Introduction: Navigating the Global Market for lv leather fabric

In the competitive landscape of global sourcing, identifying high-quality LV leather fabric can pose significant challenges for international B2B buyers. As a premium material widely sought after for its durability and aesthetic appeal, LV leather fabric is essential for various applications, from luxury fashion to high-end upholstery. This guide serves as a comprehensive resource to navigate the complexities of sourcing LV leather fabric, addressing critical factors such as types, applications, supplier vetting processes, and cost considerations.

Understanding the nuances of LV leather fabric is crucial for businesses looking to make informed purchasing decisions. This guide empowers buyers from diverse regions, including Africa, South America, the Middle East, and Europe, to confidently engage with suppliers and evaluate options that best meet their specific needs. By providing insights into market trends, quality assessments, and pricing structures, we equip you with the knowledge to secure the best deals and establish reliable supplier relationships.

Whether you are a seasoned buyer or new to the market, this resource will help you effectively navigate the global landscape of LV leather fabric, ensuring that your business remains competitive and meets the high standards of your clientele. Explore the intricacies of this luxurious material and discover how to enhance your product offerings with our expert guidance.

Table Of Contents

- Top 7 Lv Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for lv leather fabric

- Understanding lv leather fabric Types and Variations

- Key Industrial Applications of lv leather fabric

- 3 Common User Pain Points for ‘lv leather fabric’ & Their Solutions

- Strategic Material Selection Guide for lv leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for lv leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘lv leather fabric’

- Comprehensive Cost and Pricing Analysis for lv leather fabric Sourcing

- Alternatives Analysis: Comparing lv leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for lv leather fabric

- Navigating Market Dynamics and Sourcing Trends in the lv leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of lv leather fabric

- Strategic Sourcing Conclusion and Outlook for lv leather fabric

- Important Disclaimer & Terms of Use

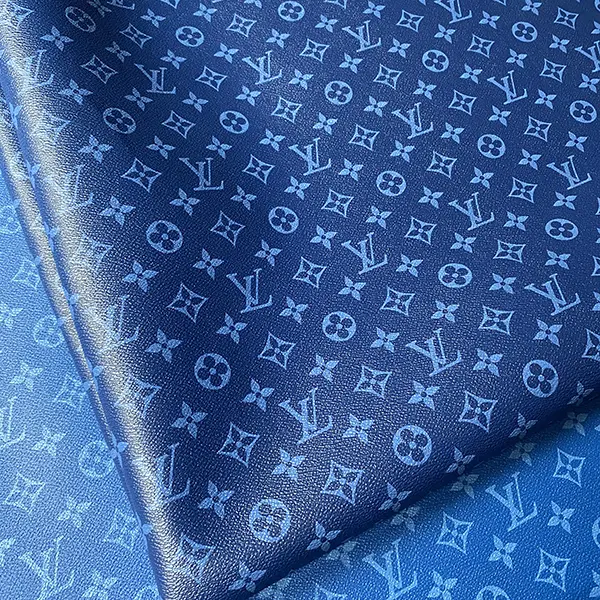

Understanding lv leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Empreinte Leather | Textured finish with a unique embossed pattern | Luxury handbags, accessories | Pros: High durability, premium aesthetic. Cons: Higher cost than standard leather. |

| Vinyl Leather | Synthetic alternative that mimics real leather | Upholstery, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Less durable than genuine leather. |

| Denim-Look Leather | Fabric resembling denim, available in various colors | Casual bags, clothing, and footwear | Pros: Trendy appearance, versatile use. Cons: May lack the luxury feel of genuine leather. |

| Embossed Vinyl | Features intricate patterns for visual appeal | Specialty items, promotional products | Pros: Unique design options, affordable. Cons: Can wear down quicker than leather. |

| Stretch Leather | Elasticity allows for flexible applications | Clothing, form-fitting accessories | Pros: Comfortable fit, innovative design potential. Cons: May require special care to maintain shape. |

What Are the Key Features of Empreinte Leather?

Empreinte leather is distinguished by its textured finish, characterized by a unique embossed pattern that adds depth and sophistication. This type of leather is often used in high-end handbags and accessories, appealing to luxury markets. B2B buyers should consider its durability and premium aesthetic, which justify the higher price point. However, it is essential to evaluate the cost against the potential return on investment in luxury segments.

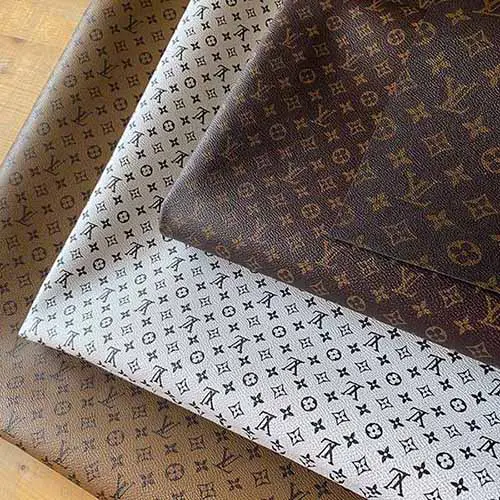

How Does Vinyl Leather Compare to Other Types?

Vinyl leather serves as a synthetic alternative that closely mimics the look and feel of real leather. This type is popular in upholstery and fashion accessories due to its cost-effectiveness and ease of maintenance. B2B buyers can benefit from lower prices and a variety of colors and patterns. However, it is crucial to recognize that vinyl leather may not offer the same durability as genuine leather, which could affect long-term use in high-traffic applications.

Why Choose Denim-Look Leather for Your Business Needs?

Denim-look leather provides a trendy appearance, resembling traditional denim fabric while maintaining the advantages of leather. This versatile material is suitable for casual bags, clothing, and footwear. B2B buyers should note its appeal to younger demographics and fashion-forward markets. However, while it offers a stylish option, it may lack the luxury feel associated with higher-end leather products, which could limit its market.

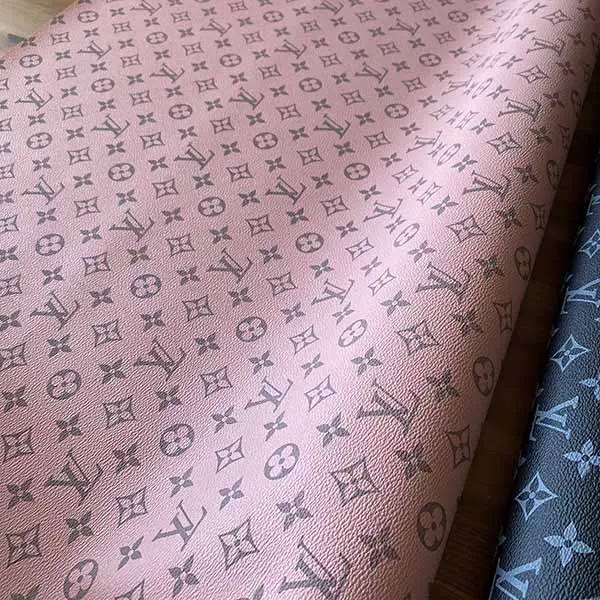

Illustrative image related to lv leather fabric

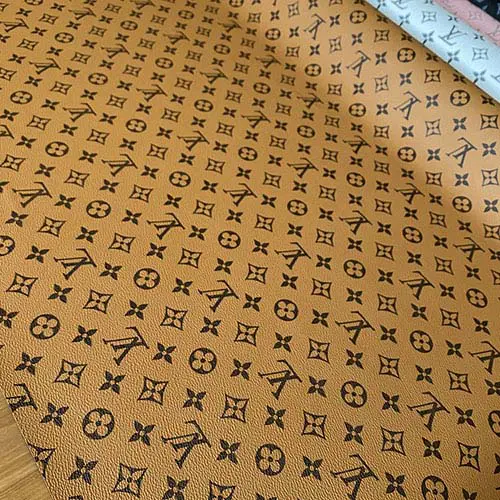

What Advantages Does Embossed Vinyl Offer?

