Introduction: Navigating the Global Market for leather machine company

In an increasingly competitive global market, sourcing high-quality leather machinery poses a significant challenge for B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe. The right leather machine company can make all the difference in ensuring the success of manufacturing operations, whether you’re producing fashion accessories, footwear, or automotive interiors. This guide serves as a comprehensive resource, detailing the various types of leather machinery available, their applications across different sectors, and essential insights into supplier vetting processes.

Moreover, we delve into crucial aspects such as pricing, warranty options, and financing solutions, enabling buyers to make informed purchasing decisions that align with their operational needs. By understanding the nuances of sourcing leather machines—from heavy-duty stitchers to specialized skiving equipment—international buyers can enhance their production capabilities while maintaining a competitive edge.

This guide is tailored to empower decision-makers with actionable insights and expert recommendations, ensuring they navigate the complexities of the leather machinery market with confidence. Whether you’re a seasoned industry player or new to the leather trade, our aim is to equip you with the knowledge necessary to choose the right machinery partner for your business.

Table Of Contents

- Top 5 Leather Machine Company Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather machine company

- Understanding leather machine company Types and Variations

- Key Industrial Applications of leather machine company

- 3 Common User Pain Points for ‘leather machine company’ & Their Solutions

- Strategic Material Selection Guide for leather machine company

- In-depth Look: Manufacturing Processes and Quality Assurance for leather machine company

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather machine company’

- Comprehensive Cost and Pricing Analysis for leather machine company Sourcing

- Alternatives Analysis: Comparing leather machine company With Other Solutions

- Essential Technical Properties and Trade Terminology for leather machine company

- Navigating Market Dynamics and Sourcing Trends in the leather machine company Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather machine company

- Strategic Sourcing Conclusion and Outlook for leather machine company

- Important Disclaimer & Terms of Use

Understanding leather machine company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Leather Stitchers | Designed for thick leather, high durability, multiple stitch options | Tack, upholstery, leather goods manufacturing | Pros: Robust construction, versatile. Cons: Higher initial investment. |

| Skiving Machines | Specialized for thinning leather edges, precise cutting capabilities | Footwear production, leather garment making | Pros: Enhances material efficiency. Cons: Requires skilled operation. |

| Leather Splitters | Splits leather into thinner layers, adjustable blade settings | Custom leather goods, crafting, upholstery | Pros: Increases material yield. Cons: Maintenance can be intensive. |

| Walking Foot Sewing Machines | Offers consistent feeding of multiple layers, suitable for various materials | Bags, belts, and heavy-duty leather items | Pros: Ensures even stitching. Cons: Can be complex to operate. |

| Strap Cutting Machines | Efficiently cuts straps to specific widths, often programmable | Belt production, strap manufacturing | Pros: Increases production speed. Cons: Limited to strap cutting tasks. |

What are Heavy-Duty Leather Stitchers and Their B2B Applications?

Heavy-duty leather stitchers are engineered to handle thick leather, making them essential for industries like tack manufacturing and upholstery. They typically feature robust construction, allowing for a variety of stitching techniques. When considering a purchase, B2B buyers should evaluate the machine’s durability and versatility, as these factors can significantly impact production efficiency and output quality.

How Do Skiving Machines Enhance Leather Production?

Skiving machines are designed to thin leather edges with precision, facilitating cleaner seams and reducing material waste. They are particularly valuable in the footwear and leather garment sectors, where edge finishing is critical. Buyers should assess the machine’s cutting capabilities and the skill level required for operation, as these elements can influence overall production quality and labor costs.

What Makes Leather Splitters Essential for Custom Leather Goods?

Leather splitters are specialized machines that allow manufacturers to split leather into thinner layers for custom products. This capability is crucial for artisans and manufacturers looking to maximize material yield and create unique leather goods. When purchasing, buyers should consider the machine’s blade quality and adjustability, as these features will affect the precision and versatility of their production processes.

Why Choose Walking Foot Sewing Machines for Diverse Applications?

Walking foot sewing machines provide consistent feeding of leather layers, making them suitable for various applications, including bags and belts. Their design ensures even stitching, which is vital for maintaining product quality. B2B buyers should prioritize the machine’s ease of use and maintenance requirements, as these factors can influence operational efficiency and the learning curve for staff.

How Do Strap Cutting Machines Streamline Production?

Strap cutting machines are designed to cut leather into specific widths quickly and accurately, significantly enhancing production speed in belt and strap manufacturing. These machines often come with programmable features that allow for precise cuts tailored to specific product requirements. Buyers should evaluate the machine’s cutting speed and versatility, as these aspects directly impact production timelines and operational flexibility.

