Introduction: Navigating the Global Market for leather texture

In today’s competitive landscape, sourcing high-quality leather texture can be a daunting task for B2B buyers, particularly those looking to enhance their product offerings in markets across Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying the right type of leather but also in navigating the complexities of supplier reliability, cost-effectiveness, and the diverse applications that leather can serve. Whether you are seeking luxurious textures for fashion, durable materials for upholstery, or unique finishes for artisanal products, understanding the nuances of leather textures is essential.

This comprehensive guide aims to empower international buyers by delving into various leather types, including full grain, top grain, and suede, as well as their respective applications in industries ranging from automotive to fashion. We will provide insights on supplier vetting processes, enabling you to establish trustworthy partnerships that align with your business needs. Additionally, we will explore cost factors to help you make informed financial decisions, ensuring that you achieve the best value for your investment.

By equipping yourself with this knowledge, you can confidently navigate the global market for leather texture, transforming challenges into opportunities. This guide serves as your essential resource for making informed purchasing decisions that will elevate your product quality and enhance your brand’s reputation in the marketplace.

Table Of Contents

- Top 6 Leather Texture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather texture

- Understanding leather texture Types and Variations

- Key Industrial Applications of leather texture

- 3 Common User Pain Points for ‘leather texture’ & Their Solutions

- Strategic Material Selection Guide for leather texture

- In-depth Look: Manufacturing Processes and Quality Assurance for leather texture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather texture’

- Comprehensive Cost and Pricing Analysis for leather texture Sourcing

- Alternatives Analysis: Comparing leather texture With Other Solutions

- Essential Technical Properties and Trade Terminology for leather texture

- Navigating Market Dynamics and Sourcing Trends in the leather texture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather texture

- Strategic Sourcing Conclusion and Outlook for leather texture

- Important Disclaimer & Terms of Use

Understanding leather texture Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Natural surface with visible grain patterns; durable and ages beautifully. | High-end furniture, luxury goods | Pros: Exceptional durability, high-end appeal. Cons: Higher cost, may require special care. |

| Top Grain Leather | Slightly sanded surface, retains some natural grain; more uniform appearance. | Automotive upholstery, handbags | Pros: Affordable luxury, easier to maintain. Cons: Less durable than full grain, may not age as well. |

| Suède | Soft, napped finish; created from the underside of the hide. | Apparel, accessories, upholstery | Pros: Soft touch, unique appearance. Cons: Less durable, can stain easily. |

| Nubuck | Similar to suede but made from the outer side of the hide; velvety feel. | Footwear, luxury bags | Pros: Soft, luxurious feel; breathable. Cons: Susceptible to water damage, requires careful maintenance. |

| Kunstleer | Synthetic alternative designed to mimic real leather; available in various finishes. | Budget-friendly products, fashion | Pros: Cost-effective, animal-friendly. Cons: Less durable, may lack the authentic feel of real leather. |

What are the characteristics of Full Grain Leather and its B2B suitability?

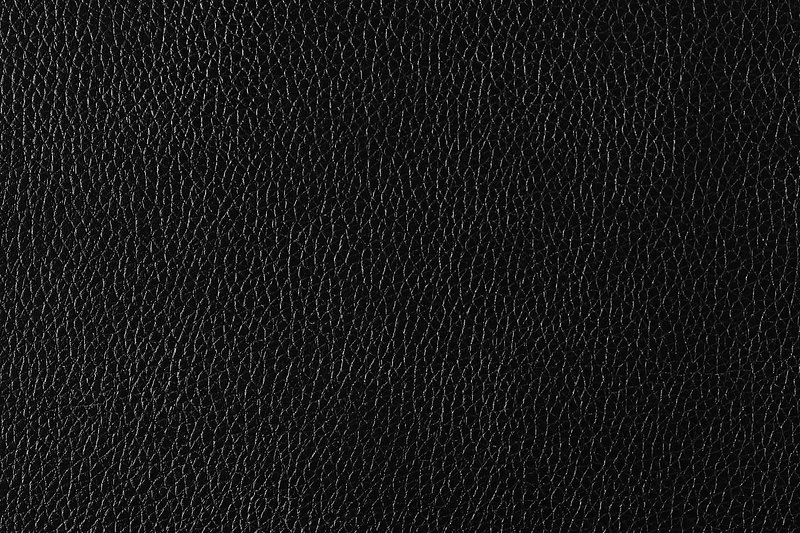

Full grain leather is recognized for its natural surface, which retains the hide’s original texture and imperfections. This type of leather is highly durable, making it suitable for high-end furniture and luxury goods that require longevity and aesthetic appeal. B2B buyers should consider the investment value of full grain leather, as it tends to age beautifully, gaining character over time. However, its higher price point and maintenance requirements may be a consideration for budget-conscious businesses.

How does Top Grain Leather differ from Full Grain and where is it best applied?

Top grain leather is characterized by a slightly sanded surface that provides a more uniform look while still retaining some of the hide’s natural grain. This type is commonly used in automotive upholstery and handbags, where a balance between luxury and practicality is essential. For B2B buyers, top grain leather offers a more affordable alternative to full grain, with easier maintenance. However, it may not provide the same level of durability or aging characteristics, which could affect long-term value.

What makes Suede a popular choice in the fashion industry?

