Introduction: Navigating the Global Market for custom made leather bags

In the competitive landscape of international trade, sourcing custom made leather bags presents a unique set of challenges for B2B buyers. With a rising demand for personalized products that reflect individual style and brand identity, companies must navigate an array of options, from bespoke designs to high-quality materials, all while ensuring cost-effectiveness and supplier reliability. This guide serves as a comprehensive resource for international buyers, particularly those in Africa, South America, the Middle East, and Europe, including regions like Vietnam and Nigeria.

Within this guide, you will discover an in-depth exploration of various types of custom made leather bags, including handbags, backpacks, and briefcases, along with their applications across different industries. We will delve into the intricacies of supplier vetting, helping you identify manufacturers who meet your quality and ethical standards. Furthermore, you will find insights on pricing structures, lead times, and customization options, enabling you to make informed purchasing decisions that align with your business goals.

By leveraging this guide, B2B buyers will be empowered to enhance their product offerings, meet customer expectations, and ultimately drive sales growth in a global market increasingly characterized by personalization and quality craftsmanship.

Table Of Contents

- Top 4 Custom Made Leather Bags Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom made leather bags

- Understanding custom made leather bags Types and Variations

- Key Industrial Applications of custom made leather bags

- 3 Common User Pain Points for ‘custom made leather bags’ & Their Solutions

- Strategic Material Selection Guide for custom made leather bags

- In-depth Look: Manufacturing Processes and Quality Assurance for custom made leather bags

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom made leather bags’

- Comprehensive Cost and Pricing Analysis for custom made leather bags Sourcing

- Alternatives Analysis: Comparing custom made leather bags With Other Solutions

- Essential Technical Properties and Trade Terminology for custom made leather bags

- Navigating Market Dynamics and Sourcing Trends in the custom made leather bags Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom made leather bags

- Strategic Sourcing Conclusion and Outlook for custom made leather bags

- Important Disclaimer & Terms of Use

Understanding custom made leather bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Handbags | Tailored design, material options, personalized features | Retail, promotional gifts, corporate branding | Pros: Unique branding opportunity; Cons: Higher cost |

| Bespoke Backpacks | Fully customized dimensions, compartments, and finishes | Corporate gifting, employee merchandise | Pros: Functional and personalized; Cons: Longer lead time |

| Leather Briefcases | Professional designs, various sizes, and organizational features | Business professionals, executives | Pros: Enhances professional image; Cons: Can be heavy |

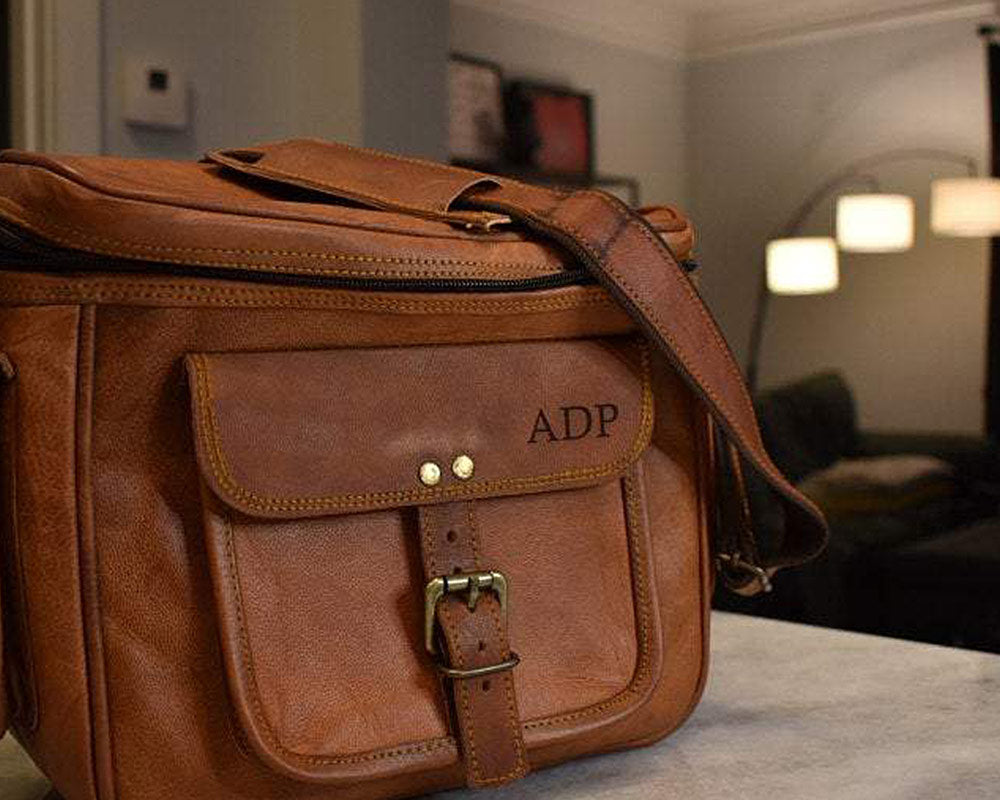

| Personalized Duffles | Size and color customization, monogramming options | Travel companies, promotional events | Pros: Practical for travel; Cons: Limited business use |

| Specialty Bags | Unique designs for specific industries (e.g., camera bags) | Niche markets, specialized retail | Pros: Meets specific needs; Cons: May have limited appeal |

What are the Characteristics of Custom Handbags for B2B Buyers?