Key Industrial Applications of leather machine company

| Industry/Sector | Specific Application of leather machine company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Heavy-duty leather sewing machines for boot construction | Enhanced production efficiency and durability in footwear | Machine compatibility with various leather thicknesses |

| Automotive Upholstery | Specialized stitching machines for car interiors | Improved aesthetics and quality of automotive interiors | Need for precision and ability to handle diverse materials |

| Leather Goods & Accessories | Multi-purpose machines for bags, wallets, and belts | Versatility in product offerings and reduced lead times | Availability of spare parts and after-sales support |

| Tack & Equestrian Gear | Equipment for creating saddles and bridles | High-quality craftsmanship that meets industry standards | Compliance with safety regulations and material sourcing |

| Fashion & Apparel | Skiving and splitting machines for garment production | Cost-effective material usage and enhanced design flexibility | Training and support for machine operation |

How Are Leather Machine Companies Transforming Footwear Manufacturing?

In the footwear manufacturing sector, leather machine companies provide heavy-duty sewing machines that are essential for constructing boots and other leather footwear. These machines enable manufacturers to sew through thick materials, ensuring durability and longevity in their products. International buyers must consider the machine’s ability to handle various leather thicknesses and the availability of technical support to address any operational challenges.

Illustrative image related to leather machine company

What Role Do Leather Machines Play in Automotive Upholstery?

Leather machine companies supply specialized stitching machines tailored for automotive upholstery. These machines enhance the quality and aesthetics of car interiors, allowing for intricate designs and robust seams that can withstand wear and tear. Buyers in this sector should prioritize machines that offer precision stitching capabilities and compatibility with diverse upholstery materials to meet specific automotive standards.

How Do Leather Machines Support the Production of Leather Goods & Accessories?

In the leather goods and accessories industry, companies utilize multi-purpose machines for crafting items like bags, wallets, and belts. These machines streamline production processes, allowing businesses to offer a wider variety of products while reducing lead times. For international buyers, sourcing considerations should include the machine’s versatility and the availability of after-sales support to ensure consistent production quality.

Why Are Tack & Equestrian Gear Manufacturers Investing in Leather Machines?

Tack and equestrian gear manufacturers rely on specialized equipment to produce high-quality saddles, bridles, and other riding gear. Leather machine companies provide tools that facilitate craftsmanship and ensure compliance with industry standards. Buyers should focus on sourcing machines that comply with safety regulations and can efficiently handle the specific materials used in tack production.

How Are Skiving and Splitting Machines Enhancing Fashion & Apparel Production?

In the fashion and apparel sector, leather machine companies offer skiving and splitting machines that are crucial for optimizing material use and enhancing design flexibility. These machines allow for the precise thinning of leather, which is essential for creating stylish yet functional garments. Buyers should consider the training and support available for machine operation to maximize their investment and ensure efficient production workflows.

3 Common User Pain Points for ‘leather machine company’ & Their Solutions

Scenario 1: Navigating Complex Specifications for Leather Machinery

The Problem: Many B2B buyers from sectors such as fashion, upholstery, and leather goods manufacturing often find themselves overwhelmed by the technical specifications of various leather machines. This complexity can lead to purchasing machines that do not meet their specific needs, resulting in operational inefficiencies and wasted investment. For example, a buyer may require a sewing machine that can handle both thick and thin leather but ends up with a model that is only suited for one type, leading to production delays and additional costs.

The Solution: To effectively navigate the intricate specifications of leather machinery, buyers should start by clearly defining their production needs, including the types of leather they work with and the volume of production. Engaging with leather machine companies through detailed consultations can provide insights into the best machinery for their specific applications. Buyers should request product demonstrations, if possible, to evaluate how well a machine handles their particular materials. Additionally, leveraging online resources, such as machine comparison charts and user reviews, can help buyers make informed decisions.

Scenario 2: Overcoming Limited After-Sales Support

The Problem: A common pain point among B2B buyers is the lack of reliable after-sales support after purchasing leather machinery. Buyers often report difficulties in obtaining timely maintenance, spare parts, or technical assistance, which can severely disrupt their production lines. For instance, a company in South America might face a critical breakdown in their sewing machine but find it challenging to get prompt support due to geographical constraints.

The Solution: To mitigate this issue, buyers should prioritize sourcing leather machines from companies that offer robust after-sales support and warranty services. Before making a purchase, inquire about the availability of local service centers or authorized technicians. It’s advisable to establish a service agreement that includes regular maintenance checks and emergency support. Buyers can also join online forums or community groups related to leather machinery, where they can share experiences and solutions for common issues. This proactive approach will ensure that they have a support network ready to address any potential challenges.

Scenario 3: Managing High Operational Costs

The Problem: Operating leather machinery can come with significant costs, including electricity consumption, maintenance, and the price of consumables like thread and needles. For manufacturers operating in regions with fluctuating electricity prices or expensive maintenance services, these costs can quickly escalate, affecting profit margins. A leather goods manufacturer in Europe, for example, may find that their stitching machines consume more energy than anticipated, leading to unplanned expenses.

Illustrative image related to leather machine company

The Solution: To manage operational costs effectively, buyers should consider investing in energy-efficient machinery that offers lower power consumption without compromising performance. Before purchasing, request information on the energy ratings of the machines and compare the long-term operational costs, not just the initial purchase price. Additionally, establishing relationships with suppliers for bulk purchasing of consumables can lead to significant savings. Buyers should also keep track of maintenance schedules and invest in training for their operators to ensure that machines are used optimally, reducing wear and tear. By taking these steps, buyers can streamline their operational expenses and enhance their overall profitability.

