Introduction: Navigating the Global Market for tandy leather factory stamps

In today’s competitive landscape, sourcing high-quality Tandy leather factory stamps can present a significant challenge for international B2B buyers. Whether you’re a manufacturer in Africa, a retailer in South America, or a craftsman in Europe, the pressure to find reliable suppliers who offer durability and intricate designs is paramount. This guide aims to demystify the complexities of the global market for Tandy leather factory stamps, providing you with the insights necessary to make informed purchasing decisions.

Within this comprehensive resource, we explore various types of stamps, from classic Craftool® designs to modern 2D and 3D options, each tailored for diverse applications in leathercraft. We delve into supplier vetting processes, helping you identify trustworthy manufacturers and distributors who meet international standards. Additionally, we provide a detailed analysis of cost factors, ensuring you understand the financial implications of your investments.

By equipping you with essential knowledge about materials, designs, and market dynamics, this guide empowers B2B buyers to enhance their product offerings and streamline their sourcing strategies. Whether you’re looking to elevate your craftsmanship or expand your product line, understanding the nuances of Tandy leather factory stamps will enable you to make choices that resonate with your target market and drive business success.

Table Of Contents

- Top 1 Tandy Leather Factory Stamps Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for tandy leather factory stamps

- Understanding tandy leather factory stamps Types and Variations

- Key Industrial Applications of tandy leather factory stamps

- 3 Common User Pain Points for ‘tandy leather factory stamps’ & Their Solutions

- Strategic Material Selection Guide for tandy leather factory stamps

- In-depth Look: Manufacturing Processes and Quality Assurance for tandy leather factory stamps

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘tandy leather factory stamps’

- Comprehensive Cost and Pricing Analysis for tandy leather factory stamps Sourcing

- Alternatives Analysis: Comparing tandy leather factory stamps With Other Solutions

- Essential Technical Properties and Trade Terminology for tandy leather factory stamps

- Navigating Market Dynamics and Sourcing Trends in the tandy leather factory stamps Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tandy leather factory stamps

- Strategic Sourcing Conclusion and Outlook for tandy leather factory stamps

- Important Disclaimer & Terms of Use

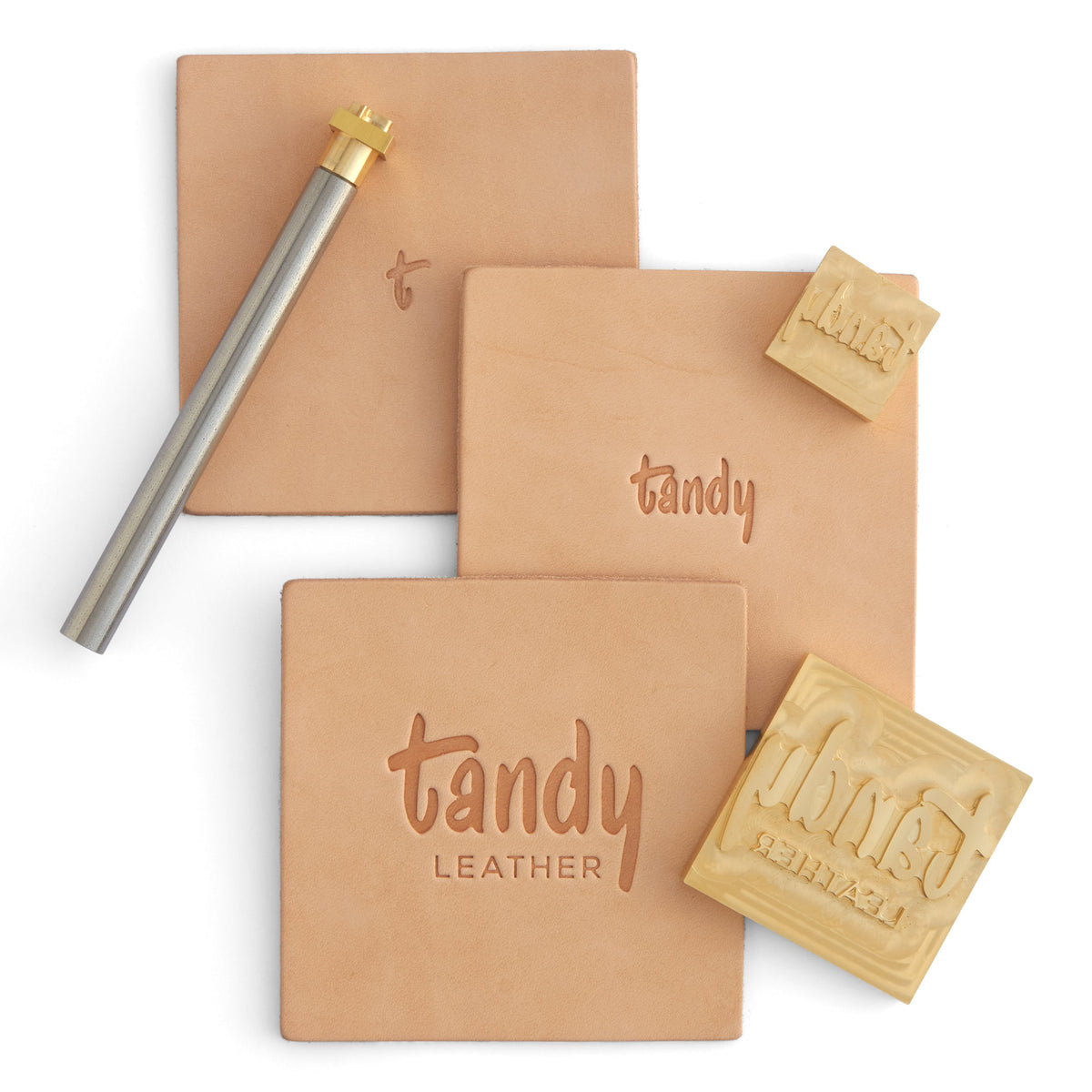

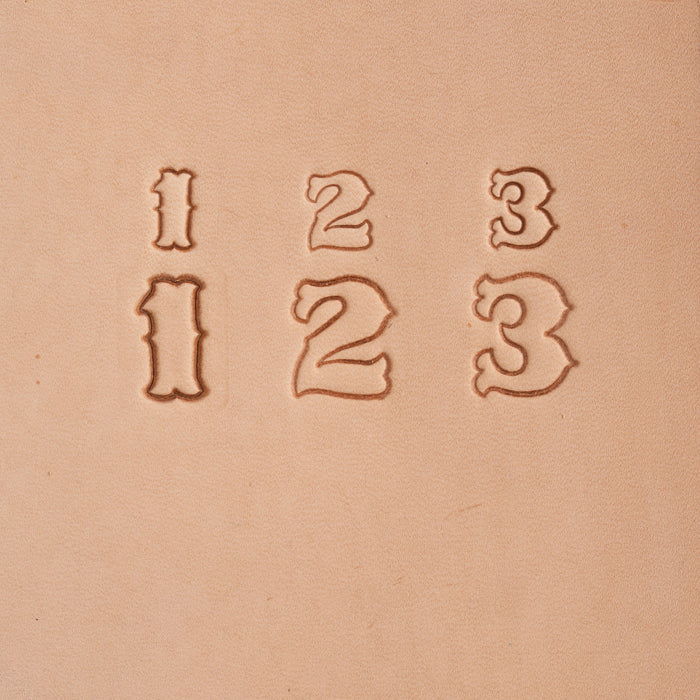

Understanding tandy leather factory stamps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Design Stamps | Intricate patterns; available in various motifs | Custom leather goods, fashion accessories | Pros: Enhances creativity; consistent results. Cons: May require skill for optimal use. |

