Introduction: Navigating the Global Market for alcantara fabric for car interior

In the competitive landscape of automotive interior design, sourcing Alcantara fabric for car interiors presents a unique challenge for international B2B buyers. As luxury and performance vehicles increasingly adopt this premium material, understanding its diverse applications and types becomes essential. This guide offers a comprehensive exploration of Alcantara fabric, detailing its various forms—from unbacked panels to foam-backed options—alongside insights into their optimal uses. By addressing critical factors such as supplier vetting processes, pricing structures, and maintenance requirements, this resource equips decision-makers with the knowledge necessary to make informed purchasing choices.

For businesses in regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Saudi Arabia—navigating the intricacies of Alcantara sourcing can be daunting. This guide empowers buyers by demystifying the characteristics and advantages of Alcantara, including its durability, ease of cleaning, and aesthetic appeal. By leveraging the insights provided, B2B buyers can confidently select the right Alcantara products that align with their branding and performance needs, ensuring their automotive offerings stand out in an increasingly discerning market.

Table Of Contents

- Top 7 Alcantara Fabric For Car Interior Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara fabric for car interior

- Understanding alcantara fabric for car interior Types and Variations

- Key Industrial Applications of alcantara fabric for car interior

- 3 Common User Pain Points for ‘alcantara fabric for car interior’ & Their Solutions

- Strategic Material Selection Guide for alcantara fabric for car interior

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric for car interior

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric for car interior’

- Comprehensive Cost and Pricing Analysis for alcantara fabric for car interior Sourcing

- Alternatives Analysis: Comparing alcantara fabric for car interior With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara fabric for car interior

- Navigating Market Dynamics and Sourcing Trends in the alcantara fabric for car interior Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric for car interior

- Strategic Sourcing Conclusion and Outlook for alcantara fabric for car interior

- Important Disclaimer & Terms of Use

Understanding alcantara fabric for car interior Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Panel | Unbacked, lightweight, and highly workable. | Headliners, door panels, dashboards | Pros: Excellent for lightweight applications. Cons: Less durable than backed options. |

| Alcantara Cover | Backed with laminated scrim for added strength. | Automotive seats, high-wear areas | Pros: Durable and strong; ideal for seating. Cons: Slightly heavier than unbacked variants. |

| Alcantara Soft | Foam-backed for a softer feel and cushioning. | Headliners, luxury seating | Pros: Provides comfort; reduces noise. Cons: May not be suitable for high-traffic areas. |

| Alcantara EXO | Weather-resistant and UV protected for outdoor use. | Boats, motorcycles, outdoor furniture | Pros: Durable against elements; easy maintenance. Cons: Limited color options compared to standard Alcantara. |

| Alcantara Multilayer | Extra thickness for enhanced durability and stretch. | Steering wheels, luxury seating | Pros: Excellent grip; ideal for performance vehicles. Cons: More expensive due to additional layers. |

What Are the Key Characteristics of Alcantara Panel Fabric?

Alcantara Panel fabric is characterized by its unbacked, single-layer design, making it a lightweight and highly workable option. It is often used in applications where flexibility and stretch are crucial, such as headliners and door panels. When considering B2B purchases, companies should note that while it offers excellent aesthetic appeal, it may not provide the same durability as backed alternatives. This fabric is ideal for manufacturers looking to create a luxurious look without significantly increasing vehicle weight.

How Does Alcantara Cover Stand Out in Automotive Applications?

Alcantara Cover is distinguished by its backing with a laminated scrim, enhancing its strength and durability. This fabric is primarily utilized in automotive seating, where the need for resilience against wear and tear is paramount. B2B buyers should consider the trade-off between weight and durability when selecting this fabric, as it is heavier than unbacked options but provides superior performance in high-wear areas. Its reliable nature makes it a preferred choice for many luxury automotive brands.

Why Choose Alcantara Soft for Luxury Interiors?

Alcantara Soft features a layer of foam backing, adding a plush feel and cushioning effect, making it particularly suitable for headliners and luxury seating. This type is favored for its ability to reduce noise and enhance comfort, making it an attractive option for high-end vehicles. B2B buyers should assess whether the softer feel aligns with their target market’s expectations, as it may not be ideal for areas that experience heavy use. The comfort it provides can significantly enhance the overall driving experience.

What Makes Alcantara EXO Ideal for Outdoor Applications?

Alcantara EXO is specifically designed for outdoor use, featuring weather-resistant properties that protect against UV rays and moisture. It is commonly used in applications such as boats, motorcycles, and outdoor furniture, where durability against the elements is crucial. B2B buyers should consider the specific environmental conditions their products will face, as this fabric excels in harsh weather but may offer fewer color choices compared to standard Alcantara. Its easy maintenance also adds to its appeal in outdoor settings.

Illustrative image related to alcantara fabric for car interior

How Does Alcantara Multilayer Enhance Performance in Vehicles?

Alcantara Multilayer incorporates additional thickness, making it particularly effective for applications requiring both durability and stretch, such as steering wheels and luxury seating. This fabric is designed for performance vehicles where grip and control are essential. B2B buyers should weigh the increased cost against the benefits of enhanced durability and performance, especially if targeting high-performance automotive markets. Its premium nature positions it well for luxury brands looking to elevate their product offerings.

Key Industrial Applications of alcantara fabric for car interior

| Industry/Sector | Specific Application of alcantara fabric for car interior | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Seat Upholstery | Provides luxury feel, durability, and ease of maintenance | Ensure compliance with automotive standards and certifications |

| Luxury Vehicle Customization | Dashboard and Trim Finishes | Enhances aesthetic appeal and perceived value | Source from reputable suppliers offering color matching |

| Motorsport | Steering Wheel Covers | Increases grip and control under extreme conditions | Prioritize materials that meet fire safety regulations |

| Public Transport | Interior Panels for Buses and Trains | Improves passenger comfort and reduces glare | Consider bulk purchasing for cost efficiency |

| Aviation | Aircraft Interior Upholstery | Lightweight and fire-resistant options for safety | Verify compliance with aviation industry standards |

How is Alcantara Fabric Used in Automotive Manufacturing?

