Catalog

Material Insight: Is Vegan Leather Durable

B2B Product Guide: Understanding Vegan Leather Durability

The question “Is vegan leather durable?” is central to strategic material selection for forward-thinking brands. In commercial applications—from high-traffic hospitality furniture and automotive interiors to performance-driven footwear and accessories—durability directly impacts product lifespan, total cost of ownership, and brand reputation. Modern vegan leather, specifically engineered synthetic alternatives, has evolved far beyond early iterations, delivering exceptional resilience, consistency, and longevity that meet or exceed the demands of rigorous B2B use cases.

Why Engineered Faux Leather is the Optimal Choice for Commercial Applications

Faux leather (synthetic leather) is the superior choice for durability-focused B2B applications due to its precision-engineered performance characteristics:

- Consistent Performance: Unlike natural leather, which varies by hide and cut, synthetic leather offers uniform strength, abrasion resistance, and colorfastness across every batch, ensuring predictable product quality at scale.

- Enhanced Resilience: Advanced polymer formulations provide superior resistance to cracking, peeling, UV degradation, and moisture—critical for products exposed to frequent use, cleaning chemicals, or environmental stressors.

- Tailored Engineering: Properties like tensile strength, tear resistance, and flexibility can be precisely calibrated during manufacturing to match specific application requirements (e.g., automotive seat durability vs. luggage abrasion resistance).

- Lower Lifecycle Costs: Reduced maintenance needs, longer replacement cycles, and minimized waste during cutting translate to significant operational savings over time.

- Ethical & Traceable Sourcing: Eliminates supply chain risks associated with animal agriculture while providing full transparency—a growing requirement for corporate sustainability reporting.

Introducing WINIW: Precision Synthetic Leather Solutions Since 2002

WINIW stands at the forefront of sustainable material innovation, leveraging over 20 years of specialized expertise in developing high-performance synthetic leather for global B2B markets. We partner with leading brands in automotive, furniture, fashion, and technical textiles to deliver:

- Proven Durability: Our proprietary PU and water-based resin technologies undergo rigorous ASTM/ISO testing, consistently exceeding industry benchmarks for abrasion, flexing, and environmental resistance.

- Eco-Conscious Engineering: From solvent-free production processes to certified bio-based content and recyclable end-of-life pathways, we embed circularity without compromising performance.

- Application-Specific Innovation: Our R&D team collaborates closely with clients to formulate materials meeting exact mechanical, aesthetic, and regulatory demands—turning durability challenges into competitive advantages.

For B2B decision-makers, selecting WINIW means investing in synthetics engineered for real-world resilience, operational efficiency, and verifiable sustainability—proving that responsible materials are inherently durable materials.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Advantages for B2B Applications

WINIW specializes in high-performance synthetic leather engineered for durability, sustainability, and industrial adaptability. Our vegan leather solutions are designed to meet the rigorous demands of commercial and industrial applications while maintaining environmental responsibility and cost efficiency. Below is a detailed overview of the technical advantages that position WINIW as a trusted partner for B2B clients.

Key Technical Advantages

-

Exceptional Durability

WINIW’s vegan leather is constructed with high-density polyurethane (PU) and reinforced backings, offering superior abrasion resistance, tensile strength, and tear resistance. It withstands over 50,000 double rubs (Martindale test), making it ideal for high-traffic environments such as public transportation, office furniture, and hospitality interiors. -

Cost-Effective Alternative to Genuine Leather

With no reliance on animal hides, our production process reduces material waste and variability. WINIW’s vegan leather delivers consistent quality at a lower total cost of ownership, with reduced maintenance and longer service life compared to both natural leather and lower-grade synthetics. -

Customizable Color Options

Our advanced dyeing and finishing technology supports full color customization. Clients can choose from standard palettes or develop bespoke colors (Pantone matching available) with excellent color fastness (rated 4–5 on the Blue Wool Scale). This flexibility supports branding consistency and design innovation across product lines. -

REACH Compliant & Eco-Conscious

WINIW’s synthetic leather complies with EU REACH regulations, ensuring the absence of SVHCs (Substances of Very High Concern) and harmful phthalates. Our manufacturing process minimizes VOC emissions and avoids the use of DMF (Dimethylformamide), aligning with global sustainability standards. -

ISO 9001-Certified Quality Management

WINIW operates under ISO 9001-certified quality systems, guaranteeing consistent product performance, traceability, and process control. This certification ensures reliability in batch-to-batch uniformity, on-time delivery, and continuous improvement in product development.