| 2D & 3D Stamps | Flat or dimensional impressions; diverse themes | Branding, personalized items | Pros: Versatile for different projects; eye-catching. Cons: Higher investment for 3D options. |

| Craftool® Alphabet Stamps | Crisp, clear letter designs; available in sets | Name tagging, custom messages | Pros: Ideal for personalization; easy to use. Cons: Limited to letter designs only. |

| Border Stamps | Decorative edges; various patterns available | Finishing touches on leather products | Pros: Adds professional finish; simple to apply. Cons: Less flexibility in design. |

| Specialty Stamps (e.g., Animal) | Unique thematic designs; specific to cultural motifs | Niche markets, themed products | Pros: Attracts specific customer demographics. Cons: May have limited appeal outside niche. |

What Are the Key Characteristics of Design Stamps and Their B2B Suitability?

Design stamps are essential for transforming ordinary leather into artistic pieces. With intricate patterns ranging from floral motifs to Celtic designs, they allow artisans to express creativity while ensuring consistent quality across projects. For B2B buyers, these stamps are perfect for custom leather goods or fashion accessories, enhancing product appeal. When purchasing, consider the skill level required, as achieving optimal results may necessitate some expertise.

How Do 2D & 3D Stamps Differ and What Are Their Applications?

2D and 3D stamps provide unique options for creating flat or dimensional impressions on leather. These stamps cover a wide array of themes, making them suitable for branding and personalized items. B2B buyers should weigh the investment against the versatility these stamps offer. While 2D stamps are often more affordable, 3D options can significantly enhance the visual impact of products, making them ideal for businesses looking to stand out in competitive markets.

Why Are Craftool® Alphabet Stamps Valuable for B2B Buyers?

Craftool® Alphabet stamps feature clean, crisp letter designs, making them indispensable for personalized branding and name tagging. Available in sets, these stamps allow for easy incorporation into various leather products, from bags to wallets. B2B buyers should consider their utility in creating custom messages as a selling point. However, their limitation to letter designs may require businesses to supplement with other types of stamps for more intricate designs.

Illustrative image related to tandy leather factory stamps

What Benefits Do Border Stamps Provide for Leathercraft?

Border stamps are designed to add decorative edges to leather projects, providing a professional finish. With various patterns available, they can enhance the overall aesthetic of leather goods. B2B buyers can benefit from these stamps by using them in the finishing stages of production, ensuring that products are visually appealing. However, the simplicity of their design may limit creative flexibility compared to more intricate stamps.

