Introduction: Navigating the Global Market for faux leather bulk

In the dynamic landscape of the global market, sourcing high-quality faux leather in bulk can be a daunting challenge for B2B buyers, especially for those looking to meet diverse consumer demands while balancing cost and sustainability. Faux leather offers a versatile, cruelty-free alternative to traditional leather, ideal for a range of applications from fashion apparel to automotive upholstery. This comprehensive guide delves into the myriad types of faux leather available, their applications across various industries, and the critical considerations for supplier vetting and cost evaluation.

International buyers from regions such as Africa, South America, the Middle East, and Europe (including markets like Vietnam and Brazil) will find actionable insights tailored to their specific needs. By understanding the nuances of faux leather sourcing—from material composition to durability and aesthetic appeal—businesses can make informed purchasing decisions that align with their operational goals and customer expectations.

This guide not only simplifies the procurement process but also empowers buyers to navigate the complexities of the faux leather market with confidence. Whether you’re looking to enhance your product offerings or meet specific industry standards, the insights provided will ensure you are well-equipped to leverage faux leather’s potential in your business strategy.

Table Of Contents

- Top 7 Faux Leather Bulk Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faux leather bulk

- Understanding faux leather bulk Types and Variations

- Key Industrial Applications of faux leather bulk

- 3 Common User Pain Points for ‘faux leather bulk’ & Their Solutions

- Strategic Material Selection Guide for faux leather bulk

- In-depth Look: Manufacturing Processes and Quality Assurance for faux leather bulk

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather bulk’

- Comprehensive Cost and Pricing Analysis for faux leather bulk Sourcing

- Alternatives Analysis: Comparing faux leather bulk With Other Solutions

- Essential Technical Properties and Trade Terminology for faux leather bulk

- Navigating Market Dynamics and Sourcing Trends in the faux leather bulk Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faux leather bulk

- Strategic Sourcing Conclusion and Outlook for faux leather bulk

- Important Disclaimer & Terms of Use

Understanding faux leather bulk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Faux Leather | Made from polyvinyl chloride; often shiny and stiff | Upholstery, automotive interiors, fashion | Pros: Cost-effective, water-resistant. Cons: Less breathable than other types. |

| PU Faux Leather | Crafted from polyurethane; softer and more flexible | Fashion accessories, apparel, furniture | Pros: Eco-friendlier, more durable. Cons: Can be pricier than PVC. |

| Mikrofaser-Kunstleder | Ultra-fine fibers; resembles real leather closely | High-end fashion, upholstery, automotive | Pros: Luxurious feel, excellent durability. Cons: Higher cost may deter some buyers. |

| Veganes Leder | Plant-based materials; sustainable and cruelty-free | Eco-friendly fashion, accessories, upholstery | Pros: Sustainable, unique textures. Cons: Availability may be limited. |

| Embossed Faux Leather | Features raised patterns or textures; visually appealing | Fashion, upholstery, bags | Pros: Aesthetic appeal, diverse designs. Cons: Patterns may wear over time. |

What Are the Key Characteristics of PVC Faux Leather for B2B Buyers?

PVC faux leather is a widely used synthetic option made from polyvinyl chloride. It is characterized by its shiny finish and relative stiffness, making it a popular choice for upholstery and automotive interiors. B2B buyers should consider its cost-effectiveness and water-resistant properties, which make it suitable for various applications. However, it is less breathable than other types, which may impact comfort in certain uses, particularly in apparel.

How Does PU Faux Leather Compare in Terms of Suitability and Durability?

Polyurethane (PU) faux leather offers a softer and more flexible alternative to PVC. It is often favored for fashion accessories and apparel due to its closer resemblance to genuine leather. B2B buyers appreciate its eco-friendliness and durability, as PU is generally more resistant to wear and tear. However, it can be more expensive than PVC, so businesses must weigh the benefits of quality against budget constraints.

What Makes Microfiber Faux Leather a Premium Choice for B2B Applications?

Microfiber faux leather is crafted from ultra-fine synthetic fibers, providing a luxurious feel that closely mimics real leather. It is ideal for high-end fashion, upholstery, and automotive applications. B2B buyers looking for a premium product will find its durability and aesthetic appeal advantageous. However, the higher price point may be a consideration for businesses focused on cost management.

Why Should B2B Buyers Consider Vegan Leather for Sustainable Practices?

Vegan leather is made from plant-based materials, making it a sustainable and cruelty-free option. Its unique textures and eco-friendliness appeal to businesses committed to sustainability. While it offers distinct advantages in terms of environmental impact, buyers should be aware that availability can sometimes be limited, potentially affecting supply chains.

How Do Embossed Faux Leather Options Enhance Aesthetic Appeal?

Embossed faux leather features raised patterns or textures that add visual interest to products. This type is commonly used in fashion, upholstery, and bags, appealing to brands that prioritize aesthetics. While embossed faux leather can enhance product appeal, B2B buyers should consider that patterns may wear over time, affecting the longevity of the visual design.

Key Industrial Applications of faux leather bulk

| Industry/Sector | Specific Application of faux leather bulk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel and Fashion | Manufacturing jackets, bags, and footwear | Cost-effective, stylish alternative to leather | Ensure durability, colorfastness, and compliance with local regulations. |

| Automobilindustrie | Upholstery for car interiors | Enhances aesthetic appeal and comfort | Look for materials that meet safety standards and are easy to clean. |

| Furniture and Home Decor | Upholstery for sofas and chairs | Adds luxury feel at a lower cost | Focus on stain resistance, durability, and a variety of textures. |

| Marine Industry | Boat upholstery and covers | Water-resistant and easy to maintain | Source materials that are UV resistant and designed for marine environments. |

| Event and Exhibition | Custom displays and furniture | Customizable and visually appealing | Consider weight, ease of transport, and fire-retardant properties. |

How is Faux Leather Bulk Used in the Apparel and Fashion Industry?

