Introduction: Navigating the Global Market for leather apparel fabric

Navigating the global market for leather apparel fabric can be a daunting task for B2B buyers, particularly those seeking to source high-quality materials that balance durability, aesthetics, and ethical considerations. With a growing demand for stylish yet sustainable leather options, international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Saudi Arabia—must carefully evaluate their sourcing strategies. This guide aims to demystify the complexities of leather apparel fabric, offering insights into various types, applications, and the nuances of supplier vetting.

Within this comprehensive resource, we will explore the diverse range of leather materials available, from traditional animal hides to innovative synthetic alternatives that align with eco-friendly initiatives. Additionally, we will delve into the multiple applications of leather in apparel, footwear, and accessories, equipping buyers with the knowledge to make informed decisions. Understanding cost factors and quality indicators will empower businesses to negotiate better terms and ensure a sustainable supply chain.

By leveraging the insights provided in this guide, B2B buyers can confidently navigate the leather apparel fabric market, making choices that not only meet their business needs but also resonate with their customers’ preferences for quality and sustainability.

Table Of Contents

- Top 9 Leather Apparel Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather apparel fabric

- Understanding leather apparel fabric Types and Variations

- Key Industrial Applications of leather apparel fabric

- 3 Common User Pain Points for ‘leather apparel fabric’ & Their Solutions

- Strategic Material Selection Guide for leather apparel fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for leather apparel fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather apparel fabric’

- Comprehensive Cost and Pricing Analysis for leather apparel fabric Sourcing

- Alternatives Analysis: Comparing leather apparel fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for leather apparel fabric

- Navigating Market Dynamics and Sourcing Trends in the leather apparel fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather apparel fabric

- Strategic Sourcing Conclusion and Outlook for leather apparel fabric

- Important Disclaimer & Terms of Use

Understanding leather apparel fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather | Retains the natural grain and markings, very durable | High-end apparel, luxury goods | Pros: Extremely durable, develops a rich patina. Cons: Expensive, requires maintenance. |

| Top-Grain Leather | Sanded and refinished for a smoother surface | Fashion apparel, bags, wallets | Pros: Softer than full-grain, more affordable. Cons: Less durable than full-grain. |

| Suede | Soft, napped finish, derived from the underside of the hide | Casual wear, footwear, accessories | Pros: Luxurious feel, lightweight. Cons: Less water-resistant, can stain easily. |

| Faux Leather | Synthetic alternative, often more affordable | Budget-friendly apparel, fashion items | Pros: Vegan option, easy to clean. Cons: Less durable, may not have the same aesthetic appeal. |

| Bonded Leather | Made from leftover leather scraps and bonded together | Cost-effective options for various goods | Pros: Affordable, eco-friendly. Cons: Less durable, may not last as long as genuine leather. |

What Are the Characteristics of Full-Grain Leather and Its B2B Suitability?

Full-grain leather is renowned for its durability and natural aesthetic, showcasing the hide’s inherent imperfections and grain patterns. This type of leather is often used in high-end apparel and luxury goods due to its ability to develop a rich patina over time, adding character and uniqueness. B2B buyers should consider the long-term investment benefits, as full-grain leather products can last for decades with proper care. However, the initial cost is higher, and maintenance is required to preserve its appearance and longevity.

How Does Top-Grain Leather Compare to Other Leather Types in B2B Applications?

Top-grain leather is sanded and refinished to create a smoother surface, making it softer and more pliable than full-grain. It is commonly used in fashion apparel, bags, and wallets, appealing to a broader market due to its balance of quality and price. For B2B buyers, top-grain leather offers a desirable combination of luxury and affordability. However, it is essential to note that while it is more accessible than full-grain, it may not be as durable, potentially leading to shorter product lifespans.

Why Choose Suede for Casual Wear and Accessories in B2B Markets?

Suede, characterized by its soft, napped finish, is derived from the underside of animal hides, making it a popular choice for casual wear, footwear, and accessories. This leather type provides a luxurious feel and lightweight characteristics, appealing to consumers seeking comfort and style. For B2B buyers, the versatility of suede can enhance product offerings. However, it is crucial to consider its susceptibility to stains and water damage, necessitating protective treatments and careful marketing.

What Are the Benefits and Limitations of Faux Leather for Budget-Conscious Buyers?

Faux leather is a synthetic alternative to genuine leather, often used in budget-friendly apparel and fashion items. It offers an ethical choice for consumers and is easier to clean, making it attractive for mass-market applications. B2B buyers can benefit from its lower production costs and the growing demand for vegan products. However, faux leather may not match the durability and aesthetic appeal of genuine leather, which can affect consumer perception and brand positioning.

How Does Bonded Leather Serve as an Eco-Friendly Option for Businesses?

Bonded leather is created from leftover leather scraps that are bonded together, providing a cost-effective alternative for various products. This type of leather appeals to environmentally conscious buyers due to its sustainable production process. For B2B buyers, bonded leather offers an affordable option for a range of goods, from furniture to accessories. However, its durability is less than that of genuine leather, which may limit its application in high-wear environments.

