Introduction: Navigating the Global Market for imitation suede fabric

Navigating the global market for imitation suede fabric can be a complex challenge for international B2B buyers, particularly those sourcing materials for various applications such as upholstery, fashion, and event decor. As demand for sustainable and cost-effective alternatives to genuine leather rises, understanding the nuances of imitation suede fabric becomes crucial. This guide aims to equip buyers with essential insights into the different types of imitation suede, their applications across diverse industries, and the key factors to consider when vetting suppliers.

In an increasingly competitive landscape, this resource provides a comprehensive overview of the market, including vital information on pricing structures, quality differentiation, and sourcing strategies tailored to regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria. By addressing critical considerations such as material composition, color variety, and care instructions, this guide empowers decision-makers to make informed purchasing choices that align with their business goals.

Moreover, understanding the intricacies of imitation suede fabric not only enhances product offerings but also supports sustainable practices within various sectors. With this knowledge, B2B buyers can navigate the complexities of the market with confidence, ensuring they select the best materials for their specific needs while fostering long-term supplier relationships.

Table Of Contents

- Top 6 Imitation Suede Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for imitation suede fabric

- Understanding imitation suede fabric Types and Variations

- Key Industrial Applications of imitation suede fabric

- 3 Common User Pain Points for ‘imitation suede fabric’ & Their Solutions

- Strategic Material Selection Guide for imitation suede fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for imitation suede fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘imitation suede fabric’

- Comprehensive Cost and Pricing Analysis for imitation suede fabric Sourcing

- Alternatives Analysis: Comparing imitation suede fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for imitation suede fabric

- Navigating Market Dynamics and Sourcing Trends in the imitation suede fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of imitation suede fabric

- Strategic Sourcing Conclusion and Outlook for imitation suede fabric

- Important Disclaimer & Terms of Use

Understanding imitation suede fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microsuede | Soft, velvety texture; typically made from 100% polyester; dense, durable weave | Upholstery, fashion apparel, accessories | Pros: Soft feel, easy to clean; Cons: Limited color fastness, may require dry cleaning. |

| Ultra suede | High-quality faux suede; often resembles genuine leather; available in various textures | Luxury upholstery, high-end fashion | Pros: Luxurious appearance, durable; Cons: Higher cost, may have limited availability. |

| Faux suede (polyester) | Made from synthetic fibers; versatile and available in various colors and patterns | Home décor, automotive interiors, apparel | Pros: Cost-effective, wide variety; Cons: Can be less breathable, may not have the same feel as real suede. |

| Microfiber suede | Extremely soft and lightweight; often water-resistant; made from fine synthetic fibers | Fashion items, sportswear, upholstery | Pros: Lightweight, easy to maintain; Cons: Can be less durable in high-wear applications. |

| Eco-suede | Made from recycled materials; environmentally friendly; soft texture | Sustainable fashion, eco-conscious products | Pros: Eco-friendly, unique appeal; Cons: May be more expensive, variable quality. |

What are the key characteristics of Microsuede fabric for B2B buyers?

Microsuede is a popular choice for B2B buyers due to its soft, velvety texture and durability. This fabric is typically made from 100% polyester, offering a dense weave that enhances its strength while maintaining a luxurious feel. Common applications include upholstery, fashion apparel, and accessories. Buyers should consider its ease of cleaning and maintenance; however, microsuede can sometimes lack color fastness and may require dry cleaning, which could be a consideration for high-traffic environments.

How does Ultra Suede stand out in the market?

Ultra suede is known for its high-quality faux suede appearance, often mimicking genuine leather closely. It is available in a variety of textures and colors, making it an ideal choice for luxury upholstery and high-end fashion applications. The key advantages of ultra suede are its luxurious look and durability, which can justify its higher price point. However, B2B buyers should be aware that its availability may be limited depending on suppliers, potentially impacting production timelines.

Why is Faux Suede (Polyester) a versatile option?

Faux suede made from polyester is a versatile fabric that offers a wide range of colors and patterns. This fabric is cost-effective, making it a popular choice for home décor, automotive interiors, and apparel. While it provides a budget-friendly alternative to genuine suede, buyers should note that it may not be as breathable and can lack the authentic feel of real suede. Understanding the balance between cost and quality is crucial for B2B buyers when selecting this fabric for their projects.

What advantages does Microfiber Suede offer for specific applications?

Microfiber suede is characterized by its extremely soft and lightweight nature, often featuring water-resistant properties. This makes it particularly suitable for fashion items, sportswear, and upholstery where comfort and functionality are key. The ease of maintenance is a significant advantage for B2B buyers, as it allows for simple cleaning and upkeep. However, it is essential to consider that microfiber suede may not hold up as well in high-wear applications, which could be a factor in purchasing decisions.

How does Eco-Suede appeal to environmentally conscious buyers?

Eco-suede is an innovative fabric made from recycled materials, appealing to environmentally conscious buyers. Its soft texture and sustainable production methods make it a popular choice for sustainable fashion and eco-friendly products. While eco-suede can offer a unique appeal, B2B buyers should be prepared for potentially higher costs and variable quality compared to traditional faux suede options. Understanding the market demand for sustainable materials can help buyers make informed decisions in their sourcing strategies.

