Introduction: Navigating the Global Market for hot stamping leather

In the dynamic world of leather goods, sourcing high-quality hot stamping leather presents a unique challenge for international B2B buyers. This process not only involves understanding the nuances of various stamping techniques but also navigating the diverse preferences and regulations across markets, especially in regions such as Africa, South America, the Middle East, and Europe. Whether you’re looking to personalize luxury handbags, create distinctive labels, or enhance the branding of leather products, selecting the right supplier and technique can significantly influence your product’s appeal and marketability.

This comprehensive guide delves into the intricacies of hot stamping leather, covering essential topics such as the different types of leather suitable for hot stamping, the applications of each method, and the critical factors to consider when vetting suppliers. Additionally, we will explore cost implications and best practices to ensure you make informed purchasing decisions that align with your business goals. By equipping yourself with this knowledge, you can confidently navigate the global market and establish strong partnerships that enhance your product offerings. This guide serves as a valuable resource for B2B buyers who aspire to elevate their leather goods through effective branding solutions that resonate with their target audience.

Table Of Contents

- Top 4 Hot Stamping Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for hot stamping leather

- Understanding hot stamping leather Types and Variations

- Key Industrial Applications of hot stamping leather

- 3 Common User Pain Points for ‘hot stamping leather’ & Their Solutions

- Strategic Material Selection Guide for hot stamping leather

- In-depth Look: Manufacturing Processes and Quality Assurance for hot stamping leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot stamping leather’

- Comprehensive Cost and Pricing Analysis for hot stamping leather Sourcing

- Alternatives Analysis: Comparing hot stamping leather With Other Solutions

- Essential Technical Properties and Trade Terminology for hot stamping leather

- Navigating Market Dynamics and Sourcing Trends in the hot stamping leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hot stamping leather

- Strategic Sourcing Conclusion and Outlook for hot stamping leather

- Important Disclaimer & Terms of Use

Understanding hot stamping leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chrome Tanned Leather | Durable, water-resistant, and often more affordable. | Fashion accessories, bags, and wallets. | Pros: Cost-effective, versatile. Cons: Limited heat tolerance. |

| Vegetable Tanned Leather | Eco-friendly, retains natural appearance and texture. | High-end goods, custom leather products. | Pros: Premium quality, customizable. Cons: Higher cost, longer production time. |

| Suede Leather | Soft texture, provides a unique aesthetic. | Footwear, luxury goods, and fashion. | Pros: Distinctive look, tactile feel. Cons: Prone to stains, requires care. |

| Bonded Leather | Made from leather scraps, cost-effective alternative. | Budget-friendly products, promotional items. | Pros: Affordable, good for mass production. Cons: Less durable, lower quality. |

| Exotic Leather | Unique patterns and textures (e.g., snake, alligator). | Luxury items, high-end fashion. | Pros: Unique appeal, high market value. Cons: Ethical concerns, high cost. |

What Are the Key Characteristics of Chrome Tanned Leather for Hot Stamping?

Chrome tanned leather is known for its durability and water resistance, making it a popular choice for various leather goods, particularly in fashion accessories like bags and wallets. It is often more affordable than other types of leather, which can be an attractive factor for B2B buyers looking to manage costs. However, it has limited heat tolerance, which means that care must be taken during the hot stamping process to avoid damaging the material.

Why Choose Vegetable Tanned Leather for Hot Stamping?

Vegetable tanned leather is prized for its eco-friendliness and ability to retain a natural look and feel. This type of leather is ideal for high-end goods and custom leather products, appealing to businesses that prioritize quality and craftsmanship. While it offers excellent customization options, the higher cost and longer production time may be a consideration for buyers focused on budget and timeline.

How Does Suede Leather Enhance Hot Stamping Applications?

Suede leather is recognized for its soft texture and unique aesthetic, making it a favored choice for footwear and luxury goods. Its tactile feel can enhance the appeal of stamped products. However, suede is more prone to staining and requires careful maintenance, which could be a factor for B2B buyers concerned about product longevity and customer satisfaction.

What Are the Benefits and Drawbacks of Bonded Leather for Hot Stamping?

Bonded leather, created from leather scraps, is a cost-effective alternative for businesses looking to produce budget-friendly products or promotional items. It allows for mass production while maintaining a leather-like appearance. However, it may not offer the same durability or quality as full-grain leather, which could impact brand perception for businesses focused on premium offerings.

Why Consider Exotic Leather for Hot Stamping?

Exotic leather types, such as snake or alligator, provide unique patterns and textures that can significantly enhance the appeal of high-end products. This type of leather is often used in luxury items and fashion, attracting buyers willing to invest in distinctive materials. However, ethical concerns and high costs associated with sourcing exotic leathers should be carefully evaluated by businesses aiming to align with consumer values.

