Introduction: Navigating the Global Market for leather pu material

As global businesses increasingly seek cost-effective and sustainable materials, navigating the complexities of the leather PU material market has become a pressing challenge for B2B buyers. Sourcing high-quality PU leather that meets both aesthetic and functional requirements is essential for various applications, from furniture to fashion. However, with a myriad of options available, discerning the right supplier and understanding the nuances of different types of PU leather can be overwhelming.

This comprehensive guide aims to demystify the world of PU leather by exploring its various types, applications, and characteristics. We delve into the critical aspects of supplier vetting, ensuring that you can confidently partner with reputable manufacturers who meet international standards. Additionally, we provide insights into pricing structures, helping you make informed purchasing decisions that align with your business goals.

Designed specifically for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Vietnam—this guide empowers you with the knowledge to navigate the global market effectively. By understanding the benefits and limitations of PU leather, you can select the right materials that not only enhance your product offerings but also align with your sustainability objectives. Ultimately, this resource is your roadmap to making informed choices that drive business success in an increasingly competitive landscape.

Table Of Contents

- Top 8 Leather Pu Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather pu material

- Understanding leather pu material Types and Variations

- Key Industrial Applications of leather pu material

- 3 Common User Pain Points for ‘leather pu material’ & Their Solutions

- Strategic Material Selection Guide for leather pu material

- In-depth Look: Manufacturing Processes and Quality Assurance for leather pu material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather pu material’

- Comprehensive Cost and Pricing Analysis for leather pu material Sourcing

- Alternatives Analysis: Comparing leather pu material With Other Solutions

- Essential Technical Properties and Trade Terminology for leather pu material

- Navigating Market Dynamics and Sourcing Trends in the leather pu material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather pu material

- Strategic Sourcing Conclusion and Outlook for leather pu material

- Important Disclaimer & Terms of Use

Understanding leather pu material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 100% PU Leather | Fully synthetic, vegan, available in various colors and textures | Upholstery, fashion accessories | Pros: Cost-effective, easy to clean, diverse styles. Cons: Less durable, can crack or peel. |

| Bicast Leather | Real leather base with a PU coating, offers a leather-like finish | Furniture, automotive interiors | Pros: More durable than 100% PU, retains some leather qualities. Cons: Limited breathability, can still show wear. |

| Split Leather | Made from the fibrous part of real leather, coated with PU | Footwear, bags, and small goods | Pros: Economical, combines natural leather with synthetic benefits. Cons: Prone to wear and lacks the prestige of full grain leather. |

| Bonded Leather | Composed of leather scraps bonded with a polyurethane layer | Low-cost furniture, bookbinding | Pros: Affordable, eco-friendly by using scraps. Cons: Short lifespan, often perceived as inferior quality. |

| Corrected Grain Leather | Real leather that has been treated to remove imperfections | High-end upholstery, luxury goods | Pros: Enhanced appearance, maintains some leather traits. Cons: Can be less durable than full grain leather, may feel less authentic. |

What Are the Characteristics of 100% PU Leather and Its B2B Suitability?

100% PU leather is a fully synthetic material designed to mimic the appearance and feel of genuine leather. Its affordability and ease of maintenance make it suitable for a variety of applications, particularly in upholstery and fashion accessories. For B2B buyers, the primary consideration is cost-effectiveness, especially for high-volume orders. However, the material’s susceptibility to cracking and peeling over time can impact long-term customer satisfaction, making it crucial to weigh immediate savings against potential future costs.

Illustrative image related to leather pu material

How Does Bicast Leather Compare to Other PU Variants for B2B Use?

Bicast leather features a real leather substrate topped with a layer of PU, offering a balance between authenticity and durability. This variation is particularly popular in the furniture and automotive sectors, where a premium look is desired without the higher price tag of full-grain leather. B2B buyers should consider that while bicast leather provides a more robust option than 100% PU, it may still lack breathability and can show wear over time. Evaluating the target market’s expectations for durability and aesthetics is key when selecting this material.

What Are the Advantages and Disadvantages of Split Leather in B2B Purchases?

Split leather is derived from the fibrous leftovers of real leather production, coated with PU to enhance its durability. This type is often used in footwear and small leather goods, appealing to buyers looking for an economical solution that still incorporates natural leather elements. While it offers a competitive price point, B2B buyers should be aware of its limitations in terms of durability and prestige compared to higher-grade leathers. Understanding the end-use and customer expectations can help inform purchasing decisions.

Why Choose Bonded Leather for Cost-Effective B2B Solutions?

Bonded leather is made from leather scraps that are bonded together with a polyurethane layer, making it an eco-friendly option for businesses focused on sustainability. Its affordability makes it an attractive choice for low-cost furniture and bookbinding applications. However, B2B buyers should be cautious of its shorter lifespan and potential perception as lower quality. It is essential to align this material with the brand’s positioning and customer expectations to avoid compromising on perceived value.

How Does Corrected Grain Leather Fit into the B2B Market?

Corrected grain leather is treated to remove imperfections, resulting in a more uniform appearance while retaining some characteristics of natural leather. This type is often utilized in high-end upholstery and luxury goods, appealing to buyers seeking a polished look at a relatively lower cost. However, B2B buyers should consider that corrected grain leather may not be as durable as full grain options, which could affect long-term customer satisfaction. Understanding the balance between aesthetics and functionality is crucial for successful procurement.

Key Industrial Applications of leather pu material

| Industry/Sector | Specific Application of leather pu material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Cost-effective, easy to clean, and customizable | Ensure compliance with international quality standards; check for VOC emissions in production. |

| Footwear | Production of shoes and boots | Affordable alternative to leather; diverse styles | Assess durability and wear resistance; verify ethical sourcing practices. |

| Automotive | Interior finishes for vehicles | Lightweight, water-resistant, and easy maintenance | Confirm material performance under varying climate conditions; check for colorfastness. |

| Fashion Accessories | Handbags and wallets | Versatile design options and lower production costs | Investigate brand reputation and environmental impact of production processes. |

| Sports Equipment | Protective gear and bags | Lightweight and easy to clean; enhances aesthetics | Ensure compliance with safety standards; consider material performance under stress. |

How is leather PU material used in furniture manufacturing?