Custom handbags are a popular choice for businesses seeking to enhance their brand visibility. These bags can be tailored with specific designs, materials, and personalized features such as logos or initials. Ideal for retail settings or corporate gifting, custom handbags provide a unique branding opportunity. However, buyers should consider the higher cost associated with bespoke designs, which may impact budget constraints.

How Do Bespoke Backpacks Cater to Business Needs?

Bespoke backpacks offer fully customizable dimensions and compartment designs, making them suitable for various business applications. They are particularly appealing for corporate gifting, allowing companies to present employees with functional and personalized items. While these bags provide a unique touch, potential buyers should be aware of the longer lead times associated with bespoke orders, which may affect project timelines.

Why Choose Leather Briefcases for Professional Use?

Leather briefcases are synonymous with professionalism and elegance. They come in various sizes and can be customized for organizational features, catering to the needs of business professionals and executives. The enhanced professional image they provide is a significant advantage. However, buyers should consider the weight of leather briefcases, which may be a drawback for some users.

What Makes Personalized Duffles Attractive for B2B Opportunities?

Personalized duffle bags allow businesses to offer customized options in size and color, along with monogramming capabilities. These bags are particularly useful for travel companies and promotional events, as they combine practicality with a personal touch. However, their use may be limited in strictly professional settings, which buyers should consider when assessing their overall utility.

How Do Specialty Bags Serve Niche Markets?

Specialty bags are designed for specific industries, such as camera bags or medical bags, making them ideal for niche markets. These bags meet unique requirements and can be tailored to specific needs, providing businesses with a competitive edge in specialized retail. While they address particular demands effectively, buyers should note that their appeal may be limited to a smaller audience, potentially impacting sales volume.

Key Industrial Applications of custom made leather bags

| Industry/Sector | Specific Application of custom made leather bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Retail | Bespoke handbags for luxury brands | Enhances brand identity and customer loyalty | Quality of leather, craftsmanship, turnaround time, and design flexibility |

| Corporate & Executive | Customized briefcases and laptop bags | Professional appearance and brand representation | Material durability, customization options, and corporate branding |

| Travel & Hospitality | Personalized luggage and travel bags | Unique customer experience and brand differentiation | Weight, size options, personalization features, and shipping logistics |

| Promotional Products | Branded leather bags for corporate giveaways | Increased brand visibility and customer engagement | Cost-effectiveness, design options, and production lead times |

| Education & Training | Custom leather backpacks for educational institutions | Strengthens institutional branding and student pride | Quality assurance, durability, and design that accommodates educational needs |

How Are Custom Made Leather Bags Utilized in the Fashion & Retail Sector?

In the fashion and retail industry, custom made leather bags serve as a vital tool for luxury brands looking to differentiate themselves. These bespoke handbags can be tailored to reflect the unique identity of the brand, enhancing customer loyalty through personalized experiences. Buyers should focus on sourcing high-quality materials and craftsmanship, as these factors significantly impact the perceived value of the product. Additionally, flexibility in design options allows brands to cater to specific market trends, making it essential for suppliers to offer diverse customization capabilities.

What Role Do Customized Briefcases Play in Corporate Settings?

For corporate and executive environments, customized leather briefcases and laptop bags are essential for creating a professional image. These bags not only serve practical purposes but also act as a form of brand representation. Businesses benefit from sourcing durable materials that withstand daily use while ensuring the bags can be personalized with logos or initials. Key considerations include the balance between aesthetics and functionality, as well as the supplier’s ability to meet bulk order requirements and timely delivery schedules.

How Do Personalized Luggage Bags Enhance the Travel & Hospitality Industry?

In the travel and hospitality sector, personalized luggage and travel bags create memorable customer experiences. Customization options, such as monogramming, allow hotels and travel agencies to provide unique gifts or branded items that stand out. Buyers should prioritize lightweight materials and versatile designs that accommodate various travel needs. Furthermore, understanding shipping logistics is crucial for international buyers, especially when sourcing from regions like Europe or South America, where lead times and customs regulations may vary.

Why Are Branded Leather Bags Effective Promotional Products?

Branded leather bags are increasingly popular as promotional products for businesses aiming to boost visibility and engage customers. These bags serve as functional items that recipients are likely to use, effectively promoting the brand every time they are seen. Cost-effectiveness is a key consideration for buyers, alongside the availability of diverse design options that align with the brand’s image. Suppliers should also be prepared to meet production lead times to ensure timely delivery for promotional events.

How Can Custom Leather Backpacks Benefit Educational Institutions?

Custom leather backpacks are an excellent choice for educational institutions looking to strengthen their branding. By offering personalized bags to students, schools can foster a sense of pride and belonging within the community. Buyers in this sector must focus on quality assurance and durability to withstand the rigors of student life. Additionally, designs should accommodate educational needs, such as compartments for laptops and books, making it essential for suppliers to understand the specific requirements of the educational market.

