Introduction: Navigating the Global Market for leather boot companies

In today’s competitive landscape, sourcing high-quality leather boots presents a significant challenge for international B2B buyers. With a myriad of options flooding the market, it can be overwhelming to identify suppliers that offer not only stylish and durable products but also reliable service and competitive pricing. This guide is designed to simplify the process of navigating the global market for leather boot companies, providing insights into the various types of boots available, their applications, and essential supplier vetting strategies.

Buyers from Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Brazil, will find comprehensive information tailored to their specific needs. We delve into the nuances of different boot styles, from rugged work boots to fashionable dress options, while also exploring the factors that affect pricing and quality. This guide empowers B2B buyers to make informed purchasing decisions by equipping them with the knowledge necessary to evaluate suppliers effectively, understand market trends, and assess the long-term value of their investments. By the end of this guide, you will be well-prepared to engage confidently with leather boot manufacturers and secure the best products for your business.

Table Of Contents

- Top 6 Leather Boot Companies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather boot companies

- Understanding leather boot companies Types and Variations

- Key Industrial Applications of leather boot companies

- 3 Common User Pain Points for ‘leather boot companies’ & Their Solutions

- Strategic Material Selection Guide for leather boot companies

- In-depth Look: Manufacturing Processes and Quality Assurance for leather boot companies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather boot companies’

- Comprehensive Cost and Pricing Analysis for leather boot companies Sourcing

- Alternatives Analysis: Comparing leather boot companies With Other Solutions

- Essential Technical Properties and Trade Terminology for leather boot companies

- Navigating Market Dynamics and Sourcing Trends in the leather boot companies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather boot companies

- Strategic Sourcing Conclusion and Outlook for leather boot companies

- Important Disclaimer & Terms of Use

Understanding leather boot companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Boot Makers | Handcrafted, bespoke designs tailored to individual needs | Specialized industries like logging, firefighting | Pros: Unique fit, high durability. Cons: Higher price, longer lead times. |

| Work Boot Manufacturers | Focus on safety and functionality, often using rugged materials | Construction, industrial sectors | Pros: Meets safety standards, high durability. Cons: May lack style, heavier. |

| Fashion Boot Brands | Emphasis on aesthetics and trendiness, often with seasonal collections | Retail and fashion boutiques | Pros: High style appeal, brand recognition. Cons: May compromise on durability. |

| Heritage Boot Companies | Traditional craftsmanship with time-tested methods | Premium retail, lifestyle markets | Pros: Quality materials, long-lasting. Cons: Premium pricing, limited styles. |

| Sustainable Boot Makers | Focus on eco-friendly materials and ethical production practices | Eco-conscious retailers, corporate social responsibility initiatives | Pros: Appeals to ethical consumers, innovative materials. Cons: Potentially higher costs. |

What Are the Characteristics of Custom Boot Makers?

Custom boot makers focus on creating handcrafted boots that are tailored specifically to the wearer’s needs. They often utilize premium materials and traditional crafting techniques, which can result in unique designs that cater to specialized applications, such as logging or firefighting. For B2B buyers, the key consideration is the balance between the higher costs associated with bespoke products and the long-term benefits of a perfect fit and enhanced durability.

How Do Work Boot Manufacturers Serve Industrial Needs?

Work boot manufacturers prioritize safety and functionality, producing boots designed to withstand the rigors of industrial environments. These boots often feature reinforced toes, slip-resistant soles, and waterproof materials, making them essential for construction and manufacturing sectors. B2B buyers should consider the specific safety regulations of their industry, as well as the durability and comfort of the boots, ensuring that they meet both safety standards and employee satisfaction.

What Makes Fashion Boot Brands Unique?

Fashion boot brands focus on aesthetics and current trends, offering a wide range of styles that appeal to retailers and consumers looking for stylish footwear. These boots often change with the seasons, making them ideal for fashion boutiques. However, B2B buyers should weigh the benefits of brand recognition and style against potential compromises in durability and functionality, particularly for customers who may require more rugged options.

Why Are Heritage Boot Companies Valued in the Market?

Heritage boot companies are known for their commitment to traditional craftsmanship and high-quality materials. These boots often reflect a rich history and are marketed as premium products, appealing to lifestyle markets and discerning consumers. B2B buyers should consider the investment in these boots, as they typically come at a higher price point but offer longevity and a classic aesthetic that can enhance brand reputation.

What Is the Importance of Sustainable Boot Makers in Today’s Market?

Sustainable boot makers focus on environmentally friendly materials and ethical production practices, catering to the growing demand for eco-conscious products. These boots are increasingly popular among businesses committed to corporate social responsibility. For B2B buyers, the main consideration is the potential for higher costs, balanced by the appeal of innovative, sustainable materials that attract ethically-minded consumers, thereby enhancing brand image and loyalty.