Strategic Material Selection Guide for leather machine company

What Are the Key Materials Used in Leather Machinery Manufacturing?

When selecting materials for leather machinery, several key factors influence performance and suitability. Here, we analyze four common materials—aluminum, steel, plastic composites, and rubber—focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Aluminum Perform in Leather Machinery?

Aluminum is a lightweight metal known for its excellent corrosion resistance and good thermal conductivity. Its low density makes it ideal for portable machinery, while its strength-to-weight ratio allows for durable designs. However, aluminum can be more expensive than other metals, and its lower tensile strength compared to steel may limit its use in high-stress applications.

For international buyers, particularly in regions like Africa and South America, aluminum’s lightweight nature can reduce shipping costs, but compliance with local regulations regarding metal quality and recycling may need consideration.

Illustrative image related to leather machine company

What Are the Benefits of Using Steel in Leather Machinery?

Steel is a robust material that offers high tensile strength and durability, making it suitable for heavy-duty applications in leather machinery. It can withstand high temperatures and pressures, which is essential for machines that operate under demanding conditions. The main downside is that steel is heavier, which can increase shipping costs and complicate machinery design.

For B2B buyers in Europe and the Middle East, steel’s compliance with standards like ASTM and DIN is a significant advantage, as it ensures quality and reliability. However, buyers should be aware of potential corrosion issues unless protective coatings are applied.

Why Choose Plastic Composites for Leather Machinery?

Plastic composites provide a balance between strength and weight, making them suitable for various components in leather machines. They offer excellent resistance to chemicals and moisture, which can be beneficial in leather processing environments. However, their durability may not match that of metals, and they can be more expensive to manufacture.

International buyers should consider the specific applications of plastic composites, as they may need to meet different standards depending on the region. For example, compliance with JIS standards in Japan or other local regulations may be necessary.

How Does Rubber Contribute to Leather Machinery Performance?

Rubber is often used for seals, gaskets, and various cushioning applications in leather machinery. It provides excellent flexibility and shock absorption, which can enhance machine performance and reduce wear. However, rubber can degrade over time when exposed to certain chemicals or extreme temperatures.

Illustrative image related to leather machine company

For buyers in regions like Africa and South America, the availability of high-quality rubber products can vary, and understanding local sourcing options is crucial. Additionally, ensuring that rubber components meet international quality standards can prevent operational issues.

Summary Table of Material Properties for Leather Machinery

| Material | Typical Use Case for leather machine company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight machine frames | Excellent corrosion resistance | Lower tensile strength than steel | Medium |

| Steel | Heavy-duty sewing machines | High durability and tensile strength | Heavier, increasing shipping costs | High |

| Plastic Composites | Components like housings and covers | Good chemical resistance | Less durable than metals | Medium |

| Rubber | Seals and cushioning | Excellent flexibility and shock absorption | Can degrade under certain conditions | Low |

This guide should provide international B2B buyers with valuable insights into material selection for leather machinery, helping them make informed decisions that align with their operational needs and local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather machine company

What Are the Key Stages in the Manufacturing Process for Leather Machines?

The manufacturing process of leather machines involves several critical stages that ensure the final product meets the high standards required in the leatherworking industry.

Material Preparation

Material preparation is the foundational stage in the manufacturing of leather machines. This involves sourcing high-quality raw materials, such as steel, aluminum, and specialized components like needles and gears. Suppliers often conduct rigorous inspections to verify material quality, ensuring compliance with international standards. The selection of materials is crucial, as they directly affect the durability and performance of the machines.

Forming Techniques

Once materials are prepared, the forming process begins. This includes cutting, bending, and machining components to precise specifications. Advanced techniques such as CNC (Computer Numerical Control) machining are commonly employed to achieve high accuracy. For instance, CNC machines can produce intricate parts with minimal human intervention, thereby reducing the chances of error. Other methods, such as stamping and forging, may also be utilized for more robust components, ensuring that the machines can withstand the rigors of leatherwork.

Assembly Process

After forming, the assembly stage takes place. Skilled technicians meticulously assemble the various components, adhering to strict guidelines to ensure quality and functionality. This stage often involves multiple sub-assemblies, where smaller groups of components are put together before final assembly. Quality control checks during this phase are vital; any misalignment or defect can compromise the machine’s performance.

Finishing Touches

The finishing stage includes painting, coating, and polishing the machines to enhance both aesthetics and protection against wear. This is also the point where final adjustments are made to ensure that all moving parts operate smoothly. Additionally, final inspections are conducted to verify that the machines meet design specifications and customer requirements before they are packaged for shipment.

How Is Quality Assurance Implemented in Leather Machine Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for leather machines, ensuring that each unit produced meets the highest standards of performance and reliability.

What Are the Relevant International Standards for Quality Assurance?

