environmental impact, and product efficacy, which are particularly important for B2B buyers in regulated markets. -

Quality Checkpoints:

Multiple checkpoints are integrated into the manufacturing process:

– Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the production stages to identify any defects early in the process.

– Final Quality Control (FQC): Comprehensive inspection of finished products before they are packaged and shipped. This includes testing for durability, appearance, and functionality.

What Common Testing Methods Are Used in QC for Oil on Leather Products?

To ensure the integrity and performance of oil on leather products, several common testing methods are employed:

-

Physical Testing:

This includes assessments of tensile strength, abrasion resistance, and flexibility to ensure that the leather can withstand everyday use without degrading. -

Chemical Testing:

Products may be subjected to tests that evaluate the effects of various substances, such as oils, solvents, and water, to determine how well the leather holds up against potential stains and damage. -

Environmental Testing:

This involves exposing leather products to various environmental conditions, such as humidity and temperature fluctuations, to assess their long-term durability and resistance to environmental stressors.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial to ensure reliable partnerships. Here are several strategies buyers can employ:

-

Supplier Audits:

Conducting regular audits of suppliers’ manufacturing facilities can provide insights into their quality control practices and adherence to industry standards. Audits should assess production processes, quality management systems, and compliance with relevant certifications. -

Requesting Quality Reports:

Buyers should ask suppliers for detailed quality control reports, including results from IQC, IPQC, and FQC. These reports can help evaluate the effectiveness of a supplier’s quality assurance processes. -

Third-Party Inspections:

Engaging independent third-party inspection services can add an additional layer of assurance. These inspections can verify compliance with international standards and provide unbiased evaluations of product quality.

What Are the Quality Control and Certification Nuances for B2B Buyers in Different Regions?

When dealing with suppliers from various regions, B2B buyers must be aware of the nuances in quality control and certification processes:

-

Regional Compliance:

Different regions may have specific regulatory requirements for leather products. For instance, products sold in the European Union must comply with REACH regulations regarding chemical safety, while buyers in the Middle East may need to adhere to local standards. -

Cultural Considerations:

Understanding the cultural context in which suppliers operate can impact negotiations and quality expectations. For example, the emphasis on craftsmanship in some regions may lead to different quality benchmarks compared to mass production facilities. -

Language and Communication Barriers:

Effective communication is crucial for quality assurance. Buyers should ensure that language barriers do not hinder the understanding of quality requirements and standards. Engaging local representatives or consultants can facilitate smoother interactions.

In summary, a comprehensive understanding of manufacturing processes and quality assurance practices is vital for B2B buyers in the oil on leather market. By focusing on key stages of production, implementing robust quality control measures, and verifying supplier practices, buyers can ensure they receive high-quality products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oil on leather’

When sourcing oil for leather care, B2B buyers must navigate various factors to ensure they procure the best quality products. This guide provides a practical checklist to help you make informed decisions, catering to the diverse needs of your clientele across different regions.

Illustrative image related to oil on leather

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring the oil meets your leather care requirements. Consider the type of leather you will be treating, the desired finish (matte or glossy), and any specific conditioning properties you need. Documenting these specifications helps streamline your procurement process and communicate effectively with potential suppliers.

Step 2: Research Supplier Credentials

Conduct thorough research on potential suppliers to validate their industry standing. Look for certifications that demonstrate compliance with international quality standards, such as ISO or equivalent. Additionally, investigate their experience in the leather care sector and whether they have supplied to businesses in your region, as local knowledge can be beneficial.

Step 3: Evaluate Product Formulations

Before placing an order, assess the formulations of the leather oils available. Different oils (e.g., neatsfoot oil, mink oil, or synthetic options) offer varying benefits in terms of penetration and conditioning. Request samples to evaluate the effectiveness and absorption rate of the oils on different leather types, ensuring they meet your quality expectations.