Key Industrial Applications of imitation suede fabric

| Industry/Sector | Specific Application of imitation suede fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Clothing and Accessories | Offers a luxurious look at a lower cost than real suede; versatile for various designs. | Ensure color consistency and quality; consider local regulations for fabric imports. |

| Furniture and Upholstery | Sofas, Chairs, and Decorative Items | Durable and easy to clean; provides a stylish alternative to leather. | Evaluate fabric weight and durability; check for compliance with fire safety standards. |

| Automotive | Interior Upholstery for Cars | Enhances aesthetics while being cost-effective; lightweight and easy to maintain. | Assess color options and finish quality; consider regional climate impacts on material performance. |

| Home Textiles | Curtains, Cushions, and Bed Linens | Adds a touch of elegance and comfort; resistant to wear and tear. | Verify fabric treatment for stain resistance; ensure availability in desired colors and patterns. |

| Event Planning | Decorative Elements for Events and Exhibitions | Creates a sophisticated ambiance; lightweight for easy transport and setup. | Confirm bulk order capabilities and delivery timelines; evaluate fabric samples for color accuracy. |

How is Imitation Suede Fabric Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, imitation suede fabric is widely used for clothing, bags, and accessories. Its soft texture and stylish appearance mimic real suede, allowing designers to create high-quality garments at a fraction of the cost. For international buyers, especially from regions like Africa and South America, sourcing from manufacturers that provide consistent color and quality is essential. Additionally, understanding local fashion trends can help buyers select the right styles and colors that appeal to their markets.

What Role Does Imitation Suede Fabric Play in Furniture and Upholstery?

Imitation suede fabric is increasingly popular in the furniture industry for sofas, chairs, and decorative items. It offers durability and ease of maintenance, making it an attractive choice for both residential and commercial applications. For B2B buyers, especially in Europe and the Middle East, it’s crucial to assess the fabric’s weight and durability to ensure it meets the demands of everyday use. Additionally, compliance with local fire safety regulations is a significant consideration when sourcing upholstery fabrics.

How is Imitation Suede Fabric Utilized in the Automotive Sector?

In the automotive industry, imitation suede fabric is often used for interior upholstery, enhancing the aesthetic appeal of vehicles while being cost-effective. Its lightweight nature and ease of maintenance make it a practical choice for manufacturers. Buyers from regions with varied climates, such as Africa and Europe, should evaluate the fabric’s performance under different environmental conditions. Additionally, color options and finish quality are vital to ensure that they align with automotive design standards and customer preferences.

What are the Benefits of Imitation Suede Fabric in Home Textiles?

Imitation suede fabric is an excellent choice for home textiles, including curtains, cushions, and bed linens. Its luxurious feel and resistance to wear and tear add elegance to home decor. For B2B buyers, verifying the fabric treatment for stain resistance is crucial, especially in markets where durability is a priority. Ensuring that the desired colors and patterns are available in bulk can also facilitate smoother inventory management and customer satisfaction.

Illustrative image related to imitation suede fabric

How is Imitation Suede Fabric Used in Event Planning?

In the event planning sector, imitation suede fabric is used for decorative elements in exhibitions and events. Its ability to create a sophisticated ambiance while being lightweight makes it ideal for transport and setup. Buyers should confirm the supplier’s ability to handle bulk orders and meet delivery timelines, as event planning often involves tight schedules. Evaluating fabric samples for color accuracy ensures that the final decorations align with the event’s theme and branding.

3 Common User Pain Points for ‘imitation suede fabric’ & Their Solutions

Scenario 1: Sourcing Quality Imitation Suede Fabric

The Problem:

B2B buyers often face challenges when sourcing imitation suede fabric that meets their quality standards. With numerous suppliers claiming to offer high-quality materials, it can be difficult to differentiate between genuine high-grade fabrics and subpar alternatives. This can lead to costly mistakes, such as receiving materials that do not hold up under use, resulting in increased returns and dissatisfied customers.

The Solution:

To mitigate this risk, buyers should establish a systematic approach to sourcing. First, prioritize suppliers with a proven track record and positive reviews from other businesses in the industry. Request samples before committing to large orders; this allows you to assess the fabric’s texture, durability, and color accuracy firsthand. Additionally, consider suppliers that provide detailed product specifications, including fabric weight and content, which can help in evaluating quality. Engaging in direct communication with suppliers can also clarify any doubts about their production processes and quality control measures, ensuring you make informed purchasing decisions.

Scenario 2: Navigating Color Consistency Issues

The Problem:

Color inconsistency is a common pain point when dealing with imitation suede fabric. Dye lots can vary significantly from one production run to another, leading to discrepancies that can disrupt production schedules and affect product aesthetics. This is particularly problematic for businesses that require uniformity in bulk orders, such as fashion brands or upholstery manufacturers.

The Solution:

To address color consistency, always request dye lot information from your supplier before placing an order. Building a relationship with a reliable supplier who offers consistent dye lots can significantly reduce variability. Implementing a color matching system in your production process can also help, where you keep a reference sample of the desired color for all future orders. Additionally, consider ordering extra fabric to account for potential color discrepancies, which allows for adjustments during production without significant delays. By taking these proactive steps, you can maintain the quality and consistency that your brand promises.

