Introduction: Navigating the Global Market for perforated leatherette

In today’s competitive landscape, sourcing high-quality perforated leatherette poses unique challenges for B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. The need for durable, aesthetically appealing, and functional materials is paramount, as businesses seek to enhance their product offerings while managing costs effectively. This comprehensive guide delves into the intricacies of perforated leatherette, exploring various types, applications, and the essential factors to consider when selecting suppliers.

The scope of this guide extends beyond mere product descriptions; it provides actionable insights on how to vet suppliers, assess quality, and navigate pricing structures across different regions. Understanding the advantages of perforated leatherette—such as breathability, ease of maintenance, and versatility—enables buyers to make informed decisions that align with their operational needs and customer expectations.

Whether you’re involved in automotive upholstery, fashion, or furniture design, this guide equips you with the knowledge necessary to elevate your sourcing strategies. By addressing the complexities of the global market for perforated leatherette, we aim to empower B2B buyers with the tools needed to ensure successful partnerships and optimal purchasing decisions. Join us as we explore the potential of this innovative material and uncover the best practices for navigating the global supply chain.

Table Of Contents

- Top 8 Perforated Leatherette Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for perforated leatherette

- Understanding perforated leatherette Types and Variations

- Key Industrial Applications of perforated leatherette

- 3 Common User Pain Points for ‘perforated leatherette’ & Their Solutions

- Strategic Material Selection Guide for perforated leatherette

- In-depth Look: Manufacturing Processes and Quality Assurance for perforated leatherette

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘perforated leatherette’

- Comprehensive Cost and Pricing Analysis for perforated leatherette Sourcing

- Alternatives Analysis: Comparing perforated leatherette With Other Solutions

- Essential Technical Properties and Trade Terminology for perforated leatherette

- Navigating Market Dynamics and Sourcing Trends in the perforated leatherette Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of perforated leatherette

- Strategic Sourcing Conclusion and Outlook for perforated leatherette

- Important Disclaimer & Terms of Use

Understanding perforated leatherette Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Perforated Leatherette | Consistent hole size, typically 3/8 inch diameter | Automotive interiors, furniture upholstery | Pros: Good breathability; Cons: Limited aesthetic options. |

| Micro Perforated Leatherette | Smaller holes, usually 1/16 inch diameter | High-end automotive seats, luxury items | Pros: Enhanced luxury feel; Cons: Higher cost. |

| Decorative Perforated Leatherette | Unique patterns and designs, varying hole sizes | Fashion accessories, custom upholstery | Pros: Aesthetic appeal; Cons: May compromise durability. |

| UV-Protected Perforated Leatherette | Treated for UV resistance, maintains color | Outdoor furniture, vehicle interiors | Pros: Long-lasting color; Cons: Potentially higher price. |

| Eco-Friendly Perforated Leatherette | Made from sustainable materials, biodegradable | Green building projects, eco-conscious brands | Pros: Sustainable choice; Cons: Limited availability. |

What Are the Characteristics of Standard Perforated Leatherette?

Standard perforated leatherette features evenly spaced holes, typically around 3/8 inch in diameter, providing a balance of breathability and durability. This type is widely used in automotive interiors and furniture upholstery due to its practical benefits, such as reducing heat buildup and enhancing comfort. B2B buyers should consider the material’s compatibility with their design requirements and the intended use, as the standard perforation size is ideal for mass production yet may lack uniqueness.

How Does Micro Perforated Leatherette Stand Out?

Micro perforated leatherette is characterized by its smaller holes, usually around 1/16 inch in diameter, offering a refined appearance ideal for luxury applications. This type is frequently used in high-end automotive seating and premium fashion products, where aesthetics play a crucial role. Buyers should weigh the increased cost against the benefits of a sophisticated look and feel, ensuring that the investment aligns with their brand’s positioning and customer expectations.

Why Choose Decorative Perforated Leatherette?

Decorative perforated leatherette is distinguished by its unique patterns and varying hole sizes, making it a popular choice for fashion accessories and custom upholstery projects. This type allows for creative expression, catering to brands looking to differentiate their products. However, buyers must consider the potential trade-off between aesthetic appeal and durability, as intricate designs may be less resilient than simpler options.

What Advantages Does UV-Protected Perforated Leatherette Offer?

UV-protected perforated leatherette is specially treated to resist fading and damage from sunlight, making it suitable for outdoor applications such as patio furniture and vehicle interiors exposed to sunlight. This type of leatherette ensures longevity and maintains its visual appeal over time. B2B buyers should assess the cost implications of UV treatment against the expected lifespan and usage environment of their products.

