Introduction: Navigating the Global Market for different types of leather

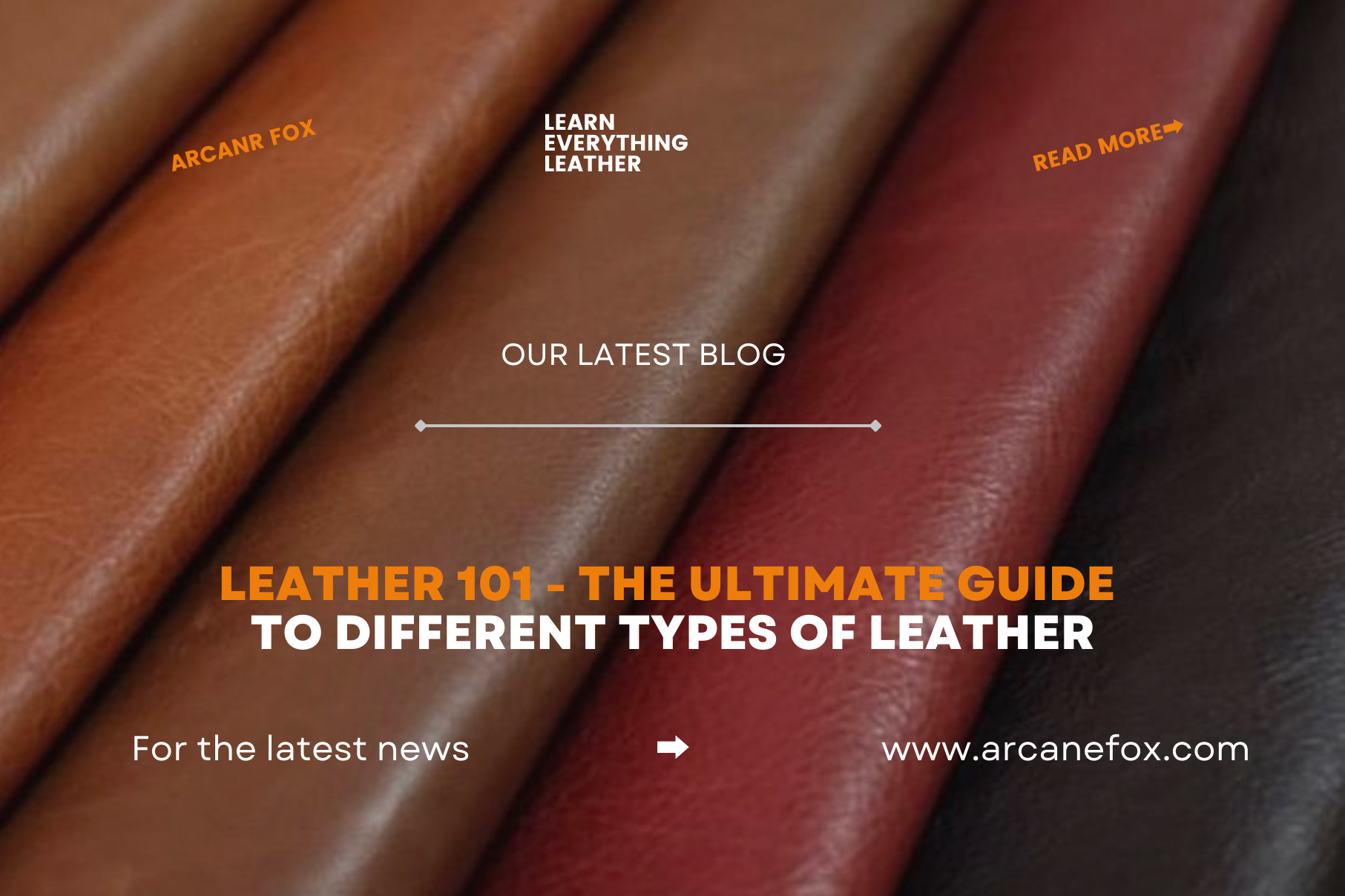

In the dynamic landscape of global trade, sourcing high-quality leather products presents a significant challenge for B2B buyers. With an array of leather types available—from full grain to patent leather—making informed choices that align with specific business needs is crucial. This comprehensive guide delves into the diverse types of leather, exploring their unique characteristics, applications, and the nuances of supplier vetting. By providing insights into cost considerations and market trends, we aim to equip international buyers, especially those from Africa, South America, the Middle East, and Europe, with the knowledge necessary to navigate the complexities of leather sourcing.

Understanding the distinctions between leather types is essential for optimizing product offerings and ensuring customer satisfaction. For instance, full grain leather is renowned for its durability and unique aesthetic, while nubuck offers a luxurious feel but requires more maintenance. This guide not only clarifies these differences but also emphasizes the importance of supplier reliability and ethical sourcing practices. By leveraging this information, businesses can make strategic purchasing decisions that enhance their product lines and build strong relationships with suppliers. As the global leather market continues to evolve, staying informed will empower buyers to seize opportunities and mitigate risks, ultimately leading to more successful business outcomes.

Table Of Contents

- Top 4 Different Types Of Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for different types of leather

- Understanding different types of leather Types and Variations

- Key Industrial Applications of different types of leather

- 3 Common User Pain Points for ‘different types of leather’ & Their Solutions

- Strategic Material Selection Guide for different types of leather

- In-depth Look: Manufacturing Processes and Quality Assurance for different types of leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘different types of leather’

- Comprehensive Cost and Pricing Analysis for different types of leather Sourcing

- Alternatives Analysis: Comparing different types of leather With Other Solutions

- Essential Technical Properties and Trade Terminology for different types of leather

- Navigating Market Dynamics and Sourcing Trends in the different types of leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of different types of leather

- Strategic Sourcing Conclusion and Outlook for different types of leather

- Important Disclaimer & Terms of Use

Understanding different types of leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Highest quality, retains natural grain, develops patina | Luxury goods, high-end fashion, furniture | Pros: Exceptional durability, unique character. Cons: Expensive, requires skilled craftsmanship. |

| Top Grain Leather | Corrected grain, smoother finish, more affordable | Handbags, wallets, upholstery | Pros: Uniform appearance, easier to work with. Cons: Less unique than full grain, reduced breathability. |

| Nubuck Leather | Soft, velvety texture, requires regular maintenance | Footwear, handbags, luxury upholstery | Pros: Elegant appearance, durable. Cons: Susceptible to staining and water damage, needs care. |

| Patent Leather | Glossy finish, water-resistant, highly durable | Formal wear, accessories | Pros: Attractive sheen, easy to clean. Cons: Can scratch easily, requires careful storage. |

| Genuine Leather | Variable quality, lower layer of hide, often artificially finished | Budget goods, casual accessories | Pros: Affordable, decent durability. Cons: Lacks the quality and longevity of higher-grade leathers. |

What Are the Key Characteristics of Full Grain Leather?