Scenario 3: Understanding Care and Maintenance Requirements

The Problem:

Many B2B buyers may overlook the care and maintenance requirements for imitation suede fabric, leading to misunderstandings regarding its usability and longevity. Since imitation suede often requires specific cleaning methods—such as dry cleaning only—failure to adhere to these guidelines can result in fabric damage, diminishing the overall quality of the finished products.

The Solution:

Educate yourself and your team on the specific care instructions for the imitation suede you intend to use. When sourcing fabric, ensure that suppliers provide clear care guidelines and incorporate this information into your product documentation. Training staff on proper cleaning methods can help prevent mishaps and maintain the fabric’s integrity over time. Additionally, consider creating a maintenance guide for your end customers, outlining how to care for products made with imitation suede. This not only enhances customer satisfaction but also reduces the likelihood of returns due to fabric damage, ultimately protecting your bottom line.

Strategic Material Selection Guide for imitation suede fabric

What are the Common Materials Used in Imitation Suede Fabric?

Imitation suede fabric is primarily constructed from synthetic fibers, with several key materials dominating the market. Understanding these materials is essential for B2B buyers looking to make informed purchasing decisions. Here, we analyze four common materials used in imitation suede, focusing on their properties, advantages and disadvantages, and considerations for international buyers.

1. Polyester Microfiber

Key Properties:

Polyester microfiber is a finely woven synthetic fiber known for its softness and durability. It typically has a weight of around 225 grams per square meter, making it suitable for various applications, including upholstery and fashion.

Pros & Cons:

The primary advantage of polyester microfiber is its resistance to wear and tear, making it an excellent choice for high-traffic areas. It is also easy to clean and maintain, often requiring dry cleaning. However, it can be more expensive than other synthetic options, and its production process may involve complex dyeing techniques, which can increase costs.

Impact on Application:

Due to its soft texture and durability, polyester microfiber is widely used in clothing, upholstery, and accessories. Its compatibility with various dyeing methods allows for a broad color palette, appealing to diverse markets.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for textile safety and quality. Additionally, awareness of local preferences for fabric softness and color variety is crucial, especially in regions like Europe and the Middle East.

2. Polyurethane (PU) Coated Fabric

Key Properties:

PU-coated fabrics provide a leather-like appearance and feel, combining a polyester base with a polyurethane coating. This material is known for its water resistance and flexibility.

Illustrative image related to imitation suede fabric

Pros & Cons:

The main advantage of PU-coated fabric is its aesthetic appeal, resembling genuine leather while being more affordable. However, it may not be as durable as other materials, particularly in extreme temperatures, which can affect its longevity.

Impact on Application:

This material is often used in fashion items, furniture, and automotive interiors due to its stylish look and ease of maintenance. However, its limited temperature tolerance may restrict its use in certain climates, particularly in hotter regions.

Considerations for International Buyers:

Buyers in hot climates, such as parts of Africa and South America, should evaluate the temperature performance of PU-coated fabrics. Additionally, understanding local regulations regarding chemical content in textiles is essential for compliance.

3. Recycled Polyester

Key Properties:

Recycled polyester is made from post-consumer plastic bottles and offers similar properties to virgin polyester, including durability and resistance to shrinking and stretching.

Pros & Cons:

The key advantage of recycled polyester is its environmental sustainability, appealing to eco-conscious buyers. However, the production process can be more complex, potentially leading to higher costs and variability in quality.

Illustrative image related to imitation suede fabric

Impact on Application:

Recycled polyester is increasingly popular in the fashion industry, particularly among brands focusing on sustainability. It is suitable for a wide range of applications, from clothing to upholstery.

Considerations for International Buyers:

Sustainability certifications (like GRS) are crucial for buyers in Europe, where eco-friendly products are in high demand. Understanding the supply chain and sourcing practices is vital to ensure compliance with international standards.

4. Nylon Suede

Key Properties:

Nylon suede is a synthetic fabric that mimics the texture of natural suede while offering enhanced durability and resistance to abrasion.

Illustrative image related to imitation suede fabric

Pros & Cons:

Nylon suede is highly durable and resistant to fading, making it suitable for outdoor applications. However, it may lack the softness of other materials, which can be a drawback for certain fashion applications.

Impact on Application:

This material is often used in outdoor apparel and accessories due to its durability. Its resistance to moisture and UV rays makes it ideal for various environmental conditions.

Considerations for International Buyers:

Buyers should consider the climate and intended use of the fabric when selecting nylon suede. Compliance with international textile standards is also necessary to ensure product safety and quality.

Summary Table of Material Properties

| Material | Typical Use Case for imitation suede fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester Microfiber | Upholstery, fashion, accessories | High durability and softness | Higher cost due to complex dyeing | Medium |

| PU Coated Fabric | Fashion items, furniture, automotive | Aesthetic appeal, leather-like | Limited durability in extreme temps | Medium |

| Recycled Polyester | Fashion, upholstery | Eco-friendly and sustainable | Higher production complexity | Medium |

| Nylon Suede | Outdoor apparel, accessories | High durability and UV resistance | Less softness compared to others | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in various international markets, enabling them to make informed decisions when sourcing imitation suede fabric.

