Introduction: Navigating the Global Market for who makes good leather jackets

In the quest for sourcing high-quality leather jackets, international B2B buyers face the challenge of navigating a diverse and competitive market. With various suppliers around the globe, discerning who makes good leather jackets is crucial for ensuring quality and durability in this premium apparel segment. This comprehensive guide is designed to equip buyers from Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil, with the insights necessary to make informed purchasing decisions.

Throughout this guide, we will explore the various types of leather jackets, from classic bombers to modern motorcycle styles, and delve into their specific applications across different markets. We will provide a detailed framework for supplier vetting, highlighting essential criteria such as material quality, craftsmanship, and sustainability practices. Additionally, we will discuss cost factors and pricing strategies to help you understand the value proposition of leather jackets in your local market.

By empowering buyers with actionable insights and industry best practices, this guide aims to streamline the sourcing process and enhance your confidence in selecting reputable suppliers. Whether you are looking to expand your product line or establish long-term partnerships, understanding who makes good leather jackets is essential for driving success in your business.

Table Of Contents

- Top 4 Who Makes Good Leather Jackets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for who makes good leather jackets

- Understanding who makes good leather jackets Types and Variations

- Key Industrial Applications of who makes good leather jackets

- 3 Common User Pain Points for ‘who makes good leather jackets’ & Their Solutions

- Strategic Material Selection Guide for who makes good leather jackets

- In-depth Look: Manufacturing Processes and Quality Assurance for who makes good leather jackets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘who makes good leather jackets’

- Comprehensive Cost and Pricing Analysis for who makes good leather jackets Sourcing

- Alternatives Analysis: Comparing who makes good leather jackets With Other Solutions

- Essential Technical Properties and Trade Terminology for who makes good leather jackets

- Navigating Market Dynamics and Sourcing Trends in the who makes good leather jackets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of who makes good leather jackets

- Strategic Sourcing Conclusion and Outlook for who makes good leather jackets

- Important Disclaimer & Terms of Use

Understanding who makes good leather jackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bomber Leather Jackets | Short, fitted style with ribbed cuffs and waistband | Fashion retail, promotional events | Pros: Timeless style; Cons: Limited warmth in colder climates. |

| Motorcycle Leather Jackets | Durable construction, often with reinforced areas | Motorcycle gear suppliers, apparel outlets | Pros: High durability; Cons: Heavier than other styles. |

| Vintage Leather Jackets | Distressed look, unique character from age | Vintage clothing stores, niche markets | Pros: Unique appeal; Cons: May require more care. |

| Shearling Leather Jackets | Soft lining, excellent insulation | High-end fashion boutiques, luxury retailers | Pros: Warmth and comfort; Cons: Higher price point. |

| Quilted Leather Jackets | Diamond-patterned stitching, padded insulation | Outdoor apparel retailers, fashion brands | Pros: Stylish and functional; Cons: Can be bulky. |

What are the Key Characteristics of Bomber Leather Jackets?

Bomber leather jackets are characterized by their short, fitted silhouette and ribbed cuffs and waistband. This style has its roots in military aviation, providing both functionality and style. For B2B buyers, bomber jackets are an excellent choice for fashion retail or promotional events due to their timeless appeal and versatility. However, they may not provide sufficient warmth in colder climates, which could limit their marketability in regions with harsh winters.

Illustrative image related to who makes good leather jackets

How Do Motorcycle Leather Jackets Stand Out in the Market?

Motorcycle leather jackets are designed for durability, featuring reinforced areas to withstand wear and tear. They often include protective padding and ventilation for comfort during rides. B2B applications for motorcycle jackets include motorcycle gear suppliers and apparel outlets, catering to a niche market of enthusiasts. While they offer high durability, their heavier construction may deter some buyers looking for lighter options.

What Makes Vintage Leather Jackets Unique?

Vintage leather jackets offer a distinct, distressed look that appeals to consumers seeking uniqueness and character in their clothing. These jackets often come with a history and can be a significant draw for vintage clothing stores and niche markets. B2B buyers should consider that while vintage jackets can command higher prices due to their rarity, they may require more care and attention to maintain their quality over time.

Why Are Shearling Leather Jackets Considered Luxury Items?

Shearling leather jackets feature a soft lining that provides excellent insulation, making them highly desirable in colder climates. They are often marketed in high-end fashion boutiques and luxury retailers. B2B buyers should note that while shearling jackets offer warmth and comfort, their higher price point may limit their audience to more affluent consumers or luxury markets.

Illustrative image related to who makes good leather jackets

What Are the Benefits of Quilted Leather Jackets?

Quilted leather jackets are known for their distinctive diamond-patterned stitching and padded insulation, combining style with functionality. They are popular in outdoor apparel retailers and fashion brands, appealing to consumers looking for both aesthetics and practicality. However, the bulkiness of quilted jackets can be a drawback for buyers who prefer a more streamlined silhouette in their offerings.

