Introduction: Navigating the Global Market for best custom leather holster makers

Navigating the intricate landscape of custom leather holster makers can present a significant challenge for international B2B buyers seeking quality and reliability. Whether you’re sourcing custom leather holsters for law enforcement, military applications, or personal use, understanding the diverse offerings and capabilities of suppliers is essential. This guide delves deep into the world of custom leather holster manufacturing, exploring various types, applications, and key factors to consider when vetting suppliers.

From traditional craftsmanship to modern design innovations, we will equip you with the insights needed to make informed purchasing decisions. Expect to find detailed information on pricing structures, customization options, and the importance of quality materials, ensuring you choose a supplier that aligns with your specific needs. This guide is particularly tailored for buyers from Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Brazil, providing a global perspective on sourcing practices and supplier reliability.

By consolidating critical data and expert recommendations, we empower you to confidently navigate the market for the best custom leather holster makers, ensuring your investments translate into superior products that meet your operational demands.

Table Of Contents

- Top 4 Best Custom Leather Holster Makers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best custom leather holster makers

- Understanding best custom leather holster makers Types and Variations

- Key Industrial Applications of best custom leather holster makers

- 3 Common User Pain Points for ‘best custom leather holster makers’ & Their Solutions

- Strategic Material Selection Guide for best custom leather holster makers

- In-depth Look: Manufacturing Processes and Quality Assurance for best custom leather holster makers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best custom leather holster makers’

- Comprehensive Cost and Pricing Analysis for best custom leather holster makers Sourcing

- Alternatives Analysis: Comparing best custom leather holster makers With Other Solutions

- Essential Technical Properties and Trade Terminology for best custom leather holster makers

- Navigating Market Dynamics and Sourcing Trends in the best custom leather holster makers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best custom leather holster makers

- Strategic Sourcing Conclusion and Outlook for best custom leather holster makers

- Important Disclaimer & Terms of Use

Understanding best custom leather holster makers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OWB (Outside the Waistband) | Designed to be worn outside the waistband for easy access | Law enforcement, security personnel | Pros: Quick access, comfortable for daily wear. Cons: Less concealed, may be bulkier. |

| IWB (Inside the Waistband) | Fits inside the waistband for better concealment | Concealed carry, personal defense | Pros: Highly concealable, comfortable for extended use. Cons: Requires proper fit for comfort. |

| Shoulder Holsters | Worn over the shoulder, often with a harness system | Law enforcement, undercover operations | Pros: Distributes weight evenly, allows for easy draw. Cons: Can be bulky under clothing. |

| Crossdraw Holsters | Designed for draw across the body, ideal for seated carry | Vehicle carry, specific tactical situations | Pros: Comfortable for sitting, easy access with a cross-draw motion. Cons: Can be less secure if not fitted properly. |

| Custom Engraved Holsters | Personalized designs and engravings for branding or style | Promotional gifts, corporate branding | Pros: Unique branding opportunity, enhances customer loyalty. Cons: Longer production time, potentially higher cost. |