Full grain leather is renowned for its exceptional quality and durability, as it is derived from the top layer of the hide, maintaining the natural grain. This type of leather develops a unique patina over time, enhancing its character. B2B buyers in the luxury goods sector often seek full grain leather for high-end handbags, furniture, and accessories, where longevity and aesthetics are paramount. However, the high cost and the need for skilled artisans to work with this material can be a barrier for some businesses.

How Does Top Grain Leather Compare to Full Grain Leather?

Top grain leather is the second-highest quality and is characterized by its smooth, uniform appearance due to the removal of natural imperfections. It is more affordable and easier to work with than full grain leather, making it a popular choice for high-end leather goods such as handbags and wallets. B2B buyers should consider top grain leather for products where a polished look is desired, although it may lack the unique character and breathability found in full grain options.

What Makes Nubuck Leather a Unique Option?

Nubuck leather offers a luxurious, soft texture that is achieved by sanding the grain side of the top layer of hide. It is commonly used in high-quality footwear and handbags, appealing to businesses focused on elegance and comfort. However, its susceptibility to stains and water damage necessitates regular maintenance, which may be a consideration for B2B buyers looking for longevity in their products. Proper care can extend the life of nubuck leather items, ensuring they remain attractive and functional.

Why Choose Patent Leather for Fashion Products?

Patent leather is known for its glossy finish and water-resistant properties, making it ideal for formal wear and accessories. Its distinctive shine can elevate the appearance of products, appealing to fashion-forward consumers. B2B buyers should note that while patent leather is durable and easy to clean, it is also prone to scratches and requires careful storage to maintain its aesthetic. This balance of durability and style makes it a popular choice for businesses in the fashion industry.

What Should Buyers Know About Genuine Leather?

Genuine leather is a catch-all term that indicates the product contains real leather, but its quality can vary significantly. Often derived from the lower layers of hide, genuine leather is more affordable but lacks the durability and aesthetic qualities of higher-grade leathers. B2B buyers looking for budget-friendly options may consider genuine leather for casual accessories, but they should be aware that it may not provide the same longevity or appeal as full grain or top grain leather.

Key Industrial Applications of different types of leather

| Industry/Sector | Specific Application of different types of leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Handbags and wallets made from full grain and top grain leather | High durability and unique aesthetics, enhancing brand prestige | Quality certification, artisan craftsmanship, and material sourcing transparency |

| Automotive | Upholstery and interiors using split grain and genuine leather | Cost-effective durability for high-traffic areas while maintaining a premium feel | Supplier reliability, compliance with environmental regulations, and customization options |

| Footwear | Shoes crafted from nubuck and patent leather | Enhanced comfort and style, catering to luxury markets | Material sourcing integrity, waterproofing treatments, and design versatility |

| Furniture & Upholstery | Sofas and chairs upholstered with genuine and nubuck leather | Aesthetic appeal combined with durability, appealing to high-end consumers | Supply chain transparency, availability of various textures and colors, and maintenance requirements |

| Sports Equipment | Protective gear and accessories made from split grain leather | Cost-effectiveness and durability for high-performance applications | Product testing certifications, safety compliance, and material sourcing ethics |

How is Full Grain and Top Grain Leather Used in Fashion and Accessories?

Full grain and top grain leather are highly sought after in the fashion industry for products like handbags and wallets. Their durability ensures longevity, appealing to consumers looking for quality, while the unique characteristics of full grain leather provide an exclusive aesthetic that enhances brand prestige. Buyers should prioritize sourcing from reputable suppliers who can guarantee quality certifications and transparency in their material sourcing processes, especially when targeting international markets.

What Role Does Split Grain and Genuine Leather Play in the Automotive Sector?

In the automotive industry, split grain and genuine leather are commonly used for upholstery and interiors. These leathers offer a balance between cost-effectiveness and durability, making them suitable for high-traffic areas within vehicles. For B2B buyers, ensuring supplier reliability and compliance with environmental regulations is crucial, as is the ability to customize materials to meet specific design requirements.

How Do Nubuck and Patent Leather Enhance Footwear Products?

Nubuck and patent leather are popular choices in the footwear sector, especially for high-end shoes. Nubuck provides a soft, luxurious feel, while patent leather offers a glossy, stylish appearance. These materials cater to luxury markets, enhancing comfort and aesthetics. Buyers should consider the integrity of material sourcing, including waterproofing treatments and design versatility, to meet consumer expectations for both style and functionality.

