Introduction: Navigating the Global Market for leather for garments

The global market for leather used in garments presents unique challenges for international B2B buyers, particularly when it comes to sourcing high-quality materials that meet diverse consumer demands. As companies strive to create fashionable and durable leather garments, they often grapple with the complexities of supplier vetting, cost fluctuations, and varying quality standards across regions. This guide aims to equip B2B buyers with actionable insights into the multifaceted world of leather for garments, covering key types of leather, applications, and best practices for selecting reliable suppliers.

Within these pages, you will find a comprehensive examination of the different leather varieties suitable for garment production, including their specific properties and applications. We will delve into supplier evaluation techniques to help you identify trustworthy partners, as well as strategies for negotiating favorable pricing that aligns with your budget and quality expectations. Special attention will be given to market trends and innovations that can enhance your product offerings in regions such as Africa, South America, the Middle East, and Europe, including Germany and Brazil.

By understanding the intricacies of the leather garment supply chain, B2B buyers will be empowered to make informed purchasing decisions that not only meet their immediate needs but also support sustainable and ethical practices in the leather industry. As you navigate this dynamic marketplace, our guide will serve as a vital resource, ensuring that your business remains competitive and adaptable to evolving consumer preferences.

Table Of Contents

- Top 7 Leather For Garments Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather for garments

- Understanding leather for garments Types and Variations

- Key Industrial Applications of leather for garments

- 3 Common User Pain Points for ‘leather for garments’ & Their Solutions

- Strategic Material Selection Guide for leather for garments

- In-depth Look: Manufacturing Processes and Quality Assurance for leather for garments

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather for garments’

- Comprehensive Cost and Pricing Analysis for leather for garments Sourcing

- Alternatives Analysis: Comparing leather for garments With Other Solutions

- Essential Technical Properties and Trade Terminology for leather for garments

- Navigating Market Dynamics and Sourcing Trends in the leather for garments Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather for garments

- Strategic Sourcing Conclusion and Outlook for leather for garments

- Important Disclaimer & Terms of Use

Understanding leather for garments Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chrome-Tanned Cowhide | Smooth texture, durable, water-resistant | Jackets, pants, skirts, vests | Pros: Cost-effective, versatile. Cons: Less environmentally friendly due to tanning process. |

| Vegetable-Tanned Leather | Natural finish, environmentally friendly | High-end garments, accessories | Pros: Biodegradable, develops a unique patina. Cons: Requires more care and maintenance. |

| Suede Leather | Soft, napped finish, lightweight | Fashion apparel, bags, shoes | Pros: Luxurious feel, versatile. Cons: Less durable, sensitive to stains and water. |

| Pull-Up Leather | Rich color with a distressed look | Casual wear, bags, upholstery | Pros: Unique aesthetic, ages well. Cons: Can be more expensive, varies in thickness. |

| Oil-Tanned Leather | Oily finish, water-resistant, durable | Outdoor gear, rugged apparel | Pros: Highly durable, excellent for outdoor use. Cons: Heavier, may require specific care. |

What Are the Characteristics of Chrome-Tanned Cowhide Leather?

Chrome-tanned cowhide leather is known for its smooth texture and durability, making it ideal for a variety of garments such as jackets, pants, and skirts. This leather undergoes a chemical tanning process that enhances its water resistance and flexibility. B2B buyers should consider the cost-effectiveness of chrome-tanned leather, especially for mass production. However, its environmental impact due to the tanning chemicals used can be a downside for eco-conscious brands.

How Does Vegetable-Tanned Leather Stand Out?

Vegetable-tanned leather is prized for its natural finish and eco-friendly characteristics, appealing to brands that prioritize sustainability. This type of leather develops a unique patina over time, adding to its charm. It is often used in high-end garments and accessories, making it a preferred choice for luxury brands. However, buyers should note that vegetable-tanned leather requires more care and maintenance, which could influence the overall production process.

Why Choose Suede Leather for Garment Production?

Suede leather offers a soft, napped finish that provides a luxurious feel, making it a popular choice for fashion apparel, bags, and shoes. Its lightweight nature allows for comfortable wear and versatility in design. However, B2B buyers should be aware that suede is less durable than other leather types and is particularly sensitive to stains and water, which may affect its longevity in high-use applications.

What Are the Benefits of Pull-Up Leather?

Pull-up leather is characterized by its rich colors and distressed appearance, appealing to consumers looking for unique, stylish options. It is often used in casual wear, bags, and upholstery, providing a rugged yet refined aesthetic. B2B buyers should consider the unique aging process of pull-up leather, which can enhance its appeal. However, it can be more expensive than other types and may vary in thickness, necessitating careful sourcing.

What Makes Oil-Tanned Leather Suitable for Outdoor Gear?

Oil-tanned leather is known for its durability and water resistance, making it an excellent choice for outdoor gear and rugged apparel. Its oily finish provides added protection against the elements, ensuring longevity in demanding conditions. B2B buyers should appreciate the practical benefits of oil-tanned leather, particularly for products intended for outdoor use. However, it is typically heavier and may require specific care, which could impact production decisions.