Faux leather bulk is increasingly utilized in the apparel and fashion industry for creating jackets, bags, and footwear. Its cost-effective nature allows manufacturers to offer stylish products without the ethical concerns associated with real leather. International buyers, particularly from regions like Africa and South America, should prioritize sourcing options that ensure durability and colorfastness to meet the demands of fast fashion. Compliance with local regulations regarding material safety and environmental impact is also crucial.

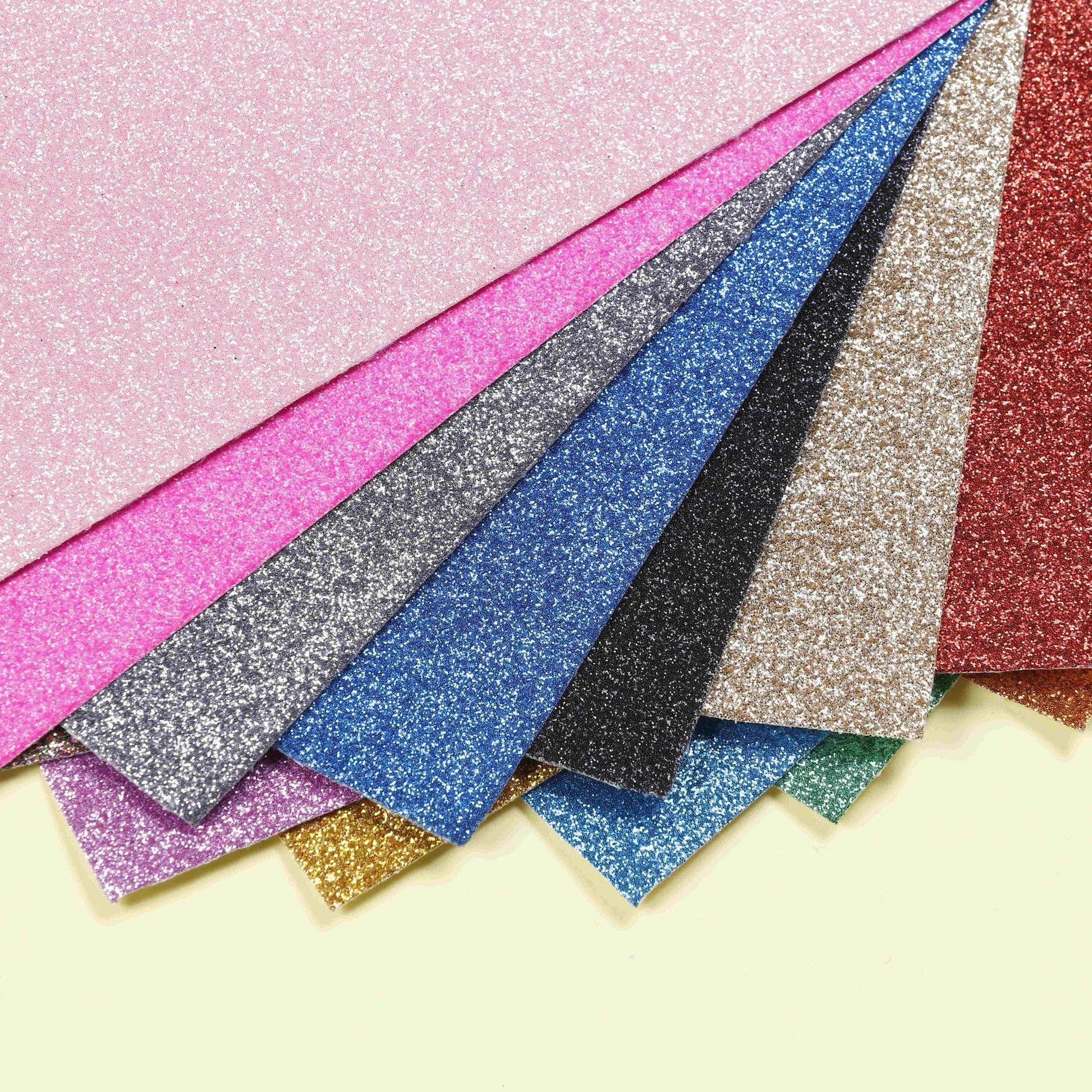

Illustrative image related to faux leather bulk

What Role Does Faux Leather Bulk Play in Automotive Upholstery?

In the automotive sector, faux leather bulk is a popular choice for upholstery in car interiors, providing an aesthetic appeal that rivals traditional leather. It offers businesses the advantage of enhancing passenger comfort while being more affordable. When sourcing faux leather for automotive applications, buyers should ensure that materials meet safety standards, are easy to clean, and can withstand wear and tear from daily use. This is particularly relevant for buyers in the Middle East and Europe, where vehicle aesthetics are highly valued.

How is Faux Leather Bulk Applied in Furniture and Home Decor?

Faux leather is widely used in the furniture and home decor industries for upholstery on sofas, chairs, and decorative accents. It provides a luxurious feel at a fraction of the cost of genuine leather, making it an attractive option for budget-conscious consumers. Buyers should focus on sourcing materials that are stain-resistant and durable, as these factors are critical for maintaining the longevity of furniture pieces. Additionally, a variety of textures can cater to different design preferences, appealing to diverse markets in Europe and South America.

What Advantages Does Faux Leather Bulk Offer the Marine Industry?