Key Industrial Applications of who makes good leather jackets

| Industry/Sector | Specific Application of who makes good leather jackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | High-end leather jackets for boutiques and fashion stores | Enhances brand prestige and attracts discerning customers | Quality of leather, craftsmanship, and style trends |

| Automotive | Custom leather jackets for automotive enthusiasts and brands | Promotes brand loyalty and creates a lifestyle image | Durability, design compatibility with brand aesthetics |

| Motorcycle Gear | Protective leather jackets for motorcycle riders | Increases safety and comfort for riders, enhancing product appeal | Safety certifications, comfort features, and fit |

| Outdoor Apparel | Leather jackets for outdoor and adventure clothing lines | Appeals to outdoor enthusiasts seeking durability and style | Weather resistance, functionality, and rugged design |

| Corporate Gifting | Premium leather jackets as corporate gifts | Strengthens client relationships and brand loyalty | Personalization options, quality assurance, and delivery timelines |

How is ‘who makes good leather jackets’ utilized in the Fashion Retail sector?

In the fashion retail industry, high-end leather jackets serve as a staple for boutique and upscale clothing stores. Retailers benefit from sourcing jackets that reflect current trends and craftsmanship, enhancing their brand prestige. Buyers should consider the quality of leather, the reputation of the manufacturer, and the uniqueness of designs to ensure they meet the expectations of discerning customers, particularly in markets like Europe and the Middle East, where fashion standards are high.

What role do leather jackets play in the Automotive sector?

In the automotive industry, custom leather jackets are often marketed to car enthusiasts and brand loyalists. These jackets can be designed to reflect the aesthetics of specific vehicle models, promoting brand loyalty and creating a lifestyle image associated with the automotive brand. Sourcing considerations include the durability of materials, design compatibility with the brand’s identity, and the ability to meet safety standards, which can be particularly important in regions like South America where outdoor activities are prevalent.

Illustrative image related to who makes good leather jackets

Why are leather jackets essential for Motorcycle Gear?

Motorcycle gear manufacturers prioritize protective leather jackets due to their ability to enhance rider safety and comfort. These jackets are designed to withstand the rigors of riding while providing style. Buyers in this sector must ensure that the jackets meet safety certifications and comfort features, such as ventilation and fit. International buyers, especially from regions with a strong motorcycle culture, should look for manufacturers that understand local preferences and climatic conditions.

How do leather jackets enhance Outdoor Apparel offerings?

For outdoor apparel brands, leather jackets represent a blend of durability and style, appealing to adventurers seeking reliable gear. These jackets are often designed to withstand harsh weather conditions while maintaining a fashionable appearance. When sourcing, businesses should prioritize weather resistance, functionality, and rugged design to meet the demands of outdoor enthusiasts. This is particularly relevant in markets across Africa and South America, where outdoor activities are a significant part of the lifestyle.

In what ways can Corporate Gifting leverage leather jackets?

In the corporate gifting sector, premium leather jackets can serve as high-value gifts that enhance client relationships and foster brand loyalty. Companies can leverage these jackets for branding opportunities through personalization options, such as logos or custom designs. Key sourcing considerations include quality assurance, the ability to meet customization requests, and adherence to delivery timelines, ensuring that gifts arrive on time for events or holidays. This approach is particularly effective in regions like the Middle East, where corporate gifting is a well-established tradition.

Illustrative image related to who makes good leather jackets

3 Common User Pain Points for ‘who makes good leather jackets’ & Their Solutions

Scenario 1: Sourcing Quality Leather Jackets from Reliable Manufacturers

The Problem: B2B buyers often struggle to identify reputable manufacturers that produce high-quality leather jackets. This challenge is compounded by the prevalence of subpar materials and construction in the market. Buyers may find themselves overwhelmed by the sheer number of options, leading to the risk of investing in products that do not meet their standards, which can damage their business reputation and customer satisfaction.

The Solution: To effectively source quality leather jackets, B2B buyers should prioritize manufacturers with a proven track record and positive customer feedback. Start by conducting thorough research online, utilizing platforms such as Alibaba or Global Sources to find suppliers. Request samples to evaluate the quality of materials and craftsmanship before committing to larger orders. Additionally, consider establishing relationships with manufacturers who can provide transparency about their sourcing practices, production methods, and material specifications. Look for certifications that indicate adherence to industry standards, such as ISO or leather quality grades. This strategic approach will help ensure that the jackets not only meet your aesthetic needs but also align with your quality expectations.

Scenario 2: Understanding the Diverse Styles and Their Market Demand

The Problem: B2B buyers often face confusion regarding which styles of leather jackets will resonate with their target market. The variety of styles—from bomber to biker to vintage—can make it challenging to align product offerings with current trends. Misjudging market demand can lead to unsold inventory, impacting cash flow and overall profitability.

Illustrative image related to who makes good leather jackets

The Solution: To navigate the complexities of style selection, B2B buyers should invest time in market research. Utilize tools like Google Trends or social media analytics to gauge consumer interest in specific leather jacket styles. Attend trade shows and fashion expos to observe emerging trends and engage with industry experts. Collaborating with fashion influencers or industry consultants can provide valuable insights into customer preferences. Additionally, consider starting with a diverse range of styles in smaller quantities to test market response before scaling up production. This approach minimizes risk while ensuring that you remain competitive and relevant in a dynamic market.