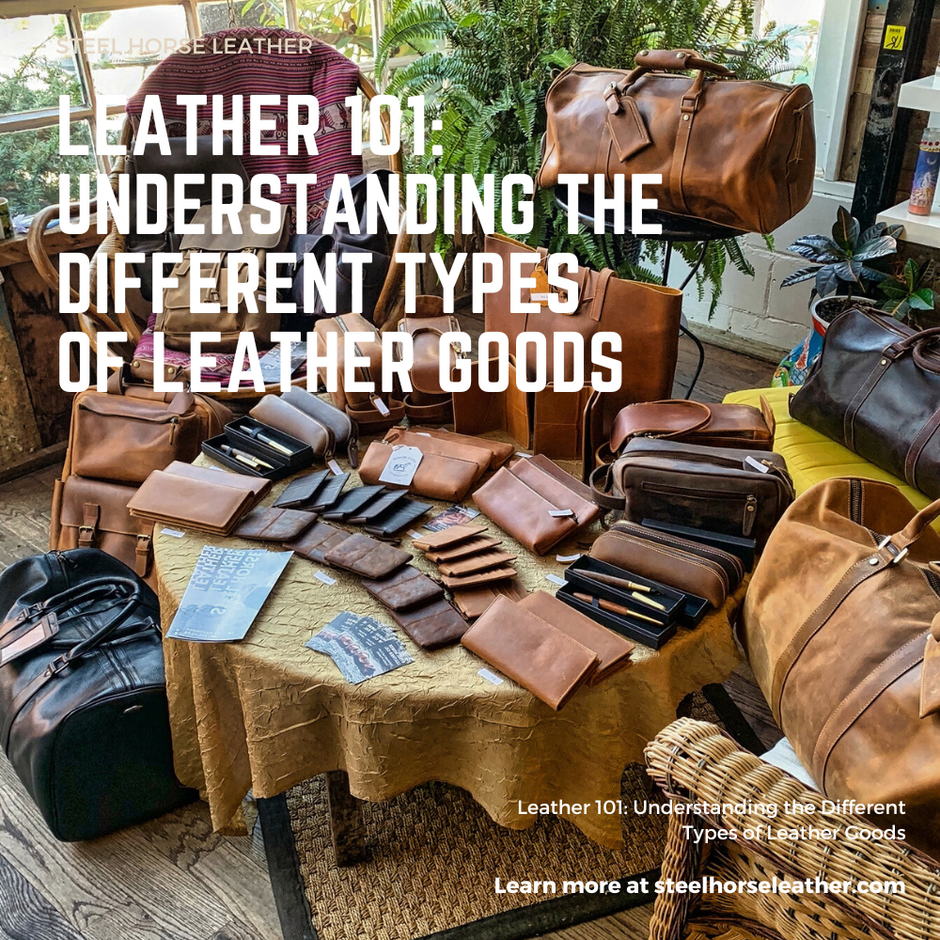

Illustrative image related to different types of leather

What Are the Benefits of Using Genuine and Nubuck Leather in Furniture?

Genuine and nubuck leather are frequently employed in the furniture industry for items such as sofas and chairs. These materials deliver a blend of aesthetic appeal and durability, making them attractive to high-end consumers seeking luxury home furnishings. Buyers should focus on supply chain transparency, ensuring that the leather’s texture and color options align with market trends, while also considering maintenance requirements to sustain product quality.

How is Split Grain Leather Utilized in Sports Equipment?

In the sports sector, split grain leather is often used for protective gear and accessories. Its cost-effectiveness combined with durability makes it ideal for high-performance applications, where wear and tear are prevalent. B2B buyers should ensure that products meet safety compliance standards and are backed by product testing certifications, while also emphasizing ethical material sourcing to appeal to increasingly conscious consumers.

3 Common User Pain Points for ‘different types of leather’ & Their Solutions

Scenario 1: Difficulty in Quality Assessment of Leather Products

The Problem: B2B buyers often struggle to determine the quality of leather when sourcing products, especially when dealing with varying definitions of terms like “genuine leather” versus “full grain” or “top grain.” This can lead to significant issues, such as receiving inferior products that do not meet quality standards or expectations, ultimately impacting brand reputation and customer satisfaction. Buyers may find themselves overwhelmed by the nuances of leather types and unsure of how to assess the quality effectively.

The Solution: To overcome this challenge, buyers should prioritize establishing strong relationships with reputable suppliers who can provide detailed documentation of leather grades and sourcing practices. Implementing a rigorous quality assurance protocol is essential. This can include requiring samples of the leather before placing larger orders, conducting physical inspections, and even utilizing third-party testing services for leather durability and quality. Additionally, buyers should educate themselves on the characteristics of different leather types, focusing on aspects such as grain structure, thickness, and treatment methods. Leveraging resources such as industry guides or attending trade shows can also enhance knowledge and confidence in assessing leather quality.

Scenario 2: Managing Leather Maintenance and Care

The Problem: Once leather products are sourced, maintaining their quality can be a significant challenge. B2B buyers often encounter issues related to the care and longevity of leather, particularly with types that require more intensive maintenance, such as nubuck and suede. Buyers may face high return rates or customer dissatisfaction due to premature wear or damage, which can be exacerbated in markets with varying climate conditions that affect leather performance.

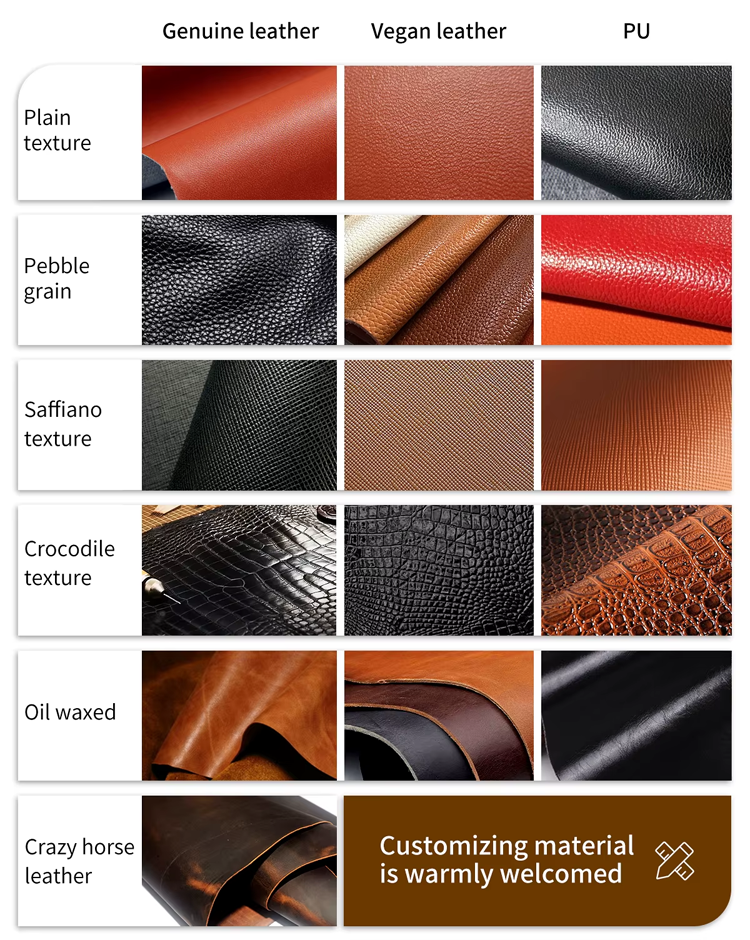

Illustrative image related to different types of leather

The Solution: To address these maintenance concerns, it is crucial for buyers to integrate proper care instructions into their product offerings. This can include providing detailed care guides that outline the best practices for cleaning and protecting different leather types. For example, recommending specific waterproofing sprays for nubuck and suede can help prevent staining and water damage. Additionally, buyers should consider packaging these products with maintenance kits that include brushes, cleaning solutions, and protective sprays. Training sales staff to educate customers on proper leather care can also enhance customer experience and loyalty, reducing return rates and ensuring product longevity.