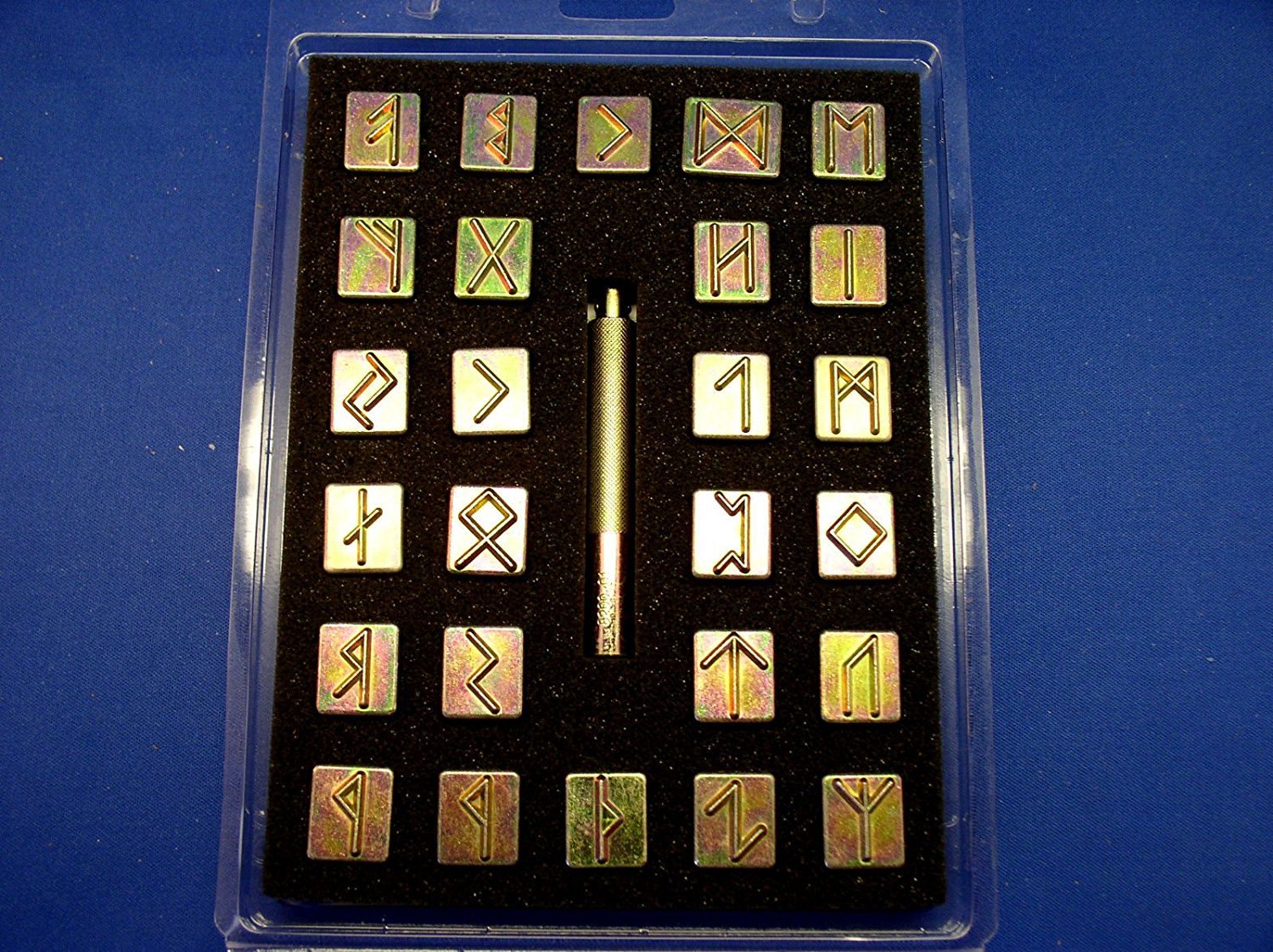

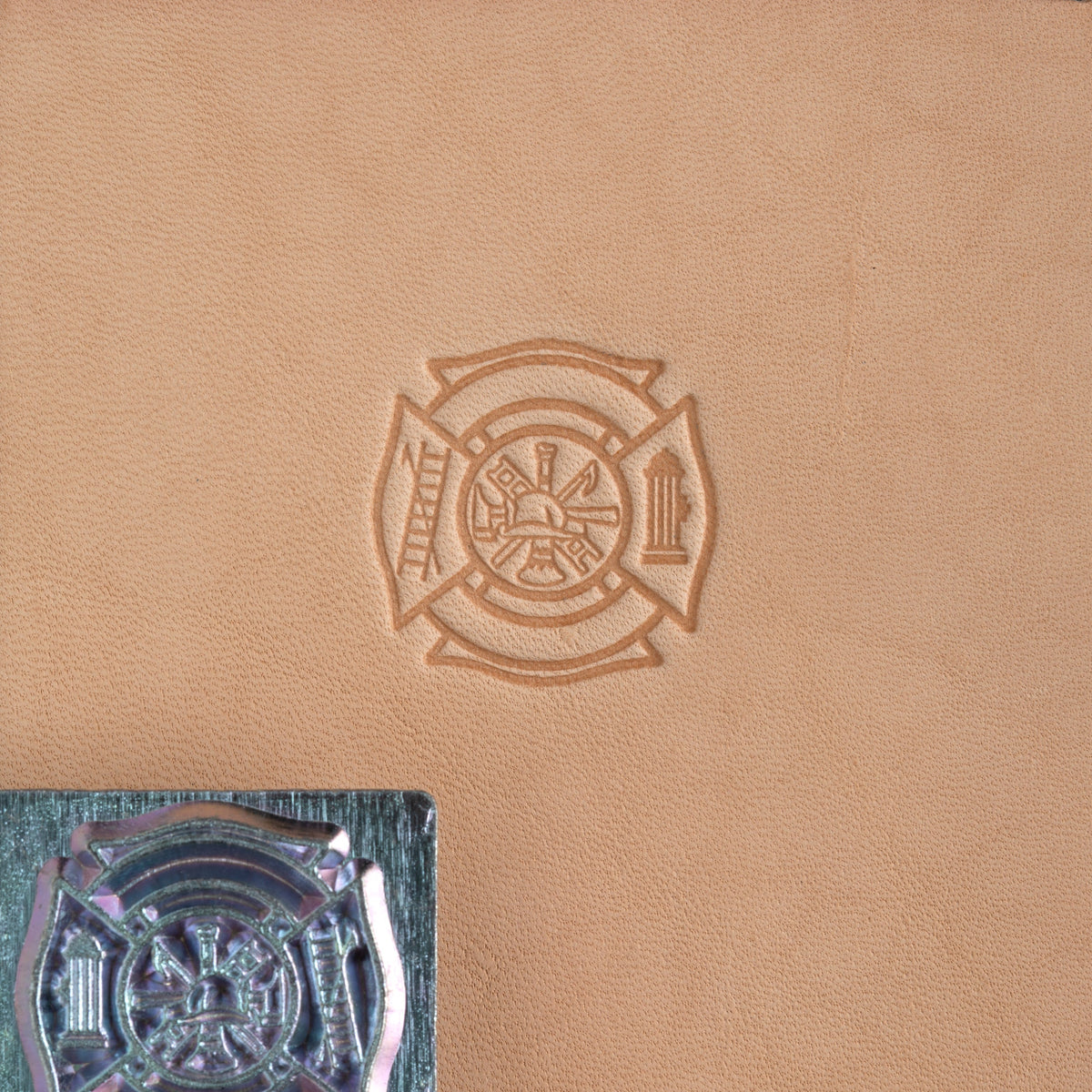

How Can Specialty Stamps Cater to Niche Markets?

Specialty stamps, including animal-themed or culturally specific designs, cater to niche markets and can significantly enhance product uniqueness. These stamps can attract specific customer demographics, making them valuable for businesses targeting specialized audiences. When considering these stamps, B2B buyers should assess the potential market demand and the appeal of such designs in their target regions. However, the limited appeal outside niche markets may pose a risk for broader applications.

Key Industrial Applications of tandy leather factory stamps

| Industry/Sector | Specific Application of Tandy Leather Factory Stamps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Customizing leather goods with unique designs and patterns | Enhances brand identity and product differentiation | Quality of materials, durability of stamps, and design options |

| Furniture Manufacturing | Creating decorative leather accents on furniture pieces | Adds aesthetic value and can justify premium pricing | Compatibility with furniture materials and production scale |

| Automotive | Personalizing leather interiors of vehicles | Increases customer satisfaction and perceived value | Availability of specific designs and customization options |

| Craft & Hobby Supplies | Providing tools for artisans and hobbyists in leather crafting | Supports local craftsmanship and small business growth | Variety of designs, ease of use, and affordability |

| Gift & Promotional Items | Stamping logos and messages on leather items for corporate gifts | Strengthens brand recognition and customer loyalty | Customization capabilities and lead times for orders |

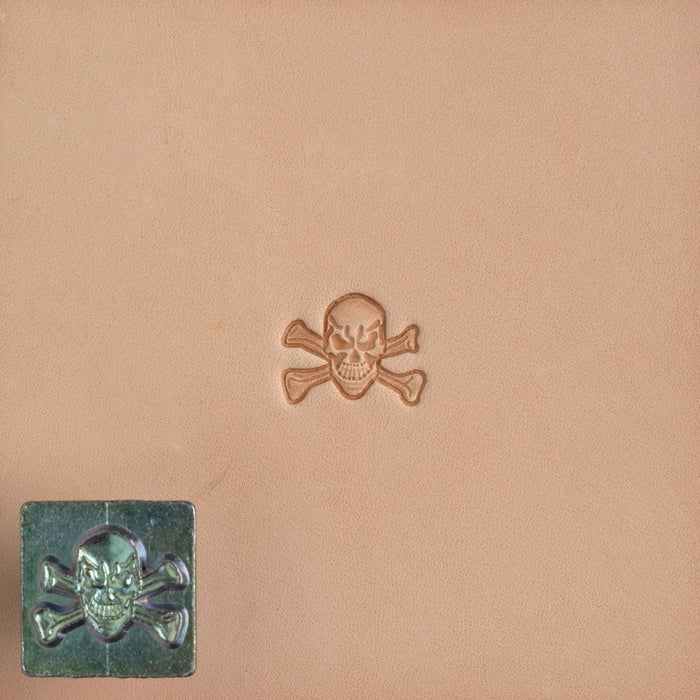

How Are Tandy Leather Factory Stamps Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, Tandy leather factory stamps are utilized to customize leather products, allowing designers to incorporate unique patterns and motifs that resonate with their brand identity. This application not only enhances the aesthetic appeal of items such as handbags and belts but also helps in differentiating products in a competitive market. International buyers, particularly from regions like Africa and South America, should consider the quality of materials and the durability of the stamps to ensure they can withstand high-volume production.