Key Industrial Applications of leather boot companies

| Industry/Sector | Specific Application of leather boot companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Safety and work boots for construction sites | Enhanced worker safety and productivity through durable footwear | Compliance with safety standards, material quality, and fit |

| Agriculture | Specialized boots for farming and ranching | Protection against harsh environmental conditions and injuries | Waterproofing, slip resistance, and comfort for long hours |

| Oil and Gas | Heavy-duty boots for oil field operations | Resilience in extreme conditions and protection against hazards | Heat resistance, chemical protection, and rugged design |

| Manufacturing | Industrial boots for factory workers | Increased comfort and safety leading to higher employee retention | Customization options, durability, and ease of maintenance |

| Logistics and Transport | Boots for warehouse and logistics personnel | Improved mobility and safety in dynamic work environments | Lightweight materials, traction, and support for long hours |

How Are Leather Boots Used in the Construction Industry?

In the construction sector, leather boot companies supply safety and work boots designed to protect workers from various hazards. These boots typically feature reinforced toes, slip-resistant soles, and waterproof materials, making them essential for maintaining safety on-site. For international buyers, particularly in regions with stringent safety regulations, sourcing boots that comply with local standards is crucial. Additionally, comfort and durability are paramount, as workers often spend long hours on their feet, which can impact productivity.

What Role Do Leather Boots Play in Agriculture?

Agricultural professionals rely on specialized leather boots to navigate challenging terrains and weather conditions. These boots offer essential protection against mud, water, and sharp objects, ensuring that farmers can work efficiently and safely. For B2B buyers in regions with diverse agricultural practices, sourcing boots that provide features like waterproofing and slip resistance is vital. Comfort during long working hours is also a key consideration, as farmers often work in varying conditions.

How Are Leather Boots Beneficial for the Oil and Gas Industry?

In the oil and gas industry, leather boots are crucial for workers operating in extreme conditions. These heavy-duty boots are designed to withstand heat, chemicals, and rough terrains, thereby providing essential protection. For international buyers, sourcing boots that meet specific safety certifications and can endure harsh environments is critical. The resilience of the materials used not only ensures worker safety but also reduces the frequency of replacements, offering long-term cost benefits.

Illustrative image related to leather boot companies

Why Are Leather Boots Important in Manufacturing?

Manufacturing environments require durable footwear that can withstand the rigors of factory work. Leather boot companies provide industrial boots that enhance comfort and safety for factory workers, reducing the risk of injuries from heavy machinery and slippery floors. B2B buyers should consider customization options that cater to the specific needs of their workforce, such as additional cushioning or support. Sourcing boots that are easy to maintain and repair can also extend their lifespan, contributing to overall operational efficiency.

How Do Leather Boots Support Logistics and Transport Workers?

In logistics and transport, leather boots are essential for warehouse personnel who navigate dynamic work environments. These boots enhance mobility and safety, allowing workers to move quickly while minimizing the risk of slips and falls. For international buyers, it is important to prioritize lightweight materials that do not compromise on durability. Additionally, sourcing boots that provide excellent traction can significantly improve safety in busy logistics operations, ensuring a more efficient workflow.

3 Common User Pain Points for ‘leather boot companies’ & Their Solutions

Scenario 1: Sizing and Fit Issues with Leather Boots

The Problem: Many B2B buyers often face challenges when it comes to the sizing and fit of leather boots. Sizing can vary significantly between manufacturers, leading to discrepancies that result in returns and exchanges. This is especially problematic for companies looking to outfit large teams, as incorrect sizes can lead to delays in delivery and increased operational costs. Furthermore, the nature of leather boots often requires a break-in period, which can lead to discomfort for workers if not properly accounted for.

The Solution: To mitigate sizing issues, B2B buyers should establish a clear communication line with suppliers about sizing standards and last shapes. It’s crucial to request detailed sizing charts and potentially invest in sample pairs to assess fit before placing bulk orders. Additionally, providing employees with a comprehensive fitting guide that includes information on measuring their feet can enhance accuracy. Consider partnering with companies that offer customizable options, allowing for adjustments based on specific needs. This proactive approach not only reduces the likelihood of returns but also ensures that workers receive boots that fit well from the start.

Scenario 2: Quality Assurance and Longevity of Leather Boots

The Problem: Quality assurance is a significant concern for B2B buyers, particularly in industries where durability is paramount. Leather boots may appear robust but can suffer from issues like cracking, peeling, or sole separation if not manufactured to high standards. This not only impacts the reputation of the purchasing company but also leads to unexpected replacement costs and employee dissatisfaction.

The Solution: Establishing a relationship with reputable manufacturers who prioritize quality control is essential. Buyers should conduct thorough research and seek certifications or endorsements from industry bodies that validate the craftsmanship of leather boots. Implementing a quality assurance protocol during the sourcing process—such as requesting samples for testing or visiting production facilities—can provide insight into the materials and methods used. Additionally, consider suppliers that offer warranties or repair services, ensuring longevity and reducing the total cost of ownership over time. This strategic approach helps secure a reliable supply of high-quality boots that meet operational demands.

Scenario 3: Navigating Supply Chain Disruptions

The Problem: Supply chain disruptions have become increasingly common, affecting lead times and the availability of leather boots. B2B buyers may experience delays due to factors such as raw material shortages, transportation issues, or geopolitical factors. This unpredictability can hinder business operations, particularly for companies that rely on timely delivery of workwear for their teams.