Illustrative image related to oil on leather

Step 4: Inquire About Sourcing Practices

Understanding how your suppliers source their materials is crucial for ensuring product quality and sustainability. Ask about the origins of their oils and whether they adhere to ethical sourcing practices. This information is especially relevant in markets where environmental and social responsibility is a priority for consumers.

Step 5: Assess Packaging and Shelf Life

Packaging plays a significant role in the quality preservation of leather oils. Ensure that the oils are packaged in containers that protect them from light and air exposure, which can degrade their effectiveness. Inquire about the shelf life of the products to avoid procurement of oils that may expire before use.

Step 6: Request Customer References

Before finalizing your supplier selection, ask for customer references from similar industries or geographic locations. Engaging with these references allows you to gain insights into the supplier’s reliability, product quality, and customer service. This step can help mitigate risks associated with new supplier relationships.

Step 7: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms that align with your business needs. Discuss pricing, minimum order quantities, payment terms, and delivery timelines. Ensure that these terms are documented in a contract to protect both parties and facilitate a smooth transaction process.

By following this checklist, B2B buyers can effectively source quality oils for leather care, ensuring they meet their clients’ diverse needs while maintaining high standards of product efficacy and sustainability.

Comprehensive Cost and Pricing Analysis for oil on leather Sourcing

When sourcing oil on leather, understanding the comprehensive cost structure and pricing analysis is crucial for B2B buyers. This involves dissecting the various cost components and price influencers that can significantly impact the overall procurement process.

What Are the Key Cost Components in Oil on Leather Sourcing?

-

Materials: The primary cost driver in oil on leather sourcing is the quality of the leather and the type of oil used. Premium leathers, such as full-grain or top-grain, can command higher prices. Additionally, specific oils that enhance durability and appearance may also increase material costs.

-

Labor: Skilled labor is essential for quality leather processing. This includes the craftsmanship involved in cutting, stitching, and finishing leather products. Labor costs can vary significantly based on the region, with countries offering lower wages potentially providing more cost-effective solutions.

-

Manufacturing Overhead: This encompasses expenses related to facilities, utilities, and administrative costs associated with production. Efficient manufacturing processes can help minimize these overheads, making it essential for buyers to consider the operational efficiencies of potential suppliers.

-

Tooling: The cost of tooling can be significant, particularly for custom designs or specialized leather treatments. Buyers should inquire about any one-time tooling charges that may apply when ordering specific styles or sizes.

-

Quality Control (QC): Implementing stringent quality control measures ensures that the final products meet industry standards and buyer specifications. This can involve additional costs but is critical for maintaining product integrity and reducing returns.

-

Logistics: Shipping costs can vary based on the geographical distance from the supplier, chosen Incoterms, and the volume of goods ordered. Buyers should factor in freight, insurance, and potential customs duties when evaluating total logistics costs.

-

Margin: Supplier margins can differ based on market positioning, demand, and competition. Understanding the margin expectations of suppliers can aid in negotiation strategies.

How Do Price Influencers Impact Oil on Leather Sourcing?

-

Volume/MOQ: Minimum Order Quantities (MOQs) often play a crucial role in pricing. Higher volume orders typically yield lower per-unit costs, making it advantageous for buyers to consolidate purchases when possible.

-

Specifications and Customization: Tailored products or unique specifications can lead to increased costs. Customization may require additional labor and materials, so buyers should clearly define their needs upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., sustainable sourcing, chemical compliance) can influence pricing. Buyers should assess the value of these certifications against their end market requirements.

-

Supplier Factors: The reliability, reputation, and location of suppliers can affect pricing. Established suppliers with a track record of quality may charge a premium but could also reduce risks associated with product defects.

-

Incoterms: Understanding Incoterms is vital for determining the responsibility for costs and risks associated with shipping. Buyers should choose terms that best align with their logistical capabilities and cost preferences.

What Are Effective Buyer Tips for Negotiating Oil on Leather Prices?

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices based on long-term relationships, volume commitments, or bundled purchases. Engaging in open dialogue with suppliers can yield favorable terms.