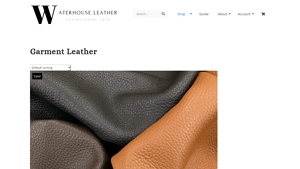

Illustrative image related to leather for garments

Key Industrial Applications of leather for garments

| Industry/Sector | Specific Application of leather for garments | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion/Apparel | High-end leather jackets and coats | Enhances brand prestige and customer loyalty | Sourcing premium hides with consistent quality and aesthetic appeal |

| Automotive | Leather upholstery for car interiors | Adds luxury, durability, and comfort to vehicles | Ensuring compliance with automotive safety and environmental standards |

| Outdoor Gear | Leather for rugged outdoor clothing | Provides durability and weather resistance | Availability of treated leather for moisture and abrasion resistance |

| Sportswear | Leather in specialized sports apparel | Offers performance benefits and aesthetic appeal | Consideration of breathability and flexibility requirements |

| Uniforms and Workwear | Leather for protective work garments | Ensures safety and durability in harsh environments | Compliance with safety regulations and sourcing of fire-retardant materials |

How is Leather Used in the Fashion and Apparel Industry?

In the fashion sector, leather is primarily utilized for creating high-end jackets, coats, and accessories. The tactile quality of leather not only enhances the aesthetic appeal of garments but also contributes to their longevity. B2B buyers in this industry seek premium hides that offer consistency in texture and color, essential for maintaining brand prestige. Sourcing from reputable tanneries that provide detailed product specifications and sustainability practices can significantly boost buyer confidence.

What Role Does Leather Play in Automotive Upholstery?

Leather is a staple in the automotive industry, particularly for upholstery in luxury vehicles. It provides an upscale look and feel while ensuring durability and comfort for passengers. B2B buyers must consider sourcing leather that meets automotive safety standards, including flame resistance and wearability. Moreover, the environmental impact of leather production is increasingly important, prompting buyers to seek suppliers who follow eco-friendly practices.

How is Leather Utilized in Outdoor Gear?

For outdoor apparel and gear, leather is favored for its robustness and ability to withstand harsh environmental conditions. It is often used in jackets, boots, and other gear that require durability and water resistance. Buyers in this sector need to ensure that the leather is treated appropriately for moisture resistance and abrasion, making it suitable for rugged use. Sourcing from suppliers who specialize in outdoor-specific leather can provide the necessary performance features.

Illustrative image related to leather for garments

What Are the Applications of Leather in Sportswear?

In the sportswear sector, leather is increasingly used in specialized apparel designed for performance. It offers unique benefits such as enhanced grip, breathability, and flexibility, which are critical for athletes. B2B buyers must prioritize sourcing leather that meets specific functional requirements, ensuring it supports the performance needs of various sports. Collaborating with suppliers who understand these nuances can lead to innovative product offerings.

How is Leather Incorporated into Uniforms and Workwear?

Leather plays a crucial role in the manufacture of protective work garments, particularly in industries like construction and manufacturing. It provides safety and durability, essential for workers exposed to challenging conditions. Buyers need to consider compliance with safety regulations, including fire-retardant properties and puncture resistance. Partnering with suppliers who specialize in industrial-grade leather can ensure that the sourced materials meet the rigorous demands of work environments.

3 Common User Pain Points for ‘leather for garments’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Garments

The Problem: Many B2B buyers struggle to find reliable suppliers that provide high-quality leather suitable for garment production. The challenge lies not only in ensuring the leather meets specific aesthetic and functional requirements but also in navigating the complexities of international trade, including varying quality standards across regions. Buyers often face inconsistent quality, leading to production delays and financial losses. Additionally, the risk of receiving subpar materials can tarnish a brand’s reputation, especially in competitive markets in Africa, South America, the Middle East, and Europe.

Illustrative image related to leather for garments

The Solution: To overcome sourcing challenges, buyers should establish robust relationships with reputable suppliers who specialize in garment leather. Start by conducting thorough due diligence on potential suppliers, including checking certifications, reviews, and their production processes. Consider visiting manufacturing facilities if possible, or request samples to assess quality firsthand. Utilizing platforms that connect buyers with verified suppliers can also streamline the sourcing process. Additionally, leveraging bulk purchasing agreements can enhance negotiation power, potentially securing better pricing and more favorable terms. Establishing clear quality benchmarks and specifications in contracts will help ensure that the leather meets the required standards consistently.

Scenario 2: Ensuring Leather Durability for Garment Applications

The Problem: Garment manufacturers often face issues with leather durability, especially in high-wear applications like jackets and trousers. Leather that wears out quickly can lead to increased returns and customer dissatisfaction, which can be particularly detrimental in markets that prioritize quality and longevity. Buyers must consider not just the leather’s appearance but also its ability to withstand daily use, environmental factors, and the specific demands of the intended garment type.

The Solution: To ensure durability, buyers should focus on the tanning process and leather type. For instance, chrome-tanned leather tends to offer superior durability and water resistance compared to vegetable-tanned options, making it ideal for outerwear. Additionally, buyers should specify the weight and thickness of the leather, as heavier hides typically perform better in high-wear situations. Implementing rigorous quality control checks during production can also help identify any weaknesses in the leather before it reaches the consumer. Collaborating with tanneries that offer customization options allows buyers to tailor the leather properties to meet specific garment requirements, enhancing overall product performance.