In automotive manufacturing, Alcantara fabric is primarily utilized for seat upholstery. Its unique blend of polyester and polyurethane offers a luxurious feel while maintaining durability and ease of maintenance. This fabric addresses common issues such as wear and tear, making it suitable for high-usage environments. International buyers, especially from regions like Africa and South America, should ensure that their suppliers provide materials that comply with local automotive standards and certifications.

What Role Does Alcantara Play in Luxury Vehicle Customization?

In the luxury vehicle customization sector, Alcantara is often employed for dashboard and trim finishes. Its aesthetic appeal elevates the overall design of the vehicle, enhancing the perceived value for consumers. Buyers should focus on sourcing Alcantara that allows for precise color matching and customization options to meet the specific branding needs of luxury automotive brands, particularly in competitive markets in Europe and the Middle East.

Why is Alcantara Important for Motorsport Applications?

In motorsport, Alcantara fabric is favored for steering wheel covers due to its superior grip and control capabilities under extreme conditions. This fabric not only enhances driver performance but also contributes to the overall aesthetics of high-performance vehicles. Buyers in this sector must prioritize sourcing materials that meet stringent fire safety regulations, ensuring both safety and compliance during high-stakes racing events.

How Does Alcantara Enhance Public Transport Interiors?

For public transport applications, such as buses and trains, Alcantara is used for interior panels to improve passenger comfort and reduce glare. This fabric’s easy-to-clean nature is a significant advantage in high-traffic environments where hygiene is crucial. B2B buyers should consider bulk purchasing options to maximize cost efficiency while ensuring that the sourced materials meet local public transport standards.

Illustrative image related to alcantara fabric for car interior

What are the Benefits of Using Alcantara in Aviation Upholstery?

In the aviation industry, Alcantara is utilized for aircraft interior upholstery due to its lightweight and fire-resistant properties. These features are essential for ensuring passenger safety and comfort during flights. International buyers should verify that their suppliers can provide Alcantara that complies with aviation industry standards, ensuring both safety and quality in the highly regulated aviation environment.

3 Common User Pain Points for ‘alcantara fabric for car interior’ & Their Solutions

Scenario 1: Difficulty in Sourcing Genuine Alcantara Fabric

The Problem: B2B buyers often struggle with sourcing genuine Alcantara fabric due to a saturated market filled with imitation products. This can lead to challenges in maintaining quality standards, especially for luxury automotive interiors where brand reputation is paramount. Buyers may find it difficult to distinguish between authentic materials and cheaper alternatives that do not meet performance or aesthetic expectations. This challenge is compounded when suppliers do not provide sufficient documentation or certification of authenticity, leaving buyers uncertain about their purchases.

The Solution: To overcome sourcing issues, buyers should prioritize suppliers who can provide comprehensive documentation proving the authenticity of their Alcantara fabric. This includes certifications from Alcantara S.p.A. that verify the material’s origin and quality. Additionally, establishing relationships with reputable distributors known for their integrity in the market can ensure a consistent supply of genuine products. Buyers can also request physical samples before making bulk purchases to verify color and texture match. Utilizing platforms that specialize in Alcantara and offer a wide range of products can help streamline the sourcing process, ensuring that buyers receive exactly what they need without compromising on quality.

Illustrative image related to alcantara fabric for car interior

Scenario 2: Challenges in Maintaining Alcantara Fabric

The Problem: Maintaining the appearance and integrity of Alcantara fabric in automotive interiors poses a significant challenge for B2B buyers. Unlike traditional leather, Alcantara requires specific cleaning and care protocols to avoid degradation. Many buyers may not be fully aware of the appropriate maintenance techniques, leading to premature wear, discoloration, or damage. This not only affects the aesthetic appeal of the vehicle but also raises concerns regarding customer satisfaction and warranty claims.

The Solution: To address maintenance challenges, buyers should invest in comprehensive training for their teams on the proper care of Alcantara fabric. This includes understanding cleaning products that are safe for use, such as pH-neutral cleaners, and avoiding harsh chemicals that can harm the material. Additionally, providing customers with detailed care instructions at the point of sale can help ensure longevity. Offering a care kit that includes recommended cleaning products and tools can also enhance customer experience and protect the fabric’s integrity. Regular maintenance schedules should be established to keep the fabric in top condition, thereby reinforcing brand commitment to quality and customer satisfaction.

Scenario 3: Customization Limitations with Alcantara Fabric

The Problem: B2B buyers often face challenges when it comes to customizing Alcantara fabric for specific automotive applications. While Alcantara is known for its versatility, some buyers may find that certain types of finishes, colors, or textures are not readily available in the market. This limitation can hinder the ability to meet unique design specifications or customer preferences, especially in luxury automotive markets where personalization is a key selling point.

The Solution: To overcome customization limitations, buyers should collaborate closely with manufacturers or suppliers who offer bespoke solutions. Engaging with suppliers who can produce custom colors, textures, or finishes based on specific requirements can significantly enhance design possibilities. Additionally, leveraging advancements in technology, such as digital printing on Alcantara, can provide new avenues for customization without compromising the material’s integrity. Buyers should also communicate their needs clearly and early in the design process to allow for sufficient lead time and options to be explored. By fostering a partnership with manufacturers who understand the nuances of customization, B2B buyers can enhance their product offerings and fulfill market demands effectively.

Illustrative image related to alcantara fabric for car interior

Strategic Material Selection Guide for alcantara fabric for car interior

What Are the Key Materials Used in Alcantara Fabric for Car Interiors?