Scenario 3: Sourcing Sustainable Leather Options

The Problem: Increasingly, B2B buyers are facing pressure to source sustainable and ethically produced leather. This trend is particularly pronounced among environmentally conscious consumers and businesses aiming to enhance their corporate social responsibility profiles. However, navigating the landscape of sustainable leather can be complex, as it involves understanding sourcing practices, tanning methods, and potential certifications.

The Solution: To effectively source sustainable leather, buyers should start by identifying suppliers who specialize in eco-friendly practices. This includes seeking out manufacturers that use vegetable tanning processes, which are less harmful to the environment compared to chemical tanning methods. Buyers should also look for certifications such as the Leather Working Group (LWG) certification, which indicates adherence to environmental standards. Building partnerships with suppliers who are transparent about their sourcing and production methods will facilitate better decision-making. Additionally, buyers can collaborate with industry groups or participate in forums focused on sustainable practices to stay informed about new developments and innovations in sustainable leather sourcing. This proactive approach will not only help meet consumer demand but also position the buyer as a leader in ethical business practices.

Strategic Material Selection Guide for different types of leather

What Are the Key Properties of Full Grain Leather for B2B Applications?

Full grain leather is recognized as the highest quality leather available, primarily due to its unique properties. It retains the natural grain of the hide, offering exceptional strength, breathability, and durability. This type of leather is resistant to wear and tear, developing a natural patina over time, which adds character. However, its manufacturing complexity is high, as only a small percentage of cowhide can be classified as full grain. For international buyers, particularly in regions like Europe and the Middle East, compliance with quality standards such as ASTM can be crucial, as full grain leather is often sought for luxury goods and high-end products.

What Are the Advantages and Disadvantages of Top Grain Leather in B2B Transactions?

Top grain leather is the second-best quality and is often used in high-end leather goods. It undergoes a process that removes imperfections, resulting in a smoother and more uniform appearance. While this makes it easier to work with and generally more affordable than full grain leather, it may lack some of the unique characteristics that buyers value in full grain leather. Top grain leather is less breathable due to finish coats applied during manufacturing, which can affect long-term durability. For B2B buyers in Africa and South America, understanding the balance between cost and quality is essential, as top grain leather is often used in products that require a blend of luxury and practicality.

How Does Nubuck Leather Perform in Various Applications for International Buyers?

Nubuck leather, made from the top grain of animal hides, features a soft, velvety surface that is both luxurious and durable. However, it requires regular maintenance to prevent staining and water damage, which can be a concern for buyers in humid climates. Its applications range from footwear to upholstery, making it versatile. The challenges associated with its care may deter some buyers, particularly in regions where maintenance resources are limited. International buyers should consider the local market’s capacity for regular upkeep and the potential for product longevity when selecting nubuck leather.

Illustrative image related to different types of leather

What Are the Specific Considerations for Genuine Leather in B2B Purchasing?

Genuine leather is a term that often leads to confusion, as it can represent varying qualities of leather. Typically, it is derived from the lower layers of hides after the top layers have been removed. While it is more affordable, it lacks the durability and aesthetic appeal of higher-quality leathers like full grain and top grain. Buyers in Europe and the Middle East may need to exercise caution when sourcing genuine leather products, as the term does not guarantee quality. Understanding the manufacturing processes and the potential for artificial finishes is crucial for making informed purchasing decisions.

| Material | Typical Use Case for different types of leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | Luxury handbags, high-end furniture | Exceptional durability and unique character | High cost and manufacturing complexity | High |

| Top Grain Leather | High-end bags, wallets, and apparel | Smooth appearance and easier to work with | Less breathable, may lack uniqueness | Med |

| Nubuck Leather | Footwear, upholstery, luxury accessories | Soft texture and luxurious feel | Requires regular maintenance, prone to staining | Med |

| Genuine Leather | Affordable bags, belts, and accessories | Cost-effective option for various products | Variable quality, often less durable | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for different types of leather

What Are the Key Manufacturing Processes for Different Types of Leather?

The manufacturing process for leather is intricate and varies based on the type of leather being produced. Understanding these processes is crucial for B2B buyers who seek high-quality leather goods. The main stages of leather manufacturing include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Leather Production?

Material preparation is the first step in leather manufacturing. This process begins with sourcing raw hides, typically from cattle, goats, or sheep, depending on the desired leather type. The hides undergo several treatments, including:

- Soaking: Hides are soaked in water to remove salt and dirt.

- Liming: This step involves treating the hides with lime to loosen hair and flesh, making it easier to remove.

- Fleshing: The residual flesh is mechanically removed, preparing the hide for tanning.

- Tanning: The hides are treated with tannins (vegetable or chrome-based) to convert them into leather. This is a crucial step that affects the leather’s properties, including durability and flexibility.

What Techniques Are Used in Forming Leather?

Once the hides are tanned, they move on to the forming stage, where they are shaped into the desired product. Various techniques are employed, including:

- Cutting: Hides are cut into patterns using precision tools or dies to ensure consistency.

- Molding: For certain products like shoes or bags, the leather is molded into specific shapes using heat and pressure.

- Sewing: Pieces are sewn together using specialized machines. The stitching must be robust to ensure the finished product’s durability.

How Is Leather Finished for Aesthetic and Functional Qualities?

The finishing stage involves applying treatments that enhance the leather’s appearance and functionality. This includes:

- Dyeing: Leather can be dyed in various colors to meet market demands.

- Coating: Protective coatings may be applied to enhance water resistance and durability, especially for top grain and patent leather.

- Buffing and Polishing: The final touch involves buffing and polishing to achieve the desired sheen and texture.

What Quality Assurance Practices Are Important in Leather Manufacturing?

Quality assurance (QA) is vital in leather manufacturing to ensure that products meet international standards and customer expectations. The following practices are commonly implemented:

Which International Standards Should B2B Buyers Consider?

International standards, such as ISO 9001, govern the quality management systems in the leather industry. Compliance with these standards indicates a commitment to quality and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are relevant for specialized leather products.