Key Industrial Applications of leather apparel fabric

| Industry/Sector | Specific Application of leather apparel fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | High-end jackets and coats | Enhances brand prestige and customer appeal | Quality of leather, sourcing transparency, and pricing |

| Automotive | Upholstery for luxury vehicles | Increases vehicle value and customer satisfaction | Durability, color options, and compatibility with models |

| Footwear | Production of durable shoes | Long-lasting products that reduce return rates | Comfort, breathability, and sourcing ethical materials |

| Sports Equipment | Manufacturing of protective gear | Enhances safety and performance for athletes | Compliance with safety standards and material durability |

| Home Decor | Upholstery for furniture | Adds aesthetic value and longevity to products | Style, texture variety, and maintenance requirements |

How is leather apparel fabric utilized in the fashion and apparel industry?

In the fashion sector, leather apparel fabric is primarily used to create high-end jackets, coats, and other stylish garments. This material not only provides a luxurious appearance but also ensures durability, making it an attractive option for discerning consumers. Buyers in this industry must consider the quality of leather, including its texture and finish, as well as the ethical sourcing of materials, especially in regions like Europe where sustainability is increasingly prioritized.

What role does leather play in automotive upholstery?

In the automotive industry, leather apparel fabric is extensively utilized for upholstery in luxury vehicles. It enhances the aesthetic appeal and adds a touch of sophistication, ultimately increasing the vehicle’s resale value. For international buyers, particularly from regions like the Middle East and South America, sourcing durable and easy-to-maintain leather is crucial. Additionally, color options and compatibility with various vehicle models should be taken into account to meet diverse consumer preferences.

How is leather used in the footwear industry?

Leather apparel fabric is a staple in the footwear industry, where it is used to produce high-quality, durable shoes. The natural properties of leather provide comfort and breathability, making it a preferred choice for both casual and formal footwear. Buyers must focus on sourcing leather that meets specific comfort and durability standards, as well as ethical considerations, particularly in markets like Africa where sustainable practices are gaining traction.

What applications does leather have in sports equipment?

In the realm of sports equipment, leather apparel fabric is often used for manufacturing protective gear, such as gloves and pads. The material’s durability and ability to withstand wear and tear are essential for ensuring athlete safety and performance. B2B buyers in this sector should prioritize compliance with safety standards and seek materials that offer both comfort and longevity, particularly in competitive markets across Europe and South America.

Illustrative image related to leather apparel fabric

How does leather enhance home decor?

Leather apparel fabric is increasingly being used in home decor, particularly for upholstery in furniture. This application not only adds aesthetic value but also ensures that pieces last longer, reducing the need for frequent replacements. Buyers should consider the variety of styles and textures available, as well as maintenance requirements, to cater to the diverse tastes of consumers in markets across Africa and the Middle East.

3 Common User Pain Points for ‘leather apparel fabric’ & Their Solutions

Scenario 1: Sourcing Quality Leather Apparel Fabric for Diverse Markets

The Problem: B2B buyers often face difficulties in sourcing high-quality leather apparel fabric that meets the specific demands of various international markets. For instance, a buyer in Nigeria may require fabric that is both durable and suitable for the hot climate, while a buyer in Europe may prioritize eco-friendly materials. Additionally, variations in tanning processes and quality standards can lead to inconsistent products, making it challenging for buyers to ensure they are offering the best to their customers.

The Solution: To address these sourcing challenges, B2B buyers should establish partnerships with reputable suppliers that provide transparency about their manufacturing processes and materials. It’s crucial to request samples and detailed specifications before making bulk purchases. Buyers should also consider engaging in direct communication with suppliers to clarify the fabric’s characteristics, such as its breathability, water resistance, and environmental impact. Additionally, leveraging platforms that specialize in leather products can help in finding suppliers who adhere to international quality standards and certifications, ensuring that the fabric is suitable for their target market.

Illustrative image related to leather apparel fabric

Scenario 2: Managing Cost and Waste in Leather Fabric Production

The Problem: Another common issue for B2B buyers is managing costs and minimizing waste during the production of leather apparel. Leather is a premium material, and any miscalculations in pattern cutting can lead to significant material loss, impacting overall profitability. Moreover, the challenge of varying prices based on leather grades can make budgeting difficult, especially for small to medium-sized enterprises.

The Solution: Buyers can mitigate these challenges by investing in advanced cutting technologies, such as laser cutting or automated pattern-making software. These technologies help optimize the use of leather by minimizing waste during production. Additionally, buyers should negotiate with suppliers for bulk purchasing discounts or explore alternative grades of leather that maintain quality but are more cost-effective. Implementing a lean manufacturing approach can also help streamline production processes, reducing waste and ultimately lowering costs.

Scenario 3: Ensuring Compliance with Environmental Regulations

The Problem: Compliance with environmental regulations regarding leather production and treatment can be a significant pain point for B2B buyers, especially in regions like Europe where standards are stringent. Buyers may struggle to find leather apparel fabric that meets these regulations, risking fines and damage to their brand reputation if they fail to comply.

The Solution: To navigate this regulatory landscape, buyers should prioritize sourcing from suppliers who are certified in environmental management systems, such as ISO 14001. It is essential to conduct due diligence on suppliers, ensuring they utilize sustainable practices, such as vegetable tanning or other eco-friendly treatments. Buyers can also consider collaborating with organizations that specialize in sustainable textiles to stay updated on compliance requirements. Regular audits of the supply chain can further ensure that all materials meet the necessary environmental standards, thereby protecting the buyer’s business from potential legal issues and enhancing their brand’s commitment to sustainability.

