Introduction: Navigating the Global Market for best leather for belts

In the dynamic world of fashion and accessories, sourcing the best leather for belts presents a unique challenge for B2B buyers across the globe. The quality of leather not only influences the durability and aesthetics of belts but also impacts brand reputation and customer satisfaction. This comprehensive guide delves into the various types of leather available, their specific applications, and critical factors for vetting suppliers, enabling international buyers—especially those from Africa, South America, the Middle East, and Europe, including countries like Germany and Brazil—to make well-informed purchasing decisions.

Understanding the nuances of leather grades, cuts, and thickness is essential for selecting materials that align with market demands and consumer preferences. From full-grain leather to the lesser-known bonded variants, each type offers distinct characteristics that can affect the final product’s performance and appeal. This guide equips buyers with actionable insights into cost considerations, supplier credibility, and market trends, allowing them to navigate the complexities of leather sourcing confidently. By leveraging this knowledge, businesses can enhance their product offerings, ensuring they meet the diverse needs of their clientele while maintaining high standards of quality and sustainability.

Table Of Contents

- Top 5 Best Leather For Belts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best leather for belts

- Understanding best leather for belts Types and Variations

- Key Industrial Applications of best leather for belts

- 3 Common User Pain Points for ‘best leather for belts’ & Their Solutions

- Strategic Material Selection Guide for best leather for belts

- In-depth Look: Manufacturing Processes and Quality Assurance for best leather for belts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best leather for belts’

- Comprehensive Cost and Pricing Analysis for best leather for belts Sourcing

- Alternatives Analysis: Comparing best leather for belts With Other Solutions

- Essential Technical Properties and Trade Terminology for best leather for belts

- Navigating Market Dynamics and Sourcing Trends in the best leather for belts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best leather for belts

- Strategic Sourcing Conclusion and Outlook for best leather for belts

- Important Disclaimer & Terms of Use

Understanding best leather for belts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains natural grain and imperfections; highly durable | High-end belts, luxury leather goods | Pros: Excellent durability, develops unique patina. Cons: Higher cost, requires more care. |

| Top Grain Leather | Sanded surface for uniformity; strong and flexible | Mid to high-end belts, fashion accessories | Pros: Good durability, easier to maintain. Cons: Less character than full grain. |

| Corrected Grain Leather | Embossed for uniform appearance; versatile | Fashion belts, casual accessories | Pros: Cost-effective, good durability. Cons: Takes longer to develop patina, less natural look. |

| Split Grain Leather | Thinner, weaker leather; fuzzy texture | Low-cost belts, non-durable goods | Pros: Inexpensive. Cons: Not durable, prone to wear. |

| Bonded Leather | Made from leather scraps; synthetic bonding agent | Budget belts, promotional items | Pros: Low cost. Cons: Very low durability, not true leather. |

What Are the Characteristics of Full Grain Leather for Belts?

Full grain leather is regarded as the highest quality leather for belts due to its natural finish, which retains the original grain and imperfections of the hide. This type of leather is exceptionally durable and develops a rich patina over time, making it highly desirable for luxury products. B2B buyers should consider full grain leather for high-end belt lines, as its unique characteristics can justify a premium price point and attract discerning consumers looking for quality.

How Does Top Grain Leather Differ from Other Types?

Top grain leather is the second highest quality and is known for its smooth, uniform surface due to the sanding process. While it lacks some of the character of full grain leather, it offers excellent durability and is more affordable. This makes it suitable for mid to high-end belts and fashion accessories. B2B buyers should evaluate their target market; top grain leather strikes a balance between quality and cost, appealing to a broader audience.

Why Choose Corrected Grain Leather for Fashion Belts?

Corrected grain leather undergoes an embossing process to create a uniform appearance, making it versatile for various applications, including fashion belts. It is a good option for companies looking to produce stylish products at a lower price point. While it can be durable, B2B buyers should note that corrected grain leather may take longer to develop a desirable patina compared to full grain leather. This can influence customer perceptions of quality over time.

What Are the Limitations of Split Grain Leather?

Split grain leather, derived from the inner layers of the hide, is generally thinner and less durable than higher-grade leathers. Its fuzzy texture can make it less appealing for belts, as it tends to wear out more quickly. B2B buyers should be cautious when considering split grain leather for belts, as it is best suited for low-cost items or non-durable goods. This type of leather may be suitable for budget-friendly promotional items but is unlikely to satisfy quality-conscious consumers.

Is Bonded Leather a Viable Option for Belt Production?

Bonded leather is made from leather scraps that are bonded together with synthetic materials, resulting in a product that lacks the durability of genuine leather. While its low cost may be appealing for budget-conscious buyers, the quality is significantly compromised, making it unsuitable for long-lasting products. B2B buyers should consider the implications of using bonded leather, as it may damage brand reputation if customers associate it with low quality.