Many leather machine manufacturers adhere to international quality standards such as ISO 9001, which outlines the requirements for an effective quality management system. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specialized applications may also apply, depending on the machine’s intended use.

What QC Checkpoints Are Commonly Used in Manufacturing?

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): Conducts checks during the manufacturing process to identify defects early, reducing waste and rework.

-

Final Quality Control (FQC): A thorough inspection of the completed machines before they leave the factory. This includes functionality tests and performance evaluations.

What Testing Methods Are Commonly Used in Leather Machine Manufacturing?

Testing methods are essential for verifying the quality and performance of leather machines. Common methods include:

-

Functional Testing: Machines are run under various conditions to ensure they perform as expected, including speed, precision, and durability tests.

-

Material Testing: Components may undergo tensile, fatigue, and corrosion tests to evaluate their resilience and longevity.

-

Safety Testing: Ensures that machines comply with safety standards, protecting both operators and end-users.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are effective strategies:

Conducting Audits

Buyers should perform regular audits of potential suppliers, which can include on-site inspections of manufacturing facilities. This provides insight into the production processes, quality control measures, and overall operational standards.

Reviewing Quality Reports

Requesting and reviewing quality reports from suppliers can give buyers a clearer picture of their performance over time. These reports should detail any defects, corrective actions taken, and compliance with international standards.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. These inspectors can verify compliance with both international and industry-specific standards.

What Are the Quality Control Nuances for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the quality control nuances is essential.

-

Cultural and Regulatory Differences: Different regions may have varying quality standards and regulatory requirements. Buyers should familiarize themselves with local regulations to ensure compliance.

-

Supply Chain Dynamics: The complexity of global supply chains can introduce additional risks. Buyers should consider the logistics involved in shipping and the potential for delays or damage during transit.

-

Communication Barriers: Language and cultural differences can hinder effective communication. Establishing clear lines of communication and setting expectations upfront can mitigate misunderstandings.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting leather machine suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather machine company’

This guide aims to provide B2B buyers with a clear, actionable checklist for sourcing leather machinery from reputable suppliers. Whether you’re a manufacturer in Africa, a designer in South America, or a retailer in Europe, understanding the nuances of procurement in this specialized market is essential for ensuring quality and reliability.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the types of leather you will be working with, the range of thicknesses, and the specific tasks you need the machinery to perform (e.g., stitching, skiving, or splitting). Having a detailed specification will help streamline communications and ensure that you select a machine that meets your operational needs.

- Consider the volume of production: Estimate how much leather you will process to choose a machine that can handle your production scale.

- Identify essential features: Determine which features are non-negotiable versus those that are nice to have.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the leather machinery market. Look for companies that specialize in leather equipment and have a solid track record.

- Check online reviews and testimonials: Platforms like industry forums and social media can provide insights into customer experiences.

- Evaluate their product range: A supplier offering a diverse range of machinery may be better equipped to meet your needs.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers adhere to international quality and safety standards. This is crucial for ensuring the machinery’s reliability and longevity.

- Request certifications: Ask for ISO certifications or compliance with local regulations to guarantee quality.

- Verify warranty terms: Understand the warranty offered and what it covers, as this can indicate the manufacturer’s confidence in their product.

Step 4: Assess Customer Service and Technical Support

Reliable customer service is vital for ongoing support after the purchase. Assess the level of technical assistance you can expect from the supplier.

- Inquire about training and resources: Check if they provide training for your staff or access to online resources for troubleshooting.

- Evaluate response times: Quick response times for service inquiries can be crucial during downtimes.

Step 5: Request Quotes and Compare Pricing

Once you have narrowed down your options, request detailed quotes from multiple suppliers. Comparing prices will help you gauge market rates and identify the best value for your investment.

- Look for transparency in pricing: Ensure that quotes include all potential costs such as shipping, taxes, and installation fees.

- Consider financing options: Some suppliers may offer financing plans that can ease the financial burden of a large purchase.

Step 6: Conduct Site Visits or Virtual Tours

If possible, visit the supplier’s facility or request a virtual tour. This step allows you to see the machinery in action and assess the manufacturing quality firsthand.

- Observe the production process: This can provide insights into the supplier’s operational capabilities.

- Meet the team: Interacting with their technical staff can clarify their expertise and responsiveness.

Step 7: Finalize the Purchase Agreement

Once you’ve made your decision, carefully review the purchase agreement before signing. Ensure that all terms discussed are included, particularly regarding delivery timelines and warranty conditions.

Illustrative image related to leather machine company

- Negotiate terms if necessary: Don’t hesitate to negotiate pricing or additional services based on your research and comparisons.

- Clarify after-sales support: Ensure the agreement outlines how support will be provided post-purchase.

Following this checklist will help you make informed decisions when sourcing leather machinery, ultimately enhancing your operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for leather machine company Sourcing

What Are the Key Cost Components in Leather Machine Manufacturing?

Understanding the cost structure of leather machines is vital for B2B buyers aiming to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts costs. High-quality leather and durable components typically lead to higher upfront costs but can enhance the machine’s lifespan and performance.