Technical Specifications

| Property | Specification | Test Method |

|---|---|---|

| Material Composition | High-performance PU with polyester backing | ISO 1133 |

| Thickness | 0.6 mm – 1.8 mm (customizable) | ISO 2589 |

| Tensile Strength | ≥ 80 N/cm (warp & weft) | ISO 1421 |

| Elongation at Break | ≤ 30% | ISO 1421 |

| Martindale Abrasion | ≥ 50,000 cycles (no wear-through) | ISO 12947-2 |

| Color Fastness to Rubbing | Dry: Class 4–5; Wet: Class 4 | ISO 105-X12 |

| Color Fastness to Light | Grade 4–5 (100 hrs Xenon arc) | ISO 105-B02 |

| REACH Compliance | Pass (No SVHCs, Phthalates < 0.1%) | GC-MS / LC-MS |

| Formaldehyde Content | < 30 mg/kg | ISO 17226-1 |

| ISO 9001 Certification | Certified (Quality Management System) | ISO 9001:2015 |

WINIW’s synthetic leather is engineered for long-term performance and environmental responsibility, supporting B2B clients in furniture, automotive, electronics, and architectural sectors. Our scalable production and technical support ensure seamless integration into your supply chain, offering durability you can rely on—without compromising sustainability or design.

Why Choose Synthetic over Real Leather

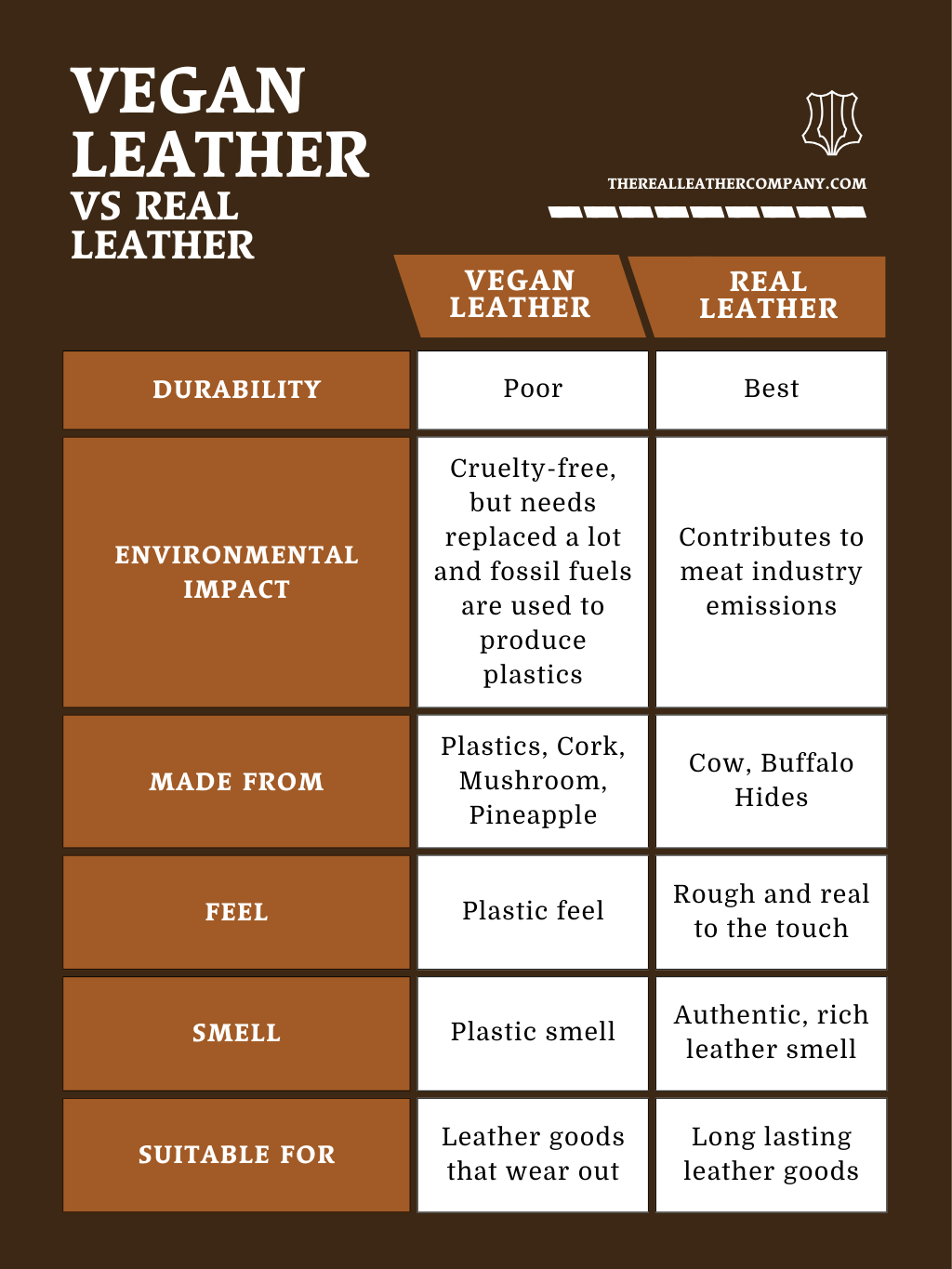

B2B Product Guide: Vegan Leather vs. Real Leather Durability & Sustainability Comparison

Understanding material performance is critical for informed procurement decisions. While “vegan leather” (primarily synthetic leather, including PU and PVC-based materials) is often evaluated for its ethical and environmental profile, its durability compared to genuine leather is a frequent consideration. Durability is not absolute; it depends on application, quality tier, and environmental exposure. Below is an objective comparison focused on key business metrics.

Key Durability Considerations:

– Vegan leather (modern high-end PU variants) offers excellent resistance to stains, moisture, and UV fading in controlled environments, making it suitable for consistent indoor applications like furniture upholstery or automotive interiors.

– Real leather develops a patina over time and generally withstands physical abrasion better long-term, especially in high-flex or high-wear scenarios (e.g., footwear, heavy-use seating). However, it is susceptible to water damage, drying, and requires conditioning.

– Low-cost PVC-based vegan leathers often crack or peel within 2–3 years, significantly underperforming real leather. Premium, engineered PU synthetics (like WINIW’s water-based formulations) achieve lifespans comparable to mid-tier real leather in appropriate uses.