When considering alcantara fabric for car interiors, several material compositions are commonly utilized, each offering distinct properties and applications. Below, we analyze four prevalent materials, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Alcantara Soft (Foam-Backed)

Key Properties: Alcantara Soft is composed of 68% Polyester and 32% Polyurethane, featuring a 3mm foam backing. This construction provides a soft touch while enhancing durability and comfort. It remains cool to the touch, making it ideal for car interiors that experience varying temperatures.

Pros & Cons: The foam backing offers increased cushioning and sound insulation, which can enhance the driving experience. However, the additional layer may complicate manufacturing processes and increase costs. While it is easier to clean than traditional leather, it may not withstand extreme wear and tear as effectively as unbacked options.

Impact on Application: This material is particularly suitable for headliners and seating surfaces where comfort and aesthetics are prioritized. Its ability to reduce glare is beneficial for driver visibility.

Illustrative image related to alcantara fabric for car interior

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local automotive standards, as Alcantara Soft may not meet all durability requirements in extreme climates. Familiarity with ASTM and ISO standards is crucial for ensuring product suitability.

2. Alcantara Cover (Backed)

Key Properties: Alcantara Cover features a laminated backing of 65% Polyester and 35% Cotton, providing enhanced strength and durability. This material is designed to withstand the rigors of daily use in high-traffic areas of the vehicle.

Pros & Cons: The backed design offers superior durability and resistance to stretching, making it ideal for seat covers. However, it may be heavier and less flexible compared to unbacked options, which could limit its application in certain designs.

Impact on Application: This material is commonly used for seating and high-contact areas, ensuring longevity and maintaining aesthetic appeal. Its robust nature makes it suitable for vehicles in regions with high passenger traffic.

Considerations for International Buyers: Buyers in Europe and South America should be aware of the varying preferences for material softness and durability. Compliance with local automotive regulations is essential, particularly regarding fire safety standards.

Illustrative image related to alcantara fabric for car interior

3. Alcantara Panel (Unbacked)

Key Properties: Alcantara Panel is a single-layer textile that is lightweight and flexible, making it easy to work with. It is typically used in applications requiring increased stretch and durability.

Pros & Cons: Its lightweight nature allows for versatile applications, including headliners and door panels. However, being unbacked, it may not offer the same level of durability as backed options, making it less suitable for high-wear areas.

Impact on Application: This material is ideal for aesthetic applications where flexibility and lightweight characteristics are prioritized, such as in luxury vehicle interiors.

Considerations for International Buyers: Buyers should ensure that the material meets local regulations regarding emissions and safety. Understanding the specific requirements of the automotive industry in regions like Nigeria and Saudi Arabia is vital for compliance.

4. Alcantara EXO (Outdoor)

Key Properties: The EXO range is designed with additional water repellency and UV protection, making it suitable for outdoor applications. This material includes a laminated middle layer that enhances its durability against environmental factors.

Illustrative image related to alcantara fabric for car interior

Pros & Cons: Its weather-resistant properties make it ideal for outdoor vehicle applications, such as marine upholstery and outdoor furniture. However, the added layers may increase the cost and complexity of production.

Impact on Application: This material is perfect for vehicles exposed to harsh weather conditions, ensuring longevity and maintaining appearance. Its versatility allows for use in various outdoor settings.

Considerations for International Buyers: Buyers in regions with extreme weather should prioritize materials that can withstand their specific conditions. Knowledge of local climate impacts on material performance is essential for making informed purchasing decisions.

Summary Table of Alcantara Fabric Materials

| Material | Typical Use Case for alcantara fabric for car interior | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara Soft | Headliners, seating surfaces | Soft touch and comfort | Higher manufacturing complexity | Medium |

| Alcantara Cover | Seat covers, high-contact areas | Superior durability and strength | Heavier, less flexible | Hoch |

| Alcantara Panel | Aesthetic applications (headliners, door panels) | Lightweight and flexible | Less durable for high-wear areas | Medium |

| Alcantara EXO | Outdoor upholstery, marine applications | Weather-resistant and UV protected | Increased cost and complexity | Hoch |

This strategic material selection guide provides B2B buyers with a comprehensive understanding of alcantara fabric options, enabling informed decisions that align with their specific requirements and regional standards.

Illustrative image related to alcantara fabric for car interior

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric for car interior

What Are the Key Stages in the Manufacturing Process of Alcantara Fabric for Car Interiors?

The manufacturing of Alcantara fabric involves several critical stages that ensure the final product meets the high standards expected in the automotive industry. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality raw materials. Alcantara is primarily composed of 68% polyester and 32% polyurethane. These components are sourced from reputable suppliers who adhere to environmental and quality standards. The materials undergo a thorough inspection to verify their quality and suitability for use.

-

Forming: Once the raw materials are approved, they are processed to create the fabric. This involves a series of chemical and mechanical processes that transform the raw components into a soft, suede-like texture. Techniques such as spinning, weaving, and coating are employed to ensure the fabric has the desired characteristics, such as durability and aesthetic appeal.

-

Assembly: After forming, the Alcantara fabric is cut and assembled into the required shapes and sizes for various automotive applications. This stage may involve laminating the fabric with additional backing materials for enhanced performance, especially in high-stress areas such as seating and dashboards.

-

Finishing: The final stage includes treating the fabric to improve its properties further. This may involve dyeing, applying surface treatments for water resistance, or enhancing UV protection. The finishing process not only contributes to the aesthetic quality of the fabric but also ensures it meets specific performance standards required for automotive interiors.

What Quality Control Measures Are Implemented During Alcantara Fabric Production?