Strategic Material Selection Guide for leather apparel fabric

What Are the Key Properties of Different Types of Leather Apparel Fabrics?

When selecting leather apparel fabrics for B2B applications, understanding the specific properties of various materials is crucial. Here, we analyze four common types of leather fabrics: genuine leather, synthetic leather (PU), suede, and nubuck. Each material has unique characteristics that influence its performance, durability, and suitability for different applications.

Illustrative image related to leather apparel fabric

What Are the Key Properties of Genuine Leather?

Genuine leather is derived from animal hides and is known for its durability and natural aesthetic. It typically offers excellent temperature regulation and breathability, making it suitable for various climates. Genuine leather can withstand significant wear and tear, making it ideal for high-quality apparel like jackets and shoes.

Pros:

– Highly durable and long-lasting.

– Natural look and feel, appealing to premium markets.

– Can be treated for water resistance.

Cons:

– Higher cost compared to synthetic options.

– Requires regular maintenance to retain its appearance.

– Environmental concerns related to sourcing and tanning processes.

For international buyers, particularly in regions like Africa and the Middle East, compliance with ethical sourcing standards is essential. Buyers should be aware of regulations regarding animal welfare and environmental impact.

How Does Synthetic Leather (PU) Compare?

Synthetic leather, often made from polyurethane (PU), offers a cost-effective alternative to genuine leather. It mimics the appearance of leather while providing a lightweight and water-resistant option. PU leather is easy to clean and maintain, making it suitable for mass-produced apparel.

Illustrative image related to leather apparel fabric

Pros:

– Lower cost and easier to produce.

– Available in a wide range of colors and finishes.

– No animal products, appealing to vegan markets.

Cons:

– Generally less durable than genuine leather.

– May not provide the same level of breathability.

– Environmental concerns regarding plastic production and disposal.

International buyers should consider local preferences for sustainability. In regions like Europe, there is a growing demand for eco-friendly materials, which may influence the choice of synthetic leather.

Illustrative image related to leather apparel fabric

What Are the Unique Characteristics of Suede?

Suede is a type of leather with a napped finish, giving it a soft texture. It is often used for fashion apparel, such as jackets and skirts, due to its luxurious feel. However, suede is less durable than other leather types and is more susceptible to stains and moisture.

Pros:

– Soft and luxurious appearance.

– Lightweight and comfortable for wear.

– Can be dyed easily for color variety.

Cons:

– Requires special care to maintain its appearance.

– Less durable and more prone to damage from water.

– Higher cost compared to synthetic options.

For B2B buyers, understanding the care requirements for suede is crucial, especially in humid climates like those in parts of Africa and South America, where moisture can significantly impact the fabric’s lifespan.

Illustrative image related to leather apparel fabric

What Are the Characteristics of Nubuck Leather?

Nubuck is similar to suede but is made from the outer side of the hide, resulting in a more durable material. It has a velvety texture and is often used in high-end footwear and apparel. Nubuck can be treated for water resistance, enhancing its functionality.

Pros:

– Durable and resistant to wear.

– Luxurious texture that appeals to premium markets.

– Can be treated for water resistance.

Cons:

– Requires careful maintenance to prevent staining.

– Higher cost than standard leather.

– Limited availability compared to more common leather types.

International buyers should be aware of the specific care instructions for nubuck, especially in regions with varying climates, as improper care can lead to premature wear.

Illustrative image related to leather apparel fabric

Summary Table of Leather Apparel Fabrics

| Material | Typical Use Case for leather apparel fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end jackets, shoes, and accessories | Exceptional durability and aesthetics | Higher cost and maintenance needs | High |

| Synthetic Leather | Mass-produced apparel and accessories | Cost-effective and easy to maintain | Less durable and environmental concerns | Low |

| Suede | Fashion jackets, skirts, and footwear | Luxurious feel and lightweight | Requires special care and less durable | Medium |

| Nubuck | High-end footwear and apparel | Durable and luxurious texture | Care-intensive and higher cost | High |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding leather apparel fabrics, considering both performance and regional market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for leather apparel fabric

What Are the Key Stages in the Manufacturing Process of Leather Apparel Fabric?

The manufacturing process of leather apparel fabric is intricate, involving several critical stages that ensure the final product meets both aesthetic and functional requirements. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing and Tanning

The journey begins with the sourcing of raw materials, primarily animal hides or synthetic alternatives. For genuine leather, hides are typically sourced from cattle, sheep, or goats. In contrast, synthetic leather is made from materials such as polyurethane or polyvinyl chloride (PVC), catering to eco-conscious consumers.

Once the raw materials are sourced, they undergo tanning to preserve the hides and enhance durability. Tanning methods can vary significantly, with chrome tanning and vegetable tanning being the most common. Chrome tanning is faster and yields a softer leather, while vegetable tanning is more environmentally friendly, albeit slower. Each method results in distinct characteristics that may appeal to different markets.

How Is Leather Formed into Apparel Fabric?

The next stage involves forming the leather into usable fabric. This process includes cutting the tanned hides into specific shapes based on design specifications. Advanced cutting techniques, such as die-cutting and laser cutting, are often employed to ensure precision.