-

Labor: Labor costs can vary greatly based on the region. Countries with lower labor costs may offer competitive pricing, but this can come at the expense of quality. Skilled labor is essential for assembly and maintenance, especially for complex machinery.

-

Manufacturing Overhead: This encompasses all indirect costs, including utilities, rent, and administrative expenses. Efficient production processes can help reduce overhead and lower the overall price.

-

Tooling: This refers to the equipment and tools necessary for production. Initial investment in high-quality tooling can reduce long-term costs by improving efficiency and reducing waste.

-

Quality Control: Implementing rigorous QC processes may increase costs but is crucial for ensuring product reliability and minimizing returns or repairs.

-

Logistics: Shipping and handling costs can vary based on destination, mode of transport, and volume. International buyers should consider these factors, as they can significantly affect the final price.

-

Margin: Finally, manufacturers typically include a profit margin in their pricing. Understanding the typical margins in the leather machine industry can help buyers negotiate better deals.

How Do Price Influencers Impact Leather Machine Costs?

Several factors influence the pricing of leather machines, including order volume, specifications, materials, and quality certifications.

Illustrative image related to leather machine company

-

Volume/MOQ: Bulk purchases often lead to discounts. Buyers should inquire about minimum order quantities (MOQ) and explore opportunities for bulk pricing, especially when sourcing for larger operations.

-

Specifications and Customization: Customized machines tailored to specific needs may incur higher costs due to additional design and manufacturing processes. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials and Quality Certifications: Machines built with premium materials or those that meet specific quality certifications may have higher price tags. However, investing in certified equipment can lead to long-term savings through enhanced durability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers with a history of quality and service may charge a premium, but the assurance of support and reliability can justify the cost.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Different terms can affect pricing by altering the responsibilities of buyers and sellers regarding shipping, insurance, and duties.

What Negotiation Tips Can Help B2B Buyers Secure Better Prices?

When negotiating prices for leather machines, consider the following strategies:

-

Research Market Prices: Gather data on average pricing for similar machines to establish a baseline for negotiations.

-

Highlight Long-Term Partnerships: Emphasize the potential for ongoing business, which can incentivize suppliers to offer better pricing or terms.

-

Explore Financing Options: Many suppliers offer financing plans. Understanding these options can help buyers manage cash flow while acquiring necessary equipment.

-

Assess Total Cost of Ownership: Evaluate the total cost, including maintenance, spare parts, and operational costs, rather than focusing solely on initial price. This holistic view can lead to better purchasing decisions.

-

Be Aware of Pricing Nuances: For international buyers, currency fluctuations, tariffs, and taxes can impact the final price. Staying informed about these factors can enhance negotiation outcomes.

In summary, understanding the cost structure, price influencers, and negotiation strategies can empower B2B buyers to make informed decisions when sourcing leather machines. By considering these aspects, companies can optimize their procurement processes and ensure they are getting value for their investment.

Alternatives Analysis: Comparing leather machine company With Other Solutions

In the competitive landscape of leather machinery, buyers often face the challenge of selecting the most effective solution for their specific needs. Understanding the various alternatives available in the market can significantly influence purchasing decisions. This analysis compares Leather Machine Company’s offerings with two prominent alternatives: Tandy Leather’s TandyPro Machines and American Leatherworks’ COBRA series.

Comparison Table

| Comparison Aspect | Leather Machine Company | Tandy Leather TandyPro Machines | American Leatherworks COBRA Series |

|---|---|---|---|

| Performance | High-performance heavy-duty machines | Moderate performance, versatile | High-performance, specialized |

| Cost | Mid to high range ($2,362.50 – $4,357.50) | Mid range ($1,575 – $3,640) | Mid to high range ($1,496.50 – $6,772.50) |

| Ease of Implementation | Straightforward, well-supported | User-friendly, good training options | Requires some technical knowledge |

| Maintenance | Limited lifetime warranty, easy service | Good support, but parts may be harder to find | Strong customer service, parts readily available |

| Best Use Case | Professional leatherwork, heavy-duty applications | Hobbyist to semi-professional use | Professional leatherwork, custom applications |

Detailed Breakdown of Alternatives

What are the advantages and disadvantages of Tandy Leather’s TandyPro Machines?

TandyPro Machines are designed for a broad range of leatherworking tasks, making them suitable for hobbyists and semi-professionals. They are generally more affordable than some of the heavy-duty options, which can be appealing for businesses operating on a budget. However, while they offer versatility, their performance may not match the heavy-duty capabilities of Leather Machine Company’s machines. Additionally, while Tandy provides good customer support, sourcing specific parts can sometimes be a challenge, potentially leading to longer downtime.