Embossed vinyl features intricate patterns that enhance its visual appeal, making it ideal for specialty items and promotional products. This type of fabric allows for unique design options at an affordable price point, attracting businesses looking for cost-effective solutions. Nevertheless, B2B buyers must consider that embossed vinyl may wear down quicker than traditional leather, potentially impacting product longevity and customer satisfaction.

When Should You Use Stretch Leather in Your Products?

Stretch leather is notable for its elasticity, allowing for flexible applications in clothing and form-fitting accessories. This type is particularly advantageous for businesses focused on comfort and innovative design. B2B buyers should assess the potential for creating unique, comfortable products that stand out in the market. However, it is essential to implement proper care instructions, as stretch leather may require special handling to maintain its shape and longevity.

Key Industrial Applications of lv leather fabric

| Industry/Sector | Specific Application of lv leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | High-end garment production | Enhances brand prestige and product appeal | Quality assurance, authenticity verification, and design versatility. |

| Automotive | Interior upholstery | Provides luxury feel and durability | Compliance with automotive standards and color matching. |

| Furniture & Interior Design | Custom upholstery for luxury furniture | Adds elegance and comfort to living spaces | Sourcing from reputable suppliers and ensuring material integrity. |

| Leather Goods Manufacturing | Handbags and accessories production | Attracts affluent consumers and boosts sales | Focus on sourcing authentic materials and consistent supply. |

| Crafting & DIY Projects | Home decor items and accessories | Enables unique, personalized creations | Availability of various colors and patterns for customization. |

How is lv leather fabric utilized in the Fashion & Apparel industry?

In the fashion sector, lv leather fabric is predominantly used in the production of high-end garments and accessories. Its luxurious texture and aesthetic appeal make it a preferred choice for designers looking to elevate their collections. By integrating this fabric, businesses can enhance their brand prestige, attracting affluent consumers. International buyers, especially from regions like Europe and the Middle East, should prioritize quality assurance and authenticity verification to ensure the integrity of their products.

What role does lv leather fabric play in Automotive applications?

In the automotive industry, lv leather fabric is essential for interior upholstery, including seats and dashboards. Its durability and luxurious appearance contribute to a vehicle’s overall appeal, which is critical in a competitive market. Businesses must consider compliance with automotive standards and the need for precise color matching to maintain brand consistency. Buyers from Africa and South America should also be aware of local regulations regarding material sourcing and sustainability.

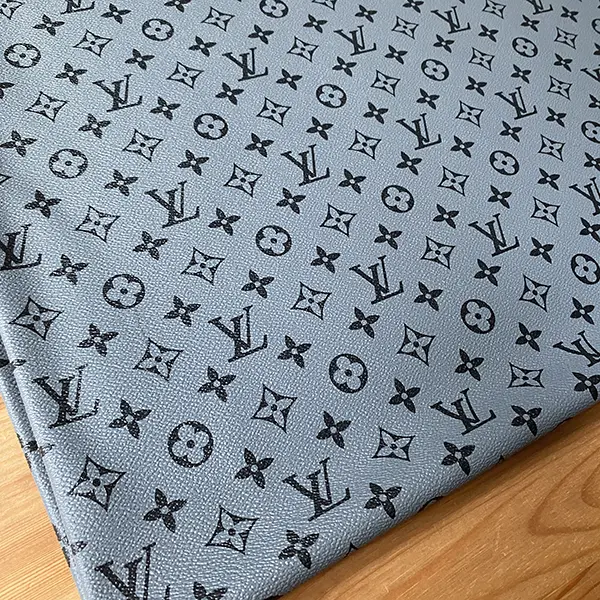

Illustrative image related to lv leather fabric

Why is lv leather fabric favored in Furniture & Interior Design?

The furniture and interior design sector utilizes lv leather fabric for custom upholstery, providing a touch of elegance and comfort to high-end furniture pieces. This material enhances the aesthetic value of living spaces, making it a sought-after option for luxury interior projects. When sourcing, businesses should focus on reputable suppliers who can guarantee material integrity and offer a range of colors and textures to meet diverse design needs.

How does lv leather fabric benefit Leather Goods Manufacturing?

In leather goods manufacturing, lv leather fabric is used to create premium handbags, wallets, and accessories. Its high quality not only attracts affluent consumers but also boosts sales through perceived value. For international B2B buyers, particularly in markets like Brazil and Saudi Arabia, it is crucial to source authentic materials consistently to maintain product quality and brand reputation.

What advantages does lv leather fabric offer for Crafting & DIY Projects?

For crafting and DIY projects, lv leather fabric provides a versatile option for creating unique home decor items and accessories. Its availability in various colors and patterns allows artisans to personalize their creations, appealing to a niche market of consumers seeking individuality. Sourcing considerations include ensuring a steady supply of diverse materials to facilitate creativity and meet customer demands effectively.

3 Common User Pain Points for ‘lv leather fabric’ & Their Solutions

Scenario 1: Sourcing Authenticity and Quality Concerns

The Problem: B2B buyers often face challenges in sourcing authentic LV leather fabric, especially in regions like Africa and South America, where counterfeit products may flood the market. The fear of investing in low-quality or fake materials can lead to significant financial losses and damage to a company’s reputation. Buyers may struggle to differentiate between genuine and imitation products, making it hard to find reliable suppliers who can guarantee authenticity.