Illustrative image related to leather apparel fabric

Following cutting, the leather pieces are shaped and assembled. This may involve techniques such as stitching, bonding, or welding, depending on the intended application and design. For example, leather jackets may require intricate stitching patterns, while bags may be assembled using bonding techniques for a seamless finish.

What Quality Control Measures Are Essential for Leather Apparel Fabric?

Quality control (QC) is vital in ensuring that leather apparel fabric meets international standards and customer expectations. Several QC checkpoints are established throughout the manufacturing process, which include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with international standards such as ISO 9001, which outlines quality management system requirements. This certification demonstrates a company’s commitment to maintaining high-quality processes and continuous improvement. For leather products, additional certifications like CE marking (indicating compliance with health, safety, and environmental protection standards) and API specifications (for industrial applications) may also be relevant.

Illustrative image related to leather apparel fabric

How Are Quality Control Checkpoints Implemented?

-

Incoming Quality Control (IQC): This initial checkpoint occurs when raw materials arrive at the manufacturing facility. Here, suppliers should provide documentation confirming that the materials meet specified standards. IQC may involve visual inspections and physical testing of the leather for defects, such as holes or discoloration.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC is implemented to monitor adherence to production specifications. This may include checking dimensions, stitching quality, and color consistency. Regular audits during this phase help identify potential issues before they escalate.

-

Final Quality Control (FQC): Once the leather apparel is completed, FQC assesses the final product against quality standards. This includes thorough inspections for defects, functional tests (e.g., zippers, buttons), and aesthetic evaluations. Documentation of FQC results should be available for buyers to review.

What Common Testing Methods Are Used in Leather Quality Assurance?

Various testing methods are employed to ensure leather quality, including:

-

Physical Testing: This includes abrasion resistance tests, tensile strength tests, and flexibility tests, which measure the durability and wearability of the leather.

-

Chemical Testing: Evaluating the leather for harmful substances, such as heavy metals and formaldehyde, is crucial, especially for compliance with regulations in markets like Europe.

-

Water Resistance Testing: This assesses the leather’s ability to repel water, a critical feature for apparel exposed to moisture.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is essential to ensure product reliability. Here are several actionable steps:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes, quality control measures, and compliance with international standards. Consider scheduling both announced and unannounced audits to gauge consistency.

-

Request Quality Assurance Reports: Suppliers should provide detailed reports on their quality control procedures, including testing results, inspection records, and compliance certifications. Scrutinize these documents to verify adherence to standards.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of the supplier’s quality control. Third-party inspectors can conduct on-site evaluations and testing, offering peace of mind to buyers.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers should be aware of specific nuances that may affect quality control:

-

Regulatory Compliance: Different regions may have varying regulations regarding leather products, particularly concerning environmental impact and safety standards. Familiarize yourself with these regulations to ensure compliance.

-

Cultural Sensitivity: Understanding cultural expectations regarding leather products can influence quality perceptions. For example, buyers from different regions may have unique preferences for leather texture, color, and finish.

-

Supply Chain Transparency: Engage suppliers who are transparent about their sourcing and manufacturing processes. This transparency can enhance trust and facilitate smoother transactions.

Conclusion: Prioritizing Quality in Leather Apparel Fabric Manufacturing

In the competitive landscape of leather apparel fabric, ensuring high-quality products through robust manufacturing processes and stringent quality control measures is paramount for B2B buyers. By understanding the intricacies of manufacturing and actively engaging in the quality assurance process, buyers can secure reliable partnerships that meet their business needs and exceed customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather apparel fabric’

Introduction

Sourcing leather apparel fabric requires careful consideration and strategic planning to ensure quality and sustainability. This guide provides a step-by-step checklist designed for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Following these steps will help you navigate the complexities of sourcing, ensuring you make informed decisions.

1. Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the leather fabric meets your quality and usage requirements. Consider factors such as thickness, texture, finish, and durability. This clarity will help you communicate effectively with suppliers and streamline the sourcing process.

2. Research Supplier Options

Conduct thorough research to identify potential suppliers of leather apparel fabric. Look for manufacturers with a proven track record in your target market. Utilize online directories, trade shows, and industry networks to gather a list of reputable suppliers that align with your specifications.

Illustrative image related to leather apparel fabric

3. Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications to ensure compliance with industry standards. Look for certifications related to environmental practices, animal welfare, and quality control, such as ISO or Leather Working Group certifications. This step is crucial for maintaining ethical sourcing practices and ensuring product quality.

4. Request Samples for Quality Assessment

Always request samples before making bulk orders. Assess the quality of the leather fabric firsthand to ensure it meets your specifications regarding texture, finish, and durability. Additionally, consider testing the samples for specific performance criteria, such as water resistance or colorfastness.

5. Negotiate Terms and Pricing

Once you’ve narrowed down your supplier options, enter negotiations to establish favorable terms. Discuss pricing, payment terms, minimum order quantities, and delivery timelines. Clear communication during this phase can prevent misunderstandings and ensure a smooth transaction process.