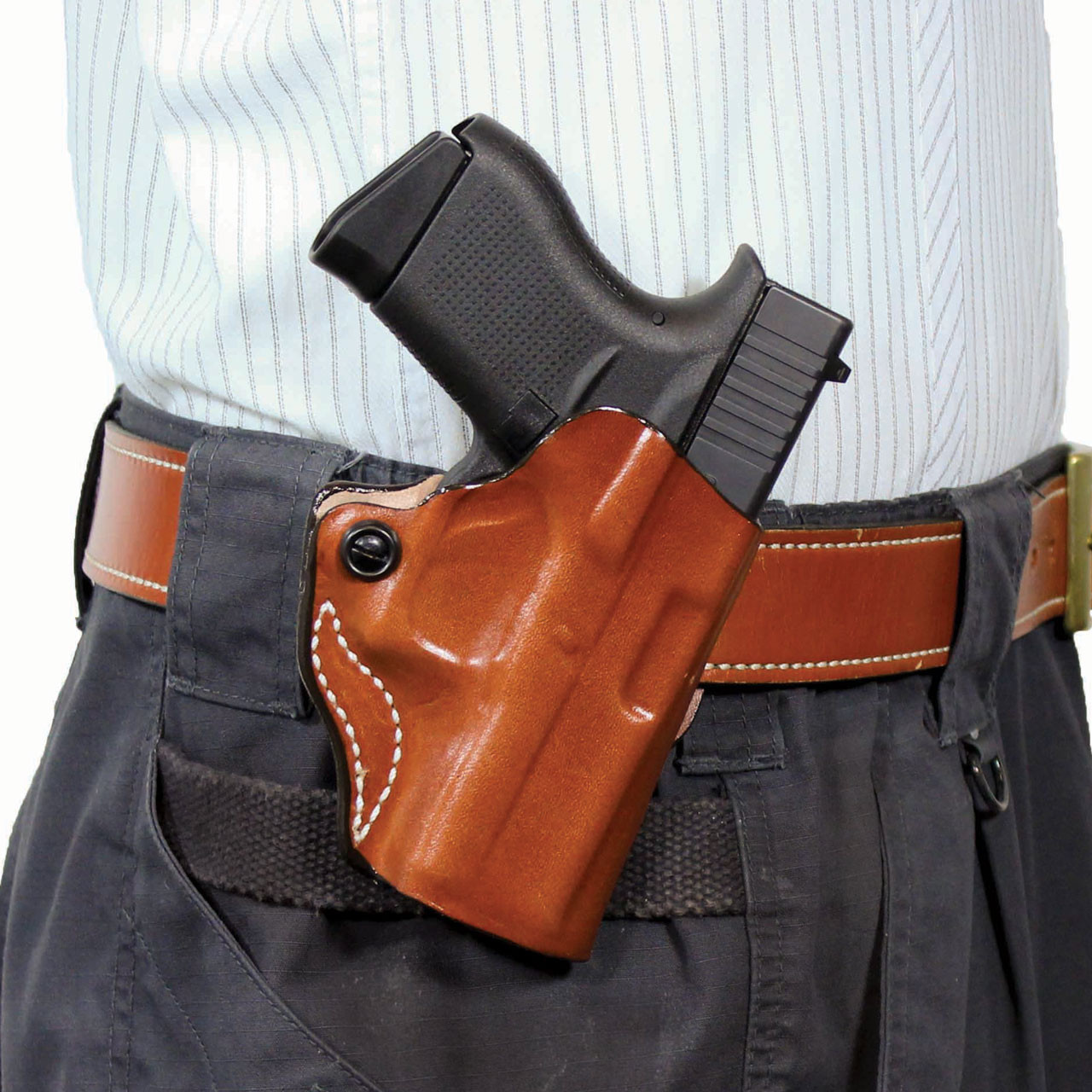

What Are the Key Characteristics of OWB Holsters?

OWB holsters are characterized by their external placement on the belt, allowing for rapid access to firearms. They are especially popular among law enforcement and security personnel who require quick draw capabilities. When considering OWB holsters for B2B purchases, businesses should evaluate the balance between comfort and accessibility, as well as the specific needs of their personnel in various operational environments.

How Do IWB Holsters Enhance Concealment?

IWB holsters provide a discreet option for concealed carry, fitting snugly inside the waistband. They are ideal for personal defense and everyday carry, making them a popular choice among individuals who prioritize concealment. B2B buyers should consider the fit and comfort of these holsters, as well as the ease of access, especially in high-stress situations where quick response is crucial.

What Advantages Do Shoulder Holsters Offer?

Shoulder holsters distribute the weight of the firearm across the shoulders, making them a comfortable option for extended wear. They are favored in undercover operations where discreet carry is essential. For B2B buyers, the choice of shoulder holsters should focus on the design’s adaptability to various body types and the specific requirements of the users, such as the need for quick access while seated.

Why Choose Crossdraw Holsters for Specific Situations?

Crossdraw holsters allow for a firearm to be drawn across the body, making them particularly effective for individuals who spend a lot of time seated, such as in vehicles. They offer an ergonomic solution for drawing a weapon quickly. B2B buyers should assess the security features of crossdraw holsters, as improper fitting can lead to safety concerns in high-stakes environments.

How Can Custom Engraved Holsters Enhance Brand Identity?

Custom engraved holsters provide a unique opportunity for branding, offering businesses a way to distinguish their products or services. They can serve as promotional gifts or corporate branding tools. B2B buyers should weigh the benefits of unique designs against the potential for longer lead times and higher costs associated with customization, ensuring that the investment aligns with their branding strategy.

Key Industrial Applications of best custom leather holster makers

| Industry/Sector | Specific Application of best custom leather holster makers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Custom duty holsters for firearms | Ensures safety and quick access to firearms in emergencies | Compliance with local regulations and standards |

| Military | Tactical holsters for operational use | Enhances readiness and functionality during missions | Durability and adaptability to various environments |

| Outdoor Sports & Hunting | Holsters for hunting firearms | Provides secure transport and accessibility during hunts | Customization for specific firearm models and user comfort |

| Competitive Shooting | Holsters designed for competition shooting | Improves performance and speed in competitive settings | Precision fit and quick-draw capabilities |

| Security & Personal Defense | Concealed carry holsters for personal safety | Facilitates discreet carry for personal protection | Comfort, concealment, and accessibility features |

How Are Custom Leather Holsters Used in Law Enforcement?

In law enforcement, custom duty holsters are essential for officers who require immediate access to their firearms. These holsters are designed to securely hold the weapon while allowing for a quick draw in critical situations. For international buyers, especially from regions like Africa and the Middle East, it’s vital to ensure that the holsters meet local regulations regarding firearm carrying. Additionally, the holsters must be durable enough to withstand rigorous daily use while providing comfort and safety to the officer.

Illustrative image related to best custom leather holster makers

What Role Do Custom Holsters Play in Military Applications?

Military applications necessitate tactical holsters that are robust and versatile. Custom leather holsters designed for military personnel enhance operational readiness by ensuring that firearms are easily accessible during missions. For buyers in South America or Europe, it’s crucial to source holsters that can withstand diverse environmental conditions and are compatible with various military gear. The focus should be on durability, ease of use, and the ability to integrate with tactical vests or belts.

Why Are Custom Holsters Important for Outdoor Sports and Hunting?

In the outdoor sports and hunting sectors, custom holsters provide a secure and convenient way to transport firearms. Hunters require holsters that not only hold their firearms securely but also allow for quick access when needed. For international buyers, especially in regions like Africa, sourcing holsters that are specifically tailored to different hunting firearms is essential. Comfort, weight, and the ability to withstand outdoor elements are key considerations for these buyers.

How Do Competitive Shooters Benefit from Custom Holsters?

Competitive shooters rely on holsters designed specifically for their shooting sports, as these can significantly impact performance. Custom holsters allow for a precision fit, ensuring that the firearm is held securely while enabling a rapid draw. Buyers from Europe or the Middle East should consider sourcing holsters that enhance speed and accuracy, as well as those designed for specific competition requirements. The combination of comfort and functionality is paramount in this sector.

Illustrative image related to best custom leather holster makers

What Are the Advantages of Concealed Carry Holsters for Security and Personal Defense?

In the realm of security and personal defense, concealed carry holsters are designed for discreet firearm transportation. These holsters allow individuals to carry firearms securely while ensuring easy access in emergencies. For international B2B buyers, particularly in regions with high security concerns, sourcing holsters that prioritize comfort, concealment, and quick accessibility is crucial. Additionally, understanding local laws regarding concealed carry is essential to ensure compliance and safety.

