Introduction: Navigating the Global Market for custom leather armor

In the dynamic landscape of B2B procurement, sourcing custom leather armor presents a unique challenge for international buyers, especially those from Africa, South America, the Middle East, and Europe. The demand for high-quality, bespoke leather armor is on the rise, driven by diverse applications ranging from reenactments and live-action role-playing (LARP) to theatrical productions and specialized costume events. However, the intricacies involved in selecting the right suppliers, ensuring product quality, and understanding cost implications can be daunting.

This guide serves as a comprehensive resource for B2B buyers navigating the global market for custom leather armor. It delves into various types of armor available, their specific applications, and the critical factors to consider when vetting suppliers. Additionally, it provides insights into pricing structures, ensuring buyers can make informed decisions that align with their budget and quality expectations.

By equipping international buyers with actionable insights and expert recommendations, this guide empowers them to confidently engage with suppliers and secure the best products for their unique needs. Whether you are a buyer in Brazil looking for intricate designs or a procurement officer in Germany seeking durable options, our guide will facilitate a streamlined purchasing process that meets your specific requirements. With this knowledge, you can navigate the complexities of the market and enhance your offerings with exceptional custom leather armor.

Table Of Contents

- Top 4 Custom Leather Armor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather armor

- Understanding custom leather armor Types and Variations

- Key Industrial Applications of custom leather armor

- 3 Common User Pain Points for ‘custom leather armor’ & Their Solutions

- Strategic Material Selection Guide for custom leather armor

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather armor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather armor’

- Comprehensive Cost and Pricing Analysis for custom leather armor Sourcing

- Alternatives Analysis: Comparing custom leather armor With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather armor

- Navigating Market Dynamics and Sourcing Trends in the custom leather armor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather armor

- Strategic Sourcing Conclusion and Outlook for custom leather armor

- Important Disclaimer & Terms of Use

Understanding custom leather armor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Breastplates | Durable, often molded to fit the torso, offers front protection | LARP, Cosplay, Historical Reenactment | Pros: Good protection; customizable. Cons: May restrict movement if poorly fitted. |

| Armored Bracers | Protects forearms; can include decorative elements | SCA, LARP, Theatrical Performances | Pros: Lightweight; easy to wear. Cons: Limited coverage compared to full armor. |

| Leather Cuirasses | Complete torso coverage; often includes back and front plates | Combat Sports, Historical Reenactment | Pros: Comprehensive protection; stylish. Cons: Heavier and may require custom fitting. |

| Leg Armor (Greaves) | Protects shins and knees; often paired with thigh armor | LARP, Medieval Combat, Cosplay | Pros: Enhances mobility; protects vital areas. Cons: Can be cumbersome without proper design. |

| Custom Decorative Armor | Unique designs, often with intricate details; made to order | Film, Theater, High-End Collectibles | Pros: One-of-a-kind pieces; artistic expression. Cons: Higher cost and longer production time. |

What are the Characteristics of Leather Breastplates in Custom Armor?

Leather breastplates are a staple in custom leather armor, providing essential protection for the torso. Typically molded to fit the wearer’s body, they can be designed with various embellishments, such as embossing or painting, to reflect personal style or historical accuracy. B2B buyers should consider the balance between protection and mobility, ensuring that the fit allows for comfortable movement during activities like LARP or reenactment.

How Do Armored Bracers Enhance Protection?

Armored bracers are designed to protect the forearms, often incorporating decorative elements that enhance their aesthetic appeal. Lightweight and easy to wear, they are ideal for participants in SCA events or theatrical performances where ease of movement is crucial. When purchasing, buyers should assess the balance between decorative features and functional protection, ensuring that the bracers do not hinder arm mobility.

What Makes Leather Cuirasses a Popular Choice?

Leather cuirasses provide comprehensive protection by covering both the front and back of the torso. They are particularly sought after in combat sports and historical reenactments for their durability and style. B2B buyers should prioritize custom fitting to ensure comfort and effectiveness in movement, as a poorly fitted cuirass can hinder performance and safety.

Illustrative image related to custom leather armor

Why Invest in Leg Armor (Greaves)?

Leg armor, or greaves, protects the shins and knees, making it a critical component for activities such as LARP and medieval combat. These pieces can be designed to allow for greater mobility while still providing vital coverage. Buyers should consider the design and fit of leg armor to prevent discomfort during prolonged use, as well as the potential for customization to match existing armor styles.

What are the Advantages of Custom Decorative Armor?

Custom decorative armor is characterized by unique designs and intricate details, making each piece a work of art. This type of armor is often used in film, theater, or by high-end collectors seeking one-of-a-kind items. While the artistic value is high, buyers must be prepared for increased costs and longer production times. Ensuring clear communication with manufacturers about design specifications and timelines is crucial for successful procurement.