In the marine industry, faux leather bulk is essential for boat upholstery and covers due to its water-resistant properties. This material allows for easy maintenance and cleaning, making it ideal for the harsh marine environment. Buyers should prioritize sourcing faux leather that is UV resistant to prevent fading and deterioration from sun exposure. This is particularly important for businesses in tropical regions, where boats are frequently used and exposed to the elements.

How is Faux Leather Bulk Beneficial for Events and Exhibitions?

Faux leather bulk serves as a versatile material for creating custom displays and furniture for events and exhibitions. Its customizable nature allows businesses to create visually appealing setups that attract attention. When sourcing faux leather for these applications, considerations such as weight, ease of transport, and fire-retardant properties are crucial, especially for international events. Buyers from diverse regions, including the Middle East and Europe, can leverage these attributes to enhance their exhibition presentations while adhering to safety regulations.

Illustrative image related to faux leather bulk

3 Common User Pain Points for ‘faux leather bulk’ & Their Solutions

Scenario 1: Sourcing Quality Faux Leather Without Compromising on Standards

The Problem: For B2B buyers in diverse markets, sourcing faux leather in bulk can be daunting. Many suppliers offer low-quality materials that don’t meet durability and aesthetic expectations, leading to product returns and dissatisfied customers. This is particularly concerning for businesses in the fashion and upholstery industries, where material quality directly impacts brand reputation and customer loyalty. Buyers may also face challenges in verifying the authenticity of the product specifications, especially when dealing with international suppliers.

The Solution: To navigate this challenge, B2B buyers should establish clear criteria for quality assessment before engaging with suppliers. This includes requesting samples of the faux leather, checking for certifications that ensure environmental standards and material safety. Additionally, engaging in direct communication with suppliers can clarify material specifications, such as the thickness, texture, and finish. Utilizing platforms that aggregate supplier reviews can also provide insights into the reliability of potential partners. By investing time upfront to vet suppliers, businesses can mitigate risks and ensure they receive high-quality faux leather that aligns with their product standards.

Scenario 2: Managing Supply Chain Issues with Faux Leather Bulk Orders

The Problem: Supply chain disruptions can severely impact the availability of faux leather, leading to project delays and lost revenue opportunities. For international buyers, fluctuations in shipping costs and timelines can complicate order fulfillment. Additionally, varying customs regulations and documentation requirements can cause unexpected holdups, further complicating the procurement process.

The Solution: To effectively manage supply chain issues, B2B buyers should develop strong relationships with multiple suppliers to ensure alternative sourcing options are available. Establishing a diversified supplier base can provide flexibility in times of disruption. It’s also beneficial to plan orders well in advance, taking into account potential delays in shipping and customs processing. Implementing inventory management systems can help track stock levels and forecast needs, allowing businesses to order faux leather in bulk strategically. Finally, staying informed about global shipping trends and potential disruptions can enable buyers to adapt their procurement strategies proactively.

Scenario 3: Understanding Faux Leather Characteristics for Specific Applications

The Problem: Different faux leather products have unique characteristics that make them suitable for specific applications, such as apparel, upholstery, or automotive uses. B2B buyers may struggle to determine which type of faux leather is best for their intended purpose, leading to poor purchasing decisions that can affect product performance and customer satisfaction. Misunderstanding the properties of faux leather—such as water resistance, flexibility, and durability—can result in material failures that harm business reputation.

The Solution: To overcome this issue, buyers should invest in educating themselves about the various types of faux leather available and their specific uses. This involves not only researching the material properties but also consulting with suppliers who can provide insights based on their expertise. Attending trade shows or industry seminars focused on textiles can enhance understanding and help buyers make informed decisions. Furthermore, creating a material specification guide that outlines the desired characteristics for each product application can streamline the decision-making process and ensure the chosen faux leather meets all necessary requirements. By aligning material selection with application needs, businesses can enhance product quality and customer satisfaction.

Strategic Material Selection Guide for faux leather bulk

What Are the Key Materials Used in Faux Leather Bulk Production?

Faux leather, a versatile and sustainable alternative to genuine leather, is manufactured using various synthetic materials. Understanding the properties, advantages, disadvantages, and specific considerations of these materials is essential for B2B buyers, especially those targeting diverse international markets such as Africa, South America, the Middle East, and Europe.

Which Synthetic Polymers Are Commonly Used in Faux Leather?

-

Polyvinyl Chloride (PVC)

– Key Properties: PVC faux leather is known for its durability, water resistance, and ease of cleaning. It can withstand a range of temperatures, making it suitable for various climates.

– Pros & Cons: The material is relatively inexpensive and offers good resistance to wear and tear. However, it may not be as breathable as other materials, leading to discomfort in warmer conditions. Additionally, PVC can be less environmentally friendly due to its production process.

– Impact on Application: PVC is widely used in upholstery, automotive interiors, and fashion accessories. Its compatibility with dyeing and printing processes allows for vibrant designs.

– Considerations for International Buyers: Buyers should be aware of compliance with environmental regulations, particularly in Europe where restrictions on PVC usage are becoming more stringent. Standards such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) may apply. -

Polyurethane (PU)

– Key Properties: PU faux leather mimics the look and feel of genuine leather closely, offering a soft texture and high flexibility. It is also resistant to abrasion and UV light.

– Pros & Cons: PU is generally more breathable than PVC, making it a better choice for apparel. However, it tends to be more expensive and may have a shorter lifespan under heavy use compared to PVC.

– Impact on Application: PU is ideal for high-end fashion items, upholstery, and automotive applications where aesthetics and comfort are paramount.