Quality assurance is paramount in the production of Alcantara fabric, particularly for automotive applications where safety and durability are critical. Manufacturers typically adhere to international standards such as ISO 9001, which sets out the criteria for a quality management system. Here are the key quality control checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Suppliers must provide documentation verifying compliance with quality standards. Random sampling of materials may be conducted to ensure consistency.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checkpoints are established to monitor the production stages. This includes assessing the fabric’s texture, color consistency, and physical properties. Any deviations from specifications are addressed immediately to prevent defects in the final product.

-

Final Quality Control (FQC): Before the Alcantara fabric is shipped to customers, a comprehensive final inspection is conducted. This includes visual inspections for defects, measurement of physical properties, and performance testing to ensure the fabric meets industry standards.

How Can B2B Buyers Verify Quality Control Standards of Alcantara Suppliers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of Alcantara suppliers is crucial. Here are actionable steps buyers can take:

Illustrative image related to alcantara fabric for car interior

-

Request Documentation: Suppliers should provide certifications that demonstrate compliance with international standards (e.g., ISO 9001) and any relevant industry-specific certifications (e.g., CE, API). Buyers should review these documents to ensure the supplier maintains rigorous quality control practices.

-

Conduct Audits: Buyers can conduct on-site audits of potential suppliers to assess their manufacturing processes and quality control systems. This firsthand observation can provide insight into the supplier’s commitment to quality and compliance with standards.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These services can perform independent quality assessments at various stages of the manufacturing process, ensuring that the fabric produced meets the specified quality standards.

-

Review Testing Methods: Inquire about the specific testing methods employed by the supplier. Common tests include tensile strength, colorfastness, and abrasion resistance. Understanding these testing protocols helps buyers gauge the reliability and durability of the fabric.

What Specific Quality Control Challenges Do International B2B Buyers Face?

International buyers may encounter specific challenges when assessing the quality of Alcantara fabric from suppliers in different regions. Here are some nuances to consider:

-

Regulatory Variations: Different countries may have varying regulations regarding materials used in automotive interiors. Buyers must ensure that the fabric complies with local regulations in their respective markets, which may differ from those in the supplier’s country.

-

Language and Communication Barriers: Miscommunication can lead to misunderstandings regarding quality expectations. Buyers should ensure clear communication with suppliers regarding specifications and quality standards, potentially involving bilingual representatives or translators if necessary.

-

Cultural Differences in Quality Standards: Different regions may have varying perceptions of quality. Buyers should clearly outline their quality expectations and requirements to avoid discrepancies that could affect product acceptance in their markets.

-

Logistical Considerations: Transportation and storage conditions can impact the quality of Alcantara fabric. Buyers should verify that suppliers have protocols in place to protect the fabric during shipping and storage, ensuring that it arrives in optimal condition.

Conclusion

Understanding the manufacturing processes and quality assurance measures for Alcantara fabric is essential for B2B buyers in the automotive sector. By focusing on key stages of production and implementing robust quality control measures, suppliers can deliver a product that not only meets but exceeds market expectations. For international buyers, actively engaging in quality verification processes, addressing challenges, and maintaining open communication with suppliers will ensure successful procurement of high-quality Alcantara fabric for automotive interiors.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric for car interior’

To successfully procure Alcantara fabric for automotive interiors, it’s essential to follow a structured approach. This guide outlines a practical checklist designed to streamline the sourcing process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is foundational in sourcing Alcantara fabric. Consider the intended application within the vehicle—whether for seats, headliners, or dashboards—as each area may require different fabric properties. Additionally, specify color, texture, and durability requirements to ensure that the fabric meets your aesthetic and performance standards.

Step 2: Identify Reputable Suppliers

Finding reliable suppliers is critical to securing high-quality Alcantara. Research potential suppliers who specialize in automotive textiles and have a proven track record with well-known car manufacturers. Look for suppliers that are recognized as official distributors of Alcantara, as they are more likely to provide authentic and high-quality materials.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your chosen suppliers hold relevant certifications. Certifications can indicate compliance with industry standards for quality and safety, particularly for materials used in automotive applications. Look for certifications related to environmental impact, such as ISO standards, which can also enhance your brand’s sustainability profile.

Step 4: Request Material Samples

Always request samples of the Alcantara fabric before placing a bulk order. This step allows you to assess the texture, color accuracy, and overall quality of the material. Pay attention to how the fabric feels and performs under different conditions, such as exposure to sunlight and moisture, to ensure it meets your durability expectations.

Illustrative image related to alcantara fabric for car interior

Step 5: Review Pricing and Payment Terms

Once you have identified potential suppliers and assessed their products, compare pricing structures. Be sure to understand the payment terms, including minimum order quantities, bulk discounts, and shipping costs. Aim to negotiate favorable terms that align with your budget while also ensuring you receive quality materials.

Step 6: Discuss Lead Times and Delivery Options

Inquire about lead times for production and delivery to avoid project delays. Understanding the supplier’s capacity to fulfill orders promptly is crucial, especially in industries with tight production schedules. Additionally, discuss delivery options to ensure you can receive materials in a manner that aligns with your operational needs.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the materials received against your specifications. This may include visual inspections and testing for durability and performance. Establishing quality benchmarks can help ensure that the Alcantara fabric consistently meets your standards for automotive applications.

Illustrative image related to alcantara fabric for car interior

By following this checklist, you can effectively navigate the procurement process for Alcantara fabric, ensuring you select the best materials that meet your business requirements while maintaining quality and performance standards.

Comprehensive Cost and Pricing Analysis for alcantara fabric for car interior Sourcing

Alcantara fabric has emerged as a premium choice for automotive interiors, especially among luxury car manufacturers. Understanding the cost structure and pricing dynamics is crucial for B2B buyers looking to source this material effectively.

What are the Key Cost Components of Alcantara Fabric for Automotive Interiors?

-

Materials: The primary components of Alcantara fabric include polyester and polyurethane, which constitute around 68% and 32%, respectively. The cost of raw materials can fluctuate based on market conditions, impacting the overall pricing of the fabric.