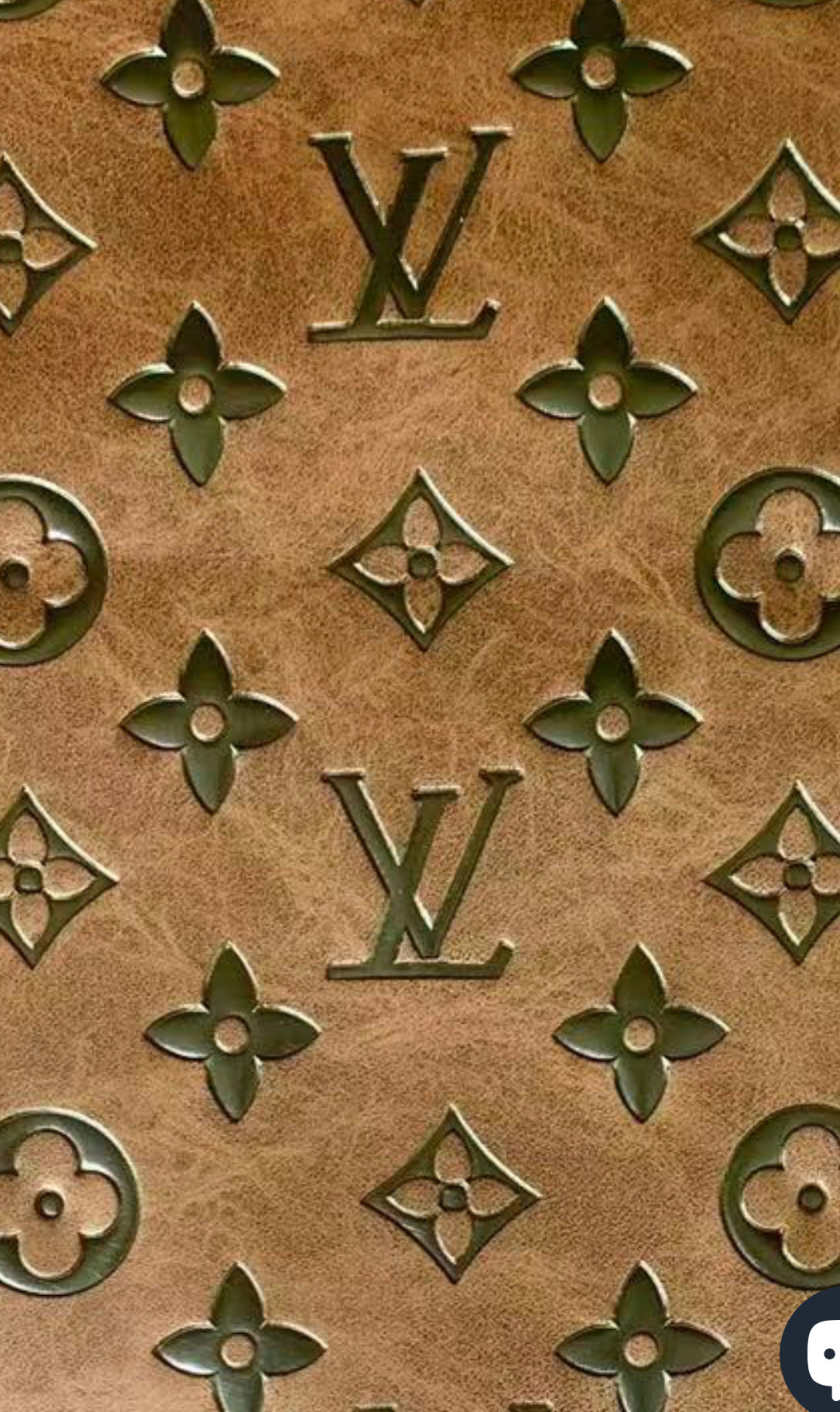

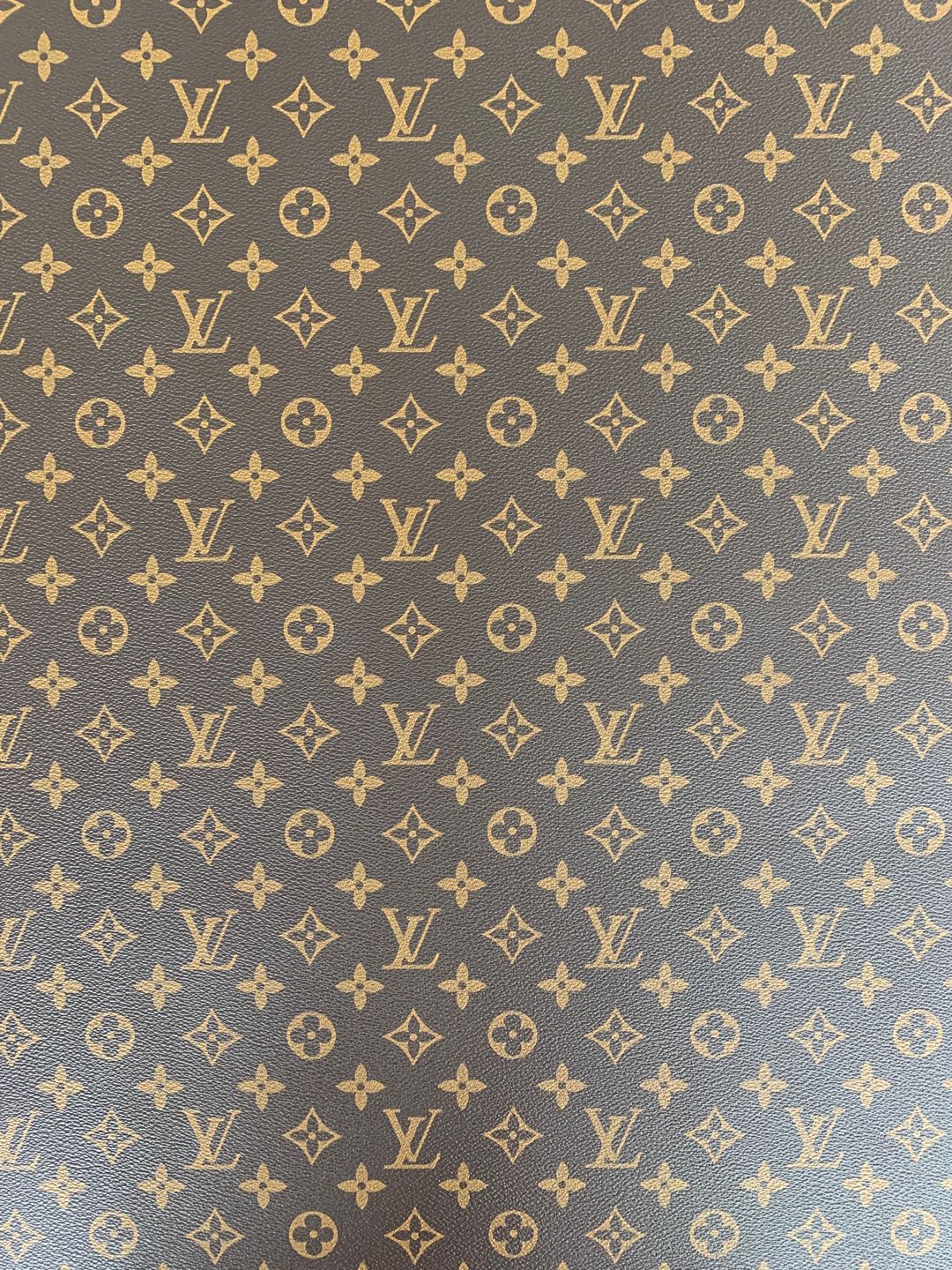

Illustrative image related to lv leather fabric

The Solution: To mitigate authenticity and quality concerns, buyers should establish relationships with reputable distributors or manufacturers that have a track record of providing genuine LV leather fabric. Conducting thorough due diligence is crucial—requesting certifications and product samples can help verify quality before placing bulk orders. Additionally, utilizing platforms that specialize in high-end materials can streamline the sourcing process. Buyers should also consider attending trade shows or industry exhibitions where they can meet suppliers face-to-face, inspect products, and build trust. Leveraging digital tools to check supplier reviews and ratings can further enhance confidence in sourcing decisions.

Scenario 2: Managing Pricing and Cost Variability

The Problem: Fluctuations in the price of LV leather fabric can be a major pain point for B2B buyers. Factors such as supply chain disruptions, changes in demand, and currency exchange rates can lead to unpredictable pricing. This variability makes it difficult for businesses to budget effectively and can impact profit margins, especially for small to mid-sized companies that rely heavily on precise cost management.