Suede features a soft, napped finish that is derived from the underside of the hide, making it a favorite for apparel, accessories, and upholstery. Its unique texture and appearance appeal to consumers seeking comfort and style. B2B buyers should be aware that while suede is visually appealing, it is less durable than other leather types and can be prone to staining. This means that its application might be limited to items that are less exposed to wear and tear.

Illustrative image related to leather texture

Why is Nubuck considered a premium choice for footwear and luxury items?

Nubuck is similar to suede in its soft, velvety texture but is crafted from the outer side of the hide, offering a more robust finish. This leather type is highly breathable and is often used in footwear and luxury bags. B2B buyers should note that while nubuck provides a luxurious feel, it can be susceptible to water damage and requires diligent care to maintain its appearance. The investment in nubuck can be justified by its upscale aesthetic and consumer demand for quality.

How does Faux Leather serve budget-conscious markets?

Faux leather, or synthetic leather, is designed to mimic the look and feel of real leather without the associated costs. It is versatile and widely used in budget-friendly products and fashion items. For B2B buyers, faux leather offers a cost-effective solution that appeals to environmentally conscious consumers. However, it is essential to consider that faux leather may not match the durability or authentic feel of genuine leather, which could impact customer satisfaction in high-end markets.

Key Industrial Applications of leather texture

| Industry/Sector | Specific Application of leather texture | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats and interiors | Enhances luxury appeal, durability, and comfort | Compliance with safety standards, sourcing sustainable leather options, regional availability |

| Fashion & Apparel | High-end clothing and accessories | Provides a premium look and feel, brand differentiation | Quality of leather grain, color options, ethical sourcing practices |

| Furniture | Sofas, chairs, and other upholstered items | Offers aesthetic appeal and long-lasting durability | Fabric compatibility, maintenance requirements, and design versatility |

| Footwear | Premium shoe manufacturing | Increases product value and consumer appeal | Flexibility of leather, breathability, and sourcing from reputable suppliers |

| Interior Design | Wall coverings and decorative elements | Adds sophistication and texture to spaces | Texture variety, fire resistance, and sourcing local materials for reduced shipping costs |

How is Leather Texture Used in the Automotive Industry?

In the automotive sector, leather texture is primarily utilized for upholstery in seats and interior panels. This application not only enhances the luxury appeal of vehicles but also provides durability and comfort for passengers. International B2B buyers must consider compliance with safety standards, such as fire resistance and chemical treatment, when sourcing leather. Additionally, the demand for sustainable and ethically sourced leather is rising, prompting buyers to evaluate suppliers based on their environmental practices.

What Role Does Leather Texture Play in Fashion & Apparel?

Leather texture is a cornerstone of high-end fashion, used in clothing, bags, and accessories to convey luxury and sophistication. The tactile quality of leather enhances the overall aesthetic, making products more appealing to consumers. Buyers in this sector should focus on the quality of the leather grain and the variety of color options available. Ethical sourcing practices are increasingly important, as consumers demand transparency regarding the origins of materials.

How is Leather Texture Applied in the Furniture Sector?

In furniture design, leather texture is often employed in sofas, chairs, and other upholstered items. Its natural durability and timeless appeal contribute to the longevity and value of furniture pieces. B2B buyers should consider fabric compatibility and maintenance requirements when selecting leather for furniture. Additionally, the versatility of design options allows manufacturers to cater to diverse consumer tastes, making it essential to source from suppliers who offer a range of textures and colors.

In What Ways is Leather Texture Important for Footwear Production?

Leather texture is integral to the footwear industry, particularly in the production of premium shoes. The unique characteristics of leather, such as flexibility and breathability, enhance comfort and fit, thereby increasing consumer satisfaction. When sourcing leather for footwear, buyers should prioritize the flexibility of the material and its ability to withstand wear and tear. Establishing relationships with reputable suppliers ensures access to high-quality leather that meets industry standards.

How is Leather Texture Used in Interior Design Projects?

In interior design, leather texture serves as a versatile material for wall coverings and decorative elements. Its ability to add sophistication and texture to spaces makes it a popular choice among designers. B2B buyers should focus on the variety of textures available, including embossed and smooth finishes, as well as fire resistance for safety compliance. Sourcing locally can also reduce shipping costs and support regional economies, an important consideration for international buyers.

3 Common User Pain Points for ‘leather texture’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather Textures for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality leather textures that meet specific design needs across various projects. This challenge is particularly pronounced for businesses in industries such as fashion, furniture, and automotive, where the quality and aesthetic of leather directly impact brand perception. Many suppliers provide a limited range of textures, which can result in compromised quality or mismatched specifications. Additionally, navigating the vast array of suppliers can lead to inconsistencies in texture and finish, affecting the final product’s overall quality and appeal.

The Solution: To effectively source high-quality leather textures, B2B buyers should prioritize building relationships with reputable suppliers known for their diverse product offerings. Conduct thorough market research to identify suppliers who specialize in leather textures, and request samples to assess quality firsthand. When specifying leather textures, provide detailed requirements, including grain type, finish, and durability standards. Utilize digital tools and platforms that offer high-resolution images and 3D models of leather textures to visualize how they will look in the final product. This proactive approach not only ensures consistency in quality but also enhances the buyer’s ability to meet specific project demands.