-

Focus on Cost Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the purchase price. This includes evaluating maintenance, durability, and potential resale value of leather products.

-

Understand Pricing Nuances for International Transactions: Buyers from regions such as Africa, South America, the Middle East, and Europe should consider currency fluctuations, import tariffs, and local regulations that may impact overall costs.

-

Stay Informed About Market Trends: Keeping abreast of trends in the leather industry can provide insights into pricing dynamics and help buyers make informed purchasing decisions.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing in oil on leather sourcing, actual prices may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing oil on leather With Other Solutions

Exploring Alternatives to Oil on Leather: A Comparative Analysis

In the realm of leather care, the use of oil is a common method for maintaining and preserving the material’s integrity and appearance. However, various alternative solutions exist that can effectively achieve similar outcomes. Understanding the differences in performance, cost, ease of implementation, maintenance, and best use cases is crucial for B2B buyers seeking the most suitable leather care method.

| Comparison Aspect | Oil On Leather | Saddle Soap | Leather Conditioner |

|---|---|---|---|

| Performance | Restores moisture and suppleness but can darken leather if over-applied. | Cleans and protects, removes dirt and grime effectively. | Enhances shine and protects against drying out. |

| Cost | Moderate; prices vary based on quality and type. | Generally low; a small amount goes a long way. | Moderate; recurring costs for regular application. |

| Ease of Implementation | Requires careful application; can be tricky to avoid over-saturation. | Simple to use; involves lathering and rinsing. | Easy to apply; typically just rub in and leave. |

| Maintenance | Needs reapplication based on usage and exposure to elements. | Regular use recommended for optimal cleaning. | Should be used periodically to maintain leather quality. |

| Best Use Case | Ideal for restoring older leather items needing moisture. | Best for regular cleaning of leather goods. | Perfect for ongoing maintenance of new or gently used leather. |

Saddle Soap: A Reliable Alternative for Leather Care

Saddle soap is a traditional cleaning solution that effectively removes dirt and grime from leather surfaces. Its cleaning properties make it an excellent choice for regular maintenance, especially for items exposed to the elements. One of the main advantages of saddle soap is its ease of use; it requires minimal effort to apply and rinse off. However, it does not offer the same level of moisture restoration as oil, which can leave leather feeling dry if not followed by a conditioning treatment.

Leather Conditioner: Maintaining the Softness and Luster of Leather

Leather conditioner is specifically formulated to nourish and protect leather from drying and cracking. It not only enhances the appearance of the leather but also creates a protective barrier against future damage. This method is incredibly easy to implement, as it typically involves applying the conditioner and allowing it to absorb. However, it may not clean or remove stains as effectively as saddle soap, making it less suitable for heavily soiled items. Regular use is necessary to maintain leather quality, which can lead to recurring costs.

Conclusion: Selecting the Right Solution for Leather Care

When choosing the appropriate leather care method, B2B buyers should consider the specific needs of their leather goods. If the focus is on cleaning and maintaining appearance, saddle soap could be the optimal choice. For ongoing protection and moisture retention, a leather conditioner may be more suitable. Oil on leather serves its purpose well for restoration but requires careful application to avoid potential discoloration. Ultimately, the right solution will depend on factors such as the type of leather, the level of exposure to wear and tear, and the desired maintenance routine. Buyers should evaluate these aspects to make an informed decision that aligns with their operational needs and budget.

Essential Technical Properties and Trade Terminology for oil on leather

What Are the Key Technical Properties of Oil on Leather?

When dealing with oil on leather, understanding its critical technical properties is essential for ensuring quality, durability, and customer satisfaction. Here are some vital specifications:

1. Material Grade

Material grade refers to the quality classification of leather, which can significantly affect its resistance to oil penetration and overall longevity. Higher-grade leathers, such as full-grain or top-grain leather, offer better resistance to oils and are less likely to stain. For B2B buyers, selecting the right material grade is crucial, as it impacts product performance and customer satisfaction.