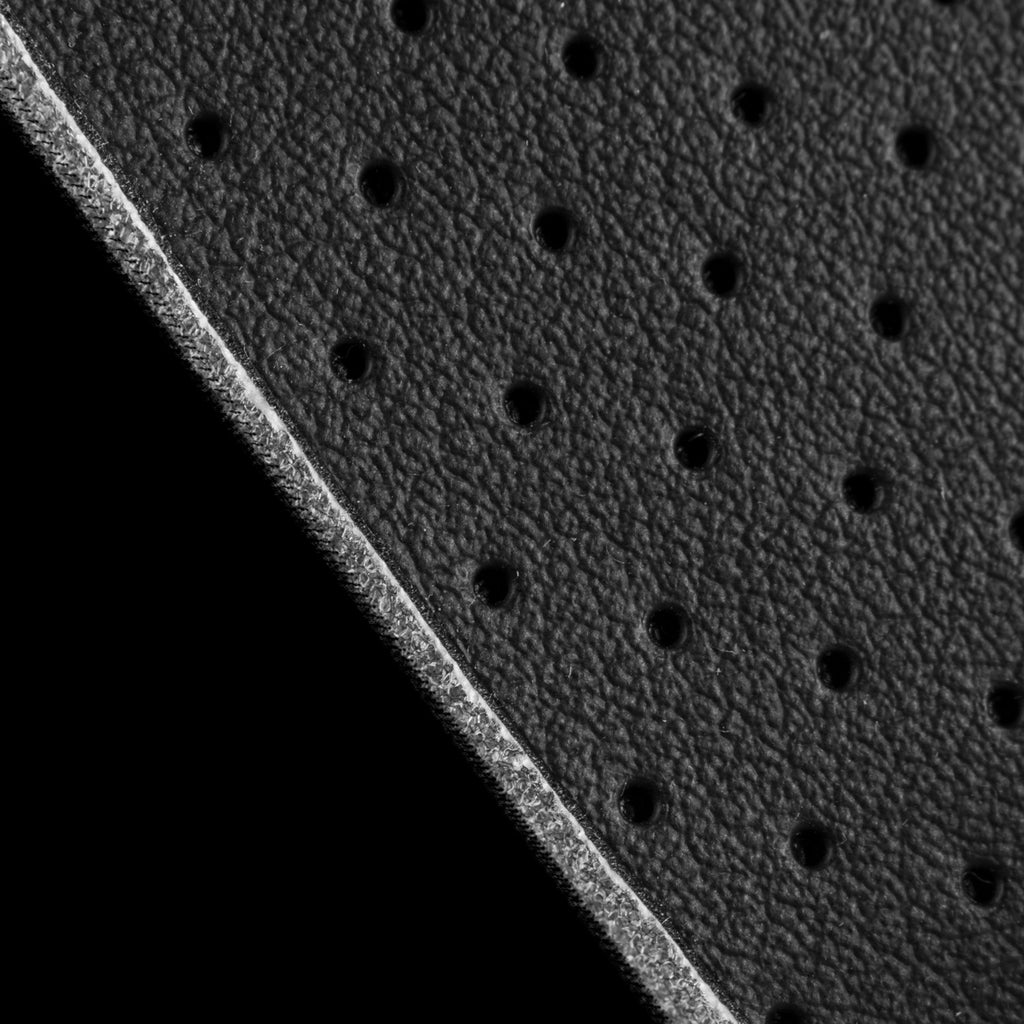

Illustrative image related to perforated leatherette

How Does Eco-Friendly Perforated Leatherette Benefit Buyers?

Eco-friendly perforated leatherette is crafted from sustainable materials, often biodegradable, appealing to brands focused on environmental responsibility. This type is gaining traction in green building projects and among eco-conscious consumers. Buyers should evaluate the availability of eco-friendly options and consider how incorporating sustainable materials can enhance their brand image while meeting growing consumer demand for responsible products.

Key Industrial Applications of perforated leatherette

| Industry/Sector | Specific Application of Perforated Leatherette | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automobilindustrie | Upholstery for car seats and interiors | Enhanced comfort, breathability, and luxury | Quality assurance, customization options, and durability |

| Furniture | Upholstery for sofas, chairs, and cushions | Aesthetic appeal, durability, and easy maintenance | Fabric weight, perforation patterns, and color options |

| Fashion Accessories | Handbags, wallets, and belts | Trendy appearance, lightweight, and versatile | Material thickness, design flexibility, and sourcing reliability |

| Sports Equipment | Protective gear and sports bags | Breathability, reduced weight, and comfort | Compliance with safety standards, material resilience, and color options |

| Home Decor | Wall coverings and decorative items | Unique design, easy installation, and comfort | Adhesive compatibility, texture, and environmental impact |

How is Perforated Leatherette Used in the Automotive Sector?

In the automotive industry, perforated leatherette is primarily used for upholstery in car seats and interiors. Its perforated design enhances breathability, reducing perspiration in hot climates, which is crucial for comfort during long drives. Additionally, the aesthetic appeal of perforated leatherette adds a touch of luxury to vehicle interiors, potentially increasing resale value. International buyers, particularly from regions like Europe and Africa, should prioritize sourcing high-quality materials that meet automotive standards for durability and safety.

What are the Applications of Perforated Leatherette in Furniture?

Perforated leatherette finds significant application in furniture upholstery, particularly for sofas, chairs, and cushions. Its unique perforation not only enhances the visual appeal but also improves durability and ease of maintenance. For B2B buyers in South America and the Middle East, it is essential to consider the fabric weight and customization options to align with local design preferences and climate conditions. Ensuring that the sourced material is resistant to wear and easy to clean will also enhance customer satisfaction.

How is Perforated Leatherette Used in Fashion Accessories?

In the fashion industry, perforated leatherette is utilized for creating trendy handbags, wallets, and belts. The lightweight and versatile nature of this material makes it an attractive choice for fashion designers looking to combine style with functionality. B2B buyers should focus on the material thickness and design flexibility to cater to varying fashion trends across different regions, including Europe and Africa. Reliable sourcing is critical to ensure consistent quality and availability of the desired styles.

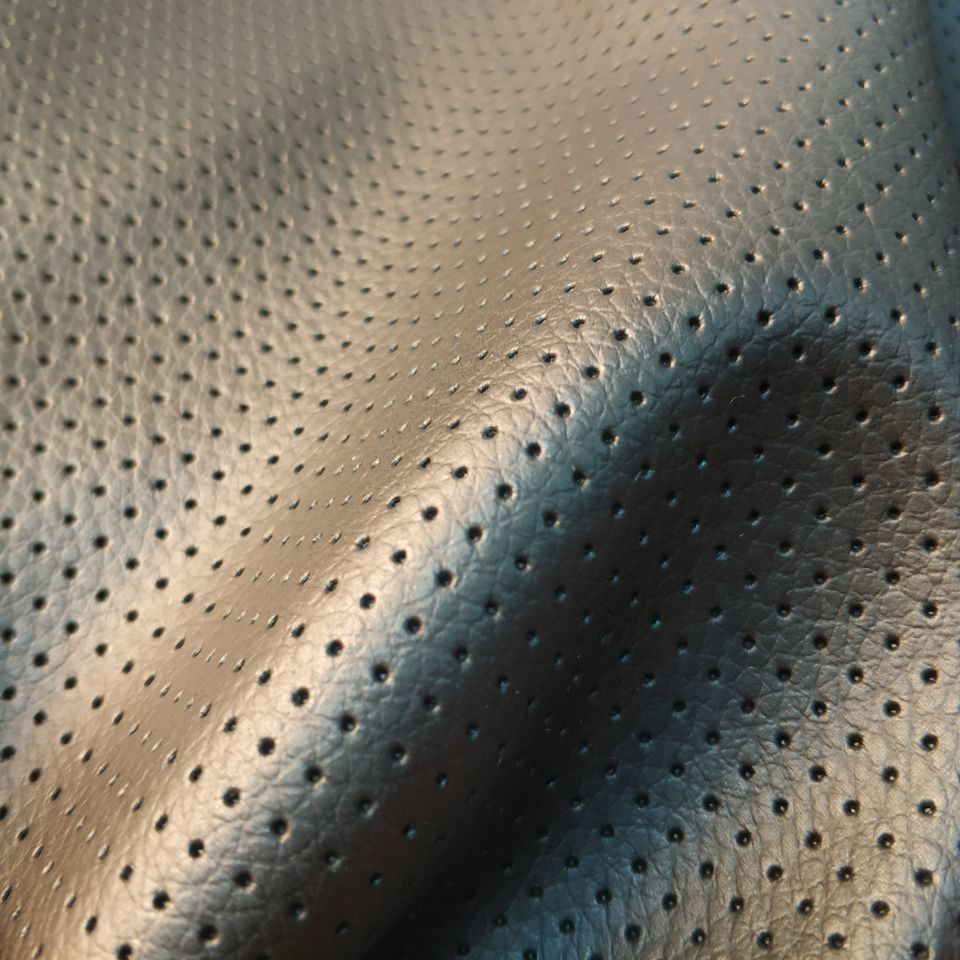

Illustrative image related to perforated leatherette

What is the Role of Perforated Leatherette in Sports Equipment?