Key Industrial Applications of best leather for belts

| Industry/Sector | Specific Application of Best Leather for Belts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | High-end fashion belts for luxury brands | Enhances brand image and customer loyalty through quality | Sourcing full-grain leather from reputable tanneries; ensuring consistent thickness and color. |

| Industrial Workwear | Durable belts for uniforms | Provides longevity and functionality in demanding environments | Focus on top-grain leather for durability; consider weather-resistant treatments. |

| E-commerce | Customizable leather belts for online sales | Increases customer engagement and personalization options | Ensure flexibility in sourcing various leather types for customization; maintain stock for quick fulfillment. |

| Agricultural Equipment | Utility belts for farming and ranching | Offers strength and reliability for heavy-duty use | Prioritize double butt cuts for resilience; check for local sourcing to reduce lead times. |

| Automotive Accessories | Leather belts for car interiors | Adds luxury and comfort, enhancing vehicle aesthetics | Source high-quality leather that complements automotive design; consider color matching and finishing options. |

How is Best Leather for Belts Utilized in the Fashion Retail Sector?

In the fashion retail industry, high-end belts crafted from the best leather, particularly full-grain leather, are essential for luxury brands. These belts not only serve a functional purpose but also enhance the brand’s image and appeal to discerning customers. Buyers in this sector must prioritize sourcing from reputable tanneries that guarantee consistent quality, thickness, and color to maintain product integrity. The ability to offer unique leather textures and finishes can significantly impact consumer loyalty and brand differentiation.

What Role Does Best Leather for Belts Play in Industrial Workwear?

In the industrial workwear sector, durable belts made from top-grain leather are critical for uniforms used in demanding environments. These belts must withstand wear and tear while providing functional support for tools and equipment. For B2B buyers, sourcing leather that combines durability with comfort is essential. Additionally, considering weather-resistant treatments can enhance the longevity of these belts, making them a practical investment for companies looking to outfit their workforce with reliable and sturdy gear.

How Can E-Commerce Benefit from Customizable Leather Belts?

E-commerce businesses are increasingly tapping into the trend of customizable leather belts to engage customers. By offering options for personalization, such as different leather types and finishes, businesses can enhance customer satisfaction and drive sales. It’s crucial for buyers to ensure flexibility in sourcing various leather types to meet diverse consumer preferences. Maintaining a sufficient stock of materials for quick fulfillment can further strengthen customer relationships and boost repeat business.

Why Are Utility Belts Important in Agricultural Equipment?

In the agricultural equipment industry, utility belts made from the best leather are vital for farmers and ranchers who require reliable gear for daily tasks. The strength and resilience of double butt cuts make them ideal for heavy-duty applications. B2B buyers in this sector should focus on sourcing high-quality leather that can withstand the rigors of outdoor use. Local sourcing options may also reduce lead times, ensuring that equipment is readily available for urgent needs.

How Do Automotive Accessories Utilize Best Leather for Belts?

In the automotive accessories market, leather belts are often used in car interiors to enhance luxury and comfort. High-quality leather can significantly elevate the aesthetic appeal of vehicles, making it a valuable component for manufacturers. Buyers must consider sourcing leather that not only meets durability standards but also complements the design and color schemes of automotive interiors. Customization options, such as stitching and finishing, can further enhance the appeal of these products in a competitive market.

Illustrative image related to best leather for belts

3 Common User Pain Points for ‘best leather for belts’ & Their Solutions

Scenario 1: Difficulty in Identifying Quality Leather for Belts

The Problem: B2B buyers often struggle to distinguish between various grades of leather, particularly when it comes to sourcing materials for high-quality belts. With many suppliers offering misleading labels, such as “genuine leather,” it can be challenging to ensure that the leather will meet customer expectations for durability and appearance. This confusion can lead to purchasing inferior materials that compromise the final product’s quality and brand reputation.

The Solution: To effectively source the best leather for belts, buyers should prioritize partnerships with reputable tanneries that provide transparency regarding their materials. When selecting leather, focus on full-grain and top-grain options, as these are the highest quality and most durable choices. Request samples to evaluate texture, thickness, and overall quality before placing bulk orders. Additionally, consider establishing a checklist for assessing leather quality, which includes verifying the leather’s grade, cut, and thickness specifications (ideally between 8.5 and 9.5 ounces for belts). By doing this, buyers can ensure they are investing in leather that will meet both their standards and those of their customers.

Scenario 2: Inconsistent Leather Sizing and Cuts

The Problem: Another common issue faced by B2B buyers is the inconsistency in leather sizing and cuts from different suppliers. Variations in leather thickness and shape can lead to waste during production and affect the overall fit and finish of the belts. This inconsistency not only increases production costs but can also result in delays and unsatisfactory final products.

The Solution: To mitigate these challenges, buyers should establish clear specifications regarding leather cuts and thickness when communicating with suppliers. Opt for leather sourced from double butt cuts, which provide the most consistent thickness and least waste. Additionally, negotiate terms that allow for quality assurance checks before shipping, ensuring that the delivered leather meets the agreed-upon standards. Implementing a standardized protocol for measuring and testing the leather upon receipt can also help identify any discrepancies early in the process, allowing for quick resolutions and minimizing disruptions in production.

Scenario 3: Balancing Cost and Quality in Leather Procurement

The Problem: B2B buyers frequently face the dilemma of balancing cost with quality when purchasing leather for belts. While it may be tempting to opt for lower-priced options, this often leads to the procurement of subpar materials that do not hold up over time, resulting in higher return rates and dissatisfied customers. Buyers need to find a way to secure high-quality leather without exceeding their budget constraints.