Illustrative image related to leather machine company

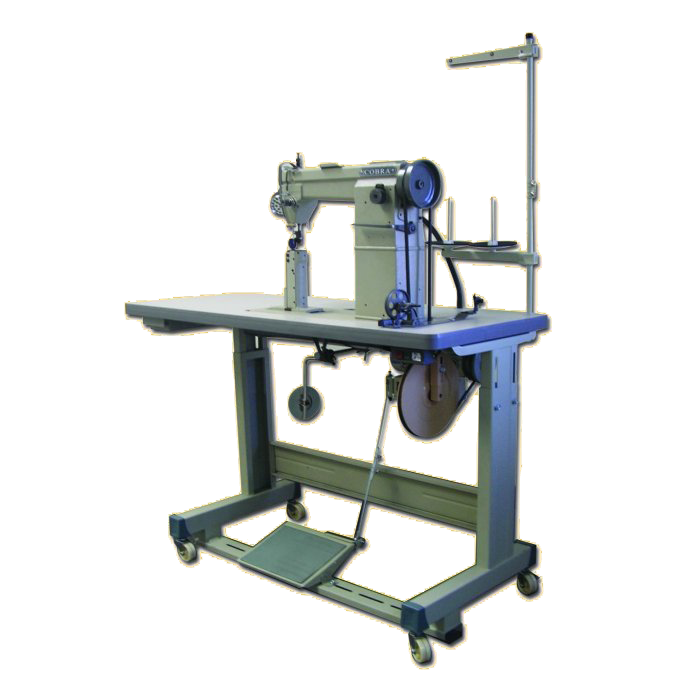

How does American Leatherworks’ COBRA Series compare?

The COBRA series is renowned for its high-performance capabilities, particularly in specialized applications such as heavy-duty leather stitching and skiving. These machines offer advanced features that appeal to professional leatherworkers. While the initial investment may be higher, the durability and efficiency can lead to better long-term value. However, these machines may require a steeper learning curve, as they are built for users with some technical knowledge. Fortunately, American Leatherworks is known for its exceptional customer service, ensuring that users can get the support they need.

Conclusion: How can B2B buyers choose the right leather machine solution?

When selecting the right leather machine, B2B buyers should carefully assess their specific needs, including the volume of production, types of leather work, and budget constraints. Leather Machine Company is an excellent choice for those requiring robust, high-performance machines for professional applications. In contrast, TandyPro Machines may be more suited for entry-level users or those on a tighter budget, while the COBRA series caters to professionals seeking advanced capabilities. Ultimately, the decision should align with the operational goals and skill levels of the users to ensure optimal productivity and satisfaction.

Essential Technical Properties and Trade Terminology for leather machine company

What Are the Essential Technical Properties for Leather Machinery?

Understanding the technical specifications of leather machinery is crucial for making informed purchasing decisions. Here are some key properties to consider:

1. Material Grade

The quality of materials used in manufacturing leather machines directly affects their durability and performance. Higher-grade materials, such as stainless steel or aerospace-grade aluminum, enhance longevity and resistance to wear and tear. For buyers, investing in machines made from superior materials means lower maintenance costs and longer machine life, ensuring better ROI.

2. Stitching Capacity

This specification indicates the thickness and type of leather the machine can handle. For example, machines like the COBRA Class 4 can sew leather up to 7/8″ thick, making them suitable for heavy-duty applications such as tack and upholstery. Understanding stitching capacity helps buyers select machines that can meet their specific production needs, ensuring efficiency and quality in their manufacturing processes.

3. Speed and Power

The speed of a sewing machine, usually measured in stitches per minute (SPM), affects productivity. More powerful machines can handle tougher materials and maintain consistent performance at high speeds. Buyers should assess their production volume requirements and choose machines that can keep up without compromising quality.

4. Precision and Tolerance

Tolerance refers to the allowable deviation from a specified measurement in the manufacturing process. High precision and low tolerance are essential for producing quality leather goods, especially in industries like fashion and automotive. Machines that offer precise stitching capabilities enable manufacturers to maintain high standards, minimizing waste and enhancing product quality.

5. User-Friendly Features

Modern leather machines often come equipped with user-friendly features such as adjustable presser feet, automated threading, and digital displays. These innovations simplify operation and reduce the learning curve for new operators. For B2B buyers, machines with these features can translate to less downtime and a more skilled workforce, ultimately improving productivity.

What Are Common Trade Terms in the Leather Machinery Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather machinery sector, buyers often seek OEM products for reliability and compatibility with existing equipment. Understanding OEM relationships can help buyers evaluate the quality and support they can expect.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For leather machinery, understanding MOQ is crucial for budgeting and inventory management. Buyers must negotiate MOQs that align with their production needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process by allowing them to compare offers and select the best value.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and the point at which ownership transfers, ensuring clarity and reducing disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is received. In the leather machinery industry, understanding lead times is vital for planning production schedules and meeting customer demands. Buyers should always inquire about lead times to avoid disruptions in their supply chain.

By grasping these technical specifications and industry terms, B2B buyers can make more informed decisions, ensuring they invest in leather machinery that meets their operational needs and aligns with their business goals.

Navigating Market Dynamics and Sourcing Trends in the leather machine company Sector

What Are the Key Market Dynamics and Trends in the Leather Machine Sector?