3 Common User Pain Points for ‘best custom leather holster makers’ & Their Solutions

Scenario 1: Difficulty in Finding Quality Craftsmanship and Customization

The Problem: B2B buyers often encounter challenges in sourcing high-quality custom leather holsters that meet specific requirements. Many suppliers may offer generic products, lacking the unique craftsmanship and customization options that businesses need. Buyers may feel overwhelmed by the number of options available, making it hard to discern which makers truly provide the level of quality and personalization required for their clientele. This can lead to dissatisfaction, especially if the final product does not meet expectations or fails to resonate with the target market.

The Solution: To overcome this hurdle, B2B buyers should focus on establishing direct communication with potential leather holster makers. Engaging in detailed discussions about specific needs, such as materials, design preferences, and functionality, is crucial. Buyers can request samples or detailed portfolios showcasing previous work to evaluate craftsmanship. Additionally, leveraging online reviews and testimonials from other businesses can provide insights into a maker’s reliability and quality. Creating a clear specification document that outlines design expectations, dimensions, and material preferences can streamline the customization process, ensuring that the final product aligns with the buyer’s vision.

Scenario 2: Long Lead Times Affecting Inventory Management

The Problem: One of the primary pain points for B2B buyers is the long lead times often associated with custom leather holsters. Many manufacturers may operate on a first-come, first-served basis, resulting in delays that can disrupt inventory management and sales strategies. This is particularly concerning for businesses that operate in fast-paced markets or have specific promotional events planned. Delayed shipments can lead to lost sales opportunities and a damaged reputation among end customers.

Illustrative image related to best custom leather holster makers

The Solution: To mitigate lead time issues, buyers should prioritize partnering with manufacturers that offer expedited services. Researching makers that provide quick-turnaround options can save significant time. Establishing a long-term relationship with a selected holster maker can also lead to preferential treatment during busy periods. Buyers should inquire about production schedules and set clear expectations regarding delivery timelines upfront. Additionally, maintaining an open line of communication can allow buyers to track the progress of their orders and adjust their inventory strategies accordingly, ensuring they remain prepared for fluctuations in demand.

Scenario 3: Concerns Over Material Quality and Sustainability

The Problem: As sustainability becomes an increasingly important factor in purchasing decisions, B2B buyers may struggle to find custom leather holster makers who prioritize high-quality, ethically sourced materials. Concerns over animal welfare, environmental impact, and the durability of materials can complicate the decision-making process. Buyers may fear that opting for lower-cost options could result in inferior products that don’t meet their quality standards or align with their brand values.

The Solution: To address these concerns, buyers should conduct thorough research into the sourcing practices of potential holster makers. Asking for certifications or documentation that verifies the ethical sourcing of materials can provide peace of mind. Buyers can also inquire about the production processes to understand how sustainability is integrated into the manufacturing of leather holsters. Engaging in conversations about the longevity and maintenance of materials can help assess their potential return on investment. By prioritizing manufacturers who are transparent about their practices and offer eco-friendly options, buyers can ensure that their purchases reflect their values while still delivering high-quality products.

Strategic Material Selection Guide for best custom leather holster makers

What Materials Are Best for Custom Leather Holsters?

When selecting materials for custom leather holsters, it is essential to consider various types of leather and their properties. The choice of material not only affects the performance and durability of the holster but also influences the overall cost and manufacturing complexity. Below are four common materials used by top custom leather holster makers, along with their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to best custom leather holster makers

What Are the Key Properties of Cowhide Leather?

Cowhide leather is one of the most widely used materials in the production of custom holsters. Known for its durability, cowhide can withstand significant wear and tear, making it ideal for everyday use. It typically has a temperature resistance range of -20°F to 120°F, which ensures it maintains its shape and performance under various environmental conditions.

Pros: Cowhide leather is relatively affordable and easy to work with, making it suitable for mass production. It also offers a good balance between flexibility and rigidity, allowing for comfortable wear while securely holding firearms.

Cons: While durable, cowhide may not be as weather-resistant as other materials, requiring additional treatments for water and moisture resistance. It can also be heavier than synthetic alternatives, which may impact comfort during extended use.

Impact on Application: Cowhide is compatible with a variety of firearms and is often used for both concealed carry and open carry holsters.

Considerations for International Buyers: Buyers should ensure that the cowhide used complies with international standards such as ASTM for leather quality. Additionally, preferences for specific tanning processes may vary across regions, influencing the choice of suppliers.

How Does Premium Steerhide Compare?

Premium steerhide leather is a step up from standard cowhide, offering enhanced durability and aesthetic appeal. It is thicker and more robust, providing excellent protection for firearms. Steerhide can endure high-pressure applications and is resistant to abrasion, making it an excellent choice for holsters that see frequent use.

Pros: The durability of steerhide makes it ideal for long-term use, and its natural grain provides a visually appealing finish. It also molds well to the shape of the firearm, enhancing retention and accessibility.

Cons: The cost of steerhide is generally higher than that of cowhide, which may deter budget-conscious buyers. Its thickness can also complicate the manufacturing process, requiring skilled artisans for proper crafting.

Illustrative image related to best custom leather holster makers

Impact on Application: Steerhide is particularly suitable for tactical and outdoor holsters due to its resilience against harsh conditions.

Considerations for International Buyers: Buyers should verify that steerhide meets local regulations regarding animal products. In regions like Europe, compliance with environmental standards is crucial.

What Are the Benefits of Synthetic Leather?

Synthetic leather, often made from polyurethane or PVC, is becoming increasingly popular among custom holster makers. It offers a lightweight alternative to traditional leather while providing a similar aesthetic.