Illustrative image related to imitation suede fabric

In-depth Look: Manufacturing Processes and Quality Assurance for imitation suede fabric

What Are the Key Stages in the Manufacturing Process of Imitation Suede Fabric?

The manufacturing of imitation suede fabric, commonly made from polyester or a blend of synthetic fibers, involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure that the final product meets the desired quality standards and performance characteristics.

Material Preparation: Sourcing and Processing

The first step in the manufacturing process is sourcing high-quality polyester fibers. These fibers are often treated with various chemicals to enhance their properties, such as softness and durability. After sourcing, the fibers are cleaned and processed to remove impurities. This stage may also include dyeing the fibers to achieve the desired color before they are spun into yarn.

Forming: Weaving and Knitting Techniques

Once the fibers are prepared, they are woven or knitted into a fabric. For imitation suede, a common method is to use a twill weave, which creates a textured surface that mimics the softness of real suede. The choice of weaving technique can significantly affect the final texture and appearance of the fabric. Advanced techniques like microdenier technology may also be employed to produce finer, softer fibers that enhance the overall feel and aesthetic of the fabric.

Assembly: Cutting and Shaping

After the fabric is formed, it undergoes a cutting process where it is shaped into various dimensions based on customer specifications. This is particularly important for B2B buyers who may require specific sizes for upholstery, fashion, or other applications. During this stage, it’s crucial to ensure that the fabric is cut accurately to prevent waste and maintain cost-effectiveness.

Finishing: Quality Enhancement Processes

The finishing stage involves several treatments that enhance the fabric’s properties. This may include applying a water-repellent coating, anti-static treatments, or softening agents to improve the touch and usability of the fabric. Finishing processes can also involve additional dyeing or printing, depending on the design requirements. The goal is to ensure that the imitation suede not only looks appealing but also performs well in various applications.

Illustrative image related to imitation suede fabric

How is Quality Assurance Implemented in Imitation Suede Fabric Production?

Quality assurance (QA) is a vital component of the manufacturing process, particularly for B2B buyers who depend on consistent quality and compliance with international standards. Various checkpoints and testing methods are employed to ensure that the fabric meets required specifications.

What International Standards Govern Quality Assurance for Imitation Suede Fabric?

International standards such as ISO 9001 provide a framework for quality management systems that manufacturers can follow. Compliance with these standards indicates a commitment to quality and continuous improvement. In addition to ISO standards, specific industry certifications like CE and API may be relevant depending on the end-use of the fabric.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet required standards.

- In-Process Quality Control (IPQC): Monitoring the production process at various stages to catch any defects early.

- Final Quality Control (FQC): Conducting thorough inspections of the finished product to ensure it meets all specifications before shipping.

These checkpoints help ensure that any defects are identified and rectified before the product reaches the buyer.

Illustrative image related to imitation suede fabric

What Common Testing Methods Are Used for Imitation Suede Fabric?

Manufacturers employ several testing methods to assess the quality of imitation suede fabric, including:

- Physical Testing: Evaluating properties such as tensile strength, abrasion resistance, and colorfastness to ensure the fabric can withstand everyday use.

- Chemical Testing: Analyzing the fabric for harmful substances to comply with safety regulations, particularly important for products intended for children or sensitive applications.

- Performance Testing: Assessing water resistance, breathability, and other performance characteristics that impact the fabric’s usability.

These tests help ensure that the final product is not only visually appealing but also functional and safe.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring that they receive high-quality products consistently. Here are some actionable steps:

-

Conduct Supplier Audits: Regularly assess suppliers’ manufacturing processes and quality control measures. This can involve site visits or audits to verify compliance with international standards.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, testing results, and compliance with relevant standards. This information can give buyers insight into the supplier’s commitment to quality.

-

Engage Third-Party Inspection Services: Utilizing independent inspection services can provide an unbiased assessment of the fabric’s quality before shipment. These services can conduct tests and verify compliance with specified standards.

-

Check Certifications: Ensure that the supplier holds relevant certifications that validate their adherence to quality standards. This is particularly important when sourcing from international markets.

What Are the QC and Certification Nuances for International B2B Buyers?

For B2B buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and compliance requirements is essential. Different countries may have specific quality standards and certifications that need to be adhered to.

Illustrative image related to imitation suede fabric

-

Regional Standards: Buyers should be aware of any local regulations regarding textile safety and environmental impact, as these can vary significantly.

-

Cultural Considerations: In regions like the Middle East and Africa, cultural preferences may influence the type of imitation suede fabric required. Understanding these nuances can enhance supplier relationships and ensure product acceptance in local markets.

-

Logistics and Shipping: International buyers must also consider logistics and the impact of shipping on quality. Ensuring that suppliers have robust packaging and shipping processes can prevent damage during transport.

By focusing on these key areas of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing imitation suede fabric, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘imitation suede fabric’

Introduction

This guide provides a practical checklist for B2B buyers looking to source imitation suede fabric. As a versatile and popular material used in various applications—from upholstery to fashion—understanding the key steps in sourcing can help ensure that you select the right product and supplier for your needs.

Step 1: Define Your Technical Specifications

Before starting your search for imitation suede fabric, clearly outline your technical specifications. Consider factors such as weight, thickness, and texture, as well as the intended use of the fabric.