The Solution: To navigate the cost-quality balance effectively, buyers should adopt a strategic sourcing approach. Start by conducting a thorough market analysis to identify suppliers who offer competitive pricing for premium leather. Consider forming long-term partnerships with tanneries that can provide consistent quality at favorable rates. Additionally, explore options for bulk purchasing or establishing contracts that lock in prices for extended periods, which can help manage costs. Educate your sales team on the value of investing in quality materials, emphasizing how this can enhance the brand’s reputation and lead to increased customer loyalty. By taking a proactive approach to sourcing, buyers can ensure they are making informed decisions that align with both quality and budgetary constraints.

Strategic Material Selection Guide for best leather for belts

What Are the Key Properties of Full-Grain Leather for Belts?

Full-grain leather is considered the gold standard for belt manufacturing due to its superior strength and durability. Sourced from the uppermost layer of the hide, it retains the natural grain and imperfections, which contribute to its unique character. Full-grain leather is resistant to wear and develops a beautiful patina over time, enhancing its aesthetic appeal. Its thickness typically ranges from 8.5 to 9.5 ounces, making it robust enough to withstand daily use while remaining supple.

Pros & Cons: The primary advantage of full-grain leather is its longevity; it can last for years with proper care. However, it is more expensive than other grades, which may deter budget-conscious buyers. The manufacturing process is also more complex due to the need for careful handling to preserve its natural qualities.

Impact on Application: Full-grain leather belts are well-suited for various climates, maintaining their integrity in both hot and humid conditions. This makes them ideal for international markets, particularly in Africa and South America, where such climates are prevalent.

How Does Top-Grain Leather Compare to Full-Grain for Belt Production?

Top-grain leather, while slightly less durable than full-grain, still offers excellent quality and performance. It is made from the second layer of the hide and is often sanded and treated to remove imperfections, resulting in a more uniform appearance. This type of leather is also quite flexible, making it comfortable for daily wear.

Pros & Cons: The main advantage of top-grain leather is its affordability compared to full-grain, making it a popular choice for mid-range products. However, it may not develop the same rich patina over time, which can be a drawback for consumers seeking long-lasting beauty.

Impact on Application: Top-grain leather belts are suitable for various uses, including casual and formal settings. Buyers in Europe, particularly in Germany, may prefer this leather for its balance of quality and cost-effectiveness.

What Are the Limitations of Split Grain Leather for Belt Manufacturing?

Split grain leather is derived from the lower layers of the hide and lacks the durability and strength of full and top-grain leathers. It is often used in lower-quality products and is characterized by a softer, fuzzier texture.

Pros & Cons: While split grain leather is cheaper to produce, its limitations in strength and longevity make it unsuitable for high-quality belts. It can stretch and deform over time, leading to a poor fit and appearance.

Impact on Application: Given its lower durability, split grain leather is not recommended for belts intended for regular use. International buyers should be cautious of products labeled as “genuine leather,” which often refer to split grain and may not meet quality expectations.

Why Is Bonded Leather Considered Unsuitable for Belt Production?

Bonded leather is a composite material made from leather scraps that are bonded together with adhesives. While it may appear similar to genuine leather, its durability is significantly compromised.

Illustrative image related to best leather for belts

Pros & Cons: The primary advantage of bonded leather is its low cost, making it accessible for mass production. However, its susceptibility to cracking and splitting under regular use renders it unsuitable for quality belts.

Impact on Application: Buyers should be aware that bonded leather products have a short lifespan, often lasting only a few months. This is particularly relevant for markets in the Middle East and Africa, where consumers may prioritize durability and quality over price.

Summary Table of Leather Types for Belt Manufacturing

| Material | Typical Use Case for best leather for belts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Premium belts for everyday wear | Exceptional durability and patina | Higher cost compared to other types | High |

| Top-Grain Leather | Mid-range casual and formal belts | Good balance of quality and price | Less character than full-grain | Medium |

| Split Grain Leather | Low-quality belts or budget products | Lower manufacturing cost | Poor durability and fit | Low |

| Bonded Leather | Mass-produced, low-cost belts | Very affordable | Short lifespan, prone to damage | Low |

This strategic material selection guide provides essential insights for international B2B buyers looking to source high-quality leather for belt production, highlighting the importance of material choice in meeting market demands and consumer expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for best leather for belts

What Are the Key Stages in the Manufacturing Process of Quality Leather Belts?

The manufacturing of high-quality leather belts involves several stages, each critical to ensuring the final product meets both aesthetic and functional standards. Understanding these stages helps B2B buyers evaluate potential suppliers effectively.

1. Material Preparation: How Are Leather Hides Selected and Treated?

The journey of a leather belt begins with the selection of the right hides. High-quality leather for belts is typically derived from full-grain or top-grain cuts, specifically from double butt sections, which provide the necessary thickness and durability.

Once selected, the hides undergo a tanning process, which can be either vegetable-based or chrome-based. Vegetable tanning is preferred for its eco-friendliness and the unique patina it develops over time. After tanning, the leather is conditioned to enhance its suppleness and prevent cracking.