Key Industrial Applications of custom leather armor

| Industry/Sector | Specific Application of custom leather armor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Entertainment | Costumes for Film, TV, and Theater | Unique, high-quality designs enhance production value | Expertise in custom design and craftsmanship; timely delivery |

| Historical Reenactment | Authentic period armor for reenactments | Enhances realism and audience engagement | Accurate historical designs; durable materials for repeated use |

| Sports and Recreation | Protective gear for LARP and cosplay events | Safety and comfort for participants | Custom fitting options; variety of styles and colors |

| Military and Security | Tactical leather gear for personnel | Provides protection while maintaining mobility | Compliance with safety regulations; custom design features |

| Fashion and Lifestyle | Unique leather pieces for fashion shows and events | Distinctive products that stand out in the market | High-quality materials; collaboration on design aesthetics |

How is Custom Leather Armor Used in the Entertainment Industry?

In the entertainment sector, custom leather armor is primarily used for costumes in film, television, and theater productions. These pieces are crafted to not only reflect the character’s persona but also to withstand the rigors of performance. B2B buyers in this industry seek unique, high-quality designs that enhance the overall production value and authenticity. Key considerations include the expertise of the armor makers in creating bespoke designs, the use of durable materials, and the ability to meet tight deadlines for production schedules.

Illustrative image related to custom leather armor

What Role Does Custom Leather Armor Play in Historical Reenactments?

Custom leather armor is essential in historical reenactments, where authenticity is paramount. Participants require armor that closely resembles historical designs to enhance realism and engage audiences effectively. Buyers must ensure that the armor reflects accurate historical details and is constructed from durable materials to withstand repeated use. Sourcing from artisans who specialize in historical accuracy and craftsmanship is crucial, as is the ability to accommodate specific requests for customization based on the era being represented.

How is Custom Leather Armor Utilized in Sports and Recreation?

In the realm of sports and recreation, particularly for live-action role-playing (LARP) and cosplay events, custom leather armor serves both protective and aesthetic functions. It ensures safety while allowing participants to embody their characters fully. Businesses in this sector look for armor that is not only stylish but also comfortable for extended wear. Key sourcing considerations include the availability of custom fitting options, a wide variety of styles and colors, and the ability to produce lightweight yet durable armor that meets the needs of active participants.

Why is Custom Leather Armor Important for Military and Security Applications?

In military and security contexts, custom leather armor is utilized for tactical gear designed for personnel protection. This armor provides essential safety while allowing for mobility, which is critical in operational environments. B2B buyers in this sector must consider compliance with safety regulations, the incorporation of custom design features for specific operational needs, and the availability of materials that can withstand harsh conditions. The ability to source armor that combines functionality with tactical aesthetics is vital for effective procurement.

Illustrative image related to custom leather armor

How Does Custom Leather Armor Benefit the Fashion Industry?

In the fashion industry, custom leather armor is increasingly popular for creating unique pieces showcased in fashion shows and events. Designers utilize custom armor to produce distinctive products that stand out in a competitive market. Buyers must prioritize high-quality materials and the potential for collaboration with artisans to achieve specific design aesthetics. Sourcing considerations also include the ability to create limited-edition pieces that cater to niche markets, ensuring exclusivity and appeal to fashion-forward consumers.

3 Common User Pain Points for ‘custom leather armor’ & Their Solutions

Scenario 1: Sizing and Fit Challenges for Unique Body Types

The Problem: Many B2B buyers face difficulties when sourcing custom leather armor that accommodates a diverse range of body shapes and sizes. Traditional sizing options often fail to meet the needs of those outside the “industry standard,” resulting in discomfort or inadequate protection during use. This issue can be particularly pronounced in regions where body positivity and inclusivity are gaining traction, yet the armor options remain limited, leading to dissatisfaction and lost sales.

The Solution: To address sizing challenges, B2B buyers should partner with manufacturers that offer bespoke fitting services. For instance, companies like TheSmokinSmithy provide a comprehensive fitting process, including body molding techniques that ensure the armor is tailored specifically to the individual. Buyers should inquire about the process, requesting details on how the armor will be crafted based on precise measurements or custom molds. Additionally, encouraging manufacturers to adopt a wider range of size options and styles can help cater to a more inclusive market, ultimately enhancing customer satisfaction and loyalty.

Scenario 2: Design Customization and Artwork Limitations

The Problem: B2B buyers often struggle with the limitations imposed by standard designs and artwork on custom leather armor. Clients may seek unique designs that reflect cultural heritage, branding, or specific thematic elements for events like cosplay, LARPing, or reenactments. However, many suppliers offer only generic templates, which can stifle creativity and lead to a lack of differentiation in a competitive marketplace.

The Solution: To overcome design limitations, buyers should actively seek manufacturers that provide extensive customization options. Engaging with artisans who have a strong portfolio in custom artwork and design, such as those who can incorporate laser etching or hand-tooling techniques, can yield impressive results. Buyers should discuss their vision and ask for samples of previous work to gauge the manufacturer’s capabilities. Establishing a clear communication channel with the supplier can facilitate the creation of bespoke designs that resonate with the end-users, making the armor more appealing and distinctive.

Scenario 3: Durability and Weather Resistance Concerns

The Problem: Buyers often express concerns about the durability and weather resistance of custom leather armor, especially in regions with extreme weather conditions. Leather is susceptible to moisture, which can compromise its structural integrity over time, leading to dissatisfaction among users who expect their gear to withstand rigorous use in various environments.