Scenario 2: Understanding Leather Grain Types and Their Impact on Design

The Problem: Buyers often face confusion regarding the different types of leather grains—such as full grain, top grain, and corrected grain—and how these variations affect the overall design and functionality of the final product. This lack of understanding can lead to poor purchasing decisions, resulting in products that do not align with consumer expectations or brand identity. For instance, using corrected grain leather in a luxury handbag could detract from its perceived value, affecting customer satisfaction and brand reputation.

The Solution: To overcome this knowledge gap, B2B buyers should invest time in understanding leather grain types and their applications. Engaging with industry experts or participating in workshops can provide valuable insights into the characteristics and uses of different leather grains. Buyers should also create a comprehensive guide that outlines the benefits and drawbacks of each grain type concerning their specific products. This guide can serve as a reference when making purchasing decisions, ensuring that the selected leather texture aligns with the intended use and target market. Additionally, collaborating with designers to select the appropriate grain type can enhance product appeal and functionality.

Scenario 3: Managing Texture Consistency Across Large Orders

The Problem: When placing large orders for leather textures, B2B buyers often encounter issues with texture consistency, which can lead to significant production challenges. Variations in color, texture, and finish can arise from different production batches, resulting in products that do not match or meet quality standards. This inconsistency can be especially problematic for brands that require uniformity in products, such as furniture manufacturers or fashion retailers, where even minor discrepancies can affect customer satisfaction and brand loyalty.

The Solution: To ensure texture consistency across large orders, buyers should establish clear quality control measures with their suppliers. Implementing a standardized approval process for samples before finalizing large orders can help identify potential inconsistencies early in the production process. Additionally, buyers should consider working with suppliers that offer full transparency about their production processes and materials used. Regular communication with suppliers throughout the production timeline can also help address any concerns and ensure that the final products meet the expected quality and aesthetic standards. Leveraging technology, such as digital quality assurance tools, can further enhance the ability to maintain consistency and monitor production quality.

Strategic Material Selection Guide for leather texture

When selecting materials for leather texture applications, B2B buyers must consider various options, each with unique properties, advantages, and limitations. This analysis focuses on four common materials: Genuine Leather, Faux Leather, Suede, and Nubuck. Each material presents specific characteristics that influence product performance and suitability for different applications.

Illustrative image related to leather texture

What Are the Key Properties of Genuine Leather?

Genuine leather, derived from animal hides, is renowned for its durability and aesthetic appeal. Its key properties include high tensile strength, natural breathability, and resistance to wear and tear. Genuine leather can withstand a range of temperatures and pressures, making it suitable for various applications, from upholstery to fashion accessories.

Pros and Cons: While genuine leather offers exceptional durability and a luxurious feel, it comes at a higher cost compared to synthetic alternatives. The manufacturing process is more complex, often requiring extensive processing and finishing. Additionally, genuine leather may require regular maintenance to preserve its appearance and longevity.

Impact on Application: Genuine leather is compatible with various media, including dyes and finishes, allowing for customization. However, it is essential to consider environmental regulations regarding animal sourcing and processing, especially for buyers in regions with strict animal welfare laws.

What Advantages Does Faux Leather Offer for B2B Buyers?

Faux leather, or synthetic leather, is made from materials like polyurethane (PU) or polyvinyl chloride (PVC). Its primary advantage lies in its affordability and ease of maintenance. Faux leather is resistant to stains and can be easily cleaned, making it suitable for high-traffic areas.

Illustrative image related to leather texture

Pros and Cons: While faux leather is cost-effective, it may not match the durability and breathability of genuine leather. It can also be less environmentally friendly, depending on the production process. Buyers should consider the end-use application, as faux leather may not provide the same premium feel as genuine leather.

Impact on Application: Faux leather is widely accepted in various industries, including fashion, automotive, and furniture. Compliance with international standards, such as ASTM for material safety, is crucial, especially for buyers in regions like Europe, where regulations are stringent.

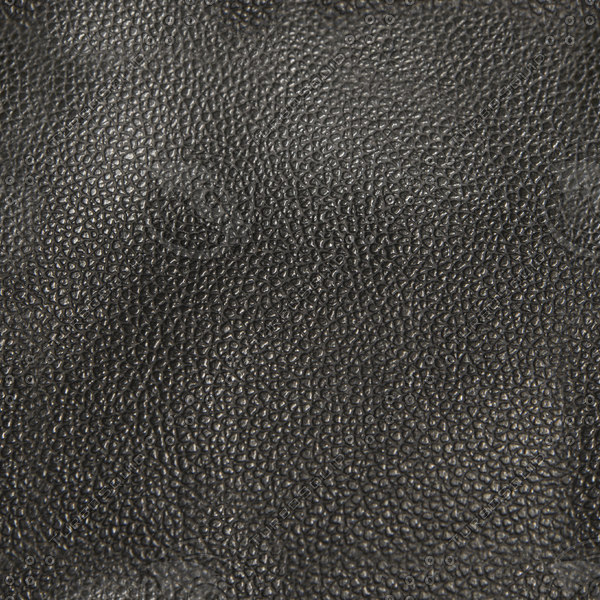

How Do Suede and Nubuck Compare in Terms of Performance?