Buyers should ensure that suppliers provide documentation on the sourcing and tanning methods used, as this impacts both quality and sustainability.

2. Forming: What Techniques Are Used to Shape Leather Into Belts?

The forming stage involves cutting the leather into the desired shapes and sizes for belts. Precision cutting techniques, often using die-cutting machines, ensure that each piece meets the specifications required for assembly.

At this stage, manufacturers may also incorporate design features such as stitching patterns or embossed logos. Advanced technologies, like laser cutting, may be used for intricate designs, providing an edge in customization.

B2B buyers should inquire about the technology and techniques used in the forming stage to assess the potential for customization and design versatility.

3. Assembly: How Are Leather Belts Constructed?

Assembly involves stitching and securing the various components of the belt together. This step typically uses high-strength nylon or polyester threads to ensure durability.

Quality control during assembly is crucial. Skilled artisans often inspect each belt for alignment and secure stitching before proceeding to the finishing stage. Automated stitching machines may also be employed for consistency.

Illustrative image related to best leather for belts

Buyers should request information on the assembly techniques and the experience of artisans involved, as these factors significantly influence the final product’s quality.

4. Finishing: What Processes Are Used to Achieve the Final Look?

Finishing is the last stage in the manufacturing process, where belts are polished, dyed, and treated with protective coatings. This stage enhances the aesthetic appeal and durability of the belts.

Common finishing techniques include edge burnishing, which seals the edges to prevent fraying, and applying waxes or oils for added luster and protection. Some manufacturers also offer customization options like color matching and unique textures.

Illustrative image related to best leather for belts

B2B buyers should seek details on the finishing processes to ensure that the final product aligns with their brand standards and customer expectations.

What Quality Control Measures Are Essential for Leather Belt Manufacturing?

Quality assurance is paramount in leather belt production. International and industry-specific standards guide manufacturers in maintaining high-quality outputs.

1. What International Standards Should Leather Belt Manufacturers Adhere To?

ISO 9001 is a widely recognized international standard that outlines criteria for a quality management system. Manufacturers adhering to this standard demonstrate their commitment to consistent quality and customer satisfaction.

In addition, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, especially for belts intended for specific industrial uses. Buyers should prioritize suppliers who can provide these certifications as part of their quality assurance process.

2. What Are the Key Quality Control Checkpoints in Leather Belt Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process. The following are essential stages:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before processing. Leather hides are inspected for defects, thickness, and consistency.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks ensure that the processes meet quality standards. This may involve monitoring stitching consistency, alignment, and cutting precision.

-

Final Quality Control (FQC): After assembly, a thorough inspection of the finished belts occurs. This includes checking for defects, confirming that specifications are met, and assessing overall appearance.

B2B buyers should ensure that potential suppliers have documented procedures for these quality control stages.

3. What Common Testing Methods Are Used to Ensure Leather Belt Quality?

Various testing methods are employed to validate the quality of leather belts:

-

Physical Testing: This includes tensile strength tests to measure how much force the leather can withstand before breaking.

-

Durability Testing: Abrasion resistance tests evaluate how well the leather holds up against wear and tear.

-

Environmental Testing: Tests for water resistance, UV exposure, and temperature variations help assess how the belts will perform in different conditions.

Buyers can request test reports and certifications from manufacturers to verify the quality of their products.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for maintaining standards in your own product offerings. Here are actionable steps for buyers:

-

Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should consider conducting both announced and unannounced audits.

-

Quality Reports: Request detailed quality reports that outline the results of IQC, IPQC, and FQC inspections. This documentation should also include records of any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engage third-party inspection services to conduct independent evaluations of the supplier’s facilities and processes. This can provide an unbiased view of the supplier’s quality assurance capabilities.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of several nuances:

-

Regulatory Compliance: Understand the specific regulatory requirements in your region regarding leather products. Different markets may have unique standards for safety and environmental impact.

-

Cultural Expectations: Quality perceptions can vary by region. Be aware of local preferences and standards to ensure that the leather belts meet the expectations of your target market.

-

Logistics and Shipping: Quality control should also extend to logistics. Ensure that suppliers have robust processes to handle transportation and storage, minimizing the risk of damage during transit.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for leather belts will empower B2B buyers to make informed decisions. By focusing on quality standards, inspection processes, and supplier verification, you can ensure that the leather products you source meet the highest standards of excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best leather for belts’

Introduction

Sourcing the best leather for belts is a critical process for B2B buyers aiming to deliver high-quality products to their customers. This guide provides a structured checklist to help you navigate the complexities of leather procurement, ensuring that you select materials that meet your standards for durability, aesthetics, and ethical sourcing.

Illustrative image related to best leather for belts

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to outline your specific requirements for leather quality, thickness, and cut. Determine whether you need full-grain or top-grain leather, as these options are known for their durability and premium finish. Consider the intended use of the belts—will they be fashion-forward or functional?

- Quality: Full-grain leather is ideal for luxury belts, while top-grain leather offers a balance of quality and cost.

- Thickness: Aim for a thickness of 8.5 to 9.5 ounces for optimal durability.