Key Industrial Applications of hot stamping leather

| Industry/Sector | Specific Application of hot stamping leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Custom branding on leather goods (bags, wallets, belts) | Enhances brand identity and customer loyalty | Consistency in heat application and logo detail accuracy |

| Automotive | Interior leather branding (seats, trims) | Adds luxury appeal and personalization | Compatibility with various leather types and thicknesses |

| Hospitality & Events | Customized leather gifts (keychains, coasters) | Unique promotional items that enhance brand visibility | Durability of branding under frequent use |

| Sports & Recreation | Personalized gear (leather gloves, bags) | Differentiates products in a competitive market | Ability to handle high-volume orders with consistent quality |

| Home Decor & Furniture | Custom leather upholstery branding | Increases perceived value and uniqueness | Sourcing from reliable suppliers who ensure quality control |

How is Hot Stamping Leather Used in the Fashion & Accessories Sector?

In the fashion industry, hot stamping leather is a prevalent technique for branding items such as handbags, wallets, and belts. This method allows brands to imprint their logos and designs with precision, creating a modern aesthetic that appeals to consumers. For international buyers, especially in regions like Europe and South America, the ability to maintain consistency in heat application across different leather types is critical to ensure that branding remains intact and visually appealing over time.

What Role Does Hot Stamping Play in the Automotive Sector?

The automotive industry utilizes hot stamping leather for branding and enhancing the interior of vehicles. By applying logos or designs on leather seats and trims, manufacturers can elevate the luxury feel of their cars, catering to high-end markets. Buyers should consider the compatibility of hot stamping processes with various leather types and thicknesses to ensure that the final product meets quality standards, particularly in demanding environments.

How is Hot Stamping Beneficial for Hospitality & Events?

In the hospitality sector, businesses often use hot stamping leather to create customized gifts such as keychains and coasters for guests. This personalization not only serves as a memorable takeaway but also enhances brand visibility. For international B2B buyers in Africa and the Middle East, sourcing durable materials that withstand frequent use is essential to ensure the longevity of these promotional items.

Illustrative image related to hot stamping leather

Why is Hot Stamping Important for Sports & Recreation Products?

Hot stamping leather is increasingly used in the sports and recreation industry for personalizing gear such as leather gloves and bags. This customization helps brands stand out in a crowded market by offering unique products tailored to consumer preferences. Buyers should focus on suppliers capable of handling high-volume orders while maintaining consistent quality, as this can significantly impact brand reputation and customer satisfaction.

How Can Hot Stamping Enhance Home Decor & Furniture?

In the home decor sector, hot stamping leather is employed to brand upholstery and furniture items, adding a touch of uniqueness and luxury. This technique not only increases the perceived value of products but also allows for creative branding opportunities. Buyers in this sector should prioritize sourcing from reliable suppliers who can guarantee quality control to ensure that the branding remains intact and visually appealing over time.

3 Common User Pain Points for ‘hot stamping leather’ & Their Solutions

Scenario 1: Inconsistent Mark Quality Across Batches

The Problem: B2B buyers often struggle with the inconsistency of marks when hot stamping leather products, particularly when producing large quantities. Variations in heat settings, leather types, or even the positioning of the branding tool can result in uneven impressions, which compromise the professional appearance of the final product. This inconsistency can lead to customer dissatisfaction and additional costs due to rework or waste, especially for businesses that prioritize quality and branding.

Illustrative image related to hot stamping leather

The Solution: To achieve uniform quality in hot stamping, it’s essential to invest in a variable-temperature electric branding iron. This type of equipment allows users to set precise temperatures tailored to different leather types—vegetable tanned, chrome tanned, or suede—ensuring that the heat is just right for each batch. Additionally, implementing a standard operating procedure (SOP) for the stamping process can help. This includes consistent leather preparation (such as dampening), careful alignment of the branding iron, and maintaining the same pressure during the stamping process. By documenting and training staff on these practices, businesses can significantly reduce variability and improve product quality.

Scenario 2: Difficulty in Stamping Various Leather Thicknesses

The Problem: Buyers often face challenges when working with leather of varying thicknesses. Thinner leathers can be easily damaged if stamped with too much pressure or heat, while thicker leathers may not yield a clear impression if the stamping tool isn’t robust enough. This can limit a buyer’s ability to offer diverse product lines, impacting their market competitiveness and customer satisfaction.

The Solution: To address the issue of varying leather thicknesses, buyers should consider using specialized stamping tools designed for different leather types. For instance, electric branding irons with adjustable pressure settings can provide the necessary force without damaging thinner materials. It is also beneficial to conduct a test run on scrap pieces of leather to determine the optimal settings before full production. Additionally, sourcing leather from suppliers that provide detailed specifications on thickness and suitability for hot stamping can guide buyers in their choices, ensuring they select materials that align with their production capabilities.

Illustrative image related to hot stamping leather

Scenario 3: Challenges with Complex Designs

The Problem: As B2B buyers seek to differentiate their products, they often want to incorporate intricate designs or larger logos through hot stamping. However, achieving clarity and detail in complex designs can be problematic, leading to impressions that are either too faint or misaligned. This can detract from the brand’s image and reduce the perceived value of the leather goods.