The Solution: To navigate these challenges, B2B buyers should diversify their supplier base, sourcing from multiple manufacturers across different regions. This strategy reduces reliance on a single supplier and enhances resilience against localized disruptions. Establishing long-term partnerships with suppliers can also facilitate better communication and transparency about potential delays. Additionally, leveraging technology such as supply chain management software can provide real-time insights into inventory levels and order statuses, allowing companies to anticipate shortages and adjust their procurement strategies accordingly. By proactively managing the supply chain, businesses can mitigate risks and maintain operational continuity even in turbulent times.

Strategic Material Selection Guide for leather boot companies

When selecting materials for leather boots, companies must consider various factors that affect performance, durability, and cost. This guide analyzes four common materials used in leather boot manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Full-Grain Leather for Leather Boots?

Full-grain leather is renowned for its durability and breathability. It retains the natural grain of the hide, making it resistant to wear and tear while allowing moisture to escape. This material can withstand a wide range of temperatures and is generally resistant to corrosion, making it suitable for various environments.

Pros & Cons: The primary advantage of full-grain leather is its longevity and ability to develop a unique patina over time, enhancing its aesthetic appeal. However, it is more expensive than other leather types and requires careful maintenance to prevent damage from moisture and dirt.

Impact on Application: Full-grain leather is ideal for high-performance boots that require durability and comfort, such as work and hiking boots. It is compatible with various media, including water and oils, but should be treated with appropriate waterproofing agents for optimal performance.

Illustrative image related to leather boot companies

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards regarding leather sourcing and treatment. Understanding regulations such as ASTM or DIN can facilitate smoother transactions and product acceptance.

How Does Suede Compare as a Material for Leather Boots?

Suede, made from the underside of animal hides, offers a softer texture and a unique aesthetic. It is lightweight and comfortable, making it a popular choice for casual footwear.

Pros & Cons: Suede’s softness provides immediate comfort, but it is less durable than full-grain leather and more susceptible to staining and water damage. While it is generally less expensive, its maintenance can be more demanding, requiring special cleaning products to preserve its appearance.

Illustrative image related to leather boot companies

Impact on Application: Suede is often used in fashion boots and casual wear, where style is prioritized over rugged performance. It is less suitable for environments where exposure to moisture or heavy wear is common.

Considerations for International Buyers: Buyers should be aware of the environmental impact of suede production and seek suppliers that adhere to ethical sourcing practices. Compliance with international standards for animal welfare may also be a concern.

What Are the Benefits of Synthetic Leather for Leather Boots?

Synthetic leather, often made from polyurethane or PVC, has gained popularity due to its cost-effectiveness and versatility. It can mimic the look and feel of real leather while offering additional benefits.

Pros & Cons: The primary advantage of synthetic leather is its affordability and ease of maintenance. It is also water-resistant and can be produced in various colors and textures. However, it may lack the breathability and durability of natural leather, leading to a shorter lifespan.

Impact on Application: Synthetic leather is suitable for budget-friendly boots and fashion items but may not perform well in demanding environments. Its compatibility with various applications can be advantageous for companies targeting diverse markets.

Considerations for International Buyers: Buyers should ensure that synthetic materials meet local regulations regarding chemical safety and environmental impact. Awareness of standards like REACH in Europe can help avoid compliance issues.

How Does Rubber Contribute to the Performance of Leather Boots?

Rubber is often used in the soles of leather boots due to its excellent traction and shock absorption properties. It is resistant to wear and provides a good grip on various surfaces.

Pros & Cons: The key advantage of rubber is its durability and ability to withstand harsh conditions. However, rubber soles can be heavier and may not provide the same level of breathability as leather. The manufacturing process can also be complex, impacting overall production costs.

Illustrative image related to leather boot companies

Impact on Application: Rubber is ideal for work boots and outdoor footwear, where safety and comfort are paramount. Its compatibility with various terrains makes it a preferred choice for rugged applications.

Considerations for International Buyers: Buyers should verify that rubber materials comply with local safety standards and regulations. Understanding the specific requirements for footwear in different regions can enhance market acceptance.

| Material | Typical Use Case for leather boot companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-performance boots | Exceptional durability and breathability | Higher cost and maintenance requirements | Hoch |

| Wildleder | Fashion and casual boots | Soft texture and comfort | Less durable and more maintenance needed | Medium |

| Synthetic Leather | Budget-friendly and fashion boots | Cost-effective and easy to maintain | Lacks breathability and durability | Low |

| Rubber | Work and outdoor boots | Excellent traction and shock absorption | Heavier and less breathable | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for leather boot companies

What Are the Key Stages in the Manufacturing Process of Leather Boots?

The manufacturing process of leather boots involves several critical stages that ensure both quality and durability. Understanding these stages can help B2B buyers assess potential suppliers effectively.

1. Material Preparation: What Goes Into Making Quality Leather Boots?

The first stage involves selecting high-quality leather and other materials. This includes sourcing full-grain or top-grain leather, which are known for their durability and aesthetic appeal. The leather is then treated to enhance its properties, including waterproofing and resistance to wear.