What Role Do Tandy Leather Stamps Play in Furniture Manufacturing?

In furniture manufacturing, Tandy leather factory stamps are used to create decorative leather accents on items like chairs, sofas, and headboards. This application adds a layer of sophistication and uniqueness to furniture pieces, which can justify a higher price point in the market. Buyers in Europe, such as those in Germany, must pay attention to the compatibility of stamps with various furniture materials and the scalability of production to meet demand.

Illustrative image related to tandy leather factory stamps

How Are Tandy Leather Stamps Beneficial for the Automotive Sector?

For the automotive industry, Tandy leather factory stamps are essential in personalizing leather interiors, including seats and dashboards. This customization enhances the overall customer experience and increases the perceived value of vehicles. International buyers in the Middle East, where luxury vehicles are prevalent, should focus on the availability of specific designs and customization options to meet the preferences of their clientele.

Why Are Tandy Leather Stamps Important for Craft & Hobby Supplies?

In the craft and hobby sector, Tandy leather factory stamps serve as vital tools for artisans and hobbyists engaged in leather crafting. These stamps enable creators to produce intricate designs easily, fostering local craftsmanship and supporting small business growth. Buyers, particularly from South America, should prioritize a variety of designs and the ease of use of the stamps to cater to different skill levels in the crafting community.

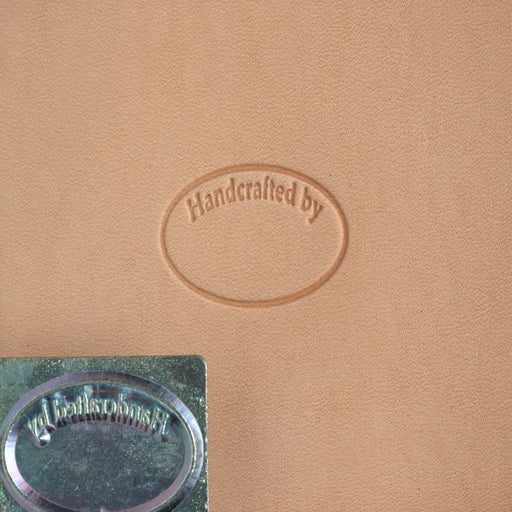

How Do Tandy Leather Stamps Enhance Gift & Promotional Items?

Tandy leather factory stamps are widely used in the creation of gift and promotional items, allowing businesses to stamp logos and messages on leather goods. This application strengthens brand recognition and fosters customer loyalty by providing personalized gifts that resonate with recipients. B2B buyers need to consider the customization capabilities of the stamps and the lead times for orders to ensure timely delivery for promotional campaigns.

3 Common User Pain Points for ‘tandy leather factory stamps’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Impressions

The Problem: B2B buyers often face the challenge of obtaining consistent, high-quality impressions when using leather stamps. This issue can arise from various factors such as uneven pressure applied during stamping, inadequate leather preparation, or the quality of the stamps themselves. When the impressions are inconsistent, it not only affects the aesthetic quality of the leather products but can also lead to increased rework and wasted materials, ultimately impacting profitability.

The Solution: To achieve consistent impressions, it is crucial to ensure that the leather is properly conditioned before stamping. This means using a suitable leather preparation technique, such as dampening the leather slightly to allow for better imprint absorption. Additionally, when sourcing Tandy leather factory stamps, buyers should prioritize stamps made from high-quality materials, such as rust-resistant brass or stainless steel, which provide durability and sharp detail. Furthermore, employing a proper stamping technique is essential. Buyers should consider using a heavy-duty mallet with even strikes to ensure uniform pressure. Practicing on scrap leather can also help in mastering the technique before moving on to production pieces.

Illustrative image related to tandy leather factory stamps

Scenario 2: Limited Availability of Design Variety

The Problem: International buyers may struggle with finding a diverse range of design stamps that cater to specific cultural or regional preferences. This limitation can hinder their ability to create unique, marketable leather goods that resonate with local customers. For example, buyers in Africa or South America might be seeking specific motifs or patterns that reflect their cultural heritage but find that available options are too generic or limited.

The Solution: To address this challenge, buyers should engage with Tandy’s extensive catalog and consider custom orders for specific designs that reflect their target market’s preferences. Tandy leather offers a variety of thematic stamps, including botanical, Celtic, and indigenous designs. By collaborating with Tandy’s customer service team, buyers can explore options for sourcing unique stamps that align with their creative vision. Additionally, buyers could consider investing in custom stamp designs tailored to their specifications, which can further enhance their product offerings and set them apart in competitive markets.

Scenario 3: Challenges in Sourcing and Importing Stamps Efficiently

The Problem: International buyers often encounter logistical hurdles when sourcing Tandy leather factory stamps, such as high shipping costs, customs delays, and limited local suppliers. These challenges can lead to increased lead times for production and potential disruptions in meeting customer demand, which are particularly critical in B2B environments where timing is essential.

Illustrative image related to tandy leather factory stamps

The Solution: To streamline the sourcing and importing process, buyers should establish a reliable supply chain strategy. This includes working directly with Tandy to understand their shipping options and exploring bulk purchasing to reduce per-unit shipping costs. Establishing relationships with local distributors or agents who specialize in leathercraft supplies can also provide easier access to Tandy products. Additionally, buyers should stay informed about customs regulations and logistics to anticipate any potential delays. Utilizing a freight forwarder familiar with the specific needs of importing craft supplies can further alleviate challenges, ensuring a smoother procurement process and timely availability of essential stamping tools.

Strategic Material Selection Guide for tandy leather factory stamps

What Are the Key Materials Used in Tandy Leather Factory Stamps?

When selecting materials for Tandy leather factory stamps, it is crucial to consider the properties and performance characteristics that align with the needs of your leathercraft projects. Below, we analyze four common materials used in the production of these stamps, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Brass Perform as a Material for Leather Stamps?

