Introduction: Navigating the Global Market for nubuck leather maintenance

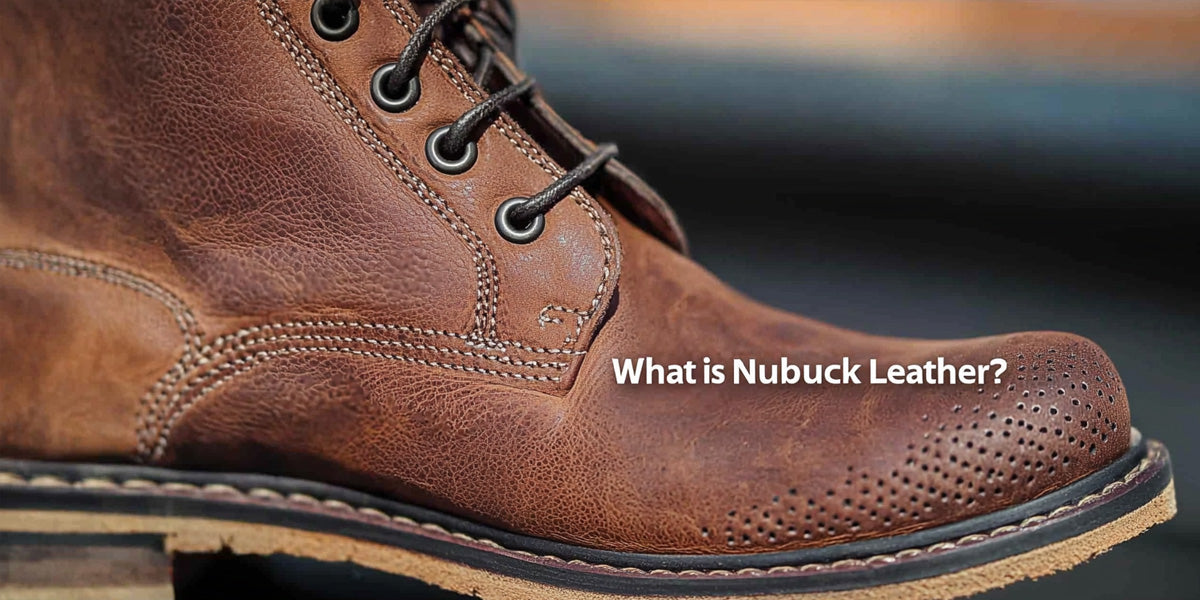

Navigating the complexities of nubuck leather maintenance can present a significant challenge for international B2B buyers seeking to source high-quality leather goods. With its unique characteristics and luxurious appeal, nubuck leather is favored for various applications, from footwear to high-end fashion accessories. However, its porous nature makes it susceptible to stains and wear, necessitating a well-informed approach to care and maintenance. This guide aims to equip buyers from diverse regions, including Africa, South America, the Middle East, and Europe—specifically countries like Saudi Arabia and Nigeria—with comprehensive insights into nubuck leather maintenance.

Throughout this guide, we will explore the different types of nubuck leather, effective cleaning and conditioning techniques, and the best practices for protecting these investments. Additionally, we will delve into the critical aspects of supplier vetting, cost considerations, and the latest market trends that can influence purchasing decisions. By providing actionable insights and expert recommendations, this resource empowers B2B buyers to make informed choices, ensuring the longevity and aesthetic appeal of their nubuck leather products. Whether you are looking to enhance your inventory or seeking to maintain quality standards, understanding the nuances of nubuck leather maintenance is essential for success in today’s competitive market.

Table Of Contents

- Top 5 Nubuck Leather Maintenance Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for nubuck leather maintenance

- Understanding nubuck leather maintenance Types and Variations

- Key Industrial Applications of nubuck leather maintenance

- 3 Common User Pain Points for ‘nubuck leather maintenance’ & Their Solutions

- Strategic Material Selection Guide for nubuck leather maintenance

- In-depth Look: Manufacturing Processes and Quality Assurance for nubuck leather maintenance

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘nubuck leather maintenance’

- Comprehensive Cost and Pricing Analysis for nubuck leather maintenance Sourcing

- Alternatives Analysis: Comparing nubuck leather maintenance With Other Solutions

- Essential Technical Properties and Trade Terminology for nubuck leather maintenance

- Navigating Market Dynamics and Sourcing Trends in the nubuck leather maintenance Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of nubuck leather maintenance

- Strategic Sourcing Conclusion and Outlook for nubuck leather maintenance

- Important Disclaimer & Terms of Use

Understanding nubuck leather maintenance Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Nubuck | Soft, velvety texture; made from top-grain leather | Footwear, bags, upholstery | Pros: Durable, breathable; Cons: Prone to staining, requires regular care. |

| Oily Nubuck | Treated for water resistance; retains oil for durability | Outdoor gear, rugged footwear | Pros: Water-repellent, low maintenance; Cons: Limited color options, specific care needed. |

| Nubuck with Coating | Enhanced protection layer; easier to clean | High-traffic areas, commercial use | Pros: Improved stain resistance, easy upkeep; Cons: May alter natural feel of nubuck. |

| Nubuck for Fashion | Fashion-forward designs; often dyed or embellished | Luxury accessories, fashion items | Pros: Aesthetic appeal, unique textures; Cons: Higher price point, sensitive to wear. |

| Nubuck Leather Care Kits | Comprehensive maintenance products; includes brushes, sprays | Retail, manufacturing, service sectors | Pros: All-in-one solution, promotes longevity; Cons: Initial investment, requires user education. |

What are the Characteristics of Standard Nubuck Leather Maintenance?

Standard nubuck leather is known for its soft, velvety texture, made from the top grain of animal hides. This type is widely used in footwear, bags, and upholstery due to its durability and breathability. However, it is prone to staining and requires regular maintenance, such as brushing and conditioning. B2B buyers should consider the specific care needs and potential for wear in high-traffic applications when investing in standard nubuck products.

How Does Oily Nubuck Differ in Maintenance Requirements?

Oily nubuck has been treated to enhance its water resistance and durability, making it ideal for outdoor gear and rugged footwear. This variation retains oil within its fibers, which helps repel water and dirt. While it requires less frequent maintenance compared to standard nubuck, buyers must be aware that specific care products are necessary to maintain its unique properties. The trade-off for ease of care is often a limited selection of colors and styles.