The Solution: To better manage pricing and cost variability, buyers should develop a flexible sourcing strategy that includes multiple suppliers. By diversifying their supplier base, companies can hedge against price increases from any single source. Additionally, negotiating long-term contracts with fixed pricing can provide stability and predictability. Buyers should also stay informed about market trends and economic indicators that affect leather prices, enabling them to make proactive purchasing decisions. Implementing just-in-time inventory practices can help reduce holding costs and mitigate the impact of sudden price changes, ensuring that businesses remain agile in a fluctuating market.

Illustrative image related to lv leather fabric

Scenario 3: Ensuring Versatility for Diverse Applications

The Problem: B2B buyers often require LV leather fabric for a variety of applications, from fashion accessories to upholstery. However, the challenge lies in ensuring that the selected fabric meets the specific durability, texture, and aesthetic requirements for each application. This can be particularly complex when dealing with a diverse clientele that demands unique characteristics from their products.

The Solution: To address the need for versatility, buyers should focus on collaborating closely with manufacturers to understand the properties of different LV leather fabric types. Conducting tests on fabric samples can help determine their suitability for various applications, such as wear and tear resistance for handbags or softness for garments. Buyers should also consider customizing orders based on specific project needs, which may involve requesting unique finishes or colors. Training staff to understand the nuances of fabric selection can enhance decision-making and ensure that the right materials are chosen for each application. Additionally, maintaining an open line of communication with clients about their needs can guide the selection process, ensuring that the final products meet or exceed expectations.

Strategic Material Selection Guide for lv leather fabric

What Are the Key Properties of Common Materials Used in lv Leather Fabric?

When selecting materials for Louis Vuitton (lv) leather fabric, understanding the properties of different materials is crucial for B2B buyers. The following analysis focuses on four common materials used in the production of lv leather fabric: genuine leather, synthetic leather (PU), vinyl, and embossed leather. Each material has its unique characteristics that impact performance, durability, and suitability for various applications.

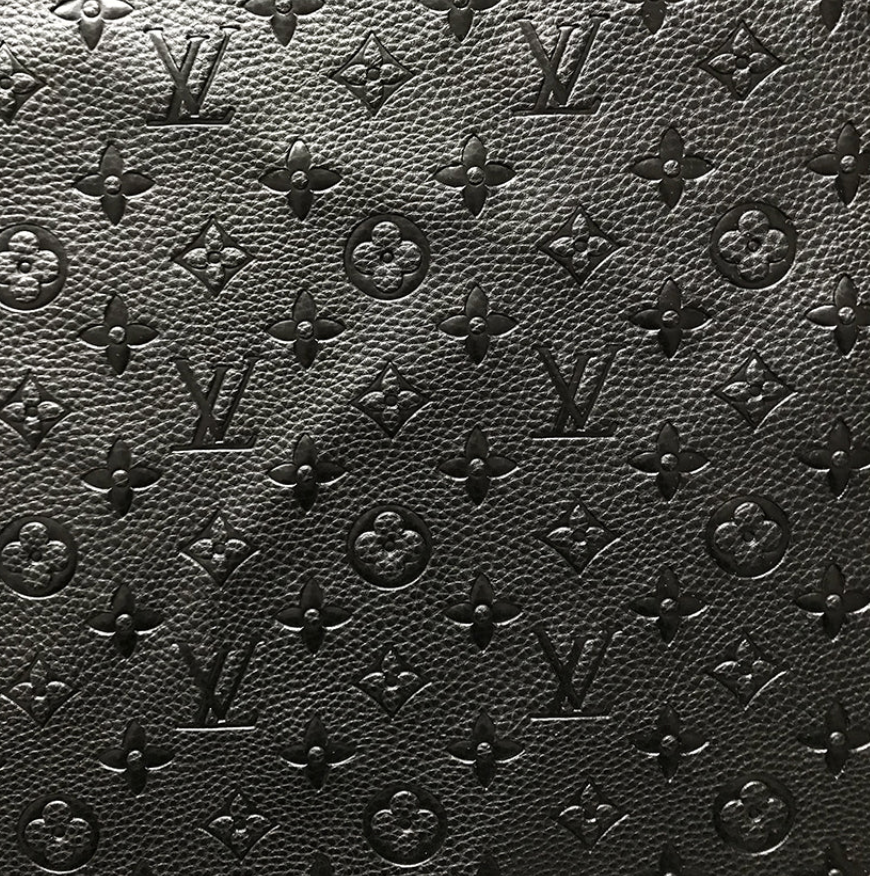

Illustrative image related to lv leather fabric

How Does Genuine Leather Perform in Various Applications?

Genuine leather is known for its durability, breathability, and aesthetic appeal. It can withstand varying temperatures and pressures, making it suitable for high-end applications such as luxury handbags and apparel. However, genuine leather is susceptible to moisture and requires regular maintenance to prevent damage.

Pros:

– Excellent durability and longevity.

– Natural aesthetic appeal with unique textures.

– Breathable, providing comfort in wear.

Cons:

– Higher cost compared to synthetic alternatives.

– Requires more complex manufacturing processes.

– Vulnerable to moisture and stains.

For international buyers, especially those from Africa and the Middle East, compliance with local regulations regarding animal welfare and sourcing is essential. Buyers should also be aware of the varying standards for leather quality, such as the ISO 17076 for leather testing.

Illustrative image related to lv leather fabric

What Advantages Does Synthetic Leather (PU) Offer?

Synthetic leather, particularly polyurethane (PU), has gained popularity due to its affordability and versatility. It mimics the look and feel of genuine leather while being more resistant to moisture and stains. PU leather is also easier to clean and maintain, making it suitable for a wide range of applications, including upholstery and fashion accessories.

Pros:

– Cost-effective alternative to genuine leather.

– Easier to clean and maintain.

– Available in a variety of colors and textures.

Cons:

– Generally less durable than genuine leather.

– May not have the same luxurious feel.

– Environmental concerns regarding production processes.

For buyers in South America and Europe, understanding the environmental impact of synthetic materials is crucial. Compliance with standards such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is necessary for market entry.

Illustrative image related to lv leather fabric

How Does Vinyl Compare to Other Materials?

Vinyl is a synthetic material that is highly versatile and often used in applications requiring water resistance, such as bags and outdoor furniture. It is available in various colors and finishes, making it a popular choice for fashion and design.

Pros:

– Excellent water and stain resistance.

– Cost-effective and widely available.

– Easy to clean and maintain.

Cons:

– Less breathable than genuine leather.

– Can be less durable under extreme conditions.

– May not provide the same luxury feel as leather.

International buyers, particularly from regions with humid climates like parts of Africa, should consider vinyl for its moisture resistance. However, they must also be aware of the potential for vinyl to degrade over time if exposed to UV light.