6. Conduct a Factory Visit or Virtual Audit

If possible, visit the supplier’s manufacturing facility to assess their production capabilities and working conditions. If an in-person visit is not feasible, request a virtual tour or an audit report. This step will provide insights into the supplier’s operational practices and commitment to quality and sustainability.

Illustrative image related to leather apparel fabric

7. Finalize the Contract with Clear Terms

Before placing your order, ensure that all terms are clearly outlined in a formal contract. Include specifications, delivery schedules, payment terms, and any penalties for non-compliance. A well-defined contract protects both parties and lays the groundwork for a successful partnership.

By following this checklist, B2B buyers can navigate the sourcing process for leather apparel fabric with confidence, ensuring they select the best suppliers while maintaining quality and ethical standards.

Comprehensive Cost and Pricing Analysis for leather apparel fabric Sourcing

What Are the Key Cost Components for Leather Apparel Fabric Sourcing?

When sourcing leather apparel fabric, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The cost of raw materials is a significant factor. Natural leather, derived from animal hides, typically commands higher prices due to its quality and durability. Synthetic alternatives may offer cost savings but can vary widely in quality and performance.

-

Labor: Labor costs can fluctuate based on the complexity of the manufacturing process. Skilled artisans are often required for high-quality leather products, especially for custom designs. Regions with lower labor costs may provide competitive advantages but may also compromise on quality.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help lower overhead costs, influencing the final price.

-

Tooling: Initial tooling costs for molds and dies can be significant, especially for custom designs. These costs are often amortized over the production run, so larger orders can mitigate the impact on per-unit pricing.

-

Quality Control (QC): Rigorous QC processes ensure that the leather meets specified standards. While this adds to the cost, it is essential for maintaining product quality and reducing returns.

-

Logistics: Shipping and handling costs can vary based on distance, shipping methods, and import/export duties. International buyers must consider these costs when evaluating total expenses.

-

Margin: Suppliers typically add a markup to cover their costs and profit margins. This margin can vary based on market conditions, competition, and the perceived value of the leather.

How Do Price Influencers Affect Leather Apparel Fabric Costs?

Several factors can influence the pricing of leather apparel fabric, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers with substantial needs.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should assess whether the added expense aligns with their branding and market positioning.

-

Material Quality and Certifications: Higher-quality leather and certifications (e.g., sustainable sourcing, environmental impact) can significantly impact pricing. Buyers should weigh the benefits of premium materials against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role. Established suppliers may charge more due to their brand equity, while new entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can influence total costs. For instance, using Ex Works (EXW) may lower upfront costs but place the burden of logistics on the buyer, potentially increasing overall expenses.

What Are the Best Negotiation Tips for B2B Buyers in Leather Apparel Fabric Sourcing?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial price. TCO includes logistics, potential tariffs, and maintenance costs. A lower upfront price may result in higher long-term expenses.

-

Negotiate on Multiple Fronts: Instead of focusing solely on price, negotiate on payment terms, delivery schedules, and quality assurances. Flexible terms can lead to better overall deals.

-

Leverage Competitive Quotes: Gather quotes from multiple suppliers to create a competitive environment. This can empower buyers during negotiations and help secure better pricing.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service over time. Trust can often yield favorable terms that are not available in transactional relationships.

Why Are Pricing Nuances Important for International B2B Buyers?

International buyers must be cognizant of various pricing nuances that can affect their sourcing decisions:

-

Currency Fluctuations: Exchange rates can impact pricing, making it essential to negotiate in a stable currency when possible.

-

Import Duties and Tariffs: Understand the tariffs applicable to leather imports in your country. These additional costs can significantly alter the overall pricing structure.

-

Cultural Sensitivity in Negotiations: Different regions have varying approaches to business negotiations. Understanding these cultural nuances can enhance communication and lead to more fruitful negotiations.

Disclaimer on Indicative Prices

Please note that prices for leather apparel fabric can vary widely based on the factors discussed above. It is advisable to conduct thorough research and obtain multiple quotes to ensure competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing leather apparel fabric With Other Solutions

When evaluating the use of leather apparel fabric, it is essential for B2B buyers to consider alternative materials that can serve similar purposes in various applications. This analysis will help buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and the best use case for each material.

| Comparison Aspect | Leather Apparel Fabric | Faux Leather (Synthetic Leather) | Cotton Canvas |

|---|---|---|---|

| Performance | Durable, breathable, insulating | Less durable, may peel or crack over time | Highly breathable, but less durable than leather |

| Cost | Higher initial investment | Generally lower cost | Low-cost and widely available |

| Ease of Implementation | Requires specialized sewing techniques | Easy to work with and sew | Straightforward to sew, widely used |

| Maintenance | Requires conditioning and care | Easy to clean; wipeable surface | Machine washable, but may stain |

| Best Use Case | High-end apparel and accessories | Budget-friendly apparel and upholstery | Casual wear, bags, and outdoor gear |

What Are the Pros and Cons of Faux Leather as an Alternative?

Faux leather, also known as synthetic leather, is a popular alternative to traditional leather. It is generally more affordable and easier to maintain, making it an attractive option for businesses aiming to reduce costs. Faux leather is waterproof and easy to clean, making it suitable for various applications, from clothing to upholstery. However, it tends to be less durable than genuine leather, with a propensity to peel or crack over time, which can limit its lifespan in high-wear environments.