– Considerations for International Buyers: Buyers should ensure that PU products comply with local regulations regarding chemical safety. In regions like the Middle East, where high temperatures are common, the material’s performance under heat should be evaluated. -

Recycled Materials (e.g., Recycled PET)

– Key Properties: Made from recycled plastics, this material is eco-friendly and offers similar durability and water resistance as traditional faux leathers.

– Pros & Cons: The use of recycled materials can significantly reduce environmental impact and appeal to eco-conscious consumers. However, the manufacturing process may be more complex and costly.

– Impact on Application: This material is suitable for sustainable fashion brands and products aimed at environmentally aware consumers. Its compatibility with various printing techniques allows for creative designs.

– Considerations for International Buyers: Buyers should look for certifications that validate the sustainability claims of recycled materials. Compliance with international standards such as ISO 14001 for environmental management may also be necessary. -

Acrylic

– Key Properties: Acrylic faux leather is lightweight, durable, and resistant to UV rays, making it suitable for outdoor applications.

– Pros & Cons: Its vibrant colors and resistance to fading are significant advantages. However, acrylic may not be as durable as PVC or PU in heavy-use scenarios.

– Impact on Application: Acrylic is commonly used in outdoor furniture, marine applications, and fashion accessories. Its water resistance enhances its usability in various environments.

– Considerations for International Buyers: Buyers should ensure that acrylic products meet international safety standards, particularly for outdoor use. Understanding local climate conditions can also guide material selection.

Summary Table of Faux Leather Materials

| Material | Typical Use Case for faux leather bulk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Upholstery, automotive interiors, fashion accessories | Durable and cost-effective | Less breathable, environmental concerns | Low |

| Polyurethane (PU) | High-end fashion, upholstery, automotive applications | Soft texture, breathable | More expensive, shorter lifespan | Medium |

| Recycled Materials (e.g., Recycled PET) | Sustainable fashion, eco-friendly products | Eco-friendly, reduces waste | Complex manufacturing process | Medium |

| Acrylic | Outdoor furniture, marine applications, fashion accessories | Lightweight, UV resistant | Less durable under heavy use | Medium |

This comprehensive guide provides valuable insights into the strategic material selection for faux leather bulk, helping B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for faux leather bulk

What are the Key Stages in the Manufacturing Process of Faux Leather Bulk?

The production of faux leather involves several intricate stages, each vital for ensuring the quality and durability of the final product. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing synthetic polymers, primarily polyvinyl chloride (PVC) or polyurethane (PU), which are the foundational materials for faux leather. These materials are processed and blended with additives to enhance properties such as flexibility, durability, and water resistance. The preparation stage may also involve dyeing the base material to achieve the desired color before it proceeds to the forming stage.

-

Forming: In this stage, the prepared materials are transformed into a leather-like texture. Techniques such as calendaring, where the polymer mixture is pressed between rollers, or coating, where the substrate is coated with a layer of synthetic material, are employed. The choice of technique affects the final appearance and feel of the faux leather. Specialized machinery can create various textures, including smooth, embossed, or suede-like finishes.

-

Assembly: After forming, the faux leather sheets are cut and assembled according to specific designs or patterns. This stage may include stitching, bonding, or other joining techniques to create finished products such as upholstery, bags, or clothing. It’s crucial that skilled labor is involved in this process to ensure precision and adherence to design specifications.

-

Finishing: The final stage involves applying additional treatments to enhance the product’s performance and aesthetics. This may include applying a protective coating to improve durability, water resistance, or UV protection. The finishing process can also involve quality checks to ensure that the faux leather meets industry standards for texture, color consistency, and overall quality.

What Quality Assurance Measures are Essential for Faux Leather Manufacturing?

Quality assurance (QA) is crucial in the faux leather industry to ensure that products meet international standards and customer expectations. Here are the key elements of a robust QA process:

-

International Standards Compliance: Buyers should look for compliance with recognized international standards, such as ISO 9001, which focuses on quality management systems. Other relevant certifications may include CE marking for safety standards in the European market and API standards for performance requirements in specific applications.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are conducted to monitor the production quality, ensuring adherence to specifications.

– Final Quality Control (FQC): Before shipping, a final inspection is conducted to ensure that the finished products meet all quality criteria and are free from defects. -

Common Testing Methods: Various testing methods are employed to assess the performance and durability of faux leather, including:

– Tensile Strength Testing: To evaluate the material’s strength and elasticity.

– Water Resistance Testing: To ensure that the faux leather can withstand moisture without degrading.

– Colorfastness Testing: To assess how well the color holds up against washing, light exposure, and rubbing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is paramount. Here are actionable steps:

-

Supplier Audits: Conducting on-site audits can provide firsthand insights into a supplier’s manufacturing processes and quality control measures. This involves evaluating their facilities, equipment, and adherence to quality standards.

-

Requesting Quality Reports: Buyers should request detailed quality control reports from suppliers, including the results of various testing methods and compliance with international standards. This documentation can help buyers assess the reliability and consistency of the supplier’s products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspections can occur at various stages of the manufacturing process, ensuring that the products meet the required standards before shipment.

-

Understanding Certification Nuances: Different regions may have specific quality certifications that are more relevant than others. For instance, in Europe, CE marking is crucial for compliance, while in the Middle East, local standards may differ. Buyers should familiarize themselves with these nuances to ensure that the products they source are compliant with local regulations.

What are the Challenges in Quality Assurance for International Buyers?

International B2B buyers often face unique challenges when it comes to quality assurance in faux leather manufacturing. These challenges may include:

Illustrative image related to faux leather bulk

-

Cultural Differences: Variations in business practices and quality expectations across different regions can lead to misunderstandings. It is essential for buyers to communicate their quality standards clearly and ensure that suppliers understand these requirements.