Suede and nubuck are both derived from animal hides but differ in texture and finish. Suede has a soft, napped finish, while nubuck is sanded to create a velvety surface. Both materials offer excellent aesthetics and comfort.

Illustrative image related to leather texture

Pros and Cons: Suede is lightweight and offers a luxurious feel, but it can be more susceptible to stains and water damage. Nubuck, while more durable than suede, requires careful maintenance to avoid damage. Both materials are generally more affordable than genuine leather but may not have the same longevity.

Impact on Application: Suede and nubuck are popular in fashion and upholstery. Buyers should consider the climate of their target market, as moisture can significantly affect the performance of these materials. Additionally, understanding local preferences for texture and finish can guide material selection.

What Should International Buyers Consider When Sourcing Leather Textures?

For international B2B buyers, understanding compliance with local and international standards is paramount. Different regions may have varying regulations regarding material sourcing, environmental impact, and product safety. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with standards like ASTM, DIN, and JIS to ensure compliance and market acceptance.

Furthermore, cultural preferences can influence material selection. For instance, buyers in Europe may prioritize sustainable sourcing and animal welfare, while those in Africa may focus on durability and cost-effectiveness.

Summary Table of Material Selection for Leather Texture

| Materiaal | Typical Use Case for leather texture | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Upholstery, high-end fashion | Exceptional durability and feel | High cost and maintenance | Hoog |

| Kunstleer | Budget-friendly fashion, upholstery | Cost-effective and easy to maintain | Less durable than genuine leather | Low |

| Suède | Fashion accessories, upholstery | Luxurious feel and lightweight | Susceptible to stains and water | Medium |

| Nubuck | Footwear, high-end upholstery | Durable and attractive finish | Requires careful maintenance | Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific market needs and compliance requirements.

Illustrative image related to leather texture

In-depth Look: Manufacturing Processes and Quality Assurance for leather texture

What Are the Key Stages in the Manufacturing Process of Leather Textures?

The manufacturing of leather textures involves a series of well-defined stages that ensure the final product meets the aesthetic and functional requirements of B2B buyers. Understanding these stages can help international buyers make informed decisions when sourcing leather products.

Material Preparation: What Is Involved?

The first stage in leather manufacturing is material preparation, which involves selecting and sourcing the raw materials. Typically, this begins with the selection of hides from various animals, with cowhide being the most common.

Once the hides are sourced, they undergo a cleaning process to remove hair, fat, and any impurities. This is followed by soaking in a solution to soften the hides and facilitate the removal of remaining impurities. After cleaning, hides are treated with preservatives to prevent decay before proceeding to the tanning process.

How Is Leather Formed During Production?

The forming stage is crucial for shaping the leather into the desired texture and thickness. The tanning process, which can be either vegetable or chrome-based, transforms raw hides into durable leather.

During tanning, the hides are immersed in tanning solutions that chemically alter the collagen structure, making it more robust and less susceptible to decomposition. Following tanning, the leather is stretched and dried to achieve the desired thickness and texture.

Additional processes, such as splitting (to separate the hide into layers) and buffing (to create a smooth finish), may also occur during this stage. The choice of techniques here greatly influences the final texture of the leather.

What Are the Steps for Assembly and Finishing?

Once the leather is formed, it proceeds to the assembly stage, where it is cut into specific shapes for various products, such as bags, wallets, and upholstery. This often involves using cutting dies and precision machinery to ensure accuracy.

The finishing stage is where the leather’s final texture is applied. Techniques include dyeing, embossing, and applying protective coatings. This stage not only enhances the visual appeal but also adds functional properties like water resistance and UV protection.

Illustrative image related to leather texture

Finishing techniques can vary widely, from natural finishes that highlight the leather’s original grain to synthetic coatings that provide durability and uniformity.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance (QA) is essential in the leather manufacturing process to ensure that the final product meets international standards and buyer expectations. B2B buyers should be familiar with the various QA measures in place to verify the quality of leather textures.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a significant role in the leather industry. This standard focuses on quality management systems and continuous improvement, ensuring that manufacturers maintain high-quality outputs.

Additionally, industry-specific standards, such as the CE marking in Europe, certify that products meet health, safety, and environmental protection standards. Buyers from regions like Africa and South America should also consider local regulations that may apply to leather imports.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process.

-

Incoming Quality Control (IQC): This initial checkpoint occurs when raw materials arrive at the manufacturing facility. It involves inspecting the hides for defects, such as tears or discoloration, and verifying that they meet predefined specifications.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checks ensure that the processes adhere to quality standards. This can involve monitoring the tanning and finishing processes to ensure consistency and adherence to color and texture specifications.

-

Final Quality Control (FQC): Before products are shipped, FQC involves a comprehensive inspection of the finished leather items. This includes checking for defects in stitching, color consistency, and overall craftsmanship.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is critical to ensuring product reliability.

What Methods Are Effective for Supplier Audits?

Conducting supplier audits is one of the most effective methods for verifying quality control. These audits can be either announced or unannounced and should evaluate the supplier’s adherence to international standards and internal quality protocols.

Buyers can also request detailed quality reports, including test results for durability, colorfastness, and other relevant metrics.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can conduct thorough evaluations of the manufacturing process and the final products, ensuring compliance with both international standards and specific buyer requirements.