How Does Cotton Canvas Compare as an Alternative Material?

Cotton canvas is another viable alternative, particularly for casual wear and outdoor products. It is lightweight, breathable, and cost-effective, making it an excellent choice for businesses targeting budget-conscious consumers. Cotton canvas is easy to sew and widely available, allowing for flexibility in manufacturing. However, it lacks the durability and luxury appeal of leather, which may make it unsuitable for high-end apparel or products that require insulation and robust performance.

How Can B2B Buyers Decide on the Right Fabric for Their Needs?

Choosing the right fabric involves understanding the specific requirements of your products and target market. For high-end apparel or products requiring durability and thermal regulation, leather apparel fabric remains the superior choice despite its higher cost. Conversely, if budget constraints are a primary concern, faux leather provides a cost-effective solution with reasonable durability and maintenance. Cotton canvas is best suited for casual applications where cost and ease of use are prioritized. Ultimately, B2B buyers should evaluate their customer base, product requirements, and long-term goals to select the most suitable material for their needs.

Essential Technical Properties and Trade Terminology for leather apparel fabric

What Are the Key Technical Properties of Leather Apparel Fabric?

When evaluating leather apparel fabric for procurement, understanding its technical properties is crucial for ensuring quality and performance. Here are several key specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality of the leather, which can vary significantly. It is classified into several categories, including full-grain, top-grain, genuine leather, and bonded leather. Full-grain leather, for instance, is the highest quality and retains the natural texture and durability of the hide, making it ideal for high-end apparel. Understanding these grades helps buyers select the appropriate leather for their specific applications, impacting product longevity and customer satisfaction.

Illustrative image related to leather apparel fabric

2. Thickness

Measured in millimeters or ounces, the thickness of leather affects its durability, flexibility, and suitability for various uses. Thicker leather is generally more robust and better for outerwear or heavy-duty applications, while thinner leather is more suitable for intricate designs or lining. Buyers should specify thickness requirements to ensure the final product meets their design and functional needs.

3. Tolerance

Tolerance refers to the permissible variation in dimensions and properties of the leather. This is particularly important for bulk orders, where consistency is key to maintaining product quality. Tolerances can impact how leather behaves during cutting and sewing processes. Buyers should define acceptable tolerances to ensure uniformity across their production runs, reducing waste and potential rework.

4. Finish

The finish of leather pertains to the treatment applied to its surface, influencing both aesthetics and performance. Common finishes include aniline, semi-aniline, and pigmented. Each offers different levels of protection against wear and moisture. Understanding the finish allows buyers to match the leather’s appearance and durability with their intended use, whether it’s for fashion apparel or functional outerwear.

Illustrative image related to leather apparel fabric

5. Breathability

Breathability refers to the ability of leather to allow air circulation, which is essential for comfort, especially in apparel. High-quality leather tends to be more breathable, helping to regulate temperature and moisture. Buyers should assess breathability according to the end-use of the product, ensuring comfort for consumers.

6. Water Resistance

Water resistance indicates how well the leather can repel moisture. While some leathers are naturally more resistant due to their grain structure, others may require additional treatment. For buyers in regions with high humidity or frequent rain, selecting water-resistant leather can enhance product durability and customer satisfaction.

What Are Common Trade Terms Used in Leather Apparel Fabric Sourcing?

Navigating the procurement landscape for leather apparel fabric involves familiarizing oneself with specific industry jargon. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are marketed under another company’s brand. In the leather industry, this can involve manufacturers who create leather goods for fashion brands. Understanding OEM relationships can help buyers identify reliable partners for production.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for buyers to know, as it can impact inventory costs and production schedules. Understanding MOQs helps buyers plan their orders effectively, ensuring they meet demand without overstocking.

Illustrative image related to leather apparel fabric

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific quantities and specifications of leather fabric. This process allows buyers to compare offers and make informed purchasing decisions. Clarity in RFQs can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They dictate who pays for shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their liabilities and negotiate better shipping agreements.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. This is particularly significant in the leather industry, where sourcing can be affected by tanning and finishing processes. Buyers must consider lead times in their planning to align with product launch schedules.

6. Certification

Certification involves the validation of the leather’s quality and sustainability practices, such as compliance with environmental standards. Certifications like LWG (Leather Working Group) can enhance a product’s marketability and appeal to environmentally conscious consumers.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed decisions when sourcing leather apparel fabric, ultimately leading to better product outcomes and business success.

Navigating Market Dynamics and Sourcing Trends in the leather apparel fabric Sector

What Are the Current Market Dynamics and Key Trends in the Leather Apparel Fabric Sector?

The leather apparel fabric market is witnessing significant transformation driven by a combination of consumer preferences, technological advancements, and economic conditions. Globally, demand for high-quality leather products is on the rise, particularly in regions such as Africa, South America, the Middle East, and Europe. The luxury market is expanding, with consumers increasingly favoring leather for its durability, aesthetic appeal, and status symbol. This trend is particularly pronounced in countries like Nigeria and Saudi Arabia, where luxury leather goods are in high demand.

