Introduction: Navigating the Global Market for custom leather embossing stamp

In the dynamic landscape of global commerce, sourcing high-quality custom leather embossing stamps presents a unique challenge for B2B buyers. With the increasing demand for personalized leather products across various industries, businesses must navigate a complex market filled with diverse suppliers, materials, and pricing structures. This guide aims to demystify the process of acquiring custom leather embossing stamps, providing insights into types of stamps available, their applications, and essential considerations for supplier vetting.

As a comprehensive resource, this guide equips international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe (including Germany and Brazil)—with the knowledge needed to make informed purchasing decisions. From understanding the nuances of different materials, such as brass and high-density resin, to exploring the intricacies of design customization and production timelines, we cover it all. Additionally, we delve into cost considerations and shipping options, ensuring that buyers are well-prepared to select the most suitable products for their specific needs.

By addressing common challenges and providing actionable insights, this guide empowers businesses to confidently engage with suppliers, streamline their sourcing processes, and ultimately enhance their product offerings in the competitive leather market. Whether you’re looking to create unique branding for your products or simply expand your leather crafting capabilities, understanding the landscape of custom leather embossing stamps is essential for success.

Table Of Contents

- Top 8 Custom Leather Embossing Stamp Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather embossing stamp

- Understanding custom leather embossing stamp Types and Variations

- Key Industrial Applications of custom leather embossing stamp

- 3 Common User Pain Points for ‘custom leather embossing stamp’ & Their Solutions

- Strategic Material Selection Guide for custom leather embossing stamp

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather embossing stamp

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather embossing stamp’

- Comprehensive Cost and Pricing Analysis for custom leather embossing stamp Sourcing

- Alternatives Analysis: Comparing custom leather embossing stamp With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather embossing stamp

- Navigating Market Dynamics and Sourcing Trends in the custom leather embossing stamp Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather embossing stamp

- Strategic Sourcing Conclusion and Outlook for custom leather embossing stamp

- Important Disclaimer & Terms of Use

Understanding custom leather embossing stamp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Brass Leather Stamp | Made from durable brass; ideal for high-volume use. | Branding, marking logos on leather goods. | Pros: Long-lasting, high-quality impression. Cons: Higher initial cost. |

| Handheld Steel Stamp | Versatile for various materials; can be hammered. | Small-scale production, artisan crafts. | Pros: Cost-effective, easy to use. Cons: Limited lifespan compared to brass. |

| Custom Leather Roll Dies | Designed for continuous patterns; can cover large areas. | Mass production of leather goods. | Pros: Efficient for large runs, consistent quality. Cons: Higher setup cost, less flexibility. |

| Heated Branding Iron | Electric or manual; allows for heat embossing. | Decorative branding, high-end products. | Pros: Creates a clean, professional finish. Cons: Requires more equipment and setup. |

| High-Density Resin Stamp | Affordable alternative; limited durability. | Short-term projects, promotional items. | Pros: Lower cost, quick turnaround. Cons: Less durable, not suitable for high-volume use. |

