Introduction: Navigating the Global Market for who makes good leather jackets

Navigating the global market for sourcing high-quality leather jackets presents a unique set of challenges for B2B buyers. With an overwhelming array of options available, identifying reputable manufacturers who deliver both quality and value can be daunting. This comprehensive guide delves into the intricacies of the leather jacket industry, covering various types—from classic bombers to modern racers—and their applications across different markets. Additionally, we provide in-depth insights into supplier vetting processes, cost structures, and the importance of material sourcing, ensuring that buyers can make informed purchasing decisions.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including Brazil and Saudi Arabia) seek to enhance their product offerings, understanding the nuances of the leather jacket market becomes crucial. This guide empowers decision-makers by equipping them with essential knowledge about quality indicators, industry trends, and key players in the market. By addressing common pitfalls and providing actionable strategies, we aim to facilitate successful sourcing endeavors, ultimately leading to profitable partnerships and satisfied customers. Whether you are looking to expand your retail collection or supply unique leather products, this guide serves as your trusted resource in navigating the complex landscape of leather jackets.

Table Of Contents

- Top 5 Who Makes Good Leather Jackets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for who makes good leather jackets

- Understanding who makes good leather jackets Types and Variations

- Key Industrial Applications of who makes good leather jackets

- 3 Common User Pain Points for ‘who makes good leather jackets’ & Their Solutions

- Strategic Material Selection Guide for who makes good leather jackets

- In-depth Look: Manufacturing Processes and Quality Assurance for who makes good leather jackets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘who makes good leather jackets’

- Comprehensive Cost and Pricing Analysis for who makes good leather jackets Sourcing

- Alternatives Analysis: Comparing who makes good leather jackets With Other Solutions

- Essential Technical Properties and Trade Terminology for who makes good leather jackets

- Navigating Market Dynamics and Sourcing Trends in the who makes good leather jackets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of who makes good leather jackets

- Strategic Sourcing Conclusion and Outlook for who makes good leather jackets

- Important Disclaimer & Terms of Use

Understanding who makes good leather jackets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Motorcycle Jackets | Durable leather, reinforced stitching, and protective padding | Retail motorcycle gear, fashion boutiques | Pros: High durability, safety features; Cons: Heavier, may not appeal to all demographics. |

| Fashion Jackets | Trendy designs, various leather types, often lighter weight | High-end fashion retailers, online platforms | Pros: Stylish, diverse styles; Cons: May lack durability compared to utilitarian options. |

| Vintage Replicas | Authentic materials, historical accuracy, unique designs | Specialty vintage shops, collector markets | Pros: Unique appeal, high craftsmanship; Cons: Higher price point, limited availability. |

| Custom Jackets | Tailored fit, premium materials, personalized designs | Bespoke clothing retailers, luxury brands | Pros: Perfect fit, high quality; Cons: Longer production time, premium pricing. |

| Casual Jackets | Comfortable fit, versatile styles, often made from softer leathers | Everyday fashion retailers, online stores | Pros: Versatile, suitable for various occasions; Cons: May not offer the same level of protection as other types. |

What Are the Key Characteristics of Motorcycle Jackets?

Motorcycle jackets are designed with functionality and safety in mind. They typically feature durable leather, reinforced stitching, and protective padding to withstand the rigors of riding. B2B buyers in the motorcycle gear sector should consider the jacket’s protective features and overall durability, as these are critical for customer safety. Furthermore, the appeal of motorcycle jackets extends beyond functionality; they are often seen as a style statement in fashion, making them suitable for both retail motorcycle gear and fashion boutiques.

How Do Fashion Jackets Stand Out in the Market?

Fashion jackets prioritize aesthetics while still offering quality leather. These jackets come in trendy designs and a variety of leather types, appealing to a broader audience. B2B buyers should focus on current fashion trends and consumer preferences when selecting styles for their inventory. While fashion jackets can attract customers with their stylish appeal, they may not offer the same durability as utilitarian options, which could be a consideration for buyers targeting more rugged markets.

Why Are Vintage Replicas Popular Among Collectors?

Vintage replica jackets capture the essence of historical designs and craftsmanship, making them highly sought after by collectors and enthusiasts. These jackets use authentic materials and replicate unique styles from past eras. B2B buyers in specialty vintage shops should be aware of the craftsmanship and authenticity that appeal to customers. While vintage replicas can command higher price points, their unique appeal and quality often justify the investment.

Illustrative image related to who makes good leather jackets

What Are the Advantages of Custom Jackets for B2B Buyers?

Custom jackets offer a tailored fit and the option to choose premium materials, making them ideal for luxury brands and bespoke clothing retailers. This personalization aspect allows businesses to cater to specific customer preferences, enhancing customer satisfaction. However, B2B buyers must consider longer production times and higher costs associated with custom jackets, which may affect inventory turnover and pricing strategies.

How Do Casual Jackets Fit into the B2B Market?

Casual jackets focus on comfort and versatility, often made from softer leathers that cater to everyday fashion needs. They are suitable for a wide range of occasions, making them an attractive option for everyday fashion retailers and online stores. While casual jackets may lack the protective features of motorcycle jackets, their broad appeal and adaptability can drive sales. B2B buyers should consider stocking these jackets to meet diverse consumer demands while maintaining a balance between style and comfort.