In the furniture manufacturing sector, PU leather is widely utilized for upholstery on sofas, chairs, and other seating solutions. Its cost-effectiveness and ease of maintenance make it an attractive option for both manufacturers and consumers. PU leather does not absorb water, making it easy to clean and maintain, which is crucial in regions with high humidity or rainfall, such as parts of Africa and South America. International buyers should prioritize suppliers who adhere to quality standards and can provide documentation regarding VOC emissions, ensuring safety and compliance with environmental regulations.

Illustrative image related to leather pu material

What are the applications of leather PU material in footwear production?

PU leather is a popular choice in the footwear industry for creating stylish and affordable shoes and boots. Its versatility allows for a range of colors and designs, catering to diverse market preferences. For B2B buyers, it is essential to assess the durability and wear resistance of PU leather products, particularly in regions with varying climates, such as Europe and the Middle East. Additionally, verifying the ethical sourcing of materials can enhance brand reputation and consumer trust, which is increasingly important in today’s market.

How is leather PU material utilized in automotive interiors?

In the automotive sector, PU leather is commonly used for vehicle interior finishes, including seats, dashboards, and door panels. Its lightweight nature contributes to fuel efficiency, while its water-resistant properties enhance durability and ease of maintenance. International buyers, especially from regions with extreme weather conditions, should ensure that the PU leather meets performance standards for temperature and humidity resistance. Furthermore, understanding the manufacturing process and the presence of any harmful chemicals is crucial for compliance with global automotive regulations.

What role does leather PU material play in fashion accessories?

In the fashion accessories industry, PU leather is extensively used to manufacture handbags, wallets, and belts. Its affordability allows brands to offer a variety of trendy designs without compromising on style. For B2B buyers, it is vital to investigate the brand reputation and the environmental impact of the production processes, especially as consumers increasingly favor sustainable options. Additionally, ensuring that the PU leather is of high quality and free from toxic chemicals can help businesses maintain a positive brand image.

How is leather PU material applied in sports equipment?

PU leather is utilized in the production of protective gear and sports bags, offering a lightweight, durable, and aesthetically appealing option for athletes and sports enthusiasts. Its easy-to-clean surface is particularly beneficial for equipment exposed to outdoor conditions. Buyers in the sports equipment sector should ensure that the materials comply with safety standards and can withstand the rigors of athletic use. Considering the performance of PU leather under stress, especially in high-impact scenarios, is essential for ensuring the safety and satisfaction of end-users.

Illustrative image related to leather pu material

3 Common User Pain Points for ‘leather pu material’ & Their Solutions

Scenario 1: Struggling with Durability and Longevity of PU Leather Products

The Problem: Many B2B buyers, especially in industries like furniture and fashion, face a significant challenge with the durability of PU leather products. Frequent reports indicate that PU leather can start cracking and peeling within just a year or two of use, leading to complaints from customers and increased return rates. This not only impacts brand reputation but also results in higher costs due to replacements and repairs. Buyers are often left wondering if they made the right choice in selecting PU leather over genuine leather, which is typically more durable but also more expensive.

The Solution: To mitigate the issues of durability, B2B buyers should focus on sourcing higher-quality PU leather that has been treated for enhanced longevity. When selecting suppliers, inquire about the specific manufacturing processes and the quality of materials used. Look for PU leather that incorporates a protective coating to improve resistance to wear and tear. Additionally, consider specifying reinforced seams and stitching in your products to prolong their lifespan. Educating your customers on proper care and maintenance can also extend the life of PU leather items. Recommend that they clean the material regularly with a mild soap solution and avoid exposing it to extreme heat or direct sunlight, which can accelerate degradation.

Scenario 2: Concerns Over Chemical Exposure and Safety Standards

The Problem: In various regions, especially where regulatory scrutiny is high, B2B buyers are increasingly concerned about the safety of PU leather materials due to the potential presence of volatile organic compounds (VOCs) and other harmful chemicals. These compounds can pose health risks to end-users and may even violate local safety regulations, leading to costly legal issues and damaged reputations for businesses that sell PU leather products.

Illustrative image related to leather pu material

The Solution: To address safety concerns, it is crucial for B2B buyers to prioritize sourcing PU leather from manufacturers that adhere to strict environmental and safety standards. Request Material Safety Data Sheets (MSDS) to ensure that the products comply with local regulations regarding VOCs and other hazardous substances. Opt for PU leather that is certified by reputable organizations for low chemical emissions. Additionally, consider incorporating an eco-friendly narrative into your marketing strategy, emphasizing your commitment to safety and sustainability. By promoting transparency in sourcing and manufacturing, you can build trust with your clients and end consumers, positioning your brand as a responsible choice in the market.

Scenario 3: The Challenge of Differentiating Between PU and Genuine Leather

The Problem: B2B buyers often struggle with the confusion surrounding the labeling of PU leather products. With terms like “vegan leather,” “faux leather,” and “bicast leather” commonly used, it can be difficult for buyers to distinguish between authentic and synthetic options. This ambiguity can lead to misinformed purchasing decisions, resulting in dissatisfaction among customers who expect the quality and characteristics of genuine leather.

The Solution: To overcome this challenge, B2B buyers should invest in training for their sales teams to ensure they can effectively communicate the differences between PU leather and genuine leather. Establish clear labeling practices for your products, using standardized terminology to avoid confusion. Educate your customers on how to identify PU leather through simple tests, such as checking for water absorption or assessing the material’s texture and scent. Providing detailed product descriptions and transparent information about the manufacturing process can also enhance customer understanding and satisfaction. By positioning your offerings clearly in the market, you can not only build trust but also attract a customer base that appreciates transparency and quality.