-

Labor: Labor costs are significant, particularly in regions where Alcantara is manufactured, such as Italy. Skilled labor is essential for the production of high-quality Alcantara, which can drive up costs but also ensures superior craftsmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations, maintenance, and utilities. Manufacturers often allocate a portion of these overhead costs to each yard of fabric produced, contributing to the final price.

-

Tooling: The initial setup for production, including machinery and molds, can be expensive. However, these costs are typically amortized over larger production runs, making them less impactful on bulk orders.

-

Quality Control (QC): Given Alcantara’s use in luxury vehicles, stringent QC measures are employed to ensure that the fabric meets industry standards. This process incurs additional costs but is vital for maintaining brand reputation.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. International shipping may involve customs duties and tariffs, which should be factored into the total cost of ownership.

-

Margin: Suppliers will add their profit margin to the cost of production. This margin can vary based on supplier reputation, market demand, and competition.

What Influences the Pricing of Alcantara Fabric for B2B Buyers?

-

Volume and Minimum Order Quantity (MOQ): Pricing often reflects the volume ordered. Larger quantities can lead to discounts, while smaller orders may incur higher per-unit costs due to lower economies of scale.

-

Specifications and Customization: Custom colors, textures, or specifications can increase costs. Buyers should assess their needs carefully to avoid unnecessary expenses.

-

Material Quality and Certifications: Fabrics that meet specific environmental or safety standards may carry a premium price. Certifications can be crucial for compliance, especially in international markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their quality assurance and customer service.

-

Incoterms: Understanding the agreed terms of trade is essential. Different Incoterms can significantly affect the final cost by determining who bears responsibility for shipping, insurance, and tariffs.

What Tips Can Help Buyers Negotiate Better Prices for Alcantara Fabric?

-

Leverage Volume Discounts: Consolidate orders to meet MOQ requirements and negotiate better rates based on larger volumes.

-

Evaluate Total Cost of Ownership: Consider not just the initial price but also long-term costs associated with maintenance and durability. Alcantara’s longevity can justify its higher upfront cost.

-

Be Informed About Market Trends: Stay updated on market conditions and material costs to negotiate from an informed position. Understanding price fluctuations can help in timing purchases effectively.

-

Consider Local Suppliers: For buyers in Africa or South America, sourcing from local distributors can reduce shipping costs and lead times, making the total cost more favorable.

-

Request Samples: Before committing to a large order, request samples to ensure the material meets quality expectations. This also allows for better negotiation based on the quality observed.

Conclusion

In conclusion, navigating the costs associated with sourcing Alcantara fabric requires a comprehensive understanding of its cost components and pricing influencers. By employing strategic negotiation tactics and assessing total ownership costs, B2B buyers can make informed decisions that align with their budget and quality requirements. As prices can vary widely, it is advisable to obtain multiple quotes and conduct thorough due diligence before finalizing purchases.

Alternatives Analysis: Comparing alcantara fabric for car interior With Other Solutions

Exploring Alternatives to Alcantara Fabric for Car Interiors

In the automotive industry, selecting the right material for car interiors is crucial for both aesthetics and functionality. Alcantara fabric, known for its luxurious feel and performance, is a popular choice among premium vehicle manufacturers. However, there are viable alternatives that can meet similar needs. This analysis will compare Alcantara fabric with two prominent alternatives: synthetic leather and natural leather, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Alcantara Fabric For Car Interior | Synthetic Leather | Natural Leather |

|---|---|---|---|

| Performance | High grip, durable, reduces glare | Good durability, varied textures | Excellent durability, luxurious feel |

| Cost | Moderate ($125 – $135 per yard) | Lower ($30 – $60 per yard) | High ($150 – $400 per hide) |

| Ease of Implementation | Requires specialized sewing techniques | Easy to cut and sew | Requires skilled labor for installation |

| Wartung | Easy to clean, stain-resistant | Moderate; can be wiped clean | High; requires conditioning |

| Best Use Case | Luxury vehicles, high-performance cars | Economy and mid-range vehicles | High-end, luxury vehicles |

What Are the Benefits and Drawbacks of Synthetic Leather?

Synthetic leather, also known as faux leather or vegan leather, is made from polyurethane or polyvinyl chloride (PVC). It offers a more affordable alternative to Alcantara and is often used in economy and mid-range vehicles. The primary advantages include cost-effectiveness and ease of maintenance, as it can be easily wiped down. However, synthetic leather often lacks the luxurious feel and breathability of Alcantara, which can impact the overall driving experience, especially in high-performance applications.

Why Consider Natural Leather as an Alternative?

Natural leather is a traditional material that has been used in car interiors for decades. It exudes luxury and sophistication, making it a favored choice for high-end vehicles. The durability and character of natural leather can enhance the aesthetic appeal of a car’s interior. However, it comes with a higher price tag and requires more maintenance, including regular conditioning to prevent cracking and fading. Additionally, installation can be labor-intensive, requiring skilled artisans to ensure quality workmanship.

Conclusion: How to Choose the Right Material for Car Interiors

When selecting the ideal material for car interiors, B2B buyers must consider their specific requirements, including budget, target market, and desired aesthetic. Alcantara fabric stands out for its combination of luxury, performance, and ease of maintenance, making it suitable for high-end applications. Synthetic leather offers a budget-friendly alternative, ideal for mid-range vehicles, while natural leather appeals to those seeking a classic, upscale look. By weighing these factors carefully, buyers can make informed decisions that align with their brand’s identity and consumer expectations.

Essential Technical Properties and Trade Terminology for alcantara fabric for car interior

What Are the Key Technical Properties of Alcantara Fabric for Car Interiors?