3 Common User Pain Points for ‘custom made leather bags’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Custom Leather Bags

The Problem: B2B buyers often struggle to find suppliers who provide high-quality leather and sustainable materials for custom bags. In regions like Africa and South America, where local sourcing may be limited, buyers face the challenge of ensuring that their suppliers meet quality standards without sacrificing ethical practices. This can lead to inconsistencies in product quality, which directly affects customer satisfaction and brand reputation.

The Solution: To overcome this challenge, B2B buyers should conduct thorough research on potential suppliers. Look for manufacturers with established reputations for quality and ethical sourcing. Request samples of the leather and other materials to assess their quality firsthand. Engaging in partnerships with suppliers who prioritize transparency in their sourcing processes can also build trust. Consider attending trade shows or industry events to network with suppliers and learn about their sourcing practices. Additionally, establishing long-term relationships with reliable suppliers can facilitate better communication and ensure consistent quality over time.

Illustrative image related to custom made leather bags

Scenario 2: Customization and Design Limitations

The Problem: Many buyers encounter limitations in customization options when ordering custom leather bags, which can hinder their ability to meet specific market demands. For example, a buyer may want a bag designed for a particular demographic or occasion but find that the manufacturer’s offerings are too generic or inflexible. This lack of customization can lead to missed sales opportunities and an inability to stand out in a competitive market.

The Solution: To address this issue, buyers should communicate their unique design requirements clearly to manufacturers. Providing detailed specifications, sketches, or even mood boards can help convey the desired vision. Collaborating with a designer or an experienced manufacturer can facilitate more tailored solutions. Additionally, consider working with suppliers that offer a broader range of customization options, such as various colors, materials, and compartment configurations. Establishing a feedback loop with the manufacturer during the design process can also ensure that the final product aligns with market expectations.

Scenario 3: Managing Lead Times and Delivery Expectations

The Problem: Timely delivery is a critical concern for B2B buyers of custom leather bags, especially when dealing with international suppliers. Long lead times can disrupt inventory management and affect the ability to meet customer demands. Buyers may find themselves in a predicament if a supplier fails to deliver on time, leading to lost sales and damaged relationships with clients.

The Solution: To mitigate lead time issues, B2B buyers should establish clear timelines and expectations upfront with their suppliers. Discuss production schedules and potential bottlenecks during the initial negotiations to set realistic delivery dates. Implementing a project management tool can help track the production process and keep communication lines open. Additionally, consider building a buffer into your inventory planning to accommodate unforeseen delays. Diversifying your supplier base can also provide backup options in case one supplier is unable to meet deadlines, ensuring that your business remains agile and responsive to market demands.

Strategic Material Selection Guide for custom made leather bags

What Are the Key Properties of Common Materials Used in Custom Made Leather Bags?

When selecting materials for custom made leather bags, understanding the properties and performance characteristics of each option is crucial. Here, we analyze four common materials used in the production of leather bags: full-grain leather, top-grain leather, suede, and synthetic leather. Each material offers distinct advantages and limitations that can impact the final product’s durability, aesthetics, and cost.

How Does Full-Grain Leather Perform in Custom Made Leather Bags?

Full-grain leather is the highest quality leather available, retaining the natural grain and texture of the hide. This material is known for its exceptional durability and resistance to wear and tear. It develops a unique patina over time, enhancing its aesthetic appeal. However, full-grain leather can be more expensive due to its sourcing and processing requirements.

Pros:

– Highly durable and long-lasting

– Develops a beautiful patina

– Breathable and moisture-resistant

Cons:

– Higher cost compared to other leathers

– Requires special care to maintain appearance

– May be heavier than synthetic alternatives

For international buyers, particularly in regions like Africa and South America, understanding the sourcing practices and compliance with environmental standards is essential. Full-grain leather often adheres to strict regulations regarding animal welfare and tanning processes, which may vary by country.

What Are the Advantages of Top-Grain Leather for Custom Bags?

Top-grain leather is slightly less durable than full-grain leather but is more affordable and easier to work with. It is created by sanding down the surface of the hide to remove imperfections, resulting in a smoother finish. This material is more stain-resistant and often treated with protective coatings.

Illustrative image related to custom made leather bags

Pros:

– More affordable than full-grain leather

– Easier to clean and maintain

– Versatile for various styles and designs

Cons:

– Less durable than full-grain leather

– May not develop a patina as beautifully

– Potentially less breathable than full-grain options

For B2B buyers in Europe and the Middle East, top-grain leather is often preferred for its balance of quality and cost. Compliance with EU regulations on leather production and environmental impact is a significant consideration in sourcing.

How Does Suede Compare as a Material for Custom Made Leather Bags?

Suede, made from the underside of animal hides, offers a soft texture and a unique aesthetic. It is lightweight and provides a luxurious feel but is generally less durable than full-grain or top-grain leather. Suede is more susceptible to staining and water damage, which can limit its application in certain environments.