Strategic Material Selection Guide for leather pu material

What Are the Key Properties of PU Leather Materials for B2B Buyers?

PU leather, or polyurethane leather, is a synthetic alternative to genuine leather, made by coating fabric with a thermoplastic polymer. Its properties vary based on the manufacturing process and the specific materials used. Understanding these properties is crucial for international B2B buyers who need to make informed decisions based on product performance, durability, and compliance with regional standards.

1. Polyurethane Coated Fabric

Key Properties:

Polyurethane coated fabric is the most common form of PU leather. It exhibits good flexibility and can withstand moderate temperatures, making it suitable for various applications, including furniture and automotive interiors.

Pros & Cons:

The main advantage of this material is its cost-effectiveness compared to genuine leather, along with its ease of cleaning and maintenance. However, it lacks breathability and can be prone to cracking and peeling over time, which affects durability.

Impact on Application:

This type of PU leather is compatible with a wide range of media, including dyes and adhesives, making it versatile for manufacturers. However, its lower durability may not be suitable for high-wear applications.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider local climate conditions, as extreme temperatures can affect the material’s longevity. Compliance with local standards, such as ASTM for safety and performance, is also essential.

Illustrative image related to leather pu material

2. Bicast Leather

Key Properties:

Bicast leather consists of a layer of genuine leather that is coated with a polyurethane layer. This combination provides a unique texture and appearance similar to real leather while maintaining some of the benefits of PU.

Pros & Cons:

The key advantage is its aesthetic appeal, which offers a more upscale look than standard PU leather. However, it is still less durable than full-grain leather and may not withstand heavy use, leading to a shorter lifespan.

Impact on Application:

Bicast leather is often used in fashion accessories and furniture, where appearance is crucial. However, its limited durability means it may not be suitable for products requiring high durability.

Considerations for International Buyers:

Buyers in Europe may prefer this material for its upscale look, but they must ensure that it meets relevant EU regulations on material safety and environmental impact.

3. Vegan Leather

Key Properties:

Vegan leather is a broader category that includes PU leather but can also encompass other synthetic materials. It is designed to mimic the look and feel of leather without using any animal products.

Pros & Cons:

The primary advantage is its ethical appeal, attracting consumers looking for cruelty-free options. However, the durability can vary significantly based on the manufacturing process, and some vegan leathers may not perform as well as traditional materials.

Impact on Application:

Vegan leather is suitable for a variety of applications, including fashion, upholstery, and automotive interiors. However, its performance can be inconsistent, which may impact product quality.

Considerations for International Buyers:

In regions like the Middle East, where ethical sourcing is becoming increasingly important, vegan leather may meet growing consumer demand. Buyers should verify compliance with local environmental regulations.

Summary Table of PU Leather Materials

| Material | Typical Use Case for leather pu material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Coated Fabric | Furniture, automotive interiors | Cost-effective and easy to maintain | Prone to cracking and peeling | Low |

| Bicast Leather | Fashion accessories, furniture | Upscale appearance | Less durable than full-grain leather | Medium |

| Vegan Leather | Fashion, upholstery, automotive | Ethical appeal | Inconsistent durability | Medium |

This strategic material selection guide provides a comprehensive overview of PU leather materials, enabling B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for leather pu material

What Are the Main Stages in the Manufacturing Process of PU Leather?

The manufacturing of PU leather involves several key stages, each critical to ensuring the quality and durability of the final product. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for PU Leather Production?

The first step in the manufacturing process is material preparation. This involves selecting the appropriate base fabric, often polyester or cotton, which will serve as the substrate for the polyurethane coating. The base fabric is treated to enhance its adhesion properties and durability. Chemical treatments may be applied to improve the fabric’s water resistance and overall performance.

The polyurethane itself is prepared by mixing polyols and isocyanates in controlled environments to ensure the right chemical properties are achieved. This mixture is then processed to create a smooth, flexible coating that mimics the look and feel of genuine leather.

Illustrative image related to leather pu material

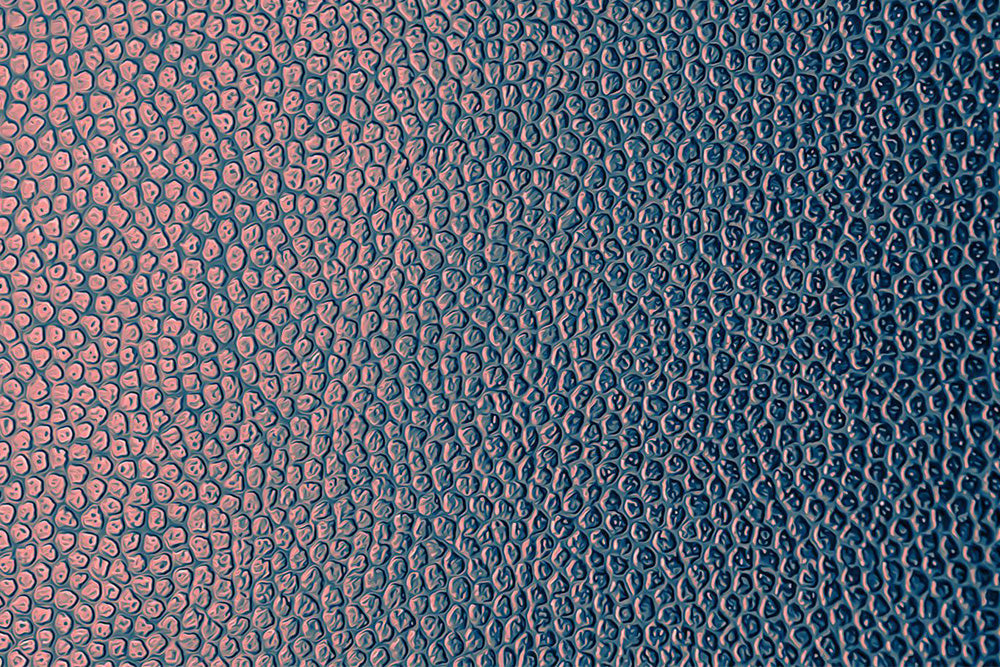

What Forming Techniques Are Used in PU Leather Production?

