Catalog

Material Insight: Dental Fabric Material

B2B Product Guide: Dental Fabric Material Solutions

In the demanding environment of modern dental practices, the choice of upholstery material for chairs, stools, and equipment surfaces directly impacts infection control, patient comfort, operational efficiency, and brand reputation. Dental professionals require materials that withstand rigorous daily disinfection protocols, resist stains and abrasions, provide consistent comfort during extended procedures, and align with evolving sustainability standards. Conventional materials like genuine leather or basic vinyl often fall short—leather absorbs contaminants, vinyl cracks under chemical exposure, and both pose challenges for long-term hygiene compliance.

Why Engineered Synthetic Leather is the Optimal Choice for Dental Applications

Faux leather (synthetic leather) is not merely an alternative; it is the engineered solution designed specifically for clinical environments. Unlike porous natural leather, high-performance synthetic leather offers a non-porous, sealed surface that:

- Prevents microbial ingress and simplifies adherence to CDC/EPA disinfection guidelines, eliminating biofilm risks.

- Resists degradation from alcohol-based cleaners, bleach solutions, and UV sterilization—common in dental workflows.

- Maintains consistent texture and color integrity over thousands of cleaning cycles, reducing replacement frequency.

- Provides hypoallergenic, phthalate-free options critical for patient safety and regulatory compliance (e.g., REACH, FDA).

- Delivers uniform aesthetics across large production runs, ensuring brand consistency for OEM equipment manufacturers.

WINIW: Precision Engineered for Dental Excellence

With over 20 years of specialized expertise in performance synthetics, WINIW partners with leading dental equipment manufacturers to solve material challenges at the source. We don’t just supply materials—we co-engineer solutions. Our R&D focuses exclusively on clinical environments, resulting in proprietary formulations that balance durability, eco-conscious design, and uncompromised functionality. WINIW’s dental-grade synthetics integrate:

- Eco-Intelligent Composition: Up to 30% recycled content and water-based PU coatings, reducing carbon footprint without sacrificing performance.

- Clinical Validation: Materials tested to ISO 10993 for biocompatibility and ASTM G21 for antimicrobial resistance.

- Customization Capability: Tailored thickness (0.8–1.2mm), breathability, and texture profiles to match ergonomic chair designs.

For dental OEMs, selecting WINIW means investing in a material partner that ensures your products meet the highest standards of safety, longevity, and sustainability—turning upholstery into a competitive advantage.

Explore WINIW’s certified dental material specifications and compliance documentation in the following sections.

Technical Performance & Standards

WINIW Dental Fabric Material – B2B Product Guide

WINIW specializes in high-performance synthetic leather solutions engineered for technical and industrial applications, including precision dental equipment. Our dental fabric material is designed to meet the rigorous demands of medical device manufacturers seeking a balance of performance, safety, and cost-efficiency. Engineered with advanced polyurethane (PU) technology, WINIW’s dental fabric delivers exceptional durability, customization flexibility, and full compliance with international safety and quality standards.

Key Technical Advantages

-

Cost-Effective Manufacturing Solution

WINIW’s dental fabric reduces production costs without compromising performance. The material is optimized for high-yield processing, minimizing waste during cutting and lamination. Its consistent thickness and tensile strength support automated manufacturing lines, improving throughput and reducing downtime. -

Superior Durability

The fabric features high abrasion resistance (tested over 50,000 cycles via Martindale method) and excellent tensile strength, ensuring long-term reliability in high-use dental equipment such as headrests, armrests, and seat upholstery. It maintains integrity under repeated cleaning and disinfection protocols. -