Brass is a popular choice for leather stamps due to its excellent durability and resistance to corrosion. This metal can withstand high temperatures and pressures, making it suitable for various stamping applications. Brass stamps are often CNC-routed, ensuring precision in design and a crisp impression on leather surfaces.

Pros: Brass offers a long lifespan, allowing for repeated use without significant wear. Its aesthetic appeal also enhances the quality of the stamped design, making it ideal for high-end leather products.

Cons: Brass can be more expensive than other materials, which may impact cost-sensitive projects. Additionally, it requires careful handling to avoid tarnishing, which could affect the final product’s appearance.

Impact on Application: Brass is compatible with various types of leather, including vegetable-tanned and chrome-tanned, making it versatile for different crafting needs.

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with local regulations regarding metal content and environmental standards, as brass may contain lead.

What Are the Benefits of Stainless Steel for Leather Stamps?

Stainless steel is another material frequently used in the production of leather stamps. Known for its exceptional corrosion resistance and strength, stainless steel can withstand harsh conditions, making it ideal for heavy-duty applications.

Pros: The durability of stainless steel ensures that stamps maintain their shape and functionality over time, even under rigorous use. Additionally, it is easy to clean and maintain, which is advantageous for crafters.

Cons: The initial cost of stainless steel can be higher than other materials, such as aluminum. Its rigidity may also limit the intricacy of designs compared to softer metals.

Illustrative image related to tandy leather factory stamps

Impact on Application: Stainless steel stamps work well with all types of leather and are particularly effective in creating detailed impressions, which is crucial for intricate designs.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is essential, especially for buyers in Europe and the Middle East, where quality assurance is paramount.

How Does Aluminum Compare in Terms of Cost and Performance?

Aluminum is a lightweight and cost-effective option for leather stamps. While it may not offer the same level of durability as brass or stainless steel, it is still a viable choice for certain applications.

Illustrative image related to tandy leather factory stamps

Pros: The affordability of aluminum makes it accessible for small businesses and individual crafters. Its lightweight nature allows for easy handling during the stamping process.

Cons: Aluminum is more prone to wear and deformation over time, which can affect the quality of impressions. It is less suitable for high-volume production runs where durability is critical.

Impact on Application: Aluminum stamps are best suited for lighter leather types and simpler designs, making them ideal for hobbyists or low-budget projects.

Considerations for International Buyers: Buyers should verify that aluminum stamps meet local safety and quality standards, particularly in regions with strict manufacturing regulations.

What Role Does Plastic Play in Leather Stamping?

Plastic stamps, particularly those made from high-density polyethylene (HDPE), are gaining popularity for specific applications. These stamps are often used for less intricate designs and are favored for their affordability and ease of use.

Pros: Plastic is lightweight, making it easy to handle and maneuver during stamping. It is also resistant to moisture, which can be beneficial in humid environments.

Cons: The durability of plastic is significantly lower than that of metal options, which may lead to quicker wear and less defined impressions.

Impact on Application: Plastic stamps are best for simple designs and are often used in educational settings or by beginners in the leathercraft community.

Considerations for International Buyers: It is important for buyers to check for compliance with safety standards, especially in regions like Africa and South America, where product safety regulations may vary.

Illustrative image related to tandy leather factory stamps

Summary Table of Material Selection for Tandy Leather Factory Stamps

| Material | Typical Use Case for Tandy Leather Factory Stamps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-end leather products requiring detailed designs | Excellent durability and corrosion resistance | Higher cost and requires maintenance | High |

| Stainless Steel | Heavy-duty applications needing precision | Exceptional strength and easy maintenance | Higher initial cost and rigidity | High |

| Aluminum | Lightweight projects and simpler designs | Cost-effective and easy to handle | Prone to wear and deformation | Low |

| Plastic | Educational and beginner projects | Lightweight and moisture-resistant | Lower durability and less defined impressions | Low |

This strategic material selection guide provides actionable insights for B2B buyers in various regions, ensuring that they make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tandy leather factory stamps

What Are the Key Stages in the Manufacturing Process of Tandy Leather Factory Stamps?

The manufacturing of Tandy leather factory stamps involves several critical stages, each designed to ensure the highest quality and durability of the final product. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality materials, primarily brass and stainless steel, known for their durability and rust resistance. Raw materials undergo rigorous inspection to ensure they meet industry standards. This stage also includes cutting the materials into appropriate sizes for further processing.

-

Forming: Utilizing advanced CNC (Computer Numerical Control) machinery, the raw materials are precisely shaped into the desired stamp designs. This technology allows for high levels of detail and consistency, essential for creating intricate patterns and motifs. The forming process is crucial as it directly impacts the clarity and quality of the impressions made on leather.

-

Assembly: After forming, the individual components of the stamps are assembled. This includes attaching handles to the stamp heads, ensuring that they are securely fastened for ease of use. The assembly process is also where any additional features, such as ergonomic handles, are integrated to enhance user experience.

-

Finishing: The final stage involves polishing and coating the stamps. This not only improves the aesthetic appeal but also provides additional protection against wear and corrosion. Quality checks are conducted during this phase to ensure that all stamps meet the specified design and performance criteria before they are packaged for distribution.

How is Quality Assurance Implemented in Tandy Leather Factory Stamps?

Quality assurance (QA) is a critical component of the manufacturing process for Tandy leather factory stamps, ensuring that every product meets stringent quality standards. The QA process includes adherence to international standards such as ISO 9001 and industry-specific certifications like CE and API.

-

International Standards Compliance: ISO 9001 sets the framework for a quality management system that organizations can use to ensure they meet customer and regulatory requirements. Compliance with these standards indicates a commitment to quality and continuous improvement. For B2B buyers, especially in regions like Africa and South America, sourcing from ISO-certified manufacturers can significantly mitigate risks related to product quality.

-

Quality Control Checkpoints: The quality control process includes several key checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet the required specifications.

– In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted to identify and rectify issues early. This includes checks on the forming and assembly stages.

– Final Quality Control (FQC): Before packaging, each stamp undergoes a final inspection to verify that it meets all design and performance standards. -

Common Testing Methods: Various testing methods are employed throughout the manufacturing process, including:

– Dimensional Checks: Ensuring that the dimensions of the stamps conform to specifications.

– Durability Testing: Evaluating the stamps’ ability to withstand repeated use without degradation.

– Corrosion Resistance Testing: Assessing the material’s resistance to rust and wear, especially critical for products intended for diverse environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability and compliance with local regulations. Here are some actionable steps:

-

Conducting Audits: Buyers should consider conducting on-site audits of manufacturing facilities to assess quality control practices firsthand. This helps in verifying compliance with international standards and understanding the overall manufacturing environment.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certificates. This transparency is crucial for buyers who need to ensure that the products meet both international and local standards.