Pros: Synthetic leather is generally more affordable and easier to maintain than natural leather. It is also resistant to moisture and UV rays, making it suitable for various climates.

Illustrative image related to best custom leather holster makers

Cons: While synthetic leather can mimic the look of real leather, it may not offer the same level of durability or comfort. Over time, it can wear down more quickly, especially in high-friction areas.

Impact on Application: Synthetic leather is often used for budget-friendly holsters and is compatible with a wide range of firearms.

Considerations for International Buyers: Buyers should ensure that synthetic materials comply with environmental regulations, particularly in Europe, where there are strict guidelines regarding plastic use.

How Does Exotic Leather Stand Out?

Exotic leathers, such as ostrich or alligator, provide a unique and luxurious option for custom holsters. These materials are known for their distinctive patterns and textures, making them highly sought after for premium products.

Pros: Exotic leathers offer exceptional aesthetics and can command higher prices due to their rarity. They are also highly durable when properly cared for.

Cons: The cost of exotic leathers can be prohibitively high, limiting their use to high-end markets. Additionally, they may require specialized care and maintenance.

Impact on Application: Exotic leathers are often used for display or collector holsters rather than everyday carry due to their price and maintenance requirements.

Considerations for International Buyers: Buyers should be aware of international trade regulations regarding exotic leathers, as many countries have strict rules about sourcing and selling these materials.

Summary of Material Selection for Custom Leather Holsters

| Material | Typical Use Case for best custom leather holster makers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | Everyday carry holsters | Affordable and durable | Less weather-resistant | Medium |

| Premium Steerhide | Tactical and outdoor holsters | High durability and aesthetic | Higher cost and manufacturing complexity | Hoch |

| Synthetic Leather | Budget-friendly holsters | Lightweight and moisture-resistant | Less durable over time | Low |

| Exotic Leather | Luxury or collector holsters | Unique aesthetics and rarity | Very high cost and care required | Hoch |

This strategic material selection guide provides valuable insights for B2B buyers looking to partner with custom leather holster makers. Understanding the properties and implications of each material can help buyers make informed decisions that align with their specific needs and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for best custom leather holster makers

What Are the Main Stages of Manufacturing Custom Leather Holsters?

The manufacturing process for custom leather holsters involves several key stages, each critical to ensuring the final product meets the highest standards of quality and functionality.

Illustrative image related to best custom leather holster makers

-

Material Preparation

The journey begins with the selection of high-quality leather, typically sourced from reputable tanneries. The leather is inspected for any imperfections, and only the best hides are chosen. The preparation process may also involve cutting the leather into the necessary shapes, which requires precision to reduce waste and ensure uniformity. Additionally, leather may undergo treatment processes to enhance durability and resistance to wear and moisture. -

Forming

Once the leather is prepared, the forming stage commences. This involves molding the leather to the specific shape of the firearm it will accommodate. Techniques such as wet forming or heat molding can be employed, allowing the leather to conform perfectly to the contours of the firearm. This step is crucial as it impacts the holster’s retention, comfort, and accessibility. -

Assembly

After forming, the various components of the holster are assembled. This may include attaching straps, clips, or any additional hardware needed for functionality. Skilled artisans often hand-stitch these components using high-strength thread to ensure durability. This stage also includes quality checks to assess alignment and fit before moving on to the finishing touches. -

Finishing

The final stage of production involves applying finishes that enhance both the aesthetics and protection of the leather. This may include dyeing, edge burnishing, and the application of protective coatings. Each holster is polished to achieve a smooth and attractive finish. This attention to detail not only improves visual appeal but also contributes to the longevity of the product.

What Quality Control Measures Are Essential for Custom Leather Holsters?

Quality control (QC) is paramount in the production of custom leather holsters, ensuring that each product meets international standards and customer expectations. Below are some key aspects of QC that B2B buyers should consider.

-

International Standards Compliance

Custom leather holster manufacturers often adhere to international quality standards, such as ISO 9001. This certification ensures that the manufacturer has a quality management system in place, focusing on customer satisfaction and continuous improvement. Additionally, industry-specific standards may apply, such as CE marking for products sold within the European Union or API standards for products related to the oil and gas industry. -

Quality Checkpoints

A robust QC process typically includes several checkpoints throughout the production cycle:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality requirements.

– In-Process Quality Control (IPQC): Ongoing checks during production help identify any deviations from quality standards, allowing for immediate corrective actions.

– Final Quality Control (FQC): This is the last inspection before products are packaged and shipped. It ensures that the holsters function correctly and meet all design specifications. -

Common Testing Methods

Testing methods used in the QC process may include physical tests for durability, moisture resistance, and retention strength. These tests help to ensure that the holsters can withstand regular use while providing the necessary protection for firearms.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source custom leather holsters should take proactive steps to verify the quality control measures of potential suppliers. Here are some effective strategies:

-

Supplier Audits

Conducting audits of suppliers can provide valuable insights into their manufacturing processes and QC practices. This may include evaluating their facilities, equipment, and workforce capabilities. Audits can help buyers ensure that suppliers adhere to international standards and maintain high-quality production practices. -

Quality Assurance Reports

Requesting detailed quality assurance reports from suppliers can help buyers understand the QC processes in place. These reports should include data on defect rates, corrective actions taken, and compliance with relevant standards. Transparency in reporting is a good indicator of a supplier’s commitment to quality. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services often conduct inspections at various stages of production, offering buyers an additional layer of assurance regarding product quality before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing custom leather holsters internationally, buyers must navigate various certification and quality control nuances specific to different regions, particularly in Africa, South America, the Middle East, and Europe.