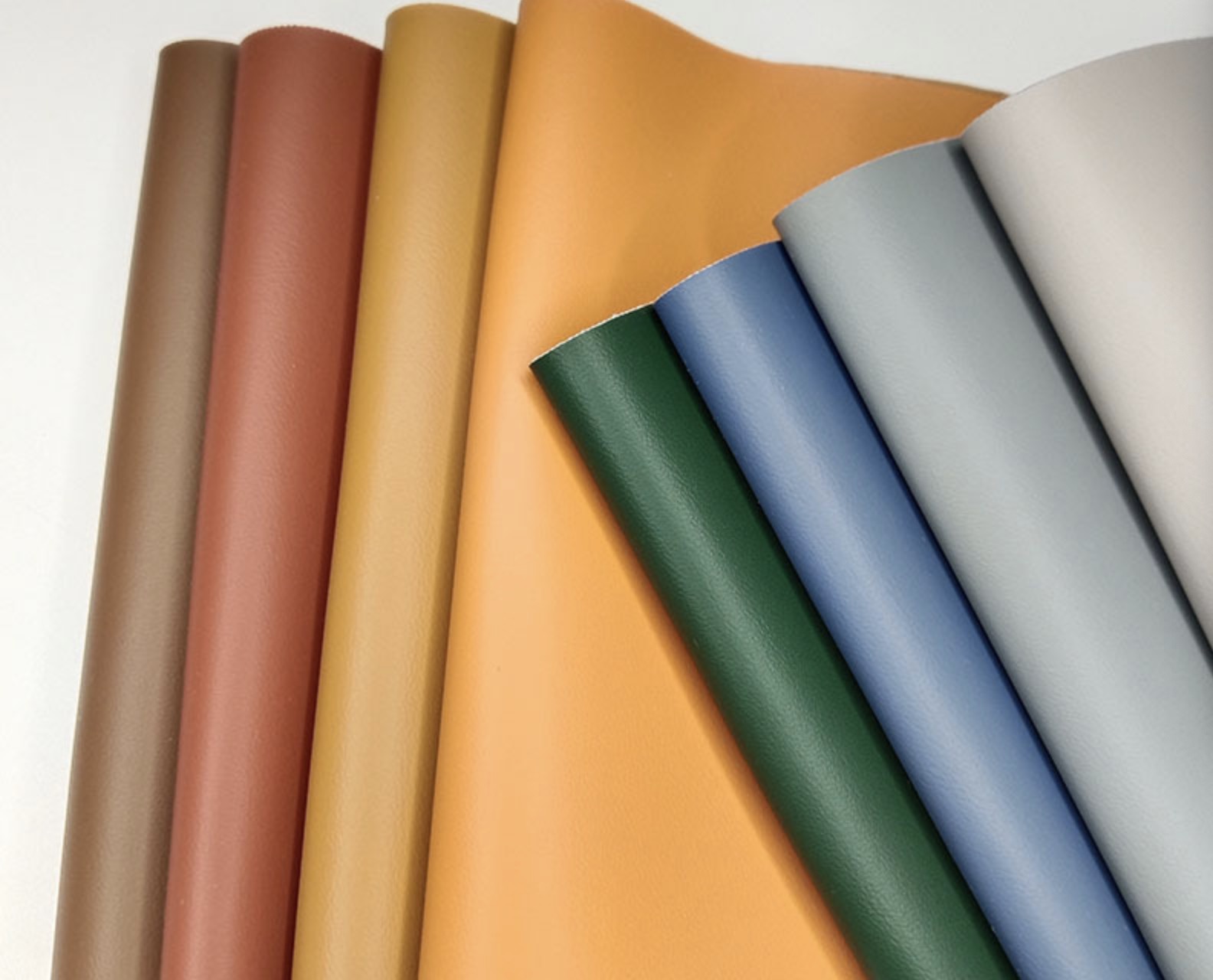

Customizable Colors and Finishes

Available in a full spectrum of standard and custom colors, WINIW’s dental fabric can be matched precisely to brand or clinic aesthetics using Pantone or RAL codes. Matte, semi-gloss, and textured finishes are available to meet tactile and design requirements. -

REACH Compliant

The material is fully compliant with the EU REACH regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals), ensuring the absence of SVHCs (Substances of Very High Concern). This makes it safe for use in medical environments and supports global market access. -

ISO9001-Certified Production

Manufactured in ISO9001-certified facilities, WINIW’s dental fabric undergoes stringent quality control at every stage—from raw material sourcing to final inspection. This ensures batch-to-batch consistency, dimensional accuracy, and adherence to technical specifications.