Perforated leatherette is increasingly being integrated into sports equipment, such as protective gear and sports bags. Its breathable properties help reduce heat retention, thereby enhancing comfort during physical activities. For international buyers, particularly from regions with diverse climates, sourcing materials that comply with safety standards while being lightweight and durable is paramount. Additionally, color options and design patterns can be tailored to meet specific market demands.

How is Perforated Leatherette Used in Home Decor?

In home decor, perforated leatherette is employed for wall coverings and decorative items. Its unique design allows for creative expression while providing comfort and a modern aesthetic. Buyers in the international market should consider adhesive compatibility and environmental impact when sourcing these materials, as these factors can influence installation processes and sustainability goals. Ensuring that the material is easy to clean and maintain will also enhance its appeal in residential settings.

3 Common User Pain Points for ‘perforated leatherette’ & Their Solutions

Scenario 1: Managing Quality Assurance in Perforated Leatherette Sourcing

The Problem: B2B buyers often encounter challenges in ensuring the quality of perforated leatherette products. Given the diverse manufacturing standards across regions, buyers might receive materials that do not meet their specifications, leading to issues like premature wear, inconsistent perforation sizes, or inadequate durability. This can result in costly returns, project delays, and dissatisfaction from end customers, especially in industries like automotive or high-end furniture where quality is paramount.

The Solution: To effectively manage quality assurance, buyers should establish clear specifications and standards before sourcing perforated leatherette. This includes defining the desired thickness, perforation size, and pattern consistency. It’s advisable to request samples from multiple suppliers to compare quality firsthand. Additionally, establishing a relationship with a reputable manufacturer that offers transparent production processes can help ensure consistent quality. Implementing a third-party quality inspection service prior to shipment can further mitigate risks. Regular communication with suppliers about quality expectations and feedback loops can also enhance product consistency over time.

Scenario 2: Addressing Environmental Concerns in Material Sourcing

The Problem: In today’s market, B2B buyers face increasing pressure to choose sustainable materials. Many perforated leatherette products are made from synthetic materials that may not be environmentally friendly, leading to potential backlash from consumers and stakeholders concerned about sustainability. This poses a significant challenge for companies aiming to align with eco-friendly practices while still meeting aesthetic and functional requirements.

The Solution: Buyers should actively seek out perforated leatherette that is produced from recycled or eco-friendly materials. Engaging suppliers who are transparent about their manufacturing processes and material sourcing can provide assurance of sustainability. Additionally, investigating certifications like OEKO-TEX or GRS (Global Recycle Standard) can help validate the environmental claims of the products. Buyers can also consider establishing partnerships with suppliers who specialize in sustainable materials, allowing them to offer eco-conscious options to their clients without compromising on quality or performance.

Scenario 3: Navigating Design Limitations with Perforated Leatherette

The Problem: Another common pain point is the perceived limitation in design options when using perforated leatherette. Some buyers find that the standard perforation patterns do not meet the unique aesthetic requirements of their projects, particularly in industries like fashion or custom automotive interiors. This can lead to frustration, as limited options can stifle creativity and result in a less appealing end product.

The Solution: To overcome design limitations, buyers should consider working with manufacturers that offer customizable perforation options. This allows for tailored designs that align with specific brand aesthetics or project requirements. When communicating with suppliers, be explicit about the desired perforation patterns, sizes, and layouts. Some manufacturers may also provide design assistance or prototype services, enabling buyers to visualize how different perforation styles will look in their final product. Additionally, exploring partnerships with design firms that specialize in leather goods can help integrate innovative design solutions into the procurement process, ensuring that the final product meets both functional and visual expectations.

Strategic Material Selection Guide for perforated leatherette

What Are the Common Materials Used for Perforated Leatherette in B2B Applications?

When selecting perforated leatherette for various applications, it is crucial to understand the properties and performance characteristics of the materials available. Below, we analyze four common materials used in the production of perforated leatherette, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. PVC (Polyvinyl Chloride)

Key Properties:

PVC is a synthetic plastic polymer known for its durability and resistance to moisture and chemicals. It can withstand a temperature range of -10°C to 60°C, making it suitable for various environments.

Pros & Cons:

PVC is cost-effective and easy to manufacture, allowing for mass production with consistent quality. However, its rigidity can limit comfort in applications like automotive seating. Additionally, while it is durable, it may not have the same aesthetic appeal as natural materials.

Impact on Application:

PVC is compatible with various media, including water and oils, making it ideal for automotive and furniture applications. However, it may not be suitable for high-end fashion products due to its synthetic nature.

Considerations for International Buyers:

Buyers from regions like Europe may need to ensure compliance with REACH regulations concerning chemical safety. In contrast, buyers in Africa and South America may prioritize cost and availability.

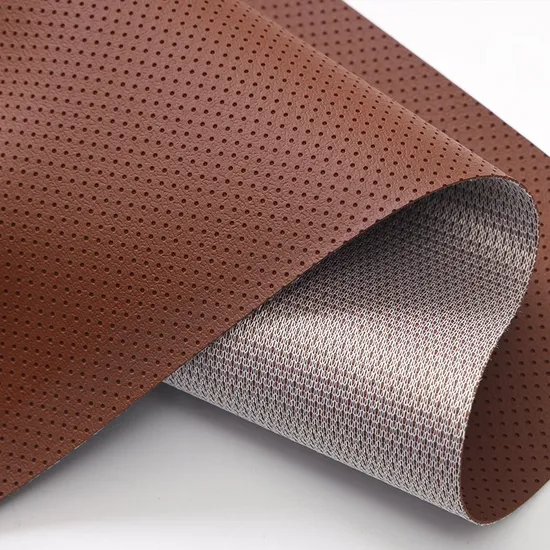

Illustrative image related to perforated leatherette

2. PU (Polyurethane)

Key Properties:

Polyurethane leatherette offers excellent flexibility and can mimic the look and feel of genuine leather. It has a temperature tolerance of -20°C to 80°C, making it versatile for different climates.