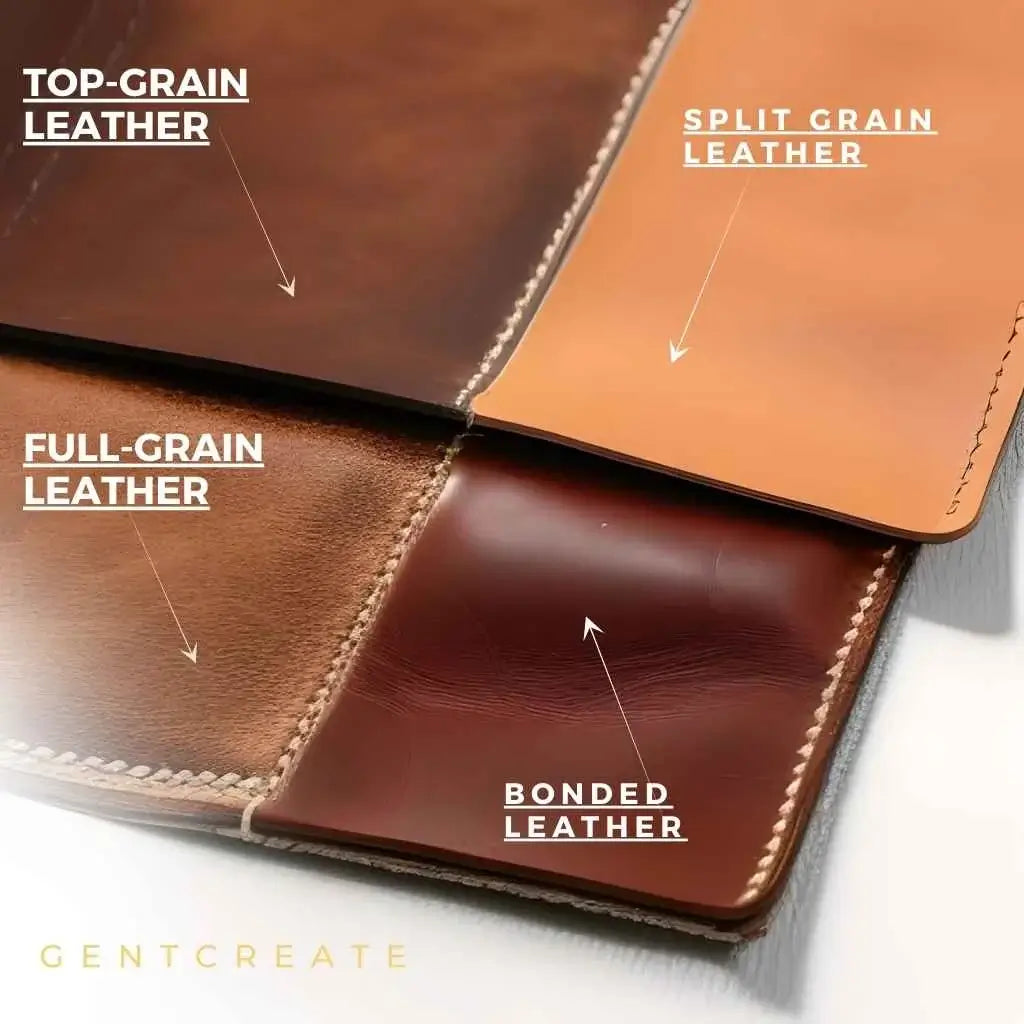

Illustrative image related to different types of leather

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) checkpoints play a crucial role throughout the leather manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early. This can include checking for consistency in dye color, stitching quality, and adherence to design specifications.

- Final Quality Control (FQC): Finished products undergo a thorough inspection to ensure they meet all quality criteria before shipping.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are actionable steps:

-

Conduct Audits: Regular audits of suppliers can help ensure compliance with quality standards. Consider hiring third-party auditing firms to provide an unbiased assessment.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, including any certifications obtained.

-

Third-Party Inspections: Engage third-party inspection services to verify the quality of leather products before shipment. This can minimize risks associated with receiving substandard goods.

-

Establish Long-Term Relationships: Building relationships with trusted suppliers can foster transparency and reliability. Regular communication can help address any quality concerns proactively.

What Are the Nuances of Quality Control for Different Regions?

Quality control practices can vary significantly across regions due to differences in regulations, market expectations, and manufacturing capabilities. B2B buyers should be aware of the following nuances:

Illustrative image related to different types of leather

-

Africa: Buyers may encounter challenges related to infrastructure and regulatory compliance. Ensuring that suppliers adhere to international standards is critical.

-

South America: The leather industry in South America is growing, but buyers should look for suppliers who are certified and have robust QC processes in place to ensure product quality.

-

Middle East: The demand for high-quality leather goods is increasing, and suppliers often aim to meet international standards. However, buyers should verify claims of quality assurance.

-

Europe (e.g., Germany): European buyers often have stringent quality expectations. Suppliers should be prepared to meet these standards and demonstrate compliance with relevant certifications.

Conclusion

Understanding the manufacturing processes and quality assurance practices in leather production is essential for B2B buyers. By focusing on the key stages of manufacturing, being aware of international standards, and implementing thorough verification processes, buyers can ensure they source high-quality leather products that meet their specific needs. Engaging with suppliers who prioritize quality control can lead to more successful partnerships and ultimately, satisfied end customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘different types of leather’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure various types of leather. With an understanding of the unique characteristics and applications of each leather type, buyers can make informed decisions that align with their quality, durability, and aesthetic requirements. This checklist outlines essential steps to ensure a successful procurement process.

Step 1: Identify Your Leather Type Needs

Determining the type of leather required for your products is crucial. Consider the specific applications, such as footwear, accessories, or upholstery, and the qualities needed, like durability or softness. Each leather type, from full grain to suede, offers different attributes that can significantly impact the final product.

Illustrative image related to different types of leather

Step 2: Define Your Technical Specifications

Clearly outline the specifications that your leather must meet. This includes factors such as thickness, finish, and color. Providing detailed requirements helps suppliers understand your needs and ensures that the leather you receive matches your expectations in terms of quality and usability.

Step 3: Evaluate Potential Suppliers

Conduct thorough research to vet potential suppliers. Review their company profiles, certifications, and production capabilities. Request references or case studies from buyers in your industry to gauge their reliability and quality of products. This step is vital to ensure that you partner with reputable suppliers who can deliver the desired leather quality.