What Nuances Should International Buyers Consider?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality assurance that may affect their procurement process.

Illustrative image related to leather texture

How Do Local Regulations Impact Quality Assurance?

Different regions have varying regulations regarding leather products. For instance, buyers in Europe may face stricter compliance requirements compared to those in Africa or South America. Understanding these regulations can help buyers navigate potential challenges in sourcing leather products.

Why Is Traceability Important in the Leather Supply Chain?

Traceability is becoming increasingly important in the leather industry, especially concerning sustainability and ethical sourcing. Buyers should inquire about the origin of the hides and the environmental practices employed by suppliers. This not only ensures product quality but also aligns with the growing demand for ethically sourced materials.

Conclusion: Ensuring Quality in Leather Textures

In summary, understanding the manufacturing processes and quality assurance measures for leather textures is vital for B2B buyers. By familiarizing themselves with the key stages of production and the associated quality control checkpoints, buyers can make informed decisions when sourcing leather products. Emphasizing international standards, supplier audits, and traceability will further enhance the integrity and quality of the leather textures procured from global suppliers.

Illustrative image related to leather texture

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather texture’

In the competitive landscape of leather sourcing, understanding the nuances of leather texture is crucial for B2B buyers aiming for quality and durability. This guide offers a step-by-step checklist to streamline the procurement process, ensuring you make informed decisions that align with your business needs.

1. Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your requirements regarding leather texture. Consider aspects such as grain type (e.g., smooth, pebbled, or distressed), finish (e.g., matte or gloss), and intended use (e.g., upholstery, apparel, or accessories). This clarity will help you communicate effectively with suppliers and reduce the risk of receiving products that do not meet your expectations.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in leather textures. Utilize online directories, industry trade shows, and recommendations from industry peers. Assess their reputation through customer reviews and testimonials, focusing on their experience in your specific market or region, such as Africa or South America.

Illustrative image related to leather texture

3. Evaluate Supplier Certifications

It’s essential to verify that your chosen suppliers adhere to industry standards and certifications, such as ISO and Leather Working Group (LWG) certifications. These certifications indicate a commitment to quality and sustainability, which are increasingly important to consumers. Look for suppliers that can provide documentation to back up their claims.

4. Request Samples of Leather Textures

Before making a bulk purchase, request samples of the leather textures you are considering. This step allows you to assess the quality, feel, and appearance of the leather firsthand. Pay attention to the consistency of the texture and color, as variations can impact the final product’s quality.

5. Discuss Customization Options

If your project requires specific leather textures not readily available, discuss customization options with your suppliers. Many suppliers can offer bespoke solutions, but it’s important to understand their capabilities and any associated costs. Ensure that your specifications align with their manufacturing processes to avoid delays.

6. Negotiate Terms and Conditions

Once you have settled on a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that both parties have a clear understanding of expectations to prevent misunderstandings later. Consider including clauses that address quality assurance and return policies in case the products do not meet the agreed standards.

Illustrative image related to leather texture

7. Establish a Quality Control Process

Implement a quality control process for receiving and inspecting the leather textures upon delivery. This step is critical to ensure that the products meet your specifications and quality standards. Establish criteria for acceptance, such as texture consistency, color accuracy, and any specific finish requirements.

By following this checklist, B2B buyers can navigate the complexities of sourcing leather textures with confidence, ultimately leading to successful procurement and enhanced product offerings.

Comprehensive Cost and Pricing Analysis for leather texture Sourcing

What Are the Key Cost Components in Leather Texture Sourcing?

When sourcing leather textures, several cost components contribute to the overall price structure. The primary costs include:

-

Materials: The type of leather used (e.g., full-grain, top-grain, or synthetic) significantly impacts material costs. Premium leathers often command higher prices due to their durability and aesthetic appeal.

-

Labor: Skilled craftsmanship is essential in leather production. Labor costs vary based on the region; for instance, labor is typically more affordable in developing countries compared to Europe or North America.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: The initial investment in specialized tools and machinery can be substantial, especially for customized leather textures. However, these costs are amortized over large production runs.

-

Quality Control (QC): Implementing strict quality control measures ensures that the leather meets buyer specifications and industry standards. This adds to the overall cost but is crucial for maintaining quality assurance.

-

Logistics: Shipping costs can vary widely depending on the origin of the leather and the destination country. Factors such as freight costs, customs duties, and insurance should be carefully considered.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks, which can vary based on market conditions and competition.

How Do Price Influencers Affect Leather Texture Sourcing?

Several factors influence pricing in the leather texture market, including:

-

Volume/MOQ: Higher order quantities often lead to lower unit prices. Negotiating minimum order quantities (MOQs) can provide significant savings.

-

Specifications and Customization: Custom designs or specific textures may incur additional costs. Clearly defining requirements upfront can mitigate unexpected expenses.

-

Materials and Quality Certifications: The presence of certifications (like eco-friendly or ethical sourcing) can affect price. Buyers should weigh the benefits of certified materials against their costs.

-

Supplier Factors: Relationships with suppliers, their reputation, and reliability can influence pricing. A reputable supplier may charge more but offer better quality and service.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is essential for cost transparency. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who bears responsibility for shipping costs and risks.

What Tips Can Buyers Use for Effective Leather Texture Sourcing?