Illustrative image related to best custom leather holster makers

-

Understanding Regional Regulations

Different regions have specific regulations governing the manufacturing and sale of leather goods. For instance, the EU has stringent environmental regulations impacting leather production, while some countries in Africa may have less formalized standards. Buyers should familiarize themselves with the relevant regulations in their target markets to ensure compliance. -

Cultural Considerations in Quality Expectations

Cultural differences can influence quality expectations. In some regions, the emphasis may be on craftsmanship and artisanal methods, while in others, efficiency and volume may take precedence. Understanding these nuances can help buyers select suppliers that align with their quality expectations and market demands. -

Language and Communication Barriers

Language differences can pose challenges in understanding quality documentation and certifications. Buyers should ensure that they have access to clear and accurate translations of quality reports and standards to avoid misunderstandings that could impact product quality.

In summary, the manufacturing processes and quality assurance protocols employed by the best custom leather holster makers are crucial for delivering high-quality products. By understanding these processes and implementing effective verification strategies, B2B buyers can make informed decisions and establish partnerships with reliable suppliers in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best custom leather holster makers’

Einführung

Navigating the landscape of custom leather holster procurement can be intricate, especially for international B2B buyers. This checklist is designed to streamline your sourcing process, ensuring that you select the best custom leather holster makers who align with your business needs. By following these steps, you can make informed decisions that will lead to high-quality products and reliable partnerships.

Step 1: Define Your Technical Specifications

Begin by establishing the specific requirements for the leather holsters you need. This includes the type of leather, design (e.g., OWB, IWB, shoulder holsters), and any custom features such as engraving or color options. Clearly defined specifications help to communicate your expectations and ensure that potential suppliers can meet your needs effectively.

- Consider your target market: Different regions may have unique preferences regarding holster styles and functionalities.

- Identify compliance requirements: Ensure your specifications align with any local regulations concerning holster manufacturing and usage.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential custom leather holster makers. Look for companies with a strong reputation in the industry, especially those with experience serving international clients. Investigate their product range, craftsmanship, and customer reviews to gauge their reliability and quality.

- Utilize industry directories: Websites like ThomasNet or Alibaba can help you find reputable suppliers.

- Check social media and forums: Engage with communities on platforms like LinkedIn or specialized forums to gather insights and recommendations.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their manufacturing capabilities and quality control processes. Request information about their production methods, materials used, and any certifications they hold. This step is crucial to ensure that the supplier can deliver products that meet your quality standards.

- Look for craftsmanship: Examine product samples if possible to evaluate the quality of stitching, leather, and overall design.

- Assess their production capacity: Ensure they can meet your order quantities and timelines, especially if you anticipate high demand.

Step 4: Verify Supplier Certifications

It’s essential to confirm that your chosen suppliers adhere to industry standards and certifications. This not only assures quality but also enhances credibility. Certifications such as ISO 9001 can indicate a commitment to quality management and continuous improvement.

- Request documentation: Ask for copies of relevant certifications and quality assurance processes.

- Look for sustainability practices: Understanding their sourcing and manufacturing ethics can be important, especially for eco-conscious markets.

Step 5: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the holsters you are interested in. This allows you to evaluate the quality, fit, and functionality firsthand. It also provides an opportunity to assess the supplier’s responsiveness and willingness to accommodate custom requests.

Illustrative image related to best custom leather holster makers

- Evaluate usability: Test the holster with the intended firearm to ensure it meets performance expectations.

- Solicit feedback: Share samples with team members or potential customers to gather diverse opinions on design and comfort.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish clear terms and conditions. Discuss pricing, payment terms, delivery schedules, and warranty policies. Clear agreements will help prevent misunderstandings and build a solid foundation for your partnership.

- Be transparent about your needs: Ensure both parties understand expectations regarding quality and timelines.

- Document agreements: Keep a written record of all terms to refer back to in case of discrepancies.

Step 7: Establish a Long-Term Relationship

After completing your initial procurement, focus on building a long-term relationship with your supplier. Regular communication, feedback, and joint planning can foster collaboration and lead to better product offerings in the future. A strong partnership can facilitate smoother transactions and provide you with a reliable source for future needs.

- Schedule regular check-ins: Maintain communication to discuss performance, new product ideas, or market trends.

- Engage in joint marketing efforts: Collaborating on promotional activities can benefit both parties and enhance brand visibility.

Following this checklist will position you to effectively source high-quality custom leather holsters that meet your business’s unique requirements.

Comprehensive Cost and Pricing Analysis for best custom leather holster makers Sourcing

What Are the Key Cost Components in Custom Leather Holster Manufacturing?

When sourcing custom leather holsters, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to best custom leather holster makers

-

Materials: The choice of leather significantly impacts the price. Premium, full-grain leather tends to be more expensive but offers durability and aesthetic appeal. Other materials, such as thread and hardware, also contribute to the overall cost.

-

Labor: Skilled artisans are required for crafting high-quality holsters. Labor costs can vary based on geographical location, with regions that have a high cost of living typically commanding higher wages.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. Efficient production processes can help mitigate these costs.

-

Tooling: Custom molds and machinery setup can add to initial costs, particularly for unique designs or high-volume orders.

-

Quality Control (QC): Ensuring that each holster meets stringent quality standards is crucial. QC processes can add to labor and overhead costs but are essential for maintaining brand reputation.

-

Logistics: Shipping costs can vary widely based on destination, weight, and delivery speed. For international buyers, understanding Incoterms is critical to anticipating additional charges.

-

Margin: Suppliers typically mark up prices to cover their costs and generate profit. The margin can vary based on competition, brand reputation, and product uniqueness.

How Do Price Influencers Affect Custom Leather Holster Costs?

Several factors influence the pricing of custom leather holsters, which include:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounted pricing. Suppliers may have MOQs that affect unit costs, which is vital for buyers planning large purchases.