Key Industrial Applications of who makes good leather jackets

| Industry/Sector | Specific Application of who makes good leather jackets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | High-end leather jacket collections | Enhances brand image and attracts discerning customers | Quality of leather, craftsmanship, and brand reputation |

| Automotive | Leather jackets for motorcycle riders | Provides safety and style, appealing to motorcycle enthusiasts | Durability, comfort, and compliance with safety standards |

| Film & Entertainment | Costumes for film productions | Creates authentic character portrayals, enhancing viewer experience | Authenticity of design, sourcing from reputable manufacturers |

| Export & Import | Trade of leather jackets across international markets | Expands market reach and diversifies product offerings | Compliance with import/export regulations, quality assurance |

| Corporate Gifting | Customized leather jackets for corporate gifts | Strengthens client relationships and brand loyalty | Customization options, delivery timelines, and pricing |

How Are High-End Leather Jackets Used in Fashion Retail?

In the fashion retail industry, high-quality leather jackets serve as signature pieces that elevate brand identity. Retailers often curate collections featuring well-crafted jackets to appeal to a luxury market, particularly in regions like Europe and the Middle East, where fashion trends are influential. Buyers must prioritize sourcing from reputable manufacturers known for their craftsmanship and quality materials, ensuring the products meet the expectations of discerning customers.

Illustrative image related to who makes good leather jackets

What Role Do Leather Jackets Play in the Automotive Sector?

Leather jackets are integral to the automotive industry, especially among motorcycle manufacturers and retailers. They offer both safety and style, catering to a niche market of motorcycle enthusiasts who value durability and comfort. When sourcing, businesses should consider the leather’s resistance to wear and tear, as well as its compliance with safety regulations to ensure that it meets the needs of their customers.

How Are Leather Jackets Utilized in Film and Entertainment?

In the film and entertainment sector, leather jackets are often used as costumes to convey character authenticity. Filmmakers seek high-quality jackets that reflect the era and personality of their characters, enhancing the overall viewer experience. B2B buyers in this sector must focus on sourcing from manufacturers who can provide authentic designs and materials, ensuring that the jackets align with the production’s vision.

Why Is Export and Import Important for Leather Jacket Trade?

The export and import of leather jackets are crucial for businesses looking to expand their market reach. International buyers from regions like Africa and South America often seek unique leather products that reflect local tastes while adhering to global quality standards. Sourcing considerations should include compliance with international trade regulations, quality assurance processes, and the ability to meet varying demand levels across different markets.

How Can Customized Leather Jackets Benefit Corporate Gifting?

Customized leather jackets are increasingly popular in corporate gifting, serving as a unique way to strengthen client relationships and enhance brand loyalty. Companies can offer personalized jackets that reflect their brand identity, making a memorable impression. When sourcing these jackets, businesses should consider customization options, production timelines, and competitive pricing to ensure they deliver value to their clients while maintaining high standards of quality.

3 Common User Pain Points for ‘who makes good leather jackets’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather Jackets for Diverse Markets

The Problem: B2B buyers often struggle to find reliable manufacturers that can deliver high-quality leather jackets tailored to the varying preferences of consumers across different regions, such as Africa, South America, and Europe. This challenge is compounded by the risk of receiving inferior products that do not meet quality standards or brand expectations. Buyers may face difficulties in assessing the quality of leather, craftsmanship, and overall design aesthetics that resonate with their target demographics.

The Solution: To effectively source high-quality leather jackets, buyers should first conduct thorough research on potential suppliers. Look for manufacturers with a proven track record and positive reviews from previous clients. Establish direct communication with suppliers to discuss specific requirements, such as leather types (e.g., cowhide, lambskin, horsehide) and design elements that appeal to your market. It can be beneficial to request samples to evaluate leather quality and craftsmanship firsthand. Additionally, consider partnering with local distributors who understand regional tastes and preferences, which can streamline the supply chain and reduce the risk of misalignment with consumer expectations.

Scenario 2: Understanding Leather Quality and Construction for Long-Term Investment