What Advantages Does Nubuck with Coating Offer?

Nubuck with a protective coating provides enhanced stain resistance and easier cleaning, making it suitable for high-traffic areas and commercial applications. This variation maintains the luxurious look of nubuck while offering practical benefits for environments where durability is essential. However, the coating may alter the natural feel of the leather, which could affect the buyer’s perception of quality. Consideration of the balance between aesthetics and functionality is crucial for B2B buyers.

Why is Nubuck for Fashion a Unique Category?

Nubuck leather designed for fashion purposes often features unique dyes and embellishments, appealing to luxury accessory markets. Its aesthetic appeal makes it a popular choice for high-end products, though it is more sensitive to wear and tear. Buyers in the fashion industry should weigh the benefits of visual impact against the potential for increased maintenance and higher costs associated with these premium products.

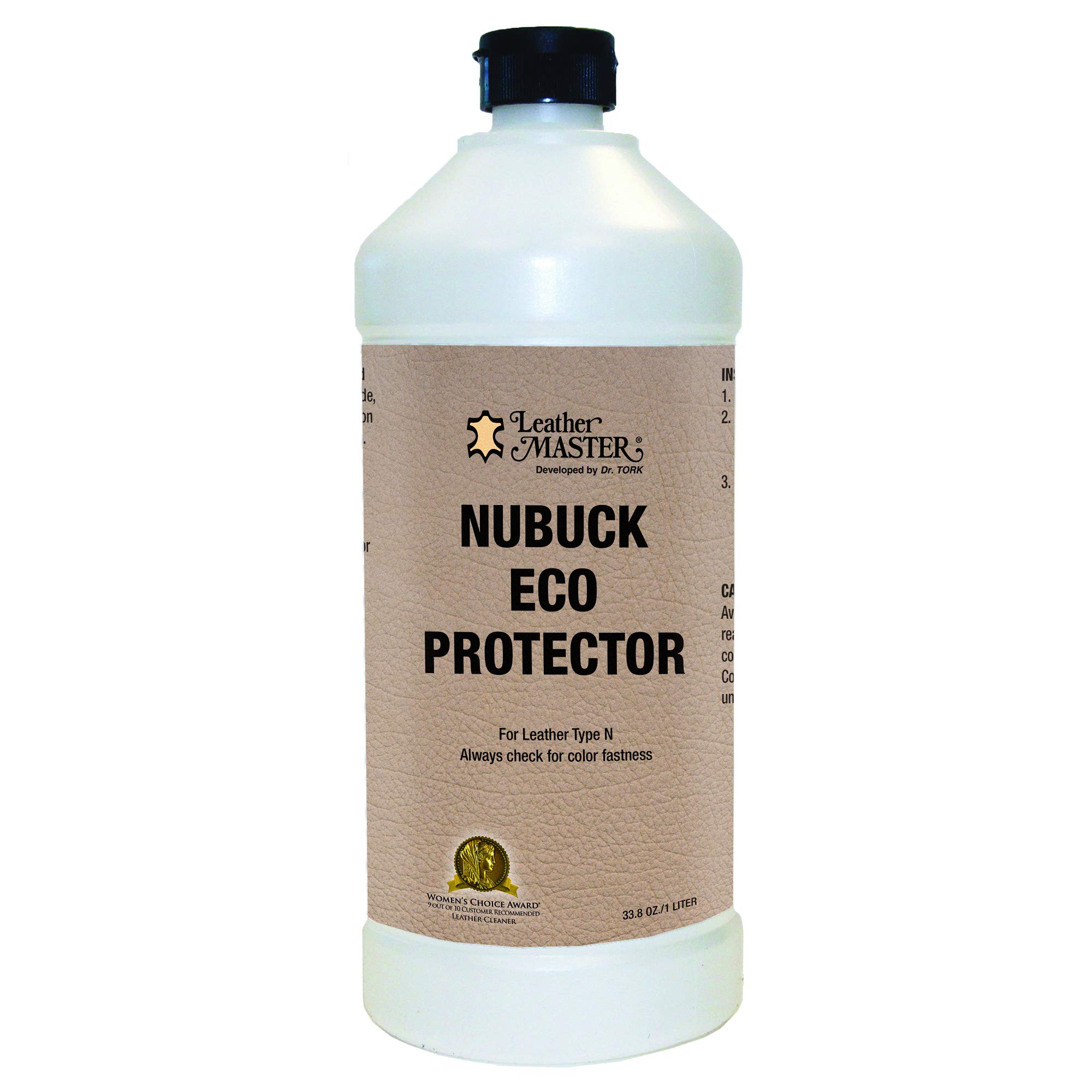

Illustrative image related to nubuck leather maintenance

How Can Nubuck Leather Care Kits Benefit Businesses?

Nubuck leather care kits provide a comprehensive solution for maintaining the longevity of nubuck products. These kits typically include brushes, cleaning sprays, and conditioners tailored to the specific needs of nubuck. For businesses in retail, manufacturing, or service sectors, investing in these kits can ensure that customers receive adequate support for their purchases, enhancing customer satisfaction and reducing returns. However, educating users on proper maintenance is essential to maximize the benefits of these products.

Key Industrial Applications of nubuck leather maintenance

| Industry/Sector | Specific Application of nubuck leather maintenance | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Accessories | Maintenance of nubuck leather handbags and shoes | Extends product lifespan, enhances aesthetic appeal | Sourcing high-quality cleaners and conditioners specific to nubuck. |

| Automotive | Upholstery maintenance for nubuck leather interiors | Maintains luxury appeal, preserves resale value | Require specialized cleaning solutions that are safe for automotive use. |

| Furniture Manufacturing | Care of nubuck leather sofas and chairs | Increases durability and customer satisfaction | Need bulk purchasing options for maintenance kits and protective sprays. |

| Footwear | Cleaning and conditioning of nubuck boots | Improves performance and comfort, reduces returns | Focus on sourcing products that cater specifically to outdoor or work footwear. |

| Hospitality | Maintenance of nubuck leather furnishings in hotels | Enhances guest experience, reduces replacement costs | Consider eco-friendly cleaning products to align with sustainability goals. |

How is nubuck leather maintenance applied in the fashion and accessories industry?