-

Specifications and Customization: Custom features—such as stitching patterns, colors, and additional functionality—can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Premium materials or eco-friendly certifications can raise the price. Buyers should consider the long-term value of investing in higher-quality products.

-

Supplier Factors: The reputation, location, and experience of the supplier can affect pricing. Established brands may charge a premium for their products due to perceived reliability and quality.

-

Incoterms: Understanding the shipping terms is crucial for international buyers. Different Incoterms can influence the total landed cost of goods, impacting the overall budget.

What Are the Best Tips for Negotiating Custom Leather Holster Prices?

B2B buyers looking to optimize their sourcing strategies can benefit from the following tips:

-

Conduct Thorough Market Research: Understanding the market rates for custom leather holsters allows buyers to negotiate effectively. Gathering quotes from multiple suppliers can provide leverage.

-

Focus on Total Cost of Ownership (TCO): Rather than solely looking at upfront costs, consider factors like durability, warranty, and maintenance. A higher initial investment may yield savings in the long run if the product lasts longer.

-

Negotiate Based on Volume: If you anticipate repeat orders, leverage that potential to negotiate better pricing. Suppliers may be willing to offer discounts for long-term commitments.

-

Discuss Payment Terms: Flexible payment terms can alleviate cash flow issues. Explore options for staggered payments or discounts for upfront payments.

-

Be Mindful of International Pricing Nuances: For buyers from regions such as Africa, South America, the Middle East, and Europe, consider currency fluctuations, import duties, and taxes that can impact the total cost.

Disclaimer for Indicative Prices

While this analysis provides a framework for understanding costs and pricing, it is essential to note that prices can vary widely based on specific requirements and supplier negotiations. Always obtain detailed quotes to ensure accurate budgeting for your custom leather holster needs.

Alternatives Analysis: Comparing best custom leather holster makers With Other Solutions

Understanding Alternatives to Custom Leather Holster Makers

In the pursuit of reliable and aesthetically pleasing holsters, buyers often explore various options. While custom leather holsters are revered for their craftsmanship and tailored fit, alternative solutions exist that may offer different benefits. This analysis compares the best custom leather holster makers against viable alternatives, helping international B2B buyers make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Best Custom Leather Holster Makers | Kydex Holster Manufacturers | Universal Holster Solutions |

|---|---|---|---|

| Performance | High durability and comfort; tailored fit for specific firearms | Excellent retention and quick draw; lightweight | Versatile for multiple firearm models; adequate retention |

| Cost | $130 – $700 per holster | $30 – $150 per holster | $20 – $100 per holster |

| Ease of Implementation | Requires custom orders; longer wait times | Generally in stock; quick availability | Widely available off-the-shelf |

| Wartung | Requires regular conditioning; prone to wear over time | Low maintenance; easy to clean | Minimal maintenance; durable materials |

| Best Use Case | Ideal for collectors and enthusiasts seeking personalized craftsmanship | Suitable for tactical applications and everyday carry | Good for budget-conscious users needing flexibility |

Detailed Breakdown of Alternatives

Kydex Holster Manufacturers

Kydex holsters are made from a thermoplastic material, offering a rigid structure that provides excellent retention and a quick draw. They are lightweight and often favored in tactical environments due to their durability and ease of use. However, they lack the aesthetic appeal and comfort of custom leather holsters. While Kydex options are generally more affordable, their design does not allow for personalization, which can be a significant drawback for buyers looking for a unique touch.

Illustrative image related to best custom leather holster makers

Universal Holster Solutions

Universal holsters are designed to accommodate multiple firearm models, making them an attractive option for budget-conscious buyers. They are widely available and can often be found at lower price points than custom leather holsters or Kydex alternatives. However, their versatility comes at the cost of fit and retention; they may not securely hold specific firearms as well as tailored options. Additionally, universal holsters often lack the craftsmanship and aesthetic quality that custom leather provides, making them less appealing to gun enthusiasts.

How to Choose the Right Holster Solution for Your Needs

When selecting the right holster, B2B buyers should evaluate their specific requirements, including performance, cost, and intended use. Custom leather holsters excel in durability, comfort, and aesthetic appeal, making them ideal for collectors and enthusiasts. Kydex holsters offer tactical advantages and quicker accessibility, suitable for those in dynamic environments. Universal solutions present a cost-effective and flexible option for users who may switch firearms frequently. By weighing these factors, buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for best custom leather holster makers

What Are the Key Technical Properties for Custom Leather Holsters?

In the custom leather holster industry, certain technical properties are critical for ensuring product quality, durability, and functionality. Understanding these properties not only aids in supplier selection but also helps in negotiating terms that align with your business needs.

Illustrative image related to best custom leather holster makers

1. Material Grade

The material used in leather holsters significantly impacts their performance. High-quality leather, often full-grain or top-grain, offers superior durability, flexibility, and resistance to wear. When sourcing, it’s essential to inquire about the leather grade to ensure it meets your quality standards, as this affects both product longevity and customer satisfaction.

2. Stitching Strength

Stitching is a critical component of holster construction, influencing both aesthetics and durability. The use of bonded nylon thread is common, as it provides high tensile strength and resistance to fraying. Evaluate the stitching techniques employed (e.g., double-stitching) to ensure that the holster can withstand the rigors of daily use, which is particularly important for law enforcement and military applications.

3. Retention and Fit Tolerance

Retention refers to how securely a firearm is held within the holster. Proper fit tolerance is crucial; it ensures that the holster accommodates various firearm models without compromising safety or accessibility. A well-designed holster should allow for a smooth draw while maintaining adequate retention during movement. Understanding these specifications helps buyers ensure that the holsters will meet their operational needs.