Illustrative image related to leather boot companies

In addition to leather, components such as rubber or leather soles, insoles, and linings are prepared. This stage may also involve cutting the leather into specific patterns using advanced techniques like laser cutting or die-cutting to minimize waste and ensure precision.

2. How Are Leather Boots Formed?

Once the materials are prepared, the next step is forming the boot. This involves several techniques:

- Lasting: The leather is stretched over a mold (the last) to shape the boot. This is a crucial step, as it determines the fit and comfort of the final product.

- Stitching: The various leather pieces are sewn together using durable threads. Techniques such as Goodyear welting or Blake stitching are common, as they enhance the boot’s longevity and allow for resoling.

- Cementing: For some models, particularly those with rubber soles, a cementing process may be employed. This involves adhering the sole to the upper portion of the boot using strong adhesives.

3. What Does the Assembly Process Entail?

The assembly process brings together all components of the boot. This typically includes:

- Attaching Soles: Depending on the design, soles may be stitched or glued to the upper.

- Fitting Hardware: Any additional components such as eyelets, hooks, or zippers are added at this stage.

- Quality Checks: Each boot is inspected for alignment and finish before moving to the finishing stage.

What Are the Final Touches in the Finishing Stage?

The finishing stage is where the boots are given their final appearance and protective treatments. This includes:

- Polishing: Boots are polished to enhance their aesthetic appeal and provide a protective layer.

- Applying Treatments: Water-repellent treatments and conditioners are often applied to ensure longevity and maintain the leather’s suppleness.

- Final Inspection: Each boot undergoes a rigorous inspection to ensure it meets quality standards before packaging.

How Is Quality Assurance Ensured in Leather Boot Manufacturing?

Quality assurance (QA) is paramount in the leather boot manufacturing process. It ensures that the final products meet both international standards and customer expectations.

Relevant International Standards: What Should Buyers Know?

For B2B buyers, understanding the applicable quality standards is crucial. Key international standards include:

- ISO 9001: This standard specifies requirements for a quality management system and is applicable to all organizations. Manufacturers adhering to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction.

- CE Marking: In Europe, CE marking indicates that products meet health, safety, and environmental protection standards. This is particularly important for boots intended for specific industries, such as construction or firefighting.

What Are the Key QC Checkpoints in Leather Boot Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. Common checkpoints include:

- Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC ensures that processes are being followed correctly and that products meet defined standards.

- Final Quality Control (FQC): A comprehensive assessment of the finished product, FQC checks for defects, ensuring that only boots that meet quality criteria are shipped to customers.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control practices is essential for B2B buyers to ensure they receive high-quality products. Here are actionable steps:

-

Request Documentation: Ask suppliers for their quality management certifications, inspection reports, and any third-party audit results.

-

Conduct Audits: Schedule on-site audits to observe the manufacturing process and quality control measures firsthand. This can provide insights into the supplier’s operational standards and practices.

-

Engage Third-Party Inspectors: Consider hiring third-party inspection services to conduct independent checks on the products before shipment. This adds an extra layer of assurance regarding quality.

What Are the Nuances of QC for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it’s essential to understand the nuances of quality control:

-

Cultural Differences: Recognize that manufacturing practices may vary significantly across regions. It’s vital to communicate expectations clearly and establish trust with suppliers.

-

Regulatory Compliance: Ensure that the products comply with local regulations in the importing country, including any specific labeling or safety requirements.

-

Logistics Considerations: Quality assurance doesn’t stop at manufacturing. Buyers should also consider the logistics of shipping, including how products are handled during transit, which can affect quality.

Conclusion: Ensuring Quality in Leather Boot Procurement

Understanding the manufacturing processes and quality assurance practices in the leather boot industry is essential for B2B buyers. By focusing on the key stages of production, relevant standards, and effective QC checkpoints, buyers can make informed decisions and ensure they partner with suppliers committed to quality. This not only enhances their product offerings but also builds long-term relationships based on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather boot companies’

Einführung

Sourcing leather boots for your business requires a strategic approach to ensure quality, reliability, and alignment with your market’s needs. This guide provides a step-by-step checklist to help B2B buyers effectively navigate the procurement process, ensuring that you partner with reputable leather boot companies that meet your specific requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. This includes determining the type of leather, construction methods (e.g., Goodyear welted, stitchdown), and design features that align with your target market’s preferences. By outlining these specifications, you can streamline your search and ensure potential suppliers can meet your quality standards.

Illustrative image related to leather boot companies

Step 2: Conduct Market Research

Before reaching out to suppliers, conduct thorough market research to understand the latest trends and demands in the leather boot industry. Analyze competitor offerings and customer reviews to identify gaps in the market that your products can fill. This insight will help you select suppliers who can provide innovative solutions and cater to your specific customer base.

Step 3: Evaluate Potential Suppliers

Before making any commitments, it’s essential to vet potential suppliers meticulously. Request detailed company profiles, production capabilities, and references from other businesses in your industry. Pay attention to factors like their experience in exporting to your region and their understanding of local market dynamics, which can significantly impact your partnership’s success.