Pros & Cons:

PU is softer and more comfortable than PVC, enhancing user experience in seating applications. However, it is generally more expensive and may not be as resistant to wear and tear as PVC.

Impact on Application:

Due to its breathable nature, PU is often used in automotive interiors and high-end fashion items. It provides a luxurious feel while maintaining functionality.

Considerations for International Buyers:

B2B buyers should be aware of varying standards for PU materials, such as ASTM D-1238 for melt flow and DIN 53357 for abrasion resistance. Buyers from Germany may expect higher standards due to stringent regulations.

3. Recycled Leatherette

Key Properties:

Recycled leatherette is made from repurposed leather scraps blended with synthetic materials. It retains some properties of genuine leather, including breathability and a unique texture.

Illustrative image related to perforated leatherette

Pros & Cons:

This material is environmentally friendly and offers a sustainable alternative to traditional leatherette. However, its durability can vary depending on the manufacturing process, and it may be less consistent in quality compared to virgin materials.

Impact on Application:

Recycled leatherette is suitable for eco-conscious brands in the fashion and automotive sectors. Its unique appearance can appeal to consumers looking for sustainable options.

Considerations for International Buyers:

Buyers in Europe may prioritize sustainability certifications, while those in Africa and South America might focus on cost and availability. Compliance with environmental regulations is also crucial.

4. Microfiber Leatherette

Key Properties:

Microfiber leatherette is made from ultra-fine synthetic fibers, providing a soft, durable surface. It is highly resistant to stains and can withstand temperatures from -30°C to 70°C.

Pros & Cons:

This material is highly durable and easy to clean, making it suitable for high-traffic areas. However, it can be more expensive than traditional leatherette options.

Impact on Application:

Microfiber leatherette is ideal for automotive interiors, furniture, and fashion accessories due to its luxurious feel and durability.

Considerations for International Buyers:

International buyers should consider the availability of microfiber leatherette and its compliance with international standards like ISO 9001 for quality management systems. Buyers from the Middle East may also look for UV resistance due to high sun exposure.

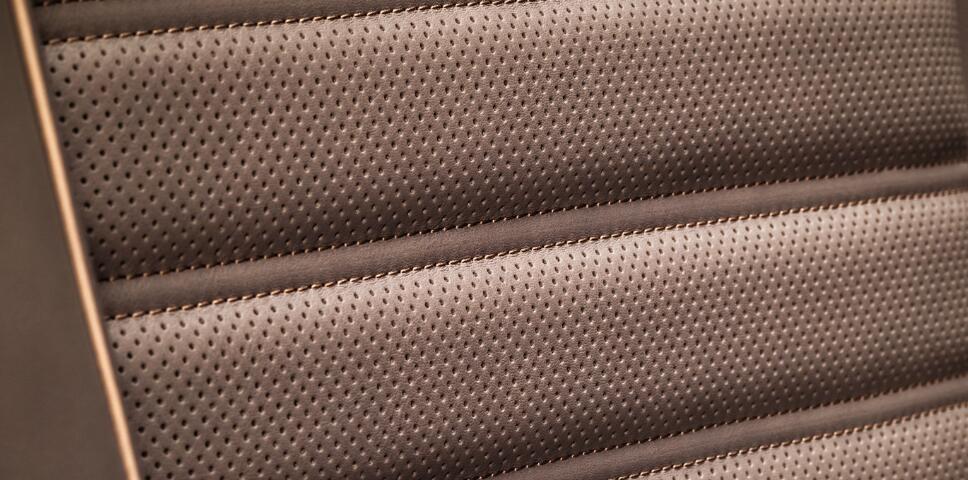

Illustrative image related to perforated leatherette

Summary Table of Material Selection

| Material | Typical Use Case for perforated leatherette | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Automotive interiors, furniture | Cost-effective and durable | Less comfortable, limited aesthetic appeal | Low |

| PU | High-end fashion, automotive interiors | Soft, luxurious feel | More expensive, less wear-resistant | Medium |

| Recycled Leatherette | Eco-friendly fashion, automotive | Sustainable and unique appearance | Variable durability, inconsistent quality | Medium |

| Microfiber Leatherette | Luxury automotive, high-end furniture | Highly durable and easy to clean | Higher cost compared to traditional options | Hoch |

This strategic material selection guide offers B2B buyers critical insights into the various types of perforated leatherette materials available, helping them make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for perforated leatherette

What Are the Key Stages in the Manufacturing Process of Perforated Leatherette?

The manufacturing of perforated leatherette involves several critical stages, each crucial for ensuring the final product meets quality and durability standards. Here are the main stages:

Material Preparation: What Materials Are Used and How Are They Processed?

The process begins with the selection of high-quality synthetic materials, typically a blend of PVC (polyvinyl chloride) or PU (polyurethane) backed with a fabric substrate. These materials are chosen for their durability, resistance to wear, and ease of maintenance.

Once the materials are selected, they undergo pre-treatment processes, which may include cleaning and conditioning to remove any impurities. This ensures the surface is ready for the perforation stage.

How Is the Perforation of Leatherette Achieved?

The perforation process is a critical step that involves creating small holes in the leatherette material. This is usually done through automated machines that employ laser or die-cutting technology.

- Laser Cutting: This technique offers precision, allowing manufacturers to create intricate patterns and hole sizes tailored to specific customer requirements.

- Die Cutting: This method is typically faster and is used for mass production, where uniformity in perforation is essential.

Both techniques enhance the material’s aesthetic appeal while improving its breathability, making it suitable for applications in automotive interiors, furniture, and fashion accessories.

What Finishing Techniques Are Commonly Used in Perforated Leatherette Production?

After perforation, the leatherette undergoes several finishing processes to enhance its appearance and functionality. This may include:

- Coating: A protective layer is applied to improve resistance to stains, UV rays, and abrasions. This is especially important for automotive applications, where exposure to sunlight and wear is common.

- Texturing: This step involves adding a textured finish to mimic the look and feel of genuine leather, thereby enhancing its market appeal.

- Quality Inspection: Before the final product is packaged, it undergoes a thorough inspection to ensure it meets the specified design and quality standards.