Illustrative image related to leather for garments

Scenario 3: Managing Environmental Sustainability in Leather Sourcing

The Problem: Increasingly, consumers and regulatory bodies are demanding sustainable practices in the fashion industry, including the sourcing of leather. B2B buyers often find it challenging to reconcile the need for high-quality leather with environmental considerations, such as the ecological impact of tanning processes and the sourcing of raw materials. This challenge is particularly pronounced in regions where environmental regulations may differ significantly, leading to potential reputational risks and compliance issues.

The Solution: To address sustainability concerns, buyers should prioritize sourcing leather from suppliers that adhere to eco-friendly practices, such as using chrome-free tanning methods and sustainable raw material sourcing. Requesting certifications, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification, can help ensure that suppliers meet recognized environmental standards. Additionally, engaging in transparent supply chain practices and opting for traceable leather can enhance brand credibility. Consider collaborating with suppliers to innovate sustainable leather alternatives, such as plant-based or recycled leather options, which can resonate well with environmentally conscious consumers. By integrating sustainability into sourcing strategies, buyers can not only comply with regulations but also align their products with consumer values, fostering brand loyalty.

Strategic Material Selection Guide for leather for garments

When selecting leather for garments, international B2B buyers must consider various materials, each with unique properties, advantages, and limitations. Here, we analyze four common leather types: Cowhide, Lambskin, Suede, and Metallic Leather. This analysis will provide insights into their performance, suitability for different applications, and considerations for buyers from diverse regions.

What are the Key Properties of Cowhide Leather for Garments?

Cowhide leather is one of the most popular choices for garment production due to its durability and versatility. Typically, cowhide is chrome-tanned, which enhances its strength and resistance to wear and tear. It has a thickness ranging from 1.5 to 2 oz (0.6 to 0.8 mm), making it suitable for a variety of garments, including jackets and pants. Cowhide also offers good temperature resistance, making it suitable for both hot and cold climates.

Illustrative image related to leather for garments

Pros: Cowhide is highly durable, resistant to abrasion, and can withstand various environmental conditions. It is relatively cost-effective compared to other leather types, making it a popular choice for mass production.

Cons: While cowhide is durable, it can be heavier and stiffer, which may not be suitable for all garment styles. Additionally, the tanning process can involve chemicals that may not meet eco-friendly standards.

How Does Lambskin Leather Compare for Garment Applications?

Lambskin leather is known for its softness and luxurious feel, making it an excellent choice for high-end garments like coats and blazers. This leather type is lighter than cowhide, typically weighing around 0.6 to 1.2 oz (0.3 to 0.5 mm). Its fine grain and supple texture provide an elegant appearance, which is highly sought after in fashion.

Pros: The primary advantage of lambskin is its softness and comfort, which enhances the wearer’s experience. It also has a refined aesthetic that appeals to luxury brands.

Illustrative image related to leather for garments

Cons: Lambskin is less durable than cowhide, making it more susceptible to damage from abrasion and environmental factors. It is also generally more expensive, which may not align with budget constraints for all buyers.

What are the Benefits and Limitations of Suede Leather?

Suede, made from the inner layer of animal hides, offers a unique texture and appearance that sets it apart from other leather types. It is commonly used for garments such as jackets and shoes. Suede typically has a thickness of around 1 to 2 oz (0.4 to 0.8 mm) and is known for its soft, napped finish.

Pros: Suede is lightweight and provides a distinct aesthetic that is appealing in fashion. Its softness makes it comfortable to wear, and it can be dyed in various colors.

Cons: However, suede is less resistant to water and stains, which can limit its application in certain climates. Maintenance can also be more demanding compared to other leather types.

What Role Does Metallic Leather Play in Garment Design?

Metallic leather is a unique option that incorporates metallic finishes, making it ideal for fashion-forward designs. It is often used in jackets, skirts, and accessories. The tanning process typically involves adding metallic pigments to the leather, resulting in a striking appearance.

Pros: The key advantage of metallic leather is its eye-catching aesthetic, which can elevate a garment’s design. It is also relatively durable, depending on the base leather used.

Cons: The primary limitation is that metallic finishes can wear off over time, affecting the garment’s appearance. Additionally, it may not appeal to all consumer segments, particularly those preferring classic styles.

Summary Table of Leather Materials for Garments

| Material | Typical Use Case for leather for garments | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Jackets, pants, skirts | Highly durable and versatile | Heavier and stiffer than other leathers | Medium |

| Lambskin | High-end coats, blazers | Softness and luxurious feel | Less durable and more expensive | High |

| Suede | Jackets, shoes | Unique texture and aesthetic | Less water-resistant and harder to maintain | Medium |

| Metallic Leather | Fashion-forward jackets, skirts | Eye-catching design | Metallic finish can wear off | Medium to High |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions when sourcing leather for garments, considering both performance and regional preferences.

Illustrative image related to leather for garments

In-depth Look: Manufacturing Processes and Quality Assurance for leather for garments

What Are the Main Stages of Manufacturing Leather for Garments?

The manufacturing of leather for garments involves several critical stages, each essential for ensuring high-quality output.

-

Material Preparation: This initial stage begins with the selection of hides, predominantly cowhide, which is favored for its durability and texture. The hides undergo a cleaning process to remove impurities, followed by soaking to rehydrate them. This stage is crucial, as the quality of the raw material directly impacts the final product.

-

Tanning: Once prepared, the hides are subjected to tanning, a process that transforms raw hides into leather. Various tanning methods exist, including chrome tanning, which is quick and produces supple leather, and vegetable tanning, known for its eco-friendliness and rich, natural finish. The choice of tanning method can influence the leather’s characteristics, including color, texture, and flexibility.