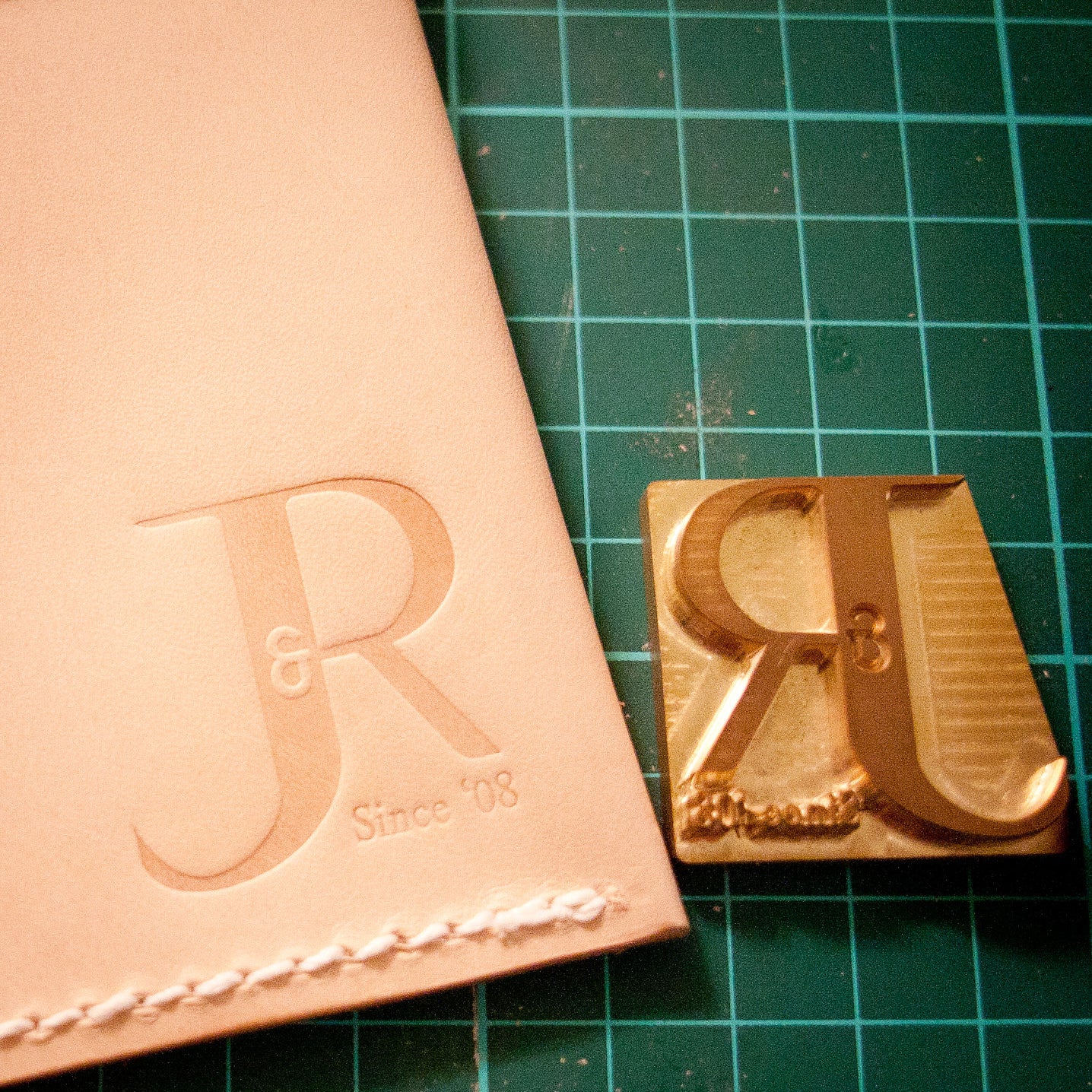

What Are the Key Characteristics of Custom Brass Leather Stamps?

Custom brass leather stamps are renowned for their durability and ability to create high-quality impressions on leather. They are ideal for businesses that require frequent branding, such as leather goods manufacturers and artisans. The primary advantage of brass is its longevity, allowing for indefinite use, making it a cost-effective solution in the long run. B2B buyers should consider the initial investment versus the potential for high-volume applications when choosing this type.

Illustrative image related to custom leather embossing stamp

How Do Handheld Steel Stamps Compare for Versatility?

Handheld steel stamps are versatile tools suitable for various materials, including leather, wood, and plastics. These stamps are particularly favored by small-scale producers and artisans who engage in custom crafts. They are easy to operate and can be economically advantageous for businesses focused on smaller production runs. However, buyers should note that while they are cost-effective, they may not last as long as brass options, limiting their use in larger projects.

Why Choose Custom Leather Roll Dies for Mass Production?

Custom leather roll dies are specifically designed for continuous patterns, making them ideal for businesses engaged in mass production. They facilitate efficient stamping over large areas, ensuring consistent quality across products. However, the initial setup cost can be higher, making them more suitable for companies that anticipate high-volume orders. B2B buyers should assess their production needs and budget to determine if this option aligns with their operational strategy.

What Are the Benefits of Using Heated Branding Irons?

Heated branding irons, available in both electric and manual forms, are used for heat embossing on leather. This method creates a clean and professional finish, making it popular for high-end products and decorative branding. While they provide a premium look, buyers must consider the additional equipment and setup required, which may increase the overall cost. This option is best suited for businesses that prioritize quality and aesthetics in their branding efforts.

When Should Businesses Consider High-Density Resin Stamps?

High-density resin stamps offer an affordable alternative for businesses looking for quick solutions for short-term projects. They are ideal for promotional items where durability is less of a concern. However, their limited lifespan—typically around 1,000 uses—makes them unsuitable for high-volume production. B2B buyers should weigh the lower cost against the potential need for frequent replacements when deciding on this option for their branding needs.

Illustrative image related to custom leather embossing stamp

Key Industrial Applications of custom leather embossing stamp

| Industry/Sector | Specific Application of custom leather embossing stamp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Branding leather goods such as handbags and belts | Enhances brand identity and customer loyalty | Material durability, design complexity, and production time |

| Leather Goods Manufacturing | Custom logos on leather products like wallets and shoes | Differentiates products in a competitive market | Precision in design, compatibility with various leather types |

| Automobilindustrie | Embossing leather interiors in vehicles | Adds luxury and personalization to automotive offerings | Heat resistance of materials, compatibility with upholstery types |

| Home Decor | Custom stamps for leather furniture and accessories | Elevates product aesthetics and brand recognition | Size specifications, engraving depth, and production methods |

| Craft and Hobby | Personalized leather craft projects | Enables unique, custom creations for artisans and hobbyists | Ease of use, affordability, and design flexibility |

How is Custom Leather Embossing Stamp Used in Fashion and Apparel?

In the fashion and apparel industry, custom leather embossing stamps are utilized to brand leather goods such as handbags, belts, and shoes. These stamps allow manufacturers to imprint unique logos or designs onto their products, enhancing brand identity and fostering customer loyalty. For international B2B buyers, particularly those in regions like Europe and South America, sourcing high-quality materials that can withstand wear while maintaining aesthetic appeal is crucial. Buyers should consider the durability of the stamp material and the intricacy of their design to ensure long-lasting impressions.

What Role Does Custom Leather Embossing Stamp Play in Leather Goods Manufacturing?

In leather goods manufacturing, custom stamps are essential for applying logos and designs to items like wallets, purses, and footwear. This process not only differentiates products in a competitive market but also adds a touch of personalization that appeals to consumers. B2B buyers must focus on sourcing stamps that can handle various leather types and thicknesses, ensuring the design is executed with precision. Additionally, understanding the production timelines and the potential for customization can significantly impact order fulfillment and customer satisfaction.

How is Custom Leather Embossing Stamp Applied in the Automotive Sector?

The automotive industry employs custom leather embossing stamps to enhance the interiors of vehicles, particularly in luxury models. By embossing logos or unique designs on leather seats and trim, manufacturers can add a level of personalization and luxury that appeals to consumers. For international buyers, especially those in the Middle East where luxury vehicles are in high demand, sourcing stamps that can withstand high temperatures and are compatible with different upholstery materials is essential. This ensures that the embossed designs remain intact and visually appealing over time.