Alcantara fabric is renowned for its exceptional performance and versatility in automotive applications. Understanding its technical properties is crucial for B2B buyers who seek to source high-quality materials for vehicle interiors. Here are some essential specifications to consider:

-

Composition and Material Grade

Alcantara is a synthetic suede primarily composed of 68% polyester and 32% polyurethane. This blend provides the fabric with a luxurious feel similar to leather, while also enhancing its durability and ease of maintenance. For B2B buyers, ensuring the right material grade is vital for meeting quality standards and customer expectations in luxury automotive interiors. -

Thickness

The thickness of Alcantara fabric typically ranges from 1.0 mm to 3.0 mm, depending on the type (e.g., soft, panel, or multilayer). Thicker materials like Alcantara Soft, which is foam-backed, offer additional cushioning, making them suitable for headliners and seating. Buyers must consider thickness when assessing the fabric’s application, as it impacts both aesthetics and functionality. -

UV Resistance

Alcantara fabric is designed to withstand UV exposure, making it an excellent choice for vehicles that may be parked in direct sunlight. This property helps prevent fading and deterioration over time, ensuring that the interiors maintain their luxurious appearance. Buyers should prioritize UV resistance, especially in markets with high sun exposure. -

Abrasion Resistance

The durability of Alcantara is reflected in its high abrasion resistance, allowing it to endure the wear and tear of daily use without showing significant signs of damage. This property is crucial for automotive applications, where fabrics are subject to frequent contact. B2B buyers must evaluate abrasion resistance to ensure long-lasting performance. -

Care and Maintenance Requirements

Alcantara fabric is relatively easy to clean compared to natural leather, often requiring only a damp cloth for routine maintenance. However, specific cleaning solutions may be recommended to preserve its texture and color. Understanding care requirements is essential for manufacturers and upholstery providers to advise end-users effectively. -

Weight

Alcantara is lightweight compared to traditional leather, which can contribute to overall vehicle efficiency. This is particularly important in automotive design, where reducing weight can enhance fuel efficiency and performance. B2B buyers should consider the weight of materials when assessing overall vehicle specifications.

What Are Common Trade Terminology and Jargon Related to Alcantara Fabric?

Familiarity with industry-specific terminology can facilitate smoother transactions and enhance communication between buyers and suppliers. Here are some common terms relevant to Alcantara fabric sourcing:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. In the context of Alcantara, many luxury car brands source fabric directly from OEM suppliers, ensuring authenticity and quality. B2B buyers should verify OEM status to ensure they are procuring genuine materials. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and avoid overcommitting to large orders that may not align with demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers should utilize RFQs to obtain competitive pricing and negotiate favorable terms for Alcantara fabric purchases. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping responsibilities, risk management, and costs associated with Alcantara procurement. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Knowing the lead time for Alcantara fabric is vital for project planning and ensuring that production schedules align with material availability. -

Customization Options

Many suppliers offer customization options for Alcantara, including color, texture, and backing types. Understanding these options allows buyers to tailor materials to specific vehicle designs and customer preferences, enhancing the overall value proposition.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing Alcantara fabric, ensuring they meet both quality and performance standards in their automotive applications.

Navigating Market Dynamics and Sourcing Trends in the alcantara fabric for car interior Sector

What Are the Current Market Dynamics and Key Trends in the Alcantara Fabric for Car Interiors?

The Alcantara fabric market for car interiors is witnessing significant evolution driven by several global factors. Increasing demand for luxury and premium automotive interiors across regions such as Africa, South America, the Middle East, and Europe reflects a growing consumer preference for quality and aesthetics. This trend is particularly strong in countries like Nigeria and Saudi Arabia, where luxury vehicle sales are on the rise. Moreover, the automotive sector’s shift towards electric vehicles (EVs) has heightened the focus on innovative materials that enhance both functionality and environmental sustainability.

Technological advancements are reshaping sourcing strategies, allowing buyers to access real-time data on material specifications, pricing, and availability. Online platforms and digital marketplaces are simplifying procurement processes, enabling international B2B buyers to source Alcantara fabric directly from manufacturers and suppliers globally. Additionally, customization options are expanding, with manufacturers offering a variety of Alcantara types, including foam-backed, perforated, and multilayered fabrics tailored for specific applications like seating and dashboards.

How Is Sustainability and Ethical Sourcing Influencing the Alcantara Fabric Market?

Sustainability is becoming a core consideration in the Alcantara fabric market, with buyers increasingly prioritizing environmentally friendly materials and ethical sourcing practices. Alcantara, a synthetic suede made from 68% polyester and 32% polyurethane, is designed to minimize environmental impact while offering superior durability and aesthetic appeal. Its production process is energy-efficient and adheres to strict environmental standards, making it a preferred choice for luxury automotive brands committed to sustainability.

Ethical supply chains are crucial for B2B buyers seeking to align with eco-conscious consumer demands. Certifications such as OEKO-TEX® and Global Recycled Standard are gaining traction, assuring buyers of the sustainable and responsible sourcing of materials. Furthermore, manufacturers are increasingly transparent about their sourcing practices, providing documentation that outlines their environmental impact and commitment to sustainability. For B2B buyers, choosing Alcantara fabric not only enhances the luxury quotient of automotive interiors but also aligns with a broader commitment to sustainability and ethical responsibility.

Illustrative image related to alcantara fabric for car interior

What Is the Historical Evolution of Alcantara Fabric in the Automotive Sector?

Alcantara fabric has its roots in the Italian textile industry, emerging in the late 1970s as a premium alternative to leather. Its unique blend of durability, aesthetic appeal, and versatility quickly attracted the attention of luxury automotive manufacturers. Over the decades, Alcantara has established itself as a staple in high-end vehicles, utilized in various applications from seats to dashboards.