-

Forming: After tanning, the leather is cut into desired shapes and sizes, often using computer-aided design (CAD) technology for precision. This stage may also include techniques such as embossing or printing to add decorative elements or textures that enhance the garment’s aesthetic appeal.

-

Assembly: The leather pieces are then stitched or bonded together. This stage often employs specialized machinery to ensure strength and durability, particularly in high-stress areas of garments like seams and zippers. Skilled artisans may also be involved in this process, especially for bespoke or high-end items.

-

Finishing: The final stage encompasses various processes to enhance the leather’s appearance and performance. This includes dyeing, applying protective coatings, and conditioning treatments. The finishing process not only improves the leather’s aesthetic but also its resistance to water, stains, and wear.

How Does Quality Assurance Fit into Leather Manufacturing?

Quality assurance (QA) is a vital component in the leather manufacturing process, ensuring that the final product meets international standards and customer expectations.

-

International Standards: Compliance with standards such as ISO 9001 is critical. This standard outlines requirements for a quality management system (QMS), focusing on continuous improvement and customer satisfaction. For leather products, adherence to ISO 14001, which addresses environmental management, is also relevant, especially in regions with strict environmental regulations.

-

Industry-Specific Certifications: Certain certifications, like CE marking for products sold in the European Economic Area, indicate compliance with safety and health standards. For leather manufacturers, obtaining these certifications can enhance credibility and open up new market opportunities.

-

Quality Control Checkpoints: Quality control (QC) is typically structured around several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify and rectify issues before they affect the final product.

– Final Quality Control (FQC): The finished products undergo a comprehensive inspection for defects, measurements, and overall quality assurance.

What Common Testing Methods Are Used in Leather Quality Control?

Testing methods for leather can vary widely, depending on the specific characteristics being assessed. Some common testing methods include:

-

Physical Testing: This includes assessments of tensile strength, tear resistance, and abrasion resistance, crucial for determining the durability of leather garments.

-

Chemical Testing: Assessing the presence of harmful substances (like chromium VI) is essential for consumer safety and compliance with international regulations.

-

Color Fastness Testing: This involves exposing leather samples to various conditions (light, water, sweat) to ensure that colors do not fade or bleed.

-

Thickness Measurement: Consistency in thickness is critical for garment manufacturing, impacting both the feel and durability of the final product.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential for mitigating risks associated with procurement.

Illustrative image related to leather for garments

-

Supplier Audits: Conducting regular audits of suppliers can help ensure compliance with quality standards and reveal potential issues in the manufacturing process. Buyers should develop a checklist based on their specific requirements and industry standards.

-

Quality Assurance Reports: Suppliers should provide comprehensive QA reports detailing their QC processes, results from various testing methods, and any certifications obtained. Regular updates on these reports can indicate ongoing compliance.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide unbiased assessments of a supplier’s quality control practices. These inspections can be particularly beneficial for buyers who are not able to visit suppliers on-site.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate various nuances in quality control when sourcing leather garments.

-

Cultural Expectations: Understanding regional preferences and standards for leather quality can help buyers set appropriate expectations and ensure alignment with local market demands.

-

Regulatory Compliance: Different countries have varying regulations regarding leather production, environmental impact, and chemical use. Buyers should familiarize themselves with these regulations to avoid compliance issues.

-

Communication Barriers: Establishing clear communication channels with suppliers is essential for addressing quality concerns swiftly. Language barriers can complicate this process, so using experienced intermediaries or translators can be beneficial.

-

Building Relationships: Developing strong relationships with suppliers can facilitate better quality control. Trust and open communication often lead to improved quality outcomes and more responsive service.

By understanding the manufacturing processes and quality assurance practices in leather production, B2B buyers can make informed decisions that ensure the procurement of high-quality leather for garments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather for garments’

To assist B2B buyers in effectively sourcing leather for garments, this guide outlines a structured checklist to streamline the procurement process. By following these actionable steps, you can ensure that the leather you acquire meets your quality standards and aligns with your business needs.

Step 1: Define Your Technical Specifications

Before initiating any sourcing activities, clearly outline the technical specifications for the leather you need. Consider factors such as thickness, tanning methods, grain types, and color.

– Thickness: Ensure the leather’s weight is appropriate for the intended garment, typically ranging from 1.5 to 2 oz. for lightweight garments.

– Tanning Method: Decide between chrome-tanned or vegetable-tanned leather based on desired durability and environmental considerations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in garment leather. Look for suppliers with a proven track record and positive reviews from previous buyers.

– Online Presence: Evaluate their website for product range and quality descriptions.

– Industry Networks: Utilize trade shows and industry forums to gather recommendations and insights from peers.

Illustrative image related to leather for garments

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is critical to ensure compliance with industry standards and ethical sourcing practices.

– Quality Certifications: Check for ISO certifications or other relevant quality assurance standards.

– Sustainability Practices: Inquire about eco-friendly practices, especially if targeting markets that prioritize sustainability.

Step 4: Request Samples for Quality Assessment

Before making bulk orders, request samples of the leather to assess quality firsthand. This step is crucial for evaluating texture, color, and overall suitability for your garments.

– Performance Tests: Consider testing for durability, colorfastness, and flexibility.