Illustrative image related to custom leather embossing stamp

How is Custom Leather Embossing Stamp Used in Home Decor?

In the home decor sector, custom leather embossing stamps are used to create unique designs on leather furniture and accessories. This application elevates the aesthetic appeal of products, allowing businesses to stand out in a crowded market. B2B buyers should consider the size specifications and engraving depth of the stamps to achieve the desired effect on various leather products. Additionally, understanding the production methods available can help buyers select the most efficient and cost-effective options for their needs.

How Does Custom Leather Embossing Stamp Benefit Craft and Hobby Industries?

For artisans and hobbyists, custom leather embossing stamps enable the creation of personalized leather craft projects, such as journals, wallets, and decorative items. This capability allows for unique, custom creations that can enhance the value of handcrafted products. When sourcing these stamps, buyers should prioritize ease of use and affordability, as well as the flexibility to accommodate various designs. This ensures that crafters can produce high-quality, personalized items that resonate with their customers and enhance their market appeal.

3 Common User Pain Points for ‘custom leather embossing stamp’ & Their Solutions

Scenario 1: Unclear Design Specifications Leading to Errors

The Problem: B2B buyers often struggle with the intricacies of providing accurate design specifications for custom leather embossing stamps. In many cases, companies may have a logo or branding concept in mind, but lack the technical knowledge to translate that into a usable format for manufacturers. This can lead to miscommunication, resulting in stamps that don’t meet the desired quality or dimensions, causing delays and additional costs.

The Solution: To overcome this issue, buyers should invest time in preparing high-quality vector files (such as AI or PDF formats) of their designs, as these are easier for manufacturers to work with. Additionally, providing clear dimensions and application details will ensure that the manufacturer understands the intended use of the stamp. Engaging in a dialogue with the supplier before finalizing the design can also be beneficial. Many companies offer mock-ups and revisions—utilize these services to refine your design and ensure it meets your specifications. By being proactive and communicative, buyers can significantly reduce the risk of errors and ensure a smoother production process.

Illustrative image related to custom leather embossing stamp

Scenario 2: Material Selection and Its Impact on Longevity

The Problem: Buyers often find themselves overwhelmed by the choices of materials available for custom leather embossing stamps, which can significantly affect the durability and effectiveness of the stamp. Many companies may choose a less durable material to save costs, only to face the consequences of a poorly performing stamp that cannot withstand high-volume use or the intricacies of their designs.

The Solution: To ensure longevity and performance, it’s crucial for buyers to select the right material based on their intended usage. Brass is often recommended for high-volume applications due to its durability, while high-density resin can be suitable for lower volumes but may wear out faster. When placing an order, buyers should assess their production needs and consult with manufacturers about the expected lifespan of different materials. Additionally, investing in a quality press or branding iron suited for the selected material can enhance the stamping process, further ensuring that the final product meets the necessary standards. By prioritizing material quality, buyers can avoid frequent replacements and enhance their production efficiency.

Scenario 3: Timely Delivery Amid Production Delays

The Problem: In the fast-paced B2B environment, timing is critical. Buyers often face challenges with production delays, which can hinder their ability to meet customer demands or launch new products on schedule. This can be particularly problematic when working with suppliers who may have extended lead times or are unable to accommodate rush orders.

The Solution: To mitigate the risk of delays, B2B buyers should conduct thorough research on potential suppliers, focusing on their production capabilities and turnaround times. When placing an order, it’s essential to communicate deadlines clearly and inquire about rush order options, as many manufacturers offer expedited services for an additional fee. Additionally, establishing a reliable relationship with a chosen supplier can facilitate better communication and prioritization of orders. For critical projects, consider ordering in advance or maintaining a small inventory of essential stamps to ensure that production can continue smoothly without interruptions. By being strategic about supplier selection and order timing, buyers can enhance their operational efficiency and customer satisfaction.

Strategic Material Selection Guide for custom leather embossing stamp

What Are the Key Materials for Custom Leather Embossing Stamps?

When selecting a custom leather embossing stamp, the choice of material significantly influences performance, durability, and cost. Here, we analyze four common materials used in the production of these stamps: brass, high-density resin, steel, and aluminum. Each material has unique properties and implications for international buyers.

Illustrative image related to custom leather embossing stamp

How Does Brass Perform in Custom Leather Embossing Stamps?

Brass is a popular choice for custom leather embossing stamps due to its excellent durability and resistance to corrosion. It can withstand high temperatures and pressures, making it suitable for repeated use. Brass stamps can last indefinitely, especially in high-volume applications, as they maintain their shape and detail over time.

Pros:

– Exceptional durability and longevity.

– High resistance to corrosion and wear.

– Suitable for both heat and pressure applications.

Cons:

– Higher initial cost compared to other materials.

– Requires more complex manufacturing processes.

Illustrative image related to custom leather embossing stamp

For international buyers, brass is often compliant with ASTM standards, ensuring quality. However, buyers should consider import regulations and potential tariffs, particularly in regions like Africa and South America.

What Are the Benefits of High-Density Resin for Leather Stamps?

High-density resin is an economical alternative to metal stamps. While it is less durable, it is suitable for low-volume applications and can produce detailed impressions. Resin stamps are typically recommended for up to 1,000 uses, making them ideal for smaller businesses or one-off projects.

Pros:

– Lower cost, making it accessible for startups.

– Lightweight and easy to handle.

Cons:

– Limited durability; not suitable for heavy-duty use.