-

Logistical Issues: Shipping faux leather products internationally can introduce risks related to handling and transportation. Buyers should work with suppliers who have robust packaging and handling processes to minimize damage during transit.

-

Regulatory Compliance: Navigating the regulatory landscape can be complex for international buyers. Understanding the specific requirements of the target market is crucial to avoid compliance issues that could lead to costly delays or penalties.

Conclusion

The manufacturing processes and quality assurance measures for faux leather bulk are critical factors that B2B buyers must consider when sourcing products. By understanding the stages of production, implementing rigorous quality control practices, and verifying supplier capabilities, international buyers can ensure they receive high-quality faux leather products that meet their specific needs. This comprehensive approach not only enhances product quality but also strengthens business relationships across global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather bulk’

Einführung

Sourcing faux leather in bulk requires careful consideration and systematic planning to ensure that the final product meets your business needs. This checklist will guide B2B buyers through the critical steps to effectively procure faux leather, ensuring quality, compliance, and cost-effectiveness while catering to diverse market demands.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes the type of faux leather (e.g., PVC, polyurethane), thickness, texture, and color options. Specifying these details helps streamline supplier selection and ensures that the final product aligns with your intended applications, whether for fashion, upholstery, or automotive uses.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in faux leather. Utilize online directories, trade shows, and industry contacts to compile a list of potential vendors. Look for suppliers with a proven track record in delivering quality products and services, as well as those with experience in your target market regions such as Africa, South America, or Europe.

Illustrative image related to faux leather bulk

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold the necessary certifications relevant to your industry. Look for compliance with international standards such as ISO and environmental certifications like REACH or OEKO-TEX. These certifications not only ensure product safety and quality but also demonstrate the supplier’s commitment to sustainable practices, which is increasingly important in global markets.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, always request samples to evaluate the quality of the faux leather. Assess the material for durability, texture, and color fidelity against your specifications. This step is crucial for confirming that the product meets your quality standards and is suitable for your intended use.

Step 5: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations to discuss pricing, payment terms, and delivery schedules. Ensure that you understand all costs involved, including shipping and potential tariffs, especially when sourcing from international suppliers. A clear agreement will prevent misunderstandings and ensure a smoother transaction process.

Step 6: Establish a Communication Plan

Set up a robust communication framework with your chosen supplier. Regular updates on production timelines, quality checks, and shipping can prevent delays and ensure that both parties are aligned throughout the process. Effective communication is vital in fostering a strong supplier relationship and addressing any issues promptly.

Step 7: Plan for Logistics and Distribution

Consider your logistics strategy for transporting the faux leather to your location. Evaluate shipping options, delivery timelines, and potential customs requirements based on your region. Having a clear logistics plan in place will help ensure timely receipt of materials and minimize disruption to your production schedule.

By following these steps, B2B buyers can navigate the complexities of sourcing faux leather in bulk effectively, ensuring that they secure high-quality materials that meet their business objectives.

Illustrative image related to faux leather bulk

Comprehensive Cost and Pricing Analysis for faux leather bulk Sourcing

What Are the Key Cost Components in Faux Leather Bulk Sourcing?

When sourcing faux leather in bulk, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The primary ingredient in faux leather is synthetic polymers, such as polyvinyl chloride (PVC) or polyurethane (PU). The choice of material significantly influences the cost, with higher-quality options commanding a premium.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with lower wage standards may offer competitive pricing, but this should be balanced against potential quality concerns.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient factories with lower overhead can provide more competitive pricing.

-

Tooling: Investment in specialized machinery or molds for producing specific faux leather designs can add to upfront costs. However, this can be amortized over large production runs.

-

Quality Control (QC): Ensuring that the faux leather meets specified standards incurs costs related to testing and inspection. Buyers should factor in these QC costs when assessing total expenses.

-

Logistics: Shipping costs can vary dramatically based on the origin of the faux leather, chosen shipping method, and distance to the destination. This is particularly relevant for international buyers.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary depending on market demand and competition.

How Do Pricing Influencers Affect Faux Leather Costs?

Several factors can influence the pricing of faux leather:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract bulk discounts. However, buyers must ensure they can effectively utilize the volume to avoid excess inventory costs.

-

Specifications and Customization: Custom designs or specifications typically increase production costs. Buyers should clarify their needs upfront to understand how these factors will affect pricing.

-

Materials Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly or hypoallergenic) can lead to higher prices. Buyers should weigh the benefits of these features against their budget.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role in pricing. Established suppliers may charge more but offer consistent quality and service.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) determine who bears the costs and risks at various stages of transport, impacting the overall cost of sourcing.

What Are Essential Buyer Tips for Cost-Efficiency in Faux Leather Sourcing?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Always negotiate pricing and terms, including payment schedules and delivery timelines. Building a strong relationship with suppliers can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, assess the long-term costs associated with storage, handling, and potential waste. This holistic view can lead to more informed purchasing decisions.

-

Understand Pricing Nuances for International Buyers: Be aware of additional costs such as tariffs, taxes, and currency fluctuations that may affect the final price. It’s essential to factor these into the budget early in the sourcing process.

-

Evaluate Supplier Options: Don’t settle for the first supplier. Compare multiple suppliers to understand the market landscape and identify the best fit for your needs.

-

Stay Informed on Market Trends: Keeping abreast of trends in faux leather pricing, material innovations, and global supply chain developments can help buyers make strategic sourcing decisions.

Disclaimer on Indicative Prices

Prices for faux leather can vary widely based on the aforementioned factors. It is advisable for buyers to request quotes from multiple suppliers and consider all costs involved to arrive at a comprehensive understanding of total expenses.