Step 2: Research Leather Grades and Cuts

Understanding the different grades and cuts of leather is crucial in making informed purchasing decisions. Familiarize yourself with terms like full-grain, corrected-grain, and double butt cuts to ensure that you select materials that align with your product goals.

- Full-Grain Leather: Known for its strength and natural beauty, it develops a unique patina over time.

- Double Butt Cut: This cut yields the most consistent and durable leather, making it an excellent choice for belts.

Step 3: Evaluate Potential Suppliers

Once you have your specifications, it’s time to assess potential suppliers. Look for companies with a proven track record in leather production and positive reviews from other B2B buyers.

- References and Case Studies: Request testimonials or case studies from other businesses that have sourced leather from them.

- Certifications: Verify any quality certifications, such as ISO or Leather Working Group certifications, to ensure ethical and sustainable practices.

Step 4: Request Samples for Quality Assessment

Before finalizing an order, request samples of the leather you are considering. This will allow you to evaluate the texture, grain, and overall quality firsthand.

- Texture and Finish: Ensure the leather has a smooth finish and meets your aesthetic requirements.

- Durability Tests: Assess the leather’s resistance to wear and tear, and check for any signs of flaws or defects.

Step 5: Negotiate Pricing and Terms

Once you are satisfied with the quality of the leather samples, begin negotiations with the supplier. Ensure that the pricing aligns with your budget while considering the quality of the material.

Illustrative image related to best leather for belts

- Volume Discounts: Inquire about discounts for bulk purchases, which can significantly reduce your overall costs.

- Payment Terms: Clarify payment conditions, lead times, and return policies to avoid any future misunderstandings.

Step 6: Confirm Logistics and Delivery Schedules

Effective logistics management is essential in the procurement process. Confirm the delivery timelines and shipping methods to ensure that your production schedules are not disrupted.

- Shipping Methods: Choose a shipping method that balances cost and speed, especially if you need the leather urgently.

- Customs and Duties: Be aware of any import duties or regulations that may apply to your shipments, particularly if you are sourcing internationally.

Step 7: Establish a Long-Term Relationship with Your Supplier

Building a long-term relationship with your leather supplier can lead to better pricing, priority access to new materials, and improved service.

- Regular Communication: Keep an open line of communication to discuss any issues or updates in your requirements.

- Feedback Loop: Provide feedback on the quality of the leather and service to foster a mutually beneficial partnership.

By following this checklist, you will be well-equipped to source the best leather for belts, ultimately enhancing the quality and appeal of your product offerings.

Comprehensive Cost and Pricing Analysis for best leather for belts Sourcing

What Are the Key Cost Components in Sourcing Leather for Belts?

When sourcing leather for belts, understanding the cost structure is crucial for B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of leather significantly influences the cost. Full-grain leather, recognized for its durability and aesthetic appeal, typically commands a higher price compared to lower grades like genuine or bonded leather. Expect costs to vary from $4 to $10 per square foot for high-quality leather.

-

Labor: Skilled craftsmanship is essential in leather belt production. Labor costs can vary based on the region and the complexity of the design. In countries with higher wage standards, such as Germany, labor costs may constitute a larger percentage of the total expenses, while in regions like South America or Africa, these costs could be lower.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient production processes can help minimize overhead costs, making it vital for suppliers to optimize their operations.

-

Tooling: The initial setup for tooling can be expensive but is amortized over the production runs. Custom designs or specialized cuts will require additional investment in tooling.

-

Quality Control: Implementing stringent QC processes ensures that the leather meets specified standards, which can add to costs. However, the investment in QC is crucial to reduce returns and maintain brand reputation.

-

Logistics: Shipping costs are influenced by the weight and volume of the leather and the distance to the destination. Using Incoterms like FOB (Free on Board) can affect who bears the shipping costs, thus influencing the overall pricing structure.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit expectations. This margin can vary widely based on market demand and competition.

What Influences the Pricing of Leather for Belts?

Several factors impact the final price of leather belts in the B2B market:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it beneficial for buyers to negotiate favorable terms based on their anticipated needs.

-

Specifications and Customization: Custom designs or specific leather treatments can raise costs. Buyers should be clear about their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Leather sourced from certified tanneries or with specific eco-friendly certifications may come at a premium. Buyers should consider the value of these certifications in relation to their target market.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record and quality assurance processes.

-

Incoterms: Understanding Incoterms is essential for international transactions. Different terms affect shipping responsibilities and costs, which can impact overall pricing.

What Are the Best Negotiation Tips for B2B Buyers Sourcing Leather for Belts?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings.

-

Research and Benchmarking: Before negotiations, conduct thorough market research to understand standard pricing and cost structures. This knowledge will empower you to negotiate effectively.

-

Focus on Total Cost of Ownership (TCO): Consider not just the upfront cost but the long-term value and durability of the leather. A higher initial investment in full-grain leather may lead to lower replacement costs over time.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better terms and pricing. Long-term partnerships often result in loyalty discounts and priority service.

-

Be Open to Compromise: Flexibility in order quantities or specifications can lead to better pricing. Suppliers may be willing to negotiate on costs if you can accommodate their production needs.

-

Leverage Incoterms: Utilize favorable Incoterms to negotiate shipping costs and responsibilities, which can further optimize your pricing strategy.