– Weight and Composition: Imitation suede typically comes in polyester blends; ensure you specify the desired weight (e.g., around 225 grams per square meter) for durability and application.

– Texture and Finish: Decide if you need a specific finish, such as a soft napped surface, which affects the aesthetic and tactile quality.

Step 2: Research Potential Suppliers

Identify and research potential suppliers who specialize in imitation suede fabric. This is critical as the quality and reliability of your source can significantly impact your business.

– Supplier Reputation: Look for suppliers with a proven track record in your target market, especially those who cater to regions like Africa, South America, the Middle East, and Europe.

– Product Range: Ensure the supplier offers a variety of colors and weights to meet diverse customer demands.

Illustrative image related to imitation suede fabric

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that your chosen suppliers have the necessary certifications. This step is essential for ensuring product quality and compliance with international standards.

– Quality Assurance: Check for certifications like ISO 9001, which indicates a commitment to quality management systems.

– Sustainability Standards: If relevant to your market, inquire about certifications like OEKO-TEX, which ensure the fabric is free from harmful substances.

Step 4: Request Samples

Always request fabric samples before placing a bulk order. This allows you to assess the quality, texture, and color accuracy of the imitation suede fabric.

– Sample Swatch Size: Opt for a sample size of at least 3″x3″ to evaluate the material effectively.

– Dye Lot Variability: Be aware that dye lots may vary; requesting samples can help ensure consistency across your order.

Step 5: Understand Pricing Structures

Clarify pricing structures with potential suppliers to avoid unexpected costs. Understanding how pricing is determined will help you budget effectively.

– Minimum Order Quantities (MOQs): Inquire about MOQs for both yards and bolts to align with your purchasing capacity.

– Shipping Costs: Confirm shipping fees and any handling charges to ensure complete transparency in your total cost.

Step 6: Assess Lead Times and Shipping Options

Confirm lead times and shipping options with your suppliers. This information is crucial for planning your production schedules.

– Production Time: Ask how long it takes to fulfill an order, especially for larger quantities.

– Shipping Logistics: Evaluate the reliability of shipping methods offered, particularly if you are importing from overseas.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Ensure that you have established reliable channels with your suppliers.

– Language and Time Zone Considerations: Be aware of any language barriers or time zone differences that may affect communication.

– Regular Updates: Set expectations for regular updates regarding order status, shipping, and any potential delays.

Illustrative image related to imitation suede fabric

Following this checklist will help you navigate the complexities of sourcing imitation suede fabric efficiently, ensuring you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for imitation suede fabric Sourcing

What Are the Key Cost Components in Imitation Suede Fabric Sourcing?

When sourcing imitation suede fabric, understanding the cost structure is crucial for B2B buyers. Key cost components include:

-

Materials: The primary material for imitation suede is often polyester, which varies in quality. Higher-grade polyester can command a higher price due to its durability and texture. The choice of dye and finishing processes also impacts material costs.

-

Labor: Labor costs can fluctuate based on the region of production. Countries with lower wage standards may offer cheaper labor, but this could affect the quality of the final product. Skilled labor is often necessary for quality control and intricate manufacturing processes.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Efficient production processes can help mitigate overhead costs, making it important to assess a supplier’s operational efficiency.

-

Tooling: Initial tooling costs for molds and machinery setup can be significant, especially for custom designs. Buyers should consider these costs in relation to their order volume, as larger orders can spread tooling expenses over more units.

-

Quality Control (QC): Implementing robust QC measures is essential for maintaining product standards. This adds to the overall cost but is critical for ensuring that the fabric meets specifications, particularly for international buyers who may face stricter regulations.

-

Logistics: Transportation costs can vary widely based on shipping methods, distances, and Incoterms. Buyers must factor in both freight and insurance when calculating total costs.

-

Margin: Suppliers typically apply a profit margin to their costs. Understanding the market rate for imitation suede can help buyers negotiate better pricing.

How Do Price Influencers Affect Imitation Suede Fabric Sourcing?

Several factors influence the pricing of imitation suede fabric, including:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect unit costs. Larger orders usually qualify for discounts, while smaller orders may incur higher per-unit prices. Buyers should evaluate their needs to optimize order sizes.

-

Specifications and Customization: Custom colors, patterns, or finishes can increase costs. Suppliers may charge a premium for custom work, so it’s beneficial to define specifications clearly before engaging suppliers.

-

Material Quality and Certifications: Fabrics with certifications, such as OEKO-TEX or recycled content, may cost more but can enhance product appeal in eco-conscious markets. Buyers should assess whether these certifications are necessary for their target audience.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can all influence pricing. Established suppliers may charge more due to their reliability and quality assurance practices.

-

Incoterms: The chosen Incoterms dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Understanding these terms can help buyers avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Imitation Suede Fabric Sourcing?

To maximize cost-efficiency when sourcing imitation suede fabric, consider the following tips:

-

Negotiate Pricing: Always approach suppliers with a clear understanding of market rates and be prepared to negotiate. Building a relationship with suppliers can lead to better terms and pricing over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as shipping, storage, and disposal. A lower upfront cost may not always result in savings if other factors increase overall expenses.

-

Understand Pricing Nuances for International Markets: For buyers in Africa, South America, the Middle East, and Europe, currency fluctuations and tariffs can significantly affect prices. It’s essential to account for these variables when budgeting for orders.