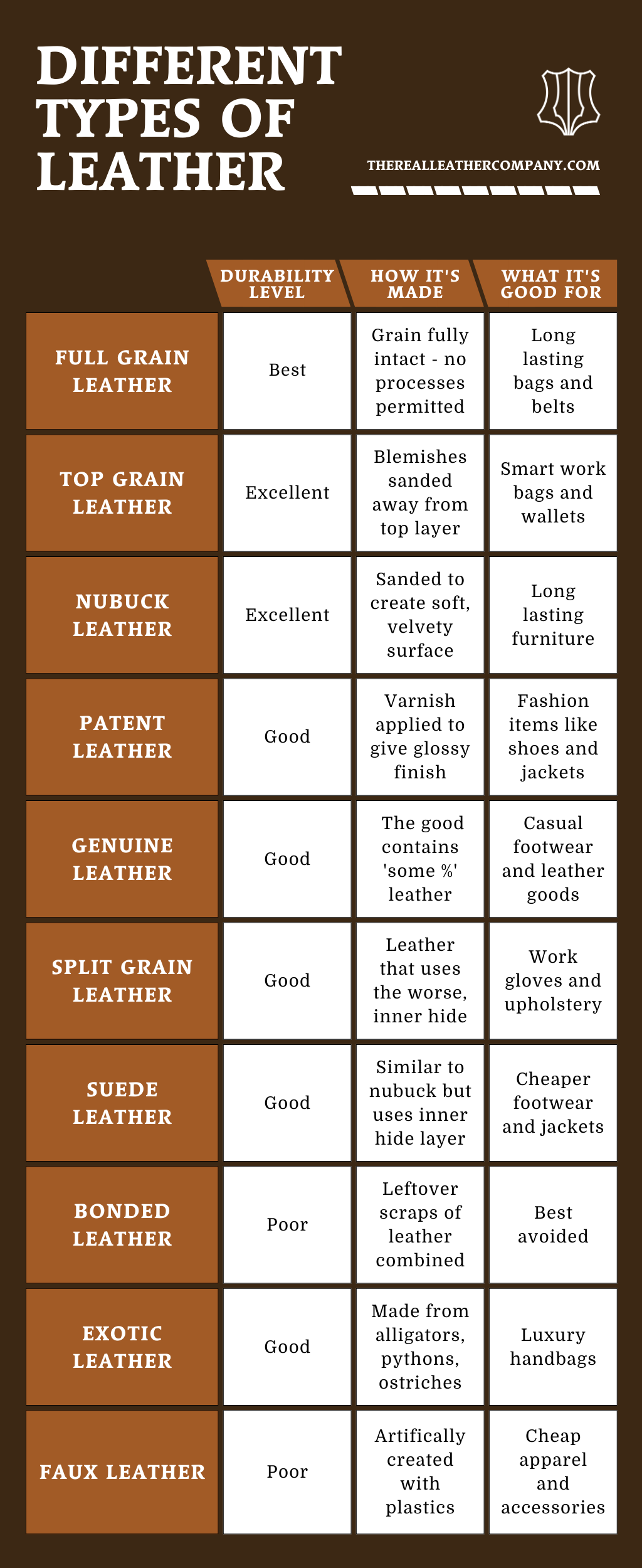

The Problem: Many B2B buyers lack a deep understanding of the various types of leather and the construction methods used in leather jackets, leading to poor purchasing decisions. This knowledge gap can result in investing in jackets that deteriorate quickly or do not provide the perceived value, which is crucial for maintaining brand reputation and customer loyalty.

The Solution: To navigate the complexities of leather quality, buyers should invest time in educating themselves about different leather grades and types. Understanding terms such as full-grain, top-grain, and corrected-grain leather can significantly impact purchasing decisions. Attend industry trade shows or workshops that focus on leather goods, and consider consulting with leather experts or industry veterans. Furthermore, buyers should familiarize themselves with the construction techniques that influence durability, such as stitching methods and the quality of zippers and hardware. Creating a checklist of these factors can help buyers make informed decisions and ensure that they are sourcing jackets that offer both style and longevity.

Illustrative image related to who makes good leather jackets

Scenario 3: Aligning Pricing Strategies with Market Expectations

The Problem: B2B buyers often face the challenge of aligning their pricing strategies with market expectations while ensuring profitability. This can be especially tricky when sourcing leather jackets, as the price range can vary significantly based on quality, brand reputation, and market demand. Misjudging the appropriate price point can lead to overstock or underpricing, affecting overall business viability.

The Solution: To establish a competitive pricing strategy, buyers should conduct a comprehensive market analysis that includes competitor pricing, customer demographics, and market trends in the leather jacket sector. Engaging in price benchmarking against similar products can provide insights into where your offerings should be positioned. Additionally, consider the total cost of ownership, including shipping, tariffs, and potential warranty costs, when calculating final pricing. Collaborating with marketing teams to understand customer perceptions of value can also guide pricing strategies. By aligning product quality with the right price point, buyers can attract and retain customers while ensuring a healthy profit margin.

Strategic Material Selection Guide for who makes good leather jackets

When considering the strategic material selection for leather jackets, it is crucial to evaluate the most common types of leather used in the industry. Each material offers unique properties, advantages, and limitations that can significantly affect the final product’s performance, durability, and appeal in various markets.

What Are the Key Properties of Cowhide Leather for Leather Jackets?

Cowhide leather is one of the most widely used materials for leather jackets due to its robustness and versatility. It typically exhibits excellent durability and resistance to wear and tear, making it suitable for everyday use and outdoor activities. The thickness of cowhide generally ranges from 1.2 to 2.4 mm, providing a good balance between protection and comfort.

Illustrative image related to who makes good leather jackets

Pros & Cons: Cowhide is relatively affordable compared to other premium leathers, making it a popular choice for mass production. However, its weight can be a disadvantage for some consumers seeking lighter options. Additionally, while cowhide offers reasonable breathability, it may not perform as well in extreme temperatures compared to more specialized leathers.

Impact on Application: Cowhide leather jackets are compatible with various climates, making them suitable for international markets, including regions in Africa and South America. However, buyers should ensure that their products comply with local regulations regarding animal products.

How Does Sheepskin Leather Compare in Terms of Performance?

Sheepskin leather is known for its softness and lightweight nature, making it a popular choice for fashion-oriented leather jackets. It typically has a thickness of around 0.6 to 1.2 mm, which enhances comfort and flexibility. Sheepskin also has excellent insulation properties, making it suitable for cooler climates.

Pros & Cons: The primary advantage of sheepskin is its luxurious feel and aesthetic appeal, which can command higher prices in the fashion market. However, it is less durable than cowhide and can be more susceptible to damage from abrasion and moisture. This limitation may affect its suitability for rugged outdoor use.

Impact on Application: Sheepskin jackets are often favored in fashion-forward markets in Europe and the Middle East. International buyers should consider the potential for higher maintenance requirements due to the material’s sensitivity to environmental factors.

What Are the Benefits of Using Goatskin Leather?

Goatskin leather is gaining popularity due to its unique combination of durability and lightweight properties. It typically features a thickness of around 0.8 to 1.6 mm, providing a good level of protection while remaining comfortable to wear. Goatskin also has a natural water-resistant quality, making it suitable for various weather conditions.

Pros & Cons: The primary advantage of goatskin is its resilience and ability to withstand wear, making it ideal for both casual and motorcycle jackets. On the downside, it can be more expensive than cowhide, which may deter cost-sensitive buyers.

Impact on Application: Goatskin jackets can appeal to international markets that prioritize both style and functionality, such as urban areas in South America and Europe. Buyers should be aware of the need for compliance with animal welfare standards in their respective regions.