Illustrative image related to oil on leather

2. Tolerance Levels

Tolerance levels denote the permissible variations in leather thickness and finish. This specification is vital for manufacturers to maintain consistency in product quality. A tolerance level that is too wide may lead to inconsistent oil absorption rates, affecting the leather’s appearance and durability. Buyers should ensure that suppliers adhere to strict tolerance levels to meet end-user expectations.

3. Oil Resistance Rating

This rating measures the leather’s ability to resist oil penetration and staining. A higher oil resistance rating indicates that the leather can withstand exposure to oils without significant degradation. For B2B buyers, understanding oil resistance ratings can guide purchasing decisions, ensuring that they select products that meet the performance requirements for specific applications.

4. Porosity

Porosity refers to the size and distribution of the pores within the leather material. Highly porous leathers may absorb oil more readily, leading to discoloration and potential damage. Buyers need to consider porosity levels when selecting leather for environments where oil exposure is likely, as it directly affects maintenance and longevity.

5. Finish Type

The finish type indicates how the leather surface has been treated and can influence its resistance to oil stains. Aniline, semi-aniline, and pigmented finishes each offer different levels of protection against oil penetration. Understanding finish types helps B2B buyers choose the right leather for their specific needs, balancing aesthetics with functional requirements.

Illustrative image related to oil on leather

What Are Common Trade Terms Used in the Oil on Leather Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B sector. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, an OEM may produce leather goods that are branded by another company. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate terms effectively.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the oil on leather industry, MOQs can vary significantly depending on the material and production processes. Buyers must be aware of MOQs to manage inventory levels and ensure cost-effectiveness in their purchasing strategies.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. In the context of oil on leather, submitting an RFQ helps buyers obtain competitive pricing and terms from multiple suppliers, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers, as they outline shipping, insurance, and delivery responsibilities, minimizing misunderstandings and disputes.

5. Leather Conditioning

Leather conditioning refers to the process of applying a treatment to maintain the leather’s suppleness and prevent damage from oils and other elements. Understanding conditioning is vital for buyers looking to offer products that have a longer lifespan and require less maintenance.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing oil on leather products, ensuring they meet quality standards and customer expectations.

Illustrative image related to oil on leather

Navigating Market Dynamics and Sourcing Trends in the oil on leather Sector

What Are the Current Market Dynamics and Key Trends Influencing the Oil on Leather Sector?

The global oil on leather market is witnessing significant growth driven by increasing demand for high-quality leather goods in fashion and automotive industries. Particularly in regions like Africa, South America, the Middle East, and Europe, there is a rising trend toward premium leather products that integrate oil treatment for enhanced durability and appearance. The use of technology in sourcing is also emerging, with B2B buyers leveraging digital platforms to streamline procurement processes and access a wider range of suppliers. Innovations such as blockchain for supply chain transparency and AI-driven analytics for market forecasting are becoming integral to effective sourcing strategies.

Furthermore, the influence of consumer preferences is shifting towards sustainable and ethically produced leather goods. This shift is prompting manufacturers to adopt eco-friendly oil treatments and processes that minimize environmental impact. Additionally, emerging markets, particularly in Africa and South America, are seeing increased investment in local leather production, which is reshaping sourcing dynamics by reducing reliance on traditional supply chains.

How Important Is Sustainability and Ethical Sourcing in the Oil on Leather Sector?

Sustainability is becoming a cornerstone of the oil on leather industry. Environmental concerns related to leather production—such as water usage, chemical runoff, and carbon emissions—are prompting B2B buyers to seek suppliers that prioritize sustainable practices. Ethical sourcing is not just a trend but a necessity, as consumers are increasingly demanding transparency in the supply chain. This has led to the emergence of certifications like the Leather Working Group (LWG) and the Global Organic Textile Standard (GOTS), which validate environmentally responsible practices.