Disclaimer on Pricing

Prices for leather can fluctuate based on market conditions, availability, and sourcing regions. The figures provided are indicative and may vary depending on specific circumstances and supplier negotiations. Buyers are encouraged to conduct their due diligence and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing best leather for belts With Other Solutions

Exploring Alternatives to Best Leather for Belts

When selecting materials for belts, high-quality leather often stands out as the prime choice. However, various alternatives can also meet the needs of different markets and applications. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and specific use cases.

| Comparison Aspect | Best Leather For Belts | Synthetic Leather | Fabric Belts |

|---|---|---|---|

| Performance | Highly durable, develops a unique patina over time | Good durability but may not match leather in longevity | Moderate durability; may wear out quickly |

| Cost | Higher upfront investment, but long-lasting | Generally more affordable | Low-cost, but less durable |

| Ease of Implementation | Requires skilled craftsmanship | Easier to work with, can be mass-produced | Simple to manufacture, no special skills required |

| Maintenance | Requires occasional conditioning | Low maintenance; easy to clean | Typically machine washable |

| Best Use Case | Premium products, luxury markets | Affordable alternatives for fashion items | Casual wear, promotional items |

What Are the Pros and Cons of Synthetic Leather?

Synthetic leather, often made from polyurethane or PVC, offers a viable alternative to traditional leather. Its primary advantage is cost-effectiveness; it is generally cheaper than high-quality leather, making it accessible for budget-conscious buyers. Additionally, synthetic leather is easier to clean and maintain, requiring no conditioning. However, it lacks the durability and unique aesthetic of natural leather, often showing signs of wear more quickly. This material may be suitable for fashion items that do not require long-term use but may not meet the quality expectations in luxury markets.

How Do Fabric Belts Compare to Leather Belts?

Fabric belts are another alternative that appeals to a different segment of the market. They are often lightweight, versatile, and come in various colors and designs, making them ideal for casual wear. Their low cost is a significant advantage, allowing businesses to purchase in bulk without heavy investment. However, fabric belts typically lack the durability and strength of leather, which can lead to faster wear and tear. They are best suited for promotional items or informal settings where style is prioritized over longevity.

Illustrative image related to best leather for belts

Conclusion: How to Choose the Right Belt Material for Your Needs?

When selecting between the best leather for belts and its alternatives, B2B buyers should consider their target market and product positioning. For luxury or high-end products, investing in high-quality leather is advisable due to its durability and unique character. Conversely, if the focus is on cost-efficiency and mass production, synthetic leather or fabric belts may serve well, especially in casual or promotional contexts. Ultimately, understanding the specific needs and expectations of your customers will guide you in making the right choice for your belt offerings.

Essential Technical Properties and Trade Terminology for best leather for belts

What Are the Key Technical Properties of Leather for Belts?

When sourcing leather for belts, understanding critical technical properties is essential to ensure durability, aesthetics, and overall quality. Here are some key specifications to consider:

1. Material Grade: How Does It Impact Quality?

Leather is classified into different grades, with full-grain and top-grain being the highest quality options for belts. Full-grain leather retains the hide’s natural texture and imperfections, resulting in unique, durable products that develop a patina over time. Top-grain leather, while slightly less robust, offers a more uniform appearance and is still highly durable. Selecting the right grade is vital as it affects the belt’s lifespan and customer satisfaction.

Illustrative image related to best leather for belts

2. Leather Thickness: What Is the Ideal Measurement?

The thickness of leather used for belts typically ranges from 8.5 to 9.5 ounces. A thicker leather provides added durability and resistance to wear and tear, making it suitable for daily use. Conversely, a belt that is too thin may lack longevity and structural integrity. Buyers should prioritize thickness specifications when selecting leather to ensure the final product meets market demands.

3. Cut of Hide: Why Is It Important?

The cut of the leather hide plays a crucial role in the belt’s quality. The double butt cut is preferred for its uniform thickness and strength, yielding minimal waste. In contrast, side and belly cuts may introduce inconsistencies and are generally not recommended for belt-making. Understanding the implications of different cuts allows buyers to make informed decisions that optimize material usage and product quality.

4. Tolerance: How Does It Affect Production?

Tolerance refers to the allowable variation in dimensions and characteristics during the manufacturing process. In leather production, maintaining strict tolerances ensures that each belt meets quality standards and fits the intended specifications. High tolerance levels can minimize defects and improve customer satisfaction, making it a critical consideration for B2B buyers.

5. Grain Pattern: What Does It Convey About Quality?

The grain pattern of leather influences both its aesthetic appeal and performance. Full-grain leather showcases natural markings and variations, which contribute to a unique character. This natural beauty is often a selling point for premium products. Buyers should consider grain patterns as they can impact the perceived value and marketability of the final belt products.

What Common Trade Terms Should B2B Buyers Know?