What Quality Assurance Measures Are Essential in the Production of Perforated Leatherette?

Quality assurance is paramount in the manufacturing of perforated leatherette, especially for B2B buyers who require reliable and consistent products.

Which International Standards Should B2B Buyers Look For?

When sourcing perforated leatherette, buyers should ensure that their suppliers adhere to international quality standards. Key certifications include:

- ISO 9001: This standard outlines the criteria for a quality management system and is vital for ensuring consistent quality in manufacturing processes.

- CE Marking: Particularly relevant for products sold in Europe, CE marking indicates compliance with safety, health, and environmental protection standards.

- API Certification: For applications in automotive or industrial sectors, API (American Petroleum Institute) certification can be a requirement, ensuring that materials meet specific performance standards.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is integrated at various stages of the manufacturing process to ensure that the final product meets the expected standards. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring during the production process helps identify any deviations from quality standards early on.

- Final Quality Control (FQC): This final inspection assesses the finished product for defects, ensuring it meets customer specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure their suppliers maintain robust quality control practices. Here are actionable strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. Buyers should consider:

- On-Site Audits: Visiting the manufacturing facility allows buyers to observe processes firsthand and evaluate adherence to quality standards.

- Document Review: Requesting quality manuals, inspection reports, and compliance certificates can provide insights into a supplier’s quality assurance practices.

How Important Are Third-Party Inspections?

Engaging third-party inspection services is crucial for buyers seeking impartial assessments. These services can conduct detailed evaluations of the manufacturing process, including material quality, production methods, and final product inspection.

What Testing Methods Are Commonly Used to Ensure Product Quality?

Quality testing methods play a vital role in verifying the performance and durability of perforated leatherette. Common testing methods include:

- Abrasion Resistance Testing: This assesses how well the material withstands wear and tear, a critical factor for automotive and furniture applications.

- Flexural Testing: This evaluates the material’s flexibility and resistance to cracking under stress.

- Colorfastness Testing: Ensuring that the color remains stable under various conditions is essential, especially for products exposed to sunlight.

How Do Regional Nuances Affect Quality Control and Certification for International B2B Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding regional nuances in quality control and certification is crucial.

Illustrative image related to perforated leatherette

Are There Specific Regulations for Different Markets?

- Europe: Compliance with CE marking is essential for products entering the European market. Buyers should ensure that suppliers have the necessary certifications to avoid compliance issues.

- Africa and South America: Buyers may encounter varying levels of regulatory scrutiny. It’s advisable to familiarize oneself with local regulations and standards to ensure compliance.

- Middle East: Quality assurance practices may differ; thus, buyers should ensure that suppliers understand and can meet local market expectations.

How Can Buyers Navigate Certification Requirements?

Navigating certification requirements can be complex. Buyers should:

- Engage with Local Experts: Collaborating with local compliance experts can provide insights into specific market requirements and help streamline the certification process.

- Establish Clear Communication: Maintaining open lines of communication with suppliers about certification needs can prevent delays and ensure compliance from the outset.

Conclusion

Understanding the manufacturing processes and quality assurance practices for perforated leatherette is essential for B2B buyers aiming to procure high-quality materials. By focusing on manufacturing stages, international standards, and robust quality control measures, buyers can make informed decisions that enhance their product offerings and satisfy market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘perforated leatherette’

The following guide serves as a comprehensive checklist for B2B buyers looking to source perforated leatherette. This material is increasingly popular for its versatility, durability, and aesthetic appeal, making it a prime choice in various industries, including automotive, furniture, and fashion. Here’s a structured approach to streamline your sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider the intended application of the perforated leatherette—whether for automotive seating, upholstery, or fashion accessories—and outline requirements such as thickness, perforation size, and pattern. This will help you communicate effectively with potential suppliers and ensure that the products meet your quality standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers in the perforated leatherette market. Look for suppliers with a strong reputation, verified customer reviews, and a history of delivering quality products. Utilize industry-specific directories, trade shows, and online marketplaces to gather a comprehensive list of potential partners.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with industry standards. Look for certifications related to quality management (such as ISO 9001) and environmental practices (like REACH compliance). These certifications not only indicate a commitment to quality but also ensure that the supplier adheres to necessary regulations, which is particularly important for international sourcing.

Step 4: Request Samples

Requesting samples is a critical step in evaluating the quality of perforated leatherette. Assess the texture, durability, and overall appearance of the material before making a bulk purchase. This hands-on approach allows you to determine if the product meets your specifications and helps prevent costly mistakes down the line.

Step 5: Negotiate Terms and Pricing

Once you have narrowed down your options, initiate negotiations on pricing, delivery terms, and payment conditions. It’s essential to have a clear understanding of the total cost, including shipping and import duties, particularly for international transactions. Aim for a mutually beneficial agreement that balances quality and cost-effectiveness.

Step 6: Establish a Communication Plan

Effective communication is key to a successful sourcing partnership. Establish a clear communication plan that outlines points of contact, response times, and preferred communication channels. This helps to ensure that any issues or queries are addressed promptly, fostering a more collaborative relationship.

Step 7: Finalize the Purchase Agreement

After finalizing terms, draft a comprehensive purchase agreement that includes all negotiated aspects, such as pricing, delivery timelines, and quality expectations. Ensure that both parties review and sign the agreement to formalize the transaction. This document serves as a reference point throughout the sourcing process and can help mitigate disputes.

Illustrative image related to perforated leatherette

By following this structured checklist, B2B buyers can enhance their sourcing strategy for perforated leatherette, ensuring that they acquire high-quality materials that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for perforated leatherette Sourcing

What Are the Key Cost Components for Sourcing Perforated Leatherette?

When sourcing perforated leatherette, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The type of leatherette used significantly impacts costs. High-quality materials may command higher prices but offer better durability and aesthetics. For instance, leatherette with UV protection or specific perforation patterns can elevate costs.

-

Labor: Labor costs vary based on the complexity of the manufacturing process. Skilled artisans may be required for custom perforation, which can increase labor expenses.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help keep these costs in check.

-

Tooling: Initial tooling costs for custom designs or perforation patterns can be significant. Buyers should consider these costs when determining the total cost of ownership.

-

Quality Control: Ensuring that the perforated leatherette meets quality standards incurs additional costs. Rigorous QC processes are essential for maintaining product integrity, especially for high-end applications.

-

Logistics: Shipping costs can vary based on the supplier’s location and the buyer’s destination. Factors such as freight charges, customs duties, and insurance should be factored into the final price.