Illustrative image related to oil on leather

B2B buyers should consider suppliers that utilize ‘green’ materials in their oil treatments, such as natural oils and biodegradable solvents. These materials not only reduce the ecological footprint but also enhance the appeal of leather goods in a market that values sustainability. By prioritizing ethical sourcing, companies can build stronger brand loyalty and meet the expectations of increasingly conscientious consumers.

What Is the Historical Context of Oil on Leather and Its Evolution for B2B Buyers?

The practice of oiling leather dates back centuries, with origins rooted in the need to protect and extend the life of leather goods. Traditionally, oils such as neatsfoot and mink oil were used to condition leather, providing water resistance and preventing cracking. Over time, the industry has evolved with advancements in chemical engineering, leading to the development of synthetic oils and treatments that offer enhanced performance characteristics.

This evolution is significant for B2B buyers as it reflects a transition towards more efficient and effective methods of leather care. The introduction of innovative oil formulations not only improves the longevity of leather products but also aligns with modern sustainability goals, making it essential for international buyers to stay informed about the latest developments in oil treatments. Understanding this historical context can aid in making informed sourcing decisions that cater to both quality and environmental stewardship.

Frequently Asked Questions (FAQs) for B2B Buyers of oil on leather

1. How do I solve oil stains on leather goods?

To effectively remove oil stains from leather, act quickly to minimize damage. Start by gently blotting the stain with a clean, dry cloth to absorb excess oil. Then, use a mild soap solution (such as dish soap mixed with warm water) or a natural cleaner like vinegar diluted with water. Apply the solution with a soft cloth, gently rubbing in circular motions. For persistent stains, consider using absorbent powders like cornstarch or baking soda, letting them sit for 15-20 minutes before brushing off. Always follow up with a leather conditioner to restore moisture and prevent cracking.

2. What is the best method for cleaning oil off leather?

The best method for cleaning oil off leather involves a combination of immediate action and gentle cleaning agents. Blot the oil with a dry cloth first, then apply a mixture of dish soap and warm water, or a 1:1 vinegar-water solution. Use a microfiber cloth to avoid scratching the leather. For deeper stains, sprinkle baby powder or cornstarch on the area and let it absorb the oil for a while before brushing it off. Always test any cleaning method on a hidden area first to ensure it doesn’t cause discoloration.

3. How can I prevent oil stains on leather products?

Preventing oil stains on leather involves a few proactive measures. First, always address spills immediately by blotting, not rubbing. Using a high-quality leather protector can create a barrier against stains. Regular cleaning with a gentle soap solution helps to maintain the leather’s integrity. Additionally, avoid placing items that may sweat or leak oil directly on leather surfaces. Finally, store leather goods in a cool, dry place, away from direct sunlight, to prevent degradation.

4. What are the minimum order quantities (MOQs) for leather oil products?

Minimum order quantities (MOQs) for leather oil products can vary significantly based on the supplier, product type, and your specific needs. Typically, MOQs can range from 50 to 500 liters for bulk orders, depending on the supplier’s production capabilities and inventory. It’s advisable to discuss your requirements directly with potential suppliers to negotiate MOQs that align with your business needs, especially if you are a smaller enterprise or a startup.

5. How do I vet suppliers for leather oil products?

Vetting suppliers for leather oil products requires a multi-step approach. Start by researching their reputation through online reviews and industry references. Request samples to assess product quality and compliance with international standards. Check for certifications related to environmental regulations and product safety. Additionally, inquire about their production processes, lead times, and flexibility in customization. Finally, establish clear communication to gauge their responsiveness and customer service capabilities.

Illustrative image related to oil on leather

6. What payment terms should I expect when sourcing leather oil products internationally?

Payment terms for international sourcing of leather oil products can vary widely. Typically, suppliers may request a deposit of 30% to 50% upfront, with the balance due upon delivery or before shipping. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established relationships. Always confirm payment methods accepted, such as wire transfers, letters of credit, or online payment platforms. Negotiating favorable terms is essential to ensure cash flow management for your business.