-

Request Samples: Always request fabric samples before placing large orders. This allows for quality assessment and helps avoid costly mistakes related to color or texture mismatches.

Disclaimer

The prices mentioned herein are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. Always conduct thorough research and consult multiple suppliers to ensure competitive pricing and quality standards.

Alternatives Analysis: Comparing imitation suede fabric With Other Solutions

Exploring Alternatives to Imitation Suede Fabric: A Comparative Analysis

In the textile industry, imitation suede fabric serves as a popular alternative to genuine suede, offering a cost-effective and ethical solution for various applications. However, buyers should consider a range of alternatives to ensure they select the most suitable material for their specific needs. This analysis compares imitation suede fabric with two viable alternatives: microfiber and faux leather, assessing performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Imitation Suede Fabric | Microfiber | Faux Leather |

|---|---|---|---|

| Performance | Soft, durable, and breathable; mimics natural suede | Highly absorbent, resistant to stains and wear | Water-resistant, versatile, and available in various textures |

| Cost | Moderate ($8.99/yard) | Affordable ($5-$15/yard) | Varies widely ($10-$50/yard) |

| Ease of Implementation | Easy to sew and manipulate | Requires specific sewing techniques | Similar to traditional leather; may require specialized tools |

| Maintenance | Dry clean only | Machine washable; easy to care for | Wipe clean; some may require special cleaning agents |

| Best Use Case | Upholstery, fashion items, cosplay | Cleaning cloths, home decor, clothing | Bags, jackets, furniture, and accessories |

What Are the Advantages and Disadvantages of Microfiber?

Microfiber is a synthetic material composed of finely woven fibers, making it exceptionally soft and lightweight. One of its key advantages is its high absorbency and resistance to stains, making it ideal for cleaning applications and home decor. Its affordability, typically ranging from $5 to $15 per yard, makes it a cost-effective option for bulk purchases. However, microfiber may lack the luxurious feel of imitation suede, which could be a downside for high-end fashion applications. Additionally, while it is machine washable, improper care can lead to wear and tear over time.

How Does Faux Leather Compare to Imitation Suede Fabric?

Faux leather, also known as synthetic leather, offers a more robust and water-resistant alternative to imitation suede. It is available in a variety of textures and finishes, allowing for versatility in design. Faux leather is often used in bags, jackets, and upholstery, providing a polished look that can mimic genuine leather. The cost can vary significantly, ranging from $10 to $50 per yard, depending on the quality and brand. One of its downsides is that it can be less breathable than imitation suede, potentially leading to discomfort in certain applications. Maintenance is relatively simple, requiring only a wipe down with a damp cloth, although some products may need specialized cleaners.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right fabric for a project, B2B buyers should assess their specific requirements, including the intended application, budget constraints, and maintenance capabilities. Imitation suede fabric excels in fashion and upholstery applications where a soft texture is paramount. In contrast, microfiber may be ideal for cleaning products and home decor, while faux leather is suited for items requiring durability and water resistance. By carefully evaluating these alternatives, buyers can make informed decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for imitation suede fabric

What Are the Key Technical Properties of Imitation Suede Fabric?

When sourcing imitation suede fabric for various applications, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

-

Material Composition

Imitation suede is primarily made from polyester, a synthetic fiber known for its durability and versatility. The blend may also include other materials to enhance specific properties like stretch or softness. Understanding the material composition helps buyers assess the fabric’s performance in different environments and applications, such as upholstery or fashion. -

Fabric Weight

Measured in grams per square meter (GSM), fabric weight indicates the density and sturdiness of the material. For imitation suede, a typical weight ranges from 200 to 300 GSM. Heavier fabrics are usually more durable and suitable for upholstery, while lighter versions are ideal for fashion items. Buyers should select the weight based on the intended use to ensure longevity and performance. -

Width

The standard width for imitation suede fabric typically ranges from 58 to 60 inches. Knowing the width is crucial for calculating material requirements for projects, ensuring efficient usage, and minimizing waste. Wider fabrics may also reduce seams in larger projects, contributing to a more polished finish. -

Abrasion Resistance

This property measures how well the fabric withstands wear and tear. A higher abrasion resistance rating indicates a longer-lasting product, which is particularly important for items subject to frequent use, such as upholstery or outerwear. Buyers should consider this factor to ensure the longevity of their products. -

Colorfastness

Colorfastness refers to the fabric’s ability to retain its color when exposed to light, washing, or friction. It is critical for maintaining the aesthetic appeal of finished products. Buyers should verify colorfastness ratings to ensure that their products will remain vibrant and not fade over time.

What Are Common Trade Terms Related to Imitation Suede Fabric?