The Solution: To ensure the longevity of leather armor, B2B buyers should prioritize manufacturers that employ advanced treatment processes and high-quality materials. For instance, sourcing armor that has been treated with wax or acrylic finishes can provide a protective barrier against moisture and UV damage. Buyers should inquire about the specific treatments used during the manufacturing process and request performance guarantees. Additionally, regular maintenance tips, such as using leather conditioners and waterproofing sprays, can be provided to end-users to enhance the armor’s lifespan. By emphasizing quality and care, buyers can ensure that their investment in custom leather armor translates into reliable performance under diverse conditions.

Illustrative image related to custom leather armor

Strategic Material Selection Guide for custom leather armor

What Are the Key Materials for Custom Leather Armor?

When selecting materials for custom leather armor, several options stand out based on their properties, advantages, and suitability for various applications. Understanding these materials is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Vegetable-Tanned Leather Perform in Custom Leather Armor?

Vegetable-tanned leather is renowned for its durability and breathability. This natural tanning process uses plant-based tannins, making the leather environmentally friendly. It exhibits excellent resistance to wear and tear, making it suitable for armor that may undergo significant stress during use. However, it can be more expensive than other types of leather due to the lengthy tanning process. For B2B buyers, especially in regions like Europe, compliance with environmental standards and preferences for sustainable materials can influence purchasing decisions.

What Are the Benefits and Drawbacks of Chrome-Tanned Leather?

Chrome-tanned leather is processed using chromium salts, resulting in a leather that is soft, flexible, and resistant to water and heat. Its durability makes it suitable for various applications, including armor for LARP and cosplay. However, the tanning process can involve harmful chemicals, raising concerns about environmental impact and compliance with regulations in certain markets. For buyers in Africa and South America, where environmental regulations may vary, understanding local compliance is essential when considering this material.

Why Choose Suede Leather for Custom Armor Applications?

Suede leather, made from the underside of animal hides, offers a unique texture and aesthetic appeal. It is lightweight and provides good flexibility, making it comfortable for wear. However, suede is less durable than other leathers and can be prone to staining and damage from moisture. For international buyers, especially those in humid climates, this could impact the long-term performance of the armor. Additionally, the cost of suede can vary significantly based on sourcing and processing methods.

What Role Does Synthetic Leather Play in Custom Armor Production?

Synthetic leather, often made from polyurethane or PVC, offers a cost-effective alternative to traditional leather. It is lightweight, easy to clean, and resistant to water and stains. However, it may lack the durability and breathability of natural leather, which can impact comfort during extended wear. For B2B buyers in regions with varying economic conditions, synthetic leather can be an attractive option due to its lower price point. However, buyers should consider the environmental implications of synthetic materials, especially in markets with stringent sustainability standards.

Illustrative image related to custom leather armor

Summary Table of Material Selection for Custom Leather Armor

| Material | Typical Use Case for Custom Leather Armor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Historical reenactments, LARP | Environmentally friendly, durable | Higher cost due to lengthy tanning | High |

| Chrome-Tanned Leather | Cosplay, LARP, protective gear | Soft, flexible, water-resistant | Environmental concerns | Medium |

| Suede Leather | Costume design, light armor | Lightweight, unique texture | Less durable, moisture-sensitive | Medium |

| Synthetic Leather | Budget-friendly armor options | Cost-effective, easy to clean | Less durable, potential environmental impact | Low |

Understanding the properties, advantages, and limitations of these materials will enable B2B buyers to make informed decisions that align with their specific needs and market conditions. Each material has its unique set of characteristics that can significantly impact the performance and suitability of custom leather armor for various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather armor

In the world of custom leather armor, the manufacturing process and quality assurance are critical components that ensure the end product meets the high standards expected by international buyers. This section will outline the key stages of production, the techniques employed, and the quality control measures that suppliers should adhere to, specifically for B2B buyers from diverse regions including Africa, South America, the Middle East, and Europe.

What Are the Main Stages of Manufacturing Custom Leather Armor?

The manufacturing process of custom leather armor typically involves several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to custom leather armor

Material Preparation: How Is Leather Selected and Processed?

The foundation of high-quality leather armor begins with the careful selection of leather. Suppliers often choose from a range of hides, including vegetable-tanned leather for its durability and ability to mold well to the body. The leather is then treated to enhance its properties, which may include dyeing, waxing, or oiling to improve water resistance and flexibility.

Once the leather is prepared, it is cut into panels based on precise patterns tailored to the client’s specifications. This step may involve advanced techniques such as laser cutting for precision, especially in designs that include intricate patterns or details.

What Techniques Are Used in Forming and Assembling Armor?

Forming leather armor involves shaping the cut panels into the desired forms. This can be achieved through techniques such as wet forming, where leather is dampened and shaped over a mold, allowing for a custom fit.

During assembly, various components such as buckles, straps, and decorative elements are attached. Stitching is a critical aspect, with techniques like double or triple stitching being employed to ensure durability. Riveting may also be used to secure heavier components, and the choice of thread and rivet material can significantly influence the armor’s final aesthetic and functionality.