When sourcing leather textures, particularly for international transactions, buyers can employ several strategies:

-

Negotiation Skills: Building rapport with suppliers can lead to better pricing and terms. Leveraging relationships and negotiating bulk discounts can be beneficial.

-

Focus on Cost-Efficiency: Analyzing the Total Cost of Ownership (TCO) rather than just the purchase price can lead to more informed decisions. Consider all associated costs, including maintenance and durability.

-

Pricing Nuances for International Buyers: Currency fluctuations can impact pricing. It is wise to discuss payment terms and consider hedging strategies to mitigate risks.

-

Cultural Sensitivity: Understanding cultural differences in business practices can enhance negotiations and foster better supplier relationships, particularly in regions like Africa, South America, and the Middle East.

Disclaimer on Indicative Prices

It is important to note that prices for leather textures can vary widely based on the aforementioned factors. Buyers should conduct thorough market research and obtain multiple quotes to ensure they are getting competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing leather texture With Other Solutions

When considering leather texture for various applications, it is essential to explore viable alternatives that can deliver similar aesthetic and functional benefits. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs, budget constraints, and project requirements.

| Comparison Aspect | Leather Texture | Kunstleer | Textile Fabrics |

|---|---|---|---|

| Performance | Durable and high-quality finish | Good durability but less breathable | Varies widely, generally less durable |

| Cost | Higher initial cost | Generally lower cost | Wide range, can be inexpensive |

| Ease of Implementation | Requires skilled craftsmanship | Easy to work with and manipulate | Generally straightforward to use |

| Maintenance | Requires regular conditioning | Easy to clean, less maintenance | Varies, some may require special care |

| Best Use Case | Luxury applications (furniture, fashion) | Budget-friendly alternatives in apparel | Versatile applications (clothing, upholstery) |

What Are the Advantages and Disadvantages of Faux Leather?

Faux leather, also known as synthetic leather, is designed to mimic the appearance of real leather while being more affordable. Its primary advantages include cost-effectiveness and ease of maintenance. It is often used in budget-conscious projects, providing a stylish look without the high price tag. However, faux leather lacks the durability and breathability of genuine leather, which can lead to wear and tear over time. For applications that require a long-lasting material, faux leather may not be suitable.

How Do Textile Fabrics Compare to Leather Texture?

Textile fabrics encompass a broad category of materials, including cotton, polyester, and blends, which can provide various textures and patterns. They are typically more affordable than leather and can be easier to source and implement. However, the performance can vary significantly based on the type of fabric chosen. While some textiles offer good durability, others may not withstand heavy use as effectively as leather. Textile fabrics can be an excellent choice for applications where cost is a primary concern, but they may not provide the same luxurious feel or longevity as leather.

What Should B2B Buyers Consider When Choosing Between Leather and Alternatives?

When selecting a material, B2B buyers should carefully evaluate their specific project requirements, including performance needs, budget constraints, and the desired aesthetic. Leather textures can provide unmatched quality and elegance for high-end applications, while faux leather and textile fabrics offer budget-friendly alternatives that can still meet functional requirements. Buyers should also consider maintenance needs, as some materials require more upkeep than others. Ultimately, the choice will depend on balancing cost, durability, and the intended use case to achieve the best overall value for the project.

Illustrative image related to leather texture

Essential Technical Properties and Trade Terminology for leather texture

What Are the Key Technical Properties of Leather Textures That B2B Buyers Should Know?

When sourcing leather textures for commercial applications, understanding critical technical properties is essential for ensuring quality and suitability for specific projects. Here are several key specifications to consider:

Material Grade

Material grade refers to the quality of the leather, which can be classified into full grain, top grain, genuine leather, and bonded leather. Full grain leather, for instance, is the highest quality, retaining the natural texture and imperfections, making it durable and aesthetically appealing. Understanding the material grade helps buyers assess durability, cost, and overall product performance, which is crucial for long-term investment.

Tolerance and Thickness

Tolerance indicates the allowable variation in leather thickness, typically measured in millimeters. Common thicknesses range from 0.6 mm to 3.0 mm, depending on the intended use, such as upholstery, garments, or accessories. A precise tolerance is vital for achieving consistent quality across batches, ensuring that the final products meet design specifications and performance standards.

Finish Type

The finish type of leather affects its appearance and durability. Common finishes include aniline, semi-aniline, pigmented, and embossed. Aniline leather, for example, is dyed with transparent dyes, showcasing the natural grain, while pigmented leather has a more uniform appearance and is more resistant to stains. Buyers should evaluate finish types based on aesthetic preferences and functional requirements, as they can significantly impact maintenance and longevity.

Texture and Grain Pattern

The texture and grain pattern of leather can vary significantly, including smooth, pebbled, or distressed finishes. These characteristics not only contribute to the aesthetic appeal but also influence tactile experience and usability in different applications. Understanding the nuances of texture and grain is essential for making informed decisions that align with brand identity and customer expectations.

Illustrative image related to leather texture

Color Fastness

Color fastness is a measure of how well a leather maintains its color when exposed to light, moisture, and friction. This property is particularly important for products that will be subjected to wear and tear, such as upholstery or footwear. Buyers should inquire about color fastness testing standards, as this will help ensure that the leather will maintain its appearance over time, reducing the need for replacements or repairs.