Pros:

– Soft and luxurious texture

– Lightweight and comfortable to carry

– Unique aesthetic appeal

Cons:

– Less durable and more prone to damage

– Requires special care to avoid stains

– Not suitable for all weather conditions

For buyers from regions with varying climates, such as Africa and South America, the application of suede may be limited. Understanding local weather conditions and consumer preferences is essential for successful product positioning.

What Role Does Synthetic Leather Play in Custom Made Leather Bags?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to natural leather. It is available in a wide range of colors and textures, making it highly customizable. While synthetic leather is generally easier to clean and maintain, it lacks the breathability and durability of genuine leather.

Illustrative image related to custom made leather bags

Pros:

– Cost-effective and widely available

– Easy to clean and maintain

– Highly customizable in terms of color and design

Cons:

– Less durable than natural leathers

– Can appear less luxurious

– Environmental concerns regarding production

For B2B buyers, particularly in emerging markets, synthetic leather can be an attractive option due to its affordability and versatility. However, awareness of environmental regulations regarding synthetic materials is crucial, especially in regions like Europe where sustainability is a priority.

Illustrative image related to custom made leather bags

Summary of Material Selection for Custom Made Leather Bags

| Material | Typical Use Case for custom made leather bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end bags, luxury items | Extremely durable and long-lasting | Higher cost | High |

| Top-Grain Leather | Everyday bags, versatile designs | Affordable and easy to maintain | Less durable than full-grain | Medium |

| Suede | Fashion bags, lightweight designs | Soft texture and unique aesthetic | Prone to stains and less durable | Medium |

| Synthetic Leather | Budget-friendly options, trendy styles | Cost-effective and highly customizable | Less luxurious and durable | Low |

This guide provides B2B buyers with essential insights into material selection for custom made leather bags, enabling informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom made leather bags

What Are the Key Stages in the Manufacturing Process of Custom Made Leather Bags?

The manufacturing process for custom made leather bags is intricate, involving several key stages that ensure the final product meets the specifications and quality expectations of B2B buyers. Understanding these stages can help international buyers make informed decisions when selecting suppliers.

1. Material Preparation: Sourcing and Selection of Leather

The first step involves selecting high-quality leather, which is critical for durability and aesthetics. Suppliers often source leather from reputable tanneries, ensuring it meets specific criteria such as grain type, thickness, and finish. For custom bags, buyers may specify the type of leather—such as full-grain, top-grain, or suede—along with color and texture preferences.

Once the leather is sourced, it undergoes preparation, which includes cutting it into appropriate patterns based on the bag design. Suppliers may also provide options for different leather finishes, such as smooth or pebbled textures, to match the desired aesthetic.

2. Forming: Crafting the Bag Structure

The forming stage involves shaping the leather into the initial structure of the bag. This can include techniques such as die-cutting, where patterns are cut from the leather using precision tools. For more complex designs, advanced technologies like laser cutting may be employed to ensure accuracy.

At this stage, additional components like zippers, buckles, and straps are also prepared. Suppliers often allow customization options for these components, enabling buyers to choose materials and finishes that align with their brand identity.

3. Assembly: Bringing the Components Together

During the assembly phase, the cut leather pieces and additional components are stitched together. This process typically requires skilled artisans who can execute intricate stitching patterns, ensuring both durability and aesthetic appeal.

Various stitching techniques, such as saddle stitching or machine stitching, may be used depending on the design and intended use of the bag. This is also the phase where any custom features, such as personalized initials or unique compartments, are integrated into the bag.

4. Finishing: Quality Control and Detailing

The final stage of manufacturing involves finishing touches, which may include polishing, edge finishing, and applying protective coatings to enhance the bag’s longevity. Quality assurance checks are critical at this stage to ensure that the product meets the required standards before it is shipped to the buyer.

How is Quality Assurance Implemented in Custom Leather Bag Manufacturing?

Quality assurance (QA) is a vital component in the manufacturing process of custom leather bags, especially for international B2B buyers who require adherence to specific standards. Implementing robust QA processes helps in maintaining product consistency and reliability.

Illustrative image related to custom made leather bags

Relevant International Standards for Quality Assurance

Most reputable manufacturers adhere to international quality standards such as ISO 9001, which sets criteria for a quality management system. Compliance with these standards ensures that the manufacturing processes are consistently monitored and improved.

In addition to ISO standards, industry-specific certifications may be relevant. For example, CE marking indicates that a product meets EU safety and health requirements, which can be crucial for buyers in Europe. Similarly, API certifications may be relevant for products that are part of a larger industrial supply chain.

What Are the Key Quality Control Checkpoints in Leather Bag Manufacturing?

Quality control involves several critical checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting the leather and other materials upon arrival to ensure they meet specified quality standards. Any defective materials are rejected at this stage.

-

In-Process Quality Control (IPQC): As the bags are being assembled, regular checks are performed to ensure that stitching, alignment, and other aspects are consistent with the design specifications.

-

Final Quality Control (FQC): Before shipping, each bag undergoes a thorough inspection to check for defects and ensure that all customizations are correctly executed. This is the last opportunity to catch any issues before the product reaches the buyer.

Common Testing Methods for Quality Assurance

Manufacturers may employ various testing methods to assess the quality of leather bags, including:

- Durability Tests: Assessing the wear and tear of the leather under different conditions.