Step 4: Request Samples for Assessment

Before placing large orders, always request samples of the leather types you are considering. Examine the samples for texture, color consistency, and overall quality. This hands-on assessment allows you to evaluate the leather’s suitability for your intended applications and helps avoid costly mistakes.

Step 5: Verify Supplier Certifications

Ensure that your suppliers comply with relevant industry standards and certifications. Look for certifications such as ISO, REACH, or specific environmental and sustainability certifications. These credentials not only demonstrate quality but also reflect the supplier’s commitment to ethical practices, which is increasingly important in global markets.

Step 6: Discuss Pricing and Payment Terms

Engage in transparent discussions regarding pricing structures and payment terms. Understand the cost implications of different leather types and the value they bring to your products. Establish clear payment terms to avoid misunderstandings and ensure a smooth transaction process.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the leather upon arrival. Define criteria for acceptance or rejection based on your specifications and communicate these to your suppliers. Having a robust quality assurance plan in place helps maintain product consistency and enhances customer satisfaction.

By following these steps, B2B buyers can navigate the complexities of leather sourcing effectively, ensuring they procure the right type of leather that meets their business needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for different types of leather Sourcing

What Are the Key Cost Components in Leather Sourcing?

When sourcing leather, a thorough understanding of the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of leather significantly impacts the cost. Full grain leather, being the highest quality, is the most expensive, often costing several times more than split grain or genuine leather. For example, full grain leather can range from $5 to $20 per square foot, while split grain might only be $1 to $3 per square foot.

-

Labor: Skilled labor is essential for high-quality leather products, especially for full grain and top grain leather, which require artisanal skills for cutting and stitching. Labor costs can vary significantly based on the region and the complexity of the leather goods being produced.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, rent, and equipment maintenance. High-quality leather production often requires advanced machinery, which can increase overhead costs.

-

Tooling: Custom tooling for leather goods can be a substantial upfront cost. The complexity of the design and the materials used for molds and cutting dies will influence this cost.

-

Quality Control (QC): Implementing rigorous QC processes is vital, particularly for high-end leather products. This adds to overall costs but ensures that the products meet the required standards.

-

Logistics: Shipping and handling costs can vary based on the origin of the leather, destination, and transportation mode. International shipping may involve customs duties, taxes, and tariffs that can significantly affect pricing.

-

Margin: Suppliers typically add a profit margin that can range from 10% to 30%, depending on the type of leather and market demand.

What Factors Influence Leather Pricing for B2B Buyers?

Several factors influence the pricing of leather that B2B buyers should consider:

-

Volume/MOQ: Purchasing in bulk often leads to discounts. Suppliers may offer better pricing for larger orders due to reduced handling costs and improved economies of scale.

-

Specifications and Customization: Customized leather products, such as specific colors, finishes, or dimensions, can lead to increased costs. Ensure that all specifications are clearly communicated to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality leathers with certifications (e.g., eco-friendly tanning processes) typically come at a premium. Buyers should assess whether the added cost aligns with their brand’s values and customer expectations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more but can offer better quality assurance and service.

-

Incoterms: Understanding shipping terms is essential for calculating total landed costs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the final price significantly.

How Can Buyers Optimize Costs in Leather Sourcing?

To enhance cost efficiency in leather sourcing, consider the following strategies:

-

Negotiate: Leverage your purchasing power by negotiating prices, especially for large orders. Establish long-term relationships with suppliers to foster better terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider durability, maintenance, and potential resale value of the leather products to make informed decisions.

-

Understand Pricing Nuances for International Transactions: Different regions may have varying price points based on local market conditions and labor costs. For instance, leather sourced from Brazil may differ significantly in pricing and quality compared to that from Europe.

-

Stay Informed About Market Trends: Keep abreast of global leather market trends, including supply chain disruptions or shifts in demand, which can impact pricing.

Disclaimer on Pricing

Prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific product requirements. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Illustrative image related to different types of leather

Alternatives Analysis: Comparing different types of leather With Other Solutions

Exploring Alternatives to Different Types of Leather

In the evolving landscape of materials used for various applications, B2B buyers often find themselves weighing the benefits of traditional leather against innovative alternatives. Leather has long been valued for its durability, aesthetic appeal, and versatility. However, emerging materials and technologies present viable alternatives that may better suit specific business needs or sustainability goals. This section provides a comparative analysis of different types of leather against two alternative materials: synthetic leather and natural fibers.

Comparison Table

| Comparison Aspect | Different Types Of Leather | Synthetic Leather | Natural Fibers |

|---|---|---|---|

| Performance | High durability, unique aging characteristics | Moderate durability, consistent appearance | Variable durability, often less resilient |

| Cost | Higher (especially full grain and top grain) | Generally lower, but varies by quality | Often lower, depending on sourcing |

| Ease of Implementation | Requires skilled craftsmanship | Easier to produce and manipulate | Requires specialized processes for finishing |

| Maintenance | Requires regular care; varies by type | Low maintenance, easy to clean | May require special care, depending on type |

| Best Use Case | High-end fashion, luxury goods | Budget-conscious markets, fashion accessories | Eco-friendly products, casual wear |

Detailed Breakdown of Alternatives

Synthetic Leather

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is designed to mimic the look and feel of genuine leather. One of its primary advantages is its affordability; it is generally less expensive than high-quality leather, making it an attractive option for budget-conscious businesses. Synthetic leather is also easier to produce and manipulate, allowing for greater flexibility in design. However, it lacks the unique aging characteristics of natural leather and may not offer the same level of durability over time. While it is low-maintenance, it may not appeal to consumers seeking authentic, high-end products.

Natural Fibers

Natural fibers, such as cotton, hemp, or jute, present an eco-friendly alternative to leather. These materials are often more sustainable and biodegradable, aligning with the growing demand for environmentally responsible products. Natural fibers can also be less expensive than leather, making them an appealing choice for businesses focused on cost efficiency. However, their durability can be variable, and they may not withstand wear and tear as effectively as leather. Additionally, natural fibers often require specialized finishing processes to enhance their appeal and usability, which can complicate production.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between different types of leather and alternative materials, B2B buyers should consider several factors, including the intended use, target market, and brand values. High-end brands may prioritize the unique characteristics and durability of leather, while businesses targeting budget-conscious consumers might find synthetic leather or natural fibers to be more appealing. Ultimately, understanding the specific requirements of your product line and the preferences of your customer base will guide you in making the most informed decision. Balancing quality, cost, and sustainability will be key in selecting the right material for your needs.