The leather machine sector is experiencing a dynamic transformation fueled by globalization, technological advancements, and changing consumer preferences. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly seeking robust and efficient machinery capable of producing high-quality leather products. Key trends include a rise in automation and smart technologies, which enhance operational efficiency and reduce labor costs. The integration of IoT (Internet of Things) in machinery allows for real-time monitoring and predictive maintenance, enabling businesses to minimize downtime and optimize performance.

Additionally, the demand for versatile machines that can handle a variety of leather types and thicknesses is growing. Companies are investing in multi-functional equipment that can perform tasks ranging from sewing to splitting and skiving. This trend is particularly evident in regions like Germany and Vietnam, where manufacturers prioritize efficiency and adaptability in their production processes. Furthermore, the rise of e-commerce platforms is reshaping sourcing strategies, allowing buyers to access a wider array of suppliers and products globally, fostering competitive pricing and better quality.

How Is Sustainability Shaping the Leather Machine Industry?

Sustainability is becoming a critical consideration for B2B buyers in the leather machine sector. The environmental impact of leather production, including water consumption, chemical usage, and waste generation, has prompted a shift towards more sustainable practices. Companies are increasingly prioritizing ethical sourcing and the use of environmentally friendly materials. Buyers are urged to evaluate suppliers based on their commitment to sustainable practices, such as using organic or vegetable-tanned leather and ensuring minimal environmental impact throughout the production process.

Moreover, certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction among manufacturers and buyers alike. These certifications not only assure quality but also demonstrate a commitment to sustainable and ethical practices. For B2B buyers, partnering with suppliers who prioritize sustainability can enhance brand reputation and meet the growing consumer demand for ethically produced goods, especially in markets that value corporate social responsibility.

What Historical Developments Have Influenced the Leather Machine Sector?

The leather machine sector has evolved significantly over the past century. Initially dominated by manual processes, the industry began to adopt mechanization in the late 19th and early 20th centuries, which greatly increased production efficiency. The introduction of electric-powered machines in the mid-20th century revolutionized manufacturing, allowing for more precise and faster operations.

In recent decades, advancements in computer technology have led to the integration of CNC (Computer Numerical Control) systems in leather machinery. This evolution has enabled manufacturers to produce intricate designs with high precision and minimal waste. As the industry continues to innovate, the focus is now shifting towards automation and digitalization, aligning with global trends in manufacturing and addressing the demands of modern consumers. This historical context is crucial for B2B buyers to understand the trajectory of the industry and the importance of investing in advanced machinery that meets current and future market demands.

Illustrative image related to leather machine company

Frequently Asked Questions (FAQs) for B2B Buyers of leather machine company

-

How do I choose the right leather sewing machine for my business needs?

Selecting the right leather sewing machine depends on the type of leather goods you produce and the thickness of the materials involved. Consider machines that accommodate a range of thread sizes and have features suited for your specific applications, such as walking foot capabilities for thicker materials. It’s also essential to evaluate the machine’s speed, durability, and ease of use. Researching models that offer customization options can help ensure you find a machine that meets your unique production requirements. -

What are the key features to look for in a leather machine?

When evaluating leather machines, focus on features such as stitch quality, motor power, and the ability to handle various leather thicknesses. Look for machines equipped with adjustable presser feet, walking foot mechanisms, and specialized attachments for different tasks. Additionally, consider the availability of replacement parts and customer support, as these factors can significantly impact the long-term usability of the equipment. -

What are the payment terms typically offered by leather machine suppliers?

Payment terms can vary widely among suppliers, but many offer flexible options such as upfront payment, installment plans, or financing solutions. It’s advisable to inquire about any discounts for bulk purchases or early payments. For international transactions, ensure that the payment methods are secure and consider using letters of credit or escrow services to mitigate risks. -

How can I assess the quality assurance processes of a leather machine supplier?

To assess a supplier’s quality assurance (QA) processes, request documentation outlining their QA protocols, certifications, and testing procedures. Look for suppliers that adhere to international standards, such as ISO certifications. Additionally, reading customer reviews and testimonials can provide insight into the reliability of their machines and after-sales support. -

What are the logistics considerations for importing leather machines internationally?

When importing leather machines, consider the shipping methods, costs, and timelines involved. Ensure that the supplier can provide freight shipping options and that you understand any import duties and taxes applicable in your country. It’s also beneficial to work with a logistics provider experienced in handling heavy machinery to facilitate smooth customs clearance and delivery. -

What is the minimum order quantity (MOQ) for leather machines?

Minimum order quantities (MOQs) can vary based on the supplier and the specific machine models. Some suppliers may have a flexible MOQ, especially for first-time buyers or smaller businesses. Always clarify the MOQ before placing an order and inquire about the potential for sample orders or trial periods to assess the machinery before committing to larger purchases. -

Can leather machines be customized for specific production needs?

Yes, many suppliers offer customization options for leather machines to meet specific production requirements. Custom features may include specialized attachments, alterations to machine size, or modifications to stitch patterns. Discuss your needs directly with the supplier to understand the available customization options and any associated costs or lead times. -

What is the warranty policy for leather machines, and how does it work?