Scenario 3: Ensuring Proper Care and Maintenance of Leather Jackets

The Problem: One common pain point for B2B buyers is the lack of knowledge surrounding the proper care and maintenance of leather jackets. Without adequate information, buyers may struggle to provide their customers with the right guidelines, which can lead to premature wear and customer dissatisfaction. This issue is particularly critical for retailers who wish to maintain a reputation for quality and longevity.

The Solution: To address care and maintenance concerns, B2B buyers should proactively educate themselves and their customers on best practices. Develop informative materials such as care guides or instructional videos that outline how to clean, condition, and store leather jackets properly. Collaborate with manufacturers to obtain detailed care instructions that can be included with every purchase. Additionally, consider offering leather care products alongside your jackets, creating a comprehensive solution for customers. By equipping your clients with the knowledge and tools necessary for proper care, you enhance customer satisfaction and foster long-term loyalty, ultimately contributing to repeat business and positive referrals.

Strategic Material Selection Guide for who makes good leather jackets

What Are the Key Properties of Different Leather Materials Used in Jacket Manufacturing?

When selecting materials for leather jackets, several types of leather are commonly considered. Each type has unique properties that affect performance, durability, and overall suitability for various applications. Here, we analyze four primary leather types: full-grain leather, top-grain leather, lambskin leather, and suede.

How Does Full-Grain Leather Stand Out in Leather Jacket Production?

Full-grain leather is the highest quality leather available, made from the top layer of the hide, which retains the natural grain. This type of leather is known for its exceptional durability and breathability, making it suitable for jackets that need to withstand wear and tear while providing comfort.

Illustrative image related to who makes good leather jackets

Pros: Full-grain leather is highly durable and develops a rich patina over time, enhancing its aesthetic appeal. It is also resistant to moisture and can withstand various environmental conditions.

Cons: The cost of full-grain leather is generally high due to its quality and the complexity of the tanning process. Additionally, it may require more maintenance to keep it looking its best.

Impact on Application: Full-grain leather jackets are ideal for outdoor activities and fashion, providing both style and functionality. They are compatible with various climates, making them a versatile choice for international buyers.

Considerations for International Buyers: Buyers should ensure compliance with specific leather sourcing regulations and standards (e.g., ASTM) in their region. Full-grain leather is highly valued in markets like Europe and the Middle East, where quality craftsmanship is prioritized.

What Advantages Does Top-Grain Leather Offer for Jacket Manufacturers?

Top-grain leather is the second-highest quality leather, made by sanding down the top layer of the hide to remove imperfections. This process makes it more uniform in appearance and easier to work with.

Illustrative image related to who makes good leather jackets

Pros: Top-grain leather is more affordable than full-grain leather while still offering good durability and a refined look. It is less prone to staining and easier to clean.

Cons: While it is durable, top-grain leather does not develop the same rich patina as full-grain leather, which may be a drawback for some consumers. It is also less breathable compared to full-grain.

Impact on Application: This type of leather is suitable for fashion-forward jackets that prioritize aesthetics over ruggedness. It works well in urban environments and is popular in markets like South America, where style is crucial.

Considerations for International Buyers: Buyers should be aware of the varying perceptions of quality between regions. Top-grain leather may meet the standards in emerging markets but may not satisfy high-end consumers in Europe.

Why Is Lambskin Leather Preferred for Fashion Jackets?

Lambskin leather is known for its softness and luxurious feel, making it a popular choice for fashion jackets. It is derived from young sheep and is lighter than other leather types.

Pros: The primary advantage of lambskin leather is its softness and comfort, providing a premium feel. It is also lightweight, making it ideal for stylish jackets that do not compromise on comfort.

Cons: Lambskin is less durable than other leather types and is more susceptible to scratches and wear. It can also be more expensive due to its luxurious nature.

Impact on Application: Lambskin jackets are often favored in high-fashion contexts and are suitable for mild climates. They appeal to buyers looking for stylish, lightweight options.

Considerations for International Buyers: Buyers should consider the climate of their target market. In regions with harsher weather, lambskin may not be the best choice, while it could thrive in more temperate areas like Europe.

Illustrative image related to who makes good leather jackets

What Role Does Suede Play in Leather Jacket Design?

Suede is made from the underside of the hide, resulting in a soft, napped finish. It is often used in fashion jackets for its unique texture and appearance.

Pros: Suede offers a distinctive aesthetic and is available in a variety of colors. It is generally more affordable than full-grain or lambskin leather.

Cons: Suede is less durable and more challenging to clean, making it less suitable for rugged use. It is also more susceptible to water damage.

Impact on Application: Suede jackets are typically used for fashion purposes and are ideal for casual wear. They are popular in warm climates and urban settings, making them appealing to buyers in regions like South America.

Considerations for International Buyers: Buyers should ensure that suede jackets comply with local regulations regarding animal products. Additionally, they must consider maintenance requirements, as suede may not be suitable for all markets.

Summary Table of Leather Materials for Jacket Manufacturing

| Material | Typical Use Case for who makes good leather jackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Outdoor jackets, high-end fashion | Exceptional durability and breathability | High cost and maintenance required | High |

| Top-Grain Leather | Fashion jackets, urban wear | Good durability and refined look | Less patina development | Medium |

| Lambskin Leather | High-fashion jackets, lightweight wear | Softness and luxurious feel | Less durable and more expensive | High |

| Suede | Casual wear, fashion jackets | Unique texture and variety of colors | Less durable and challenging to clean | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers looking to source quality leather jackets. Understanding the properties, advantages, and limitations of each material will facilitate informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for who makes good leather jackets

What Are the Key Stages of Manufacturing High-Quality Leather Jackets?