– Cannot withstand high temperatures or be hammered.

Illustrative image related to custom leather embossing stamp

International buyers should be cautious about the material’s limitations in regions with varying climate conditions, as extreme heat can affect resin performance. Compliance with local standards should also be verified.

Why Choose Steel for Custom Leather Embossing Stamps?

Steel is known for its strength and versatility. It can be used for both stamping and embossing, making it a flexible option for various applications. Steel stamps can endure high pressure and are often used in industrial settings.

Pros:

– High strength and durability.

– Versatile for different leather types and applications.

Cons:

– Can be more expensive than brass and resin.

– Requires careful handling to avoid rusting.

For buyers in Europe, particularly Germany, steel products often meet stringent DIN standards. However, in regions like the Middle East, buyers should consider local humidity levels that may affect steel’s longevity.

What About Aluminum as a Material for Leather Stamps?

Aluminum is lightweight and cost-effective, making it a viable option for custom leather embossing stamps. While it is less durable than brass or steel, it is still capable of producing quality impressions for lighter applications.

Illustrative image related to custom leather embossing stamp

Pros:

– Lightweight and easy to transport.

– Lower cost compared to brass and steel.

Cons:

– Less durable; may wear out faster.

– Not suitable for high-pressure applications.

International buyers should consider the environmental impact of aluminum production and ensure compliance with local environmental regulations, particularly in South America and Africa.

Summary of Material Selection for Custom Leather Embossing Stamps

| Material | Typical Use Case for custom leather embossing stamp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-volume production and detailed branding | Exceptional durability | Higher initial cost | Hoch |

| High-Density Resin | Low-volume projects and detailed impressions | Lower cost | Limited durability | Low |

| Steel | Industrial applications and versatile use | High strength | Requires careful handling | Med |

| Aluminum | Lightweight applications and cost-effective solutions | Lightweight and easy to handle | Less durable | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the properties, advantages, and limitations of various materials for custom leather embossing stamps, aiding in informed decision-making for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather embossing stamp

Manufacturing custom leather embossing stamps involves a series of meticulous processes designed to ensure high-quality output tailored to the specific needs of B2B buyers. Understanding these processes and the associated quality assurance measures is essential for companies looking to invest in durable, reliable stamping solutions.

What Are the Main Stages of Manufacturing Custom Leather Embossing Stamps?

Material Preparation: Selecting the Right Components

The manufacturing process begins with the selection of appropriate materials. Brass is the most common choice for its durability and ability to produce clean, crisp impressions. High-density resin is also an option but is best suited for lower-volume applications due to its limited lifespan. During the material preparation phase, manufacturers assess the quality of the raw materials, ensuring they meet the necessary specifications for strength and resilience.

Illustrative image related to custom leather embossing stamp

Forming: Techniques for Crafting the Stamps

After the materials are prepared, the next step is forming. This is often accomplished through CNC (Computer Numerical Control) machining, which allows for precision in creating intricate designs. The CNC process can handle various materials and is particularly effective for producing detailed logos or patterns. Other forming techniques may include die casting for bulk production or handcrafting for bespoke orders, ensuring that each stamp meets the client’s specifications.

Assembly: Bringing Components Together

In the assembly phase, individual components of the stamp, such as the handle and the stamping head, are combined. For custom designs, this may involve attaching a threaded opening for easy hammering or integration into a press system. Manufacturers must ensure that all components fit securely and function correctly to prevent issues during use.

Finishing: Ensuring Quality and Aesthetic Appeal

The finishing stage focuses on enhancing the stamp’s durability and appearance. This can involve polishing the surface to eliminate rough edges and applying protective coatings to prevent corrosion. For brass stamps, finishing may also include patinas or other aesthetic treatments to align with the branding needs of the buyer. This stage is crucial for ensuring that the final product not only performs well but also aligns with the buyer’s brand image.

Illustrative image related to custom leather embossing stamp

What Quality Assurance Measures Are Essential in Manufacturing Custom Leather Embossing Stamps?

What International Standards Should Buyers Be Aware Of?

Quality assurance in the manufacturing of custom leather embossing stamps is guided by several international standards. ISO 9001 is a key certification that indicates a company has implemented an effective quality management system. Compliance with this standard ensures that the manufacturing process is consistent and that the products meet customer expectations.

Additionally, specific industry standards may apply, such as CE marking for products sold in the European market, which indicates conformity with health, safety, and environmental protection standards. Buyers should inquire about these certifications when selecting suppliers to ensure compliance with their market regulations.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several critical checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this initial stage, raw materials are inspected upon arrival. This includes checking for material specifications and integrity before they are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to ensure that each stage meets quality standards. This may include monitoring the CNC machining process and checking dimensions against specifications.

-

Final Quality Control (FQC): Once the stamps are completed, they undergo final inspections. This includes functional testing to ensure that the stamps produce the desired impressions and aesthetic evaluations to confirm that the finish meets client expectations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

-

Conduct Audits: Buyers can request to conduct on-site audits to assess the manufacturing facilities and QC processes. This allows for a firsthand evaluation of the supplier’s capabilities and adherence to standards.

-

Request Quality Reports: Suppliers should provide documentation detailing their QC processes and results. This can include inspection reports, material certifications, and evidence of compliance with international standards.

-

Engage Third-Party Inspectors: For added assurance, buyers can hire independent third-party inspectors to evaluate the manufacturing process and the final products. This can provide an unbiased perspective on the supplier’s quality assurance measures.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Different regions may have varying standards and expectations regarding product quality and safety.