Alternatives Analysis: Comparing faux leather bulk With Other Solutions

Introduction: Exploring Alternatives to Faux Leather Bulk

As the demand for sustainable and versatile materials rises, many businesses are exploring alternatives to traditional leather and faux leather. Faux leather bulk offers a cruelty-free, cost-effective option, but other materials and technologies can also meet the needs of B2B buyers. This analysis compares faux leather bulk with two viable alternatives: genuine leather and textile-based alternatives, providing insights into their performance, cost, and suitability for different applications.

Comparison Table

| Comparison Aspect | Faux Leather Bulk | Echtes Leder | Textile-Based Alternatives |

|---|---|---|---|

| Performance | Durable, water-resistant, flexible | Highly durable, breathability varies | Varies widely; can be less durable but eco-friendly |

| Cost | Generally lower than genuine leather | Higher initial cost | Typically lower than both faux and genuine leather |

| Ease of Implementation | Easy to sew and upholster | Requires specialized tools and skills | Simple to work with, but may require specific treatments |

| Wartung | Low maintenance, easy to clean | Requires regular conditioning | Often machine washable, but durability varies |

| Best Use Case | Apparel, upholstery, accessories | High-end furniture, luxury goods | Eco-friendly fashion, casual wear, home decor |

Detailed Breakdown of Alternatives

Genuine Leather: What Are the Advantages and Disadvantages?

Genuine leather is renowned for its durability and aesthetic appeal, making it a preferred choice for luxury items such as high-end furniture and designer apparel. Its breathability and natural texture offer a premium experience that faux leather cannot replicate. However, the cost of genuine leather is significantly higher, which may not align with budget constraints for many businesses. Additionally, genuine leather requires regular maintenance to prevent drying and cracking, which can add to long-term costs.

Textile-Based Alternatives: Are They a Viable Option?

Textile-based alternatives, such as organic cotton or hemp blends, provide a sustainable option that appeals to environmentally conscious consumers. These materials can be less expensive and easier to work with than both faux and genuine leather. However, their durability may not match that of leather products, making them less suitable for high-wear applications. They are ideal for casual fashion items and home decor but may require additional treatments for water resistance and longevity.

Conclusion: How to Choose the Right Solution for Your Business Needs

Choosing the right material depends on the specific requirements of your project and the values of your target market. If sustainability and cost-effectiveness are your primary concerns, faux leather bulk or textile-based alternatives may be the best fit. Conversely, if your focus is on durability and luxury appeal, genuine leather could be the superior option, despite the higher costs. By assessing your use case, budget, and desired product quality, you can make an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for faux leather bulk

What Are the Key Technical Properties of Faux Leather Bulk?

Faux leather, also known as synthetic leather or vegan leather, is a popular choice in various industries, including fashion, automotive, and furniture. Understanding its technical properties is essential for B2B buyers to make informed purchasing decisions.

1. Material Grade

Material grade refers to the quality and composition of the faux leather, often determined by the type of synthetic polymers used, such as polyurethane (PU) or polyvinyl chloride (PVC). High-grade materials provide better durability, flexibility, and resistance to wear and tear, making them suitable for high-use applications. For B2B buyers, selecting the right material grade can impact product longevity and customer satisfaction.

Illustrative image related to faux leather bulk

2. Thickness

The thickness of faux leather is usually measured in millimeters (mm) and can significantly influence its application. Thicker materials offer greater durability and are often preferred for upholstery and heavy-duty applications, while thinner options are more suitable for apparel and accessories. Buyers should consider the intended use to ensure that the thickness meets their specific requirements.

3. Tolerance

Tolerance refers to the allowable variation in dimensions and properties of the faux leather during production. A tighter tolerance generally indicates higher quality and consistency, which is crucial for manufacturers requiring precise measurements for cutting and stitching. Understanding tolerance levels helps buyers maintain quality control and reduce waste in production.

4. Water Resistance

Water resistance is a critical property for faux leather, particularly for applications in outdoor settings or products that may be exposed to moisture. Faux leather can be treated to enhance its water-resistant qualities, making it an excellent choice for items like jackets, bags, and upholstery. For B2B buyers, knowing the water resistance level ensures that the product will perform well in its intended environment.

5. Flame Retardancy

Some faux leather materials are treated to be flame-retardant, which is especially important for applications in the automotive and furniture industries. This property minimizes the risk of fire hazards and meets safety regulations. Buyers in industries with strict safety standards should prioritize flame-retardant options to ensure compliance and safety.

What Common Trade Terms Should B2B Buyers Understand in Faux Leather Bulk?

Navigating the faux leather market also requires familiarity with specific trade terminology that can affect procurement processes and negotiations.

Illustrative image related to faux leather bulk

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another company’s brand. In the faux leather industry, OEM partnerships can allow businesses to create custom designs and materials tailored to their brand identity. Understanding OEM relationships can help buyers leverage manufacturing capabilities for unique product offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity a supplier requires for an order. This term is crucial for B2B buyers as it impacts inventory costs and stock management. Suppliers often set MOQs to ensure that production runs are economically viable, so understanding these requirements is essential for effective purchasing strategies.

3. RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing on specific products or services. In the context of faux leather bulk, an RFQ allows buyers to compare prices, material specifications, and lead times from multiple suppliers, facilitating informed decision-making and cost-effective procurement.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and risk management. Familiarity with these terms is vital for B2B buyers, as they dictate who is responsible for costs and logistics at different stages of the transaction, helping to avoid misunderstandings and disputes.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the faux leather industry, lead times can vary based on factors such as material availability and production schedules. Buyers should account for lead times in their planning to ensure timely delivery of products to meet market demands.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing faux leather in bulk, ultimately leading to more successful partnerships and product offerings.