What Are Common Trade Terms Related to Leather Texture Sourcing?

Navigating the leather industry involves familiarity with specific trade terminology. Here are some essential terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the leather industry, it often pertains to suppliers who create leather products tailored to a buyer’s specifications. Understanding OEM relationships can help buyers ensure quality control and customization in their product offerings.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to consider, as MOQs can significantly affect inventory costs and cash flow. Buyers should negotiate MOQs based on their needs and capacity to store and sell the product.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to submit price quotes for specific goods or services. This process is vital for securing competitive pricing and ensuring that buyers receive detailed information about product specifications, including leather texture options.

Incoterms

Incoterms (International Commercial Terms) are internationally recognized rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is essential for ensuring that both parties are clear on delivery, risk, and cost responsibilities, thereby reducing potential disputes.

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. In the leather industry, lead times can vary based on production schedules, material availability, and shipping logistics. Buyers should factor in lead times when planning their inventory and supply chain to avoid disruptions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions in sourcing leather textures, ensuring they align with their project requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the leather texture Sector

What Are the Current Market Dynamics and Key Trends in the Leather Texture Sector?

The leather texture sector is experiencing robust growth, driven by a resurgence in demand for high-quality materials across various industries, including fashion, automotive, and furniture. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly recognizing the value of premium leather textures that enhance product aesthetics and durability. Key trends influencing this market include the rising popularity of faux leather alternatives, which cater to environmentally conscious consumers, and advancements in digital printing technologies that allow for intricate and customizable designs.

Furthermore, the demand for seamless online sourcing platforms is growing, as buyers seek efficiency and transparency in their procurement processes. Countries like Nigeria and Vietnam are emerging as pivotal players in the leather supply chain, with local manufacturers leveraging advanced techniques to produce competitive textures. The integration of AI and machine learning in supply chain management is also a notable trend, optimizing inventory control and forecasting, which is essential for meeting the dynamic demands of global markets.

How Is Sustainability Influencing Sourcing Trends in the Leather Texture Sector?

Sustainability has become a cornerstone of sourcing strategies in the leather texture sector, reflecting an increased awareness of environmental impact and ethical practices. The leather industry is often criticized for its resource-intensive processes; however, there is a growing movement towards sustainable practices, including the use of vegetable-tanned leathers and recycled materials. For B2B buyers, sourcing from suppliers who prioritize ethical practices not only mitigates environmental concerns but also enhances brand reputation and consumer trust.

Buyers should consider suppliers with certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG), which ensure adherence to sustainable practices. This trend is particularly relevant for buyers in regions like Europe, where regulatory frameworks increasingly demand transparency in sourcing. Additionally, the emergence of biobased and synthetic leathers, which offer lower environmental footprints, is reshaping the market landscape, providing options that align with sustainability goals without compromising on quality or aesthetic appeal.

What Is the Historical Context of Leather Textures and Their Evolution in B2B Markets?

The history of leather textures dates back thousands of years, with early civilizations utilizing animal hides for clothing and shelter. Over time, the craft of leatherworking evolved, giving rise to various techniques and finishes that enhanced the material’s durability and appeal. In the modern era, the leather industry has witnessed significant transformations, particularly with the advent of synthetic materials and advanced tanning processes.

Today, the evolution of leather textures is characterized by a blend of traditional craftsmanship and innovative technologies. This duality not only preserves the artisanal heritage of leather production but also meets contemporary consumer demands for unique textures and sustainable options. For B2B buyers, understanding this historical context can provide valuable insights into current trends and future directions within the leather texture sector, enabling informed sourcing decisions that align with market evolution.

Frequently Asked Questions (FAQs) for B2B Buyers of leather texture

-

1. How do I determine the right leather texture for my products?

Choosing the right leather texture depends on the intended use and aesthetic requirements of your products. Consider factors such as durability, softness, and appearance. For example, if you are manufacturing high-end luxury items, full-grain leather offers a rich texture and longevity. Alternatively, if you require a more budget-friendly option, faux leather or split leather may suffice. Always request samples to assess the texture and ensure it aligns with your brand’s quality standards. -

2. What types of leather textures are available for B2B sourcing?

There are various leather textures available, including smooth, pebbled, suede, and distressed finishes. Each type has its unique characteristics and applications. Smooth leather is often used for elegant handbags, while pebbled leather adds a casual, rugged touch to accessories. Suede offers a soft, luxurious feel, suitable for upscale products. Research and select textures that best represent your brand and appeal to your target market. -

3. How can I ensure the quality of leather textures from suppliers?

To ensure quality, conduct thorough supplier vetting. Request certifications, such as ISO or other relevant industry standards, and ask for product samples to evaluate texture and durability. It’s beneficial to visit the supplier’s facility if possible, or request third-party quality inspections. Establish clear quality assurance processes, including specifications for texture, color, and finish, to maintain consistency in your products. -

4. What are the minimum order quantities (MOQs) for leather textures?

Minimum order quantities (MOQs) for leather textures vary by supplier and type of leather. Generally, MOQs can range from a few hundred square feet to several thousand, depending on the leather’s rarity and processing requirements. It’s essential to discuss MOQs upfront and explore potential flexibility, especially for new businesses or smaller orders. Some suppliers may offer lower MOQs for specific textures to encourage trial orders. -