Illustrative image related to custom leather embossing stamp

-

Cultural Considerations: Buyers should be aware of cultural differences that may affect communication and expectations regarding quality. Establishing clear guidelines and expectations from the outset can help bridge these gaps.

-

Regulatory Compliance: Buyers must ensure that the products comply with local regulations in their respective countries. This may involve additional certifications or testing that suppliers must complete before shipping.

-

Logistical Challenges: International shipping can introduce challenges related to product integrity. Buyers should discuss packaging and transportation methods with suppliers to ensure that the stamps arrive in optimal condition.

Conclusion: Prioritizing Quality in Custom Leather Embossing Stamps

In summary, the manufacturing processes and quality assurance measures for custom leather embossing stamps are complex but crucial for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions, ensuring they select suppliers that prioritize quality and meet international standards. This knowledge not only aids in securing a reliable product but also fosters a productive and trustworthy partnership with manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather embossing stamp’

In the competitive market of custom leather embossing stamps, making informed sourcing decisions is critical for B2B buyers aiming for quality and efficiency. This guide provides a systematic approach to procuring custom leather embossing stamps, ensuring that you cover all essential aspects before finalizing your purchase.

Step 1: Define Your Technical Specifications

Understanding your specific needs is the foundation of a successful procurement process. Determine the type of leather you will be working with, the design complexity, and the size of the embossing stamp required. This clarity will help suppliers provide accurate quotes and ensure the final product meets your expectations.

- Leather Type: Different leathers require different stamping techniques.

- Design Complexity: More intricate designs may need advanced manufacturing techniques.

Step 2: Research Potential Suppliers

Finding reliable suppliers is crucial to ensure product quality and timely delivery. Look for manufacturers with a proven track record in producing custom leather embossing stamps. Utilize online marketplaces, industry-specific forums, and trade shows to gather a list of potential suppliers.

- Reputation: Check reviews and testimonials from previous clients.

- Erleben Sie: Prefer suppliers with extensive experience in the leather industry.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist, assess each supplier’s production capabilities. This includes their technology, material options, and customization flexibility. Understanding their capacity will help you determine if they can meet your volume requirements and deadlines.

- Material Options: Inquire about different materials such as brass or high-density resin.

- Production Time: Ensure they can meet your timelines, especially for rush orders.

Step 4: Request Samples and Mock-ups

Before placing a large order, it’s wise to request samples or mock-ups of your design. This allows you to evaluate the quality of the embossing and how well it aligns with your brand vision. A reliable supplier will provide you with a mock-up before production to ensure your satisfaction.

- Quality Check: Assess the clarity and durability of the stamp.

- Design Accuracy: Confirm that the mock-up matches your expectations.

Step 5: Verify Supplier Certifications

Ensure that your chosen supplier meets industry standards and certifications. This is especially important if you are sourcing from international suppliers. Certifications can provide assurance regarding quality control processes and ethical manufacturing practices.

- ISO Certifications: Look for suppliers with ISO standards that ensure quality management.

- Sustainability Practices: Consider suppliers who adhere to eco-friendly practices.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear terms will prevent misunderstandings and ensure that both parties are aligned on expectations.

- Pricing Structures: Ask for detailed breakdowns to understand the costs involved.

- Delivery Timelines: Set clear expectations for when you can expect your order.

Step 7: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Establish a clear plan for regular updates and feedback loops with your supplier to address any issues that may arise. This proactive approach can help mitigate risks and enhance collaboration.

- Regular Check-ins: Schedule periodic updates to monitor progress.

- Feedback Mechanism: Create channels for providing and receiving feedback on the product and process.

By following these steps, B2B buyers can make informed decisions that ensure they procure high-quality custom leather embossing stamps that align with their operational needs and brand identity.

Comprehensive Cost and Pricing Analysis for custom leather embossing stamp Sourcing

What Are the Key Cost Components in Custom Leather Embossing Stamp Production?

When sourcing custom leather embossing stamps, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly affects costs. Brass is a common choice for durability, with prices typically starting around $69 and going higher based on complexity and size. High-density resin options are less expensive but have limited durability. Buyers should evaluate the material based on expected usage to avoid premature replacements.

-

Labor: The labor cost associated with the design and production of custom stamps varies widely. Skilled labor for engraving and machining can increase costs, particularly if intricate designs are required. Labor costs may also fluctuate based on regional wage standards, which is especially relevant for international buyers.

-

Manufacturing Overhead: This includes the costs of utilities, equipment maintenance, and facility management. For smaller operations, these costs can be spread over fewer units, raising the per-unit cost. Larger manufacturers may achieve economies of scale, reducing the overhead allocated to each stamp.

-

Tooling: Initial tooling for custom designs can be a significant upfront investment. Costs can vary based on the complexity of the design and the technology used (CNC vs. manual engraving). This is a crucial factor for buyers ordering unique or highly customized stamps.

-

Quality Control (QC): Ensuring the quality of the stamps is vital, particularly for brands that rely on consistent performance. QC measures can add to costs but ultimately protect the brand’s reputation by reducing defects and ensuring customer satisfaction.

-

Logistics: Shipping costs can vary based on distance, weight, and shipping method. International buyers should consider Incoterms, as they define the responsibilities of buyers and sellers regarding shipping costs and risks. This can significantly impact the total landed cost of the product.

-

Margin: Suppliers will include a margin to cover their operational costs and profit. Understanding the average margins in the industry can help buyers negotiate better prices.

What Factors Influence Pricing in Custom Leather Embossing Stamps?

Several factors can influence the pricing of custom leather embossing stamps, making it essential for buyers to be aware of these elements to optimize their sourcing strategy.