The fabric’s ability to withstand wear and tear while maintaining its luxurious appearance made it a favorite among brands like Lamborghini, Ferrari, and Tesla. As consumer preferences shifted towards sustainable and ethically sourced materials, Alcantara’s eco-friendly production process positioned it favorably in the evolving market landscape. Today, Alcantara is synonymous with luxury and innovation, continuously adapting to meet the demands of modern automotive design and functionality.

In conclusion, the Alcantara fabric for car interiors represents a dynamic market influenced by technological advancements, sustainability concerns, and evolving consumer preferences. For international B2B buyers, understanding these trends is essential for making informed sourcing decisions that align with both business objectives and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric for car interior

-

How do I choose the right Alcantara fabric for automotive interiors?

Selecting the appropriate Alcantara fabric depends on the specific application within the vehicle. For seating, consider Alcantara Cover, which is backed for durability. If you need lightweight material for headliners or dashboards, Alcantara Panel is ideal. For outdoor applications, Alcantara EXO offers enhanced water and UV resistance. Always request samples to assess texture, color, and performance under different conditions. This approach ensures that the selected fabric aligns with both aesthetic and functional requirements. -

What are the customization options available for Alcantara fabric?

Alcantara fabric can be customized in various ways, including color, texture, and backing type. Many suppliers offer a range of colors and finishes to match specific branding or design requirements. Additionally, you can select different backing options, such as foam-backed or unbacked fabrics, depending on the intended use. Discussing your needs with suppliers can lead to tailored solutions that meet your design specifications and enhance the overall appeal of the vehicle interiors. -

What is the minimum order quantity (MOQ) for Alcantara fabric?

Minimum order quantities for Alcantara fabric can vary significantly between suppliers. Generally, MOQs range from a few yards to full rolls, typically around 55 yards. It’s essential to verify with your supplier regarding their specific policies, as some may offer flexibility for smaller orders, especially for first-time buyers or samples. Understanding MOQs can aid in budgeting and inventory planning for your automotive projects. -

What payment terms should I expect when sourcing Alcantara fabric?

Payment terms for Alcantara fabric purchases can vary based on the supplier and the size of the order. Common terms include a deposit upfront, with the balance due upon shipment. Some suppliers may offer net payment terms, allowing for payment within a specified period post-delivery. It’s crucial to clarify these terms during negotiations to ensure that they align with your cash flow and procurement policies. -

How can I ensure the quality of Alcantara fabric I’m purchasing?

To ensure quality, source Alcantara from reputable suppliers who provide certifications and product specifications. Request samples before placing a bulk order, and verify that the fabric meets industry standards for durability, colorfastness, and performance. Additionally, inquire about the supplier’s quality assurance processes and any guarantees they offer on their products. Regular quality checks during production can also help maintain standards. -

What logistics considerations should I keep in mind when importing Alcantara fabric?

Logistics for importing Alcantara fabric involve several key considerations, including shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with textile imports to navigate these complexities. Ensure that all shipping documents are in order to facilitate smooth customs clearance. Additionally, factor in lead times for production and shipping, especially if you’re sourcing from international suppliers in Europe or the Middle East. -

What are the environmental considerations associated with Alcantara fabric?

Alcantara is known for its commitment to sustainability, being 100% made in Italy with a focus on eco-friendly production processes. Many suppliers provide information on their environmental policies, including the use of recycled materials and adherence to strict environmental regulations. When sourcing, inquire about the supplier’s sustainability certifications and practices, ensuring that your procurement aligns with your company’s environmental goals. -

How do I handle color discrepancies when sourcing Alcantara fabric?

Color discrepancies can occur due to variations in monitor settings and dye lots. To mitigate this risk, always request physical samples before placing large orders. Many suppliers offer swatch services or color matching tools to help you select the exact shade needed. Establishing a clear communication channel with your supplier regarding color expectations can also help minimize misunderstandings and ensure satisfaction with the final product.

Top 7 Alcantara Fabric For Car Interior Manufacturers & Suppliers List

1. Keystone Bros – Alcantara Suede Automotive Fabric

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Alcantara Suede – Automotive Fabric. Product options include Alcantara Cover, Alcantara Soft, Alcantara Pannel, Alcantara EXO, Alcantara Pannel MB-4 Perf, and Alcantara Pannel S-2000 Perf. Pricing requires login to view. Features include various roll sizes, cleaning codes, abrasion ratings, and UFAC class specifications.