– Both materials require context-specific care: real leather needs conditioning to prevent brittleness, while vegan leather benefits from UV-protective coatings in sun-exposed settings.

Comparative Analysis: Cost, Durability & Eco-Friendliness

| Metric | Vegan Leather (Premium PU) | Real Leather (Full-Grain) |

|---|---|---|

| Cost Range | $15–$50/sq. ft. (mid to high tier) | $25–$200+/sq. ft. (highly variable) |

| Durability Factors | – High stain/scratch resistance (initial) – Prone to surface abrasion over time – Degrades faster under intense UV/heat – Consistent thickness, no natural flaws |

– Superior long-term abrasion resistance – Develops patina; ages gracefully – Vulnerable to moisture/staining without treatment – Natural variations affect uniformity |

| Eco-Friendliness | – Lower water/land use vs. livestock – Critical: Water-based PU (e.g., WINIW) avoids DMF, reduces VOCs by 90% – Microplastic shedding risk at end-of-life – Recyclability improving (chemical recycling emerging) |

– High water/land use in tanning – Chromium/chemical pollution risk (unless veg-tanned) – Biodegradable only if untreated – Longer lifespan offsets some footprint |

Strategic Selection Guidance for B2B Partners

- Choose Premium Vegan Leather (PU) when: Consistent aesthetics, rapid production scalability, moisture resistance, and lower operational environmental impact (e.g., water-based production) are priorities. Ideal for tech accessories, mid-cycle furniture, and automotive trims where uniformity matters.

- Choose Real Leather when: Maximum longevity under physical stress, luxury perception, and natural aging are non-negotiable. Best suited for heirloom products (e.g., high-end luggage, premium footwear) where lifetime value outweighs upfront resource costs.

- Optimize Sustainability: Specify water-based PU vegan leather (WINIW’s standard) to eliminate toxic solvents and align with ESG goals. For real leather, demand certified chrome-free or vegetable-tanned hides with traceable supply chains.

Material selection hinges on lifecycle analysis, not isolated traits. WINIW’s engineered synthetics deliver durability parity with mid-tier leather in targeted applications while significantly reducing water toxicity and carbon footprint—enabling brands to meet performance and planetary targets simultaneously. Partner with us to match material specs to your product’s functional and sustainability requirements.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our vertically integrated production capabilities and commitment to quality have positioned us as a trusted partner across industries such as automotive, furniture, apparel, and accessories.