Illustrative image related to best custom leather holster makers

4. Finish and Treatment

The finish applied to leather holsters can affect both aesthetics and functionality. Treatments such as water resistance or anti-microbial coatings enhance the holster’s usability in various environments. Buyers should consider the treatment processes used, as they can significantly impact the product’s performance in different climates, particularly in regions with high humidity or extreme temperatures.

5. Weight and Size Specifications

The weight and dimensions of a holster are vital for comfort and ease of use. Holsters should be lightweight to facilitate long-term wear without causing fatigue. Additionally, understanding size specifications ensures that the holster fits the intended firearm and can be comfortably worn by different users. This is especially important for B2B buyers catering to a diverse clientele.

What Are Common Trade Terms in the Custom Leather Holster Industry?

Familiarizing yourself with industry jargon can streamline communication and enhance negotiation processes with suppliers and manufacturers.

Illustrative image related to best custom leather holster makers

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom leather holsters, partnering with an OEM can ensure that you receive high-quality products that meet your specifications, as they are often equipped with advanced manufacturing capabilities.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for inventory planning and cost management. It helps buyers assess whether a supplier’s terms align with their purchasing needs, especially for smaller businesses or those entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to invite suppliers to bid on a project or product. It typically includes detailed specifications and quantities. Utilizing RFQs can help buyers obtain competitive pricing and identify the best suppliers based on their capabilities and pricing structures.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping costs, risks, and responsibilities. This knowledge aids in negotiating contracts and ensuring compliance with international trade regulations.

5. Customization Options

This term refers to the various ways in which a product can be tailored to meet specific customer requirements. In the context of holsters, this could include size adjustments, color choices, or added features like retention systems. Understanding customization options allows buyers to cater to diverse customer preferences and increase market competitiveness.

Illustrative image related to best custom leather holster makers

By being informed about these technical properties and trade terms, B2B buyers can make more strategic purchasing decisions that enhance their product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the best custom leather holster makers Sector

What are the Current Market Dynamics and Key Trends in Custom Leather Holsters?

The custom leather holster market is influenced by several global drivers, including the rising demand for personalized and high-quality firearm accessories. In regions like Africa, South America, the Middle East, and Europe, the appreciation for craftsmanship and durability is prompting buyers to seek holsters that not only meet functional needs but also reflect individual style and heritage. The growth of the shooting sports industry and increased participation in competitive shooting and hunting are also contributing to market expansion.

Emerging B2B technology trends are reshaping sourcing practices in this sector. Online platforms are facilitating direct connections between manufacturers and international buyers, enhancing transparency and reducing lead times. Additionally, the integration of augmented reality (AR) in the shopping experience allows customers to visualize how holsters will fit their firearms, thereby improving customer satisfaction and reducing returns. Customization options are becoming more sophisticated, enabling buyers to select materials, colors, and styles that align with their branding and personal preferences.

Market dynamics are also being affected by geopolitical factors, trade agreements, and tariffs, which can influence pricing and availability. Buyers must stay informed about these changes to effectively navigate sourcing strategies. As manufacturers adapt to these trends, they are increasingly focusing on quality assurance and customer feedback, ensuring that products meet the high standards expected by discerning buyers.

How are Sustainability and Ethical Sourcing Impacting the Custom Leather Holster Industry?

Sustainability is becoming a critical consideration for B2B buyers in the custom leather holster market. The environmental impact of leather production, including deforestation and water usage, is prompting brands to adopt more sustainable practices. Ethical sourcing is essential, as consumers and businesses alike are becoming more conscious of the origins of their materials. This has led to an increased demand for leather sourced from environmentally responsible tanneries that adhere to strict regulations and standards.

To meet these demands, many custom holster makers are pursuing certifications such as the Leather Working Group (LWG) certification, which evaluates the environmental performance of tanneries. Additionally, the use of vegetable-tanned leather, which is less harmful to the environment compared to chrome-tanned leather, is gaining traction. Brands that prioritize sustainability not only enhance their market appeal but also foster loyalty among consumers who value ethical practices.

Moreover, incorporating recycled materials and promoting circular economy principles, such as repair and reuse programs, can further enhance a brand’s sustainability credentials. B2B buyers can leverage these factors to align with their corporate social responsibility goals while appealing to environmentally conscious end-users.

What is the Evolution and History of Custom Leather Holster Making?

The custom leather holster-making industry has evolved significantly over the last century. Traditionally, holsters were handcrafted by skilled artisans, focusing on functionality and durability. The post-World War II era marked a turning point as gun ownership surged, leading to increased demand for personalized and decorative leather holsters.

Illustrative image related to best custom leather holster makers

As the industry matured, innovations in leather treatment and crafting techniques emerged, allowing for greater customization and improved product longevity. Today, established brands leverage both traditional craftsmanship and modern technology to create holsters that meet the diverse needs of international buyers. The focus has shifted from merely providing a functional product to offering a unique, high-quality accessory that reflects the owner’s identity and values.