Illustrative image related to who makes good leather jackets

Why Is Lambskin Leather Considered a Premium Option?

Lambskin leather is often regarded as a premium material due to its exceptional softness and smooth texture. It typically ranges from 0.6 to 1.0 mm in thickness, providing a luxurious feel that is highly sought after in high-fashion markets.

Pros & Cons: The key advantage of lambskin is its lightweight nature and comfort, making it ideal for stylish, fitted jackets. However, it is the least durable of the common leather types and is prone to scratches and wear over time, which may limit its lifespan.

Impact on Application: Lambskin jackets are particularly appealing in high-end fashion markets across Europe and the Middle East, where consumers are willing to pay a premium for quality. International buyers should ensure that they are sourcing from reputable suppliers who adhere to ethical production practices.

Illustrative image related to who makes good leather jackets

Summary Table of Leather Materials for Jackets

| Material | Typical Use Case for who makes good leather jackets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Everyday jackets, casual wear | Durable and affordable | Heavier than other options | Medium |

| Sheepskin | Fashion-oriented jackets, luxury wear | Soft and luxurious | Less durable, sensitive to moisture | High |

| Goatskin | Casual and motorcycle jackets | Resilient and water-resistant | Higher cost compared to cowhide | Medium to High |

| Lambskin | High-fashion jackets, fitted styles | Exceptional softness and comfort | Least durable, prone to scratches | High |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing leather jackets for their markets. Understanding the properties and implications of each material can enhance product offerings and align with consumer preferences across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for who makes good leather jackets

What Are the Main Stages of Manufacturing Quality Leather Jackets?

The manufacturing of quality leather jackets involves several critical stages that ensure the final product meets high standards of durability and aesthetic appeal. Understanding these stages can help B2B buyers identify reliable suppliers.

1. Material Preparation: How Are Leathers Selected and Processed?

The journey of a leather jacket begins with the selection of high-quality hides. Premium suppliers often use full-grain leather, which retains the natural texture and strength of the hide. The preparation process includes tanning, where hides are treated with chemicals or natural materials to preserve them and enhance their durability.

Key techniques during this stage involve vegetable tanning or chrome tanning. Vegetable tanning, while more time-consuming, results in a softer leather that develops a rich patina over time. In contrast, chrome tanning is faster and offers a wider color range but may not provide the same level of breathability. Buyers should inquire about the tanning methods used by suppliers to ensure they align with their quality standards.

2. Forming: What Techniques Are Used to Shape Leather?

Once the leather is prepared, it undergoes the forming stage, which involves cutting and shaping the material into various jacket components. This process may employ techniques such as die-cutting for precision and consistency, especially for intricate designs or patterns.

Employing skilled craftsmen at this stage is crucial, as the quality of cuts affects the overall fit and finish of the jacket. Advanced manufacturers may utilize computer-aided design (CAD) software to optimize patterns and reduce waste, ensuring cost efficiency without compromising quality.

3. Assembly: How Are Leather Jackets Constructed?

The assembly stage involves stitching together the various components of the jacket. High-quality leather jackets typically utilize double stitching, which enhances durability and reduces the risk of seams splitting.

Illustrative image related to who makes good leather jackets

Manufacturers may also employ techniques like edge finishing to ensure that raw edges are neatly trimmed and sealed, preventing fraying. Reinforcements, such as rivets or bar tacks, may be added at high-stress areas, such as pockets and zippers, to enhance the jacket’s longevity.

4. Finishing: What Enhancements Are Applied for Quality?

Finishing is the final stage of production where the jacket is polished and treated for aesthetics and protection. This may include the application of protective coatings to enhance water resistance and the final inspection of color consistency and texture.

Quality manufacturers often use hand-finishing techniques, which can include waxing or burnishing to create a unique look. Buyers should be aware that this stage significantly impacts the perceived value of the jacket, so it’s essential to ask suppliers about their finishing processes.

What Quality Control Measures Are Essential in Leather Jacket Manufacturing?

Quality control (QC) is a vital aspect of leather jacket production that ensures each item meets established standards. For B2B buyers, understanding these QC measures can help in selecting reliable suppliers.

Illustrative image related to who makes good leather jackets

1. What International Standards Should Buyers Look For?

Reputable manufacturers adhere to international quality standards such as ISO 9001, which focuses on effective quality management systems. Compliance with such standards indicates a commitment to continuous improvement and customer satisfaction.

In addition, certifications related to specific markets, like CE marking for European products, may be necessary to ensure the jackets meet safety and environmental requirements.

2. What Are the Key QC Checkpoints in Leather Jacket Production?

Quality control in leather jacket manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial inspection occurs as raw materials arrive. Buyers should confirm that suppliers check the quality of leather and other materials upon receipt to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections help identify defects early. This stage involves monitoring stitching quality, alignment, and overall craftsmanship.

-

Final Quality Control (FQC): Before shipping, finished jackets undergo a comprehensive inspection. This includes checking for defects in stitching, color consistency, and overall appearance.

Buyers should request details about these checkpoints from suppliers to ensure robust quality assurance processes are in place.

3. What Common Testing Methods Are Used for Quality Assurance?

Testing methods for leather jackets may include:

-

Physical Testing: Assessing the tensile strength, abrasion resistance, and flexibility of the leather.

-

Chemical Testing: Evaluating the leather for harmful substances or chemicals that may not comply with safety standards.

-

Durability Testing: Simulating wear and tear to ensure longevity and performance under various conditions.

By understanding these testing methods, B2B buyers can better assess the quality assurance processes of potential suppliers.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control processes of suppliers is crucial for B2B buyers, especially in international markets.