Once the materials are prepared, the next stage is forming. The treated fabric is coated with the polyurethane mixture using techniques such as:

- Roll Coating: A method where the base fabric is passed through rollers that apply a uniform layer of polyurethane.

- Spray Coating: Utilized for achieving varied textures and finishes, where the polyurethane is sprayed onto the fabric to create different surface effects.

- Foaming: In some cases, a foam layer may be added to provide additional cushioning and comfort, particularly for upholstery applications.

These techniques ensure that the PU leather has the desired texture and thickness while allowing for customization in terms of color and finish.

How Is Assembly Conducted for PU Leather Products?

The assembly phase involves cutting the coated fabric into specific shapes and sizes according to the product design. This may include patterns for handbags, furniture, or automotive upholstery. Skilled workers or automated cutting machines ensure precision in this stage.

After cutting, the pieces are sewn together using industrial sewing machines. This is a critical phase where the strength and durability of seams are tested. High-quality stitching techniques are essential to prevent fraying and ensure longevity, especially in high-wear applications like furniture.

What Finishing Techniques Enhance the Quality of PU Leather?

Finishing is the final step in the manufacturing process, where additional treatments are applied to enhance the aesthetic and functional properties of PU leather. This may include:

Illustrative image related to leather pu material

- Surface Treatments: Applying protective coatings that enhance scratch resistance and UV stability.

- Texturizing: Techniques such as embossing or debossing are used to create patterns that mimic natural leather grain.

- Coloring: Dyes and pigments are applied to achieve the desired color, ensuring uniformity and vibrancy.

This stage not only improves the visual appeal of PU leather but also contributes to its durability and ease of maintenance.

What Quality Assurance Standards Are Relevant for PU Leather Manufacturing?

Quality assurance is crucial in the production of PU leather, particularly for B2B buyers who need reliable and consistent products. Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for quality management systems.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure compliance with quality standards:

Illustrative image related to leather pu material

- Incoming Quality Control (IQC): At this stage, raw materials, including base fabrics and chemicals, are inspected for quality and compliance with specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to assess the quality of the coating, stitching, and assembly. This helps identify any defects before the product is completed.

- Final Quality Control (FQC): Finished products undergo thorough inspections to check for visual defects, durability, and overall quality. Testing methods may include physical tests for tensile strength, abrasion resistance, and water resistance.

What Common Testing Methods Are Used in PU Leather Quality Assurance?

B2B buyers should be aware of common testing methods that verify the quality of PU leather. These tests may include:

- Tensile Strength Testing: Measures the material’s resistance to being pulled apart, ensuring it can withstand everyday use.

- Abrasion Resistance Testing: Assesses how well the PU leather can resist wear and tear, particularly important for upholstery.

- Water Resistance Testing: Determines how effectively the material repels water, which is crucial for furniture and outdoor applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must ensure that their suppliers maintain rigorous quality control standards. Here are key steps to verify supplier QC processes:

- Conduct Audits: Regular audits of suppliers can help verify adherence to international standards and internal QC processes. Buyers should request documentation of past audits and corrective actions taken.

- Request QC Reports: Suppliers should provide detailed QC reports, including results from testing methods and quality assessments conducted at various stages.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide unbiased evaluations of product quality, ensuring compliance with buyer specifications and international standards.

What Are the Nuances of Quality Control and Certification for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital. Different regions may have varying standards and expectations regarding product quality.

- Regional Compliance: Buyers should familiarize themselves with local regulations and standards that may affect PU leather products. For instance, the European Union has stringent regulations regarding chemical safety that may not apply in other markets.

- Certifications: Look for suppliers that hold relevant certifications, such as OEKO-TEX, which ensures that textiles are free from harmful substances. This is especially important for products intended for sensitive markets, such as children’s furniture or clothing.

By engaging in comprehensive quality assurance practices and understanding the manufacturing processes, B2B buyers can make informed decisions when sourcing PU leather products, ensuring they receive high-quality, durable, and compliant materials for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather pu material’

Introduction

Navigating the procurement of PU leather material can be challenging, particularly for international B2B buyers seeking quality and reliability. This checklist is designed to streamline your sourcing process, ensuring you make informed decisions while mitigating risks associated with quality and compliance. By following these steps, you can confidently select suppliers that align with your business needs and sustainability goals.

Illustrative image related to leather pu material

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the type of PU leather, thickness, color, texture, and intended application (e.g., upholstery, footwear, or fashion accessories). Defining these specifications upfront helps in filtering suppliers who can meet your exact needs and reduces the risk of receiving subpar materials.

- Consider factors such as environmental compliance and certifications that may be required in your target market.

- Understand the differences between 100% PU leather and variations like bicast or bonded leather to ensure clarity in your specifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in PU leather. Look for companies with a solid reputation and positive reviews in the industry. Utilize platforms such as Alibaba, Global Sources, and trade shows to gather information.

- Pay attention to the supplier’s experience in your specific market region, such as Africa or South America, as local knowledge can be beneficial.

- Create a shortlist of suppliers that appear to align with your quality and pricing expectations.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold the necessary certifications and comply with international quality standards. Certifications such as ISO 9001 (Quality Management) and OEKO-TEX (Textile Safety) are indicators of a supplier’s commitment to quality and sustainability.

Illustrative image related to leather pu material

- Request documentation to confirm these certifications and assess their relevance to your business needs.

- Ensure that the supplier’s practices align with your corporate social responsibility (CSR) goals.

Step 4: Request Samples

Once you have narrowed down your options, request samples of the PU leather materials. This step is crucial for evaluating the quality, texture, and overall appearance of the products.

- Examine the samples for durability, flexibility, and any potential odor issues that could indicate chemical treatment.