By understanding these trends, B2B buyers can make informed decisions and identify the best custom leather holster makers that align with their sourcing strategies and ethical commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of best custom leather holster makers

-

1. What factors should I consider when selecting a custom leather holster maker?

When choosing a custom leather holster maker, assess their craftsmanship, materials used, and reputation in the industry. Look for companies with a long history and positive customer reviews, as this indicates reliability and quality. Additionally, consider their customization options, lead times, and whether they provide samples or prototypes. For international buyers, verify their experience with exporting goods and compliance with local regulations, as this can impact delivery and product usability. -

2. How can I ensure the quality of leather holsters from suppliers?

To ensure the quality of leather holsters, request samples before placing large orders. Evaluate the type of leather used—full-grain leather is generally the best option for durability and aesthetics. Additionally, inquire about the stitching techniques and hardware quality. Ask for references from previous clients and check for any certifications or quality assurance processes in place. Establishing a strong communication channel with the supplier can also help clarify expectations and standards. -

3. What is the typical lead time for custom leather holsters?

Lead times for custom leather holsters can vary significantly based on the complexity of the design, the materials used, and the supplier’s workload. Generally, you can expect anywhere from 4 to 12 weeks for production, with additional time for shipping. It’s crucial to discuss timelines upfront and include them in your contract to avoid misunderstandings. For urgent needs, some suppliers may offer expedited services at an additional cost, so inquire about these options. -

4. Are there minimum order quantities (MOQs) for custom leather holsters?

Most custom leather holster makers will have a minimum order quantity, which can range from a few pieces to several dozen, depending on the complexity of the designs and the supplier’s production capabilities. It’s advisable to clarify MOQs during your initial discussions with potential suppliers. If your order does not meet their MOQ, ask if they can accommodate smaller orders or if they have stock items available for immediate purchase. -

5. How can I negotiate payment terms with a custom leather holster supplier?

Negotiating payment terms is crucial in B2B transactions. Typically, suppliers may require a deposit upfront, with the balance due upon completion or delivery. Discuss flexible payment options, such as staggered payments based on production milestones. Ensure that all terms, including currency, payment methods, and penalties for late payments, are clearly outlined in your contract. Establishing trust with your supplier can facilitate smoother negotiations. -

6. What customization options are typically available for leather holsters?

Customization options for leather holsters can include various factors such as size, color, design, and added features like retention systems or personalized engravings. Discuss your specific needs with the supplier to understand their capabilities. Some makers may offer CAD designs or 3D models for you to visualize the final product before production. This can help ensure that the end product meets your expectations and requirements. -

7. What should I know about shipping and logistics for international orders?

When ordering custom leather holsters internationally, it’s important to discuss shipping options, costs, and estimated delivery times. Ensure that the supplier has experience with international shipping and can provide necessary documentation for customs clearance. Be aware of any import duties or taxes that may apply in your country, as these can affect the total cost. Tracking options and insurance should also be considered to protect your investment during transit. -

8. How can I vet a custom leather holster supplier before placing an order?

To vet a supplier, start by researching their company history, customer reviews, and industry reputation. Request references from previous clients and follow up to gauge their experiences. Verify any certifications that indicate adherence to quality standards. Additionally, consider visiting their facility if possible, or arrange a video call to assess their operations. Engaging in detailed discussions about your requirements and observing their responsiveness can also provide insights into their reliability as a partner.

Top 4 Best Custom Leather Holster Makers Manufacturers & Suppliers List

1. Szoneier Leather – Custom Leather Holsters

Domain: szoneierleather.com

Registered: 2025 (0 years)

Introduction: 13 best custom leather holster makers include: Kirkpatrick Leather, Galco Gunleather, Turner Leatherworks, Diamond D Custom Leather, Tucker Gunleather, Mitch Rosen Extraordinary Gunleather, Bullard Leather Mfg., Wright Leather Works, Palmetto Leather Works, Bianchi International, Simply Rugged Holsters, Rafter-L Custom Leather, and 5 Shot Leather. Key features include high-quality materials (full-…

2. Mitch Rosen – Premium Leather Gun Holsters

Domain: mitchrosen.com

Registered: 1997 (28 years)

Introduction: Premium IWB & OWB leather gun holsters, handmade in the USA. Product lines include Express Line and Full Detail Line. Holster types: OWB, IWB, shoulder, pocket, and ankle holsters. Key models include Glock (various models), Sig Sauer (P365, P320, P226, P229, P238, P938), 1911 variants, Smith & Wesson (M&P, Shield, J Frame, K Frame), Beretta (92, 96, APX, Nano), Springfield (XD, XDM, Hellcat), and …

3. Colt Faro Leather – Custom Leather Goods

Domain: forums.sassnet.com

Registered: 1997 (28 years)

Introduction: This company, Colt Faro Leather – Custom Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Holster Makers – Comprehensive Guide

Domain: highpowercollectors.proboards.com

Registered: 1999 (26 years)

Introduction: Compiled list of holster makers including: 5 Shot Leather, A.E. Nelson, A&G Custom Gun Leather, Adams Holsters, Andrews Leather, Barranti Leather Company, Bianchi, Black Hills Leather, Boston Leather, Brigade Gunleather, Brommeland Gunleather, Bullard Leather, Bulman Gunleather, C. Rusty Sherrick Leather Works, Cochise Leather Company, Combat Gun Leather, Craft Holsters, Davis Leather Company, Del…

Strategic Sourcing Conclusion and Outlook for best custom leather holster makers

In the competitive landscape of custom leather holster manufacturing, strategic sourcing emerges as a critical factor for international B2B buyers. By partnering with reputable makers, such as those recognized for their craftsmanship in the U.S. and beyond, buyers can ensure high-quality products that align with their specific needs. The focus on quality materials and skilled artisans not only guarantees durability and functionality but also enhances brand reputation in diverse markets, including Africa, South America, the Middle East, and Europe.

Moreover, understanding the unique preferences and requirements of different regions can open new avenues for business growth. Buyers are encouraged to prioritize suppliers who demonstrate a commitment to quality, heritage, and customer satisfaction, as these attributes resonate well in various cultural contexts.

Illustrative image related to best custom leather holster makers

Looking ahead, the demand for custom leather holsters will likely continue to grow, driven by the increasing interest in personal safety and outdoor activities. Now is the time for international B2B buyers to explore partnerships with the best custom leather holster makers. By doing so, they not only invest in superior products but also position themselves strategically in an evolving marketplace. Engage with trusted suppliers today to build a robust portfolio that meets the demands of discerning customers worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.