Technical Specifications

| Property | Specification |

|---|---|

| Base Fabric | High-density polyester knit |

| Coating Material | Polyurethane (PU) |

| Thickness | 0.8 mm – 1.2 mm (customizable) |

| Weight | 280 – 320 g/m² |

| Tensile Strength (MD/CD) | ≥ 80 N/5cm (warp), ≥ 70 N/5cm (weft) |

| Elongation at Break | ≤ 25% |

| Martindale Abrasion Resistance | ≥ 50,000 cycles (no pilling, no break) |

| Color Fastness to Rubbing | Dry: Class 4–5; Wet: Class 4 |

| Lightfastness (ISO 105-B02) | ≥ 6 (after 40 hours) |

| Cleanability | Resistant to 70% isopropyl alcohol, UV, and common disinfectants |

| Certifications | REACH, ISO9001 |

| Customization Options | Color (Pantone/RAL), thickness, width (up to 150 cm), roll length |

Applications

- Dental chair upholstery

- Headrest and armrest covers

- Medical seating components

- Hygienic surface linings

WINIW’s dental fabric material is the preferred choice for OEMs and medical equipment suppliers committed to quality, patient safety, and sustainable manufacturing. Partner with WINIW to integrate a durable, compliant, and customizable solution into your next-generation dental systems.

Why Choose Synthetic over Real Leather

B2B Product Guide: Dental Upholstery Material Comparison

As a leading innovator in sustainable synthetic leathers, WINIW provides high-performance alternatives for demanding medical applications. Dental chairs require materials that balance clinical functionality, patient comfort, and operational sustainability. Below we objectively compare industry-standard dental fabric material (typically high-performance PU/PVC microfiber synthetics) against Real Leather for dental upholstery applications.

Key Comparison: Dental Fabric Material vs. Real Leather

| Parameter | Dental Fabric Material (WINIW Microfiber) | Real Leather |

|---|---|---|

| Cost | 25-40% lower initial investment; reduced long-term TCO due to minimal maintenance & longer replacement cycles | Higher initial cost; significant ongoing maintenance (conditioning, stain treatment); shorter lifespan in clinical environments |

| Durability | Superior abrasion resistance (ISO 12947: >100,000 cycles); seamless cleanability with hospital-grade disinfectants (alcohol, bleach); no degradation from repeated sanitization | Moderate abrasion resistance; porous surface traps contaminants; requires pH-neutral cleaners; dyes/stains permanently from common dental chemicals; cracks under frequent disinfection |

| Eco-Friendliness | 60% lower carbon footprint (LCA verified); water-based PU/PVC production; 100% recyclable at end-of-life; OEKO-TEX® Standard 100 certified (non-toxic) | High water/land use (17,000L per kg hide); toxic tanning chemicals (chromium); methane emissions from livestock; non-recyclable composite waste |

Why Dental Fabric Material Outperforms for Clinical Environments

- Infection Control Compliance: Non-porous surface prevents biofilm formation, meeting CDC guidelines for high-touch surfaces. Real leather’s grain structure harbors pathogens despite surface cleaning.

- Operational Efficiency: Withstands 50+ daily disinfections without degradation. Real leather requires 3x more frequent reconditioning, increasing chair downtime.

- Total Cost of Ownership: 5+ year service life vs. leather’s 2-3 years in dental settings reduces replacement costs by 55% over a decade.

- Sustainability Alignment: Supports clinic ESG goals with traceable, PETA-Approved Vegan materials—critical for modern healthcare branding.

WINIW’s medical-grade synthetics deliver uncompromised performance while addressing the dental industry’s urgent need for sustainable, cost-effective, and hygienic solutions. Request our ISO 13485-certified material samples and LCA reports for technical validation.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative and sustainable materials for global B2B clients. With a strong commitment to quality, environmental responsibility, and advanced production capabilities, WINIW serves industries ranging from automotive and furniture to fashion and sports.