Our manufacturing strength is anchored in a state-of-the-art facility spanning 100,000 square meters. This extensive production space enables us to maintain high output volumes while ensuring operational efficiency and scalability to meet the demands of international clients.

Key strengths of the WINIW factory include:

- Advanced production lines equipped with automated technology for consistent material quality and precision

- In-house Research & Development (R&D) team focused on material innovation, sustainability, and performance enhancement

- Comprehensive quality control (QC) systems implemented at every stage of production, from raw material inspection to final product testing

- Compliance with international environmental and safety standards, including REACH, RoHS, and OEKO-TEX®

- Dedicated testing laboratory for physical and chemical analysis to ensure durability, color fastness, and ecological safety

WINIW exports to key markets worldwide, with a strong presence in Europe and the United States. Our global logistics network ensures timely delivery and customs compliance, supporting long-term partnerships with brands and manufacturers who value reliability and sustainable innovation.

By combining manufacturing scale, technical expertise, and a rigorous quality mindset, WINIW delivers synthetic leather solutions that meet the highest industry benchmarks.

Contact Us for Samples

WINIW Microfiber Leather: Durability-Driven Sustainable Material Solutions for Industry

As a leader in advanced synthetic leather manufacturing, WINIW addresses a critical industry question head-on: Is vegan leather durable? The answer is unequivocally yes—when engineered to exacting technical standards. Our proprietary microfiber leather technology delivers exceptional resilience while meeting rigorous environmental commitments, making it the strategic choice for forward-thinking brands in automotive, furniture, fashion, and accessories.

Why WINIW Microfiber Leather Excels in Durability

Unlike conventional PU/PVC alternatives, WINIW’s high-performance material replicates the structural integrity of top-grain leather through a non-woven microfiber base bonded with premium polyurethane resins. Key durability advantages include:

- Superior Abrasion Resistance: Withstands 100,000+ double-rub cycles (Martindale test), exceeding industry standards for upholstery and automotive seating.

- Exceptional Tear & Tensile Strength: Resists puncturing and stretching under stress, critical for handbags, footwear, and high-use furniture.

- Long-Term Color & Finish Stability: UV-resistant coatings prevent fading, cracking, or peeling even after 500+ hours of accelerated weathering tests.

- Consistent Performance in Extreme Conditions: Maintains flexibility at -30°C and stability up to 85°C, ideal for global supply chains and diverse climates.

Performance Validation: WINIW vs. Industry Benchmarks

Tested per ASTM/ISO standards; results based on WINIW Grade A series

| Property | WINIW Microfiber Leather | Standard PU Leather | Genuine Leather (Top Grain) |

|---|---|---|---|

| Martindale Abrasion (cycles) | 100,000+ | 15,000–25,000 | 80,000–120,000 |

| Tensile Strength (MPa) | 35–42 | 12–18 | 20–30 |

| Tear Strength (N) | 85–110 | 30–45 | 60–90 |

| Lightfastness (Grade) | 7–8 (ISO 105-B02) | 4–5 | 5–6 |

| Recycled Content | 30–50% (post-industrial) | 0–10% | N/A |

Built Responsibly, Engineered to Endure

WINIW’s durability is inseparable from our eco-ethos. Our closed-loop water recycling system reduces consumption by 90% versus conventional processes, while OEKO-TEX® STANDARD 100 certification guarantees zero harmful substances. This ensures:

- Reduced lifecycle waste: Longer-lasting products decrease replacement frequency and landfill burden.

- Supply chain resilience: Consistent roll-to-roll performance minimizes production waste for manufacturers.

- Compliance readiness: Meets EU REACH, California Proposition 65, and automotive OEM sustainability mandates.

Validate Performance for Your Application

Durability isn’t theoretical—it’s proven in real-world use across Mercedes-Benz interiors, Herman Miller seating, and premium footwear brands. Experience WINIW’s resilience firsthand:

- Request free physical samples to conduct your own abrasion, flex, or chemical resistance tests.

- Access full technical dossiers with test reports and compliance documentation.

- Consult our engineering team for custom formulations targeting your specific durability requirements.

→ Contact WINIW’s Material Solutions Team: MKT88@MicrofiberLeather.com

Free samples available for qualified B2B partners. Specify your application, volume needs, and performance priorities.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.