In the fashion and accessories sector, nubuck leather maintenance is crucial for preserving the quality of handbags and shoes. Regular cleaning and conditioning help prevent stains and maintain the soft, velvety texture that defines nubuck. For international buyers, particularly in regions like Europe and the Middle East, sourcing specialized nubuck care products is essential to ensure compatibility with various climate conditions, as environmental factors can accelerate wear.

What are the benefits of nubuck leather maintenance in the automotive industry?

The automotive industry leverages nubuck leather maintenance primarily for luxury vehicle interiors, where aesthetics and comfort are paramount. Regular maintenance not only enhances the visual appeal but also extends the lifespan of the upholstery, preserving the vehicle’s resale value. Buyers should prioritize sourcing cleaning solutions that are safe for automotive applications and effective in removing stains without damaging the leather finish, particularly in markets like Saudi Arabia, where heat can exacerbate wear.

Why is nubuck leather maintenance important for furniture manufacturing?

In furniture manufacturing, maintaining nubuck leather sofas and chairs is vital for ensuring durability and customer satisfaction. Regular maintenance routines, including cleaning and protective treatments, help to prevent dirt accumulation and wear, thus prolonging the life of the furniture. B2B buyers should consider bulk purchasing options for maintenance kits that include cleaners and protective sprays, especially in regions like South America, where humidity can impact leather quality.

Illustrative image related to nubuck leather maintenance

How does nubuck leather maintenance enhance footwear performance?

For the footwear industry, maintaining nubuck boots is essential for enhancing performance and comfort. Regular cleaning and conditioning help prevent moisture damage and maintain the boots’ structure, which is particularly important for outdoor or work footwear. Buyers should focus on sourcing specialized products that cater to the unique requirements of nubuck, ensuring they meet the needs of customers in varying climates, especially in Africa where rugged terrains are common.

In what ways does nubuck leather maintenance impact the hospitality sector?

In the hospitality sector, nubuck leather maintenance is key to ensuring that furnishings in hotels remain inviting and luxurious for guests. Regular upkeep not only enhances the guest experience but also reduces the need for costly replacements. B2B buyers in this sector should consider eco-friendly cleaning products that align with sustainability initiatives, particularly in Europe, where consumer preferences are increasingly leaning towards environmentally responsible choices.

3 Common User Pain Points for ‘nubuck leather maintenance’ & Their Solutions

Scenario 1: Protecting Nubuck from Stains in High-Traffic Environments

The Problem: B2B buyers in retail or hospitality sectors often face the challenge of maintaining nubuck leather products in high-traffic areas where they are exposed to dirt, spills, and potential stains. For instance, a boutique owner selling nubuck bags may find that customers frequently touch or handle the products, leaving behind oils and residues. This not only affects the aesthetic appeal but can also lead to costly replacements and diminished customer satisfaction.

Illustrative image related to nubuck leather maintenance

The Solution: To effectively protect nubuck leather products, B2B buyers should invest in high-quality nubuck protectors designed specifically for porous materials. Implementing a regular maintenance routine is crucial. Buyers should advise their staff to apply a nubuck-friendly waterproofing spray immediately upon receipt of new inventory and again every few months. This spray creates a barrier against moisture and stains. Additionally, providing customers with care instructions, including the use of a soft-bristled brush for regular upkeep, can significantly enhance product longevity. Retailers might also consider offering care kits as an add-on sale, ensuring customers have the tools they need to maintain their purchases.

Scenario 2: Addressing Surface Scratches on Nubuck Leather Goods

The Problem: A common issue faced by businesses dealing in nubuck leather is the appearance of surface scratches, which can occur during regular use or transportation. For example, a company specializing in nubuck footwear might receive returns due to visible wear and tear, leading to increased operational costs and inventory issues. Such scratches can tarnish the image of a brand that prides itself on quality and craftsmanship.

The Solution: To address scratches effectively, B2B buyers should implement a dual approach of prevention and repair. First, they should educate their teams on the importance of using a nubuck brush to regularly lift the nap and reduce the visibility of scratches. For deeper scratches, investing in specialized nubuck erasers can be beneficial; these products help to gently buff out imperfections without altering the material’s texture. Buyers can also establish a clear return policy that allows customers to return scratched items for repair, thereby enhancing customer loyalty while maintaining product integrity. Providing training sessions on proper handling and maintenance techniques can empower staff and reduce damage incidents.

Illustrative image related to nubuck leather maintenance

Scenario 3: Ensuring Longevity through Proper Conditioning

The Problem: Nubuck leather, while durable, can lose its softness and flexibility over time without proper conditioning. B2B buyers in the leather goods sector may notice that products become stiff or develop a shiny appearance, which can deter customers and affect sales. This issue often arises when products are not regularly maintained or conditioned, leading to a diminished product lifespan and increased costs for replacements.

The Solution: To ensure the longevity of nubuck leather products, B2B buyers should prioritize the use of nubuck conditioners that are specifically formulated to nourish and rejuvenate the material. It is advisable to establish a conditioning schedule, recommending that products be treated 2-3 times a year, depending on usage and environmental conditions. Buyers should also source conditioners that are compatible with the specific hue of their nubuck goods, as some conditioners may darken the leather. Providing detailed care guides, along with the sale of conditioning products, can empower customers to take ownership of their purchases. Additionally, training staff on how to properly condition nubuck can lead to better product care practices and ultimately enhance customer satisfaction and brand loyalty.

By addressing these common pain points with actionable solutions, B2B buyers can effectively maintain nubuck leather products, ensuring their durability and aesthetic appeal while minimizing costs associated with damage and replacements.

Strategic Material Selection Guide for nubuck leather maintenance

What Are the Key Materials for Nubuck Leather Maintenance?

When it comes to maintaining nubuck leather, the choice of materials for care products is critical for ensuring the longevity and aesthetic appeal of the leather. Here, we analyze four common materials used in nubuck leather maintenance: nubuck brushes, erasers, conditioners, and waterproofing sprays. Each material has unique properties, advantages, and limitations that B2B buyers should consider, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

How Do Nubuck Brushes Function in Leather Maintenance?

Nubuck brushes are essential for cleaning and revitalizing the nap of nubuck leather. Typically made from soft bristles, these brushes are designed to lift dirt and restore the texture of the leather without causing damage.