- Use the samples to conduct tests, such as water resistance and abrasion resistance, to assess performance in real-world applications.

Step 5: Discuss Pricing and Terms

Engage in discussions about pricing, payment terms, and minimum order quantities. It’s essential to understand not just the unit price but also any additional costs, such as shipping, customs, and potential tariffs.

- Negotiate terms that allow for scalability in case your demand increases in the future.

- Ensure clarity on payment methods and timelines to avoid misunderstandings later.

Step 6: Conduct a Factory Visit or Audit

If feasible, plan a visit to the supplier’s manufacturing facility. This step allows you to assess their production capabilities, working conditions, and quality control measures firsthand.

- Evaluate the factory’s machinery and processes to ensure they align with your standards for quality and sustainability.

- Speak directly with management and employees to gain insights into their operational practices and labor conditions.

Step 7: Establish a Long-Term Partnership

Once you’ve selected a supplier, focus on building a long-term relationship. Regular communication and feedback can enhance collaboration and ensure that both parties meet evolving business needs.

- Discuss potential for future product developments or exclusive agreements that can benefit both sides.

- Schedule periodic reviews to assess the quality and performance of the PU leather supplied, ensuring ongoing alignment with your requirements.

By following this checklist, B2B buyers can navigate the complexities of sourcing PU leather material effectively, ensuring they partner with suppliers who meet their quality and sustainability expectations.

Comprehensive Cost and Pricing Analysis for leather pu material Sourcing

Understanding the Cost Structure of PU Leather Material Sourcing

When sourcing PU leather, international B2B buyers must navigate a complex cost structure that includes several critical components. Each element plays a significant role in determining the overall price and can vary based on regional dynamics, supplier capabilities, and market demand.

Illustrative image related to leather pu material

What Are the Key Cost Components of PU Leather?

-

Materials: The primary cost component in PU leather is the raw materials. This includes the thermoplastic polymers used to create the synthetic leather and any additional fabrics or coatings. The choice of materials can significantly impact pricing, particularly if buyers opt for higher-quality or specialty materials.

-

Labor: Labor costs vary by region and can influence the final price of PU leather. Countries with lower labor costs may offer more competitive pricing, but this may also affect quality. Understanding the labor market in the supplier’s location is essential for assessing overall costs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize overhead, leading to cost savings that can be passed on to buyers.

-

Tooling: Initial tooling costs for molds and other production equipment can be significant, especially for customized PU leather products. Buyers should consider these costs when evaluating suppliers, particularly if they require specialized designs or features.

-

Quality Control (QC): Ensuring product quality is vital, particularly for B2B buyers who must meet specific standards. QC processes can add to the cost, but they are essential for minimizing defects and ensuring product longevity.

-

Logistics: Transportation and shipping costs can vary widely depending on the supplier’s location and the buyer’s destination. Factors such as shipping method, distance, and Incoterms can significantly influence logistics costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can fluctuate based on market conditions and competition. Buyers should be aware of the typical margins within the industry to gauge fair pricing.

What Factors Influence PU Leather Pricing?

Several factors can influence the price of PU leather beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs. Understanding a supplier’s MOQ can help buyers negotiate better pricing for bulk purchases.

-

Specifications and Customization: Customized products often incur additional costs due to the need for specialized tooling or materials. Buyers should clarify their requirements upfront to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly or compliance with safety standards) can raise costs but may be worth the investment for branding and customer satisfaction.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a track record of quality may charge more but offer better assurance regarding product performance.

-

Incoterms: Understanding the agreed-upon Incoterms is crucial, as they dictate responsibilities for shipping, insurance, and tariffs, all of which can impact overall costs.

What Are the Best Negotiation Tips for B2B Buyers of PU Leather?

-

Research and Benchmarking: Gather information on market prices and competitor offerings to strengthen your negotiating position. This helps in identifying fair pricing and potential areas for negotiation.

-

Build Long-Term Relationships: Establishing a solid relationship with suppliers can lead to better pricing and terms over time. Suppliers are often more willing to offer discounts or favorable conditions to loyal customers.

-

Focus on Total Cost of Ownership (TCO): While initial pricing is important, consider the TCO, which includes durability, maintenance, and potential replacement costs. Investing in higher-quality PU leather may reduce long-term expenses.

-

Leverage Volume Discounts: If your business model allows for it, consider consolidating orders to achieve better pricing through volume discounts. Suppliers are often more willing to negotiate on larger contracts.

-

Be Clear on Specifications: Clearly communicate your needs and expectations to avoid misunderstandings that could lead to unexpected costs. This ensures that suppliers provide accurate quotes aligned with your requirements.

Conclusion: Navigating PU Leather Sourcing Costs

In summary, understanding the comprehensive cost structure and pricing factors associated with PU leather sourcing is essential for international B2B buyers. By considering the various components and leveraging strategic negotiation tactics, buyers can achieve favorable terms and ensure they receive quality products that meet their specific needs. Always remember to account for total costs, including logistics and potential long-term value, when making sourcing decisions.