7. How do I ensure quality assurance for leather oil products?

To ensure quality assurance for leather oil products, establish clear specifications and expectations with your supplier. Request certifications for quality control processes and compliance with international standards. Implement a sampling process before large orders to evaluate product consistency. Additionally, consider hiring third-party quality inspection services to assess products before shipment. Regular communication and feedback with the supplier can help address any quality issues promptly.

8. What logistics considerations should I be aware of when importing leather oil products?

When importing leather oil products, several logistics considerations are crucial. First, understand the shipping methods available (air vs. sea) and select one based on urgency and cost. Familiarize yourself with customs regulations and import duties specific to your country. Ensure that your supplier provides accurate documentation, including invoices and packing lists, to facilitate smooth customs clearance. Lastly, consider the lead times for production and shipping to avoid stock shortages and plan accordingly for inventory management.

Top 4 Oil On Leather Manufacturers & Suppliers List

1. Reddit – Oils for Leathercraft: Petroleum-Based Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Oils for leathercraft have various types with distinct pros and cons.

1. **Petroleum-based oils** (e.g., Mineral Oil, Baby Oil, light engine oil, petroleum jelly):

– **Pros:** Low cost, good availability, clear, softens leather, deep penetration, strong waterproofing.

– **Cons:** Clogs pores, can form a surface film, breaks down leather structure, environmental impacts, dirt may stick, hig…

2. Vintage Leather – Premium Bags & Accessories

Domain: vintageleather.store

Registered: 2022 (3 years)

Introduction: Men’s and Women’s Leather Goods including Duffle Bags, Messenger Bags, Briefcases, Satchels, Backpacks, Laptop Bags, Camera Bags, Laptop Sleeves, Compendium, Notebook Covers, Toiletry Bags, Sling Bags, Wallets, Leather Journals, Wine Bags, Tobacco Pouches, Passport Wallets, Pencil Cases, Accessories, and Glass Cases. Gifts categorized for Him, Her, and under various price ranges. Free standard shi…

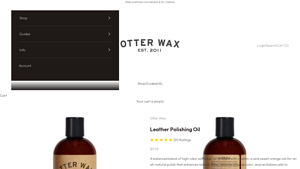

3. Otter Wax – Leather Oil

Domain: otterwax.com

Registered: 2011 (14 years)

Introduction: Otter Wax Leather Oil | Premium All-Natural Polishing Conditioner

– Price: 5oz – $9.95, 16oz – $19.95

– Description: A balanced blend of high-oleic safflower oil fortified with vitamin E and sweet orange oils for an all-natural polish that enhances natural shine, restores original color, and revitalizes cells to strengthen dehydrated leather.

– Suitable for: Sofas, boots, belts, bags, car seats, g…

4. Leatherworker – Olive Oil Conditioning Agent

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Olive oil (Extra Virgin) is used in leatherwork as a conditioning agent, particularly after molding or tooling, to replace oils depleted during the process. It is applied in light coats using paper towels, daubers, or fingers, allowing it to soak in for several hours to a full day. Olive oil does not significantly darken leather compared to neatsfoot oil, making it preferable for higher quality le…

Strategic Sourcing Conclusion and Outlook for oil on leather

In navigating the complexities of sourcing oil for leather applications, international buyers must prioritize quality and sustainability. The impact of oil on leather is significant, influencing not only the product’s longevity but also its aesthetic appeal. By understanding the intricacies of oil absorption and the potential damage from stains, buyers can make informed decisions that enhance their product offerings while minimizing waste.

Strategic sourcing plays a crucial role in ensuring the procurement of high-quality oils that meet industry standards. Buyers should consider suppliers that offer not only effective cleaning and conditioning solutions but also those committed to sustainable practices. This approach not only safeguards the integrity of leather goods but also aligns with the growing consumer demand for environmentally responsible products.

Looking ahead, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to engage with innovative suppliers who can provide tailored solutions for oil management in leather products. By fostering partnerships that prioritize quality and sustainability, businesses can elevate their offerings and meet the evolving needs of the market. Embrace the future of leather care by sourcing strategically today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.