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Higher volume orders often lead to lower per-unit costs, making it beneficial for businesses planning to order in bulk.

-

Specifications and Customization: The complexity and size of the design play a significant role in pricing. More intricate designs require additional labor and tooling, which can raise costs.

-

Material Quality and Certifications: Higher-quality materials or specialized certifications (such as eco-friendly or food-safe materials) can add to the cost. Buyers should assess whether these certifications are necessary for their specific applications.

-

Supplier Factors: The reputation and reliability of suppliers can affect costs. Established suppliers may charge more for their expertise and reliability, while newer entrants might offer competitive pricing to gain market share.

-

Geographical Considerations: Buyers from different regions may face varying costs due to local market conditions, labor costs, and material availability. For instance, sourcing from Europe may offer higher quality but at a premium compared to suppliers in South America or Africa.

What Are the Best Practices for Negotiating Prices in B2B Leather Stamp Purchases?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several negotiation strategies can lead to more favorable terms:

-

Understand Total Cost of Ownership: Consider not only the initial price but also the long-term costs associated with maintenance, durability, and replacement. This comprehensive view can justify a higher upfront investment for better quality.

-

Leverage Volume Discounts: If your business can commit to higher order volumes, use this leverage in negotiations to secure discounts or better payment terms.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide leverage in negotiations and help buyers understand the market rate for their specific requirements.

-

Be Clear About Specifications: Providing detailed specifications and expectations can minimize misunderstandings and lead to more accurate pricing, reducing the need for costly revisions.

-

Consider Incoterms: Discuss shipping terms to avoid unexpected costs. Ensure that both parties are clear on who is responsible for shipping and associated risks.

In conclusion, navigating the cost and pricing landscape for custom leather embossing stamps requires a strategic approach. By understanding the cost components, pricing influencers, and effective negotiation strategies, international B2B buyers can make informed decisions that enhance their purchasing power and ensure quality outcomes for their branding needs.

Illustrative image related to custom leather embossing stamp

Alternatives Analysis: Comparing custom leather embossing stamp With Other Solutions

Exploring Alternatives to Custom Leather Embossing Stamps

When it comes to branding leather products, B2B buyers often seek effective solutions that align with their operational needs. While custom leather embossing stamps are popular for their precision and versatility, several alternative methods also exist. Understanding these options can help businesses make informed decisions about their branding techniques.

| Comparison Aspect | Custom Leather Embossing Stamp | Handheld Steel Stamps | Electric Branding Irons |

|---|---|---|---|

| Performance | High precision; durable marks | Good for detailed impressions | Consistent results with heat |

| Cost | Moderate ($69 – $216) | Lower cost ($24 – $103) | Higher investment ($229+) |

| Ease of Implementation | Requires press or hammering | Easy to use; manual application | Requires setup; may need training |

| Wartung | Low; durable materials | Moderate; can wear down over time | Low; requires occasional cleaning |

| Best Use Case | High-volume, detailed branding | Small batches or one-off projects | Repetitive branding on various materials |

Handheld Steel Stamps: A Cost-Effective Option

Handheld steel stamps are a viable alternative for businesses looking for a more budget-friendly option. These stamps allow users to manually apply pressure to create detailed impressions on leather. While they are generally less expensive than custom leather embossing stamps, their performance can vary based on the user’s technique. They are ideal for smaller projects or when branding needs are less frequent. However, the manual effort required can be a drawback for high-volume operations.

Electric Branding Irons: Consistency Through Heat

Electric branding irons offer a different approach by utilizing heat to brand leather. They provide a consistent and permanent mark, making them suitable for high-volume production. While the initial investment is higher, the durability and reliability of the branding results can justify the cost for businesses with significant branding needs. Additionally, electric branding irons can be used on various materials beyond leather. The main downside is the need for proper training and setup, which can be a barrier for some users.

Conclusion: Selecting the Right Branding Solution

In choosing the right branding solution, B2B buyers should consider their specific needs, including production volume, budget constraints, and the desired quality of branding. Custom leather embossing stamps are ideal for businesses requiring precision and durability in high-volume settings. Handheld steel stamps may serve well for smaller operations or less frequent needs, while electric branding irons can be the best choice for consistency in larger production environments. Evaluating these factors will guide businesses toward the most effective branding solution for their leather products.

Essential Technical Properties and Trade Terminology for custom leather embossing stamp

What Are the Key Technical Properties of Custom Leather Embossing Stamps?

When sourcing custom leather embossing stamps, it’s crucial to understand the technical specifications that affect performance and longevity. Here are several critical properties to consider:

-

Material Composition

– Definition: The primary materials used in manufacturing embossing stamps include brass, steel, and high-density resin. Brass is the most durable and suitable for high-volume production, while resin is more cost-effective but less durable.

– B2B Importance: The choice of material impacts the stamp’s longevity and the quality of the impression. Buyers should consider their production volume and desired quality to select the appropriate material. -

Engraving Depth

– Definition: This refers to the depth of the design etched into the stamp, typically ranging from 2mm to 5mm.

– B2B Importance: A deeper engraving allows for more detailed designs and can produce clearer impressions on leather. Understanding engraving depth helps buyers assess whether the stamp will meet their branding needs. -

Stamp Dimensions

– Definition: The size of the stamp, often measured in square centimeters or inches, determines the area of the design it can accommodate.

– B2B Importance: Buyers need to ensure that the dimensions align with their branding requirements. Larger stamps may be needed for extensive logos, while smaller stamps are ideal for subtle branding. -

Tolerance Levels

– Definition: Tolerance refers to the permissible limit of variation in the dimensions of the stamp.