Navigating the leather belt industry requires familiarity with specific jargon and trade terms. Here are some essential terms that can aid in effective communication and negotiation:

1. OEM (Original Equipment Manufacturer)

An OEM produces products that are marketed under another company’s brand. For leather belts, working with OEMs can streamline the production process, allowing buyers to focus on branding and sales while ensuring quality manufacturing.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for B2B buyers as it impacts inventory management and initial investment costs. Buyers must balance the desire for bulk pricing with their inventory needs.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products. This is an essential tool for B2B buyers to compare offerings and negotiate better deals based on detailed specifications.

Illustrative image related to best leather for belts

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risks, and delivery obligations.

5. Tannery Certification

This refers to the recognition that a tannery meets specific environmental and quality standards. Buyers should seek suppliers with certified tanneries to ensure ethical sourcing and high-quality leather that aligns with market expectations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing leather for belts, ensuring they select high-quality materials that meet their business needs.

Navigating Market Dynamics and Sourcing Trends in the best leather for belts Sector

What Are the Key Drivers Shaping the Leather Belt Market?

The global leather belt market is currently witnessing significant growth, driven by rising consumer demand for durable and fashionable accessories. Key trends include the increasing preference for premium materials, particularly full-grain and top-grain leather, which are recognized for their durability and aesthetic appeal. As international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, navigate this landscape, they should consider the implications of shifting consumer preferences towards sustainable and ethically sourced products.

Technological advancements in tanning and manufacturing processes are also influencing sourcing strategies. The integration of digital platforms for supply chain management is allowing buyers to source high-quality leather with greater transparency and efficiency. Furthermore, the rise of e-commerce is reshaping distribution channels, enabling buyers to access a broader range of suppliers globally. In Europe, particularly in markets like Germany, there is a growing demand for customizable leather products, pushing suppliers to innovate and offer tailored solutions.

How Is Sustainability Influencing Leather Sourcing Decisions?

Sustainability is becoming a cornerstone in the leather industry, impacting sourcing decisions significantly. The environmental footprint of leather production is under scrutiny, leading to a demand for eco-friendly practices. B2B buyers are increasingly prioritizing suppliers who utilize vegetable tanning methods, which are less harmful than traditional chrome tanning processes. This shift not only meets consumer demand for sustainable products but also aligns with regulatory pressures in various regions.

Ethical sourcing is equally crucial, with buyers looking for transparency in supply chains. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for establishing credibility and trust. These certifications indicate that the leather has been sourced responsibly, minimizing environmental impact and ensuring fair labor practices. Buyers focusing on these aspects can differentiate their offerings in competitive markets, appealing to a growing base of environmentally conscious consumers.

What Historical Context Is Relevant for Today’s Leather Market?

The history of leather production dates back thousands of years, evolving from a necessity for survival to a symbol of luxury and craftsmanship. Historically, leather was primarily sourced from animals for functional purposes. However, as societal values shifted, the leather industry began to emphasize quality and aesthetics, leading to the development of various tanning techniques.

In the modern context, the leather industry faces challenges related to environmental sustainability and ethical sourcing, prompting a reevaluation of traditional practices. Today’s buyers must navigate this historical landscape while aligning with contemporary values of sustainability and ethical responsibility. Understanding this evolution can empower B2B buyers to make informed decisions that resonate with both their business objectives and consumer expectations.

In summary, as international B2B buyers engage with the leather belt market, they should remain attuned to key market drivers, the importance of sustainable practices, and the historical context that shapes current sourcing trends. By doing so, they can position themselves strategically to capitalize on emerging opportunities in this evolving industry.

Frequently Asked Questions (FAQs) for B2B Buyers of best leather for belts

-

How do I choose the best leather for belts?

When selecting leather for belts, prioritize full-grain and top-grain leather, as these grades offer superior durability and aesthetic appeal. Full-grain leather, sourced from the upper layer of the hide, showcases natural imperfections and develops a rich patina over time, making each belt unique. Consider the leather’s thickness; a range of 8.5 to 9.5 ounces is ideal for sturdiness without sacrificing comfort. Additionally, the cut of the leather matters; the double butt cut is preferred for its consistent thickness and strength, ensuring a high-quality end product. -

What are the different grades of leather suitable for belts?

The primary grades of leather used for belts include full-grain, top-grain, corrected-grain, and split grain. Full-grain leather is the highest quality, showcasing the hide’s natural texture and durability. Top-grain leather, slightly less durable, is often corrected for a uniform appearance. Corrected-grain leather can also be suitable for belts if full-grain is not available. Avoid split grain and bonded leather, as these are lower quality and lack the longevity needed for reliable belt products. -

What are the minimum order quantities (MOQ) for sourcing leather belts?

Minimum order quantities can vary significantly based on the supplier and the type of leather. Typically, for high-quality leather products, MOQs might range from 50 to 500 units. It’s essential to discuss MOQs with potential suppliers early in negotiations to ensure they align with your business needs. If you require customization, be aware that MOQs may increase, reflecting the additional labor and resources involved in producing bespoke items. -

How can I vet suppliers for leather belts?

To effectively vet suppliers, start by researching their reputation within the industry. Look for reviews, testimonials, and case studies that highlight their reliability and product quality. Request samples of their leather and finished belts to assess quality firsthand. Additionally, verify certifications related to leather sourcing and manufacturing processes, such as environmental compliance and ethical labor practices. Establishing communication and visiting their facilities, if possible, can also provide insight into their operations and commitment to quality. -

What customization options are available for leather belts?