Most reputable leather machine suppliers provide a warranty that covers defects in materials and workmanship. Warranty periods can vary, so it’s crucial to understand the terms, including what is covered and for how long. Additionally, inquire about the process for claiming warranty service, including any required documentation and the supplier’s support during the warranty period.

Top 5 Leather Machine Company Manufacturers & Suppliers List

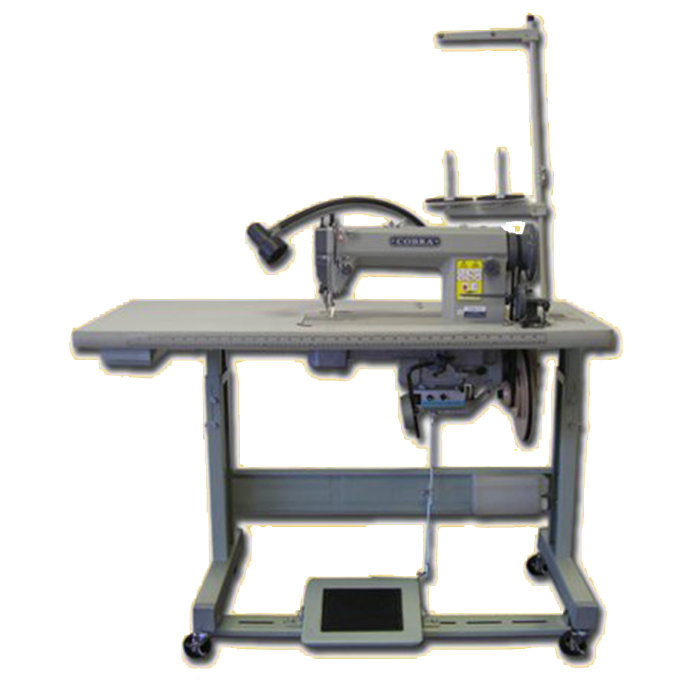

1. Cobra – Heavy Duty Stitchers

Domain: leathermachineco.com

Registered: 2009 (16 years)

Introduction: Cobra Class 4 P Heavy Duty Stitcher With EPS and Premium Package – $4,357.50; Cobra Class 4 Leather Sewing Machine with Premium Package – $3,922.00; Cobra Class 4 S Heavy Duty Stitcher With Standard Package – $3,397.00; Cobra Class 3 P Heavy Duty Stitcher With EPS And Premium Package – $3,875.00; Cobra NP10 Top and Bottom Feed Skiving Machine With Pedestal – $2,940.00; Cobra 5110 Post Machine – $2…

2. American Leatherworks – COBRA Class 26

Domain: americanleatherworks.com

Registered: 2009 (16 years)

Introduction: {“products”:[{“name”:”COBRA Class 26″,”price”:”$3,444.00″,”shipping”:”Free Shipping Bundle”},{“name”:”COBRA Class 4 ‘Dream Machine'”,”price”:”$3,460.00″,”discounted_price”:”$3,397.00″,”description”:”Sews from 6 oz. to 7/8″ leather for sewing skirting, all types of tack, bullet loops, chap leather and everything in between with ease.”},{“name”:”COBRA Class 26″,”price”:”$2,760.00″},{“name”:”COBRA MP…

3. Cobra – Class4 Leather Sewing Machine

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Cobra Class4 leather sewing machine; parts schematic with part numbers; diagram of tabletop with cutouts and holes; diagram of the stand; lifetime guarantee; exceptional customer service.

4. Tandy Leather – Sewing Machines and More

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Sewing Machines and More, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Weaver Leather Supply – Leather Machinery

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Leather machinery for all your leather working projects. Discover a full range of leather crafting and industrial equipment including skiving leather machine, leather strap cutter, leather cutting machine, leather stitching machine, leather embossing machine, hot foil stamping machine and more. Products include: Master Tool Cub Manual Leather Sewing Machine, Aluminum ($2,100.00), Weaver 303 Leathe…

Strategic Sourcing Conclusion and Outlook for leather machine company

In today’s competitive leather industry, strategic sourcing is not just an option—it’s a necessity. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must prioritize quality and reliability when selecting leather machinery suppliers. The COBRA series of machines exemplifies the advanced technology and durability required for diverse leather applications, from sewing to skiving. By leveraging suppliers that offer extensive warranties and exceptional customer service, businesses can mitigate risks and enhance their operational efficiency.

Furthermore, the availability of financing options and global shipping solutions allows companies to invest in high-quality equipment without overwhelming upfront costs. This flexibility is crucial for businesses looking to scale their operations in emerging markets.

As we look to the future, the leather machinery sector is poised for growth, driven by innovation and an increasing demand for sustainable practices. Buyers are encouraged to engage with reputable suppliers, explore the latest technologies, and seize opportunities that will elevate their production capabilities. Start your journey towards operational excellence today by evaluating your sourcing strategies and connecting with reliable partners in the leather machinery market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.