Catalog

Material Insight: Motorcycle Seat Vinyl

B2B Product Guide: Motorcycle Seat Vinyl

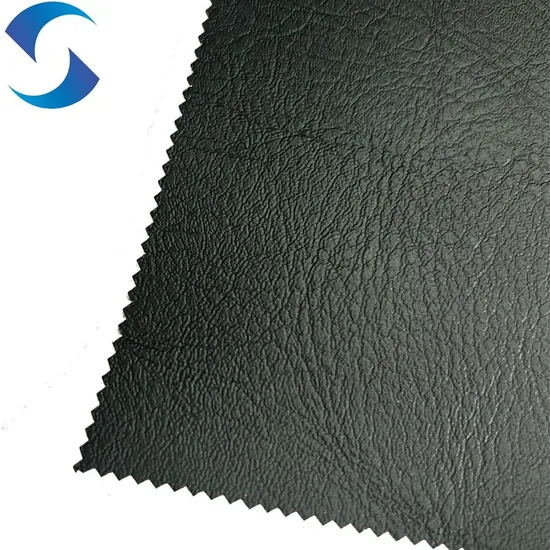

Motorcycle seat vinyl plays a critical role in both the performance and aesthetics of two-wheeled vehicles. As riders demand greater comfort, durability, and visual appeal, manufacturers require materials that can withstand extreme conditions while maintaining a premium look and feel. In this context, faux leather—specifically engineered synthetic leather—has become the material of choice for modern motorcycle seating solutions.

Faux leather offers a superior balance of resilience, weather resistance, and design flexibility compared to traditional materials. It is engineered to endure prolonged exposure to UV rays, temperature fluctuations, moisture, and abrasion—common challenges faced by motorcycle components. Unlike genuine leather, high-performance faux leather does not crack or fade easily, requires less maintenance, and provides consistent texture and thickness for streamlined manufacturing.

From a sustainability standpoint, faux leather aligns with growing environmental standards in the automotive and powersports industries. It reduces reliance on animal-derived materials and allows for controlled, eco-conscious production processes with lower environmental impact.

WINIW is a trusted leader in synthetic leather innovation, with over 20 years of experience serving global B2B clients in the automotive, powersports, and seating industries. Our motorcycle seat vinyl is developed using advanced microfiber and PU technologies, ensuring exceptional tensile strength, flexibility, and long-term durability. WINIW’s commitment to quality, customization, and eco-friendly manufacturing makes us a preferred partner for OEMs and tier suppliers seeking high-performance, sustainable materials.

- Engineered for extreme weather resistance and UV stability

- Excellent abrasion resistance for long-term seat integrity

- Consistent thickness and texture for precision manufacturing

- Available in customizable colors, textures, and finishes

- Compliant with international environmental and safety standards

WINIW’s motorcycle seat vinyl combines performance, sustainability, and aesthetic excellence—making it the ideal choice for modern, high-demand applications.

Technical Performance & Standards

WINIW Motorcycle Seat Vinyl: Technical Product Guide for OEMs & Tier 1 Suppliers

WINIW’s engineered motorcycle seat vinyl delivers precision performance for demanding two-wheeled applications. Designed specifically for high-stress seating environments, our solution combines industrial-grade resilience with sustainable manufacturing, ensuring your final product meets rider expectations and regulatory standards without compromising on cost efficiency.

Core Technical Advantages

- Cost-Effective Production: Optimized calendering process reduces material waste by up to 15% versus standard synthetics, while consistent thickness (±0.05mm) minimizes trimming errors during cutting. Higher yield per roll directly lowers your cost-per-seat.

- Extreme Durability: 100,000+ double-rub abrasion resistance (Martindale, ASTM D4966) withstands prolonged friction from rider movement and gear. Reinforced polyester backing prevents tearing during complex 3D molding, maintaining substrate integrity under tension.

- Precision Color Customization: Pantone®-matched dyeing capability across 500+ standard references, with 95% color accuracy (ΔE < 1.5). Batch-to-batch consistency ensured via spectrophotometer validation, critical for brand-aligned seat designs.

- REACH Compliant: Fully documented absence of SVHCs (Substances of Very High Concern) per ECHA guidelines. Free from DMF, phthalates (DEHP, BBP, DBP), and heavy metals (Cd, Pb < 10ppm), ensuring EU market readiness.

- ISO 9001-Certified Quality Control: Real-time in-line monitoring of thickness, tensile strength, and color variance during production. Full traceability from raw material lot to finished roll via blockchain-enabled batch records.