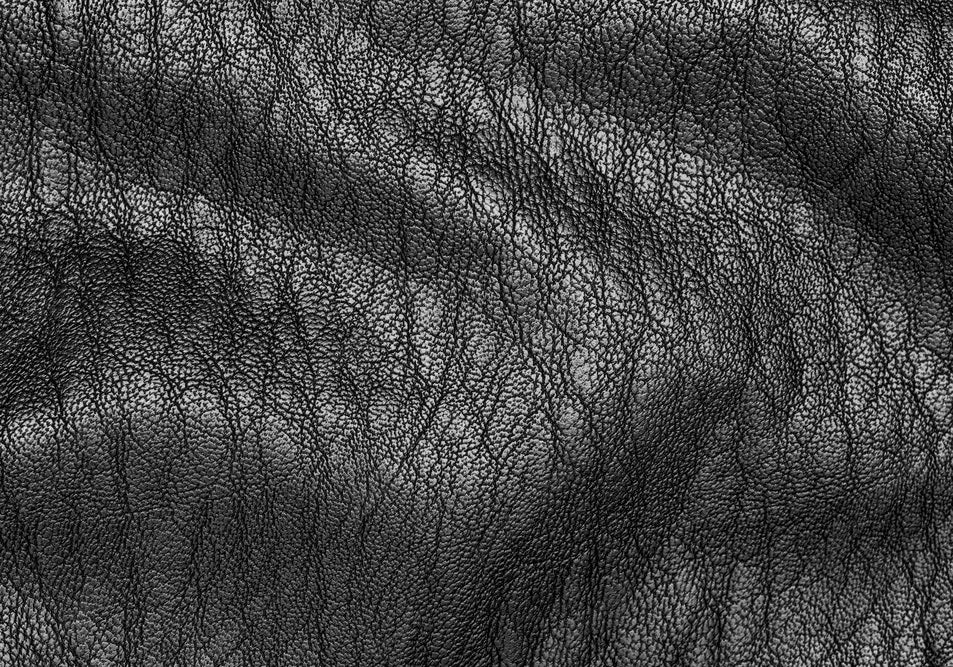

Alternatives Analysis: Comparing leather pu material With Other Solutions

Exploring Alternatives to Leather PU Material: A Comprehensive Comparison

In the competitive landscape of materials for furniture, fashion, and accessories, B2B buyers are increasingly seeking alternatives to traditional leather and synthetic options like PU leather. Understanding the strengths and weaknesses of these alternatives can empower buyers to make informed decisions that align with their business goals, budget, and environmental considerations.

| Comparison Aspect | Leather PU Material | Alternative 1: Genuine Leather | Alternative 2: Vegetable-Tanned Leather |

|---|---|---|---|

| Performance | Moderate durability; prone to cracking and peeling over time. | High durability; ages well and develops a unique patina. | Excellent durability; eco-friendly and ages beautifully without synthetic chemicals. |

| Cost | Generally low cost; affordable for mass production. | Higher initial investment; long-term cost-effectiveness due to longevity. | Moderate cost; often competitive with genuine leather but provides sustainable benefits. |

| Ease of Implementation | Easy to manufacture and widely available; quick production turnaround. | Requires skilled craftsmanship; longer lead times for high-quality products. | Involves traditional methods; can be slower but promotes artisanal production. |

| Maintenance | Low maintenance; easy to wipe clean, but can degrade quickly. | Requires occasional conditioning to maintain quality; can last decades with proper care. | Needs regular care but is less susceptible to damage over time; develops character with use. |

| Best Use Case | Ideal for budget-conscious projects or temporary solutions. | Best for luxury items and long-term investments; suitable for high-end markets. | Perfect for eco-conscious brands looking to appeal to sustainability-focused consumers. |

Detailed Breakdown of Alternatives

Genuine Leather

Genuine leather is derived from animal hides and is renowned for its superior durability and classic appeal. Its natural properties allow it to breathe, making it comfortable for various applications, including upholstery and fashion items. While the upfront cost is significantly higher than PU leather, genuine leather often represents a long-term investment due to its lifespan, which can exceed decades with proper care. However, ethical considerations regarding animal welfare and environmental impact during tanning processes may deter some buyers.

Vegetable-Tanned Leather

Vegetable-tanned leather is an eco-friendly alternative that uses natural tannins from plant materials, avoiding harmful chemicals. This method not only results in a durable product but also contributes to a lower environmental footprint. Over time, vegetable-tanned leather develops a rich patina, enhancing its aesthetic appeal. The primary drawback is its longer production time and potentially higher cost compared to synthetic options. However, for brands targeting sustainability-conscious consumers, this material aligns perfectly with their values and market demands.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating alternatives to leather PU material, B2B buyers should consider their specific requirements, including budget constraints, durability needs, and environmental impact. While PU leather offers affordability and ease of manufacturing, genuine leather and vegetable-tanned leather present unique advantages in terms of durability and sustainability. By weighing these factors carefully, businesses can select materials that not only meet their operational needs but also resonate with their brand identity and ethical commitments.

Essential Technical Properties and Trade Terminology for leather pu material

What Are the Key Technical Properties of PU Leather Material?

When sourcing PU leather for B2B applications, understanding its critical technical properties is essential for making informed purchasing decisions. Here are some key specifications to consider:

1. Material Composition

PU leather is primarily composed of a base fabric coated with a layer of polyurethane. This synthetic composition allows manufacturers to produce a material that mimics the appearance of genuine leather while being more cost-effective. For B2B buyers, knowing the exact composition can help assess the product’s quality and suitability for specific applications, such as furniture, automotive upholstery, or fashion accessories.

2. Thickness and Weight

The thickness of PU leather typically ranges from 0.5 mm to 2 mm, depending on its intended use. Thicker materials are generally more durable and suitable for high-wear applications, while thinner variants may be used for lighter products. Weight is also a consideration; lighter PU leather may reduce shipping costs but could compromise durability. Buyers should evaluate the thickness and weight to ensure the selected material meets their functional requirements.

3. Abrasion Resistance

Abrasion resistance is a critical property for any leather material, including PU leather. This property indicates how well the material can withstand wear from friction over time. A higher abrasion resistance rating is essential for products subject to heavy use, such as office furniture and automotive interiors. For B2B buyers, this specification is crucial to ensure longevity and minimize replacement costs.

4. Water Resistance

Unlike genuine leather, PU leather offers significant water resistance, making it easier to clean and maintain. This property is especially beneficial for industries where spills and stains are common, such as hospitality or healthcare. Understanding the level of water resistance can help buyers make informed decisions about product care and longevity.

5. Color Fastness

Color fastness refers to the material’s ability to retain its color when exposed to light, washing, and rubbing. High color fastness is vital for products used in bright environments or those that undergo regular cleaning. Buyers should seek PU leather with a high color fastness rating to ensure the aesthetics of their products are preserved over time.