The Solution: To effectively stamp complex designs, businesses should prioritize the quality of their branding plates. Investing in CNC-machined brass or aluminum plates can ensure crisp, clear impressions that capture the details of intricate designs. It’s also advisable to limit the size of the designs to ensure they fit well within the operational capabilities of the stamping equipment. For larger logos, consider using a multi-step stamping process, where the design is built up gradually to maintain detail and clarity. Furthermore, conducting thorough testing with different heat levels and pressures on sample pieces can help refine the process, ensuring that the final products meet the desired aesthetic standards.

Strategic Material Selection Guide for hot stamping leather

What Are the Key Materials for Hot Stamping Leather?

When selecting materials for hot stamping leather, it is crucial to consider the type of leather being used, the desired finish, and the specific requirements of the end product. Here, we analyze four common materials suitable for hot stamping leather, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Chrome Tanned Leather?

Chrome tanned leather is a popular choice due to its flexibility and durability. It can withstand high temperatures, making it suitable for hot stamping. Typically, chrome tanned leather has a temperature resistance of up to 200°C (392°F) and is less prone to warping under heat. However, it is important to note that this type of leather may not respond well to certain chemicals, which can affect the stamping quality.

Pros: Chrome tanned leather is known for its durability and resistance to wear and tear. It is also available in various colors and finishes, allowing for greater design flexibility.

Cons: The environmental impact of chrome tanning processes can be a concern, particularly in regions with strict environmental regulations. Additionally, it may be more expensive than vegetable tanned leather due to the complex tanning process.

How Does Vegetable Tanned Leather Compare?

Vegetable tanned leather is another common material used in hot stamping. It is made using natural tannins from plant sources, which gives it a unique aesthetic appeal and makes it biodegradable. This leather type typically requires lower temperatures for stamping, around 150°C (302°F), which can be advantageous for preserving the integrity of the material.

Pros: Its environmentally friendly nature and ability to develop a rich patina over time make vegetable tanned leather highly desirable for luxury products. It is also generally more affordable than chrome tanned leather.

Cons: The main drawback is its susceptibility to moisture and heat, which can lead to warping or discoloration. Additionally, the stamping process may require more care to avoid damaging the leather.

What Are the Benefits of Suede for Hot Stamping?

Suede, a type of leather with a napped finish, is often used for hot stamping due to its unique texture and appearance. It requires careful handling during the stamping process, as it can be easily damaged by excessive heat or pressure. Suede can typically withstand temperatures up to 180°C (356°F).

Pros: Suede offers a distinctive look and feel, making it ideal for high-end fashion items. Its softness and flexibility allow for intricate designs.

Cons: Suede is less durable than other leather types and can be prone to staining and wear. The hot stamping process must be carefully controlled to avoid damaging the material.

What Should International Buyers Consider When Choosing Leather Types?

When sourcing leather materials for hot stamping, international buyers must consider compliance with local regulations, such as ASTM standards in the U.S. or DIN standards in Germany. Different regions may have varying preferences for leather types based on environmental concerns and cultural factors. For instance, buyers from Europe may prefer vegetable tanned leather due to its eco-friendly attributes, while buyers from the Middle East may favor chrome tanned leather for its durability.

Illustrative image related to hot stamping leather

Summary Table of Material Selection for Hot Stamping Leather

| Material | Typical Use Case for hot stamping leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Chrome Tanned Leather | Bags, wallets, and belts | High durability and flexibility | Environmental concerns and higher cost | High |

| Vegetable Tanned Leather | Luxury goods, belts, and accessories | Eco-friendly and develops a rich patina | Susceptible to moisture and warping | Medium |

| Suede | Fashion items and luxury accessories | Unique texture and high-end appeal | Less durable and prone to staining | Medium |

| Coated Leather | Fashion and functional goods | Water-resistant and easy to clean | Limited breathability and less natural feel | Medium |

This strategic material selection guide provides insights that can help B2B buyers make informed decisions when sourcing materials for hot stamping leather products, ensuring they meet both quality and regulatory standards in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for hot stamping leather

What Are the Main Stages of the Hot Stamping Leather Manufacturing Process?

The manufacturing process for hot stamping leather involves several critical stages, ensuring that the final product meets both aesthetic and functional requirements. Here’s a breakdown of these stages:

Material Preparation: How Are Leather and Foils Selected?

The first step in the hot stamping process is the careful selection and preparation of materials. This involves choosing the right type of leather—typically chrome tanned or vegetable tanned—based on the desired finish and application. Leather thickness is crucial; it should generally be at least 1.5 mm to ensure a clean impression without compromising the integrity of the material.

Illustrative image related to hot stamping leather

Additionally, selecting the appropriate foil is essential. Foils come in various colors and finishes, including metallic, matte, and gloss. The choice of foil should align with the branding requirements of the product and the leather type being used. Proper conditioning of the leather surface, often through slight dampening, can enhance adhesion during stamping.