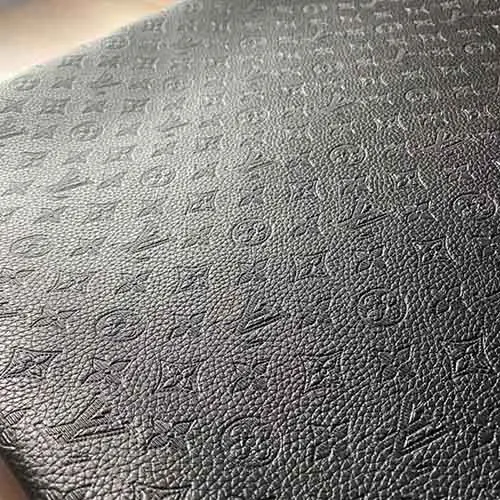

What Are the Unique Features of Embossed Leather?

Embossed leather offers a unique texture and aesthetic appeal, often used in luxury items to enhance visual interest. This material can be made from genuine leather or synthetic alternatives and is designed to mimic intricate patterns, making it suitable for high-end applications.

Illustrative image related to lv leather fabric

Pros:

– Unique and attractive designs.

– Can be made from both genuine and synthetic materials.

– Offers a luxurious appearance at a lower cost than fully embossed leather.

Cons:

– Depending on the base material, durability can vary.

– More complex manufacturing process may increase costs.

– Care must be taken to avoid wear on embossed patterns.

International buyers should consider the market preferences for embossed designs, particularly in Europe and the Middle East, where luxury and aesthetic appeal are highly valued. Compliance with local standards for material safety and quality is also essential.

Illustrative image related to lv leather fabric

Summary Table of Material Selection for lv Leather Fabric

| Material | Typical Use Case for lv leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Luxury handbags, apparel | Excellent durability and aesthetic appeal | Higher cost, requires maintenance | High |

| Synthetic Leather (PU) | Fashion accessories, upholstery | Cost-effective, easy to maintain | Less durable than genuine leather | Medium |

| Vinyl | Bags, outdoor furniture | Water and stain resistant | Less breathable, can degrade under UV | Low |

| Embossed Leather | Luxury items, fashion accessories | Unique designs and textures | Durability varies based on base material | Medium to High |

This guide provides an essential overview for B2B buyers looking to navigate the complexities of material selection for lv leather fabric, ensuring informed decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for lv leather fabric

What Are the Key Stages in the Manufacturing Process of LV Leather Fabric?

The manufacturing process of LV leather fabric involves several critical stages, each designed to ensure high-quality output and consistency. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process is the selection and preparation of raw materials. LV leather fabric typically utilizes high-quality leather and vinyl materials. Raw leather is sourced from reputable tanneries that meet stringent quality standards. The leather is then treated to enhance its durability and aesthetic qualities. For vinyl options, high-grade synthetic materials are chosen to mimic the look and feel of natural leather while providing additional benefits such as water resistance.

The preparation phase also includes cutting the materials into specified dimensions. Advanced cutting techniques such as laser cutting may be employed to ensure precision, especially for intricate designs. This stage is crucial as it sets the foundation for the quality of the final product.

Illustrative image related to lv leather fabric

Forming: What Techniques Are Used to Shape the Leather Fabric?

Once the materials are prepared, the next stage involves forming. This can include techniques such as embossing, printing, or dyeing. For instance, LV leather fabric often features distinctive patterns that require specialized printing techniques. These patterns are not only visually appealing but also serve as a hallmark of authenticity.

In the case of embossed leather, heat and pressure are applied to create textures that enhance both aesthetic appeal and tactile quality. The forming stage is critical as it directly influences the fabric’s characteristics, such as flexibility and strength.

Assembly: How Is the Fabric Constructed into Final Products?

The assembly stage involves stitching or bonding the formed leather or vinyl into the final product. This may include handbags, wallets, or other luxury items. Skilled artisans often oversee this process to ensure that the craftsmanship meets the high standards associated with LV leather fabric.

Quality control checkpoints are integrated throughout the assembly process. This includes inspections of stitching quality, alignment of patterns, and overall craftsmanship. Attention to detail at this stage is vital, as any defects can compromise the integrity of the final product.

Finishing: What Processes Ensure the Fabric Meets Quality Standards?

The finishing stage is where the product is polished and prepared for distribution. This can include additional treatments to enhance the material’s durability, such as water-repellent coatings. The finishing process is also where final inspections occur, ensuring that every item meets the required specifications.

Illustrative image related to lv leather fabric

This stage may also involve packaging, where products are carefully wrapped to prevent damage during shipping. Proper packaging is essential for maintaining the luxury appeal of LV leather fabric, especially for international shipments.

What Quality Assurance Standards Are Relevant for LV Leather Fabric?

Quality assurance is a critical aspect of the manufacturing process, particularly for LV leather fabric. Adhering to international standards such as ISO 9001 ensures that quality management systems are in place, enabling consistent production of high-quality products.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a globally recognized standard that outlines requirements for a quality management system. Compliance with this standard demonstrates a company’s commitment to quality and customer satisfaction. Additionally, industry-specific standards such as CE marking may apply, particularly for products sold in the European market.

For B2B buyers, understanding these standards is crucial for making informed purchasing decisions. Suppliers who comply with these standards are more likely to provide reliable products that meet international quality expectations.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated into various stages of the manufacturing process. Key checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

How Does Incoming Quality Control (IQC) Ensure Raw Material Quality?

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This includes checking for defects, verifying specifications, and ensuring that materials meet predetermined quality standards. A robust IQC process minimizes the risk of defects in the final product.

What Role Does In-Process Quality Control (IPQC) Play in Manufacturing?

IPQC occurs during the manufacturing process and focuses on monitoring production activities. This includes regular inspections of the forming and assembly processes to identify any issues early on. By implementing IPQC, manufacturers can address potential problems before they escalate, ensuring that the final product meets quality standards.

Why Is Final Quality Control (FQC) Critical Before Product Distribution?

FQC is the last line of defense before products are shipped to customers. This inspection verifies that the finished goods meet all specifications and quality standards. Any product that fails FQC is either reworked or discarded, which helps maintain the brand’s reputation for quality.

Illustrative image related to lv leather fabric

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. There are several methods to achieve this.

What Auditing Practices Should B2B Buyers Consider?

Conducting supplier audits is an effective way to assess quality control practices. These audits can be scheduled or unscheduled and involve a comprehensive review of the supplier’s manufacturing processes, quality control systems, and compliance with industry standards.

How Can Buyers Use Reports and Third-Party Inspections to Verify Quality?

Requesting quality assurance reports from suppliers can provide insights into their QC practices. Third-party inspections are another valuable option, as they offer an unbiased assessment of a supplier’s quality control measures. Engaging reputable third-party inspection agencies can enhance the credibility of the quality assurance process.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges when it comes to quality control. Variations in regulations, market expectations, and logistics can impact product quality.

Illustrative image related to lv leather fabric

How Can Buyers Navigate International Quality Standards?

Understanding regional differences in quality standards is vital for international buyers. Each market may have specific regulations that impact the importation and sale of leather products. Familiarizing oneself with these standards can help buyers avoid compliance issues and ensure that products meet local expectations.

Why Is Communication with Suppliers Important for Quality Assurance?

Effective communication with suppliers is crucial for addressing quality concerns promptly. Establishing clear expectations regarding quality standards and QC practices can help mitigate risks associated with international sourcing. Regular updates and feedback can foster a collaborative relationship, ultimately leading to better quality outcomes.