1. What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control measures. Buyers should establish criteria for audits, focusing on:

-

Facility Conditions: Ensuring that manufacturing environments are clean and compliant with safety regulations.

-

Process Documentation: Reviewing records related to production processes and quality inspections.

-

Employee Training: Confirming that staff are adequately trained in quality standards and production techniques.

2. How Can Buyers Utilize Reports and Third-Party Inspections?

Requesting quality control reports from suppliers can provide insights into their adherence to quality standards. In addition, engaging third-party inspection services can offer an unbiased assessment of the supplier’s processes and products.

These inspections can be particularly valuable in regions where buyers may not have direct access to suppliers, such as in Africa or South America.

3. What Are the QC/CERT Nuances for International Buyers?

International buyers should be aware of the nuances in quality certification requirements across different markets. For instance, while CE certification may be essential in Europe, buyers in the Middle East may prioritize compliance with local standards.

Understanding these differences can help buyers navigate the complexities of international sourcing and ensure they select suppliers that meet their specific quality expectations.

Conclusion

In summary, the manufacturing processes and quality assurance measures for leather jackets are multifaceted and critical for ensuring product excellence. B2B buyers should focus on understanding each stage of manufacturing, the quality control measures in place, and how to effectively verify supplier compliance. By doing so, they can make informed decisions that align with their business needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘who makes good leather jackets’

To successfully procure quality leather jackets, international B2B buyers must follow a systematic approach that ensures they select reliable manufacturers. This guide provides a practical checklist to navigate the sourcing process effectively.

Step 1: Identify Your Market Needs

Understanding the specific requirements of your target market is the first critical step. Consider factors such as local fashion trends, climate, and consumer preferences. This information will help you determine the styles, materials, and price points that will resonate with your audience.

Illustrative image related to who makes good leather jackets

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications for the leather jackets you wish to procure. This includes the type of leather (e.g., cowhide, lambskin, or horsehide), jacket styles (e.g., bomber, racer, or moto), and desired features such as zippers, stitching, and linings. This clarity will help you communicate your expectations to potential suppliers and ensure they can meet your quality standards.

Step 3: Conduct Market Research on Potential Suppliers

Before engaging with suppliers, conduct thorough market research to identify potential manufacturers renowned for quality leather jackets. Look for established brands with a strong reputation, particularly those that have experience in your target regions, such as Africa or South America. Utilize trade directories, industry reports, and online platforms like LinkedIn to gather information.

Step 4: Evaluate Supplier Capabilities and Certifications

It’s essential to assess the capabilities of potential suppliers. Request documentation that verifies their production capacity, quality control processes, and compliance with international standards. Look for certifications such as ISO 9001, which indicate a commitment to quality management.

Illustrative image related to who makes good leather jackets

- Consider visiting production facilities if feasible to assess their operations firsthand.

- Request product samples to evaluate the quality of materials and craftsmanship.

Step 5: Review Past Performance and Client References

Engage with suppliers to obtain references from previous clients in similar markets. Understanding their past performance will provide insight into reliability, delivery times, and customer service. Ask specific questions about the supplier’s ability to meet deadlines and respond to issues.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted potential suppliers, negotiate terms and conditions that align with your business objectives. Discuss pricing, minimum order quantities, payment terms, and delivery schedules. Ensure that both parties have a clear understanding of expectations to avoid misunderstandings later.

Step 7: Establish a Trial Order

Before committing to a large order, consider placing a trial order with your selected supplier. This allows you to assess the quality of the leather jackets and the supplier’s ability to fulfill your specifications. Use this opportunity to evaluate factors such as lead times, packaging, and customer service during the ordering process.

By following this structured checklist, B2B buyers can confidently source quality leather jackets that meet their market needs while establishing strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for who makes good leather jackets Sourcing

What Are the Key Cost Components in Leather Jacket Production?

When sourcing high-quality leather jackets, understanding the cost structure is critical for B2B buyers. The primary cost components include:

Illustrative image related to who makes good leather jackets

-

Materials: The type of leather used significantly impacts costs. Premium leathers like horsehide or deerskin are more expensive than standard cowhide. Additional materials such as zippers, linings, and embellishments also contribute to the overall material cost.

-

Labor: Skilled labor is essential for crafting quality leather jackets. Labor costs vary by region, with higher wages in countries known for high craftsmanship standards, such as Italy or Japan. The complexity of the design can also affect labor costs.

-

Manufacturing Overhead: This encompasses costs related to running the factory, including utilities, rent, and equipment maintenance. Efficient operations can help mitigate these costs.

-

Tooling: The initial investment in tools and machinery necessary for production can be substantial. Custom tooling for unique designs will further increase initial costs, but can lead to better margins in the long run.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the final product meets specified standards. This can involve additional labor and testing costs but is crucial for maintaining brand reputation.

-

Logistics: Shipping costs vary greatly depending on the distance and method of transport. International shipping can introduce tariffs and customs fees, which must be factored into the total cost.

-

Margin: Manufacturers typically add a markup to cover their expenses and ensure profitability. The margin can vary based on market demand, brand positioning, and competition.

How Do Price Influencers Impact Leather Jacket Sourcing?

Several factors influence the pricing of leather jackets, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Bulk orders usually attract discounts, whereas small orders may incur higher per-unit costs.

-

Specifications and Customization: Custom designs or specifications can lead to increased costs due to the need for specialized materials or processes. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., eco-friendly or sustainable practices) often come at a premium. Buyers should assess the long-term benefits of investing in quality.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established brands with a history of quality may command higher prices, but they often offer better assurance in terms of product quality and consistency.