Emerging technologies are reshaping sourcing practices in the leather industry. Innovations in digital supply chain management and e-commerce platforms are enabling B2B buyers to source leather fabrics more efficiently. For instance, blockchain technology is being implemented to enhance traceability in the leather supply chain, ensuring authenticity and ethical sourcing. Moreover, the rise of artificial intelligence (AI) in predicting market trends and consumer preferences is allowing manufacturers and suppliers to adjust their offerings proactively.

Additionally, sustainability is becoming a key consideration for buyers. The industry is witnessing a shift towards eco-friendly practices, with suppliers adopting water-efficient tanning processes and utilizing vegetable-based dyes. This movement is not only driven by consumer demand but also by regulatory pressures aimed at reducing environmental impact.

How Important Is Sustainability and Ethical Sourcing in the Leather Apparel Fabric Sector?

Sustainability and ethical sourcing have become paramount in the leather apparel fabric sector. The environmental impact of traditional leather production is significant, contributing to deforestation, water pollution, and greenhouse gas emissions. As global awareness of these issues grows, B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices.

Ethical sourcing involves ensuring that leather is obtained from farms that respect animal welfare and labor rights. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) provide assurance that the leather is produced in an environmentally friendly manner. Buyers are encouraged to seek suppliers with these certifications to align with consumer expectations and regulatory requirements.

Moreover, the demand for alternative leather materials, such as plant-based or recycled options, is rising. These alternatives not only address sustainability concerns but also appeal to a growing segment of eco-conscious consumers. By prioritizing sustainable and ethical sourcing, B2B buyers can enhance their brand reputation and meet the evolving preferences of their customers.

How Has the Leather Apparel Fabric Sector Evolved Over Time?

The evolution of the leather apparel fabric sector has been marked by significant technological, social, and economic changes. Historically, leather was primarily sourced through traditional methods involving animal hides, with little regard for environmental impact. However, the late 20th century saw the introduction of synthetic alternatives and innovations in tanning processes that aimed to reduce pollution.

In the 21st century, as consumer awareness regarding sustainability grew, the industry began to pivot towards more responsible practices. The rise of digital technology has also transformed how businesses operate, enabling more efficient sourcing and inventory management. Today, the leather sector is at a crossroads, balancing the demand for high-quality, luxurious products with the urgent need for sustainable practices. As the market continues to evolve, B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with both their business goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of leather apparel fabric

1. How do I choose the right type of leather apparel fabric for my needs?

Choosing the right leather fabric involves considering the intended use, desired aesthetics, and durability. For apparel, look for soft, pliable leather types like lambskin for jackets or sheepskin for luxury garments. If durability is crucial, consider cowhide or buffalo leather, which offers robustness for heavy wear. Assess the finish as well; treated leather can provide water resistance, while untreated leather offers a natural look. Collaborate with suppliers who can guide you based on their product offerings and your specific requirements.

2. What are the common minimum order quantities (MOQs) for leather apparel fabric?

Minimum order quantities can vary significantly based on the supplier and the type of leather. Typically, MOQs range from 50 to 500 yards for wholesale purchases. For bespoke or customized leather orders, the MOQ may be higher, reflecting the additional processing involved. Always confirm MOQs with potential suppliers and consider negotiating these terms based on your purchasing capabilities and future order projections. Understanding these requirements upfront can help you manage inventory and cash flow effectively.

3. What are the payment terms typically offered by leather fabric suppliers?

Payment terms can vary widely among suppliers, but common practices include net 30, net 60, or payment upon delivery. Some suppliers might offer discounts for early payments or require a deposit before production begins, especially for custom orders. Always clarify payment terms before finalizing orders to avoid misunderstandings. It’s advisable to establish a secure payment method that protects both parties, such as letters of credit for larger transactions, particularly in international trade.

4. How can I ensure the quality of leather apparel fabric before placing a bulk order?

To ensure quality, request samples of the leather fabric before committing to a bulk order. Inspect the samples for texture, durability, and color consistency. Additionally, inquire about the supplier’s quality assurance processes, including how they handle defects and their return policies. Certifications or third-party testing results can also provide insights into the material’s quality. Building a strong relationship with the supplier can lead to better transparency regarding their quality control measures.

5. What should I consider when vetting suppliers of leather apparel fabric?

When vetting suppliers, evaluate their reputation, experience, and capacity to meet your specific needs. Check for certifications such as ISO or any compliance with international quality standards. Request references from previous clients to gauge reliability and service quality. Additionally, assess their production capabilities, lead times, and whether they can accommodate customization requests. A thorough vetting process can significantly reduce risks associated with supplier performance and product quality.

Illustrative image related to leather apparel fabric

6. How does international trade impact sourcing leather apparel fabric?

International trade can influence the sourcing of leather fabric through factors such as tariffs, import regulations, and shipping costs. Understanding trade agreements between your country and the supplier’s country can help mitigate costs and improve sourcing efficiency. Additionally, be aware of any customs documentation required for importing leather products, as non-compliance can lead to delays. Collaborating with logistics experts can facilitate smooth international transactions and ensure timely delivery.

7. What customization options are typically available for leather apparel fabric?

Customization options for leather apparel fabric often include color, texture, and finishing treatments. Suppliers may offer dyeing services to match specific color requirements or treatments to enhance water resistance or durability. Some manufacturers can also provide embossed patterns or prints, catering to unique design needs. Discuss your customization desires early in the procurement process to ensure the supplier can meet your specifications and timelines.