The manufacturing process for high-quality leather jackets is a meticulous journey that involves several key stages: material preparation, forming, assembly, and finishing. Each stage is essential in ensuring that the final product meets the high standards expected by B2B buyers and consumers alike.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process is the careful selection of raw materials. Quality leather can be derived from various animal hides, including cow, lamb, and sheepskin. Full-grain leather is often preferred for its durability and natural aesthetic.

Once selected, the hides undergo tanning, a crucial process that preserves the leather and enhances its qualities. Vegetable tanning and chrome tanning are the two most common methods, each imparting different characteristics to the leather. B2B buyers should look for suppliers who source their leather from reputable tanneries that adhere to environmental regulations, ensuring both quality and sustainability.

What Techniques Are Employed in the Forming Stage?

After material preparation, the leather is cut and shaped into the desired pattern. Advanced techniques such as laser cutting and die-cutting are commonly used to ensure precision and reduce waste. Computer-aided design (CAD) technologies play a significant role in this stage, allowing for intricate designs and customizations to be easily replicated.

Additionally, forming may involve techniques like embossing or perforation to add unique textures and styles to the leather jacket. B2B buyers should inquire about the technologies used in the forming process, as these can impact the jacket’s final appearance and functionality.

How Is the Assembly Process Conducted for Leather Jackets?

The assembly of leather jackets is a skilled craft that often requires experienced artisans. Skilled workers sew the various pieces of leather together, ensuring that seams are strong and aesthetically pleasing. Techniques such as double stitching and reinforced seams are common in high-quality jackets to enhance durability.

Quality control checkpoints are integrated throughout the assembly process. In-process quality control (IPQC) ensures that each step meets established standards before moving on to the next phase. B2B buyers should consider suppliers who implement rigorous IPQC measures to catch any defects early on.

What Are the Final Touches During the Finishing Stage?

Finishing is the last stage in the manufacturing process, where jackets are treated to enhance their appearance and longevity. This may involve applying protective coatings, conditioning the leather, and adding final embellishments such as zippers and buttons.

The finishing stage is critical in determining the jacket’s feel, look, and longevity. B2B buyers should ask suppliers about the finishing treatments used, including any environmentally friendly options that may appeal to conscious consumers.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance (QA) is integral to the leather jacket manufacturing process, ensuring that products meet international standards and customer expectations. B2B buyers should be familiar with various QA standards, including ISO 9001, which outlines quality management principles, and CE marking, which indicates compliance with European safety standards.

How Are Quality Control Checkpoints Implemented?

Quality control in the leather jacket production process typically involves three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials upon arrival at the manufacturing facility. Suppliers should have rigorous IQC procedures to ensure that only high-quality leather enters the production process.

-

In-Process Quality Control (IPQC): During assembly, IPQC measures ensure that each step meets predetermined quality standards. This may involve visual inspections and performance tests at various stages of the production line.

-

Final Quality Control (FQC): The final inspection occurs before the jackets are packaged and shipped. FQC checks for defects, overall appearance, and adherence to specifications.

B2B buyers can request detailed reports on these quality control checkpoints from suppliers to ensure compliance with their quality expectations.

What Testing Methods Are Commonly Used in Leather Jacket Manufacturing?

Various testing methods are employed to assess the quality and durability of leather jackets. These include:

- Tensile Strength Testing: Evaluates the leather’s resistance to tearing and stretching.

- Flexural Testing: Measures how well the leather withstands bending and flexing.

- Water Resistance Testing: Assesses the leather’s ability to repel water, which is crucial for outdoor jackets.

- Colorfastness Testing: Ensures that the dye used in the leather does not fade or bleed when exposed to light or moisture.

B2B buyers should seek suppliers who conduct these tests and provide certification as part of their quality assurance processes.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should implement several verification strategies:

Illustrative image related to who makes good leather jackets

-

Audits: Regular audits of suppliers’ manufacturing facilities can provide insights into their processes, quality control measures, and adherence to international standards.

-

Reports: Request detailed quality control reports that outline the processes, testing results, and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control practices and product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, it’s essential to understand regional regulations and market expectations. Different regions may have specific standards for leather goods, including animal welfare regulations, environmental considerations, and safety certifications.

B2B buyers should familiarize themselves with these nuances to ensure that their suppliers comply with both local and international standards. Establishing a clear communication channel with suppliers can help clarify any regional requirements and enhance the overall quality assurance process.

By understanding the manufacturing processes and quality assurance measures involved in leather jacket production, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘who makes good leather jackets’

Introduction

This guide serves as a practical checklist for B2B buyers looking to source high-quality leather jackets. With a growing market demand for premium leather goods, it’s essential to navigate the sourcing process efficiently. This checklist will help you identify reliable manufacturers, ensure product quality, and establish a long-term partnership.