– B2B Importance: Higher tolerance levels ensure that the stamps produce consistent results across multiple uses. This is particularly vital for businesses that require uniform branding across products. -

Press Options

– Definition: This indicates the methods available for applying pressure when using the stamp, such as handheld presses, hydraulic presses, or branding irons.

– B2B Importance: The choice of press can affect the quality and efficiency of the stamping process. Businesses should select a method that aligns with their production capabilities.

What Are Common Trade Terms in the Custom Leather Embossing Stamp Industry?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Many businesses rely on OEMs for customized parts, including embossing stamps, which can enhance branding efforts. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Understanding the MOQ helps buyers plan their orders according to budget and inventory needs. It can also impact pricing, as larger orders often lead to better rates. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing information for specific products or services.

– Significance: An RFQ helps businesses compare costs and terms from multiple suppliers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Significance: Familiarity with Incoterms is crucial for international transactions, as they clarify cost responsibilities and shipping arrangements, minimizing potential disputes. -

Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Significance: Understanding lead times is essential for inventory management and planning production schedules, especially in industries where timely branding is critical.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing custom leather embossing stamps, ultimately enhancing their branding and production processes.

Illustrative image related to custom leather embossing stamp

Navigating Market Dynamics and Sourcing Trends in the custom leather embossing stamp Sector

What Are the Key Market Trends Influencing the Custom Leather Embossing Stamp Sector?

The global custom leather embossing stamp market is witnessing notable growth, driven by the increasing demand for personalized and branded products across various industries, including fashion, accessories, and luxury goods. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are seeking high-quality, customizable stamping solutions to enhance their product offerings. Key trends include the rise of e-commerce, which facilitates easier access to suppliers worldwide, and the growing preference for unique, handcrafted items that reflect brand identity.

Emerging technologies such as CNC machining and laser engraving are revolutionizing the production of custom stamps, allowing for higher precision and intricate designs. Additionally, the use of 3D printing is gaining traction, enabling rapid prototyping and reduced lead times for custom orders. B2B buyers are increasingly looking for suppliers who can provide swift turnaround times and flexibility in production, aligning with the fast-paced nature of modern retail.

Moreover, a focus on quality assurance and the availability of diverse materials—such as brass, high-density resin, and custom alloys—are essential for meeting varied customer needs. Buyers are advised to consider suppliers that offer mock-ups and unlimited revisions, ensuring that the final product aligns with their branding requirements.

How Is Sustainability and Ethical Sourcing Shaping the Custom Leather Embossing Stamp Market?

Sustainability and ethical sourcing are becoming paramount in the custom leather embossing stamp sector. As global awareness of environmental issues rises, buyers are increasingly scrutinizing the sourcing practices of their suppliers. The leather industry is often criticized for its environmental impact, particularly in terms of water consumption and chemical usage. Consequently, many manufacturers are adopting sustainable practices, such as utilizing vegetable-tanned leather, which is less harmful to the environment.

Furthermore, the demand for ‘green’ certifications—such as ISO 14001 (Environmental Management Systems) and Leather Working Group certification—reflects a growing commitment to responsible sourcing. B2B buyers are encouraged to prioritize suppliers who can demonstrate their adherence to ethical practices and sustainability standards. This not only enhances brand reputation but also appeals to eco-conscious consumers, particularly in markets like Europe and South America, where green consumerism is on the rise.

By focusing on sustainable materials and transparent supply chains, companies can differentiate themselves in a competitive marketplace. Engaging with suppliers who prioritize ethical practices not only mitigates environmental risks but also fosters long-term business relationships built on shared values.

What Is the Historical Context of Custom Leather Embossing Stamps for B2B Buyers?

The custom leather embossing stamp has a rich history that dates back centuries, serving as a crucial tool for artisans and craftsmen. Initially used for branding livestock, these stamps evolved to become a hallmark of quality and authenticity in leather goods. With the rise of industrialization in the 19th century, the production of leather stamps transitioned from handcrafted methods to more mechanized processes, allowing for greater precision and efficiency.

In the modern era, the introduction of advanced technologies such as CNC and laser engraving has transformed the landscape of custom leather stamping. These innovations enable manufacturers to produce intricate designs that were previously unattainable, catering to the diverse needs of B2B clients. As the market continues to evolve, understanding the historical context of these tools can provide valuable insights into current trends and future developments, helping businesses make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather embossing stamp

-

How do I choose the right custom leather embossing stamp for my business needs?

Choosing the right custom leather embossing stamp involves considering the type of leather you’ll be working with, the complexity of your design, and your production volume. For high-volume applications, a durable material like brass is recommended, while for smaller projects, high-density resin may suffice. Assess the required size and depth of the stamp, and consult with suppliers about the most suitable options. A mock-up of your design can also help visualize the final product, ensuring it meets your branding needs. -

What is the typical lead time for custom leather embossing stamps?

Lead times can vary significantly based on the supplier and the complexity of your order. Generally, expect production times of 2-6 business days for standard orders, with expedited options available for urgent requests. Shipping times also depend on your location and chosen shipping method, so it’s advisable to factor in these timelines when planning your production schedule. Always confirm current lead times with your supplier before placing an order to avoid delays. -

What customization options are available for leather embossing stamps?

Customization options for leather embossing stamps include material choice (brass, aluminum, or high-density resin), size, design complexity, and shape. Many suppliers will work with your specific logo or design, offering mock-ups for your approval before production. You can also request additional features, such as heat embossing capabilities or specific engraving depths, to suit your application. Discuss your unique requirements with potential suppliers to find the best solution for your branding needs. -

What are the minimum order quantities (MOQ) for custom leather embossing stamps?