Forming: What Techniques Are Employed for Stamping?

Once materials are prepared, the next stage involves the actual stamping process. Hot stamping typically uses an electric branding iron, which applies heat and pressure to transfer the design onto the leather. This technique is favored for its ability to produce crisp, clean designs, especially for larger logos or intricate patterns.

The process starts by preheating the branding iron to the appropriate temperature, which varies depending on the leather type. Chrome tanned leather requires higher temperatures compared to vegetable tanned leather. The heated branding iron is then pressed onto the leather, allowing the foil to bond with the material through heat activation.

Illustrative image related to hot stamping leather

Assembly: How Are Stamped Leather Products Constructed?

Post-stamping, the leather pieces are often assembled into the final product, such as wallets, belts, or bags. This may involve cutting, sewing, or adding additional components like zippers or buckles. Each piece must be meticulously aligned to maintain quality and aesthetic appeal.

Quality assurance checks should be integrated into this stage to ensure that all stamped components fit correctly and that the branding is consistent across the product range. This is especially important for B2B buyers who require uniformity across large orders.

Finishing: What Final Touches Ensure Quality?

The final stage in the manufacturing process involves finishing touches that enhance the product’s durability and appearance. This may include edge finishing, polishing, and applying protective coatings. It’s essential to avoid sealants that could interfere with the hot stamping process.

Quality checks at this stage are vital, as they ensure that the final product meets the specifications agreed upon with the buyer. Any discrepancies can lead to costly returns and affect customer satisfaction.

What Quality Assurance Measures Are Essential for Hot Stamping Leather?

Quality assurance in the hot stamping leather process is critical, especially for international B2B buyers who may face different regulatory environments.

What International Standards Should B2B Buyers Be Aware Of?

One of the most recognized quality standards is ISO 9001, which outlines criteria for a quality management system. Adhering to this standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Additionally, industry-specific certifications, such as CE marking for products sold within the European Economic Area, may also be relevant. Buyers should confirm that their suppliers comply with these standards to mitigate risks associated with product quality and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control is typically implemented at various checkpoints throughout the manufacturing process:

Illustrative image related to hot stamping leather

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter production. Ensuring that leather and foils meet specified quality standards is crucial for the overall quality of the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators should conduct regular checks to ensure that stamping temperatures and pressures are consistent, and that the quality of the stamped design meets specifications.

-

Final Quality Control (FQC): This step occurs after assembly and finishing. The final products are inspected for consistency, defects, and adherence to branding requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control systems, and overall operational standards. This firsthand observation can provide valuable insights into the supplier’s capabilities.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality control processes, including inspection reports and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the supplier’s quality claims. These independent assessments can help ensure that the products meet the necessary specifications before they are shipped.

What Nuances Should International Buyers Consider in QC?

For international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in different markets is essential.

-

Cultural Differences: Different regions may have varying expectations regarding quality and craftsmanship. Buyers should be prepared to communicate their specific requirements clearly and understand the local manufacturing culture.

-

Regulatory Compliance: Buyers must be aware of local regulations that may affect product quality, such as environmental standards or labor laws. Ensuring that suppliers comply with these regulations is crucial for maintaining a sustainable supply chain.

-

Logistical Considerations: Shipping and handling can impact product quality. Buyers should discuss packaging and transportation methods with suppliers to minimize damage during transit.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing hot stamping leather products, ensuring they receive high-quality, consistent products that meet their branding needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot stamping leather’

When sourcing hot stamping leather, it is essential to follow a systematic approach to ensure that you procure high-quality materials that meet your specific requirements. This guide provides a step-by-step checklist to help international B2B buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for successful sourcing. Consider the type of leather you need, such as chrome-tanned or vegetable-tanned, and the desired thickness, which typically should be at least 1.5 mm for optimal hot stamping results. Include additional details, such as the finish, color, and any specific branding requirements to communicate your needs effectively to suppliers.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the hot stamping leather industry. Look for suppliers who have been in the market for several years and have positive reviews from previous clients. Utilize platforms like trade directories, industry associations, and online forums to gather insights and recommendations.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications to ensure compliance with industry standards. Certifications such as ISO 9001 for quality management systems or environmental certifications can indicate a supplier’s commitment to quality and sustainability. Request copies of these certifications and assess their relevance to your sourcing criteria.

Step 4: Request Sample Products

Obtaining samples is a critical step in evaluating the quality of hot stamping leather. Request samples that closely match your specifications, and test them for durability, stamping results, and appearance. This hands-on evaluation will help you determine whether the supplier can meet your quality expectations.

Step 5: Assess Production Capabilities

Understanding a supplier’s production capabilities is essential, particularly if you plan to order large quantities. Inquire about their manufacturing processes, equipment, and lead times. A supplier with advanced technology, like CNC machining, can provide higher precision and consistency in their products, which is vital for achieving quality hot stamping results.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, it’s time to negotiate terms. Discuss pricing, payment terms, minimum order quantities, and delivery timelines. Ensure that all terms are documented in a formal agreement to avoid misunderstandings later. Pay attention to warranty and return policies as well, as these can affect your long-term satisfaction with the supplier.