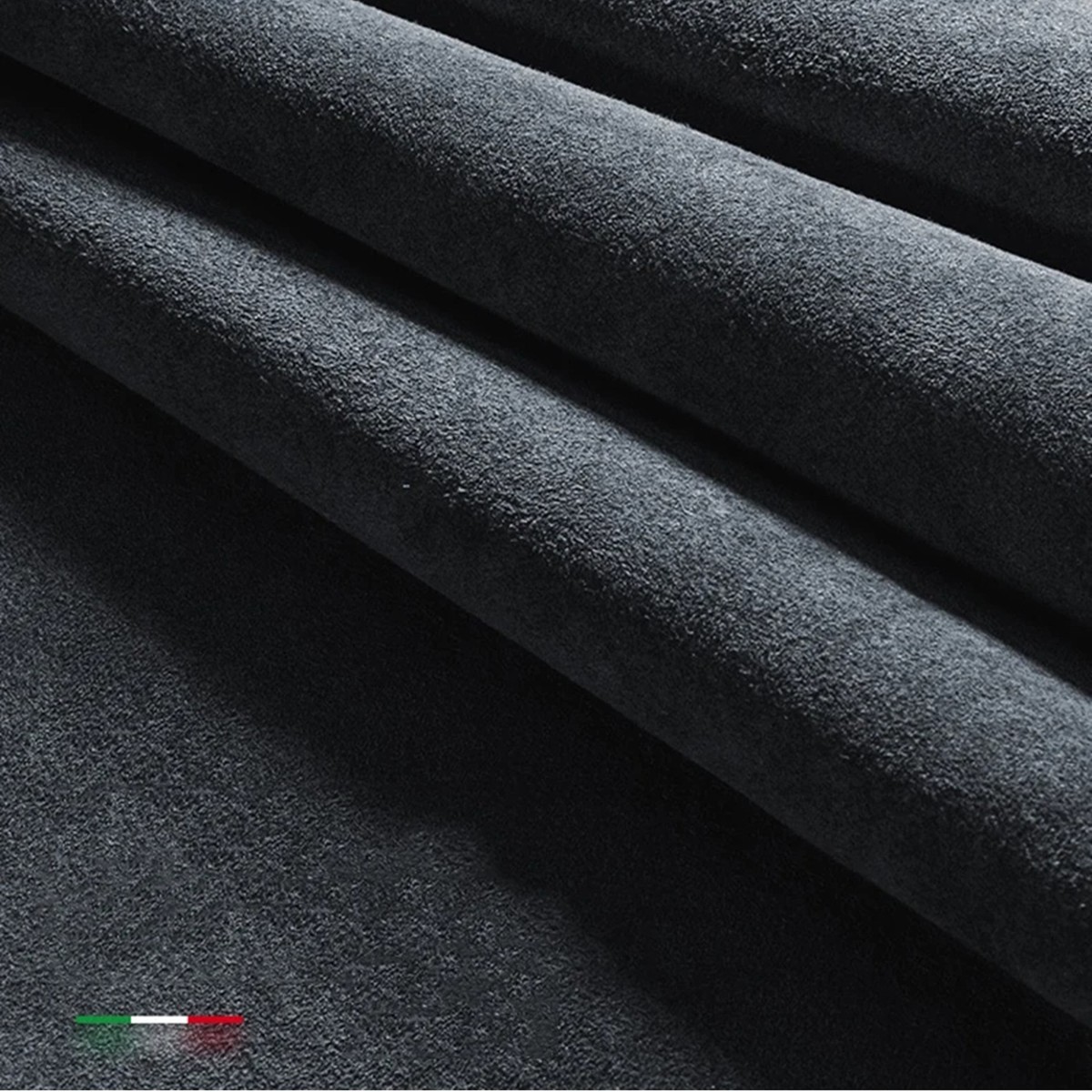

2. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft is a foam-backed, Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Available colors include Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black, Raw Amber, Dark Brown, Brombeer,…

3. Relicate – Alcantara Fabric Solutions

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Alcantara fabric available in various forms including Pannel (Unbacked), Cover (Backed), EXO Outdoor, Foam Backed, Multilayer, Perforated & Starlite. Product categories include Solid Color Leather, Nappa Italia Leather, Napali Leather, Black Leather, Distressed & Heritage Leather, Specialty Leather, Hand Woven Leather, and various textiles such as plaid and houndstooth. Specific products include A…

4. Hydes Leather – Alcantara Products

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather is the official distributor of Alcantara in North America, offering a complete range of Alcantara products. Alcantara is used by luxury auto brands in Europe and is known for its style, elegance, and functionality while being environmentally friendly. The product range includes: 1. Alcantara Panel: Unbacked, thin, and workable fabric for headliners, doors, and dashboards. 2. Alcantar…

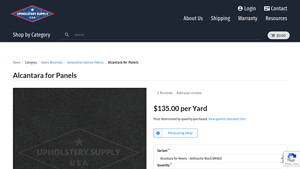

5. Upholstery Supply USA – Alcantara for Panels

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Alcantara for Panels”,”Color Options”: [“Anthracite Black (#9002)”, “Black (#9040)”, “Amber Glow (#1110)”, “Dark Brown (#9500)”, “Red (#4996)”, “Silver Grey (#4978)”, “Orion Grey (#2934)”, “Slate Grey (#2957)”],”Price”: {“1 to 9 yards”: “$135.00″,”10 to 24 yards”: “$130.00″,”25+ yards”: “$125.00″},”Material Type”: “Genuine Alcantara Textile, Unbacked”,”Origin”: “Made in Italy”,”A…

6. Alcantara – Synthetic Textile for Car Interiors

Domain: carwow.co.uk

Registered: 2011 (14 years)

Introduction: Alcantara is a synthetic textile made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is commonly used in car interiors for steering wheels, gear levers, seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic, flame ret…

7. Alcantara – Craft Fabric

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Alcantara Craft Fabric available for sale on eBay. Related searches include Alcantara Fabric Roll, Alcantara Fabric Black, Alcantara Suede Fabric, and Alcantara Trim. The fabric is categorized under Crafts and Collectibles & Art, specifically in the Fabric section. There are 43 results available for Alcantara Craft Fabric, with options to sort by best match, time ending soonest, newly listed, and …

Strategic Sourcing Conclusion and Outlook for alcantara fabric for car interior

In conclusion, the strategic sourcing of Alcantara fabric for automotive interiors presents a significant opportunity for international B2B buyers. The unique properties of Alcantara, such as its durability, ease of maintenance, and aesthetic appeal, make it an ideal choice for luxury and performance vehicles. As buyers in regions like Africa, South America, the Middle East, and Europe seek to enhance their product offerings, partnering with reputable suppliers ensures access to high-quality materials that meet industry standards.

Investing in Alcantara not only elevates the interior experience of vehicles but also aligns with sustainable practices, as it is produced ethically in Italy. Buyers should prioritize suppliers that offer a wide range of Alcantara products, including various types and finishes, to meet diverse customer demands.

Looking ahead, the market for Alcantara fabric is poised for growth as automotive trends shift toward customization and premium materials. By leveraging strategic sourcing, international buyers can position themselves advantageously within this evolving landscape. Now is the time to explore partnerships that will enhance your product line and meet the rising expectations of consumers in the luxury automotive sector.

Illustrative image related to alcantara fabric for car interior

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.