Pros: They are durable, easy to use, and relatively inexpensive. Regular use of a nubuck brush can significantly extend the life of nubuck products by maintaining their appearance.

Cons: While effective for surface cleaning, they may not be sufficient for deep stains, requiring additional products for comprehensive care.

Impact on Application: Nubuck brushes are compatible with various nubuck items, including footwear and bags, making them versatile tools in leather maintenance.

Considerations for International Buyers: Buyers should ensure that the brushes comply with local standards for materials used in consumer goods. In regions like Europe, adherence to REACH regulations is crucial, while in the Middle East, buyers may prioritize durability in high-temperature environments.

Illustrative image related to nubuck leather maintenance

What Role Do Erasers Play in Cleaning Nubuck Leather?

Erasers specifically designed for nubuck are used to tackle tougher stains that brushes cannot remove. These products often come in a block form and are effective for localized cleaning.

Pros: Nubuck erasers are highly effective at removing embedded dirt and stains without damaging the leather’s texture. They are also compact and easy to carry.

Cons: Overuse can lead to alterations in the leather’s texture, making them less suitable for frequent application.

Illustrative image related to nubuck leather maintenance

Impact on Application: They are particularly useful for footwear, where scuffs and stains are common. However, their effectiveness may vary based on the type of nubuck.

Considerations for International Buyers: Buyers should look for erasers that are free from harsh chemicals to comply with environmental regulations in their respective regions, such as the EU’s Biocidal Products Regulation.

How Do Conditioners Enhance Nubuck Leather Longevity?

Conditioners for nubuck leather are formulated to nourish the fibers and maintain flexibility. They often come in spray or cream form.

Pros: Conditioners help restore the leather’s softness and can prevent cracking, significantly enhancing the product’s lifespan. They are generally easy to apply.

Illustrative image related to nubuck leather maintenance

Cons: Some conditioners may darken the leather, which can be a concern for buyers looking to maintain the original color of their products.

Impact on Application: Conditioners are suitable for all nubuck items, but the choice of product should be aligned with the specific type of nubuck to avoid adverse effects.

Considerations for International Buyers: Buyers should ensure that the conditioners meet local safety standards, such as ASTM or DIN, particularly in regions where chemical regulations are stringent.

What Are the Benefits of Waterproofing Sprays for Nubuck Leather?

Waterproofing sprays are designed to provide a protective barrier against moisture and stains, enhancing the durability of nubuck leather.

Pros: These sprays can significantly increase the resistance of nubuck to water and dirt, making them ideal for outdoor or high-humidity environments.

Cons: The effectiveness of waterproofing sprays can diminish over time, requiring reapplication every few months, which can add to maintenance costs.

Impact on Application: Waterproofing sprays are particularly beneficial for footwear and bags exposed to the elements, ensuring that the leather maintains its appearance and integrity.

Illustrative image related to nubuck leather maintenance

Considerations for International Buyers: Buyers should look for sprays that are compatible with nubuck and comply with local regulations regarding aerosol products, especially in regions with strict environmental laws.

Summary Table of Nubuck Leather Maintenance Materials

| Material | Typical Use Case for nubuck leather maintenance | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nubuck Brush | Cleaning and revitalizing nubuck leather | Durable and easy to use | Limited effectiveness on deep stains | Low |

| Nubuck Eraser | Removing tough stains from nubuck leather | Highly effective on embedded dirt | Can alter leather texture | Low |

| Nubuck Conditioner | Nourishing and maintaining flexibility | Restores softness and flexibility | May darken the leather | Medium |

| Waterproofing Spray | Protecting nubuck from moisture and stains | Increases water resistance | Requires frequent reapplication | Medium |

This strategic material selection guide serves as a valuable resource for international B2B buyers, helping them make informed decisions regarding nubuck leather maintenance products that meet their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for nubuck leather maintenance

What are the Key Stages in the Manufacturing Process of Nubuck Leather?

The manufacturing process of nubuck leather involves several critical stages that ensure both the quality of the material and its suitability for various applications, such as fashion accessories, footwear, and upholstery. Understanding these stages can help B2B buyers make informed purchasing decisions.

Illustrative image related to nubuck leather maintenance

1. Material Preparation: How is Nubuck Leather Sourced?

The journey of nubuck leather begins with the careful selection of high-quality hides, typically from cattle. The chosen hides undergo a rigorous cleaning process to remove any impurities and contaminants. This initial step is crucial, as it lays the foundation for the durability and appearance of the final product. After cleaning, the hides are soaked in a tanning solution, which can be either vegetable-based or chrome-based, depending on the desired characteristics of the nubuck.

2. Forming: What Techniques are Used to Create Nubuck Leather?

Once the hides are tanned, the next stage involves sanding the outer layer to create the soft, velvety texture that nubuck is known for. This process, known as “buffing,” removes the top layer of the hide, exposing the fibrous structure beneath. The degree of sanding can vary, allowing manufacturers to achieve different textures and finishes. Additionally, this step enhances the breathability of the leather, making it suitable for various applications.

3. Assembly: How is Nubuck Leather Constructed into Final Products?

After the forming process, the nubuck leather is cut and shaped according to the specifications of the product being created. This can include bags, shoes, or upholstery. Skilled artisans often perform this assembly, ensuring that seams are strong and aesthetically pleasing. The assembly process may also involve stitching, gluing, and the addition of other materials, such as linings or reinforcements, which further contribute to the product’s durability.

4. Finishing: What Final Touches are Added to Nubuck Leather?

The final stage involves applying various treatments to enhance the leather’s appearance and durability. This may include conditioning agents that nourish the fibers and help maintain flexibility. A protective coating is often added to improve resistance to water and stains. The finishing process not only elevates the visual appeal of the nubuck leather but also extends its lifespan, making it more suitable for everyday use.

What Quality Control Measures are Implemented During Nubuck Leather Production?

Quality assurance is paramount in the manufacturing of nubuck leather, as it directly impacts the material’s durability and performance. B2B buyers should be aware of the international standards and quality checkpoints that suppliers should adhere to.

Relevant International Standards: Which Certifications Matter?

Many manufacturers comply with ISO 9001, which outlines the criteria for a quality management system. This standard ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications, such as CE (Conformité Européenne) for products sold in Europe, and API (American Petroleum Institute) for specific applications, may also be relevant depending on the end-use of the nubuck leather.