Step 7: Establish a Communication Plan

Effective communication is key to a successful partnership. Establish a clear communication plan with your supplier, outlining points of contact, preferred communication methods, and frequency of updates. This will facilitate better collaboration, ensure alignment on expectations, and help quickly resolve any issues that may arise during the production process.

Following this checklist will equip you with the essential steps to source high-quality hot stamping leather effectively, enabling your business to enhance its product offerings and meet customer demands.

Comprehensive Cost and Pricing Analysis for hot stamping leather Sourcing

What Are the Key Cost Components in Hot Stamping Leather Sourcing?

When sourcing hot stamping leather, understanding the cost structure is crucial for B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

Materials typically account for a significant portion of the overall cost. High-quality leather, whether chrome-tanned or vegetable-tanned, can vary in price based on origin and treatment. The choice of stamping materials, such as brass or aluminum for the stamps themselves, also affects costs.

Labor costs are influenced by the skill level required for hot stamping, with specialized labor often demanding higher wages. Manufacturing overhead encompasses facility costs, utilities, and other indirect expenses, which should be factored into the pricing model.

Tooling costs arise from the creation and maintenance of stamping plates and electric branding irons. Customization or specific branding designs can drive these costs higher. Ensuring effective quality control is essential, particularly for international buyers who may have stringent standards; this can also add to the cost.

Logistics costs, including shipping and handling, are another critical factor. The final margin applied by suppliers can vary widely based on their business strategy and market positioning.

How Do Price Influencers Affect Hot Stamping Leather Costs?

Several key factors influence pricing in the hot stamping leather market. Volume and Minimum Order Quantities (MOQ) are critical; larger orders often yield lower per-unit costs due to economies of scale. Customization requests, such as unique designs or specific leather types, can increase prices, as they often require more intricate tooling and additional labor.

The quality of materials used significantly impacts pricing. Premium leathers and high-grade stamping equipment will naturally command higher prices. Certifications, such as eco-friendly or ethical sourcing standards, can further elevate costs but may appeal to certain markets, particularly in Europe.

Supplier factors also play a role; a supplier with a strong reputation for quality and reliability may charge more than a less established competitor. Additionally, the choice of Incoterms can influence overall costs. Buyers should understand whether prices include shipping, insurance, and tariffs, as these factors can affect the total landed cost.

What Are the Best Negotiation Tips for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings. First, understanding the Total Cost of Ownership (TCO) is vital. This includes not only the purchase price but also logistics, storage, and potential quality control costs associated with sourcing from different suppliers.

Illustrative image related to hot stamping leather

Negotiation tactics should focus on building long-term relationships with suppliers. Discussing the possibility of bulk purchasing or establishing long-term contracts can lead to better pricing. Be transparent about your requirements and ask for detailed quotes that break down costs.

Buyers should also conduct market research to benchmark prices and ensure they are not overpaying. Understanding the local market conditions in the supplier’s region can provide leverage in negotiations.

What Pricing Nuances Should Buyers Consider?

International buyers must be aware of various pricing nuances when sourcing hot stamping leather. Currency fluctuations can significantly impact costs, making it important to agree on pricing terms upfront. Additionally, tariffs and trade regulations can vary by region, influencing the final cost structure.

Buyers should also consider the impact of local demand and competition on pricing. In regions with high demand for leather goods, prices may be elevated due to market pressures. Conversely, in areas with less competition, buyers may find more favorable pricing.

Disclaimer on Indicative Prices

It’s essential for buyers to understand that prices can vary widely based on the aforementioned factors. The information provided is indicative and should be verified with suppliers for accurate and up-to-date pricing. Always request detailed quotes and consider all cost components when making sourcing decisions.

Alternatives Analysis: Comparing hot stamping leather With Other Solutions

When considering branding or personalizing leather products, hot stamping is a prominent method. However, it’s essential for B2B buyers to explore alternative solutions that might better suit their specific needs, depending on factors such as budget, product type, and desired finish. This section compares hot stamping leather with other viable methods, providing insights to help buyers make informed decisions.

| Comparison Aspect | Hot Stamping Leather | Leather Stamping | Laser Engraving |

|---|---|---|---|

| Performance | Produces a clean, modern finish; ideal for larger designs | Offers a traditional, textured finish; best for smaller designs | Highly precise; can engrave intricate details and patterns |

| Cost | Moderate; requires investment in electric branding irons | Lower initial cost; affordable for small-scale operations | Higher upfront cost; laser equipment can be expensive |

| Ease of Implementation | Requires training for temperature control; suitable for mass production | Simple process; easily executed with basic tools | Requires technical knowledge and setup; may need software |

| Maintenance | Relatively low; occasional calibration of heating units | Minimal maintenance; mainly involves care of stamps | Higher maintenance; laser machines require regular servicing |

| Best Use Case | Ideal for branding large quantities with consistent results | Best for artisan goods or small batches with a classic look | Perfect for detailed designs, logos, or custom artwork |

What Are the Benefits and Drawbacks of Leather Stamping as an Alternative?