-

Utilizing Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing practices. These inspections can cover everything from material sourcing to final product testing, offering buyers additional reassurance.

What Are the Quality Control Nuances for International Buyers?

When dealing with international suppliers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, there are several nuances to consider:

-

Cultural Differences in Quality Standards: Different regions may have varying interpretations of quality standards and practices. Understanding these cultural differences can help buyers set realistic expectations and ensure effective communication with suppliers.

-

Regulatory Compliance: International buyers must be aware of the specific regulatory requirements in their home countries. For instance, products imported into the EU must comply with CE marking regulations, while other regions may have their own standards. Buyers should verify that suppliers are familiar with these requirements.

-

Supply Chain Transparency: In regions with complex supply chains, ensuring transparency is critical. Buyers should establish clear communication channels and request regular updates on the manufacturing process and quality control measures.

Conclusion

In summary, the manufacturing processes and quality assurance mechanisms for Tandy leather factory stamps are designed to deliver products that meet the highest standards of quality and durability. By understanding these processes, international B2B buyers can make informed decisions, ensuring that they source products that align with their business needs and compliance requirements. Investing time in verifying supplier quality control practices can lead to long-term partnerships that enhance product offerings and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tandy leather factory stamps’

Introduction

This guide is designed to assist international B2B buyers in the effective sourcing of Tandy leather factory stamps. By following these steps, businesses can ensure they procure high-quality, durable stamps that meet their specific leathercraft needs, ultimately enhancing their product offerings and operational efficiency.

Step 1: Identify Your Specific Needs

Before initiating the sourcing process, clearly define the types of Tandy leather stamps required for your projects. Consider factors such as design complexity, size, and material. This clarity helps narrow down options and ensures that you select stamps that align with your crafting goals.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify reputable suppliers of Tandy leather factory stamps. Utilize industry directories, trade shows, and online marketplaces to find potential suppliers. Pay attention to their experience in the leathercraft sector and their reputation among other businesses.

Illustrative image related to tandy leather factory stamps

- Look for Reviews: Check testimonials and ratings from other customers to gauge satisfaction levels.

- Assess Delivery Capabilities: Ensure the supplier can meet your shipping needs, especially if you are sourcing from international locations.

Step 3: Evaluate Product Quality

Quality is paramount when it comes to leather stamps. Request samples to assess the craftsmanship and durability of the stamps. Consider factors such as material resistance, precision of impressions, and overall design.

- Focus on Material: Look for stamps made from rust-resistant materials like brass or stainless steel, which enhance longevity.

- Check for Consistency: Ensure that the stamps produce uniform impressions, as this is crucial for professional results.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that reflect their compliance with industry standards. Certifications can indicate quality assurance and adherence to safety regulations.

- ISO Certification: Look for ISO-certified suppliers that demonstrate consistent quality management.

- Sustainability Practices: Consider suppliers who follow sustainable practices, as this can enhance your brand’s reputation in global markets.

Step 5: Understand Pricing and Payment Terms

Clarify the pricing structure and payment options with your suppliers. This understanding is vital for budgeting and financial planning.

Illustrative image related to tandy leather factory stamps

- Bulk Discounts: Inquire about potential discounts for larger orders, which can lead to significant cost savings.

- Payment Flexibility: Assess the payment terms offered, such as credit options or installment plans, which can ease cash flow management.

Step 6: Establish Communication Channels

Effective communication is essential for a successful sourcing relationship. Establish clear lines of communication with your suppliers to facilitate discussions about product specifications, order updates, and potential issues.

- Preferred Communication Tools: Determine the best methods for communication, whether through email, phone, or instant messaging.

- Regular Updates: Request regular updates on order status and any changes that may affect delivery.

Step 7: Finalize Your Order and Logistics

Once you have selected a supplier, finalize your order details, including quantities, delivery timelines, and any additional requirements. Ensure you have a logistics plan in place for receiving your stamps efficiently.

- Track Shipments: Utilize tracking services to monitor the shipment’s progress and address any potential delays proactively.

- Inspect Upon Arrival: Upon receipt, inspect the products thoroughly to confirm they meet the agreed-upon specifications.

By following this practical checklist, B2B buyers can streamline their sourcing process for Tandy leather factory stamps, ensuring they make informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for tandy leather factory stamps Sourcing

What Are the Key Cost Components in Sourcing Tandy Leather Factory Stamps?

When sourcing Tandy leather factory stamps, B2B buyers should understand the various cost components that contribute to the final price. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to tandy leather factory stamps

-

Materials: The choice of materials significantly affects costs. Tandy leather stamps are often made from high-quality brass or stainless steel, which are durable and rust-resistant. The price of these raw materials fluctuates based on market demand and availability.

-

Labor: Skilled labor is essential for manufacturing intricate designs. Labor costs can vary significantly based on the location of the manufacturing facility. For example, labor costs may be lower in countries with less stringent wage laws, but this can also affect quality.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can minimize these overhead costs, which are often passed on to buyers.

-

Tooling: Custom tooling for specific designs or sizes can be a significant upfront investment. This cost is usually amortized over the production run, impacting the price per unit, especially for smaller orders.

-

Quality Control: Ensuring that each stamp meets quality standards involves additional processes, which can add to overall costs. This is crucial for B2B buyers who require consistent quality for their products.

-

Logistics: Shipping costs, including freight, customs duties, and handling fees, are important considerations, especially for international buyers. Incoterms can influence who bears these costs, affecting the total price.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding typical industry margins can help buyers negotiate better prices.

How Do Price Influencers Affect the Cost of Tandy Leather Factory Stamps?

Several factors can influence the pricing of Tandy leather factory stamps:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit costs. Suppliers often provide discounts for bulk purchases, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom designs or unique specifications can increase costs significantly due to the additional labor and tooling required. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Premium materials or stamps with specific quality certifications (e.g., ISO) may come at a higher price. Buyers should consider whether these certifications are necessary for their end products.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The terms of shipping can greatly affect total costs. Understanding who is responsible for freight and insurance during transit can help buyers manage their expenses.

What Are the Best Buyer Tips for Negotiating Prices on Tandy Leather Factory Stamps?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic purchasing can lead to significant savings:

-

Negotiate Volume Discounts: Always inquire about pricing structures based on order quantities. Negotiating for bulk discounts can yield substantial savings.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and potential replacements. Investing in higher-quality stamps may reduce overall costs in the long run.

-

Understand Pricing Nuances: Different regions may have varying price structures based on local market conditions. Familiarize yourself with the pricing landscape in your region and the supplier’s location to negotiate effectively.