How Is the Finishing Process Conducted for Custom Leather Armor?

Finishing is the final stage in the production of leather armor and involves several important steps. Edges are typically burnished to prevent fraying and enhance durability. A protective coating, such as resoline or acrylic varnish, is applied to safeguard the leather from environmental factors while sealing in dyes.

Illustrative image related to custom leather armor

Final touches may include the application of unique artwork, whether through hand-tooling, painting, or laser etching, allowing for personalization that resonates with the buyer’s vision.

What Quality Assurance Measures Are Essential for Custom Leather Armor?

Quality assurance (QA) is paramount in the production of custom leather armor, ensuring that the final product meets both international standards and the specific needs of the buyer.

Which International Standards Should Be Considered?

B2B buyers should look for suppliers who comply with international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards indicates that the supplier has established a robust framework for consistent quality and customer satisfaction.

Illustrative image related to custom leather armor

In addition, industry-specific certifications such as CE marking (for products sold within the European Economic Area) and API standards (relevant for certain applications) can also be significant indicators of quality.

What Are the Key Quality Control Checkpoints?

Quality control in leather armor manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon receipt to ensure they meet predetermined specifications. Any defective materials can be flagged before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are conducted to monitor the production process. This includes verifying the accuracy of cuts, the quality of stitching, and the effectiveness of forming techniques.

-

Final Quality Control (FQC): Before shipping, a thorough inspection of the finished armor is conducted. This includes checking for cosmetic flaws, functional integrity, and adherence to customer specifications.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps:

Illustrative image related to custom leather armor

-

Conduct Audits: Regular audits of potential suppliers can help buyers understand their processes and adherence to quality standards. This can include site visits and assessments of production capabilities.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation detailing their quality control processes, including results from inspections and testing.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipment. This is especially important for international transactions where buyers may not have direct oversight.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers should be aware that quality control practices may vary significantly across regions. For example, suppliers in Europe may have stricter compliance requirements than those in other regions. Buyers from Africa and South America should pay particular attention to the supplier’s ability to meet international standards and certifications.

Additionally, buyers should consider the implications of shipping regulations and import restrictions that may affect the acceptance of certain materials or finishes used in the armor. Understanding these nuances can help buyers make informed decisions and avoid potential compliance issues.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance

In summary, the manufacturing processes and quality assurance measures for custom leather armor are intricate and vital for ensuring high-quality products. B2B buyers should prioritize suppliers that demonstrate rigorous quality control practices and adherence to international standards. By understanding the manufacturing process and implementing thorough verification methods, buyers can secure reliable partnerships that meet their specific needs in the custom leather armor market.

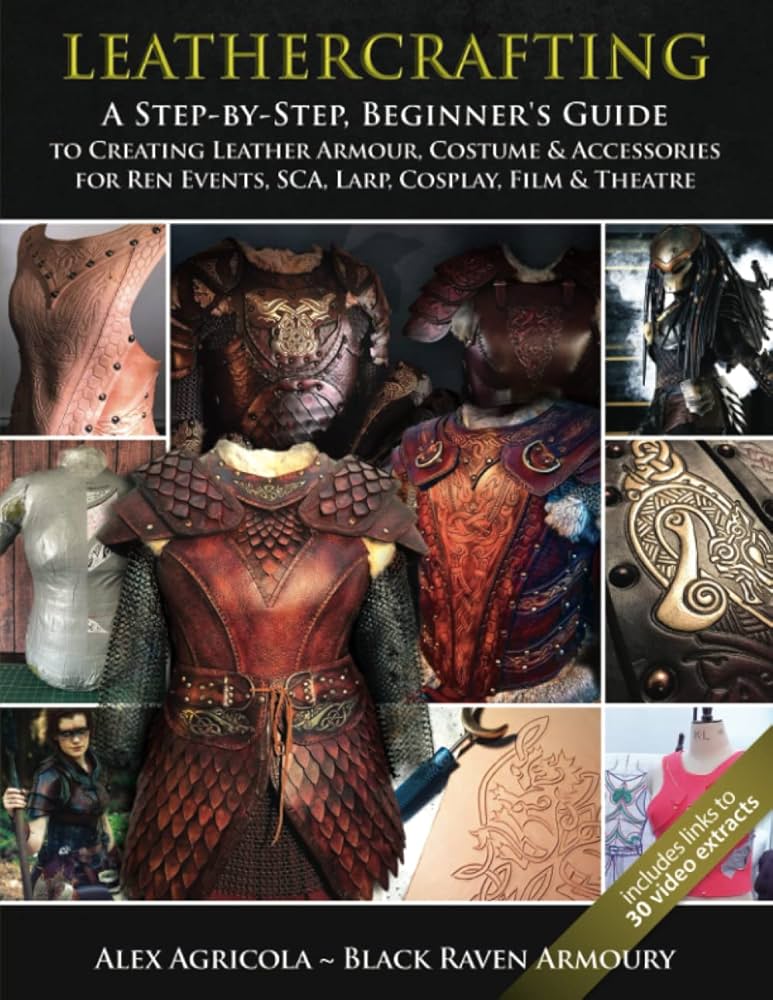

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather armor’

Introduction

This sourcing guide aims to provide B2B buyers with a comprehensive checklist for procuring custom leather armor. Whether you are sourcing for LARP events, cosplay, or historical reenactments, following these steps will ensure that you find a supplier who meets your specific needs while adhering to quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider the intended use of the armor, such as protection level, weight, and flexibility. Be specific about the styles you are interested in, like historical accuracy or fantasy designs, and outline any customization requirements.