Customization options for leather belts can include variations in leather grade, color, buckle styles, and additional features such as embossing or stitching patterns. Many suppliers offer the ability to create bespoke sizes and designs to meet specific market demands. Discuss your requirements early in the process to understand the capabilities and limitations of your supplier. Customization may impact lead times and costs, so it’s crucial to factor these into your planning. -

What payment terms should I expect when sourcing leather belts internationally?

Payment terms can vary widely among suppliers, but common practices include upfront deposits ranging from 30% to 50% of the total order value, with the balance due upon completion or delivery. Some suppliers may offer flexible payment methods such as letters of credit, PayPal, or bank transfers, especially for international transactions. It’s advisable to negotiate terms that provide security for both parties and clarify any penalties for late payments to avoid misunderstandings. -

How can I ensure quality assurance for leather belts?

Implementing a quality assurance process begins with setting clear specifications for materials and finished products. Work with suppliers who have established quality control measures, such as inspections at various production stages. Consider third-party quality audits to verify compliance with your standards. Additionally, request samples before full production to evaluate the leather’s quality and craftsmanship. Establishing a feedback loop with your supplier can also help address any quality concerns promptly. -

What logistics considerations should I keep in mind when importing leather belts?

When importing leather belts, consider the complexities of shipping, customs regulations, and potential tariffs. Work with a logistics provider experienced in international trade to navigate these challenges effectively. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate smooth customs clearance. Also, factor in lead times for production and shipping, as delays can impact your inventory management and market responsiveness. Regular communication with your supplier about shipping schedules can help mitigate risks.

Top 5 Best Leather For Belts Manufacturers & Suppliers List

1. Obscure Belts – High Quality Full Grain Leather Belts

Domain: obscurebelts.com

Registered: 2005 (20 years)

Introduction: High quality leather belts are made using full grain leather from a double butt cut hide in 8.5 – 9.5 ounce thickness. The main types of leather used in belt making include: 1. Full-grain leather – known for its durability, style, eco-friendly qualities, and natural variation. 2. Corrected grain leather – a type of top grain leather that is sanded and embossed, offering a uniform appearance. 3. Sp…

2. Leather Belts Online – Types of Leather

Domain: leatherbeltsonline.com

Registered: 2015 (10 years)

Introduction: Types of Leather for Belts: 1. Full-Grain Leather: Pros – Durability, Strength, Natural beauty; Cons – Cost. 2. Top-Grain Leather: Pros – Affordability, Versatility; Cons – Less durability. 3. Bonded Leather: Pros – Cost-effectiveness; Cons – Less durability, Less natural look. 4. Genuine Leather: Pros – Affordability; Cons – Quality can vary. 5. Vegetable-Tanned Leather: Pros – Environmentally fr…

3. Facebook – Veg Tan Belts

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Veg Tan Belts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

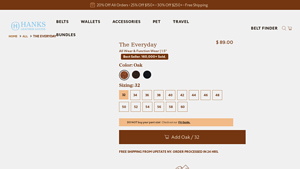

4. Hank’s Belts – The Everyday Work Belt

Domain: hanksbelts.com

Registered: 2015 (10 years)

Introduction: Product Name: The Everyday Work Belt

Price: $89.00

Discounts: 20% Off All Orders, 25% Off $150+, 30% Off $250+

Shipping: Free Shipping from Upstate NY

Width: 1.5 inches

Material: Full-Grain Leather, 13 oz steer hide

Warranty: 100 Years

Country of Manufacture: USA

Features: Rugged durability, handcrafted, solid construction, interchangeable buckle, matte black powder-coated buckle with tactical scr…

5. Leatherworker – Key Leather Types

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 1. Leather Types:

– Horween CXL: 9-10 oz, noted for stretching, not ideal for casual belts.

– Hermann Oak Bridle: 9-10 oz, stiff and cardboard-like, suitable for belts.

– Wickett and Craig Bridle: 9-10 oz, stiff, recommended for belts.

– English Bridle: Similar to Bridle leather, traditionally made in England, slightly waxier.

– Latigo: Good for utility/casual belts, canno…

Strategic Sourcing Conclusion and Outlook for best leather for belts

In conclusion, the strategic sourcing of leather for belts is pivotal for ensuring product quality and customer satisfaction. Prioritizing full-grain leather from double butt cuts offers durability and uniqueness, making it a preferred choice for premium belt manufacturers. International buyers must understand the nuances of leather grades and cuts, as these factors significantly impact the final product’s performance and aesthetic appeal.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, sourcing high-quality leather will not only differentiate your offerings but also enhance brand loyalty among discerning consumers. Engaging with reputable tanneries and suppliers who prioritize sustainable practices can further position your business as a leader in quality and ethics.

Looking ahead, it is essential for B2B buyers to stay informed about advancements in leather sourcing and production technologies. By investing in superior materials and fostering strong supplier relationships, you can meet the growing demand for quality leather products in a competitive landscape. Embrace this opportunity to elevate your brand and connect with customers who value craftsmanship and authenticity in every belt they wear.

Illustrative image related to best leather for belts

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.