Key Quality Control Checkpoints: How is Quality Monitored?

Quality control in nubuck leather production typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial stage inspects the raw materials for defects before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, random sampling is conducted to ensure that the production process adheres to quality standards. Any deviations are corrected immediately to avoid defective products.

- Final Quality Control (FQC): Once the nubuck leather products are completed, a thorough inspection is performed to ensure they meet the specified quality criteria before they are packaged and shipped.

Common Testing Methods: What Tests Ensure Quality?

Testing methods for nubuck leather can include:

- Physical Tests: Assessing tensile strength, flexibility, and abrasion resistance.

- Chemical Tests: Checking for harmful substances or residues that could affect the leather’s safety and performance.

- Water Resistance Tests: Evaluating the leather’s ability to repel water and resist stains.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to rigorous quality control standards, B2B buyers should adopt a proactive approach.

Conducting Audits: What to Look For?

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. During these audits, buyers should assess compliance with international standards, evaluate the effectiveness of quality checkpoints, and review testing results.

Requesting Quality Reports: What Information is Essential?

Buyers should request detailed quality reports from suppliers, which should include:

- Testing Results: Documentation of the various tests conducted on the leather.

- Certification Copies: Proof of compliance with relevant international standards.

- Traceability Information: Details on the sourcing of raw materials and any applicable certifications for those materials.

Utilizing Third-Party Inspections: How Can They Help?

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control practices. These inspections can occur at various stages of production, providing buyers with additional assurance of the product’s quality before it reaches the market.

Illustrative image related to nubuck leather maintenance

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Factors such as import regulations, regional standards, and cultural expectations may vary significantly.

Navigating Import Regulations: What Are the Key Considerations?

Buyers must familiarize themselves with the import regulations specific to their region, including any compliance standards that must be met before products can enter the market. This may involve additional testing or certification processes.

Understanding Regional Standards: How Do They Differ?

Different regions may have varying standards for leather products. For instance, European buyers may prioritize environmental sustainability and compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations. In contrast, buyers from the Middle East may focus more on durability and performance due to climate considerations.

By understanding the manufacturing processes and quality assurance measures in nubuck leather production, B2B buyers can make informed decisions that align with their standards and expectations, ensuring they procure high-quality products that meet the demands of their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nubuck leather maintenance’

The following guide serves as a comprehensive checklist for B2B buyers focused on procuring nubuck leather maintenance products. This practical sourcing guide will streamline your purchasing process and ensure that you are equipped with the necessary tools to maintain nubuck leather products effectively.

Step 1: Identify Essential Maintenance Products

Before making any purchases, outline the specific maintenance products needed for nubuck leather. Common items include nubuck brushes, erasers, cleaning solutions, conditioners, and waterproofing sprays. Each product plays a vital role in extending the life of nubuck leather and maintaining its aesthetic appeal.

Step 2: Evaluate Product Quality and Specifications

Assess the quality of the maintenance products you are considering. Look for items that are specifically formulated for nubuck leather, as generic products may not provide the desired results. Key specifications to consider include:

– Material Composition: Ensure that brushes have soft bristles to avoid damaging the leather.

– Effectiveness: Research product reviews and test reports to gauge performance.

Step 3: Source from Reputable Suppliers

Partnering with established suppliers can significantly impact the quality of maintenance products you procure. Seek out suppliers with a proven track record in the leather care industry. Important factors to verify include:

– Company Certifications: Ensure suppliers have certifications that guarantee product safety and quality standards.

– Customer Feedback: Look for testimonials from businesses similar to yours to validate supplier reliability.

Step 4: Assess Availability and Supply Chain Reliability

Consider the availability of products and the reliability of the supplier’s logistics. This is crucial to avoid potential disruptions in your maintenance schedule. Important aspects to check include:

– Lead Times: Inquire about delivery times to ensure you can maintain an adequate supply of products.

– Inventory Levels: Confirm that the supplier can consistently meet your demand without significant delays.

Step 5: Review Pricing Structures and Terms

Understanding the pricing structures and terms of your potential suppliers is essential for budget management. Analyze factors such as:

– Bulk Purchase Discounts: Many suppliers offer discounts for larger orders, which can significantly reduce costs.

– Payment Terms: Review the payment terms and conditions, including any options for credit or installment payments.

Step 6: Establish a Maintenance Schedule

Once products are procured, develop a structured maintenance schedule. Regular maintenance is key to prolonging the life of nubuck leather. Consider including:

– Routine Cleaning: Set intervals for cleaning and conditioning to prevent buildup of dirt and oils.

– Seasonal Treatments: Plan for additional waterproofing treatments during wet seasons, especially in regions prone to moisture.

Step 7: Train Staff on Proper Maintenance Techniques

Finally, ensure that your team is trained in proper nubuck leather maintenance techniques. Providing training sessions on how to use maintenance products effectively can enhance the longevity of your leather goods. Key areas to cover include:

– Application Methods: Demonstrate the correct way to apply cleaning solutions and conditioners.

– Handling Techniques: Educate staff on how to handle nubuck leather to prevent damage during maintenance.

Illustrative image related to nubuck leather maintenance

By following this structured checklist, B2B buyers can ensure they are well-prepared to maintain nubuck leather products, ultimately enhancing their durability and appearance while fostering long-term customer satisfaction.

Comprehensive Cost and Pricing Analysis for nubuck leather maintenance Sourcing

What Are the Key Cost Components for Nubuck Leather Maintenance?

Understanding the cost structure for nubuck leather maintenance is crucial for B2B buyers aiming to optimize their sourcing strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of specialized cleaning and conditioning products is significant. A basic nubuck care kit may include brushes, erasers, cleaners, and waterproofing sprays, each varying in price based on quality and brand. High-quality materials ensure better results and longevity, impacting the overall cost.

-

Labor: Skilled labor is essential in the production and application of nubuck care products. Labor costs may differ based on the region and the complexity of the product formulation. In regions like Africa and South America, labor costs can be lower, potentially offering cost advantages.

-

Manufacturing Overhead: Overhead costs encompass utilities, rent, and equipment maintenance, which vary by location. Suppliers with efficient manufacturing processes may offer more competitive pricing, making it important for buyers to evaluate potential partners based on operational efficiency.