Step 2: Research Potential Suppliers

Invest time in researching various suppliers to identify those who specialize in custom leather armor. Look for companies with a strong online presence, customer reviews, and portfolios showcasing their work. Pay attention to their experience with similar projects and their reputation in the industry.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their ability to meet your specifications, including their craftsmanship, material sourcing, and design capabilities.

- Look for:

- Craftsmanship quality through sample pieces.

- Availability of different leather types and finishes.

Step 4: Verify Compliance and Certifications

Ensure that your chosen suppliers comply with relevant industry standards and regulations. This is particularly important if the armor will be used in competitive environments. Certifications can indicate quality assurance and adherence to safety standards.

Illustrative image related to custom leather armor

- Check for:

- Quality management system certifications (e.g., ISO 9001).

- Compliance with local regulations regarding materials used.

Step 5: Discuss Customization Options

Customization is often a key selling point for custom leather armor. Engage with suppliers to discuss the extent of customization available, including designs, colors, and fittings. A good supplier will work collaboratively with you to create a product that meets your needs.

- Inquire about:

- Design capabilities (e.g., laser engraving, painting).

- Options for tailoring fit based on customer measurements.

Step 6: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes to assess the quality and fit of the armor. This step allows you to evaluate not only the craftsmanship but also the comfort and functionality of the pieces.

- What to look for:

- Durability of materials used.

- Comfort during wear, especially in movement.

Step 7: Establish Clear Terms and Conditions

Finally, ensure that you have a clear understanding of the terms and conditions of the purchase. Discuss payment terms, lead times, and return policies. Having these details documented will help prevent misunderstandings and ensure a smooth transaction.

- Key aspects to cover:

- Payment schedules and methods.

- Shipping options and expected delivery times.

By following this checklist, B2B buyers can effectively navigate the sourcing process for custom leather armor, ensuring they select the right suppliers and products for their specific needs.

Comprehensive Cost and Pricing Analysis for custom leather armor Sourcing

What Are the Key Cost Components for Custom Leather Armor?

When evaluating the cost structure of custom leather armor, several critical components come into play:

-

Materials: The choice of leather significantly affects pricing. High-quality, durable leather such as vegetable-tanned hides or exotic leathers commands a premium. Additionally, supplementary materials like metal fittings, dyes, and protective coatings contribute to overall costs.

-

Labor: Labor costs vary based on the complexity of the design and the skill level required. Custom armor often involves detailed craftsmanship, which can increase labor expenses. Artisans skilled in techniques such as tooling, stitching, and fitting are essential for quality assurance.

-

Manufacturing Overhead: This includes fixed costs associated with production facilities, equipment maintenance, and utilities. Suppliers with advanced machinery for processes like laser cutting may have higher overhead but can offer precision and efficiency.

-

Tooling: Custom designs may require unique patterns or molds, increasing initial costs. Tooling is a significant investment, particularly for bespoke orders, as it often necessitates the creation of new templates.

-

Quality Control (QC): Ensuring that each piece meets quality standards adds to costs. Rigorous QC processes can prevent defects but may also slow production, impacting pricing.

-

Logistics: Shipping and handling expenses can fluctuate based on the destination and mode of transport. International buyers must consider import duties and customs fees, which can add to the total cost.

-

Margin: Manufacturers typically include a profit margin in their pricing. This margin varies based on brand reputation, market demand, and competition.

How Do Price Influencers Affect Custom Leather Armor Costs?

Several factors can influence the pricing of custom leather armor:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders may qualify for discounts, reducing the per-unit cost. Conversely, small orders might lead to higher prices due to less favorable economies of scale.

-

Specifications and Customization: Highly customized products with specific design elements or functionalities can drive up costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice between standard and premium materials significantly impacts pricing. Customizations like unique dye jobs or intricate tooling will also incur additional costs.

-

Quality and Certifications: Suppliers offering certified materials (e.g., eco-friendly or ethically sourced) may charge more. However, these certifications can enhance a product’s marketability.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. Established brands may charge a premium for their expertise, while emerging suppliers might offer competitive rates.

-

Incoterms: Understanding the terms of sale (e.g., FOB, CIF) is crucial for calculating total costs, including shipping and insurance.

What Are Effective Buyer Tips for Sourcing Custom Leather Armor?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Terms: Leverage volume orders or long-term contracts to negotiate better pricing. Establishing a good relationship with suppliers can lead to more favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and potential resale value. High-quality armor may have a higher upfront cost but can save money in the long run due to lower replacement rates.