-

Leverage Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority during production, and access to exclusive products.

-

Request Samples: Before committing to a large order, request samples to assess quality and suitability. This can also provide leverage during negotiations.

In conclusion, understanding the cost structure and pricing influencers associated with Tandy leather factory stamps can empower B2B buyers to make informed purchasing decisions, ultimately enhancing their competitive edge in the market.

Alternatives Analysis: Comparing tandy leather factory stamps With Other Solutions

When considering leather stamping solutions, it’s essential to explore various alternatives to Tandy Leather Factory Stamps. Each option comes with its unique features, benefits, and limitations, which can significantly impact the final output in leathercraft projects. This analysis aims to provide B2B buyers with a clear understanding of how Tandy’s offerings compare with other popular alternatives.

Illustrative image related to tandy leather factory stamps

| Comparison Aspect | Tandy Leather Factory Stamps | Alternative 1: Custom CNC Leather Stamps | Alternative 2: Hand-Carved Leather Stamps |

|---|---|---|---|

| Performance | High detail and consistency | Extremely precise and customizable | Varies greatly based on the artisan’s skill |

| Cost | Affordable ($6.99 – $19.99) | Higher initial investment ($100+) | Moderate to high, depending on the craftsman |

| Ease of Implementation | User-friendly, readily available | Requires design and manufacturing time | Requires artisan skills; can be time-consuming |

| Maintenance | Low maintenance; durable materials | Moderate; depends on material used | Low; requires care to preserve the carving |

| Best Use Case | Ideal for mass production and consistent designs | Best for unique, high-end custom pieces | Excellent for artisanal, bespoke projects |

What Are the Pros and Cons of Custom CNC Leather Stamps?

Custom CNC (Computer Numerical Control) leather stamps represent a modern alternative to traditional stamping methods. These stamps are designed using specialized software, allowing for intricate designs that can be produced in bulk. The primary advantage of this method is its precision and the ability to create highly detailed and customized designs tailored to specific needs. However, the initial investment can be significant, often exceeding $100, which may not be feasible for smaller businesses or hobbyists. Additionally, the setup time for design and manufacturing can delay project timelines.

How Do Hand-Carved Leather Stamps Compare?

Hand-carved leather stamps are another alternative, appealing to those who value artisanal craftsmanship. These stamps are crafted by skilled artisans, resulting in unique designs that can carry a distinctive character. While they offer a high level of customization and artistic expression, the quality and detail can vary based on the artisan’s skill. The cost can range widely, influenced by the complexity of the design and the craftsman’s expertise. Furthermore, the time required to create these stamps can be a drawback for businesses needing quick turnaround times.

Conclusion: How Should B2B Buyers Choose the Right Leather Stamping Solution?

Selecting the right leather stamping solution hinges on several factors, including the specific needs of the project, budget constraints, and desired outcomes. For businesses focused on consistency and efficiency, Tandy Leather Factory Stamps are an excellent choice due to their affordability and ease of use. Conversely, companies looking for unique, high-quality designs may find custom CNC stamps or hand-carved options more suitable, despite the higher costs and longer lead times. Ultimately, understanding the trade-offs between performance, cost, and customization will empower B2B buyers to make informed decisions that align with their operational needs and creative aspirations.

Illustrative image related to tandy leather factory stamps

Essential Technical Properties and Trade Terminology for tandy leather factory stamps

What Are the Key Technical Properties of Tandy Leather Factory Stamps?

Understanding the technical properties of Tandy Leather Factory stamps is essential for B2B buyers to ensure they select the right tools for their leathercraft projects. Here are some critical specifications to consider:

-

Material Composition

Tandy leather stamps are commonly made from high-grade materials such as brass and stainless steel. Brass is known for its durability and rust resistance, making it ideal for long-term use. Stainless steel handles offer strength and comfort during operation. For B2B buyers, selecting stamps made from these materials ensures longevity and consistent performance, reducing the need for frequent replacements. -

Impression Size and Depth

Each stamp is designed to create specific impression dimensions, often around 0.38 inches or customizable sizes. The depth of the impression affects how detailed the final product will be. Understanding these dimensions is crucial for manufacturers who aim to produce products that meet specific design standards and customer expectations. -

CNC Routed Design

Many Tandy stamps utilize CNC (Computer Numerical Control) routing technology for precision crafting. This process ensures that each stamp produces crisp, detailed impressions, which is vital for high-quality leather goods. B2B buyers should look for stamps that incorporate CNC technology to guarantee consistent quality across large production runs. -

Durability and Rust Resistance

The durability of the stamps is often linked to their rust resistance, especially for those used in humid environments. Rust-resistant materials help maintain the integrity of the stamp and the quality of the leatherwork. For businesses, investing in durable products translates into lower maintenance costs and higher production efficiency. -

Handle Comfort and Weight

The design of the stamp handle can significantly influence user experience. Stamps with ergonomic handles and appropriate weight distribution allow for better control and reduce hand fatigue. Buyers should consider the comfort of the handle, particularly for high-volume stamping applications, as this can impact productivity.

What Are Common Trade Terms Related to Tandy Leather Factory Stamps?

Familiarizing yourself with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that may be sold under another brand’s name. In the context of Tandy stamps, buyers should be aware of whether they are purchasing directly from Tandy or through an OEM, as this can affect warranty, quality assurance, and support. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding the MOQ is essential for businesses to manage inventory effectively and ensure they meet their production needs without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a standard business process wherein buyers request a quote from suppliers for specific products or services. When considering Tandy leather stamps, submitting an RFQ allows businesses to compare prices and terms from multiple suppliers, aiding in making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Knowing which Incoterms apply can help B2B buyers understand shipping costs, risks, and responsibilities when sourcing Tandy leather stamps from global suppliers. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for businesses that rely on timely deliveries to meet production schedules. Buyers should inquire about lead times when ordering Tandy leather stamps to ensure they can fulfill customer orders promptly.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions, optimizing their investments in Tandy leather factory stamps for enhanced productivity and product quality.

Navigating Market Dynamics and Sourcing Trends in the tandy leather factory stamps Sector

What Are the Current Market Dynamics and Key Trends Influencing Tandy Leather Factory Stamps?

The global market for leathercraft supplies, particularly Tandy leather factory stamps, is witnessing robust growth driven by a resurgence in artisanal craftsmanship and DIY culture. Factors such as the increasing popularity of personalized leather goods and the rise of e-commerce platforms have significantly transformed the sourcing landscape. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Illustrative image related to tandy leather factory stamps

Emerging trends indicate a shift toward 3D stamp technologies, allowing for greater precision and customization. Additionally, the demand for diverse design categories—from intricate Celtic patterns to modern geometric shapes—reflects a broader consumer interest in unique, artistic expressions. Buyers should prioritize suppliers that offer a wide range of options to cater to varying market demands, thereby enhancing their product offerings.