Essential Technical Properties and Trade Terminology for different types of leather

What Are the Key Technical Properties of Different Types of Leather?

Understanding the technical properties of leather is crucial for B2B buyers, particularly when sourcing materials for high-quality products. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the quality classification of leather, which is typically categorized as full grain, top grain, genuine, or split grain. Full grain leather, being the highest quality, offers superior durability, breathability, and natural aesthetics. For B2B buyers, selecting the appropriate material grade impacts the product’s longevity and marketability, as higher grades often command premium pricing.

2. Tolerance Levels

Tolerance levels in leather refer to the acceptable variations in thickness, texture, and appearance. These tolerances are critical for manufacturers who require consistency across batches. For example, a variance in thickness may affect the leather’s performance in applications such as upholstery or fashion accessories. Understanding these tolerances helps buyers ensure they receive products that meet their specific manufacturing needs.

3. Grain Type

The grain type indicates the surface texture and finish of the leather. Full grain retains the hide’s natural imperfections, while top grain is treated for a smoother finish. This property is essential for B2B buyers who need to match the leather’s aesthetic with their branding and product requirements. Choosing the right grain type can enhance the visual appeal of the final product.

4. Durability and Wear Resistance

Durability assesses the leather’s ability to withstand wear and tear over time. Certain types, like full grain and split grain, are recognized for their strength, making them suitable for high-use items like bags and shoes. Buyers need to evaluate durability to ensure that the leather will meet customer expectations and reduce returns or complaints.

5. Breathability

Breathability refers to the leather’s ability to allow air circulation, which affects comfort in products such as footwear and clothing. Full grain leather offers excellent breathability compared to lower grades, which can be crucial in maintaining product integrity and user satisfaction. Understanding breathability helps buyers select leather that enhances the end-user experience.

What Are Common Trade Terms in the Leather Industry?

Familiarity with trade terminology is vital for effective communication and negotiation in the leather industry. Here are some key terms every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are purchased by another company and sold under that company’s brand name. In the leather industry, understanding OEM relationships can help buyers identify potential suppliers and negotiate better terms for custom leather goods.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of goods a supplier is willing to sell. This term is significant for B2B buyers, as it affects inventory management and financial planning. Knowing the MOQ can assist buyers in determining the feasibility of a purchase and the associated costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. For leather buyers, submitting an RFQ can lead to competitive pricing and detailed offers from multiple suppliers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for B2B buyers in the leather industry to understand shipping costs, insurance, and delivery obligations, thus ensuring smooth transactions across borders.

5. Tannage

Tannage is the process of treating animal hides to produce leather. Different tanning methods, such as vegetable or chrome tanning, affect the leather’s final properties, including durability and appearance. Buyers should be aware of the tanning process to align their product requirements with the desired characteristics of the leather.

By understanding these technical properties and trade terms, B2B buyers can make more informed purchasing decisions, ultimately leading to better product quality and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the different types of leather Sector

What Are the Current Market Dynamics and Key Trends in the Leather Sector?

The global leather market is undergoing significant transformation driven by evolving consumer preferences, technological advancements, and changing regulatory landscapes. The demand for premium leather, especially full grain and top grain, is surging among B2B buyers due to an increasing focus on quality and durability. Meanwhile, the popularity of alternative materials, such as vegan leathers and sustainable synthetics, is shaping sourcing strategies, particularly in regions like Europe where eco-consciousness is paramount.

Emerging technologies are also influencing the leather industry, with innovations in tanning processes and digital supply chain management improving efficiency and traceability. B2B buyers are increasingly leveraging data analytics to forecast demand and manage inventory, enabling more agile responses to market fluctuations. In regions such as Africa and South America, where leather production is a vital economic sector, partnerships with local artisans and manufacturers can enhance product authenticity while meeting global standards.

Illustrative image related to different types of leather

Moreover, the integration of e-commerce platforms is streamlining purchasing processes, allowing international buyers to source leather products more conveniently. As markets become more interconnected, understanding local trends and consumer behavior will be essential for B2B buyers looking to tap into new opportunities across various regions, including the Middle East and Europe.

How Does Sustainability and Ethical Sourcing Impact the Leather Industry?

Sustainability has become a crucial consideration for B2B buyers in the leather sector, with growing awareness of environmental impacts associated with traditional leather production. The tanning process, particularly when it involves toxic chemicals, poses risks not only to ecosystems but also to human health. Consequently, there is a rising demand for eco-friendly tanning methods, such as vegetable tanning, which utilizes natural substances and minimizes chemical waste.

Ethical sourcing is also gaining traction, as buyers seek to establish transparent supply chains that prioritize animal welfare and fair labor practices. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) provide assurance regarding the environmental and ethical standards of leather products. By aligning with suppliers who adhere to these certifications, B2B buyers can enhance their brand reputation and meet the increasing consumer demand for responsibly sourced materials.

Furthermore, the adoption of circular economy principles is gaining momentum, with companies exploring options for recycling and upcycling leather products. This approach not only reduces waste but also creates new revenue streams for businesses, positioning them as leaders in sustainability within the leather market.

What Is the Historical Context of Leather Sourcing and Its Evolution?

The history of leather dates back thousands of years, with its use tracing back to ancient civilizations for clothing, armor, and shelter. Initially, leather was sourced primarily through hunting, but as agriculture developed, so did the practice of animal husbandry, leading to a more systematic approach to leather production.

Throughout the centuries, advancements in tanning techniques and craftsmanship have significantly improved the quality and durability of leather. The industrial revolution introduced mechanization to the leather industry, making production more efficient but also raising concerns about environmental impact and labor conditions. Today, the leather sector is at a crossroads, balancing traditional artisanal methods with modern technological innovations while increasingly focusing on sustainability and ethical practices. This evolution reflects the ongoing transformation of consumer expectations and regulatory pressures, shaping a more responsible and innovative leather industry.

Illustrative image related to different types of leather

Frequently Asked Questions (FAQs) for B2B Buyers of different types of leather

-

How do I choose the right type of leather for my products?