Step 4: Verify Supplier Certifications

Ensure that your potential suppliers have the necessary certifications that validate their compliance with industry standards. Look for certifications related to quality management systems (e.g., ISO), environmental sustainability, and ethical labor practices. These certifications not only assure you of product quality but also align your brand with ethical sourcing practices, which is increasingly important to consumers.

Step 5: Request Samples for Quality Assessment

Once you’ve narrowed down your list of suppliers, request product samples to assess quality firsthand. Evaluate the craftsmanship, material durability, and overall design. This step is crucial as it provides a tangible representation of what you can expect from the supplier and helps you make informed decisions based on actual product performance.

Step 6: Negotiate Terms and Conditions

Engage in negotiations regarding pricing, minimum order quantities, and payment terms. Be clear about your expectations and seek to establish terms that are beneficial for both parties. Consider factors such as lead times and shipping logistics to ensure a smooth procurement process that aligns with your business timeline.

Step 7: Establish a Long-term Relationship

Once you finalize your supplier, focus on building a strong, long-term relationship. Open lines of communication and regular feedback can lead to improved product offerings and better service. Establishing a partnership mindset will help you adapt to market changes and foster innovation, ultimately benefiting both your business and your supplier.

By following these steps, you can confidently navigate the sourcing process and establish a successful partnership with leather boot companies that meet your business needs.

Comprehensive Cost and Pricing Analysis for leather boot companies Sourcing

What Are the Key Cost Components in Leather Boot Manufacturing?

Understanding the cost structure of leather boot companies is essential for B2B buyers aiming to make informed purchasing decisions. The primary components influencing the total cost include:

-

Materials: Leather quality significantly affects pricing. Premium leathers, such as full-grain or top-grain, typically command higher prices due to their durability and aesthetic appeal. Additionally, materials for linings, insoles, and outsoles contribute to overall costs.

-

Labor: Skilled craftsmanship is required for high-quality boot production. Labor costs can vary significantly based on geographic location. For instance, manufacturers in regions with higher labor costs, like Europe and North America, may have higher prices compared to those in developing regions.

-

Manufacturing Overhead: This encompasses factory expenses, utilities, and equipment maintenance. Efficient production processes can help lower overhead costs, but initial investments in technology may be substantial.

-

Tooling: Custom molds and machinery for specific boot designs represent a fixed cost that can be amortized over the production volume. Custom tooling can be a significant upfront investment but may reduce per-unit costs in larger production runs.

-

Quality Control (QC): Ensuring product quality is critical, especially in the B2B sector. Implementing rigorous QC processes can incur additional costs but is essential for maintaining brand reputation and minimizing returns.

-

Logistics: Shipping costs vary widely depending on the destination, weight, and shipping method. International buyers must consider tariffs and customs duties, which can significantly impact final costs.

-

Margin: Manufacturers typically include a margin to cover risks, profit, and future investments. Margins can fluctuate based on market demand and competition.

How Do Price Influencers Affect Leather Boot Costs?

Several factors influence the pricing strategy of leather boot companies:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often result in lower per-unit costs. Establishing a relationship with manufacturers can lead to favorable terms for large orders.

-

Specifications and Customization: Custom designs and specific material requests can increase costs. Buyers should be clear about their requirements to avoid unexpected charges.

-

Quality and Certifications: Certifications related to sustainability, labor practices, and material quality can elevate costs but may be essential for certain markets, especially in Europe and North America.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established brands may charge a premium for their proven track record, while new entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding shipping terms can affect total costs. Different Incoterms dictate who is responsible for shipping, insurance, and tariffs, influencing the final price to the buyer.

What Are the Best Negotiation Tips for B2B Buyers of Leather Boots?

Effective negotiation strategies can help buyers secure better deals:

-

Conduct Market Research: Understanding current market prices and trends enables buyers to negotiate from a position of knowledge.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better terms and pricing. Frequent communication fosters trust and can open doors for negotiation.

-

Consider Total Cost of Ownership (TCO): When evaluating costs, buyers should consider not just the purchase price but also maintenance, durability, and resale value.

-

Be Prepared to Walk Away: Knowing your budget and limits is crucial. If a supplier cannot meet your needs, being willing to explore other options can strengthen your negotiating position.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and shipping costs that can affect overall pricing.

Conclusion: Why Are Indicative Prices Essential for B2B Buyers?

While indicative prices provide a baseline for budgeting, they can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Therefore, B2B buyers should engage in thorough discussions with suppliers to obtain tailored quotes that reflect their unique needs and circumstances. By understanding the complexities of pricing and costs in the leather boot industry, buyers can make more informed decisions and secure better deals.

Alternatives Analysis: Comparing leather boot companies With Other Solutions

Exploring Alternatives to Leather Boot Companies

In the dynamic landscape of footwear, particularly for B2B buyers, evaluating alternatives to traditional leather boot companies can lead to better decisions that align with specific business needs. While leather boots are renowned for their durability and craftsmanship, alternative solutions also exist that may meet or exceed expectations in certain contexts. This analysis will compare leather boot companies against synthetic footwear options and custom-made boot solutions.