Navigating Market Dynamics and Sourcing Trends in the faux leather bulk Sector

What Are the Key Market Dynamics and Trends in the Faux Leather Bulk Sector?

The faux leather bulk market is experiencing robust growth, driven by a combination of consumer demand for sustainable alternatives to genuine leather and innovations in manufacturing technologies. Key factors include the rise of ethical consumerism, particularly in regions like Europe and North America, where buyers are increasingly prioritizing eco-friendly materials. For international B2B buyers from Africa, South America, and the Middle East, this trend is particularly relevant as they seek to align their sourcing strategies with global sustainability goals.

Emerging technologies, such as digital printing and automated cutting processes, are streamlining production, allowing manufacturers to offer custom designs and reduced lead times. This technological advancement is particularly beneficial for businesses in countries like Vietnam and Brazil, where competitive pricing and quick turnaround are essential. Furthermore, the expansion of e-commerce platforms facilitates easier access to faux leather products, enabling buyers to source materials directly from manufacturers worldwide.

Illustrative image related to faux leather bulk

Another significant trend is the diversification of faux leather applications, extending beyond traditional uses in fashion and upholstery into automotive, home decor, and even medical fields. This diversification presents new opportunities for B2B buyers to explore niche markets and innovative product offerings. Overall, understanding these dynamics will empower international buyers to make informed sourcing decisions that align with market demands.

How Important Is Sustainability and Ethical Sourcing in the Faux Leather Bulk Sector?

Sustainability is a critical concern in the faux leather bulk sector, influencing purchasing decisions and brand reputations. Faux leather, often made from synthetic polymers like polyurethane and polyvinyl chloride, provides an ethical alternative to traditional leather, which is associated with environmental degradation and animal welfare issues. However, the production processes for faux leather can also have environmental impacts, including significant resource consumption and potential pollution.

B2B buyers should prioritize suppliers that demonstrate commitment to sustainable practices. This includes sourcing materials from manufacturers who adhere to strict environmental regulations and invest in eco-friendly production methods. Certifications such as Global Recycled Standard (GRS) or OEKO-TEX can serve as indicators of responsible sourcing. Additionally, the trend towards bio-based faux leather, made from renewable resources like plant-based polyols, is gaining traction. These innovative materials not only reduce environmental impact but also appeal to a growing segment of eco-conscious consumers.

In regions like Africa and South America, where the demand for sustainable products is on the rise, implementing ethical sourcing strategies can help businesses enhance their marketability and align with global sustainability initiatives. By fostering transparency in the supply chain and opting for certified materials, B2B buyers can contribute to a more sustainable future while meeting their customers’ expectations.

Illustrative image related to faux leather bulk

What Is the Evolution of Faux Leather and Its Implications for B2B Buyers?

The evolution of faux leather dates back to the early 20th century, initially emerging as a cost-effective alternative to leather. Early versions, often made from paper or fabric coated with chemicals, were primarily used in clothing and furniture. However, advancements in polymer technology in the latter half of the century led to the development of more durable and versatile synthetic leathers, such as vinyl and polyurethane, enhancing their appeal across various industries.

Today, faux leather represents a significant segment of the textiles market, with applications extending into fashion, automotive interiors, and home furnishings. This evolution is crucial for B2B buyers as it reflects the material’s adaptability and the continuous improvement in quality and design. The current landscape offers a plethora of options tailored to specific industry needs, allowing businesses to source products that not only meet functional requirements but also resonate with consumer values around sustainability and ethical sourcing.

Understanding the historical context of faux leather can provide valuable insights for B2B buyers, enabling them to appreciate the advancements that have shaped the market and anticipate future trends that could influence their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of faux leather bulk

-

How do I ensure the quality of faux leather when sourcing in bulk?

To ensure the quality of faux leather, request samples from suppliers before committing to a bulk order. Assess the material’s durability, texture, and flexibility to ensure it meets your specifications. Additionally, inquire about the manufacturing process, certifications, and whether the faux leather is tested for factors such as tear strength and colorfastness. Establishing clear quality assurance protocols with your supplier can further help maintain consistent quality across your orders. -

What factors should I consider when choosing a faux leather supplier?

When selecting a faux leather supplier, evaluate their reputation, experience, and product range. Look for suppliers who provide comprehensive product information, including material composition and applications. Check customer reviews and testimonials to gauge satisfaction levels. Ensure they have robust quality control measures and can accommodate your specific needs, such as customization and bulk order capabilities. It’s also beneficial to confirm their ability to meet delivery timelines and provide after-sales support. -

What is the minimum order quantity (MOQ) for faux leather?

The minimum order quantity for faux leather can vary significantly by supplier, often ranging from 50 to 500 yards, depending on the type of faux leather and the supplier’s policies. Some suppliers may have lower MOQs for specific items, especially if they offer a diverse range of products. Always communicate your requirements upfront, as many suppliers are willing to negotiate on MOQs for long-term partnerships or larger orders. -

Can I customize the faux leather colors or patterns for my business?

Yes, many suppliers offer customization options for faux leather, including specific colors, patterns, and finishes. To initiate this process, discuss your design requirements and minimum quantities with the supplier. Be prepared to provide color swatches or design files, and inquire about the lead times for custom orders. Customization may involve additional costs, but it can greatly enhance your brand’s uniqueness and appeal in the market. -

What payment terms are common in international faux leather transactions?

Payment terms can vary widely among suppliers, but common practices include upfront deposits (often 30% to 50%) with the balance due prior to shipment. Some suppliers may offer payment upon delivery or through letters of credit, especially for larger transactions. Ensure you clearly understand the payment terms and methods accepted, including wire transfers, credit cards, or platforms like PayPal, to facilitate smooth transactions and avoid potential issues. -

How do I handle logistics and shipping for faux leather orders?