- Colorfastness Tests: Ensuring that colors do not fade or bleed when exposed to light or moisture.

- Structural Integrity Tests: Checking that seams and components can withstand regular use.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is essential for mitigating risks. Here are some effective strategies:

-

Conducting Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality control processes. Buyers may choose to conduct these audits themselves or hire third-party inspection services.

-

Requesting Quality Reports: Suppliers should be able to provide quality assurance reports that detail their compliance with international standards and any testing results from their QC processes.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of the manufacturing processes and product quality. This is particularly useful for ensuring compliance with relevant standards.

-

Understanding QC/CERT Nuances for International Buyers: Buyers should be aware of the specific regulations and standards that apply in their region. For instance, some regions may have stricter requirements for leather goods, and understanding these can help buyers choose compliant suppliers.

Conclusion

In summary, the manufacturing processes and quality assurance measures for custom made leather bags are comprehensive and require careful attention to detail. For B2B buyers, understanding these processes not only aids in selecting the right suppliers but also ensures that the final products meet both quality and compliance standards. By leveraging robust quality control measures, buyers can confidently invest in custom leather bags that will meet their needs and enhance their brand offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom made leather bags’

To ensure a successful procurement process for custom made leather bags, this guide provides a comprehensive checklist designed specifically for B2B buyers. Each step addresses critical aspects of sourcing to help you make informed decisions, reducing risks and enhancing product quality.

Step 1: Define Your Technical Specifications

Clearly outlining your requirements is the foundation of a successful sourcing process. This includes determining the type of leather, design specifications, dimensions, and any custom features like pockets or compartments. Providing detailed specifications ensures that suppliers understand your needs, reducing the likelihood of miscommunication.

Illustrative image related to custom made leather bags

- Considerations:

- Types of leather (e.g., calfskin, full-grain)

- Desired finishes (e.g., pebbled, smooth)

- Customization options (e.g., colors, branding)

Step 2: Research Potential Suppliers

Identifying reliable suppliers is crucial. Look for manufacturers with a strong reputation in the industry, especially those specializing in custom leather products. Research their business history, client reviews, and portfolio to gauge their expertise.

- Tips:

- Utilize B2B platforms and trade shows to discover potential partners.

- Check for certifications that indicate quality standards, such as ISO or leather certification.

Step 3: Evaluate Supplier Capabilities

Before committing, assess each supplier’s production capabilities. This includes their ability to handle your order volume, meet deadlines, and maintain quality. Understanding their manufacturing process can provide insights into potential issues that may arise.

- Key questions to ask:

- What is your typical lead time for custom orders?

- Can you provide samples of previous custom work?

- What quality control measures do you have in place?

Step 4: Request and Compare Quotes

Once you have shortlisted suppliers, request detailed quotes. Ensure that quotes include all costs such as materials, labor, shipping, and any potential tariffs. Comparing multiple quotes will help you understand the market rate and identify any discrepancies.

- Important factors to compare:

- Pricing structure (fixed vs. variable)

- Payment terms (e.g., deposits, full payment upfront)

- Additional costs (e.g., customization fees)

Step 5: Verify Quality Assurance Processes

Quality assurance is vital for custom leather bags, as it impacts durability and customer satisfaction. Verify what quality control processes each supplier has in place, including inspections and testing procedures.

- What to look for:

- Evidence of quality certifications

- Sample review processes

- Feedback mechanisms from previous clients

Step 6: Assess Communication and Support

Effective communication is essential throughout the sourcing process. Evaluate how responsive and supportive each supplier is during your initial interactions. A supplier who is communicative and provides timely updates can significantly ease the procurement process.

Illustrative image related to custom made leather bags

- Key indicators:

- Responsiveness to inquiries

- Clarity in communication

- Willingness to provide ongoing support

Step 7: Finalize Contracts and Terms

Once you’ve selected a supplier, it’s crucial to formalize your agreement through a contract. Ensure that all terms, including delivery schedules, payment schedules, and quality expectations, are clearly outlined. A well-structured contract protects both parties and sets clear expectations.

- Essential elements to include:

- Detailed specifications of the products

- Agreed timelines for production and delivery

- Clauses for handling disputes or quality issues

By following this step-by-step checklist, B2B buyers can enhance their procurement strategies for custom made leather bags, ensuring that they receive high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for custom made leather bags Sourcing

What Are the Key Cost Components in Custom Made Leather Bags?

When sourcing custom made leather bags, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of leather—such as calf, cowhide, or exotic leathers—significantly impacts the cost. Premium materials often command higher prices but provide better durability and aesthetics.

-

Labor: Skilled craftsmanship is essential in producing high-quality leather bags. Labor costs can vary based on the region, with countries offering lower labor costs sometimes sacrificing quality.

-

Manufacturing Overhead: This includes the costs associated with running the production facility, including utilities, maintenance, and administrative expenses.

-

Tooling: Custom designs may require specialized tools or molds, which can add to initial costs. This is particularly relevant for bespoke items tailored to specific customer specifications.

-

Quality Control (QC): Implementing rigorous QC processes ensures that each bag meets the required standards, which can add to overall costs but is critical for maintaining brand reputation.