Step 1: Identify Your Target Market and Consumer Preferences

Understanding your target market is crucial in sourcing leather jackets. Different regions have varying preferences regarding style, material, and pricing. For instance, while European consumers might lean towards classic cuts and high-quality full-grain leather, buyers in South America may prefer more colorful and trendy designs.

- Research regional trends: Utilize market reports and surveys to identify popular styles in your target regions.

- Engage with local influencers: Collaborate with fashion influencers who can provide insights into consumer preferences.

Step 2: Define Your Quality Standards

Establishing clear quality standards will help you filter potential suppliers effectively. High-quality leather jackets should be durable, comfortable, and aesthetically pleasing.

- Specify leather types: Decide on the types of leather you wish to use, such as cowhide, lambskin, or sheepskin, based on your target market’s preferences.

- Outline construction requirements: Detail stitching, lining, and finishing processes to ensure consistency across your product range.

Step 3: Research and Shortlist Potential Suppliers

Begin your supplier search by gathering a list of manufacturers known for producing leather jackets. Look for companies with a solid reputation in the industry.

- Utilize B2B platforms: Websites like Alibaba, Global Sources, and TradeIndia can help you find reputable suppliers.

- Check reviews and ratings: Investigate supplier backgrounds through online reviews and testimonials to gauge reliability and product quality.

Step 4: Request Samples for Evaluation

Before making a bulk purchase, request samples from shortlisted suppliers. This step is vital for assessing the quality of materials and craftsmanship firsthand.

- Evaluate craftsmanship: Inspect stitching, zippers, and overall finish to ensure they meet your quality standards.

- Test material durability: Consider conducting wear tests to assess how the leather holds up over time.

Step 5: Verify Supplier Certifications and Compliance

Ensuring that your suppliers comply with industry standards is essential for avoiding legal issues and ensuring product safety.

- Request certifications: Look for certifications related to quality management (e.g., ISO 9001) and environmental management (e.g., ISO 14001).

- Confirm ethical sourcing: Verify that the leather is sourced sustainably and that labor practices meet international standards.

Step 6: Negotiate Terms and Establish a Contract

Once you have selected a supplier, it’s time to negotiate terms and establish a contract. This step will help protect your interests and set clear expectations.

- Discuss payment terms: Agree on pricing, payment methods, and any potential discounts for bulk orders.

- Outline delivery schedules: Ensure that timelines for production and delivery are clearly defined to avoid future misunderstandings.

Step 7: Plan for Ongoing Quality Control

After establishing a partnership, implement a quality control plan to maintain product standards throughout the manufacturing process.

Illustrative image related to who makes good leather jackets

- Conduct regular audits: Schedule site visits or third-party audits to ensure compliance with quality standards.

- Collect feedback from customers: Use customer feedback to continuously improve product offerings and address any quality concerns swiftly.

By following this checklist, B2B buyers can ensure they source high-quality leather jackets that meet market demands and maintain competitive advantage.

Comprehensive Cost and Pricing Analysis for who makes good leather jackets Sourcing

What Are the Key Cost Components in Sourcing Good Leather Jackets?

When sourcing high-quality leather jackets, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of leather significantly impacts the cost. Full grain leather is typically more expensive due to its durability and quality, while lambskin may offer a softer feel at a lower price point. Additional materials for linings and embellishments can also affect overall pricing.

-

Labor: Labor costs vary by region and the complexity of the jacket design. Skilled artisans who specialize in leatherworking command higher wages, reflecting their expertise and the quality of craftsmanship involved in producing high-end jackets.

-

Manufacturing Overhead: This includes expenses related to the facilities, utilities, and administrative costs incurred during production. Efficient manufacturing processes can help minimize these costs, making it essential for buyers to evaluate potential suppliers’ operational efficiencies.

-

Tooling: The initial investment in machinery and tools necessary for production can be substantial, especially for customized designs. Suppliers may pass these costs onto buyers, so understanding tooling requirements is vital.

-

Quality Control (QC): Ensuring that each jacket meets quality standards incurs costs. Rigorous QC processes may add to the overall price but are essential for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping and handling costs vary based on the destination and shipping method. International buyers should consider these costs, as they can significantly affect the total price.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers negotiate effectively.

How Do Price Influencers Impact Leather Jacket Sourcing?

Several factors can influence the pricing of leather jackets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize their purchasing strategy.

-

Specifications and Customization: Custom designs and specific requests can increase costs. Buyers should weigh the benefits of customization against the potential increase in price.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., eco-friendly or ethical sourcing) can lead to higher prices. Buyers should assess the value of these factors based on their target market.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers with proven track records may charge more, but they often provide better quality assurance and reliability.

-

Incoterms: Understanding the agreed terms of shipping can impact costs significantly. Buyers should clarify who bears the risk and costs at different stages of the shipping process.

What Are Essential Buyer Tips for Negotiating Leather Jacket Prices?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Effective Negotiation: Leverage your purchasing power by negotiating prices based on order volume and long-term partnerships. Establishing a relationship with suppliers can lead to better terms over time.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership, including logistics, tariffs, and potential returns. A lower upfront price may not always be the most cost-effective option in the long run.

-

Understand Pricing Nuances: Different markets have varying expectations regarding quality and pricing. Research local market trends and consumer preferences to inform your purchasing decisions.