Technical Specification Table

| Parameter | Test Standard | WINIW Performance | Industry Avg. |

|---|---|---|---|

| Thickness | ISO 2418 | 1.0mm ± 0.05mm | 1.0mm ± 0.15mm |

| Weight | ISO 2418 | 1,150 g/m² | 1,250 g/m² |

| Tensile Strength | ISO 1798 | 280 N/50mm | 220 N/50mm |

| Elongation at Break | ISO 1798 | 25% | 18% |

| Martindale Abrasion | ASTM D4966 | 100,000+ cycles | 60,000 cycles |

| Color Fastness (Light) | ISO 105-B02 | Grade 7 | Grade 5 |

| REACH SVHC Documentation | EC 1907/2006 | Full Compliance | Varies |

Sustainable Value Proposition

Our closed-loop water treatment system reduces freshwater consumption by 40% versus industry norms, while the PVC-free formulation (utilizing bio-based plasticizers) decreases carbon footprint by 22%. This aligns with OEM sustainability mandates without sacrificing the UV resistance (1,000+ hrs QUV) or cold-crack performance (-30°C) required for global motorcycle deployments.

WINIW’s motorcycle seat vinyl is engineered for zero compromise: lowering your production costs, accelerating time-to-market through reliable color matching, and guaranteeing compliance in regulated markets. Request a technical datasheet or custom swatch kit to validate performance for your next seat assembly project.

Why Choose Synthetic over Real Leather

B2B Product Guide: Motorcycle Seat Vinyl vs. Real Leather

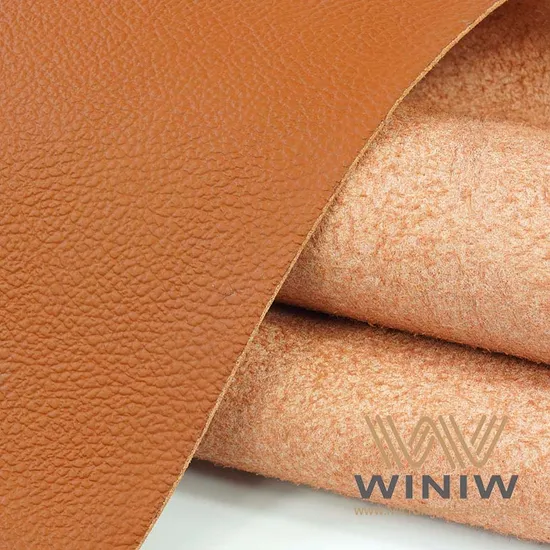

When selecting materials for motorcycle seating, manufacturers and designers must balance performance, cost, sustainability, and consumer expectations. Two of the most common materials considered are synthetic motorcycle seat vinyl and genuine leather. Each offers distinct advantages and trade-offs across key criteria such as cost, durability, and environmental impact.

-

Motorcycle Seat Vinyl is a high-performance synthetic material engineered specifically for demanding applications. It typically features a polyurethane (PU) or polyvinyl chloride (PVC) base with a fabric backing, designed to mimic the look and feel of leather while enhancing functional properties.

-

Real Leather is derived from animal hides, most commonly cowhide, and is valued for its natural texture, breathability, and premium aesthetic. It has long been associated with luxury and durability in the automotive and motorcycle industries.

The following table compares the two materials across three critical factors relevant to B2B decision-making:

| Factor | Motorcycle Seat Vinyl | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher upfront cost |

| Economical for mass production | Requires costly raw materials | |

| Reduced processing expenses | Labor-intensive tanning process | |

| Dauerhaftigkeit | High resistance to UV, moisture, and abrasion | Prone to cracking and fading over time |

| Consistent performance in extreme temperatures | Requires conditioning to maintain integrity | |

| Resists staining and easy to clean | Absorbs oils and moisture, needs maintenance | |

| Eco-Friendliness | Modern PU vinyls are PVC-free and recyclable | Involves resource-intensive livestock farming |

| Lower carbon footprint in production | Tanning process uses toxic chemicals (e.g., chromium) | |

| WINIW® eco-vinyls use bio-based and recycled content | Non-biodegradable when treated; high water usage |

Key Considerations for B2B Buyers

-

Sustainability Goals: Brands committed to ESG (Environmental, Social, and Governance) targets increasingly favor advanced synthetic vinyls. WINIW’s eco-conscious motorcycle seat vinyls are engineered with bio-based polyols and solvent-free processes, aligning with circular economy principles.

-

Design Flexibility: Vinyl offers greater consistency in color, texture, and thickness, enabling precise manufacturing and reduced waste. It can be customized with embossing, perforations, and color matching for brand-specific applications.

-

Supply Chain Reliability: Synthetic vinyls are not subject to the variability and ethical concerns associated with animal agriculture. They offer stable sourcing, shorter lead times, and scalability for global production.