-

Logistics: Shipping and handling costs can vary significantly depending on the origin and destination of the goods, as well as the chosen Incoterms.

-

Margin: Suppliers will typically add a margin to cover risks and ensure profitability, which can vary widely based on competition and demand.

How Do Price Influencers Affect Custom Leather Bag Pricing?

Several factors influence the pricing of custom leather bags:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often result in better pricing due to economies of scale. Suppliers may offer discounts for bulk orders.

-

Specifications and Customization: More complex designs or additional features (like custom compartments or unique finishes) can lead to higher prices. Buyers should be clear about their specifications to avoid unexpected costs.

-

Materials Quality and Certifications: Higher-quality materials and certifications (such as eco-friendly or sustainable sourcing) can increase costs but may appeal to certain markets, particularly in Europe.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established brands may charge a premium for their perceived quality and service.

-

Incoterms: The chosen Incoterms can significantly affect the total landed cost. For instance, DDP (Delivered Duty Paid) includes all shipping and customs fees, while EXW (Ex Works) places the burden of logistics on the buyer.

What Are Effective Buyer Tips for Negotiating Prices?

B2B buyers should consider the following strategies to enhance cost efficiency when sourcing custom leather bags:

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, lead times, and pricing. Establishing a relationship with suppliers can lead to better terms over time.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and potential resale value. Higher-quality bags may have a higher upfront cost but lower long-term expenses.

-

Understand Pricing Nuances: Be aware that prices may vary based on regional market trends. For instance, sourcing from countries like Vietnam or Nigeria may offer different pricing dynamics due to local economic factors.

-

Request Sample Products: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes later.

-

Stay Informed on Market Trends: Regularly research market conditions and competitor pricing to ensure you’re getting a fair deal.

Conclusion

While sourcing custom made leather bags, it’s essential for buyers to understand the intricate cost structure and pricing influencers. By leveraging negotiation tactics and considering the total cost of ownership, businesses can make informed decisions that enhance their profitability in the competitive leather goods market.

Disclaimer: The prices and costs discussed in this analysis are indicative and can vary based on specific orders, supplier negotiations, and market conditions. Always conduct thorough due diligence before finalizing any contracts.

Alternatives Analysis: Comparing custom made leather bags With Other Solutions

When considering custom made leather bags, it’s essential to evaluate other viable alternatives that may meet similar needs for functionality, style, and durability. This comparison will assist international B2B buyers in making informed decisions based on performance, cost, and suitability for their unique markets.

| Comparison Aspect | Custom Made Leather Bags | Alternative 1: Synthetic Leather Bags | Alternative 2: Canvas Bags |

|---|---|---|---|

| Performance | High durability, unique customization options | Good durability, less natural feel | Moderate durability, versatile use |

| Cost | Higher price point due to craftsmanship | Generally lower cost | Affordable, budget-friendly |

| Ease of Implementation | Requires time for customization | Quick production and availability | Easy to source and produce |

| Maintenance | Requires specific care to maintain quality | Easy to clean and maintain | Simple to wash and dry |

| Best Use Case | Luxury markets, corporate gifts, branding | Everyday use, mass-market appeal | Casual, promotional items |

How Do Synthetic Leather Bags Compare to Custom Made Leather Bags?

Synthetic leather bags offer a cost-effective alternative with a variety of styles and colors. They are generally easier to produce and maintain, making them suitable for mass-market appeal. However, they lack the unique, high-quality feel of custom leather bags, which may deter buyers in luxury markets. While they are durable, they may not provide the same level of prestige or long-term value as custom leather options.

What Advantages Do Canvas Bags Offer Compared to Custom Made Leather Bags?

Canvas bags present an affordable solution for businesses looking for promotional items or casual use. They are lightweight, versatile, and easy to clean, making them ideal for everyday wear. However, their durability and aesthetic appeal typically do not match that of custom leather bags. Canvas bags may also lack the personalized touch that many B2B buyers seek when investing in products meant to represent their brand.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate bag solution hinges on understanding the specific requirements of your target market. If you are catering to a luxury clientele that values customization and quality, custom made leather bags are likely the superior choice. Conversely, if you aim to provide functional, budget-friendly options for a broader audience, synthetic leather or canvas bags might be more suitable. By carefully assessing performance, cost, and maintenance needs, B2B buyers can align their product offerings with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for custom made leather bags

What Are the Key Technical Properties of Custom Made Leather Bags?

When investing in custom made leather bags, understanding the technical specifications is crucial for ensuring product quality and longevity. Below are some critical specifications that buyers should consider:

Illustrative image related to custom made leather bags

1. Material Grade

The grade of leather significantly impacts the bag’s durability, aesthetics, and cost. Full-grain leather, for example, is the highest quality and retains the natural grain, offering superior strength and beauty. In contrast, corrected-grain leather, while less expensive, is treated to remove imperfections, potentially compromising its longevity. For B2B buyers, selecting the right material grade is vital for meeting customer expectations and ensuring the product’s marketability.