-

Seek Multiple Quotes: Always obtain quotes from multiple suppliers to compare prices and terms. This practice not only helps in finding the best deal but also provides leverage during negotiations.

-

Stay Informed on Market Trends: Keep abreast of global trends in leather sourcing, including shifts in material costs and labor markets. Being informed can enhance your negotiating position.

Disclaimer on Indicative Prices

Prices in the leather jacket market can fluctuate based on various factors, including material availability, labor costs, and global economic conditions. It is advisable for buyers to conduct thorough market research and consult with suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing who makes good leather jackets With Other Solutions

Understanding Alternatives to Quality Leather Jackets

When it comes to sourcing leather jackets, B2B buyers have a variety of options to consider. While finding a reputable manufacturer of quality leather jackets is essential, alternative solutions may provide comparable benefits or meet specific needs. This analysis compares the traditional leather jacket manufacturing against two alternatives: synthetic leather jackets and custom apparel production.

| Comparison Aspect | Who Makes Good Leather Jackets | Synthetic Leather Jackets | Custom Apparel Production |

|---|---|---|---|

| Performance | High durability and longevity, improves with age | Generally less durable, but can mimic leather appearance | Quality varies; can be tailored for specific needs |

| Cost | Higher upfront investment but long-term value | Generally lower cost, making them budget-friendly | Variable costs; can be expensive depending on design |

| Ease of Implementation | Requires finding reliable suppliers and managing logistics | Widely available and easy to source | More complex due to design and manufacturing processes |

| Maintenance | Requires proper care for longevity | Easier to maintain; often machine washable | Maintenance depends on materials used; may require special care |

| Best Use Case | Ideal for luxury markets and fashion-forward brands | Suitable for budget-conscious consumers or fast fashion | Best for unique designs or specific market niches |

What are the Advantages and Disadvantages of Synthetic Leather Jackets?

Synthetic leather jackets are an increasingly popular alternative for businesses looking to offer stylish options at a lower price point. These jackets typically use polyurethane or PVC to replicate the look and feel of genuine leather. The primary advantage is cost; they are generally more affordable than real leather, which makes them appealing for budget-conscious consumers. Additionally, they often require less maintenance and can be machine washed. However, the trade-off is durability; synthetic materials may not withstand the test of time as well as genuine leather and can lose their aesthetic appeal over time.

How Does Custom Apparel Production Compare?

Custom apparel production offers a unique alternative for businesses seeking tailored solutions. This method allows companies to create jackets that meet specific design requirements, catering to niche markets or unique branding needs. The ability to customize aspects such as color, fit, and material can significantly enhance brand identity. However, this option can be more complex and costly, especially if the production runs are small. Furthermore, the quality can vary widely based on the manufacturer and the materials used, making it crucial for buyers to conduct thorough research before committing to custom production.

Making the Right Choice for Your Business Needs

In conclusion, choosing the right solution for leather jackets involves assessing specific business needs, target markets, and budget constraints. While traditional leather jackets offer durability and a timeless appeal, alternatives like synthetic leather and custom apparel production may better serve particular segments or price points. B2B buyers should weigh the pros and cons of each option, considering factors such as performance, cost, and ease of sourcing to ensure they align with their long-term business strategy. By doing so, they can effectively position their offerings in the competitive apparel market.

Illustrative image related to who makes good leather jackets

Essential Technical Properties and Trade Terminology for who makes good leather jackets

What Key Technical Properties Should B2B Buyers Consider When Sourcing Leather Jackets?

When sourcing leather jackets for B2B needs, understanding the technical properties is crucial to ensuring quality, durability, and marketability. Here are some essential specifications to consider:

1. Material Grade: What Types of Leather Are Best for Jackets?

The type of leather used significantly affects the jacket’s quality and durability. Common grades include:

- Full Grain Leather: The highest quality, retains the original texture and character of the hide. It develops a patina over time, enhancing its appeal.

- Top Grain Leather: Slightly less durable than full grain, it’s sanded and treated for a more uniform appearance but still offers good quality.

- Lambskin: Softer and lighter, ideal for fashion-forward designs, though less durable than cowhide.

Understanding the material grade helps buyers assess the product’s longevity and price point, ensuring alignment with consumer expectations.

2. Stitching Quality: Why Is It Important for Leather Jackets?

The stitching in leather jackets should be robust and consistent. Look for:

- Double-Stitched Seams: These provide added strength, preventing rips and tears.

- Thread Type: Polyester or nylon threads are preferred for their durability and resistance to fraying.

High-quality stitching not only enhances the jacket’s durability but also contributes to its aesthetic appeal, making it a critical factor for B2B buyers who prioritize quality.

3. Tolerance Levels: How Do They Impact Fit and Comfort?

Tolerance levels refer to the acceptable variations in measurements during production. Important tolerances include:

- Size Tolerances: Ensuring that jackets are manufactured within specific measurements to maintain consistent sizing across batches.

- Material Thickness: Variations can affect the jacket’s weight and feel.

Accurate tolerances are vital for maintaining quality control, ensuring that each jacket meets the standards expected by retailers and consumers.

4. Finish Type: How Does It Affect the Jacket’s Appearance?

The finish of leather jackets can greatly influence their look and feel. Key types include:

- Aniline Finish: Allows the natural grain to show but is more susceptible to staining.