-

Margin: Supplier margins can vary significantly. Understanding the market rate and negotiating effectively can help secure a more favorable deal.

How Do Price Influencers Affect Perforated Leatherette Costs?

Several factors influence the pricing of perforated leatherette, and understanding these can empower buyers to make informed decisions.

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger volumes typically lead to lower per-unit costs, making bulk purchasing an attractive option for businesses.

-

Specifications/Customization: Customized designs or specific performance specifications can increase costs. Standardized products are generally more economical, so buyers should weigh the benefits of customization against the additional costs.

-

Materials Quality/Certifications: Higher quality materials or those with specific certifications (e.g., eco-friendly or fire-resistant) can increase costs. Buyers should assess whether these attributes align with their needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their reliability and product quality.

-

Incoterms: Understanding international shipping terms (Incoterms) is essential. They define who is responsible for shipping, insurance, and tariffs, impacting overall costs.

What Are Effective Buyer Tips for Negotiating Prices?

B2B buyers should adopt strategic approaches when negotiating prices for perforated leatherette to ensure cost-efficiency and value.

-

Negotiate Early: Initiating negotiations early in the sourcing process can provide leverage. Suppliers may be more willing to offer discounts for larger or repeat orders.

-

Focus on Total Cost of Ownership (TCO): Buyers should evaluate the TCO, which includes purchase price, maintenance, and potential waste. A higher initial investment in quality materials can lead to lower long-term costs.

-

Research Market Prices: Understanding the market landscape helps buyers negotiate effectively. Familiarity with competitor pricing and supplier offerings can strengthen negotiation positions.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, local suppliers may offer better shipping rates and reduced lead times, affecting overall costs favorably.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of fluctuating currency exchange rates and tariffs, which can impact the final price. Staying informed about these factors can help avoid unexpected costs.

Conclusion

Sourcing perforated leatherette involves a multifaceted approach to understanding costs and pricing dynamics. By considering key cost components, recognizing price influencers, and employing effective negotiation strategies, B2B buyers can make informed purchasing decisions that align with their business objectives. Always remember to factor in the specific needs of your market and the unique challenges associated with international sourcing.

Illustrative image related to perforated leatherette

Alternatives Analysis: Comparing perforated leatherette With Other Solutions

Introduction to Alternative Solutions for Perforated Leatherette

In the quest for optimal materials in various applications, particularly in automotive and furniture upholstery, understanding the alternatives to perforated leatherette is essential for B2B buyers. Each alternative brings unique benefits and challenges, impacting performance, cost, and suitability for specific projects. This analysis compares perforated leatherette with synthetic leather and traditional perforated leather, providing insights that can guide informed purchasing decisions.

Comparison Table

| Comparison Aspect | Perforated Leatherette | Synthetic Leather | Traditional Perforated Leather |

|---|---|---|---|

| Performance | Durable, breathable, and easy to clean | Generally durable; breathability varies | High breathability, premium feel |

| Cost | Moderate ($60/yard) | Lower ($30-$50/yard) | Higher ($100-$200/yard) |

| Ease of Implementation | Simple to cut and sew | Easy to manipulate | Requires skilled craftsmanship |

| Wartung | Low maintenance, wipe clean | Low maintenance, wipe clean | Higher maintenance, requires conditioning |

| Best Use Case | Automotive interiors, furniture | Fashion accessories, upholstery | High-end automotive, luxury furniture |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Synthetic Leather?

Synthetic leather, often made from polyurethane or PVC, serves as a cost-effective alternative to perforated leatherette. Its lower price point makes it attractive for bulk purchases, especially for fashion accessories and general upholstery needs. However, while synthetic leather is typically easy to clean and maintain, it may lack the breathability found in perforated leatherette and traditional leather. This can result in discomfort in hotter climates, making it less suitable for applications requiring significant airflow.

How Does Traditional Perforated Leather Compare?

Traditional perforated leather offers a luxurious aesthetic and exceptional breathability, making it a preferred choice for high-end automotive interiors and upscale furniture. The premium feel and natural materials contribute to a sophisticated appearance that can enhance resale value. However, this option comes at a higher cost and may require more intensive maintenance, including regular conditioning to keep the leather supple. Additionally, sourcing quality perforated leather often involves longer lead times and specialized craftsmanship.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right material hinges on understanding the specific requirements of your project. For automotive applications where durability and ease of cleaning are paramount, perforated leatherette provides a balanced solution at a moderate cost. If budget constraints are critical, synthetic leather may serve well for less demanding environments. Conversely, for projects that demand luxury and high-end appeal, traditional perforated leather stands out despite its higher investment and maintenance needs. By evaluating these aspects carefully, B2B buyers can make strategic decisions that align with their operational needs and market positioning.

Essential Technical Properties and Trade Terminology for perforated leatherette

What Are the Key Technical Properties of Perforated Leatherette That B2B Buyers Should Know?

When considering perforated leatherette for your business needs, understanding its technical properties is crucial. Here are some key specifications that can significantly influence your purchasing decisions:

-

Material Grade

Perforated leatherette is typically classified by material grade, which indicates the quality and durability of the product. Higher-grade materials tend to offer better resistance to wear and tear, making them ideal for automotive and furniture applications. For B2B buyers, selecting the appropriate grade can affect product longevity and customer satisfaction. -

Thickness

The thickness of perforated leatherette can vary, usually measured in millimeters. A standard thickness range for automotive applications is between 1.0 mm and 1.5 mm. Thicker materials generally provide increased durability and comfort, while thinner options may offer more flexibility and a lighter weight. Understanding thickness is essential for ensuring the material meets the specific requirements of your project. -

Perforation Pattern and Size

The design and size of perforations are critical for both aesthetic appeal and functional performance. Common perforation sizes include small (1/4 inch) and micro (1/16 inch) patterns. The choice of pattern can influence breathability, texture, and overall style, which are important factors in product design for automotive interiors and high-end furniture. -

UV Resistance

UV resistance is a vital property for outdoor applications or environments exposed to sunlight. This characteristic helps prevent fading and degradation of the material over time. For B2B buyers in regions with intense sun exposure, selecting UV-resistant leatherette can ensure a longer-lasting and visually appealing product. -

Abrasion Resistance

Abrasion resistance measures how well the material can withstand surface wear from friction. This property is particularly important for automotive and furniture applications where high traffic is expected. A higher abrasion resistance rating indicates that the leatherette will maintain its appearance and functionality over time, which is crucial for customer retention. -

Ease of Maintenance

The ease of cleaning and maintaining perforated leatherette is another important consideration. Many products offer stain resistance and can be cleaned with simple soap and water. For B2B buyers, low-maintenance materials can save time and reduce long-term operational costs.