What Are Common Trade Terms Associated with PU Leather?

Familiarity with industry terminology can enhance communication and negotiation for B2B buyers. Here are some common terms related to PU leather procurement:

Illustrative image related to leather pu material

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of PU leather, an OEM might produce leather goods for brands that market them under their name. Understanding OEM relationships can help buyers identify potential partners for customized products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it can impact inventory levels and cash flow. Knowing the MOQ can help businesses plan their purchasing strategies and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. When sourcing PU leather, submitting an RFQ can help businesses obtain competitive pricing and terms from multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms can help B2B buyers clarify shipping responsibilities, risk transfer, and cost allocation in their agreements, ensuring smooth logistics and compliance.

Illustrative image related to leather pu material

5. Lead Time

Lead time refers to the duration between placing an order and receiving the goods. For PU leather products, understanding lead time is essential for inventory management and ensuring timely product launches. Buyers should inquire about lead times when negotiating contracts to align with their production schedules.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing PU leather more effectively, ensuring they choose the right products to meet their business needs.

Navigating Market Dynamics and Sourcing Trends in the leather pu material Sector

What Are the Key Drivers Influencing the PU Leather Market?

The global PU leather market is experiencing significant growth driven by several factors. Increasing demand for cost-effective and versatile materials in industries such as automotive, fashion, and furniture is a primary driver. B2B buyers are increasingly drawn to PU leather due to its affordability compared to genuine leather, making it an attractive option for budget-conscious businesses. Moreover, the rise of e-commerce has facilitated broader access to various PU leather products, enabling businesses from regions like Africa, South America, and the Middle East to source materials more efficiently.

Emerging technologies are also reshaping sourcing trends in the PU leather sector. Innovations in manufacturing processes, such as digital printing and automated cutting, are enhancing product customization and reducing waste. Additionally, advancements in recycling technologies are paving the way for more sustainable production methods, allowing businesses to meet the growing demand for eco-friendly materials.

Illustrative image related to leather pu material

Market dynamics are further influenced by regional preferences. For instance, European buyers often prioritize quality and sustainability, while emerging markets in Africa and South America may focus on affordability and availability. Understanding these regional nuances is crucial for international buyers to navigate the complexities of sourcing PU leather materials effectively.

How Can Sustainability and Ethical Sourcing Impact Your B2B Operations?

Sustainability is becoming a focal point in the procurement of PU leather materials. The environmental impact of traditional PU leather production, including the release of volatile organic compounds (VOCs) and the use of non-biodegradable plastics, raises concerns among conscientious buyers. Therefore, ethical sourcing practices are essential for businesses aiming to enhance their brand reputation and meet regulatory standards.

B2B buyers should seek suppliers who prioritize sustainability by obtaining certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX. These certifications ensure that the materials used in production adhere to strict environmental and social criteria. Additionally, exploring alternatives like bio-based PU leather can significantly reduce the carbon footprint associated with traditional manufacturing processes.

Establishing an ethical supply chain not only aligns with consumer expectations but can also lead to long-term cost savings. By investing in sustainable sourcing practices, businesses can mitigate risks associated with supply chain disruptions and enhance their overall resilience in a competitive market.

What is the Evolution of PU Leather in the B2B Landscape?

The evolution of PU leather dates back to the mid-20th century when manufacturers sought alternatives to genuine leather that were more accessible and affordable. Initially, PU leather was primarily viewed as a budget option for consumers. However, as technological advancements improved its quality, it began to gain traction in various industries, including automotive upholstery and fashion accessories.

In recent years, the narrative around PU leather has shifted significantly, with a growing emphasis on sustainability and ethical sourcing. As environmental concerns have risen, manufacturers are innovating to create more eco-friendly versions of PU leather that minimize waste and reduce harmful emissions. This evolution reflects a broader trend within the B2B landscape, where companies are increasingly prioritizing sustainable practices as a core component of their business strategies.

Understanding this historical context is vital for international B2B buyers, as it highlights the changing perceptions of PU leather and the importance of aligning sourcing strategies with contemporary market demands and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of leather pu material

-

How do I determine the quality of PU leather before purchasing?

To assess the quality of PU leather, look for certifications and supplier transparency. Request samples to evaluate texture, durability, and odor. A high-quality PU leather should feel soft and flexible without a strong chemical smell. Additionally, inquire about the manufacturing process to ensure it meets international standards for safety and environmental impact. Checking reviews and testimonials from other businesses can also provide insights into the supplier’s reliability. -

What is the best use for PU leather in commercial applications?

PU leather is ideal for various commercial applications, including furniture, fashion accessories, and automotive interiors. Its affordability and versatility make it suitable for budget-conscious projects, especially in the fast fashion industry. However, for high-wear items, consider the potential durability issues. Assess your specific needs—if aesthetics are crucial and longevity is less of a concern, PU leather can be an excellent choice. -

What are the typical minimum order quantities (MOQs) for PU leather from suppliers?

Minimum order quantities for PU leather can vary significantly depending on the supplier and the specific material requested. Typically, MOQs range from 100 to 1,000 meters for bulk purchases. When negotiating with suppliers, clarify their MOQ policies upfront to ensure they align with your project requirements. Some suppliers may offer lower MOQs for custom colors or designs, making it worthwhile to inquire about flexibility in orders. -

How can I ensure the supplier is compliant with international trade regulations?

To verify supplier compliance with international trade regulations, request documentation such as certificates of origin, quality assurance certifications, and compliance with safety standards. Conducting background checks or using third-party verification services can also help assess their legitimacy. Establishing a solid communication channel with suppliers will facilitate transparency and ensure they adhere to any specific regulations relevant to your region. -

What payment terms are common for international purchases of PU leather?