-

Tooling: The initial investment in tooling for production can be substantial, particularly for customized solutions. Buyers should consider the amortization of these costs over the expected product lifecycle when assessing pricing.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability, which can raise costs. However, investing in QC can reduce long-term costs by minimizing returns and dissatisfaction.

-

Logistics: Shipping costs can significantly affect pricing, particularly for international transactions. Factors such as distance, weight, and chosen transportation methods (air vs. sea freight) will influence overall logistics costs.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. Understanding the competitive landscape and supplier positioning can help buyers negotiate better terms.

What Influences Pricing for Nubuck Leather Maintenance Products?

Several factors influence the pricing of nubuck leather maintenance products that international B2B buyers should consider:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to achieve better pricing structures, particularly when sourcing from regions with lower production costs.

-

Specifications and Customization: Customized products may incur additional costs. Buyers should weigh the benefits of tailored solutions against standard options, which could be more cost-effective.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like eco-friendly or cruelty-free) can raise costs. Buyers must assess whether these certifications align with their brand values and customer expectations.

-

Supplier Factors: Relationships with suppliers can affect pricing. Long-term partnerships often lead to better terms and discounts. Evaluating suppliers based on reputation, reliability, and service quality is crucial.

-

Incoterms: Understanding the terms of sale (Incoterms) can impact total costs. Buyers should clarify whether prices include shipping, insurance, and duties to avoid unexpected expenses.

What Are the Best Negotiation Tips for B2B Buyers of Nubuck Leather Maintenance Products?

To maximize cost-efficiency and ensure a favorable Total Cost of Ownership (TCO), B2B buyers should adopt strategic negotiation practices:

Illustrative image related to nubuck leather maintenance

-

Conduct Market Research: Understanding market trends and competitor pricing helps buyers make informed offers. This knowledge can empower negotiations, enabling buyers to justify their pricing expectations.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication fosters trust and can result in favorable terms.

-

Consider Long-Term Partnerships: Committing to a supplier for a longer duration can yield discounts and benefits. Suppliers are often more willing to negotiate with buyers who demonstrate loyalty.

-

Evaluate Total Cost of Ownership: Buyers should assess not just the initial purchase price but also the long-term costs associated with maintenance, durability, and potential returns. This holistic view can reveal the true value of a product.

-

Stay Flexible: Being open to alternative solutions or product variations can provide cost savings. Flexibility in specifications may lead to more competitive pricing.

Conclusion

Navigating the cost and pricing landscape of nubuck leather maintenance requires a thorough understanding of various cost components and pricing influencers. By employing strategic negotiation tactics, B2B buyers can optimize their sourcing decisions, ensuring they secure quality products at competitive prices while maintaining operational efficiency.

Alternatives Analysis: Comparing nubuck leather maintenance With Other Solutions

Introduction: Understanding Nubuck Leather Maintenance Alternatives

When considering the maintenance of nubuck leather, it is essential for B2B buyers to explore various alternatives that can achieve similar outcomes in terms of durability and aesthetic preservation. Nubuck leather, known for its soft texture and breathability, requires specific care to maintain its unique properties. This analysis will compare nubuck leather maintenance against alternative solutions, including synthetic leather care and traditional leather care methods, to help buyers make informed decisions.

Comparison Table

| Comparison Aspect | Nubuck Leather Maintenance | Synthetic Leather Care | Traditional Leather Care |

|---|---|---|---|

| Performance | Excellent for durability and appearance if regularly maintained | Good durability, less prone to staining | Very good, but requires specific techniques for different leather types |

| Cost | Moderate, with ongoing costs for cleaning and conditioning products | Generally low, as synthetic products are often less expensive | Variable, depending on the quality of leather and care products |

| Ease of Implementation | Requires specific tools (brush, eraser, waterproof spray) | Simple and straightforward, often just wiping clean | Can be complex, needing different techniques for various leather types |

| Maintenance | Requires regular brushing and conditioning every few months | Minimal, mostly surface cleaning needed | Requires conditioning and care tailored to leather type, potentially more frequent |

| Best Use Case | High-end bags and footwear where appearance is critical | Everyday items or where cost is a concern | Classic leather goods requiring attention to detail and longevity |

Detailed Breakdown of Alternatives

Synthetic Leather Care

Synthetic leather has become increasingly popular due to its affordability and ease of maintenance. It typically requires minimal upkeep, as most synthetic materials can be cleaned with a damp cloth. This makes synthetic leather an excellent choice for businesses looking for cost-effective solutions. However, the downside is that synthetic leather does not offer the same breathability or luxurious feel as nubuck. Additionally, while synthetic options can be durable, they may not match the long-term aesthetic appeal of nubuck, particularly in high-end fashion or luxury markets.

Traditional Leather Care

Traditional leather care encompasses a range of techniques and products tailored for various types of leather, including full-grain and top-grain leathers. This method typically involves conditioning agents and specific cleaning products suited for leather’s unique characteristics. While traditional leather care can effectively prolong the life of leather goods, it can be complex and requires knowledge of different leather types. The cost can also vary significantly based on the quality of the leather and the care products used. For businesses dealing with premium leather items, investing in traditional care may be worthwhile, but it demands a higher level of expertise and commitment compared to nubuck maintenance.

Conclusion: Choosing the Right Leather Maintenance Solution

When selecting a leather maintenance solution, B2B buyers should consider their specific needs, including product type, budget, and desired longevity. Nubuck leather maintenance is ideal for businesses focused on high-quality, aesthetic products, as it requires a straightforward yet dedicated approach to preserve its unique qualities. In contrast, synthetic leather care offers a low-maintenance, budget-friendly alternative suitable for more casual applications. Traditional leather care, while effective, may require more knowledge and investment, making it best suited for specialized markets. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for nubuck leather maintenance

What Are the Key Technical Properties of Nubuck Leather Maintenance?

Nubuck leather is renowned for its unique characteristics and aesthetic appeal, making it a popular choice for luxury goods. Understanding its technical properties is crucial for B2B buyers involved in sourcing, manufacturing, or retailing nubuck products. Here are some essential specifications:

-

Material Grade: Nubuck is classified based on the quality of the hide used. The highest grade is derived from full-grain leather, which retains the natural texture and durability. This classification impacts product pricing and longevity, making it essential for buyers to ensure they are investing in high-grade nubuck for premium offerings.