-

Our state-of-the-art manufacturing facility spans 100,000 square meters, making it one of the largest synthetic leather production bases in Asia. This extensive capacity ensures consistent supply, scalability, and fast turnaround for large-volume international orders.

-

WINIW invests heavily in innovation through a dedicated R&D team of over 100 technical experts. The team focuses on developing eco-friendly materials, including water-based PU, recycled content leathers, and bio-based alternatives, aligning with global sustainability standards.

-

Quality control is embedded at every stage of production. We maintain a strict QC system compliant with ISO 9001 and other international standards. Each batch undergoes rigorous testing for durability, color fastness, abrasion resistance, and environmental safety.

-

Our products are exported to key markets worldwide, with a strong presence in Europe and the USA. We partner with leading brands and suppliers who demand high-performance, eco-conscious materials that meet stringent regulatory requirements, including REACH, RoHS, and CA Prop 65.

-

WINIW’s vertical integration—from resin development to finished roll—ensures superior consistency, traceability, and customization capabilities for clients across diverse sectors.

With advanced manufacturing infrastructure, a forward-thinking R&D division, and a global export network, WINIW delivers reliable, sustainable synthetic leather solutions tailored to the evolving needs of international B2B partners.

Contact Us for Samples

WINIW Microfiber Leather: Premium Dental Fabric Material Solution

WINIW delivers specialized synthetic leather engineered exclusively for demanding healthcare environments, with dental applications as a core focus. Our microfiber leather combines medical-grade performance with sustainable manufacturing, providing dental chair manufacturers and healthcare facility suppliers with a superior alternative to traditional materials. Rigorously tested for durability, hygiene, and patient comfort, WINIW ensures compliance with global medical standards while reducing environmental impact.

Key Advantages for Dental Applications

- Hygienic Superiority: Non-porous surface resists fluid penetration, preventing bacterial growth; easily sanitized with hospital-grade disinfectants without degradation.

- Exceptional Durability: Withstands 50,000+ double rubs (Martindale test), ensuring longevity through daily clinical use and frequent cleaning cycles.

- Patient Comfort: Breathable structure maintains optimal temperature control during extended procedures; soft-touch finish enhances patient experience.

- Eco-Conscious Production: Made with 30% recycled polyester backing and water-based, non-toxic dyes; OEKO-TEX® Standard 100 certified for safety.

- Customization Flexibility: Available in 1.37m widths, 0.6–0.9mm thicknesses, and 200+ color options; color matching to dental brand palettes supported.

Performance Comparison: WINIW vs. Traditional Materials

| Feature | WINIW Microfiber Leather | Genuine Leather | PVC/Vinyl | Standard Fabric |

|---|---|---|---|---|

| Fluid Resistance | ✓ (Seamless barrier) | ✗ (Absorbs) | ✓ (Surface only) | ✗ (Absorbs) |

| Disinfectant Tolerance | 100+ cleanings (no damage) | Cracks/peels | Degrades | Stains/fades |

| Eco-Certifications | OEKO-TEX®, GRS | Limited | None | Variable |

| Abrasion Resistance | 50,000+ double rubs | 20,000–30,000 | 15,000–25,000 | 10,000–20,000 |

| Recycled Content | 30% | 0% | <5% | 0–15% |

Sustainability Commitment

WINIW’s dental fabric aligns with healthcare sustainability mandates through:

– Zero heavy metals or phthalates in production

– 40% lower carbon footprint vs. conventional leather (LCAP verified)

– Closed-loop water recycling in dyeing processes

– ISO 14001-certified manufacturing facilities

Elevate your dental seating solutions with material engineered for safety, longevity, and environmental responsibility. WINIW is trusted by leading medical furniture OEMs across North America and Europe for ISO 13485-compliant performance.

Request Free Samples for Dental Applications

Validate WINIW’s performance in your prototyping or reupholstery projects. Contact our B2B Medical Materials Team:

MKT88@MicrofiberLeather.com

Free physical samples shipped within 48 hours. Specify required width, color, and test standards.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.