- Pigmented Finish: Offers more color options and is more resistant to wear but may not have the same natural appearance.

Choosing the right finish is essential for positioning the product in the market and meeting customer preferences.

Illustrative image related to who makes good leather jackets

What Are Common Trade Terms Relevant to Leather Jacket Manufacturing?

To navigate the B2B leather jacket market effectively, it’s important to be familiar with industry jargon. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods for other brands, often under the client’s specifications. Understanding OEM relationships can help buyers source quality products tailored to their brand’s needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell. Knowing the MOQ is essential for managing inventory and ensuring that production meets demand without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price estimates on specific products. This process is crucial for comparing costs and ensuring competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps mitigate risks associated with logistics, delivery, and customs, ensuring smooth transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is vital for inventory planning and meeting customer demand without delays.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing leather jackets, ensuring they align with both market trends and consumer expectations.

Navigating Market Dynamics and Sourcing Trends in the who makes good leather jackets Sector

What Are the Current Market Dynamics and Key Trends in the Leather Jacket Industry?

The leather jacket market is experiencing robust growth, driven by several global factors. The increasing consumer demand for high-quality, durable apparel is pushing manufacturers to innovate with new designs and materials. Emerging markets in Africa, South America, the Middle East, and Europe are becoming significant players in this sector, with countries like Saudi Arabia and Brazil showing a rising interest in premium leather goods. The trend towards personalization and unique styles is also gaining momentum, prompting brands to offer customized options that appeal to diverse consumer preferences.

Digital transformation is reshaping sourcing strategies in the leather jacket industry. B2B buyers are increasingly leveraging e-commerce platforms and digital marketplaces to source products efficiently. Technologies such as blockchain are enhancing supply chain transparency, allowing buyers to track the origins of leather and ensuring quality. Additionally, the rise of social media marketing is influencing purchasing decisions, with brands showcasing their leather jacket collections through visually-driven campaigns that resonate with younger audiences.

How Is Sustainability Influencing the Sourcing of Leather Jackets?

Sustainability has become a cornerstone of the leather industry, with B2B buyers prioritizing ethical sourcing practices. The environmental impact of traditional leather production is significant, leading to increased scrutiny from consumers and regulatory bodies alike. Brands are responding by adopting more sustainable practices, such as using vegetable-tanned leather and sourcing from certified tanneries that adhere to strict environmental standards.

Moreover, ethical supply chains are essential in maintaining brand integrity and consumer trust. Buyers are encouraged to seek out suppliers who can provide certifications for sustainable practices, such as the Leather Working Group (LWG) certification. This not only ensures environmentally friendly sourcing but also aligns with the growing consumer demand for transparency and corporate responsibility. The integration of recycled materials and eco-friendly production processes is also becoming a standard expectation in the leather jacket sector.

What Is the Historical Context of Leather Jackets and Their Evolution in B2B Markets?

The leather jacket has a rich history that dates back to the early 20th century, originally worn by aviators and later popularized by military personnel and motorcycle enthusiasts. Its evolution into a fashion staple has seen it embraced by various subcultures, from rock and punk to high fashion. This historical significance adds a layer of appeal for B2B buyers looking to source products that carry a sense of heritage and craftsmanship.

Illustrative image related to who makes good leather jackets

Over the decades, the leather jacket has transformed in terms of style and function. Modern consumers now seek jackets that not only offer durability but also reflect personal style and contemporary trends. This evolution presents opportunities for manufacturers and suppliers to innovate, blending classic designs with modern aesthetics, which can be particularly appealing in diverse markets across Africa, South America, the Middle East, and Europe. As buyers navigate this dynamic landscape, understanding the historical context of leather jackets can enhance their sourcing strategies, ensuring they select products that resonate with their target audiences.

Frequently Asked Questions (FAQs) for B2B Buyers of who makes good leather jackets

-

How do I find reliable suppliers of quality leather jackets?

To find reliable suppliers, start by researching manufacturers with established reputations in the leather industry. Utilize platforms like Alibaba or global trade directories to identify potential vendors. Check for certifications, such as ISO standards, and read reviews from other B2B buyers. It’s also beneficial to request samples to assess quality firsthand. Attend industry trade shows or expos to meet suppliers in person and discuss their production capabilities, ensuring they align with your business needs. -

What are the key factors to consider when choosing a leather jacket manufacturer?

When selecting a manufacturer, consider their experience in leather production, the types of leather they use, and their compliance with international quality standards. Evaluate their production capacity to meet your order size, and ensure they offer customization options. Communication is crucial; assess their responsiveness and willingness to collaborate. Lastly, inquire about their supply chain practices to ensure timely delivery and sustainability. -

What is the minimum order quantity (MOQ) for leather jackets?

MOQs for leather jackets can vary widely among manufacturers, often ranging from 50 to 500 units per style. Smaller boutique manufacturers may accommodate lower MOQs, while larger factories typically require higher quantities to justify production costs. Discuss your specific needs with potential suppliers to negotiate favorable terms. Additionally, consider the implications of MOQ on inventory management and cash flow when planning your purchases. -

What payment terms are common in B2B leather jacket transactions?