In conclusion, the manufacturing processes and quality assurance practices for LV leather fabric are multifaceted and critical for maintaining the brand’s reputation for luxury and quality. By understanding these processes, B2B buyers can make informed decisions and ensure that they are sourcing high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lv leather fabric’

To assist international B2B buyers in sourcing LV leather fabric effectively, this guide outlines essential steps to ensure a successful procurement process. Understanding the nuances of this luxury material is crucial for making informed decisions and fostering long-term supplier relationships.

Illustrative image related to lv leather fabric

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the LV leather fabric you intend to procure. This includes desired colors, patterns, textures, and intended use (e.g., bags, upholstery, or apparel). Having well-defined specifications will not only streamline the sourcing process but also help in communicating effectively with potential suppliers.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify reputable suppliers who specialize in LV leather fabric. Look for suppliers with a strong market presence and positive reviews. Resources such as industry directories, trade shows, and online platforms can be invaluable for discovering potential partners.

- Key Considerations:

- Verify the supplier’s experience in the luxury fabric sector.

- Assess their production capacity to meet your volume requirements.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. An in-depth evaluation helps ensure that the supplier can deliver quality products consistently.

- Important Checks:

- Assess their quality control measures.

- Inquire about their compliance with international standards and certifications.

Step 4: Request Samples for Quality Assessment

Request samples of the LV leather fabric to evaluate the quality firsthand. This step is critical to ensure that the fabric meets your specifications regarding texture, durability, and aesthetic appeal.

- Sample Evaluation:

- Compare samples against your defined specifications.

- Test the fabric for its intended application, such as abrasion resistance or colorfastness.

Step 5: Understand Pricing and Payment Terms

Discuss pricing structures with your chosen suppliers to understand the cost implications of your order. Be clear about your budget and ask for detailed quotations that include any additional costs like shipping or taxes.

Illustrative image related to lv leather fabric

- Negotiation Tips:

- Inquire about bulk order discounts.

- Ensure transparency in payment terms to avoid future disputes.

Step 6: Review Delivery and Logistics Options

Discuss delivery timelines and logistics with your supplier. Understanding their shipping capabilities and lead times is crucial for planning your production schedule effectively.

- Logistics Considerations:

- Check if they offer international shipping and the associated costs.

- Confirm the availability of tracking services for shipments.

Step 7: Establish a Communication Plan

Set up a clear communication plan with your supplier to facilitate ongoing dialogue throughout the procurement process. Regular communication helps in promptly addressing any issues that may arise and ensures that both parties are aligned on expectations.

- Communication Best Practices:

- Schedule regular check-ins during the production phase.

- Utilize project management tools for better collaboration.

By following this checklist, B2B buyers can enhance their sourcing strategy for LV leather fabric, ensuring quality procurement and establishing strong supplier partnerships that meet their business needs.

Illustrative image related to lv leather fabric

Comprehensive Cost and Pricing Analysis for lv leather fabric Sourcing

When sourcing LV leather fabric, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This insight can help in making informed purchasing decisions that align with business strategies, particularly for markets in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in LV Leather Fabric Sourcing?

-

Materials: The cost of raw materials significantly influences the overall price of LV leather fabric. High-quality leather and vinyl materials, which are often sourced from premium suppliers, contribute to higher costs. Buyers should consider the quality of the leather, as it affects durability and aesthetic appeal.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this could impact quality. It’s essential to evaluate the skill level of workers in the chosen region, as skilled labor can lead to better craftsmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and administrative costs. Buyers should inquire about the manufacturing practices of suppliers to ensure they are efficient and sustainable, as this can affect pricing.

-

Tooling: Custom tooling for specific designs or patterns adds to the initial costs. Buyers looking for unique designs should factor in these costs when budgeting for their projects.

-

Quality Control (QC): Rigorous quality control measures are crucial, especially for high-end products like LV leather fabric. The costs associated with QC can vary based on the supplier’s standards and practices.

-

Logistics: Shipping and handling costs can add significantly to the total cost, especially for international shipments. Understanding the logistics involved, including customs duties and tariffs, is essential for accurate cost assessment.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s market positioning, brand reputation, and the exclusivity of the material.

What Influences the Pricing of LV Leather Fabric?

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to bulk discounts, which can significantly reduce the per-unit cost. Buyers should assess their needs to determine the most cost-effective order size.

-

Specifications and Customization: Custom designs or specific material requests can increase costs. Buyers should clearly communicate their requirements to avoid unexpected price increases.

-

Quality and Certifications: Fabrics that meet specific quality standards or certifications (e.g., eco-friendly materials) may carry a premium price. Understanding these certifications can help buyers justify costs.

-

Supplier Factors: The supplier’s reputation, reliability, and financial stability can impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: The terms of shipping (such as FOB, CIF) can affect the total landed cost of the fabric. Buyers should negotiate these terms to ensure they understand who bears the risk and costs during shipping.

How Can Buyers Optimize Costs When Sourcing LV Leather Fabric?

-

Negotiation: Effective negotiation can lead to better pricing terms. Buyers should prepare to discuss volume discounts, payment terms, and other factors that could lower costs.

-

Cost-Efficiency: Conducting a total cost of ownership analysis helps identify all associated costs, including shipping, duties, and potential waste during production. This comprehensive view allows for better budgeting and sourcing decisions.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations, import tariffs, and local market conditions that can influence pricing.

-

Building Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and flexibility in future orders.

In conclusion, understanding the intricate cost structure and pricing dynamics of LV leather fabric sourcing is vital for international B2B buyers. By considering these factors and employing strategic approaches, buyers can optimize their purchasing decisions and achieve a favorable return on investment.

Alternatives Analysis: Comparing lv leather fabric With Other Solutions

Understanding Alternatives to LV Leather Fabric

In the competitive landscape of materials for high-end products, understanding alternatives to LV leather fabric is crucial for B2B buyers. This analysis focuses on comparing LV leather fabric with two viable alternatives: synthetic leather and genuine animal leather. Each option has unique attributes that may align differently with a buyer’s specific needs, including performance, cost, and suitability for various applications.

Comparison Table

| Comparison Aspect | LV Leather Fabric | Synthetic Leather | Genuine Animal Leather |

|---|---|---|---|

| Performance | High durability, stylish appearance | Moderate durability, versatile in use | Excellent durability, natural look |

| Cost | $35 – $59 per yard | $20 – $40 per yard | $60 – $150 per yard |

| Ease of Implementation | Requires skilled labor for crafting | Easy to work with, less skilled labor needed | Requires skilled labor for tanning and crafting |

| Maintenance | Low; easy to clean | Low; resistant to stains | Moderate; requires special care |

| Best Use Case | Luxury products, fashion items | Affordable fashion, upholstery | High-end products, luxury goods |

What Are the Advantages and Disadvantages of Synthetic Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), serves as a popular alternative. One of its primary advantages is cost-effectiveness; synthetic leather is generally less expensive than LV leather fabric, making it an appealing choice for budget-conscious brands. Additionally, synthetic leather is easier to work with and does not require the same level of craftsmanship as natural leather. However, it may lack the premium feel and longevity that LV leather fabric offers. It is also less breathable, which can impact comfort in applications like footwear and clothing.

How Does Genuine Animal Leather Compare?