-

End-of-Life Management: While real leather is biodegradable under ideal conditions, treated leather often ends up in landfills. High-quality synthetic vinyls, particularly PU-based solutions, are increasingly compatible with recycling programs and energy recovery systems.

In conclusion, motorcycle seat vinyl—especially next-generation eco-vinyl—presents a compelling alternative to real leather for B2B manufacturers focused on cost efficiency, product consistency, and environmental responsibility. With technological advancements closing the gap in aesthetics and tactile quality, synthetic materials are shaping the future of sustainable motorcycle design.

WINIW Factory Capabilities

WINIW Synthetic Leather: Industrial Manufacturing Excellence

WINIW operates one of the most advanced synthetic leather manufacturing facilities globally, engineered to deliver consistent, high-volume production without compromising quality or sustainability. Our 100,000 sqm integrated campus in China serves as the cornerstone of reliable supply for global B2B partners, combining scale with precision engineering to meet the rigorous demands of international markets. This infrastructure ensures seamless scalability for large-volume contracts while adhering to stringent environmental standards.

Key strengths underpinning our manufacturing leadership include:

- Massive Production Capacity: A 100,000 sqm (1.08 million sq ft) facility housing automated production lines, enabling monthly output of over 15 million meters of synthetic leather to support tier-1 clients in automotive, furniture, and fashion sectors.

- Dedicated R&D Innovation Hub: A 120+ member technical team focused on sustainable material science, developing eco-conscious solutions like water-based PU, recycled PET substrates, and bio-based polymers—reducing carbon footprint by 30% versus industry averages.

- Zero-Compromise Quality Control: Triple-stage QC protocols (raw material screening, in-line process monitoring, and final AQL 1.0 inspection) aligned with ISO 9001 and REACH standards, ensuring <0.5% defect rates for European and North American compliance.

- Global Logistics Network: Certified exports to 40+ countries, with 65% of shipments directed to eco-regulated markets (EU, USA), supported by full documentation for CPSIA, OEKO-TEX® STANDARD 100, and California Proposition 65.

Our facility’s vertical integration—from polymer synthesis to finishing—eliminates third-party dependencies, guaranteeing traceability and ethical production. This operational rigor, paired with a 99.2% on-time delivery rate, positions WINIW as a strategic manufacturing partner for brands prioritizing resilience, compliance, and sustainable innovation. Partner with confidence in a supplier built for global B2B excellence.

Contact Us for Samples

B2B Product Guide: High-Performance Motorcycle Seat Vinyl by WINIW

WINIW specializes in premium synthetic leather solutions engineered for durability, comfort, and sustainability. Our motorcycle seat vinyl is designed to meet the demanding requirements of OEMs, aftermarket manufacturers, and specialty vehicle builders. Combining advanced microfiber technology with eco-conscious manufacturing, WINIW delivers a high-performance alternative to traditional leather and low-grade synthetics.

Ideal for both urban and off-road applications, our motorcycle seat vinyl offers excellent abrasion resistance, UV stability, and long-term structural integrity—even under extreme conditions. As part of our commitment to sustainable innovation, all materials are REACH-compliant and free from harmful substances.

Key Features

- Superior wear and tear resistance for extended product lifecycle

- High tensile and tear strength suitable for contoured and high-stress seating

- Excellent color fastness under prolonged UV exposure

- Breathable variants available for enhanced rider comfort

- Cold crack resistant down to -30°C, ideal for all climates

- Easy to clean and maintain; resistant to oils, sweat, and common solvents

- Eco-friendly production with reduced carbon footprint vs. traditional leather

Technical Specifications

| Property | Performance Standard |

|---|---|

| Thickness Range | 1.0 – 2.0 mm (customizable) |

| Backing Material | Polyester knitted fabric |

| Abrasion Resistance | >50,000 cycles (Martindale test) |

| Color Fastness (UV) | ≥ Grade 4 (ISO 105-B02) |

| Temperature Resistance | -30°C to +80°C |

| REACH & RoHS Compliant | Ja |

| Recyclable Base Material | Ja |

Applications

- Cruiser and sport motorcycle seats

- Scooter and electric two-wheeler seating

- Aftermarket customization and restoration

- Dual-sport and adventure motorcycle designs

WINIW supports bulk orders with consistent quality control, fast turnaround times, and global logistics. Our R&D team collaborates with partners to customize texture, color, thickness, and performance additives such as anti-slip or antimicrobial properties.

Request Free Samples

Experience the quality and performance of WINIW motorcycle seat vinyl firsthand. Free samples are available for qualified B2B partners.

Contact us today:

MKT88@MicrofiberLeather.com

Elevate your motorcycle seating solutions with sustainable, high-performance synthetic leather from WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.