-

Understand Pricing Nuances: Be aware that prices may fluctuate based on exchange rates, local economic conditions, or changes in material costs. Staying informed about market trends can help in making timely purchasing decisions.

-

Research Supplier Backgrounds: Investigate potential suppliers’ reputations and customer feedback. This can help identify reliable partners who deliver quality products and services.

Disclaimer

Prices for custom leather armor can vary widely based on the factors discussed. The figures mentioned in this analysis are indicative and should be confirmed with individual suppliers to obtain accurate quotes tailored to specific needs.

Alternatives Analysis: Comparing custom leather armor With Other Solutions

Exploring Alternatives to Custom Leather Armor for B2B Buyers

In the realm of protective gear, particularly for reenactments, LARPing, and cosplay, custom leather armor stands as a prominent choice. However, buyers should consider various alternatives that may better suit their specific needs, whether in terms of performance, cost, or usability. This analysis compares custom leather armor against chainmail armor and synthetic armor solutions, providing insights into their respective advantages and disadvantages.

| Comparison Aspect | Custom Leather Armor | Chainmail Armor | Synthetic Armor |

|---|---|---|---|

| Performance | Good protection with flexibility | Excellent durability and defense | Varies; lightweight, some options offer decent protection |

| Cost | Moderate to high ($200-$800) | High ($500-$2000) | Low to moderate ($50-$500) |

| Ease of Implementation | Requires custom fitting and design | Heavy and requires skill to wear | Generally user-friendly, often off-the-shelf |

| Maintenance | Requires regular conditioning | Needs rust prevention and upkeep | Low maintenance; easy to clean |

| Best Use Case | LARP, Cosplay, Historical Reenactment | Historical reenactments, combat | Casual use, lightweight activities, cosplay |

What Are the Advantages and Disadvantages of Chainmail Armor?

Chainmail armor offers exceptional durability and protection against slashing attacks, making it a favored choice in historical reenactments and combat scenarios. Its flexible design allows for a range of movement, similar to custom leather armor. However, chainmail can be cumbersome and heavy, requiring significant effort to don and doff. Moreover, its higher price point may deter budget-conscious buyers. While it excels in protection, chainmail may not provide the aesthetic customization options that many buyers seek for events like LARPing or cosplay.

How Does Synthetic Armor Compare?

Synthetic armor represents a modern alternative, often made from materials like Kevlar or other advanced polymers. It is lightweight, making it easy to wear for extended periods, and typically requires less maintenance compared to leather or chainmail options. However, the performance of synthetic armor can vary widely depending on the specific product and intended use. While it may not offer the same level of historical authenticity or aesthetic appeal as custom leather armor, it presents a cost-effective solution for those needing basic protection without the higher investment associated with traditional materials.

Making an Informed Choice: Which Armor Solution is Right for You?

When selecting the appropriate armor solution, B2B buyers should consider their specific use case and budget constraints. Custom leather armor is ideal for those seeking a balance between protection and aesthetic appeal, particularly in LARPing and cosplay. Chainmail suits historical reenactors and those prioritizing durability and authenticity, albeit at a higher cost. On the other hand, synthetic armor is a practical choice for budget-sensitive buyers who require lightweight solutions for casual use or events. Ultimately, understanding the unique benefits and limitations of each option will empower B2B buyers to make informed decisions tailored to their needs.

Illustrative image related to custom leather armor

Essential Technical Properties and Trade Terminology for custom leather armor

What Are the Key Technical Properties of Custom Leather Armor?

When sourcing custom leather armor, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

-

Material Grade

The material grade of leather used in armor significantly affects its durability and performance. Common grades include full-grain leather, which retains the natural grain and is the most durable, and corrected grain leather, which is more affordable but less resilient. High-grade leather ensures longevity and better protection, making it a valuable investment for B2B buyers looking for reliable products. -

Thickness

Leather thickness is typically measured in ounces or millimeters. For armor, a thickness of 8-12 ounces (approximately 3-5 mm) is standard, offering a good balance between flexibility and protection. Understanding the thickness helps buyers assess the armor’s ability to withstand impacts and wear, which is crucial for activities like LARP, reenactments, or combat sports. -

Finish Type

The finish of the leather, such as waxed, oiled, or dyed, affects not only the aesthetic appeal but also the armor’s resistance to water and wear. A waxed finish provides a protective layer that enhances durability, while dyed finishes allow for customization. Buyers should consider the intended use and environmental conditions to select an appropriate finish that meets their needs. -

Weight

The weight of the armor is a critical factor, as it influences mobility and comfort. Lighter armor made from thinner materials may be suitable for cosplay or LARP, while heavier armor is preferable for reenactments or combat training. Understanding weight specifications helps buyers ensure that the armor meets their performance requirements without compromising user comfort. -

Sizing and Fit

Custom armor is often tailored to fit specific body shapes and sizes. Accurate measurements or body molds are essential for achieving the right fit, which enhances comfort and protection. B2B buyers should prioritize suppliers who offer fitting services and customization options to ensure their end-users receive armor that fits well and functions effectively.