Common payment terms in B2B transactions include a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. Some suppliers may offer letter of credit (LC) options, especially for large orders. Ensure that the payment terms are clearly outlined in your contract to avoid misunderstandings. It’s wise to establish trust with your supplier by maintaining transparent communication regarding payment schedules. -

How can I ensure the quality of leather jackets before purchasing?

To ensure quality, request detailed product specifications, including leather grade and construction methods. Ask for samples or small initial orders to evaluate the craftsmanship, fit, and finish of the jackets. Implement a quality assurance process, which may include third-party inspections during production and before shipment. Familiarize yourself with common leather types and their characteristics to make informed assessments of quality. -

What customization options should I consider for leather jackets?

Customization options can significantly enhance your product offering. Consider elements such as leather type, color, design, and additional features like lining or hardware. Embossing logos or adding unique design elements can differentiate your jackets in the market. Discuss these options with your supplier early in the negotiation process to understand the implications on cost and lead times. -

What are the logistics considerations for importing leather jackets?

Logistics involves understanding shipping methods, customs regulations, and import duties for your target market. Choose reliable freight forwarders experienced in handling leather goods to streamline the process. Be aware of the documentation required for customs clearance, including invoices and certificates of origin. Plan for potential delays and ensure your inventory management strategy accounts for lead times associated with international shipping. -

How can I establish a long-term partnership with leather jacket suppliers?

Building a long-term partnership requires consistent communication and mutual trust. Regularly provide feedback on product quality and market trends to help your supplier align with your business needs. Negotiate favorable terms that benefit both parties, and consider collaborating on new designs or exclusive collections. Foster a relationship built on transparency and reliability, as this can lead to better pricing, priority service, and collaborative growth opportunities.

Top 4 Who Makes Good Leather Jackets Manufacturers & Suppliers List

1. Buffalo Jackson – Best Selling Leather Jackets

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Best Selling Leather Jackets: 1. Bridger Leather Down Jacket – Light Brown – $534.95 2. Legacy Leather Jacket – Brown – $489.95 (Sale: $439.95) 3. Driggs Leather Jacket – Brown – $499.95 4. Thompson Leather Moto Jacket – Brown – $489.95 (Sale: $439.95) 5. Maverick Leather Bomber Jacket – Distressed Brown – $449.95 6. Bridger Leather Down Jacket – Tan & Brown – $534.95 7. Bridger Leather Down Jacke…

2. Vogue – Core Fashion Styles

Domain: vogue.com

Registered: 1994 (31 years)

Introduction: This company, Vogue – Core Fashion Styles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Lewis Leathers – Women’s Leather Jackets

Domain: thefedoralounge.com

Registered: 2003 (22 years)

Introduction: 1. Lewis Leathers – Highly recommended by multiple users for women’s leather jackets. 2. Aero – Mentioned as stylish but uncomfortable for one user. 3. Thedi – Noted for great looking women’s jackets, with custom options available. 4. Schott – Known for making women’s jackets for years, with a recommendation for their Perfecto style. 5. Ralph Lauren and high-fashion brands (Balenciaga, Rick Owens,…

4. The Jacket Maker – Men’s Leather Jackets

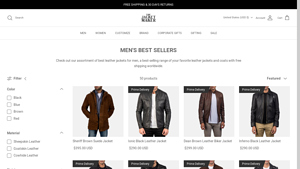

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Men’s Best Leather Jackets in Real Leather, Free Shipping & 30 Days Returns, Size Chart Updated, 50 products available, Sort options: Featured, Best Selling, Alphabetically, Price, Date, Filter options: Color (Black, Blue, Brown, Red), Material (Sheepskin, Goatskin, Cowhide), Finish (Full-Grain, Suede, Burnished, Rub-Off, Pull-Up, Glossy), Size (XS, S, M, L, XL, 2XL, 3XL, 4XL), Made to Measure ava…

Strategic Sourcing Conclusion and Outlook for who makes good leather jackets

What Are the Key Takeaways for Sourcing High-Quality Leather Jackets?

In summary, the journey to sourcing good leather jackets begins with an understanding of the diverse styles, materials, and craftsmanship that define quality. Buyers should prioritize suppliers who offer full-grain leather options, as this material not only ensures durability but also enhances the jacket’s character over time. Additionally, evaluating the manufacturing process and the brand’s reputation can provide insights into the product’s longevity and aesthetic appeal.

How Can Strategic Sourcing Enhance Your Leather Jacket Selection?

Strategic sourcing is crucial for international B2B buyers looking to make informed purchasing decisions. By establishing strong relationships with reputable manufacturers, buyers can ensure consistent quality and reliability, which are essential for maintaining customer satisfaction. Furthermore, leveraging data on market trends can help businesses anticipate consumer preferences, allowing them to stock the right styles and sizes.

What’s Next for International Buyers in the Leather Jacket Market?

As the leather jacket market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the potential for growth is significant. Buyers are encouraged to stay ahead of trends by collaborating with trusted suppliers and exploring innovative designs that resonate with local markets. Embrace the opportunity to diversify your offerings and make strategic investments that will set your business apart. The future of leather jackets is promising—seize the moment to elevate your product line today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.