Moreover, as international trade continues to evolve, logistics and supply chain efficiencies are becoming paramount. Buyers must consider suppliers that can provide timely delivery and consistent quality to maintain competitive pricing and customer satisfaction. Leveraging data analytics and market intelligence tools can help buyers identify the best sourcing opportunities and optimize inventory management.

How Are Sustainability and Ethical Sourcing Practices Shaping the Tandy Leather Factory Stamps Market?

Sustainability and ethical sourcing are increasingly becoming non-negotiable factors in the leathercraft industry. B2B buyers are now more aware of the environmental impact of leather production, prompting them to seek suppliers committed to sustainable practices. This includes sourcing materials from tanneries that employ eco-friendly processes, such as vegetable tanning, which significantly reduces harmful chemical usage.

Moreover, certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction among buyers looking for assurance of ethical practices. These certifications not only enhance brand reputation but also appeal to a growing segment of environmentally conscious consumers.

Illustrative image related to tandy leather factory stamps

For international buyers, particularly in regions with stringent environmental regulations, collaborating with suppliers who prioritize sustainability can mitigate risks and enhance compliance. Integrating these ethical sourcing practices not only helps in building trust with customers but also contributes to the overall sustainability goals of businesses in the leathercraft sector.

How Has the Tandy Leather Factory Stamps Market Evolved Over Time?

The evolution of Tandy leather factory stamps can be traced back to the increasing demand for bespoke leather goods in the mid-20th century. Initially, leathercraft was largely a hobbyist activity, but as consumer preferences shifted towards personalization, the market began to expand. Tandy’s introduction of high-quality, durable stamps played a pivotal role in democratizing leathercraft, allowing artisans to produce intricate designs with ease.

Over the years, advancements in manufacturing techniques, such as CNC routing and 3D printing, have revolutionized the production of leather stamps, making them more accessible and affordable. Today, Tandy leather factory stamps are not only a staple for hobbyists but also for commercial producers looking to enhance their product lines with unique designs. This ongoing evolution highlights the importance of innovation in meeting the diverse needs of international B2B buyers in an ever-competitive marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of tandy leather factory stamps

-

How do I select the right Tandy leather factory stamp for my business needs?

Choosing the right Tandy leather factory stamp involves understanding your specific design requirements and the type of leather projects you undertake. Consider the intricacy of the designs you want to create—Tandy offers a range of options from simple geometric patterns to detailed motifs. Additionally, assess the durability of the materials; for instance, brass stamps are more resistant to wear and tear compared to other materials. Ensure that the stamp size aligns with your project dimensions to achieve the desired visual impact. -

What are the available customization options for Tandy leather stamps?

Tandy Leather provides various customization options, allowing you to tailor stamps to your specific branding or design needs. Buyers can inquire about custom logo stamps or unique designs that reflect their business identity. The process typically involves submitting a design for approval, followed by production. It’s advisable to communicate your requirements clearly to ensure that the final product meets your expectations and aligns with your branding strategy. -

What is the minimum order quantity (MOQ) for Tandy leather factory stamps?

The minimum order quantity for Tandy leather factory stamps may vary based on the type of stamp and the customization required. Generally, standard stamps have a lower MOQ, while custom designs may require larger orders to justify production costs. It’s essential to verify the MOQ with your supplier directly, as this can influence your purchasing strategy, especially if you are planning to stock up for seasonal demand. -

What payment terms are typically offered for B2B transactions with Tandy Leather?

Tandy Leather often provides flexible payment terms for B2B buyers, which may include options such as net 30 or net 60 days, depending on the buyer’s creditworthiness and the order size. International buyers should confirm any additional payment methods available, such as wire transfers or credit terms, as these can vary by region. Always review the terms before finalizing your order to ensure compliance with your cash flow management strategies. -

How do I ensure the quality of Tandy leather factory stamps before purchasing?

To ensure the quality of Tandy leather factory stamps, request samples or product specifications from your supplier before placing a bulk order. Assess the materials used, such as rust-resistant brass or stainless steel, and verify customer reviews and testimonials regarding durability and performance. Additionally, consider conducting a small test order to evaluate the stamps in your production environment, allowing you to make informed decisions based on firsthand experience. -

What are the shipping options and logistics considerations for international orders?

When ordering Tandy leather factory stamps internationally, inquire about the shipping options available, including express and standard delivery services. Consider the lead times for production and shipping, as these can affect your project timelines. It’s also crucial to understand customs regulations in your country to avoid unexpected delays or fees. Discuss with your supplier any logistics partnerships they have, which can facilitate smoother international transactions. -

What are the best practices for maintaining Tandy leather factory stamps?

Proper maintenance of Tandy leather factory stamps is essential for longevity and performance. After each use, clean the stamps with a soft cloth to remove any leather residue or debris. Store the stamps in a dry place to prevent rust or corrosion, especially if they are made from brass or steel. Regularly inspect the stamps for wear and tear, and replace any damaged stamps to ensure consistent quality in your leathercraft projects. -

How can I verify the credibility of suppliers offering Tandy leather stamps?

To verify the credibility of suppliers offering Tandy leather stamps, conduct thorough research by checking their business credentials, customer reviews, and industry reputation. Look for certifications or affiliations with recognized trade organizations, which can signal reliability. Request references from previous clients and assess their responsiveness during initial communications. Establishing a strong relationship with your supplier through transparent discussions can also enhance trust and ensure a smooth purchasing experience.

Top 1 Tandy Leather Factory Stamps Manufacturers & Suppliers List

1. Tandy Leather – Premium Leather Stamping Tools

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Premium Leather Stamping Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tandy leather factory stamps

As the leathercraft industry continues to evolve, strategic sourcing of Tandy Leather factory stamps offers significant advantages for B2B buyers. By leveraging high-quality, durable stamps, businesses can enhance their product offerings and elevate the craftsmanship of their leather goods. The diverse range of designs—from intricate motifs to functional alphabet stamps—ensures that companies can cater to various customer preferences and market trends.

Investing in Tandy Leather stamps not only boosts production efficiency but also helps maintain consistent quality, a crucial factor in building brand loyalty. For international buyers, particularly in Africa, South America, the Middle East, and Europe, tapping into this resource can lead to competitive differentiation in an increasingly saturated market.

Illustrative image related to tandy leather factory stamps

Looking ahead, embracing innovative sourcing strategies will be essential. Consider forming partnerships with local distributors to streamline supply chains and reduce lead times. By prioritizing quality and creativity through Tandy Leather factory stamps, businesses can position themselves for growth and success in the global leathercraft landscape. Engage with Tandy Leather today to explore how these premium tools can transform your offerings and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.