Genuine animal leather is renowned for its durability and luxurious appearance. It is often preferred for high-end fashion items and accessories, providing a timeless aesthetic that synthetic options struggle to replicate. However, the cost of genuine leather is significantly higher, which can be a barrier for some buyers. Moreover, it requires more maintenance than LV leather fabric and synthetic options, as it is susceptible to stains and requires conditioning to maintain its suppleness. Ethical considerations surrounding sourcing and production may also influence buyer preferences in certain markets.

Illustrative image related to lv leather fabric

Making the Right Choice: Which Option Suits Your Needs?

When selecting a fabric for your products, it’s essential to consider your target market and the specific applications. For luxury brands targeting high-end consumers, LV leather fabric or genuine animal leather may be the best fit due to their premium quality and brand perception. Conversely, if cost and ease of manufacturing are primary concerns, synthetic leather might be a more practical choice. By evaluating the performance, costs, and maintenance requirements of each option, B2B buyers can make informed decisions that align with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for lv leather fabric

What Are the Key Technical Properties of LV Leather Fabric?

When considering LV leather fabric for procurement, understanding its critical technical properties is essential. These specifications not only define the quality and suitability of the fabric for various applications but also impact cost and performance.

-

Material Grade

The material grade of LV leather fabric refers to the quality of the leather used, which can range from full-grain to corrected grain. Full-grain leather is the highest quality, retaining the natural grain pattern, while corrected grain has been sanded and treated for imperfections. For B2B buyers, selecting the appropriate grade is crucial as it influences durability, aesthetic appeal, and pricing, impacting the end product’s marketability. -

Thickness

Thickness is a vital specification that affects the fabric’s strength and application suitability. LV leather fabric typically varies between 0.6 mm to 2.0 mm in thickness. Thicker materials are often more durable and suitable for heavy-duty applications, such as upholstery and bags, whereas thinner options might be more appropriate for clothing or accessories. Buyers must match thickness with intended use to ensure product longevity. -

Tensile Strength

Tensile strength measures the fabric’s resistance to being pulled apart. This property is crucial for applications that require durability, such as handbags or shoes. LV leather fabric is engineered to withstand significant stress, making it a preferred choice for high-end products. B2B buyers should assess tensile strength ratings to ensure the fabric meets their product requirements. -

Finish Type

The finish type refers to the treatment applied to the leather surface, which can include gloss, matte, or embossed finishes. Each finish type offers different aesthetics and functionalities. For instance, a glossy finish may enhance water resistance, while an embossed finish can add texture and design appeal. Understanding the finish type helps buyers align their product offerings with market trends and consumer preferences. -

Colorfastness

Colorfastness indicates how well the dye holds up against various conditions, such as washing, light exposure, and rubbing. This property is essential for maintaining the aesthetic quality of the final product, especially in fashion and upholstery. B2B buyers should prioritize colorfastness ratings to ensure that the fabric retains its visual appeal over time, thus minimizing returns and enhancing customer satisfaction.

What Are Common Trade Terms Used in the LV Leather Fabric Industry?

Navigating the procurement process effectively requires familiarity with industry jargon and trade terms. Here are some key terms that international buyers should know.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are then sold under another company’s brand. In the context of LV leather fabric, OEM suppliers may produce customized leather goods for brands looking to leverage high-quality materials without investing in their own manufacturing capabilities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it impacts inventory management and cash flow. Suppliers of LV leather fabric may set MOQs to ensure production efficiency, so buyers should plan their orders accordingly. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific quantities of products. For LV leather fabric, submitting an RFQ allows buyers to compare options from different suppliers, ensuring they secure the best possible pricing and terms for their needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to understand their obligations and risks in the procurement process of LV leather fabric, ensuring smoother transactions. -

Lead Time

Lead time is the period between placing an order and receiving the goods. In the LV leather fabric industry, lead times can vary significantly based on the type of fabric, customization requests, and supplier capabilities. Buyers should account for lead times in their project timelines to avoid delays in production and delivery. -

Sample Approval

Sample approval is the process of reviewing a fabric sample before full production begins. This step is vital for ensuring that the LV leather fabric meets the buyer’s specifications and quality standards. B2B buyers should prioritize this step to mitigate risks associated with poor quality or incorrect orders, ultimately safeguarding their brand reputation.

By understanding these essential properties and terms, B2B buyers can make informed decisions, ensuring they select the right LV leather fabric for their products while navigating the procurement process effectively.

Illustrative image related to lv leather fabric

Navigating Market Dynamics and Sourcing Trends in the lv leather fabric Sector

What Are the Key Market Dynamics Influencing the LV Leather Fabric Sector?

The LV leather fabric market is currently experiencing notable growth driven by several global factors. The increasing demand for luxury goods, especially in emerging markets in Africa, South America, and the Middle East, is influencing sourcing trends. Countries like Brazil and Saudi Arabia are seeing a rise in disposable income, leading to higher consumer spending on premium leather products. Furthermore, the advent of e-commerce platforms has facilitated easier access for B2B buyers to source luxury materials globally, allowing them to capitalize on the growing market without geographical constraints.

Emerging technologies such as blockchain are also reshaping the landscape of the leather fabric sector. These technologies enhance transparency in supply chains, enabling buyers to trace the origin of materials and ensure quality. Additionally, advancements in digital sourcing platforms streamline the procurement process, making it faster and more efficient for businesses to find suitable suppliers and negotiate terms. Another notable trend is the rise of customization, with buyers increasingly seeking unique patterns and colors that cater to specific market preferences.

How Is Sustainability Shaping the Sourcing of LV Leather Fabrics?

Sustainability is becoming a critical consideration for B2B buyers in the LV leather fabric market. The environmental impact of traditional leather production is significant, often involving deforestation, high water usage, and chemical pollution. Consequently, there is an increasing demand for ethically sourced materials that minimize harm to the environment.

Buyers are now prioritizing suppliers who adhere to sustainable practices, such as using eco-friendly tanning processes and sourcing from farms that practice responsible animal husbandry. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) signify a commitment to environmental stewardship and ethical sourcing. These certifications not only enhance brand reputation but also appeal to a growing segment of consumers who value sustainability. By aligning with suppliers that prioritize green practices, B2B buyers can mitigate risks and enhance their market position.

What Is the Historical Context of LV Leather Fabric for B2B Buyers?

The LV leather fabric sector has a rich history that traces back to the establishment of Louis Vuitton in 1854. Initially focused on crafting luxury trunks and travel accessories, the brand quickly became synonymous with quality and craftsmanship. Over the decades, LV expanded its product line to include leather goods, apparel, and accessories, establishing itself as a leader in luxury fashion.

Illustrative image related to lv leather fabric

For B2B buyers, understanding this historical context is essential, as it underscores the brand’s legacy of quality and innovation. The reputation of LV leather fabrics for durability and style is a significant selling point in the competitive luxury market. Buyers can leverage this historical prestige when marketing their products, aligning themselves with a brand that represents heritage, exclusivity, and sophistication.

Conclusion

Navigating the complexities of the LV leather fabric market requires an understanding of its dynamics, sustainability considerations, and historical context. By staying informed about market trends and prioritizing ethical sourcing, B2B buyers can position themselves effectively to meet the demands of modern consumers while maintaining a commitment to sustainability and quality.

Frequently Asked Questions (FAQs) for B2B Buyers of lv leather fabric

-

How do I verify the quality of LV leather fabric before purchasing?