What Are the Common Trade Terms Associated with Perforated Leatherette?

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are some essential trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end products. Understanding OEM relationships is vital for buyers looking to source perforated leatherette for manufacturing purposes, as it can affect quality and supply chain dynamics. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, especially for businesses looking to maintain optimal stock levels without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This term is crucial for B2B buyers as it initiates the procurement process and helps in comparing prices and terms from different suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms is essential for B2B transactions, as they clarify shipping responsibilities, risk transfer, and costs involved in cross-border purchases. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for B2B buyers in managing inventory and ensuring timely delivery to customers. -

Customs Duties and Tariffs

These are taxes imposed on imported goods. For international B2B buyers, being aware of potential customs duties and tariffs on perforated leatherette can impact pricing strategies and overall project budgeting.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing perforated leatherette for your business needs. This knowledge not only enhances procurement efficiency but also contributes to better product quality and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the perforated leatherette Sector

Market Overview & Key Trends

The perforated leatherette sector is witnessing robust growth, driven by increasing demand in automotive, furniture, and fashion industries. Key global drivers include the surge in vehicle production, particularly in emerging markets like Nigeria and Brazil, where automotive customization is gaining traction. B2B buyers are leveraging advanced technologies such as 3D printing and digital design tools to create personalized perforated leatherette products, enhancing their market appeal.

Current trends indicate a shift towards multifunctional materials that not only offer aesthetic value but also enhance comfort through breathability and reduced sweating. For instance, perforated leatherette is increasingly being used in high-end automotive interiors, providing both luxury and practicality by improving seat ventilation and reducing moisture retention. Additionally, the rise of e-commerce platforms is facilitating easier access to a diverse range of suppliers, allowing international buyers to source materials more efficiently.

Illustrative image related to perforated leatherette

In Europe, particularly Germany, there is a growing preference for high-quality perforated leatherette that meets stringent regulatory standards, emphasizing durability and safety. Moreover, the Middle East is seeing a trend towards customization, as consumers seek unique designs that reflect their personal style. Overall, B2B buyers must stay attuned to these dynamics to capitalize on opportunities within the evolving perforated leatherette landscape.

Sustainability & Ethical Sourcing in B2B

As global awareness of environmental issues rises, sustainability has become a pivotal concern for B2B buyers in the perforated leatherette sector. The production process often involves synthetic materials, which can have significant environmental impacts if not sourced responsibly. Ethical sourcing practices are essential not only for compliance with regulations but also for enhancing brand reputation among increasingly eco-conscious consumers.

B2B buyers should prioritize suppliers who demonstrate commitment to sustainability through certifications such as OEKO-TEX and GRS (Global Recycled Standard). These certifications indicate that materials have been tested for harmful substances and that sustainable practices were employed during production. Additionally, sourcing from manufacturers that use water-based adhesives and eco-friendly dyes can further reduce the environmental footprint of perforated leatherette products.

Incorporating sustainability into sourcing strategies can also lead to cost savings in the long term, as companies that invest in eco-friendly materials may benefit from reduced waste and energy consumption. Furthermore, demonstrating a commitment to ethical sourcing can enhance customer loyalty and attract new clients who prioritize environmental stewardship in their purchasing decisions.

Illustrative image related to perforated leatherette

Brief Evolution/History

The evolution of perforated leatherette can be traced back to the automotive industry’s need for more breathable and comfortable materials for vehicle interiors. Initially, traditional leather was the primary choice for upholstery; however, the emergence of synthetic alternatives in the late 20th century revolutionized the market. Perforated leatherette gained popularity due to its ability to combine the aesthetic appeal of leather with enhanced functionality, such as improved ventilation and reduced weight.

Today, the material is widely used across various sectors, including fashion and furniture, reflecting changing consumer preferences for both style and practicality. As technology continues to advance, the perforated leatherette landscape is expected to evolve further, offering even more innovative solutions for B2B buyers seeking high-quality and sustainable materials.

Frequently Asked Questions (FAQs) for B2B Buyers of perforated leatherette

-

How do I choose the right perforated leatherette for my project?

Selecting the right perforated leatherette involves considering several factors such as thickness, perforation size, and intended application. Evaluate the environment where the material will be used—automotive, furniture, or fashion—and consider durability and maintenance requirements. Request samples to assess texture and appearance. Additionally, consult with suppliers about customization options to ensure the product meets your specific design needs. -

What are the benefits of using perforated leatherette over traditional materials?

Perforated leatherette offers several advantages, including enhanced breathability, which helps reduce sweating and improve comfort in hot climates. Its perforated design also contributes to better sound absorption, making it ideal for automotive interiors. Additionally, this material is often more durable and easier to maintain than traditional leather, providing a stylish yet practical solution for various applications. -

What minimum order quantities (MOQs) should I expect when sourcing perforated leatherette?

MOQs for perforated leatherette can vary significantly between suppliers, often ranging from 10 to 100 yards, depending on the manufacturer’s production capabilities and your specific needs. Larger orders may qualify for discounts, so it’s advisable to communicate your project requirements early. Always confirm MOQs and pricing details before placing an order to avoid unexpected costs. -

How can I vet suppliers for perforated leatherette?

To effectively vet suppliers, start by researching their reputation through online reviews and industry references. Evaluate their certifications and compliance with international quality standards. Request samples to assess product quality firsthand and inquire about their production capabilities, lead times, and customer support. Establishing clear communication can also help gauge their responsiveness and willingness to meet your specific needs. -

What payment terms are typically offered for international B2B purchases of perforated leatherette?

Payment terms for international B2B purchases can vary by supplier, but common options include upfront payments, partial deposits, or payment upon delivery. Many suppliers may also accept letters of credit or escrow services to ensure security for both parties. Always negotiate terms that align with your financial capabilities and ensure they are documented in the purchase agreement to avoid misunderstandings. -

What quality assurance measures should I expect from suppliers of perforated leatherette?

Reputable suppliers should implement rigorous quality assurance processes, including material inspections, testing for durability, and compliance with relevant industry standards. Request information about their quality control procedures and any certifications they hold. Some suppliers may also offer a warranty or guarantee on their products, providing additional assurance regarding the quality and longevity of the perforated leatherette. -

What shipping options are available for sourcing perforated leatherette internationally?