– Comparison: Compare samples from multiple suppliers to identify the best fit for your needs.

Step 5: Negotiate Pricing and Terms

Once you’ve selected a preferred supplier, engage in negotiations to establish pricing and terms that suit both parties.

– Bulk Discounts: Inquire about volume discounts or special pricing for long-term contracts.

– Payment Terms: Clarify payment methods, delivery schedules, and any associated costs to avoid surprises later.

Step 6: Confirm Logistics and Delivery Times

Effective logistics planning is essential to ensure timely delivery of your leather. Confirm the supplier’s ability to meet your timeline and discuss shipping options.

– Lead Times: Ask about the expected lead times for production and shipping.

– Shipping Method: Evaluate options such as air freight for faster delivery or sea freight for cost-effectiveness.

Illustrative image related to leather for garments

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor leather quality throughout the production and delivery phases.

– Inspection Criteria: Define specific criteria for quality checks, including appearance, texture, and adherence to specifications.

– Feedback Loop: Maintain open communication with suppliers to address any discrepancies or issues promptly.

By following this checklist, B2B buyers can navigate the complexities of sourcing leather for garments effectively, ensuring they procure high-quality materials that meet their specific requirements.

Comprehensive Cost and Pricing Analysis for leather for garments Sourcing

What Are the Key Cost Components in Sourcing Leather for Garments?

When sourcing leather for garments, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The type of leather (e.g., cowhide, lambskin, suede) significantly impacts costs. Premium leathers often command higher prices due to their quality and sourcing challenges. For instance, chrome-tanned leather is generally less expensive than vegetable-tanned options, which can vary widely in price based on the tanning process and finish.

-

Labor: Labor costs can fluctuate based on the region of production. Countries with lower labor costs may offer competitive pricing, but this can come at the expense of quality. Skilled artisans are often required for high-quality leather garments, which can increase labor costs.

-

Manufacturing Overhead: This includes factory rent, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, but investments in technology or environmentally friendly practices may raise initial costs.

-

Tooling: Specialized machinery and tools for cutting and finishing leather can represent a significant upfront investment. Buyers should consider whether suppliers have the necessary tooling to meet their specific requirements.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the leather meets industry standards. However, this adds to the overall cost. Buyers should inquire about the QC processes used by potential suppliers.

-

Logistics: Transportation costs can vary based on the distance from the supplier, shipping method, and volume. International buyers should be aware of potential customs duties and import taxes, which can significantly affect total costs.

-

Margin: The supplier’s profit margin is influenced by their operational efficiency, market demand, and competition. Understanding the supplier’s margin can help buyers negotiate better prices.

How Do Price Influencers Affect Leather for Garments?

Several factors can influence pricing in the leather garment industry:

-

Volume/MOQ: Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their purchasing capabilities.

-

Specifications and Customization: Custom orders may incur additional costs for unique specifications, such as specific dyes or finishes. Clear communication about requirements can prevent unexpected price hikes.

-

Materials and Quality Certifications: Leather with certifications (e.g., eco-friendly, cruelty-free) can be more expensive. Buyers should assess the value these certifications add to their brand.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more, but the assurance of consistent quality and timely delivery often justifies the cost.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is essential. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, impacting the final price.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

B2B buyers should approach negotiations strategically to optimize costs:

-

Research Market Prices: Familiarize yourself with current market prices for various types of leather. This knowledge will empower you during negotiations.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Loyalty can often yield discounts or favorable terms.

-

Consider Total Cost of Ownership (TCO): Focus not only on the upfront cost but also on long-term expenses, including maintenance, durability, and potential waste. Investing in higher-quality leather may reduce replacement costs.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, local tariffs, and shipping costs that can affect the total price.

-

Flexibility on Specifications: Being open to alternative materials or designs can lead to cost savings, especially if suppliers can offer lower-priced options that still meet your quality standards.

Conclusion

While the prices of leather for garments can vary widely, understanding the cost components and price influencers enables buyers to make informed decisions. By applying effective negotiation strategies and considering the total cost of ownership, B2B buyers can achieve significant cost efficiencies in their sourcing processes.

Alternatives Analysis: Comparing leather for garments With Other Solutions

Exploring Alternatives to Leather for Garments: A Comprehensive Comparison

When considering materials for garment production, leather remains a classic choice due to its durability and aesthetic appeal. However, there are viable alternatives that can meet similar needs while potentially offering distinct advantages. This analysis compares leather for garments with two notable alternatives: synthetic leather (often referred to as faux leather) and natural fibers like cotton or linen. Understanding these options can help B2B buyers make informed decisions based on their specific requirements.

Illustrative image related to leather for garments

| Comparison Aspect | Leather For Garments | Synthetic Leather (Faux Leather) | Natural Fibers (Cotton/Linen) |

|---|---|---|---|

| Performance | Highly durable, water-resistant, ages well with time | Good durability, but may not be as breathable; can degrade over time | Soft and breathable, but less durable than leather |

| Cost | Generally higher initial investment | Typically lower cost, varies by quality | Variable; often competitive, especially for bulk purchases |

| Ease of Implementation | Requires specialized skills for crafting | Easier to work with; can be cut and sewn like fabric | Standard sewing techniques, widely accessible |

| Maintenance | Requires regular conditioning and care | Low maintenance; easy to clean and often water-resistant | Generally easy to wash, but can shrink or fade |

| Best Use Case | High-end fashion, outerwear, luxury goods | Budget-friendly apparel, fashion accessories | Casual wear, summer garments, eco-friendly products |

What Are the Benefits and Drawbacks of Synthetic Leather?