-

Incoterms: The chosen Incoterms will determine the responsibilities of buyers and sellers during shipping. Understanding these terms can help buyers avoid unexpected costs related to shipping and customs.

What Are Effective Buyer Tips for Negotiating Leather Jacket Prices?

To navigate the complexities of sourcing leather jackets effectively, consider these strategic tips:

-

Negotiate Wisely: Leverage volume and long-term relationships to negotiate better prices. Suppliers may be more willing to offer discounts to buyers who commit to larger orders or long-term contracts.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential resale value. High-quality jackets may have a higher upfront cost but can provide better longevity and lower replacement rates.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, and the Middle East should be aware of local economic conditions, currency fluctuations, and trade agreements that can impact pricing. Understanding these factors can provide leverage in negotiations.

-

Request Samples: Before placing large orders, request samples to assess quality firsthand. This can prevent costly mistakes and ensure that the product meets your specifications.

-

Stay Updated on Market Trends: Monitor trends in leather fashion and consumer preferences. This knowledge can inform your sourcing decisions and help you negotiate from a position of strength.

Disclaimer on Indicative Prices

Prices for leather jackets can vary widely based on the aforementioned factors. Buyers should conduct thorough market research and consider all cost components when evaluating potential suppliers.

Alternatives Analysis: Comparing who makes good leather jackets With Other Solutions

Exploring Alternatives to Traditional Leather Jackets

In the realm of leather apparel, particularly jackets, discerning buyers often seek the best quality, durability, and style. However, various alternatives exist that can offer similar benefits, each with its unique advantages and disadvantages. Understanding these options enables B2B buyers to make informed decisions based on their specific needs, whether they prioritize cost, performance, or sustainability.

| Comparison Aspect | Who Makes Good Leather Jackets | Faux Leather Jackets | Textile-Based Jackets |

|---|---|---|---|

| Performance | High durability and longevity | Moderate durability, less breathable | Varies widely, often less durable |

| Cost | Generally higher (from $200 to $3,000) | Lower (ranging from $50 to $200) | Moderate (typically $50 to $300) |

| Ease of Implementation | Requires skilled craftsmanship | Easier to mass-produce | Varies; often easier to produce |

| Maintenance | Requires regular care and conditioning | Low maintenance, easy to clean | Varies; generally machine washable |

| Best Use Case | Fashion-forward, high-end markets | Budget-conscious consumers | Casual wear and outdoor activities |

What Are the Pros and Cons of Faux Leather Jackets?

Faux leather jackets, made from synthetic materials, have gained popularity due to their cost-effectiveness and ethical appeal. They typically range from $50 to $200, making them accessible for budget-conscious buyers. Faux leather is generally easier to clean and maintain, requiring less care than genuine leather. However, they often lack the durability and breathability of real leather, which can lead to shorter lifespans and less comfort in varying temperatures. For businesses focused on affordability and ethical sourcing, faux leather presents a viable option, albeit with compromises in quality.

Illustrative image related to who makes good leather jackets

How Do Textile-Based Jackets Compare?

Textile-based jackets offer another alternative, often made from durable synthetic or blended fabrics. These jackets typically fall within the price range of $50 to $300, providing a mid-range option for buyers. Their ease of production and ability to be machine washed make them convenient for everyday use. However, the performance can vary significantly based on the material quality, often leading to shorter lifespans compared to leather options. Textile jackets are best suited for casual wear or outdoor activities, appealing to buyers looking for functionality over high-end fashion.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between traditional leather jackets and alternatives like faux leather or textile-based options, B2B buyers should consider several factors. The target market plays a crucial role; for high-end retailers focused on fashion and quality, genuine leather remains the gold standard. Conversely, businesses aiming at budget-conscious consumers or ethical markets may find faux leather or textiles more appealing. Additionally, understanding the longevity and maintenance requirements of each option can guide buyers in making a choice that aligns with their brand image and customer expectations. Ultimately, the right solution will depend on balancing quality, cost, and the values that resonate with the intended audience.

Essential Technical Properties and Trade Terminology for who makes good leather jackets

What Are the Key Technical Properties of High-Quality Leather Jackets?

When sourcing leather jackets for a B2B context, understanding the technical properties of the materials and construction is crucial. Here are some essential specifications to consider:

-

Material Grade

The grade of leather significantly impacts durability, aesthetics, and cost. Full-grain leather, which retains the natural texture and toughness of the hide, is considered the highest quality. In contrast, top-grain leather is slightly processed and offers a balance between quality and affordability. B2B buyers should prioritize full-grain for premium products, as it ensures longevity and a richer appearance. -

Leather Thickness

Measured in ounces, the thickness of leather influences its strength and wearability. Typically, leather jackets range from 1.0 to 1.5 ounces for lighter styles, while heavier jackets may use leather that is 2.0 ounces or thicker. Understanding thickness is vital for buyers as it affects not only the jacket’s durability but also its comfort and fit. -

Stitching Quality

Stitching specifications, such as thread type and stitch count per inch, play a critical role in the overall durability of a leather jacket. High-quality jackets often feature double-stitched seams, which enhance strength and reduce the likelihood of tearing. Buyers should seek manufacturers that adhere to stringent stitching standards, ensuring that the product can withstand regular wear. -

Finish Type

The finish applied to leather affects its appearance and protection against environmental factors. Common finishes include aniline (natural look) and semi-aniline (enhanced durability). Understanding the finish type is essential for B2B buyers, as it can impact the jacket’s maintenance requirements and overall lifespan. -

Hardware Quality

The components used in leather jackets, such as zippers, buttons, and buckles, should be made from high-quality materials like brass or stainless steel. Hardware quality not only affects functionality but also contributes to the jacket’s aesthetic appeal. B2B buyers should inquire about hardware specifications, as inferior components can lead to product failure and customer dissatisfaction.