What Are Common Trade Terminologies Related to Custom Leather Armor?

Navigating the procurement of custom leather armor requires familiarity with specific trade terms. Here are some key phrases that buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications provided by another company. In the context of custom leather armor, understanding OEM relationships can help buyers find manufacturers that can produce high-quality, bespoke items tailored to their brand’s needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers as it helps in budgeting and planning inventory. Suppliers often set MOQs to ensure production efficiency, so understanding this term can lead to better negotiation and purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products. When seeking custom leather armor, submitting an RFQ allows buyers to outline their requirements and receive competitive pricing, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to clarify shipping obligations, risk management, and cost responsibilities. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times for custom leather armor is vital for planning and ensuring that products are delivered on time for events or launches. This insight helps buyers manage expectations and maintain inventory levels effectively.

In summary, grasping both the technical properties and trade terminologies associated with custom leather armor equips B2B buyers with the knowledge necessary to make strategic purchasing decisions. This understanding leads to better product selection, negotiation, and overall satisfaction with their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the custom leather armor Sector

What Are the Current Trends Driving the Custom Leather Armor Market?

The custom leather armor market is witnessing a resurgence driven by various global factors, including the growing popularity of cosplay, LARP (Live Action Role Playing), and historical reenactments. These activities have expanded beyond niche communities, attracting broader audiences, particularly in regions like Europe and South America. The demand for unique, handcrafted items is rising, as consumers seek personalized experiences that reflect their identities and interests.

Additionally, advancements in technology are transforming the sourcing landscape. The integration of digital design tools and online platforms enables manufacturers to offer customizable options with greater efficiency. Buyers can now engage in virtual consultations, allowing for accurate fitting and design discussions, thus streamlining the sourcing process. This trend is particularly beneficial for international buyers, enabling seamless communication and collaboration across borders.

Another notable trend is the increased focus on durability and comfort in product offerings. As consumers become more discerning, they seek armor that not only looks visually appealing but also provides practical functionality. This has led manufacturers to explore innovative materials and construction techniques, ensuring that products meet both aesthetic and performance standards.

How Is Sustainability Influencing Sourcing Decisions for Custom Leather Armor?

Sustainability is becoming a critical concern for B2B buyers in the custom leather armor sector. With heightened awareness of environmental issues, companies are increasingly prioritizing ethical sourcing and production practices. The leather industry has faced scrutiny over its environmental impact, including deforestation and pollution from tanning processes. As a result, there is a growing demand for eco-friendly alternatives and certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certifications.

Illustrative image related to custom leather armor

Buyers are now more inclined to partner with suppliers who utilize sustainable materials, such as vegetable-tanned leather or recycled components. These eco-conscious practices not only reduce the environmental footprint but also resonate with end consumers who value ethical consumption. Moreover, transparency in the supply chain is becoming a key differentiator; buyers are seeking manufacturers who can provide clear information about their sourcing practices and material origins.

Incorporating sustainable practices not only enhances brand reputation but can also lead to cost savings in the long run through reduced waste and improved efficiency. B2B buyers are encouraged to evaluate potential suppliers based on their commitment to sustainability, as this can significantly influence purchasing decisions.

What Is the Historical Context of Custom Leather Armor in the B2B Market?

The evolution of custom leather armor can be traced back to its origins in ancient civilizations, where leather was a primary material for protective gear. Historically, leather armor was favored for its flexibility, availability, and ease of customization. In medieval Europe, leather was often used alongside metal for enhanced protection, catering to the needs of warriors and soldiers.

In modern times, the resurgence of interest in medieval and fantasy themes has reignited the demand for custom leather armor. This revival has transformed the market, shifting focus from purely functional pieces to artistic expressions that cater to diverse cultural and personal narratives. Today, custom leather armor is not just a product but a canvas for creativity, allowing artisans to blend traditional craftsmanship with modern design sensibilities.

As the market continues to evolve, B2B buyers can leverage this historical context to understand consumer preferences and the importance of craftsmanship, positioning themselves strategically in a competitive landscape. The interplay of history and modernity in the custom leather armor sector presents unique opportunities for buyers to source products that are not only functional but also rich in narrative and artistry.

Illustrative image related to custom leather armor

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather armor

-

How do I ensure the quality of custom leather armor before purchasing?

To guarantee quality, request samples or photographs of previous work from potential suppliers. Look for details such as stitching, finish, and the type of leather used. Additionally, inquire about their production processes, including any quality assurance measures they have in place. Consider asking for references from other B2B buyers who have worked with the supplier to validate their craftsmanship and reliability. -

What factors should I consider when choosing a supplier for custom leather armor?

When selecting a supplier, assess their experience in the industry, customer reviews, and portfolio of past projects. Evaluate their ability to customize designs according to your specifications and check their production capabilities. It’s also crucial to confirm their compliance with international trade regulations, including any necessary certifications or quality standards required for your region. -

What customization options are available for leather armor?