International shipping options for perforated leatherette typically include air freight for faster delivery and sea freight for cost-effectiveness on larger orders. Discuss shipping methods with your supplier to determine the best option based on your timeline and budget. Be sure to account for customs duties and import regulations in your country, which can impact delivery times and overall costs. -

How do I handle potential issues with perforated leatherette after purchase?

If you encounter issues with perforated leatherette, such as defects or discrepancies from the order, promptly contact your supplier to discuss the problem. Most reputable suppliers will have a return or exchange policy in place. Document any issues with photos and maintain clear communication to facilitate resolution. Understanding your supplier’s policies beforehand can help streamline this process.

Top 8 Perforated Leatherette Manufacturers & Suppliers List

1. Leather Hide Store – Perforated Leather for Automotive Use

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Perforated Leather for automotive use, available for cars and trucks. Ordering steps include selecting leather, determining quantity, and calling to place an order. Leather for perforating is shipped directly for perforation (half or whole hides). Perforation patterns include Chrysler & GM Standard, Ford Standard / GM Small, Euro Tri Star, Ford Mini, and Micro Perforation. Price is $3.00/sq ft for…

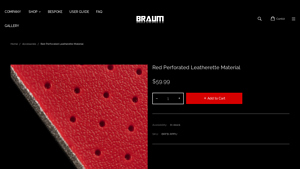

2. BRAUM – Red Perforated Leatherette Material

Domain: braumracing.com

Registered: 2014 (11 years)

Introduction: {“name”: “BRAUM Red Perforated Leatherette Material”, “price”: “$59.99”, “availability”: “In stock”, “SKU”: “BRFB-RPPU”, “description”: “Our BRAUM perforated leatherette material is durable, scratch resistant and very easy to maintain.”, “dimensions”: “Width 56””, “pricing_per_yard”: “Qty 1 = 36″ x 56″”, “note”: “REFUNDS NOT AVAILABLE FOR RAW MATERIAL ORDERS!”, “free_swatch_sample”: “upon request…

3. Keystone Bros – Perforated Automotive Leather

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Perforated Leather – Automotive Leather – Available products include Caprice MB-4 Perf Leather, Caprice Perf S-2000 Leather, Corinthian MB-4 Perf Leather, Corinthian S-2000 Perf Leather, Honda MB-4 Perf Leather, Honda S-2000 Perf Leather, Longitude MB-4 Perf Leather, Longitude S-2000 Perf Leather, Milled Pebble MB-4 Perf Leather, Milled Pebble S-2000 Perf Leather, Monaco MB-4 Perf Leather, Monaco …

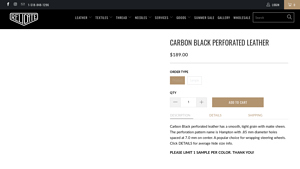

4. Relicate – Carbon Black Perforated Leather

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: {“name”: “Carbon Black Perforated Leather”, “price”: “$189.00”, “description”: “Carbon Black perforated leather has a smooth, tight grain with matte sheen. The perforation pattern name is Hampton with .85 mm diameter holes spaced at 7.0 mm on center. A popular choice for wrapping steering wheels.”, “sheen”: “Flat”, “thickness”: “1.0 – 1.2 mm”, “perf_spacing”: “7.0 mm”, “origin”: “European”, “uv_pr…

5. IPS Perforating – Perforated Automotive Leather

Domain: ipsperforating.com

Registered: 2013 (12 years)

Introduction: Perforated automotive leather features small, evenly spaced holes for decorative and functional purposes. Key benefits include: 1. Less Slippery: Provides traction to prevent slipping. 2. Less Sweating: More breathable than smooth leather, reducing perspiration in hot climates. 3. Absorbs Sound: Helps keep the car interior quieter by reducing road noise. 4. High-End Appearance: Available in variou…

6. Coast to Coast Leather – Premium Perforated Leather

Domain: coast2coastleather.com

Registered: 2007 (18 years)

Introduction: Perforated leather is a unique type of leather upholstery featuring small, precise holes that enhance ventilation and comfort, making it popular for automotive interiors, furniture, and fashion accessories. Coast to Coast Leather specializes in premium perforated leather services, offering expert craftsmanship, customization options, and unmatched quality. The types of leather perforations availab…

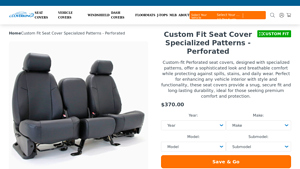

7. Coverking – Custom Fit Seat Covers

Domain: coverking.com

Introduction: Custom Fit Seat Cover Specialized Patterns – Perforated Seat Covers

– Custom Seat Covers

– Select Your Vehicle

– Durable Polycotton: From $215.00, durable, soft, washable; better fit, more comfort.

– Ballistic: From $220.00, durable, custom-fit, waterproof protection.

– Molded: From $300.00, breathable 3D warp-knitted polyester.

– Rhinohide: From $350.00, ultra-durable, waterproof vinyl; foam-back…

8. LeatherNeo – Perforated Leather Solutions

Domain: leatherneo.com

Registered: 2020 (5 years)

Introduction: Perforated leather is a unique type of leather that undergoes a stamping process to create small holes or perforations on its surface. It is popular in the fashion and automotive industries for its ventilation and breathability, enhancing comfort by improving air circulation and reducing sweating. Common uses include clothing, shoes, bags, and car interiors. In vehicles, perforated leather is ofte…

Strategic Sourcing Conclusion and Outlook for perforated leatherette

In conclusion, the strategic sourcing of perforated leatherette presents significant opportunities for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. This material not only enhances the aesthetic appeal of products but also offers practical benefits such as improved breathability, durability, and ease of maintenance. By aligning sourcing strategies with reliable suppliers who prioritize quality and customization, businesses can cater to the growing demand for perforated leatherette in automotive, fashion, and furniture industries.

Moreover, leveraging the unique attributes of perforated leatherette can elevate product offerings and enhance customer satisfaction, ultimately leading to increased competitiveness in the market. As manufacturers and designers increasingly adopt this versatile material, the importance of strategic sourcing cannot be overstated.

Illustrative image related to perforated leatherette

Looking ahead, international buyers should actively seek partnerships with reputable suppliers who can provide high-quality perforated leatherette solutions tailored to their specific needs. Embracing this trend will not only fortify your product lines but also position your business as a leader in innovation and quality. Take the next step in your sourcing strategy today and explore the potential of perforated leatherette to transform your offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to perforated leatherette

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.