Comparison Table

| Comparison Aspect | Leather Boot Companies | Synthetic Footwear Solutions | Custom-Made Boot Solutions |

|---|---|---|---|

| Performance | High durability and comfort | Moderate durability, lightweight | Tailored fit, high performance |

| Cost | Typically $200 – $750 per pair | Generally lower, $50 – $200 | High initial investment, $500+ |

| Ease of Implementation | Readily available from retailers | Widely available online and in stores | Requires lead time for production |

| Wartung | Requires regular care and conditioning | Low maintenance, easy to clean | May require specialized care |

| Best Use Case | Long-term use in rugged conditions | Casual or light-duty use | Specific fit for demanding roles |

What Are the Pros and Cons of Synthetic Footwear Solutions?

Synthetic footwear solutions, such as those made from materials like rubber or polyurethane, provide a lightweight and often cost-effective alternative to leather boots. The primary advantage is their affordability, making them attractive for companies looking to outfit large teams without incurring high costs. They are also typically easier to clean and maintain, which can be beneficial in environments where hygiene is paramount. However, synthetic options may not offer the same level of durability and comfort over time as leather boots, potentially leading to increased replacement costs in the long run.

How Do Custom-Made Boot Solutions Compare?

Custom-made boot solutions provide an exceptional fit tailored to the specific needs of the wearer, often resulting in enhanced comfort and performance. This is particularly beneficial for professionals in industries such as construction or logging, where foot comfort can significantly impact productivity. However, the main drawback is the high upfront cost and longer lead time for production. Companies may need to balance the investment against the potential productivity gains from improved comfort and fit.

Conclusion: How to Choose the Right Footwear Solution for Your Business Needs

When selecting the right footwear solution, B2B buyers should consider the specific requirements of their workforce, including the nature of their work, budget constraints, and maintenance capabilities. Leather boots offer unparalleled durability and comfort for long-term use, making them ideal for challenging environments. On the other hand, synthetic footwear may serve as a practical choice for less demanding applications, while custom-made boots can provide tailored solutions for unique occupational demands. Ultimately, understanding these alternatives empowers buyers to make informed decisions that align with their operational goals and workforce needs.

Essential Technical Properties and Trade Terminology for leather boot companies

What Are the Key Technical Properties to Consider When Sourcing Leather Boots?

When sourcing leather boots for commercial purposes, understanding the technical properties of the materials and construction methods is crucial. Here are some essential specifications to consider:

-

Material Grade:

– The quality of leather is often classified into grades, such as full-grain, top-grain, and corrected grain. Full-grain leather, made from the top layer of the hide, is the most durable and develops a patina over time, making it ideal for high-end boots. For B2B buyers, selecting the right material grade ensures the product meets durability and aesthetic requirements. -

Construction Method:

– Common construction methods include Goodyear welting, Blake stitching, and cementing. Goodyear welted boots are known for their durability and ease of resoling, which adds value in terms of longevity. Buyers should consider how construction affects both the performance and repairability of the boots. -

Sizing Tolerance:

– Tolerance refers to the acceptable deviation in size during production. For leather boots, maintaining tight tolerances is vital to ensure comfort and fit. In B2B transactions, this specification is critical to minimize returns and enhance customer satisfaction. -

Water Resistance:

– This property is vital for boots intended for outdoor or industrial use. Treatments or coatings can enhance leather’s water resistance. Buyers should assess this feature based on the end-user’s environment to ensure the boots perform adequately under various conditions. -

Flexibility and Break-in Period:

– The flexibility of leather affects comfort and ease of wear. Different leathers have varying break-in periods, which can impact customer experience. Understanding these characteristics helps buyers select boots that align with consumer expectations for comfort and usability. -

Weight:

– The weight of the boots can influence user comfort, especially for those who wear them for extended periods. Lighter boots may be preferable for everyday wear, while heavier options might offer enhanced protection for industrial use. Buyers should consider the intended use when evaluating this property.

What Trade Terminology Should B2B Buyers Know in the Leather Boot Industry?

Familiarity with industry-specific terminology can streamline communication and negotiation processes. Here are some key terms:

-

OEM (Original Equipment Manufacturer):

– An OEM refers to a company that produces parts or products that are marketed by another company. In the leather boot industry, understanding OEM relationships can help buyers ensure they are sourcing from reputable manufacturers who meet specific quality standards. -

MOQ (Minimum Order Quantity):

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can impact inventory levels and cash flow. Knowing the MOQ helps in planning purchases and managing supply chain logistics effectively. -

RFQ (Request for Quotation):

– An RFQ is a formal document requesting a price quote from suppliers. It outlines specifications, quantities, and other important details. B2B buyers should utilize RFQs to compare prices and terms from different manufacturers, ensuring they get the best deal. -

Incoterms (International Commercial Terms):

– These are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms helps buyers manage shipping costs and risks effectively, ensuring a smoother transaction process. -

Lead Time:

– This term refers to the amount of time it takes from placing an order to receiving the goods. In the leather boot industry, lead time can vary significantly based on production methods and material sourcing. Buyers should account for lead times in their inventory planning to avoid stockouts. -

Resoleable:

– This term indicates whether a boot can have its sole replaced after wear. Resoleable boots are often more appealing to buyers looking for long-term value. Understanding this feature helps B2B buyers promote sustainability and cost-effectiveness in their offerings.