Synthetic leather offers an appealing alternative to traditional leather, particularly for cost-sensitive projects. Its production involves using synthetic materials, which can be manufactured to mimic the look and feel of real leather. One of the main advantages is its affordability, making it a popular choice for fast fashion brands and budget-conscious consumers. Additionally, synthetic leather is often easier to maintain, requiring only a simple wipe down to clean. However, it may lack the breathability and longevity of genuine leather, leading to potential degradation over time. For brands targeting eco-conscious consumers, the environmental impact of synthetic materials may also be a concern.

How Do Natural Fibers Compare to Leather for Garments?

Natural fibers such as cotton and linen present another viable alternative to leather. These materials are celebrated for their comfort and breathability, making them ideal for casual wear and warmer climates. Additionally, they can be produced sustainably, appealing to environmentally conscious brands and consumers. The cost of natural fibers can be competitive, especially when purchased in bulk. However, they generally do not match the durability and water resistance of leather, making them less suitable for high-end or outdoor garments. Brands focusing on casual or eco-friendly clothing may find natural fibers to be a more appropriate choice.

How Should B2B Buyers Choose the Right Material for Their Needs?

Selecting the right material for garment production ultimately depends on the specific needs of the business and its target market. B2B buyers should consider factors such as the desired product longevity, maintenance requirements, and cost implications. For high-end fashion or durable outerwear, leather remains an unparalleled choice. In contrast, synthetic leather may serve well for budget-conscious brands seeking a leather-like appearance without the associated costs. Lastly, for brands prioritizing sustainability and comfort, natural fibers may provide the best fit. By evaluating these aspects, buyers can make informed decisions that align with their brand values and market demands.

Essential Technical Properties and Trade Terminology for leather for garments

What Are the Key Technical Properties of Leather for Garments?

Understanding the technical properties of leather is crucial for B2B buyers in the garment industry. These properties not only influence the aesthetic appeal of the final product but also determine its functionality and longevity. Here are several essential specifications to consider:

Illustrative image related to leather for garments

-

Material Grade: Leather is classified into grades such as full grain, top grain, and genuine leather. Full grain is the highest quality, retaining the natural texture and imperfections, which adds character. Top grain is sanded to remove imperfections, offering a more uniform appearance. Understanding these grades helps buyers select materials that align with their product positioning and customer expectations.

-

Thickness: The thickness of leather is measured in ounces or millimeters, commonly ranging from 1 to 6 ounces (0.4 to 2.4 mm) for garment leather. Thicker leathers are more durable and suitable for outerwear, while lighter weights are ideal for linings or fashion pieces. Specifying the right thickness is essential for ensuring the final garment meets wear and comfort standards.

-

Tannage Type: The tanning process affects the leather’s durability, flexibility, and water resistance. Chrome tanning is popular for garment leather due to its quick processing time and ability to produce softer, more pliable leather. Vegetable tanning, on the other hand, is more environmentally friendly and yields a firmer texture. Buyers should consider the intended use and market demands when selecting tannage types.

-

Finish: Leather finishes can vary widely, from aniline to semi-aniline to pigmented. Aniline finishes enhance the natural grain and feel, while pigmented finishes provide a protective layer that enhances durability and color retention. The finish impacts both the appearance and care requirements of the leather, making it a vital consideration for manufacturers.

What Trade Terminology Should B2B Buyers Understand in the Leather Garment Industry?

Navigating the leather garment supply chain requires familiarity with specific trade terms that streamline communication and transactions. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the leather industry, an OEM might create custom leather goods according to a buyer’s specifications, allowing for branding flexibility and product differentiation.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it impacts inventory management and budgeting. Suppliers may set MOQs based on production costs and material availability, making it essential to negotiate favorable terms.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to request price quotes for specific products or services. In the leather industry, an RFQ may outline desired leather types, grades, and quantities. A well-structured RFQ can lead to more accurate pricing and better supplier responses.

-

Incoterms (International Commercial Terms): These are standardized terms that define the responsibilities of buyers and sellers in international trade. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears the risk and cost at different points in the shipping process. Familiarity with Incoterms helps mitigate misunderstandings and aligns expectations in cross-border transactions.

By understanding these technical properties and trade terms, B2B buyers in the leather garment sector can make informed decisions that enhance their product offerings and streamline procurement processes.

Navigating Market Dynamics and Sourcing Trends in the leather for garments Sector

What Are the Current Market Dynamics and Key Trends in the Leather for Garments Sector?

The global leather for garments market is currently influenced by several dynamic factors. One major driver is the increasing demand for high-quality leather products in fashion and apparel, particularly in emerging markets such as Africa and South America. These regions are witnessing a growing middle class that values premium leather goods. In Europe, especially in Germany, there is a strong emphasis on craftsmanship and durability, which fuels demand for premium leather.

Technological advancements in sourcing and manufacturing, including digital platforms for procurement and supply chain management, are reshaping how international buyers engage with suppliers. B2B buyers are increasingly using online marketplaces to source diverse leather types, from chrome-tanned to vegetable-tanned options, allowing for a more efficient and transparent purchasing process. Moreover, the rise of AI and data analytics in inventory management is enabling suppliers to better forecast demand and manage stock levels, ultimately improving the buyer experience.