Minimum order quantities (MOQ) can vary by supplier and product type. Some manufacturers may offer single-unit orders for custom stamps, while others might set an MOQ to optimize production costs. When sourcing suppliers, inquire about their MOQ policies and whether they can accommodate smaller orders, especially if you’re testing a new design or entering a new market. This flexibility can be crucial for businesses looking to scale gradually. -

How do I vet suppliers for custom leather embossing stamps?

Vetting suppliers involves researching their reputation, product quality, and customer service. Start by checking online reviews, testimonials, and case studies from other B2B clients. Request samples to evaluate the quality of their work firsthand. Additionally, engage in direct communication with potential suppliers to assess their responsiveness and willingness to accommodate your specific needs. Finally, consider their production capabilities, lead times, and compliance with international trade standards. -

What payment terms should I expect when ordering custom leather embossing stamps?

Payment terms for custom leather embossing stamps can vary widely among suppliers. Common practices include upfront payments, deposits, or payment upon delivery. Some suppliers may offer net terms (e.g., net 30 or net 60) for established B2B relationships. Always clarify payment terms before finalizing your order to ensure that they align with your cash flow and budgeting processes. It’s also wise to inquire about accepted payment methods, especially for international transactions. -

How can I ensure quality assurance (QA) for my custom leather embossing stamps?

To ensure quality assurance (QA), request detailed specifications and production samples from your supplier. Discuss their QA processes, including any certifications or standards they adhere to. Many reputable suppliers will provide mock-ups and allow for revisions before final production. Once you receive the final product, conduct a thorough inspection to confirm it meets your expectations. Establishing a clear communication line with your supplier can also facilitate addressing any quality issues promptly. -

What logistics considerations should I be aware of when sourcing custom leather embossing stamps internationally?

When sourcing custom leather embossing stamps internationally, consider shipping costs, customs duties, and delivery timelines. Research the best shipping methods and carriers that suit your needs, factoring in the urgency of your order. Ensure your supplier is experienced in international trade and can provide necessary documentation for customs clearance. Additionally, be aware of any regulations regarding imported goods in your country to avoid unexpected delays or fees.

Top 8 Custom Leather Embossing Stamp Manufacturers & Suppliers List

1. Infinity Stamps – Leather Stamping Products

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Leather Stamps – Infinity Stamps Inc. offers a variety of leather stamping products including: Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, Maker Stamps, Hot Stamps, and Steel Type Stamps & Holders. All products are made in the USA and the company has been family-owned for over 25 years.

2. Custom Brand – Leather Embossing Stamp

3. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: Custom Leather Stamp for leather embossing & leather stamping\nRegular price: US$68.00\nSize options: Up to 1.25 x 1.25 inch / 3 x 3 cm, Up to 1.5 x 1.5 inch / 4 x 4 cm, Up to 2 x 2 inch / 5 x 5 cm, Up to 3 x 3 inch / 7.5 x 7.5 cm, Up to 4 x 4 inch / 10 x 10 cm\nProduction lead time: 2-5 working days (rush orders available)\nMaterial: Solid Brass\nStandard price includes size of design up to 10 cm…

4. Custom Leather Stamps – Quality Engraving Solutions

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Custom leather stamps, dies, and brands for leather stamping and embossing needs. Made from aluminum, steel, or brass. Aluminum stamps are cost-effective, while brass is popular for durability and rust resistance. Customization options include original artwork, high detail engraving, and various stamp types (hand stamps, press stamps, branding irons). Heavy-duty removable steel handles for hand st…

5. Leatherstampstools – Custom Leather Stamps

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom leather stamps, good price point, quality stamp, options from Leatherstampstools on Etsy, Springfield Leather, leatherstampmaker, TyraCraftTools, sizes and designs can vary, examples and proofs available, typical price around $55 for a 2.5 cm x 5 cm stamp.

6. Tandy Leather – Custom Logo Stamps

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Custom Logo Stamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Steel Stamps Inc – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

Introduction: Custom Leather Stamps available from Steel Stamps Inc. The collection includes various types of custom stamps for leather, including design stamps, state stamps, and specialized stamps. The product range is categorized into different series such as Pro Series, Tried & True Series, and Avant-Garde Series. Additionally, there are options for custom jewelry stamps and steel stamps for knife makers, b…

8. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets, and more. Custom stamps are CNC milled from solid brass, available up to 1″ thickness and custom size. Compatible with branding irons and standard presses. Custom leather cutting dies made from solid steel, usable with mechanical, hydraulic…

Strategic Sourcing Conclusion and Outlook for custom leather embossing stamp

In conclusion, the landscape for custom leather embossing stamps presents a wealth of opportunities for international B2B buyers. By leveraging strategic sourcing, businesses can ensure they acquire high-quality, durable stamps that meet their specific branding needs while also maximizing operational efficiency. Understanding the differences in materials, such as brass versus high-density resin, allows buyers to make informed decisions based on their usage requirements and budget constraints.

As you explore suppliers across regions, consider the advantages of local partnerships that offer fast shipping and responsive customer service. Many manufacturers provide mock-ups and unlimited alterations, ensuring that your branding vision is realized with precision. This level of customization is invaluable in competitive markets, particularly in Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for unique, high-quality leather products is set to grow, making it essential for businesses to invest in reliable stamping solutions. Now is the time to engage with reputable suppliers who can help elevate your brand through bespoke leather embossing stamps. Take the next step in enhancing your product offerings and contact potential partners today to discuss how they can support your branding needs.

Illustrative image related to custom leather embossing stamp

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.