Selecting the appropriate leather type depends on your product’s intended use and desired qualities. Full grain leather is ideal for luxury items requiring durability and a unique aesthetic, while top grain offers a balance of quality and cost-effectiveness. For items needing a soft finish, consider nubuck or suede, but be mindful of their maintenance needs. Assess your target market preferences and the end-use of your products to guide your choice. Consulting with suppliers about their specific offerings can also provide insights into the best fit for your needs. -

What is the best leather type for high-end fashion accessories?

Full grain leather is often regarded as the premier choice for high-end fashion accessories due to its durability, natural beauty, and unique character. Its ability to develop a rich patina over time adds to its appeal. However, top grain leather can also be a suitable alternative, especially if a smoother finish is preferred. Evaluate your design specifications and target demographic to determine which leather type aligns with your brand’s luxury positioning. -

What are the minimum order quantities (MOQs) for leather suppliers?

Minimum order quantities can vary widely among leather suppliers, influenced by factors such as material type, production capabilities, and customization options. Generally, MOQs may range from 50 to 500 square meters or more, depending on the supplier’s policies. It’s crucial to discuss your specific needs with potential suppliers to negotiate MOQs that fit your business model, especially if you are a smaller enterprise or looking for trial runs of new products. -

What should I consider when vetting leather suppliers for international trade?

When vetting suppliers, consider their reputation, certifications, and compliance with international quality standards. Request samples to assess leather quality and inspect for consistency in color, texture, and finish. Additionally, inquire about their production capacity and lead times to ensure they can meet your demands. It’s also beneficial to check references from other B2B clients and verify their experience in international shipping and customs processes to mitigate risks. -

What payment terms are typical in international leather transactions?

Payment terms can vary significantly by supplier and region. Common practices include upfront payments, letters of credit, or staggered payments based on production milestones. It’s advisable to negotiate terms that balance risk and cash flow, ensuring protection against potential disputes. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers or larger orders. -

How can I ensure the quality of leather products during production?

Implementing a robust quality assurance (QA) process is essential for maintaining leather quality. This includes setting clear specifications for leather characteristics, conducting regular inspections throughout the production process, and establishing checkpoints for testing durability and finish. Collaborate closely with suppliers to address any discrepancies immediately and consider third-party inspections if necessary. Documenting these processes can also help in maintaining consistency across batches. -

What are the logistical considerations for importing leather?

Importing leather involves various logistical factors, including customs regulations, tariffs, and shipping methods. Familiarize yourself with import duties specific to leather in your country and ensure that your supplier provides all necessary documentation, such as invoices and certificates of origin. Opt for reliable shipping methods to minimize transit times, and consider working with a freight forwarder who specializes in international trade to navigate the complexities of customs clearance and delivery. -

How can I customize leather products for my brand?

Customizing leather products often involves selecting specific leather types, colors, and finishes, as well as adding branding elements like embossing or stitching. Discuss your design ideas with suppliers to determine what customization options they offer. Be prepared to provide detailed specifications and, if possible, prototypes to guide the production process. Keep in mind that increased customization may affect lead times and pricing, so plan accordingly to align with your launch schedule.

Top 4 Different Types Of Leather Manufacturers & Suppliers List

1. The Real Leather Company – Premium Leather Products

Domain: therealleathercompany.com

Registered: 2019 (6 years)

Introduction: 1. Full Grain Leather: Highest quality, top layer of hide, unique imperfections, durable, develops natural patina, most expensive, best longevity. 2. Top Grain Leather: Second-best quality, corrected imperfections, smooth appearance, thinner, more affordable, protective finish coats. 3. Nubuck Leather: Soft, velvety texture, requires maintenance, susceptible to stains and water damage, luxurious a…

2. RubnRestore – Leather Types Explained

Domain: rubnrestore.com

Registered: 2010 (15 years)

Introduction: Different types of leather include: 1. Full Grain Leather: Finest quality, fully intact hide, absorbent, may have aniline or pigmented finish. 2. Top Grain Leather: Second best grade, sanded for uniform appearance, repels liquids, often thinner and more flexible. 3. Aniline & Semi-Aniline Leather: Full or top grain, marbled appearance, absorbent, prone to stains, semi-aniline has a thin finish. 4….

3. Leather Neo – Premium Leather Goods

Domain: leatherneo.com

Registered: 2020 (5 years)

Introduction: 1. Full Grain Leather: Top layer of hide, most excellent grade, authentic appearance, ages beautifully, strong, long-lasting, water-resistant, used in furniture, footwear, and saddlery. 2. Top-Grain Leather: Second layer of hide, buffed to remove flaws, more supple, used for luxury items like wallets and handbags, softer feel, less durable than full-grain. 3. Corrected/Genuine Leather: Thickest an…

4. Overland – Leather Types

Domain: overland.com

Registered: 1997 (28 years)

Introduction: Leather Types: Cowhide, Bison, Deerskin, Goatskin, Lambskin, Calfskin. Cowhide: Strong, thick, durable, water- and dirt-resistant. Bison: Strong, durable, distinctive pebbled grain. Deerskin: Soft, lightweight, contours to form. Goatskin: Soft, durable, smooth, characteristic pebble grain. Lambskin: Softest leather, lightweight, flattering drape. Calfskin: Strong, durable, supple, smooth. Leather …

Strategic Sourcing Conclusion and Outlook for different types of leather

In the evolving landscape of leather sourcing, understanding the diverse types of leather is crucial for B2B buyers aiming to make informed purchasing decisions. Full grain and top grain leathers stand out for their superior quality and longevity, appealing to high-end markets. Meanwhile, options like nubuck and patent leather offer unique aesthetics, catering to fashion-forward consumers. For those focused on cost-effectiveness, split grain and genuine leather present viable alternatives, although they come with trade-offs in durability and appearance.

Strategic sourcing is not just about cost; it involves aligning product quality with market demands and consumer preferences. As buyers navigate the complexities of the leather market across regions such as Africa, South America, the Middle East, and Europe, leveraging insights into leather types can enhance product offerings and drive competitive advantage.

Looking ahead, international B2B buyers should prioritize establishing partnerships with reputable suppliers who can provide transparency about leather origins and production processes. By doing so, companies can ensure they are not only meeting market demands but also contributing to sustainable practices. Engage with trusted suppliers today to secure quality leather that meets the evolving expectations of your customers.

Illustrative image related to different types of leather

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.