-

Permeability: Nubuck leather is more porous than traditional leather, allowing for better breathability. However, this property also means it is susceptible to water and oil stains. B2B buyers should consider this when selecting nubuck for products exposed to moisture, ensuring appropriate waterproofing treatments are applied during manufacturing.

-

Nap Texture: The “nap” refers to the fine, velvety surface created by sanding the leather. The quality and depth of the nap influence both aesthetics and tactile experience. For buyers, understanding the nap’s impact on product care and maintenance can guide decisions on suitable cleaning products and methods.

-

Durability: Nubuck is known for its durability, but it can develop scratches and wear over time if not properly maintained. B2B buyers should prioritize products that come with care instructions and recommend maintenance solutions, enhancing customer satisfaction and product lifespan.

-

Water Resistance: Although nubuck has some natural water resistance, it can benefit from specific waterproofing sprays designed for nubuck. Buyers should consider sourcing these protective products along with nubuck items to ensure comprehensive care solutions for end-users.

Which Trade Terminology Is Important for Nubuck Leather Maintenance?

Familiarity with industry terminology can facilitate smoother transactions and enhance communication between suppliers and buyers. Here are some common terms relevant to nubuck leather maintenance:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products that are used in another company’s end product. In the context of nubuck leather, understanding OEM relationships can help buyers ensure they are sourcing from reliable manufacturers who meet quality standards.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of an item that a supplier is willing to sell. For nubuck leather products, knowing the MOQ is crucial for inventory management and cost analysis, enabling businesses to plan their purchases effectively.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to invite them to bid on specific products or services. B2B buyers should utilize RFQs for sourcing nubuck leather, as they can compare prices, quality, and delivery terms from multiple vendors.

-

Incoterms (International Commercial Terms): These are predefined commercial terms used in international trade that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for buyers dealing with international suppliers of nubuck leather to avoid misunderstandings and ensure smooth logistics.

-

Care Kit: A care kit typically includes specific products designed for cleaning and maintaining nubuck leather. Buyers should look for suppliers that provide care kits with their nubuck products, as this can enhance customer experience and loyalty.

-

Conditioning Agents: These are specialized products used to nourish nubuck leather, maintaining its flexibility and appearance. Recognizing the importance of conditioning agents can guide buyers in recommending proper care to end-users, ensuring the longevity of their nubuck products.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance product quality, customer satisfaction, and overall business success in the nubuck leather market.

Navigating Market Dynamics and Sourcing Trends in the nubuck leather maintenance Sector

What Are the Current Market Dynamics and Key Trends in Nubuck Leather Maintenance?

The nubuck leather maintenance market is experiencing significant growth, driven by increasing demand for high-quality leather products across various sectors, including fashion, automotive, and furniture. As consumers become more discerning about their purchases, there is a notable shift towards long-lasting materials, with nubuck’s durability and aesthetic appeal making it a popular choice. Emerging trends indicate a rising interest in technology-driven solutions, such as automated cleaning systems and AI-driven customer service platforms, which enhance the consumer experience and streamline maintenance processes.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking reliable suppliers who can provide high-quality maintenance products tailored to local conditions. For example, in humid climates, products that offer enhanced water resistance and mold prevention are in high demand. Furthermore, e-commerce platforms are becoming essential for sourcing, enabling buyers to access a wider range of products and suppliers. This digital shift is coupled with a growing emphasis on transparency in sourcing, as buyers are more inclined to partner with suppliers who can demonstrate ethical practices and product integrity.

How Is Sustainability and Ethical Sourcing Reshaping Nubuck Leather Maintenance?

Sustainability has become a pivotal concern within the nubuck leather maintenance sector. The environmental impact of leather production and maintenance is under scrutiny, leading to increased demand for eco-friendly products. B2B buyers are prioritizing suppliers that offer biodegradable cleaners, conditioners, and protective sprays, which minimize harmful effects on the environment. Additionally, adopting sustainable practices in sourcing and production not only enhances brand reputation but also meets the expectations of environmentally conscious consumers.

Illustrative image related to nubuck leather maintenance

Ethical sourcing is equally crucial. Buyers are increasingly looking for suppliers who can provide transparency regarding their supply chains, ensuring that materials are sourced responsibly. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential indicators of ethical practices. Suppliers who can demonstrate compliance with these standards are likely to gain a competitive advantage in the market, appealing to buyers who prioritize sustainability and ethics in their procurement processes.

How Has the Nubuck Leather Maintenance Market Evolved Over Time?

The history of nubuck leather maintenance reflects broader trends in consumer preferences and technological advancements. Initially, nubuck was primarily used for high-end products, with maintenance largely relying on traditional methods like brushing and manual cleaning. However, as the market expanded, so did the variety of maintenance solutions available. The introduction of specialized cleaning kits, conditioners, and protective sprays has transformed how consumers care for their nubuck products.

In recent years, the integration of technology has further revolutionized the sector. Innovations such as online tutorials, mobile apps for product recommendations, and automated cleaning systems are now commonplace, making maintenance more accessible to consumers. This evolution underscores the importance of adapting to market demands and leveraging technology to enhance product longevity, catering to an increasingly sophisticated global audience.

Frequently Asked Questions (FAQs) for B2B Buyers of nubuck leather maintenance

-

How do I solve common stains on nubuck leather?

To effectively tackle common stains on nubuck leather, start by using a nubuck-specific eraser or brush to gently lift surface dirt. For tougher stains, apply a nubuck cleaner with a damp cloth, ensuring to follow the product’s instructions closely. Always perform a patch test on a hidden area before applying any cleaning solution. After cleaning, allow the leather to air dry completely, then use a soft-bristled brush to restore the nap. Regular maintenance, including brushing and protective sprays, can help prevent stains from setting in. -

What is the best cleaning method for nubuck leather products?

The best cleaning method for nubuck leather involves a combination of brushing and using specialized cleaning products. Begin by removing surface dirt with a soft nubuck brush, then apply a nubuck cleaner to any stained areas using a damp cloth. Avoid soaking the leather; instead, lightly blot to remove excess moisture. After cleaning, let the item air dry and finish by brushing the surface to maintain its plush texture. Consistent care, including periodic conditioning, will help preserve the leather’s appearance and durability. -

How can I ensure the longevity of nubuck leather products?