Emerging trends also highlight a shift towards customization and personalization in leather garments. Buyers are looking for unique textures, colors, and finishes that cater to specific market needs. For instance, the demand for metallic and pull-up leathers is growing, as they provide distinct aesthetic appeal. Additionally, the integration of sustainability into sourcing practices is becoming increasingly important, with buyers prioritizing eco-friendly materials and ethical production processes.

How Is Sustainability and Ethical Sourcing Influencing the Leather for Garments Market?

Sustainability and ethical sourcing have become critical components of the leather for garments sector. As consumers become more environmentally conscious, B2B buyers are under pressure to ensure that their supply chains reflect sustainable practices. The environmental impact of leather production, including water usage and chemical treatments, is a significant concern. Buyers are increasingly seeking suppliers who utilize environmentally friendly tanning processes, such as vegetable tanning, which minimizes harmful chemical exposure.

The importance of ethical supply chains cannot be overstated. Buyers are looking for transparency in sourcing practices, ensuring that materials are obtained responsibly and that labor conditions meet ethical standards. Certifications such as the Leather Working Group (LWG) and the Global Organic Textile Standard (GOTS) provide assurance that suppliers adhere to sustainable and ethical practices. As a result, B2B buyers who prioritize these certifications can enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

Moreover, the demand for ‘green’ materials is on the rise. Innovations in alternative leathers, such as those made from plant-based or recycled materials, are gaining traction. Buyers are exploring these options to diversify their product offerings and reduce their environmental footprint. Investing in sustainable materials not only meets consumer expectations but also positions brands favorably in an increasingly competitive market.

Illustrative image related to leather for garments

What Is the Historical Context of Leather for Garments That Buyers Should Consider?

The leather for garments sector has a rich history that dates back thousands of years, evolving alongside human civilization. Initially, leather was primarily used for functional purposes such as clothing and shelter. Over time, it transitioned into a symbol of status and luxury, particularly in European fashion. The 20th century saw mass production techniques transform the leather industry, making garments more accessible to the general public.

In recent decades, the sector has faced challenges related to environmental sustainability and ethical production, prompting a shift in consumer preferences. Today’s buyers are not only looking for quality and style but also for assurance that their products are sourced responsibly. This historical context emphasizes the importance of adapting to market demands while maintaining a commitment to sustainability and ethical practices. Understanding this evolution is crucial for B2B buyers aiming to navigate the complexities of the modern leather market effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of leather for garments

-

How do I solve issues with leather quality when sourcing for garments?

To address quality concerns, establish a robust supplier vetting process. Request samples of leather before committing to large orders to assess texture, durability, and finish. It’s also beneficial to inquire about the tanning process and sourcing practices, as these factors significantly affect quality. Building long-term relationships with reputable suppliers can lead to more consistent quality over time. Additionally, consider implementing quality assurance checks at various production stages to ensure the leather meets your standards. -

What is the best type of leather for garment production?

The best type of leather for garment production often depends on the intended use. For clothing like jackets and skirts, chrome-tanned cowhide is popular due to its softness and durability. Lambskin is favored for its luxurious feel, while suede offers a unique texture for fashion-forward designs. Assess the specific requirements of your garments, including weight, finish, and intended wear, to choose the most suitable leather type. Consulting with suppliers can also provide insights into trending materials. -

How can I ensure timely delivery of leather products?

To ensure timely delivery, establish clear communication with your suppliers regarding lead times and shipping methods. It’s essential to confirm production timelines and factor in any potential delays, especially during peak seasons. Utilizing reliable logistics partners with a strong track record in international shipping can also facilitate smoother deliveries. Additionally, consider placing orders well in advance of peak production times to mitigate risks associated with unforeseen delays. -

What are the typical minimum order quantities (MOQs) for leather?

Minimum order quantities for leather can vary widely depending on the supplier and the type of leather. Generally, MOQs range from 10 to 50 hides for bulk orders. However, some suppliers may accommodate smaller orders for specific types or custom requests. Always clarify MOQs upfront to avoid surprises and determine if the supplier can meet your production needs without compromising quality or financial viability. -

What payment terms should I expect when sourcing leather internationally?

Payment terms in international leather sourcing can vary significantly. Common practices include partial payments upfront (usually 30-50%) with the balance due upon delivery or a letter of credit. Always negotiate terms that align with your cash flow needs and establish a clear agreement regarding payment timelines and methods. Understanding the currency and potential exchange rate fluctuations is also crucial to avoid unexpected costs. -

How can I customize leather for my garment designs?

Customization options for leather can include color, texture, and finish. Many suppliers offer dyeing services and can match specific Pantone colors. Additionally, you can request special treatments like water resistance or embossing for added uniqueness. When discussing customization, provide detailed specifications and samples of desired finishes to ensure the final product aligns with your vision. Open communication with your supplier will facilitate a smoother customization process. -

What quality assurance practices should I implement for leather sourcing?

Implementing quality assurance practices involves setting clear quality standards before production begins. Conducting initial inspections of leather samples helps establish benchmarks. During production, consider periodic inspections to ensure compliance with your specifications. Post-production, conduct thorough quality checks on the finished garments to identify any defects. Collaborating closely with suppliers on quality control measures can enhance product consistency and reduce returns. -

What logistics considerations should I keep in mind for international leather sourcing?