Leather stamping utilizes a handheld mallet and custom stamps to create imprints on leather products. This method is straightforward and cost-effective, making it accessible for small businesses or artisans. The tactile finish appeals to consumers seeking a traditional or rustic aesthetic. However, it has limitations regarding the size and complexity of designs; larger stamps may not produce even impressions, and the technique can be labor-intensive for larger production runs.

How Does Laser Engraving Compare to Hot Stamping?

Laser engraving is a modern technology that uses high-powered lasers to etch designs onto leather surfaces. This method excels in precision and can achieve intricate detailing that other methods may struggle with. It is ideal for creating complex logos or patterns and allows for customization at scale. However, the initial investment for laser equipment can be substantial, and operators may require specialized training. Additionally, depending on the leather type, the heat generated can cause discoloration if not managed correctly.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate branding method, B2B buyers should assess their specific needs, including production volume, design complexity, and budget. For businesses focused on mass production with consistent quality, hot stamping may be the best choice. Conversely, those interested in artisanal products or smaller batches might find leather stamping more suitable. For intricate designs and high customization, laser engraving presents an advanced option, albeit at a higher cost. Ultimately, understanding the unique advantages and limitations of each method will empower buyers to make choices that align with their branding objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for hot stamping leather

What Are the Key Technical Properties of Hot Stamping Leather?

When considering hot stamping for leather products, understanding the technical specifications is crucial for ensuring quality and consistency. Here are some essential properties:

Illustrative image related to hot stamping leather

-

Material Grade

The grade of leather significantly affects the hot stamping process. Common grades include chrome-tanned and vegetable-tanned leather. Chrome-tanned leather is more durable and resistant to moisture, making it suitable for intricate designs and larger logos. Vegetable-tanned leather, while more environmentally friendly, requires careful temperature control during stamping to prevent burning. -

Thickness Tolerance

The thickness of the leather impacts how well it accepts hot stamping. A minimum thickness of 1.5 mm is recommended to avoid puncturing the material. Thicker leather allows for deeper impressions but requires precise temperature management to ensure even heating without damaging the surface. Understanding these tolerances helps buyers select the appropriate material for their branding needs. -

Temperature Control

Hot stamping requires precise temperature settings tailored to the type of leather being used. For instance, chrome-tanned leather typically requires higher temperatures compared to vegetable-tanned leather. Using a variable-temperature branding iron allows for adjustments based on leather type, ensuring that designs are crisp and clear while avoiding burns or melting of any coatings. -

Imprint Depth

The depth of the imprint affects the aesthetic and durability of the branding. A deeper impression can enhance visibility and longevity, but it must be balanced with the risk of damaging thinner leather. Understanding the ideal depth for various leather types is critical for achieving high-quality results. -

Design Complexity

The complexity of the design also plays a significant role in the stamping process. More intricate designs may require specialized tools and careful consideration of heat and pressure. Buyers should be aware of the limitations of their chosen stamping method to ensure that the final product meets their branding standards.

What Are Common Trade Terms in Hot Stamping Leather?

Familiarity with industry terminology can facilitate smoother transactions and better communication with suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products based on the designs and specifications provided by another company. In the context of hot stamping leather, OEM relationships can enable businesses to create custom branding tools that align perfectly with their brand identity. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding the MOQ is essential for budgeting and inventory planning, especially for businesses looking to scale their branding efforts across various product lines. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing on specific products or services. When planning a hot stamping project, issuing an RFQ can help buyers compare costs and services from different suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a set of international rules that define the responsibilities of sellers and buyers in shipping agreements. Familiarity with Incoterms can help businesses understand shipping costs, risks, and responsibilities associated with importing hot stamping equipment or leather products. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the goods. Lead time can vary based on the complexity of the design and the supplier’s production capacity. Knowing the lead time helps businesses plan their inventory and marketing strategies effectively.

By understanding these essential properties and terms, international B2B buyers can make informed decisions when sourcing hot stamping leather products, ensuring they meet both quality and branding expectations.

Navigating Market Dynamics and Sourcing Trends in the hot stamping leather Sector

What Are the Key Market Dynamics Influencing Hot Stamping Leather?

The hot stamping leather market is witnessing substantial growth driven by the rising demand for personalized leather products across various industries, including fashion, automotive, and luxury goods. This demand is particularly strong in regions like Africa, South America, the Middle East, and Europe, where consumers increasingly favor customized and high-quality leather items. Additionally, the advent of advanced technologies in hot stamping processes, such as variable-temperature electric branding irons, has enhanced production efficiency, allowing manufacturers to achieve consistent branding results on diverse leather types.