To ensure the longevity of nubuck leather products, implement a regular care routine. This includes brushing the leather with a soft-bristled brush to keep the nap fresh and using a nubuck conditioner to maintain flexibility. Additionally, applying a nubuck-friendly waterproofing spray 2-3 times a year will provide extra protection against moisture and stains. Proper storage, such as using cedar shoe trees or breathable bags, can also help maintain shape and prevent odors, enhancing the lifespan of your nubuck items. -

What should I consider when sourcing nubuck leather care products?

When sourcing nubuck leather care products, consider factors such as the compatibility of the product with nubuck material, effectiveness, and safety. Look for products specifically labeled for nubuck to avoid damage. Additionally, assess the supplier’s reputation and reviews for quality assurance. It’s also beneficial to inquire about the ingredients to ensure they are eco-friendly and safe for both your products and the environment. Lastly, consider the supplier’s ability to provide consistent supply and logistics support for timely deliveries. -

What minimum order quantities (MOQs) should I expect for nubuck leather maintenance products?

Minimum order quantities (MOQs) for nubuck leather maintenance products can vary significantly among suppliers. Typically, MOQs may range from 50 to 500 units depending on the product type and the supplier’s policies. It is advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Additionally, consider establishing a relationship with suppliers who offer flexibility in MOQs, especially if you are testing new products or markets. This approach can help mitigate inventory risks while meeting demand. -

How do I vet potential suppliers for nubuck leather maintenance products?

To effectively vet potential suppliers for nubuck leather maintenance products, start by researching their industry reputation and customer reviews. Request samples to evaluate product quality and effectiveness firsthand. It’s also important to inquire about their production processes, quality control measures, and compliance with international standards. Establishing clear communication regarding pricing, lead times, and payment terms is essential. Additionally, consider visiting their facilities, if feasible, to assess operational capabilities and ensure alignment with your business values. -

What are common payment terms for international orders of nubuck leather care products?

Common payment terms for international orders of nubuck leather care products typically include options such as advance payment, letter of credit, or net 30/60/90 days. Many suppliers may require a deposit upfront, especially for larger orders, with the balance due upon shipment or delivery. It’s crucial to clarify these terms during negotiations to avoid misunderstandings. Additionally, consider the exchange rates and any associated banking fees that may affect the total cost. Establishing a secure payment method can also enhance trust between you and the supplier. -

What logistics considerations are important when importing nubuck leather maintenance products?

When importing nubuck leather maintenance products, key logistics considerations include shipping methods, customs regulations, and delivery timelines. Determine whether air freight or sea freight best suits your needs based on urgency and cost. Familiarize yourself with the import regulations in your country to ensure compliance and avoid delays. Additionally, establish clear communication with your supplier regarding shipping schedules and tracking information. Working with a reliable freight forwarder can streamline the process and help navigate any potential challenges in international shipping.

Top 5 Nubuck Leather Maintenance Manufacturers & Suppliers List

1. Carl Friedrik – Nubuck Leather Care

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: Nubuck leather is durable and made from the outer layer of an animal’s hide. It has a high degree of permeability, making it breathable but also prone to oil and grease stains. Nubuck requires regular care, including brushing with a soft-bristled nubuck brush to maintain its nap and appearance. Waterproofing sprays and nubuck conditioners are recommended to protect and nourish the leather, applied…

2. Jim Green – Saphir Suede Care Products

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Jim Green African Ranger boots in crazy horse leather; recommended care includes: dry brushing, using suede saddle soap, suede cleaner, and waterproofing spray. Key products mentioned: Saphir spatula suede brush, Saphir gommadin suede cleaner, Saphir MDO super invulner waterproofing spray, Saphir omninettoyant suede shampoo, Saphir suede renovateur. Care steps include removing dirt, cleaning with …

3. Red Wing – Nubuck/Roughout Leather Care

Domain: redwingshoes.com

Registered: 1998 (27 years)

Introduction: Nubuck/Roughout Leather Care Instructions: 1. Clean: Use the Eraser Bar from the Roughout/Nubuck Cleaner Kit on soiled areas. If stains persist, wet the Eraser Bar and repeat. Allow leather to dry and use a bristle brush to restore the nap. 2. Condition: Apply a light, even coat of Leather Cream with fingers, cloth, or sponge. 3. Protect: Lightly mist footwear with Leather Protector from 6 to 8 in…

4. Otter Wax – Conditioning Suede & Nubuck Cleaner

Domain: otterwax.com

Registered: 2011 (14 years)

Introduction: Otter Wax Conditioning Suede & Nubuck Cleaner, Sale price $9.95, gently cleanses and refreshes suede and nubuck with an alcohol-free formula. Fortified with aloe vera, Vitamin C, witch hazel, and castile soap, it removes stains, blemishes, and odors while restoring essential nutrients. Temporary darkening may occur after cleaning, which will lighten back to original coloration within a few days. R…

5. COLOURLOCK – Nubuck & Suede Care

Domain: colourlock.myshopify.com

Introduction: How To Clean, Care And Protect Nubuck & Suede – Nubuck and suede have a sanded and velvet-like surface, with nubuck having a finer structure. They are sensitive to fading and stains. Recommended products include: COLOURLOCK Aniline Protector (protects against drying and fading), COLOURLOCK Waterproofing for Leather & Textiles (to be used after Aniline Protector), COLOURLOCK Leather Sanding Pad (fo…

Strategic Sourcing Conclusion and Outlook for nubuck leather maintenance

Nubuck leather maintenance is not just about preserving the aesthetic appeal of a product; it represents a strategic investment in durability and longevity. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding the unique characteristics of nubuck, such as its breathability and susceptibility to stains, is essential. Implementing a consistent care routine—including regular brushing, conditioning, and protective treatments—ensures that nubuck products remain in prime condition, ultimately enhancing their value.

By sourcing high-quality nubuck maintenance products, businesses can reduce the frequency of replacements and maintain customer satisfaction. Moreover, establishing relationships with reputable suppliers who offer specialized cleaning and protective solutions can lead to cost savings and improved product performance over time.

Looking ahead, the demand for nubuck leather is expected to grow, driven by its elegance and versatility in various applications. As a proactive measure, international B2B buyers should prioritize strategic sourcing of maintenance solutions to capitalize on this trend. Embrace the opportunity to elevate your product offerings and customer experience by investing in effective nubuck leather care today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.