What Common Trade Terms Should B2B Buyers Know in the Leather Jacket Industry?

Familiarity with industry jargon can enhance communication and negotiation for B2B buyers. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

Refers to a company that produces parts or products that are sold under another company’s brand name. For leather jackets, OEMs often provide custom designs or specifications, allowing brands to leverage specialized manufacturing capabilities without investing in their own production facilities. -

MOQ (Minimum Order Quantity)

This term defines the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can impact inventory management and cash flow. Negotiating favorable MOQs can help businesses optimize their purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers. It typically includes detailed specifications, quantities, and delivery timelines. Crafting a precise RFQ can streamline the sourcing process and ensure that buyers receive competitive bids from manufacturers. -

Incoterms (International Commercial Terms)

A set of predefined commercial terms used in international trade, Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth transactions. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Understanding lead times is vital for inventory planning and meeting customer demands. Buyers should inquire about lead times during negotiations to align their supply chain operations effectively.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing high-quality leather jackets, enhancing their product offerings and ensuring customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the who makes good leather jackets Sector

What Are the Current Market Dynamics in the Leather Jacket Sector?

The global leather jacket market is experiencing a notable shift driven by evolving consumer preferences and the rise of e-commerce. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality, durable leather products that reflect both style and functionality. Key trends indicate a growing demand for vintage-inspired designs alongside modern aesthetics, which cater to a diverse customer base. Moreover, the integration of advanced B2B technologies, such as AI-driven analytics and supply chain management software, is enhancing the sourcing process, allowing buyers to make data-informed decisions regarding inventory and supplier selection.

Emerging markets, particularly in Brazil and Saudi Arabia, are witnessing a surge in disposable income, leading to increased spending on luxury items, including leather jackets. This uptick is supported by a burgeoning middle class that values quality over quantity. B2B buyers are advised to focus on sourcing from manufacturers who emphasize craftsmanship and high-grade materials, as these factors significantly influence customer satisfaction and brand loyalty. Additionally, the trend toward customization in leather goods is gaining traction, with manufacturers offering bespoke options that appeal to discerning consumers.

How Is Sustainability Influencing Sourcing Decisions for Leather Jackets?

As environmental concerns take center stage in global commerce, sustainability has become a critical factor for B2B buyers in the leather jacket sector. The environmental impact of leather production, particularly in terms of water usage and waste generation, is prompting buyers to seek suppliers who prioritize ethical sourcing and sustainable practices. This includes the use of eco-friendly tanning processes, which minimize harmful chemical usage and reduce the ecological footprint of leather manufacturing.

Furthermore, the certification of materials plays a significant role in establishing credibility and trust. B2B buyers are increasingly looking for suppliers who can provide ‘green’ certifications, such as the Leather Working Group certification, which assesses the environmental compliance of tanneries. By sourcing from manufacturers committed to sustainable practices, buyers not only enhance their brand reputation but also align with the growing consumer demand for environmentally responsible products. This shift towards sustainability is not just a trend; it is becoming a fundamental aspect of the leather jacket market, shaping the future of sourcing strategies.

What Is the Historical Context of Leather Jackets in B2B Sourcing?

The leather jacket has a rich history that dates back to the early 20th century, initially designed for military and aviation use. Over the decades, these garments evolved into fashion staples, symbolizing rebellion and freedom in popular culture, particularly in the post-war era. The craftsmanship associated with leather jackets has also advanced, with various styles emerging, from bomber jackets to cafe racers, each catering to specific market segments.

For B2B buyers, understanding the historical context of leather jackets aids in identifying key suppliers and brands that have maintained their reputation for quality over time. Brands like Schott NYC, known for their classic designs, have become benchmarks for quality and craftsmanship. This historical insight not only informs sourcing decisions but also helps buyers recognize the value of investing in brands that have a legacy of excellence in leather manufacturing. As the market continues to evolve, this historical knowledge can serve as a competitive advantage in navigating the complex landscape of leather jacket sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of who makes good leather jackets

-

1. How do I identify reputable manufacturers of leather jackets?

To identify reputable manufacturers, start by researching companies with a solid history in leather craftsmanship. Look for certifications such as ISO or ethical sourcing credentials. Utilize trade platforms like Alibaba or Global Sources to find verified suppliers. Additionally, check reviews and testimonials from other B2B buyers. Engaging in trade shows and leather expos can also provide direct insights into quality and craftsmanship, allowing you to assess the products firsthand. -

2. What is the best type of leather for high-quality jackets?

The best type of leather for high-quality jackets is generally full-grain leather, known for its durability and natural texture. Horsehide and cowhide are popular choices among premium brands due to their strength and ability to age beautifully. For a softer feel, consider lambskin, although it may not offer the same longevity. When sourcing, inquire about the tanning process, as vegetable-tanned leather typically has better environmental credentials and durability compared to chrome-tanned options. -

3. How can I ensure quality control when sourcing leather jackets?

To ensure quality control, establish clear specifications for materials, stitching, and finish. Request samples before placing large orders to assess the quality firsthand. Implement a quality assurance (QA) process that includes inspections at various production stages. Partnering with third-party QA firms can provide unbiased evaluations and ensure compliance with your standards. Additionally, maintain open communication with suppliers to address any quality concerns promptly. -

4. What minimum order quantities (MOQs) should I expect from leather jacket manufacturers?

Minimum order quantities (MOQs) can vary widely among manufacturers, often ranging from 50 to 500 units, depending on the complexity of the design and materials used. Custom designs typically have higher MOQs due to setup costs. It’s advisable to discuss MOQs during initial negotiations and assess if the manufacturer offers flexibility for smaller orders, especially for new businesses or those testing the market. -