By grasping these technical properties and trade terminologies, B2B buyers can make informed purchasing decisions that align with their business needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the leather boot companies Sector

What Are the Current Market Dynamics and Key Trends Influencing Leather Boot Companies?

The global leather boot market is experiencing a notable transformation, driven by shifting consumer preferences, technological advancements, and economic factors. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly focused on quality, durability, and design, reflecting a preference for premium products. Key trends include the rise of direct-to-consumer (DTC) sales models, which allow manufacturers to engage directly with buyers, reducing costs and enhancing customer experience. Additionally, e-commerce platforms are expanding, making it easier for businesses to source products across borders.

Emerging technologies such as 3D printing and AI-driven design tools are reshaping the production landscape. These innovations not only streamline manufacturing processes but also allow for customization, catering to diverse market demands. Moreover, the integration of data analytics in supply chain management is enabling companies to forecast trends more accurately and optimize inventory levels, which is crucial for meeting the fast-changing demands of global markets.

The leather boot industry is also witnessing a growing emphasis on sustainability, with buyers increasingly seeking suppliers who prioritize environmentally friendly practices. This trend is particularly pronounced among European and Middle Eastern buyers, who are often influenced by stringent regulations and consumer expectations regarding sustainability.

How Is Sustainability Shaping the Leather Boot Companies Sector?

Sustainability has become a critical focus for leather boot companies as international buyers prioritize ethical sourcing and environmentally responsible practices. The leather industry traditionally faces scrutiny due to its environmental impact, particularly regarding deforestation, water usage, and chemical pollution. As a result, buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as sourcing leather from certified tanneries that adhere to environmental regulations.

The importance of ethical supply chains cannot be overstated. Buyers are looking for transparency in sourcing, which includes understanding the origins of raw materials and the labor conditions under which they are produced. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction, providing assurance to buyers that the products they source meet specific environmental and ethical standards.

Illustrative image related to leather boot companies

Furthermore, the trend towards using alternative materials, such as plant-based leathers and recycled materials, is on the rise. These innovations not only cater to the growing demand for sustainable products but also align with the values of eco-conscious consumers, creating new market opportunities for leather boot companies.

What Is the Historical Context of Leather Boot Companies for B2B Buyers?

The evolution of leather boot companies dates back centuries, with roots in artisanal craftsmanship and traditional manufacturing practices. Initially, boots were made for functionality, serving the practical needs of laborers and soldiers. Over time, advancements in materials and production techniques led to the emergence of specialized boots for various industries, including logging, firefighting, and fashion.

In the early 20th century, brands like Red Wing and Wolverine began to establish their identities by focusing on quality and durability, setting a standard that persists today. The introduction of Goodyear welting and other construction techniques further enhanced the longevity and comfort of leather boots, appealing to both individual consumers and businesses alike.

As globalization took hold in the late 20th century, the leather boot market expanded significantly, with companies seeking to tap into international markets. This trend continues today, with B2B buyers from diverse regions increasingly sourcing high-quality leather boots that combine traditional craftsmanship with modern innovations, ensuring that the legacy of leather boot-making remains relevant in a competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of leather boot companies

-

How do I evaluate the quality of leather boots from suppliers?

To assess the quality of leather boots, request samples from potential suppliers and perform a detailed inspection. Look for high-quality leather, consistent stitching, and durable soles. Familiarize yourself with the construction methods, such as Goodyear welt or Blake stitch, which significantly impact durability. Additionally, check for certifications or quality assurance processes that the manufacturer follows to ensure their products meet international standards. -

What is the best way to negotiate pricing with leather boot manufacturers?

Start by conducting market research to understand the average pricing for similar products. Prepare a clear outline of your requirements, including volume and specifications, to present during negotiations. Be open to discussing payment terms and delivery timelines, as flexibility on either side can lead to better pricing. Establish a long-term relationship based on mutual benefit, which can facilitate better deals in future transactions. -

What are the typical minimum order quantities (MOQs) for leather boots?

Minimum order quantities can vary significantly among manufacturers, often ranging from 50 to 500 pairs depending on the complexity of the design and customization options. Some manufacturers may be willing to work with lower MOQs for established buyers or repeat orders. Always inquire about MOQs before initiating a partnership, as this can influence your initial investment and inventory management. -

How can I ensure timely delivery of leather boots from international suppliers?

Establish clear timelines during the negotiation phase and include delivery deadlines in your contracts. Work with suppliers who have a proven track record of on-time deliveries and consider using freight forwarders with experience in handling international shipments. Regularly communicate with your supplier throughout the production process and use tracking systems to monitor shipment progress. -

What customization options are typically available for leather boots?

Many manufacturers offer customization options such as materials, colors, sizes, and specific design features like stitching patterns or sole types. To ensure your needs are met, clearly communicate your specifications before placing an order. Request mock-ups or samples to visualize the final product. Customization may affect lead times and pricing, so factor these into your planning. -

What payment terms should I expect when sourcing from leather boot companies?