5. What payment terms should I expect when sourcing leather textures internationally?

Payment terms for international transactions can vary significantly by supplier and region. Common terms include advance payment, letter of credit, or net 30/60 days. Ensure you negotiate terms that provide sufficient time for quality inspections and product verification upon receipt. Additionally, consider using secure payment methods that offer buyer protection to mitigate risks associated with international transactions. -

6. How do I handle logistics and shipping for international leather texture orders?

Managing logistics for international orders involves selecting reliable freight forwarders and understanding import regulations in your country. Ensure your supplier provides necessary documentation, including certificates of origin and compliance with local standards. Plan for potential delays by factoring in customs clearance times and seasonal shipping variations. It’s advisable to track shipments closely and maintain communication with your supplier throughout the process. -

7. Can I customize the leather texture to meet specific design needs?

Yes, many suppliers offer customization options for leather textures, including color, finish, and grain patterns. When discussing customization, provide detailed specifications and, if possible, samples of desired textures. Be aware that custom orders may have longer lead times and higher costs due to the additional processing involved. Ensure you clarify these aspects upfront to avoid surprises during production. -

8. What are common issues to watch out for when sourcing leather textures?

Common issues include miscommunication about specifications, quality discrepancies, and unexpected shipping delays. To mitigate these risks, maintain clear and consistent communication with your supplier, establish detailed contracts, and conduct thorough inspections upon receiving goods. Additionally, familiarize yourself with the supplier’s return policies to address any quality issues promptly. Being proactive in these areas can help build a strong, reliable supplier relationship.

Top 6 Leather Texture Manufacturers & Suppliers List

1. Poliigon – Leather Fabric Textures

Domain: poliigon.com

Registered: 2015 (10 years)

Introduction: Leather Fabric Textures – Seamless, high-resolution leather fabric textures for achieving a luxurious and sophisticated look in architectural visualizations, product designs, or any project that calls for leather materials. Categories include 82 different leather fabric textures such as Cowhide Leather, Buffalo Leather, Suede Leather, Faux Leather, and various finishes like Patina Vintage, Pebbled…

2. Unsplash – Leather Texture Collection

Domain: unsplash.com

Registered: 2013 (12 years)

Introduction: 1000+ Leather Texture Pictures available for free download on Unsplash. Includes various types of leather textures such as black leather texture, brown leather texture, and leather backgrounds. Users can filter images by relevance and aspect ratio.

3. Leather Textures – Unique Seamless Designs

Domain: sketchuptextureclub.com

Registered: 2014 (11 years)

Introduction: Leather textures available: Louis Vuitton black leather, black leather, blue leather, red leather, green leather, brown leather, Chesterfield leather, and various seamless leather textures. Each texture is labeled with a unique identifier number.

4. Adobe Stock – Seamless Leather Textures

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Seamless Leather Texture Images – 148,033 Stock Photos, Vectors, and Videos available on Adobe Stock. Options to explore plans, upload images, and access a free trial for 10 images or 1 video. Additional features include sorting results, filtering by media type (images, videos, templates), and regional content selection.

5. Pinterest – Leather Textures

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Leather texture, seamless fabric textures, material textures, cream leather texture, beige tufted leather texture, brown leather texture, close-up leather texture, smooth leather material, gray leather texture sample, dark leather texture, black leather texture, embossed fabric, faux leather texture, high resolution luxury white leather texture, beige textured leather surface.

6. Weaver Leather Supply – Premium Leather Selection

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: {“textures”: [“Top Grain”, “Pebbled”, “Smooth”, “Pull-Up”, “Waxy”, “Matte”], “leathers”: [{“name”: “Water Buffalo Leather”, “type”: “Crazy Horse”, “price”: “From $74.00”, “options”: [“Brown”, “Black”]}, {“name”: “Sao Paulo Single and Double Shoulders”, “weight”: “3-4 oz.”, “price”: “From $53.00”, “options”: [“Black”, “Red”, “Tan”, “Dark Brown”, “Cactus”, “Apricot”, “Goldenrod”, “Jade”]}, {“name”: …

Strategic Sourcing Conclusion and Outlook for leather texture

In navigating the global landscape of leather textures, B2B buyers are presented with unique opportunities to enhance their product offerings. Understanding the diverse range of leather textures—ranging from smooth to pebbled, and from vintage to modern—is crucial for selecting materials that resonate with target markets. Strategic sourcing not only ensures cost-effectiveness but also allows businesses to align their product aesthetics with consumer preferences, particularly in regions such as Africa, South America, the Middle East, and Europe.

By leveraging high-quality leather textures, businesses can elevate their brand identity and meet the rising demand for premium materials. Engaging with reputable suppliers who provide a variety of textures can lead to innovative product designs that stand out in competitive markets. Furthermore, as sustainability becomes increasingly important, sourcing eco-friendly leather options can enhance brand reputation and attract environmentally conscious consumers.

Looking ahead, international buyers should capitalize on emerging trends in leather design and production. By staying informed and proactive in their sourcing strategies, companies can not only secure competitive advantages but also foster long-term partnerships that drive growth. Embrace the potential of leather textures today—your next successful product line could be just around the corner.

Illustrative image related to leather texture

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.