When sourcing leather internationally, logistics considerations are vital for ensuring a smooth supply chain. Evaluate shipping options, including air versus sea freight, based on cost and urgency. Familiarize yourself with import regulations and tariffs in your country to avoid unexpected fees. Additionally, work with logistics partners experienced in handling leather products to navigate customs requirements efficiently. Planning for potential delays due to customs can help maintain your production schedule.

Top 7 Leather For Garments Manufacturers & Suppliers List

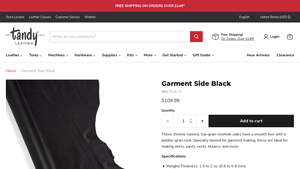

1. Waterhouse Leather – Deersoft Cowhide Leather Whole Hides

Domain: waterhouseleather.com

Registered: 2006 (19 years)

Introduction: [{‘name’: ‘Deersoft Cowhide Leather Whole Hides’, ‘original_price’: 299.95, ‘current_price’: 239.95}, {‘name’: ‘Heavy Black Upholstery/Garment Leather Sides’, ‘original_price’: 129.95, ‘current_price’: 119.95}, {‘name’: ‘Value Upholstery Leather Sides’, ‘price’: 99.95}, {‘name’: ‘Value Upholstery Leather’, ‘price’: 199.95}, {‘name’: ‘Heavy Black Upholstery/Garment Leather’, ‘original_price’: 259.9…

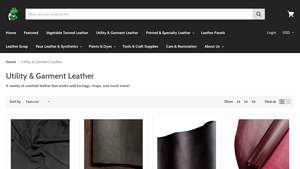

2. HideHouse – Premium Garment Hides

Domain: hidehouse.com

Registered: 1996 (29 years)

Introduction: Hides for garments for both men and women, including various types of animal hides such as goat, calf, sheep, lamb, water buffalo, deer, cow, pig, and bison. The product range includes garment hides, with options for different applications like chap, motorcycle, and bag hides. Available finishes include aniline, foil, patent, semi-aniline, waxy, nubuck, suede, pigmented, and hair on hide. Sizes ra…

3. Tandy Leather – In Stock $19.99 Delivery

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – In Stock $19.99 Delivery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Frog Jelly Leather – Italian Suede Hide

Domain: frogjellyleather.com

Registered: 2016 (9 years)

Introduction: Italian Suede Hide – Black: $29.99, Black aniline dyed suede hides with extreme softness and a matte appearance. S.B. Foot – Dark Brown Oil Tan Side 5oz-6oz: $89.99, Established in Red Wing, Minnesota. Pebble Grain Oil Tan – Mahogany Brown 5oz-6oz: $75.00, Medium weight leather with deep reddish-brown pull up, average size 22sq ft-24sq ft. Oil Tan Waxy Pull-Up – Mahogany: $159.99, Crafted from a b…

5. BuyLeatherOnline – Garment Leather & Jackets

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: Garment Leather & Leather For Jackets: Features high-quality Italian leather ideal for creating elegant and comfortable clothing such as jackets, blazers, coats, gloves, and skirts. Offers unmatched softness and lightweight properties. Available in a range of premium finishes and low thicknesses, ensuring luxury and comfort. Collection includes various colors, thicknesses, and types of leather sui…

6. Weaver Leather Supply – Leather Hides

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Leather hides for all your leather working needs including veg leather, chrome tanned leather, textured leather, holster leather, dyed leather, shearlings, suede leather, leather straps, leather panels and more. Key collections include CHAHINLEATHER® and Hermann Oak® with various types such as Veg Tan, Natural Veg Tan, Dyed, and Specialty Leather. Available cuts include Double Shoulders, Backs, Be…

7. Sewport – Leather Fabric

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: {“fabric_name”:”Leather Fabric”,”also_known_as”:”Hide, skin”,”fabric_composition”:”Tanned animal skins”,”fabric_breathability”:”Low”,”moisture_wicking_abilities”:”Low”,”heat_retention_abilities”:”High”,”stretchability”:”Low”,”prone_to_pilling_bubbling”:”Low”,”country_of_origin”:”Unknown – prehistoric origins”,”biggest_exporting_country”:”Italy (by value) or China (by volume)”,”recommended_washing_…

Strategic Sourcing Conclusion and Outlook for leather for garments

The global leather market for garments presents a wealth of opportunities for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. As the demand for high-quality leather continues to rise, strategic sourcing becomes crucial for securing competitive pricing and ensuring product availability. By leveraging diverse sourcing strategies, buyers can tap into a variety of leather types, from chrome-tanned cowhide to luxurious lambskin, catering to various market segments and consumer preferences.

Investing in strong supplier relationships not only enhances product quality but also opens avenues for innovation in design and production processes. Buyers should prioritize suppliers that demonstrate sustainable practices, as eco-friendly leather options are increasingly sought after by conscious consumers.

Looking ahead, the leather garment sector is poised for growth, driven by fashion trends and consumer demand for bespoke and ethically sourced products. To capitalize on these trends, international buyers are encouraged to actively engage with suppliers, explore new markets, and adapt to evolving consumer preferences. Now is the time to strengthen your sourcing strategies to remain competitive in this dynamic industry.

Illustrative image related to leather for garments

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.