2. Stitching and Thread Quality

The stitching technique and thread quality play a pivotal role in the durability of leather bags. Double-stitching is often preferred for its strength, while the type of thread used (e.g., polyester vs. nylon) can affect both appearance and wear resistance. B2B buyers should prioritize suppliers who adhere to high-quality stitching standards to ensure that the bags withstand daily use and maintain their structural integrity.

3. Tolerance Levels

Tolerance refers to the acceptable range of variation in the dimensions of the leather bag. Precise tolerances are essential for ensuring that components fit together seamlessly, which is particularly important for custom designs. For B2B buyers, understanding tolerance levels helps in assessing supplier capabilities and ensuring that the final product meets specific design requirements.

4. Finish Type

Leather finishes can vary widely, from matte to glossy, and can include treatments like waterproofing or oiling. The finish affects not only the bag’s appearance but also its maintenance and longevity. B2B buyers must consider the finish type in relation to the intended use of the bag, as different finishes may require different care and maintenance protocols.

5. Weight Capacity

Understanding the weight capacity is crucial, especially for bags intended for specific uses, such as travel or professional settings. This specification ensures that the bag can withstand the intended load without compromising its structure. For B2B buyers, knowing the weight capacity helps in marketing the product to the right audience, ensuring customer satisfaction.

What Are Common Trade Terms Used in the Custom Leather Bag Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces products that are sold under another company’s brand. For custom leather bags, this means that buyers can partner with manufacturers to create unique designs that carry their branding. Understanding OEM partnerships can open avenues for brand differentiation.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to produce for a single order. This term is crucial for B2B buyers to understand, as it affects inventory management and initial investment costs. Knowing the MOQ helps businesses plan their procurement strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing information for specific products. It typically includes details about the desired specifications and quantities. Using RFQs can streamline the procurement process, allowing businesses to compare offers efficiently.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is vital for B2B transactions across borders. Understanding these terms can mitigate risks associated with international trade.

5. Customization Options

This term refers to the various ways a buyer can personalize a product, such as size, color, material, or additional features like pockets or compartments. Knowing the customization options available can enhance the buyer’s ability to meet market demands and cater to specific customer preferences.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing custom made leather bags, ultimately leading to better product offerings and enhanced customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the custom made leather bags Sector

What Are the Key Market Dynamics and Trends Impacting Custom Made Leather Bags?

The global market for custom made leather bags is experiencing robust growth, driven by an increasing demand for personalized products and unique designs. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide customizable options that align with local tastes and cultural preferences. This demand is further fueled by the rise of e-commerce platforms that allow international buyers to connect with artisans and manufacturers directly, streamlining the sourcing process.

Emerging technologies such as 3D modeling and virtual reality are revolutionizing the design and customization processes. Buyers can now visualize their customizations in real-time, leading to more informed purchasing decisions. Additionally, the integration of advanced supply chain management systems has improved efficiency, enabling faster turnaround times from design to delivery. As competition intensifies, manufacturers are also focusing on enhanced customer service and post-purchase support to build long-term relationships with B2B clients.

How Does Sustainability and Ethical Sourcing Influence the Custom Leather Bag Market?

The importance of sustainability and ethical sourcing in the custom leather bags sector cannot be overstated. B2B buyers are increasingly prioritizing suppliers who adhere to environmentally friendly practices and maintain transparent supply chains. The leather industry has been criticized for its environmental impact, particularly in water usage and chemical waste. As such, manufacturers are now seeking eco-friendly tanning processes and sourcing leather from certified suppliers who practice sustainable farming.

Green certifications, such as the Leather Working Group (LWG) certification, are becoming essential for businesses looking to enhance their credibility in the market. Buyers should actively seek out suppliers who are committed to sustainability, as this not only aligns with global environmental goals but also resonates with consumers who prefer to support brands with a strong ethical foundation. This trend is particularly relevant in markets like Europe, where regulatory frameworks are becoming stricter regarding environmental compliance.

Illustrative image related to custom made leather bags

What Is the Evolution of Custom Made Leather Bags in the B2B Context?

The evolution of custom made leather bags can be traced back to traditional craftsmanship, where artisans created bespoke items tailored to individual specifications. Over the years, the demand for personalized products has surged, driven by consumer trends favoring uniqueness over mass production. Today, custom leather bags are not only viewed as functional items but also as fashion statements and symbols of status.

This shift has led to the emergence of modern manufacturing techniques and digital tools that allow for greater customization options. As a result, international B2B buyers are more empowered than ever to influence product design, ensuring that their specific needs and regional preferences are met. The historical context of custom leather bags highlights the blend of craftsmanship and innovation that continues to shape the industry today, making it a compelling segment for B2B investment.

Frequently Asked Questions (FAQs) for B2B Buyers of custom made leather bags

-

How do I request a quote for custom made leather bags?

To request a quote, you should fill out the online inquiry form provided by the manufacturer. Be sure to include specific details such as the type of leather, desired dimensions, customization options, and quantities. This information will help the supplier provide an accurate estimate. Typically, you can expect a response within two business days, allowing you to move forward with your procurement process efficiently. -

What is the minimum order quantity (MOQ) for custom leather bags?