Navigating the world of B2B sourcing involves understanding various industry-specific terms. Here are some common jargon and trade terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of imitation suede, an OEM may provide custom fabric solutions tailored to specific client needs. Understanding OEM relationships can help buyers negotiate better terms and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory levels and cash flow. Knowing the MOQ allows buyers to plan their purchases effectively and avoid overstocking. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific quantities of products. It is a formal way to initiate negotiations and can help buyers gather competitive pricing and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers, particularly when sourcing from international suppliers, as they dictate who is responsible for costs and risks at various points in the shipping process. -

Dye Lot Variations

This term refers to the variations in color that can occur between different batches of fabric produced at different times. Understanding dye lot variations is important for buyers to ensure consistency in color across multiple orders, especially for large projects. -

Sample Swatch

A sample swatch is a small piece of fabric provided to buyers to evaluate texture, color, and quality before placing a larger order. Requesting a sample swatch is a prudent step for buyers to mitigate the risk of dissatisfaction with the final product.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing imitation suede fabric, ensuring that they select the right materials for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the imitation suede fabric Sector

What Are the Key Market Drivers and Trends in Imitation Suede Fabric?

The imitation suede fabric market is experiencing significant growth, driven by increased demand for versatile and cost-effective alternatives to natural leather. Key drivers include the rising global consciousness regarding animal welfare, which has led many brands to seek cruelty-free materials. Additionally, the fashion and upholstery industries are increasingly turning to imitation suede for its aesthetic appeal and durability, making it a preferred choice for a wide range of applications, from clothing to home décor.

Emerging trends in B2B sourcing include the integration of technology in supply chain management. Platforms utilizing artificial intelligence and blockchain technology are enhancing transparency and efficiency, enabling buyers to track materials from production to delivery. This is particularly crucial for international buyers from regions like Africa and South America, who are often navigating complex logistics. Furthermore, the rise of customization options in textile manufacturing is allowing businesses to meet specific market needs, catering to local tastes and preferences, which is essential for markets in Europe, such as Germany.

How Is Sustainability Shaping the Imitation Suede Fabric Supply Chain?

Sustainability is becoming a cornerstone in the sourcing of imitation suede fabric. With growing concerns over environmental degradation, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. The production of imitation suede, primarily made from polyester, poses environmental challenges, particularly in terms of plastic waste. However, many manufacturers are now adopting recycled materials and eco-friendly dyes, which significantly reduce the environmental footprint of their products.

Ethical sourcing is also gaining traction, with businesses seeking suppliers who can provide certifications that validate their sustainability claims. Buyers are looking for ‘green’ certifications such as OEKO-TEX® or Global Recycle Standard (GRS), which assure that the fabrics are produced without harmful chemicals and through responsible labor practices. This shift towards ethical sourcing not only meets consumer demand for sustainable products but also enhances brand reputation, especially in markets where consumers are becoming more environmentally conscious.

What Is the Historical Context of Imitation Suede Fabric in the B2B Market?

The evolution of imitation suede fabric can be traced back to the mid-20th century when synthetic fibers began to gain popularity as a more affordable and versatile alternative to natural leather. Initially developed for the fashion industry, imitation suede quickly found its way into various sectors, including automotive and upholstery, due to its durability and ease of maintenance. The innovation of microfibers in the 1980s marked a significant turning point, enabling manufacturers to create fabrics that closely resemble the texture and appearance of genuine suede.

As consumer preferences shifted towards cruelty-free options, imitation suede solidified its position in the market. Today, it stands as a testament to how advancements in textile technology can meet both aesthetic demands and ethical considerations, making it an essential material for B2B buyers across diverse industries. The historical growth trajectory of imitation suede highlights its adaptability and relevance in an ever-evolving market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of imitation suede fabric

-

How do I choose the right imitation suede fabric for my project?

When selecting imitation suede fabric, consider the intended use, such as upholstery, fashion, or accessories. Evaluate the fabric weight and texture; heavier fabrics are better for upholstery, while lighter options may suit clothing. Additionally, check the available colors and patterns to ensure they align with your design vision. Requesting sample swatches is advisable to assess the fabric’s quality and feel before making a bulk purchase. -

What are the key benefits of using imitation suede fabric in B2B applications?

Imitation suede offers several advantages, including cost-effectiveness, versatility, and ease of maintenance. It mimics the luxurious appearance of genuine suede while being more durable and resistant to stains and fading. This makes it an ideal choice for various applications, from upholstery in hotels and restaurants to fashion items like bags and garments. Furthermore, it is often more environmentally friendly, as it avoids the ethical concerns associated with animal-derived materials. -

What is the minimum order quantity (MOQ) for imitation suede fabric?

The MOQ for imitation suede fabric varies by supplier, typically ranging from 2 to 10 yards for small orders, while larger manufacturers may require a minimum of 100 yards or more. It is essential to confirm the MOQ with your supplier before placing an order, as this can impact your budget and inventory management. If you require a smaller quantity, consider suppliers that offer fabric by the yard or sample swatches. -

How can I verify the credibility of a supplier for imitation suede fabric?

To ensure the reliability of a supplier, conduct thorough research by checking online reviews, asking for references, and reviewing their certifications. Verify their operational history and look for signs of professionalism, such as clear communication and timely responses. Additionally, consider visiting their manufacturing facility if possible, or request samples of their products to assess quality firsthand before committing to a larger order. -

What payment terms are typically offered for international orders of imitation suede fabric?

Payment terms for international orders can vary widely among suppliers. Common options include upfront payment, partial payment upon order confirmation with the balance due before shipping, or net payment terms (e.g., net 30 or net 60 days). Be sure to clarify payment methods accepted (e.g., wire transfer, credit card, PayPal) and any additional fees for international transactions. Establishing clear payment terms helps mitigate financial risks and ensures smoother transactions. -

What are the shipping options for importing imitation suede fabric?