Illustrative image related to hot stamping leather

Emerging B2B tech trends are also shaping the landscape. The integration of digital design tools and automation in manufacturing processes is streamlining production, enabling quicker turnaround times for customized orders. Furthermore, e-commerce platforms are expanding access to international buyers, making it easier for businesses in regions such as Vietnam and Germany to source hot stamping leather products. As international supply chains evolve, buyers are encouraged to look for suppliers who can offer both quality and technological innovation.

However, navigating this market requires a keen understanding of regional preferences and material specifications. For instance, while chrome-tanned leather is prevalent in Europe, vegetable-tanned leather is gaining traction in environmentally conscious markets. B2B buyers should remain adaptable and informed to capitalize on these dynamic market shifts.

How Is Sustainability Shaping the Sourcing of Hot Stamping Leather?

Sustainability is becoming a pivotal consideration in the hot stamping leather sector, influencing sourcing decisions among international buyers. The environmental impact of leather production is under scrutiny, prompting businesses to seek ethical supply chains that prioritize eco-friendly practices. Sourcing from suppliers who adhere to sustainable tanning processes and utilize biodegradable materials is increasingly essential for companies aiming to enhance their brand reputation and meet consumer expectations.

Illustrative image related to hot stamping leather

Buyers should also consider suppliers with ‘green’ certifications, such as the Leather Working Group (LWG) certification, which assesses tanneries based on their environmental management practices. These certifications not only reflect a commitment to sustainability but also reassure consumers about the ethical sourcing of their products. As the demand for sustainable leather goods rises, incorporating these practices into supply chain management can lead to significant competitive advantages.

Moreover, the trend towards using recycled materials in leather products is gaining momentum. This not only reduces waste but also appeals to environmentally conscious consumers. B2B buyers must engage with suppliers who are forward-thinking and committed to innovative practices that align with global sustainability goals.

What Is the Historical Context of Hot Stamping Leather in B2B Markets?

The practice of hot stamping leather has evolved significantly over the decades. Traditionally, leather stamping involved manual techniques that required skilled artisans, resulting in unique but inconsistent branding. The introduction of electric branding irons revolutionized the process, allowing for precision and uniformity in branding, which has become crucial for mass production.

In recent years, technological advancements have further enhanced the hot stamping process. Automated systems and digital design tools have made it possible for manufacturers to produce intricate designs with greater efficiency, catering to the growing demand for customization in the B2B sector. As markets continue to evolve, understanding the historical context of these processes helps buyers appreciate the innovations shaping the future of hot stamping leather.

Illustrative image related to hot stamping leather

Frequently Asked Questions (FAQs) for B2B Buyers of hot stamping leather

-

How do I choose the right hot stamping technique for my leather products?

To choose the right hot stamping technique, consider the type of leather you are using (e.g., chrome tanned, vegetable tanned, or suede) and the desired appearance of your branding. Hot stamping with an electric branding iron is ideal for achieving a modern look with larger designs, while traditional leather stamping may suit those seeking a classic impression. Additionally, assess the thickness of the leather; it’s advisable to work with leather that is at least 1.5 mm thick to ensure a clear impression and avoid damaging the material. -

What are the key factors to consider when sourcing hot stamping leather suppliers?

When sourcing hot stamping leather suppliers, evaluate their production capabilities, quality control measures, and experience in the leather industry. Look for suppliers who offer customization options to meet your branding needs and check their minimum order quantities (MOQ) to ensure they align with your business requirements. Additionally, assess their reputation through customer reviews and testimonials, as well as their responsiveness and communication practices during the negotiation process. -

What customization options are available for hot stamping leather?

Customization options for hot stamping leather typically include various sizes, shapes, and designs for branding stamps. Suppliers may offer tailored solutions for logos, initials, or specific patterns, enabling you to create a unique branding identity. You can also choose from different foil colors, allowing for added visual appeal. Ensure you discuss your specific requirements with the supplier to explore all available customization possibilities that align with your brand image. -

What are typical minimum order quantities (MOQ) for hot stamping leather?

Minimum order quantities (MOQ) for hot stamping leather can vary significantly between suppliers. Generally, MOQs can range from as low as 50 to several hundred units, depending on the supplier’s production capacity and the complexity of the customization. It’s essential to clarify these details upfront to ensure that the supplier can meet your needs without compromising on quality or delivery timelines. -

How can I ensure quality assurance (QA) in my hot stamping leather orders?

To ensure quality assurance (QA) in your hot stamping leather orders, establish clear specifications for your products, including dimensions, design, and materials. Request samples before placing a large order to evaluate the quality of craftsmanship and materials used. Additionally, consider implementing a third-party quality inspection service to assess the products during production and before shipping. Maintain open communication with your supplier to address any concerns promptly. -

What payment terms should I expect when sourcing hot stamping leather internationally?

Payment terms for international sourcing of hot stamping leather can vary by supplier and region. Common terms include a deposit upfront (often 30-50%) with the balance due upon delivery or after inspection. Some suppliers may also offer payment through letters of credit or escrow services for added security. It’s crucial to negotiate favorable terms that protect your interests while ensuring the supplier feels secure in the transaction. -

What logistics considerations should I keep in mind when importing hot stamping leather?