To ensure the quality of LV leather fabric, request samples from suppliers before placing a bulk order. Evaluate the samples for texture, durability, and color accuracy. It’s also beneficial to ask for certifications or test reports that confirm compliance with international quality standards. Additionally, consider checking reviews or testimonials from other businesses that have sourced materials from the supplier. -

What are the common uses of LV leather fabric in the B2B market?

LV leather fabric is widely used in the fashion industry for high-end handbags, shoes, and apparel. It’s also popular for upholstery in luxury furniture and automotive interiors. Other applications include crafting, accessories, and promotional items. Understanding the specific needs of your target market will help you determine how to position LV leather fabric effectively. -

What is the minimum order quantity (MOQ) for LV leather fabric?

The MOQ for LV leather fabric can vary by supplier, typically ranging from 5 to 50 yards depending on the fabric type and customization options. When negotiating with suppliers, clarify the MOQ and explore options for lower quantities if necessary, especially for new buyers or smaller businesses. Establishing a good relationship with your supplier can sometimes lead to more flexible terms. -

What payment terms should I expect when sourcing LV leather fabric internationally?

Payment terms for international transactions often include options such as advance payment, letter of credit, or payment upon receipt of goods. Most suppliers will require a deposit (usually 30-50%) before processing your order. Ensure you discuss and agree on payment methods, timelines, and any additional fees associated with currency exchange or international transactions. -

How can I customize LV leather fabric for my business needs?

Customization options for LV leather fabric may include color selection, pattern design, and material thickness. Discuss your specific requirements with suppliers, as many can accommodate custom orders. Be prepared to provide detailed specifications and, if possible, design mock-ups to ensure the final product meets your expectations. Additionally, inquire about lead times for custom orders to manage your production schedule effectively. -

What logistics considerations should I be aware of when importing LV leather fabric?

When importing LV leather fabric, consider shipping methods, customs clearance, and local regulations. Choose a reliable freight forwarder who can assist with logistics and provide guidance on import duties and taxes. Make sure to factor in shipping times when planning your inventory, as international shipments can be subject to delays. Also, verify that your supplier complies with export regulations. -

How do I assess the reliability of a supplier of LV leather fabric?

To assess a supplier’s reliability, research their business history, customer reviews, and industry reputation. Request references from previous clients and analyze their response times and communication style. Additionally, consider visiting the supplier’s facility if possible, or using third-party inspection services to evaluate their production capabilities and quality control measures. -

What quality assurance measures should I implement when sourcing LV leather fabric?

Implementing quality assurance (QA) measures involves defining clear quality standards and expectations before placing an order. Establish a QA process that includes pre-shipment inspections, where samples are checked against your specifications. Regular communication with your supplier during production can help address any issues promptly. Consider a third-party QA service for larger orders to ensure compliance with your quality standards.

Top 7 Lv Leather Fabric Manufacturers & Suppliers List

1. Louis Vuitton – Leather Fabric Range

Domain: woucom

Introduction: Louis Vuitton Leather Fabric Range for sale by the yard in 2024. Multiple variants available for each product. Price range for most fabrics is $35 to $59. Key products include: LL01 White leather fabric, LL02 Orange Leather Fabric, LL03 Green Louis Vuitton Empreinte Leather Fabric, LL04 Ivory Leather Fabric, LL06 Green Fabric, LL07 Blue Fabric, LL08 Black fabric with gold pattern, LL09 Gray Leathe…

2. Louis Vuitton – Leather Sheets

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Louis Vuitton – Leather Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. LV Fashion – Crafting Leather Fabric

Domain: jackfabricstore.com

Registered: 2024 (1 years)

Introduction: Collection: LV Fashion

Availability: In stock (423), Out of stock (7)

Price Range: From $10.00 to $620.00

Products:

1. Fashion LV vinyl crafting leather fabric for handmade goods (By Yards) – Regular price: From $10.00 USD

2. Fashion Embossed LV Crafting Leather Fabric for Handmade Bags, Shoes and DIY Handicrafts (Black) – Regular price: From $10.00 USD

3. Classic LV vinyl crafting leather fabric …

4. Louis Vuitton – Classic Louis Vuitton LV Designer Leather Sheet

Domain: wendycustom.com

Registered: 2022 (3 years)

Introduction: Collection: Louis Vuitton, Total Products: 412, In Stock: 410, Out of Stock: 2, Price Range: From $5.00 to $458.00, Key Products: 1. Classic Louis Vuitton LV Designer Leather Sheet – From $25.00 USD 2. Black embossed LV craft Faux leather fabric – From $10.00 USD 3. Classic black grey Louis Vuitton LV Designer Leather – From $5.00 USD 4. Luxury Black Velvet LV for Custom Furniture Sofa – From $15….

5. LV – Fashion Red and White Vinyl Leather Fabric

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: {“product_name”:”Fashion red and white LV vinyl leather fabric”,”usage”:”handicrafts”,”thickness”:”1mm”,”width”:”137cm (54 inch)”}

6. Jennifer’s Goodies Galore – Custom Leather Sheets

Domain: jennifersgoodiesgalore.com

Registered: 2016 (9 years)

Introduction: {“size”:”8×11 inches”,”material”:”LV Synthetic Leather”,”type”:”Custom Leather Sheets”,”design”:”Merrigold LV Leather Fabric, Plaid LV Leather”,”features”:[“Synthetic Leather Sheet”,”Faux Leather”,”Litchi”,”Glitter”,”Patent”,”Vinyl”],”usage”:”DIY Hair Bows”,”quantity”:”1 Sheet”,”price”:”$4.10″,”printing_time”:”3-5 days”,”thickness”:”0.8mm”,”cpsia_compliant”:”Yes”,”odor”:”Slight odor due to ink, di…

7. eBay – LV Fabric Collection

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Lv Fabric for sale on eBay includes various colors such as Blue, Green, Black, Multicolor, White, Pink, Red, Beige, Gray, Brown, Purple, and Yellow. Available lengths/amounts are categorized as By the Yard, 1 – 2 yards, 3 – 5 yards, 6 – 12 yards, Fat Quarters, Bundles, Jelly Rolls, Strips, Less than 1 yard, Squares, Panels, and Bolts, Tubes, Lots.

Strategic Sourcing Conclusion and Outlook for lv leather fabric

What Are the Key Insights for B2B Buyers of LV Leather Fabric?

In conclusion, the strategic sourcing of LV leather fabric offers significant opportunities for B2B buyers across diverse global markets, particularly in Africa, South America, the Middle East, and Europe. The variety of options, ranging from classic embossed designs to vibrant colors, enables businesses to cater to a wide array of consumer preferences. By prioritizing quality and durability, companies can enhance their product offerings, ensuring that they meet the expectations of discerning customers.

Illustrative image related to lv leather fabric

Moreover, leveraging strategic sourcing not only streamlines procurement processes but also fosters strong supplier relationships that can lead to better pricing and exclusive access to new materials. As the demand for luxury and premium products continues to grow, positioning your business to take advantage of this trend will be crucial.

Looking ahead, now is the time for international B2B buyers to embrace the potential of LV leather fabric. By investing in high-quality materials today, you can establish a competitive edge in your market and drive sustainable growth. Engage with reliable suppliers and explore the latest trends to ensure your offerings remain at the forefront of the industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to lv leather fabric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.