When importing imitation suede fabric, various shipping options are available, including air freight for faster delivery and sea freight for more economical transport. The choice of shipping method may depend on the urgency of your order and budget constraints. Ensure you discuss shipping costs and delivery timelines with your supplier, and consider partnering with a freight forwarder to navigate customs regulations and optimize logistics. -

How do I handle quality assurance for bulk orders of imitation suede fabric?

Implementing a quality assurance (QA) process is crucial when sourcing imitation suede fabric. Start by defining quality criteria based on your project’s requirements, including color consistency, texture, and durability. Request pre-production samples to evaluate quality before bulk production. Additionally, consider hiring a third-party inspection service to assess the fabric during production and prior to shipment, ensuring it meets your specifications. -

What customization options are available for imitation suede fabric?

Many suppliers offer customization options for imitation suede fabric, including color matching, printing, and embossing. Discuss your specific needs with the supplier to understand their capabilities and any associated costs. Customization can enhance the uniqueness of your products, making them more appealing to your target market. However, be mindful of potential minimum order quantities or longer lead times for customized fabrics.

Top 6 Imitation Suede Fabric Manufacturers & Suppliers List

1. Online Fabric Store – Faux Suede Fabric

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: Faux suede fabric available in various colors and widths, suitable for upholstery, apparel, and crafts. Soft texture, durable, and easy to clean. Ideal for creating a luxurious look without the cost of real suede.

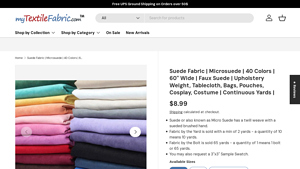

2. My Textile Fabric – Suede Fabric | Microsuede

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Suede Fabric | Microsuede”, “Colors Available”: 40, “Width”: “60 inches”, “Type”: “Faux Suede”, “Price”: “$8.99 per yard”, “Minimum Order”: “2 yards”, “Bolt Size”: “65 yards”, “Sample Swatch Size”: “3×3 inches”, “Fabric Composition”: “100% Polyester”, “Fabric Weight”: “Approximately 225 grams per square meter”, “Cleaning Instructions”: “Dry Clean Only”, “Uses”: [“Upholstery”, “Ta…

3. Mood Fabrics – Free Delivery Over $150

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: This company, Mood Fabrics – Free Delivery Over $150, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

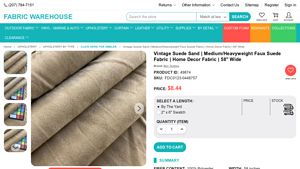

4. Ben Textiles – Vintage Suede Sand

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Vintage Suede Sand”,”Type”: “Medium/Heavyweight Faux Suede Fabric”,”Usage”: “Home Decor Fabric”,”Width”: “58 inches”,”Fiber Content”: “100% Polyester”,”Upholstery Weight”: “Medium/Heavyweight”,”Pattern”: “Solid/Plain”,”Brand”: “Ben Textiles”,”Product ID”: “49874”,”SKU”: “FDC0123-0448757-01″,”Price”: {“Sale Price”: “$3.00 – $8.44″,”Original Price”: “MSRP: You save”},”Shipping”: “F…

5. Decorative Fabrics Direct – Faux Suede Upholstery Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Faux Suede Upholstery Fabric – Microsuede Fabric

– Material: Typically 100% polyester, made to resemble genuine suede.

– Type: Lightweight faux suede made from micro denier fibers.

– Durability: More durable than real suede, less expensive, easy to care for.

– Texture: Soft and supple.

– Availability: Various colors and patterns.

– Purchase: Available by the yard at distributor wholesale prices.

-…

6. CNC Fabrics – Faux Suede Fabric

Domain: cncfabrics.com

Registered: 2011 (14 years)

Introduction: Faux Suede fabric, high quality, smooth fuzzy finish, heavyweight, suitable for apparel (pants, skirts, jackets, gloves, handbags) and upholstery (chair/couch coverings, pillows). Available in various colors and prints. Free samples available upon request. Prices range from $3.95 to $15.95 depending on the product.

Strategic Sourcing Conclusion and Outlook for imitation suede fabric

The imitation suede fabric market is poised for significant growth, driven by increasing demand across various sectors, including fashion, upholstery, and event management. By strategically sourcing faux suede, international buyers can leverage its durability, versatility, and aesthetic appeal, which mimic the luxurious feel of genuine suede without the associated costs and ethical concerns. It’s essential for businesses to consider factors such as fabric composition, color variety, and supplier reliability when making purchasing decisions.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the competitive landscape will demand innovative sourcing strategies. Engaging with reputable suppliers who offer consistent quality and flexible ordering options will be vital in maintaining supply chain efficiency and meeting customer expectations.

Looking ahead, the imitation suede fabric industry presents a robust opportunity for B2B buyers to enhance their product offerings and cater to evolving consumer preferences. Now is the time to explore partnerships with trusted fabric manufacturers and distributors to secure a competitive edge in this dynamic market. Embrace the future of faux suede and elevate your business with strategic sourcing that aligns with your growth objectives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.