Payment terms can vary widely but commonly include options such as 30% upfront deposit and 70% upon delivery. Some suppliers may offer net 30 or net 60 payment terms depending on your relationship with them. Always ensure that payment terms are documented in your contract to avoid misunderstandings. Consider using secure payment methods that provide buyer protection, especially for large orders. -

How do I conduct a supplier vetting process for leather boot manufacturers?

Start by researching potential suppliers through trade directories and industry networks. Request references from other businesses and check online reviews. Visit the manufacturing facility if possible, or conduct virtual inspections to assess their operations and quality controls. Verify certifications and compliance with international labor and environmental standards to ensure ethical sourcing practices. -

What quality assurance measures should I implement when importing leather boots?

Develop a quality assurance plan that includes pre-shipment inspections, where a third-party inspector evaluates the products against your specifications. Specify acceptable quality levels (AQL) in your contracts to protect your interests. Upon receipt, conduct thorough inspections to ensure the products meet agreed standards before distribution. Establish a clear return policy for defective items to mitigate risks.

Top 6 Leather Boot Companies Manufacturers & Suppliers List

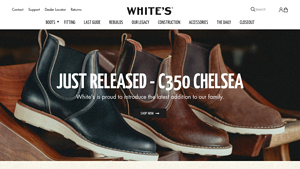

1. White’s Boots – Key Product Details

Domain: whitesboots.com

Registered: 1997 (28 years)

Introduction: Key Product Details:

– Brand: White’s Boots

– Types of Boots: Legacy Boots, Lifestyle Boots, Fire Boots, Work Boots, Grande Ronde Series

– Best Sellers and New Arrivals available

– Custom Boot Options

– Boot Care Products

– Limited Release and Sale Items

– Rebuildable/Resoleable Boots

– Hand-sewn stitchdown construction with over 25 unique stages performed by hand

– Fitting Last Guide available

– …

2. Boot Brands – Chunky & Lug Sole Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Quality boot brands mentioned include Solovair, Jack Erwin, and Red Wing. The user expresses interest in chunky and lug sole boots and notes that they initially considered Doc Martens but found their quality has declined.

3. Timberland PRO – Safety Toe Work Boots

Domain: bootworld.com

Registered: 1996 (29 years)

Introduction: Brands: Timberland PRO, Wolverine, UGG, Dr. Martens, Keen UTILITY, Reebok Work, Skechers Work; Footwear Types: Safety Toe Work, Soft Toe Work, Slip Resistant Work, Slip Resistant PRO, Sheepskin Footwear, Slippers; Activities: Work, Casual, Sport, Dress, Hiking; Safety Features: Safety Toe, Slip Resistant, Metatarsal Guard, EH Rated, Waterproof; Accessories: Insoles, Socks, Care Products, Clothing,…

4. Lucchese – Cowboy Boots & Western Wear

Domain: lucchese.com

Registered: 1997 (28 years)

Introduction: This company, Lucchese – Cowboy Boots & Western Wear, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Red Wing – Heritage Men’s Boots

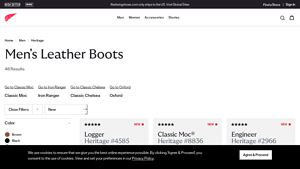

Domain: redwingshoes.com

Registered: 1998 (27 years)

Introduction: This company, Red Wing – Heritage Men’s Boots, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. FRYE – Boots, Shoes & Bags

Domain: thefryecompany.com

Registered: 2005 (20 years)

Introduction: FRYE Boots, Shoes & Bags for Men and Women | Since 1863. Free Shipping on Orders $275+. New Arrivals: Harness 12R Black, Campus 14L Light Brown, Corinne Over the Knee, Viv Short Engineer Black, Sacha at the Knee. Categories: Women Footwear (Best Sellers, Boots, Wide Calf Boots, Booties, Sneakers, Flats & Mules, Sandals), Handbags & Accessories (Handbags, Wallets, Cold Weather Accessories, Belts, F…

Strategic Sourcing Conclusion and Outlook for leather boot companies

As the global leather boot market continues to evolve, strategic sourcing remains a pivotal element for international B2B buyers. By engaging with reputable manufacturers, such as those highlighted in this guide, buyers can leverage quality craftsmanship, competitive pricing, and innovative designs. The emphasis on sustainability and ethical practices is also increasingly vital, aligning with consumer preferences in diverse markets across Africa, South America, the Middle East, and Europe.

Illustrative image related to leather boot companies

Investing in strong supplier relationships can enhance supply chain resilience, offering flexibility in response to market fluctuations and consumer demands. Moreover, understanding regional trends—such as the rising demand for durable, stylish, and functional footwear—can help buyers make informed decisions that drive profitability.

Looking ahead, the landscape of leather boot sourcing is set to become more dynamic. As buyers, you are encouraged to embrace these changes by actively seeking partnerships that prioritize quality, sustainability, and customer satisfaction. By doing so, you not only ensure the success of your business but also contribute positively to the global leather industry. Take the next step in your sourcing strategy today and explore the opportunities waiting in the thriving leather boot market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather boot companies

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.