When importing hot stamping leather, consider the shipping methods, customs regulations, and potential duties or tariffs that may apply. Choose a reliable logistics partner familiar with international trade to ensure timely delivery and compliance with local laws. Additionally, factor in lead times for production and shipping, as well as potential delays caused by customs clearance. Establishing a clear timeline and communication plan with your supplier and logistics provider can help mitigate risks. -

How can I effectively communicate my hot stamping requirements to suppliers?

To effectively communicate your hot stamping requirements to suppliers, provide detailed specifications, including design files, dimensions, and preferred materials. Use visual aids, such as sketches or prototypes, to illustrate your vision. Clearly outline your quality expectations and any specific industry standards that must be met. Encourage an open dialogue to address any questions or concerns and establish a collaborative relationship that fosters understanding and trust throughout the production process.

Top 4 Hot Stamping Leather Manufacturers & Suppliers List

1. Reddit – Leather Stamping Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Two stamps tapped at 8 mm; gold foil for hot stamping; electric handle; considering threaded rod with map gas torch or heat gun; goal to stamp on white leather; large stamp size 4 in x 5 in, small stamp size 2 in x 2.5 in; using heavy weight veg-tan leather.

2. Artisan Leather Supply – Maxita Hot Foil Stamping Machine

Domain: artisanleathersupply.com

Registered: 2020 (5 years)

Introduction: [{‘name’: ‘Maxita Hot Foil Stamping Machine’, ‘price’: ‘$950’, ‘reviews’: ‘1 review’}, {‘name’: ‘Maxita Hot Foil Stamping Machine – Compact’, ‘price’: ‘From $70’, ‘reviews’: ‘2 reviews’}, {‘name’: ‘Multi-function Stamping Machine’, ‘price’: ‘From $650’, ‘reviews’: ‘3 reviews’}, {‘name’: ‘ARTISAN Electric Creaser’, ‘price’: ‘$135’, ‘reviews’: ’21 reviews’}, {‘name’: ‘Electric Creaser Machine’, ‘pri…

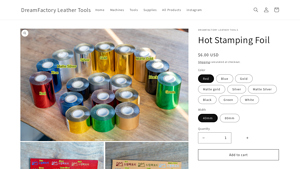

3. Dream Factory – Hot Stamping Foil

Domain: dreamfactorytools.com

Registered: 2019 (6 years)

Introduction: {‘name’: ‘Hot Stamping Foil’, ‘price’: {‘regular’: ‘$6.00 USD’, ‘sale’: ‘$6.00 USD’}, ‘colors’: [‘Red’, ‘Blue’, ‘Gold’, ‘Matte gold’, ‘Silver’, ‘Matte Silver’, ‘Black’, ‘Green’, ‘White’], ‘widths’: [’40mm’, ’80mm’], ‘variants’: [{‘color’: ‘Red’, ‘width’: ’40mm’, ‘price’: ‘$6.00’}, {‘color’: ‘Red’, ‘width’: ’80mm’, ‘price’: ‘$12.00’}, {‘color’: ‘Blue’, ‘width’: ’40mm’, ‘price’: ‘$6.00’}, {‘color’: …

4. Hot Stamping on Leather – Essential Tools

Domain: asummerspace.wordpress.com

Registered: 2000 (25 years)

Introduction: Hot stamping on leather involves using a die/custom-made leather stamp, a heat source (like an electric iron), untreated leather, water, a sponge, and a flat, hard surface. The die is typically made of brass and can be ordered online. The process requires heating the die to a temperature between 80 to 160 degrees Celsius, applying water to the leather to darken it, and then pressing the die onto t…

Strategic Sourcing Conclusion and Outlook for hot stamping leather

What Are the Key Takeaways for B2B Buyers in Hot Stamping Leather?

In the competitive landscape of leather goods, strategic sourcing of hot stamping materials and equipment is crucial for enhancing brand identity and product quality. Buyers must prioritize understanding the different leather types and stamping techniques, particularly the advantages of hot stamping over traditional methods. This knowledge allows for the selection of the most appropriate tools, like electric branding irons, which can deliver consistent, high-quality results across various leather types.

How Can International Buyers Leverage Hot Stamping for Competitive Advantage?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, investing in advanced hot stamping solutions can elevate product offerings and appeal to modern consumers. By sourcing from reliable manufacturers that provide variable-temperature systems and durable materials, businesses can ensure their branding remains intact and visually appealing.

What’s Next for Your Hot Stamping Leather Needs?

As the market evolves, embracing innovation in hot stamping techniques will be vital for staying ahead of trends. Now is the time to engage with suppliers who can meet your specific needs, ensuring you’re equipped to deliver exceptional products that resonate with your target audience. Explore opportunities to enhance your branding capabilities and solidify your position in the marketplace—your next step could redefine your brand’s legacy in the leather industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to hot stamping leather

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.