Minimum order quantities vary by supplier, but most manufacturers require a minimum of 50 to 100 units for custom orders. It’s essential to confirm the MOQ with your chosen supplier as this will affect your budgeting and inventory planning. If you’re considering a smaller order, inquire about potential options for sample orders or smaller batch production to test the market. -

What payment terms should I expect when ordering custom leather bags?

Payment terms can vary significantly among suppliers, but common practices include a deposit of 30-50% upfront, with the balance due before shipment. Some suppliers may accept various payment methods, including credit cards, bank transfers, or even letters of credit for larger orders. Ensure you discuss and confirm payment terms in advance to avoid any misunderstandings later in the process. -

How long does it take to manufacture and ship custom leather bags?

The production time for custom leather bags generally ranges from two to six weeks, depending on the complexity of the design and the supplier’s workload. After production, shipping times will vary based on the destination and chosen shipping method. It’s advisable to factor in both production and shipping times when planning your inventory needs to ensure timely delivery to your customers. -

What customization options are available for leather bags?

Most manufacturers offer a range of customization options including size, color, leather type, and additional features like compartments, straps, and personalization (e.g., initials). When discussing your requirements, be clear about your design vision and any specific needs your target market may have. This will help the supplier provide the best options that align with your brand identity. -

How do I ensure the quality of custom leather bags before finalizing my order?

To ensure quality, request samples of materials and previous work from the supplier. Conduct a thorough vetting process that includes checking references and reviews from other businesses. Additionally, consider visiting the manufacturer’s facility if possible, or request third-party quality assurance inspections to confirm that their production standards meet your expectations. -

What logistics should I consider when importing custom leather bags?

When importing, consider factors such as shipping costs, customs duties, and import regulations in your country. Research the best shipping methods (air freight vs. sea freight) based on your timelines and budget. Partnering with a reliable logistics provider can help streamline the import process, ensuring compliance with all regulations and reducing the risk of delays. -

How can I vet a supplier for custom leather bags effectively?

To vet a supplier, start by checking their business credentials, including registration and certifications. Look for reviews and testimonials from other clients, focusing on their reputation for quality and reliability. Additionally, assess their communication responsiveness and willingness to accommodate your specific needs. Conducting a factory visit or using a third-party verification service can further enhance your confidence in their capabilities.

Top 4 Custom Made Leather Bags Manufacturers & Suppliers List

1. The Jacket Maker – Custom Leather Bags

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom leather bags for women and men, available in various colors, styles, materials, finishes, and details. Options include custom handbags, tote bags, backpacks, messenger bags, briefcases, weekender and duffel bags, portfolio bags, and clutch purses.

2. Laudividni – Custom Luxury Handbags

Domain: laudividni.com

Registered: 2008 (17 years)

Introduction: Custom Made Handbags in Luxury Leathers

3. Jenny N Design – Customizable Leather Bags

Domain: jennyndesign.com

Registered: 2007 (18 years)

Introduction: Customizable American Handmade Leather Bags made in Texas, USA. Key products include: 1. Leather Zipper Pouch in various colors and patterns – Regular price $55 each. 2. Ruche Clutch in Distressed Olive – Regular price $140. 3. Ruche Clutch in Distressed Olive, Blossom – Regular price $150. 4. Packet Plus in Chestnut, Cactus Patchwork – Regular price $350. 5. Archive Micro in Olive with Blossoms -…

4. B Pozzitive Bags – Custom Upcycled Leather Bags

Domain: bpozzitivebags.com

Registered: 2019 (6 years)

Introduction: Custom Upcycled Leather Bags – B Pozzitive Bags offers made-to-order leather bags that can be customized to reflect individual style. Each bag is handmade by repurposing worn leather goods such as jackets, vests, and boots, which carry their own stories. The collection includes various designs such as Sunflowers, Dog Lover, Moose, and Large Tote. All products are currently listed with a regular pr…

Strategic Sourcing Conclusion and Outlook for custom made leather bags

What Are the Key Takeaways for B2B Buyers in Custom Made Leather Bags?

In summary, the strategic sourcing of custom made leather bags offers unparalleled opportunities for B2B buyers seeking quality, uniqueness, and brand differentiation. By collaborating with skilled artisans and manufacturers, businesses can create bespoke products tailored to their specific market needs. Understanding the importance of personalization—such as color choices, material finishes, and functional designs—enables buyers to cater to diverse consumer preferences across regions.

How Can Strategic Sourcing Enhance Your Business?

Investing in strategic sourcing not only ensures high-quality materials but also fosters long-term partnerships with manufacturers who can adapt to evolving trends. This agility is crucial in markets like Africa, South America, the Middle East, and Europe, where consumer demands are continuously shifting. Moreover, the ability to offer customized leather bags can significantly enhance brand loyalty and customer satisfaction.

What Should International Buyers Do Next?

As the market for custom leather bags expands, now is the time for international B2B buyers to engage in proactive sourcing strategies. By leveraging the insights gained from this guide, companies can streamline their procurement processes and build a distinctive product line that resonates with their target audiences. Embrace the potential of custom leather bags to elevate your brand and meet the unique demands of your customers—start your sourcing journey today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.