5. What payment terms are common in B2B leather jacket transactions?

Common payment terms in B2B transactions for leather jackets include a deposit of 30-50% upfront, with the balance due upon completion or before shipping. Some suppliers may offer letters of credit or escrow services for added security. Ensure that you discuss payment terms clearly before finalizing contracts to avoid misunderstandings. It’s also wise to consider using payment methods that provide buyer protection, especially when dealing with international suppliers. -

6. How do I navigate logistics and shipping for international leather jacket orders?

Navigating logistics involves selecting a reliable shipping partner experienced in international freight. Consider factors such as shipping costs, delivery times, and customs clearance processes. Familiarize yourself with import regulations in your country, as leather goods may require specific documentation. Engage with your supplier to understand their shipping practices and whether they can handle logistics on your behalf, which can simplify the process and reduce potential delays. -

7. Are there customization options available for leather jackets?

Many manufacturers offer customization options, including design variations, color choices, and personalized branding. When discussing customization, provide detailed specifications to ensure alignment with your vision. Be aware that custom orders may have higher MOQs and longer lead times. Confirm the manufacturer’s capabilities regarding the type of customization you seek, and request samples or prototypes to evaluate quality before final production. -

8. What are the best practices for maintaining leather jackets?

To maintain leather jackets, advise your customers to clean them regularly with a soft cloth and avoid exposing them to extreme heat or moisture. Recommend using leather conditioners to keep the material supple and prevent drying. For stain removal, suggest professional cleaning services that specialize in leather care. Educate buyers on proper storage, encouraging them to hang jackets in a cool, dry place to retain their shape and prevent creasing.

Top 5 Who Makes Good Leather Jackets Manufacturers & Suppliers List

1. Top Leather Jacket Brands – Key Styles

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Top leather jacket brands mentioned include: Real McCoy, Rainbow Country, Langlitz, Vanson, Lewis, Thedi, Himel (biker style); Goodwear, Real McCoy, Eastman, Aero, Bill Kelso (flight jacket style); Lewis Leather, Vanson, Schott (vintage); Aero Leather Clothing (new).

2. Buffalo Jackson – Bridger Leather Down Jacket

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Bridger Leather Down Jacket | Light Brown | $534.95

Legacy Leather Jacket | Brown | $499.95 | SALE $459.95 (8% Off)

Driggs Leather Jacket | Brown | $499.95

Thompson Leather Moto Jacket | Brown | $489.95 | SALE $439.95 (10% Off)

Maverick Leather Bomber Jacket | Distressed Brown | $449.95

Bridger Leather Down Jacket | Tan & Brown | $534.95

Maverick Leather Bomber Jacket | Distressed Brown | $449.95

…

3. Aero Leather Clothing – Handmade Leather Jackets

Domain: aeroleatherclothing.com

Registered: 1997 (28 years)

Introduction: Aero Leather Clothing specializes in handmade leather jackets, crafted in Scotland. They offer a variety of high-grade leathers including Chromexcel front quarter horsehide, vegetable-tanned full grain Italian horsehide, vegetable-tanned goatskin, and steerhide. The product range includes made-to-order jackets, ready-to-wear jackets, military recreations, knitwear, trousers, outerwear, shirts, foo…

4. Vogue – Minimalist and Bomber Leather Jackets

Domain: vogue.com

Registered: 1994 (31 years)

Introduction: The Minimalist: Nour Hammour Louise leather jacket – $1,340 (NET-A-PORTER), Toteme paneled textured-leather jacket – $2,600 (NET-A-PORTER), Khaite Jameson jacket – $3,900 (KHAITE), Banana Republic minimalist leather jacket – $500 (BANANA REPUBLIC). The Bomber: Frankie Shop Viper oversized leather jacket – $815 (NET-A-PORTER), Hommegirls leather bomber jacket – $1,500 (NORDSTROM), Róhe leather bomb…

5. Velasca – Ribbed Suede Bombers

Domain: apetogentleman.com

Registered: 2008 (17 years)

Introduction: The Best Leather Jacket Brands For Men in 2025 include:

1. **Velasca** – Known for Italian flair, offering ribbed suede bombers and aviator styles made in Italy with high-quality leathers.

2. **Private White V.C.** – Offers a range of leather coats with a masculine edge, including suede peacoats and long belted motorcycle jackets, renowned for craftsmanship and durability.

3. **AllSaints** – Feat…

Strategic Sourcing Conclusion and Outlook for who makes good leather jackets

In conclusion, strategic sourcing of high-quality leather jackets requires a keen understanding of the diverse landscape of manufacturers and materials. Key takeaways for B2B buyers include recognizing the importance of sourcing from reputable brands known for their craftsmanship, such as Schott and Japanese makers like Himel Bros. and Freewheelers. The focus should be on quality leather, fit, and durability, which are critical factors that can significantly influence customer satisfaction and brand loyalty.

Illustrative image related to who makes good leather jackets

For international buyers in regions like Africa, South America, the Middle East, and Europe, investing in quality leather jackets can enhance your product offerings and elevate your brand in competitive markets. As consumer demand shifts towards sustainable and long-lasting fashion, aligning your sourcing strategy with these trends will be crucial for future success.

As you navigate the sourcing landscape, consider establishing partnerships with trusted manufacturers that prioritize quality and ethical practices. This proactive approach not only ensures superior products but also positions your business for sustainable growth in an evolving marketplace. Embrace this opportunity to elevate your offerings and meet the discerning tastes of today’s consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to who makes good leather jackets

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.