8. What logistics considerations should I keep in mind when sourcing leather apparel fabric?

Logistics considerations include shipping methods, lead times, and costs associated with transportation. Depending on your location and the supplier’s, you may choose air freight for faster delivery or sea freight for cost savings. Be sure to factor in potential delays related to customs clearance, especially for international shipments. Establishing a reliable logistics partner can streamline the process, ensuring that your leather fabric arrives on time and in optimal condition for your production needs.

Top 9 Leather Apparel Fabric Manufacturers & Suppliers List

1. Fabric Wholesale Direct – Luxurious Leather Fabrics

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Luxurious Leather Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. BuyFabrics – Leather Fabric Collection

Domain: buyfabrics.com

Registered: 2001 (24 years)

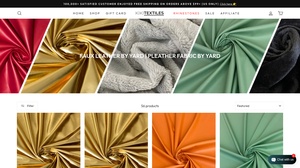

Introduction: Leather Fabric collection includes various types of leather and faux leather fabrics. Key details include: 1. Free shipping for contiguous U.S. orders over $99. 2. Discounts available: 30% off on new arrivals and famous maker fabric. 3. Various colors available: Beige, Black, Blue, Brown, Gold, Gray, Green, Ivory, Purple, White, Yellow. 4. Different fiber contents: Leather, Leather Blend, Polyeste…

3. Fashion Fabric LA – Faux Leather Vinyl Fabrics

Domain: fashionfabricla.com

Registered: 2014 (11 years)

Introduction: Faux Leather Vinyl Fabrics By The Yard – Wholesale & Retail

4. Mood Fabrics – Genuine Leather by the Yard

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: Buy Leather Fabric by the Yard | Genuine Leather Material. Free Shipping on Domestic Orders over $150.

5. Kiki Textiles – Faux Leather Fabric

Domain: kikitextiles.com

Registered: 2021 (4 years)

Introduction: Faux leather (pleather) fabric by the yard available in various colors and styles. Key features include:

– Ethical and animal-friendly alternative to genuine leather.

– Advanced technology for realistic texture, sheen, and durability.

– Suitable for fashion (jackets, handbags, clothing), upholstery (furniture), and accessories (wallets, belts, shoes).

– Easy to clean and resistant to wear and tear…

6. Fashion Fabrics Club – Leather Hides Collection

Domain: fashionfabricsclub.com

Registered: 1999 (26 years)

Introduction: Leather Hides are available in various colors including tan, black, brown, red, and more. Each hide measures approximately 5-10 square feet and is suitable for apparel, shoes, handbags, and certain home decorating uses. The collection includes 31 products with various textures and finishes, such as glossy and textured options. Prices range from $24.95 to $98.95. Notable products include Antique Gr…

7. Online Fabric Store – Vinyl & Faux Leather Fabric

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: This company, Online Fabric Store – Vinyl & Faux Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Denver Fabrics – Faux Leather and Vinyl Collection

Domain: denverfabrics.com

Registered: 1998 (27 years)

Introduction: Faux Leather and Vinyl collection includes various fabrics suitable for apparel, upholstery, and crafts. Key products include:

– Metallic Silver Solid Stretch Faux Leather Home Decorating Fabric – $10.00

– Pale Blue Famous Maker Solid Recycled Leather and Polyurethane Blend Fabric – $12.00

– Gray Famous Maker Solid Recycled Leather and Polyurethane Blend Fabric – $12.00

– Purple Famous Maker Solid…

9. Sewport – Leather Fabric

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: {“fabric_name”:”Leather Fabric”,”also_known_as”:”Hide, skin”,”fabric_composition”:”Tanned animal skins”,”fabric_breathability”:”Low”,”moisture_wicking_abilities”:”Low”,”heat_retention_abilities”:”High”,”stretchability”:”Low”,”prone_to_pilling_bubbling”:”Low”,”country_of_origin”:”Unknown – prehistoric origins”,”biggest_exporting_country”:”Italy (by value) or China (by volume)”,”recommended_washing_…

Strategic Sourcing Conclusion and Outlook for leather apparel fabric

What Are the Key Takeaways for B2B Buyers in Leather Apparel Fabric?

In summary, strategic sourcing of leather apparel fabric offers significant advantages for international B2B buyers. Understanding the nuances of leather quality, treatment options, and diverse applications—from apparel to upholstery—empowers buyers to make informed purchasing decisions. Establishing relationships with reliable suppliers ensures access to high-quality materials that meet market demands, enhancing product offerings and customer satisfaction.

How Can Buyers Leverage Trends for Future Growth?

As global demand for sustainable and ethically sourced materials continues to rise, buyers should prioritize suppliers who offer eco-friendly leather alternatives alongside traditional options. This not only aligns with consumer preferences but also positions businesses favorably in competitive markets across Africa, South America, the Middle East, and Europe.

Why Is Now the Time to Act?

The leather industry is poised for growth, driven by innovation and evolving consumer expectations. By capitalizing on strategic sourcing opportunities today, businesses can secure a competitive edge and drive long-term success. Engage with trusted suppliers, explore diverse product offerings, and enhance your portfolio with high-quality leather fabrics. The future of your business in the leather apparel market starts now.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.