Common payment terms in international transactions for PU leather include options like Letter of Credit (LC), advance payment, or a 30-50% deposit with the remainder due upon shipment. It’s essential to negotiate terms that protect both parties. Ensure clarity on the payment timeline and method to avoid any disputes. Using secure payment platforms can also provide an additional layer of protection. -

What quality assurance measures should I implement when sourcing PU leather?

Implementing robust quality assurance measures involves establishing clear specifications for the PU leather and conducting inspections at various stages of production. Arrange for third-party quality checks before shipment to ensure the material meets your standards. Additionally, maintaining regular communication with suppliers can help address any issues proactively. Documenting these processes will also help in case of disputes or quality concerns. -

How does logistics affect the cost of PU leather procurement?

Logistics can significantly impact the overall cost of procuring PU leather. Factors such as shipping method, distance, and import duties play a crucial role in determining final costs. It’s important to assess different shipping options and negotiate freight terms with your supplier. Additionally, consider local customs regulations that may affect delivery timelines and expenses to avoid unexpected costs. -

What are the environmental implications of using PU leather?

While PU leather is often marketed as a more sustainable alternative to genuine leather, its production can involve environmentally harmful processes. The manufacturing of PU leather can release volatile organic compounds (VOCs) and other pollutants. When sourcing PU leather, inquire about the supplier’s environmental practices, including waste management and the use of eco-friendly materials. Opting for suppliers who prioritize sustainability can help mitigate these environmental impacts.

Top 8 Leather Pu Material Manufacturers & Suppliers List

1. Manuel Dreesmann – PU Leather

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: This company, Manuel Dreesmann – PU Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Carl Friedrik – PU Leather Collection

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as artificial or imitation leather, is made from polyurethane, a synthetic plastic. It is created by applying a PU resin coating to natural fabrics like nylon, cotton, or vinyl, mimicking the look and feel of animal leather. 100% PU leather is vegan-friendly, while PU applied to split leather (animal hide) is not. Benefits include being softer, lighter, more UV resistant, ea…

3. Steel Horse Leather – PU Leather Products

Domain: steelhorseleather.com

Registered: 2019 (6 years)

Introduction: PU Leather (Polyurethane Leather) is a synthetic alternative to genuine leather, known for being more affordable and easier to maintain. It is often used in various products such as bags, wallets, and accessories. Genuine leather is preferred for its durability and aesthetic appeal, while PU leather offers a more budget-friendly option with a similar look.

4. Panaz – Faux Leather Upholstery Solutions

Domain: panaz.us

Registered: 2023 (2 years)

Introduction: {“Product Type”:”Faux Leather”,”End Use”:”Upholstery”,”Sectors”:[“Healthcare”,”Hospitality”,”Workspace”],”Material”:[“Cotton”,”Fire Retardant”,”Polyurethane Leather (PU)”,”Polyvinyl Chloride (PVC)”],”Width (cm)”:140,”Weight (g/m2)”:720,”Color Fastness”:”Grade 6+”,”Flammability Ratings”:[“BS 5852 IGN Source 5″,”BS 7176 Medium Hazard”,”BS EN 1021 1/2″,”CAL TB 117″,”IMO FTP CODE 2010 Part 8″,”NFPA 26…

5. Billy Tannery – PU Leather Solutions

Domain: billytannery.co.uk

Registered: 2016 (9 years)

Introduction: PU leather, also known as polyurethane leather, is a synthetic leather made from a thermoplastic polymer. It mimics the look and feel of real leather while being vegan and budget-friendly. PU leather consists of two layers: a base layer typically made from polyester for strength and stability, and a polyurethane coating that provides a smooth, shiny surface. It is used for various products like fu…

6. Yorkshire Fabric Shop – PU Leather & Faux Leather

Domain: yorkshirefabricshop.com

Registered: 2014 (11 years)

Introduction: PU leather and faux leather are both alternatives to genuine leather. PU leather is synthetic leather made from polyurethane, a plastic that mimics the feel and appearance of real leather without using animal products. Faux leather, derived from the French term for ‘fake leather’, is made from upholstery fabric such as polyester and can have a textured character, be water-resistant, and is easy to…

7. Boulies – PU Leather Solutions

Domain: boulies.com

Registered: 2017 (8 years)

Introduction: PU leather (polyurethane leather) is a synthetic material that resembles real leather but is made without animal products. It consists of a fabric base, such as polyester or cotton, coated with a thin layer of polyurethane. Key features include a layered structure, eco-friendliness (70% less carbon emissions than real leather), and ethical appeal (cruelty-free). Advantages of PU leather include be…

8. Senreve – PU Leather Handbags

Domain: senreve.com

Registered: 2016 (9 years)

Introduction: PU leather, or polyurethane leather, is an artificial leather made of thermoplastic polymer. It is 100% vegan and does not absorb water, making it more durable and easier to clean than real leather. PU leather can take on a variety of colors and decorations but has a plastic shine that may appear fake. It does not develop a patina, stretch, or breathe like real leather and is less puncture-resista…

Strategic Sourcing Conclusion and Outlook for leather pu material

As businesses navigate the complexities of sourcing materials, understanding the intricacies of PU leather is paramount. With its cost-effectiveness and versatility, PU leather presents an attractive option for various applications, particularly in regions such as Africa, South America, the Middle East, and Europe. However, strategic sourcing requires a nuanced approach, considering both the material’s benefits and limitations, including durability and environmental impact.

International B2B buyers should prioritize transparency in their supply chain, ensuring that the PU leather products they procure align with their sustainability goals and quality standards. Engaging with reputable suppliers who adhere to ethical manufacturing practices can mitigate risks associated with toxic chemicals and long-term viability.

Looking ahead, as consumer preferences shift towards sustainable and durable alternatives, businesses that invest in high-quality materials will likely gain a competitive edge. By embracing innovative sourcing strategies and staying informed about market trends, companies can position themselves for success in an evolving marketplace. For buyers in Nigeria, Vietnam, and beyond, the time is ripe to evaluate your sourcing decisions and explore the potential of PU leather as a strategic asset.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather pu material

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.