Most suppliers offer extensive customization options, including design, size, color, and materials. You can request specific features like engravings, embellishments, and textures. Discuss your exact requirements with potential suppliers to understand how flexible they are with modifications. Some manufacturers may even provide a fitting service to ensure the armor meets your specifications perfectly. -

What is the minimum order quantity (MOQ) for custom leather armor?

Minimum order quantities can vary significantly among suppliers, often depending on their production capacity and the complexity of the designs. It’s common for bespoke items like custom leather armor to have a higher MOQ due to the labor-intensive processes involved. Always confirm the MOQ with the supplier before proceeding, and inquire about the possibility of smaller orders for prototyping or initial testing. -

What are the typical payment terms for international orders of custom leather armor?

Payment terms can differ widely based on the supplier and the nature of the order. Common practices include a deposit upfront (usually 30-50%) with the balance due upon completion or shipment. For larger orders, consider negotiating terms that may allow for staggered payments based on milestones. Always ensure that payment methods are secure and offer protection for both parties. -

How can I manage shipping and logistics for custom leather armor?

When sourcing internationally, discuss shipping options with your supplier to find the most cost-effective and reliable method. Verify whether they handle logistics or if you need to engage a freight forwarder. Be aware of import duties, taxes, and customs regulations in your country, as these can impact overall costs and delivery times. Establish clear timelines for production and shipping to avoid delays. -

What are the best practices for inspecting custom leather armor upon delivery?

Upon receiving your order, inspect the armor thoroughly for any defects or discrepancies with the agreed specifications. Check for issues such as stitching quality, leather finish, and sizing accuracy. Document any concerns with photographs and contact the supplier immediately to address any discrepancies. Establishing a clear return or exchange policy beforehand can help streamline this process. -

How can I ensure a successful long-term relationship with my custom leather armor supplier?

To cultivate a successful partnership, maintain open lines of communication with your supplier. Provide clear and constructive feedback on your orders and encourage them to share updates during the production process. Regularly discuss your evolving needs and explore opportunities for collaboration on future projects. Building trust and understanding will lead to a more productive and mutually beneficial relationship over time.

Top 4 Custom Leather Armor Manufacturers & Suppliers List

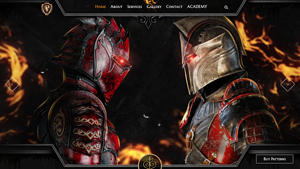

1. Prince Armory – Custom Fantasy Armor

Domain: princearmory.com

Registered: 2007 (18 years)

Introduction: Custom Fantasy Armor: Epic custom armor design and fabrication for TV, film, theater, cosplay, LARP, and serious collectors. Each piece is one of a kind and exclusive to each client, with only a handful of projects accepted each year. Armor types include medieval spin-offs and masterpiece creations. The Prince Armory Academy offers patterns and tutorials for DIY armor crafting. Testimonials highli…

2. Dark Horse Workshop – Premium Leather Armor

Domain: darkhorseworkshop.com

Registered: 2017 (8 years)

Introduction: This company, Dark Horse Workshop – Premium Leather Armor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Leather Armor – Key Considerations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Newbie interested in making leather armor for LARP. Key considerations include:

1. Time: Varies based on complexity; simple items like bracers can be made in a day, while more complex pieces may take longer, often spread out over weeks.

2. Cost: Initial costs can be higher due to purchasing tools and materials; subsequent items may be cheaper to make. Using utility grade leather can reduce costs…

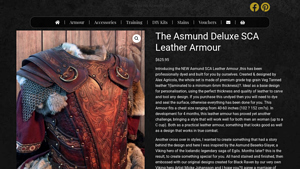

4. Black Raven Armoury – Asmund Deluxe SCA Leather Armour

Domain: blackravenarmoury.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “Asmund Deluxe SCA Leather Armour”, “material”: “Leather”, “features”: [“High-quality leather construction”, “Designed for SCA (Society for Creative Anachronism) use”, “Adjustable straps for a secure fit”, “Available in various sizes”, “Authentic medieval design”], “usage”: “Suitable for reenactments, LARP, and historical events”, “care_instructions”: “Wipe clean with a damp cloth…

Strategic Sourcing Conclusion and Outlook for custom leather armor

In navigating the intricate landscape of custom leather armor, strategic sourcing emerges as a pivotal component for B2B buyers aiming to enhance their offerings. Key takeaways highlight the importance of quality craftsmanship, customization options, and ethical sourcing practices. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers who offer a diverse range of designs and materials, ensuring that products align with local cultural aesthetics and safety requirements.

The value of strategic sourcing cannot be overstated; it not only guarantees the procurement of high-quality armor but also fosters long-term partnerships with manufacturers who understand the unique demands of the market. As demand for custom leather armor grows in sectors such as entertainment, reenactments, and cosplay, buyers are encouraged to leverage this opportunity to innovate and diversify their product lines.

Looking ahead, the future of custom leather armor appears promising. By investing in reliable suppliers and maintaining a focus on sustainability and craftsmanship, businesses can position themselves as leaders in this niche market. Engage with reputable manufacturers today to unlock the potential of bespoke leather armor tailored to your specific needs.

Illustrative image related to custom leather armor

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.