Handling logistics for faux leather orders involves coordinating with your supplier and shipping agents. Discuss shipping options, costs, and delivery timelines upfront. Depending on your location, consider freight forwarding services that specialize in international shipping. Ensure all customs documentation is prepared correctly to prevent delays. It may also be beneficial to explore incoterms (such as FOB, CIF) with your supplier to clarify responsibilities for shipping and insurance. -

What should I know about international trade regulations for faux leather?

Understanding international trade regulations is crucial when sourcing faux leather. Familiarize yourself with import duties, tariffs, and any specific regulations related to synthetic materials in your country. Some regions may have restrictions on certain chemicals used in faux leather production, so check compliance with local environmental regulations. Collaborating with a customs broker can help navigate these complexities and ensure smooth import processes. -

How can I effectively communicate my faux leather needs to suppliers?

Effective communication with suppliers is key to a successful partnership. Be clear and specific about your requirements, including the type of faux leather, desired specifications, and intended applications. Use detailed descriptions and, if possible, visual references to convey your expectations. Regular follow-ups and open dialogue can help clarify any uncertainties and ensure that both parties are aligned throughout the sourcing process.

Top 7 Faux Leather Bulk Manufacturers & Suppliers List

1. Fabric Wholesale Direct – Faux Leather Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Faux Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes 66 products available in various colors and textures. Colors include Beige, Black, Blue, Brown, Green, Grey, Navy, Orange, Pink, Purple, Red, Teal, White, and Yellow. Textures available are Alligator, Basket Weave, Crocodile, Legacy, Limited Edition, Lite, Ostrich, Pebble, Rugged, and Shimmer. The fabric is sold by quarter yard, and each piece is s…

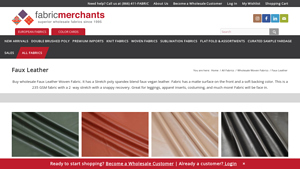

3. Fabric Merchants – Faux Leather Woven Fabric

Domain: fabricmerchants.com

Registered: 2003 (22 years)

Introduction: Faux Leather Woven Fabric, Stretch poly spandex blend, 235 GSM, 2-way stretch with snappy recovery, matte surface on the front, soft backing, cruelty-free, durable, water-resistant, versatile applications (leggings, apparel inserts, costuming, upholstery, handbags, footwear), available colors: Olive, Rust, Sand, Black, Burgundy Plum, easy maintenance, suitable for upholstery, can be sewn with a re…

4. Pip Supply – Patterned Faux Leather Collection

Domain: pipsupply.com

Registered: 2018 (7 years)

Introduction: Patterned Faux Leather Collection – Free Domestic Shipping for orders $75 and up. Current Processing Time: 4-8 Business Days.

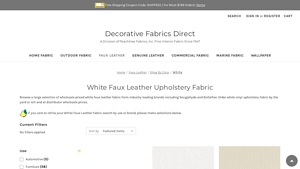

5. Faux Leather – Upholstery Vinyl

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: White Faux Leather Upholstery Vinyl available from various brands including Naugahyde and Boltaflex. Prices range from $6.97 to $33.95 per yard. Multiple colors and styles available. Stock levels vary by product, with options for automotive, furniture, and marine use. Free shipping on most orders over $199 with coupon code SHIPFREE.

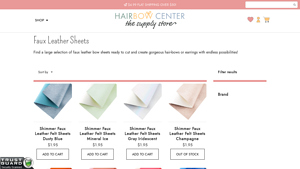

6. Hair Bow Center – Faux Leather Sheets

Domain: hairbowcenter.com

Registered: 2008 (17 years)

Introduction: Faux Leather Sheets available for DIY projects like hair-bows and earrings. Prices range from $1.95 to $2.00 per sheet. Various colors and finishes include Shimmer Faux Leather Felt Sheets (Dusty Blue, Mineral Ice, Gray Iridescent, Champagne), High Gloss Vinyl Textured Faux Leather Sheets (Orange, Peach, Watermelon, Royal Blue, Yellow, Red, Blush Pink, Maroon, Metallic Silver, Metallic Gold, Almon…

7. Vogue Fabrics – Faux Leather & Vinyl

Domain: voguefabricsstore.com

Registered: 2001 (24 years)

Introduction: Wholesale Faux Leather and Vinyl Fabrics

Strategic Sourcing Conclusion and Outlook for faux leather bulk

In conclusion, the strategic sourcing of faux leather in bulk offers significant advantages for international B2B buyers, particularly in rapidly developing markets across Africa, South America, the Middle East, and Europe. By focusing on reliable suppliers, businesses can secure high-quality materials that align with sustainability goals and consumer demand for cruelty-free alternatives. The versatility of faux leather allows for a wide range of applications, from apparel to upholstery, making it a valuable asset for manufacturers and retailers alike.

As buyers navigate the complexities of sourcing, it is essential to leverage partnerships with trusted suppliers who can provide consistent quality and competitive pricing. Emphasizing long-term relationships can enhance supply chain stability and responsiveness to market trends.

Illustrative image related to faux leather bulk

Looking ahead, the demand for faux leather is expected to grow, driven by increasing awareness of ethical consumption and environmental considerations. Buyers are encouraged to explore innovative materials and designs that resonate with their target audiences. By proactively engaging with suppliers and embracing the potential of faux leather, businesses can position themselves at the forefront of this dynamic market. Take action today and unlock the possibilities that faux leather bulk sourcing can offer your business’s growth and sustainability goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.