Catalog

Material Insight: Marine Vinyl Fabric Com

Marine Vinyl Fabric: Premium Synthetic Leather Solutions for Demanding Nautical Environments

The marine environment presents exceptional challenges: relentless UV exposure, constant saltwater contact, extreme temperature fluctuations, and heavy abrasion. Traditional materials like genuine leather quickly degrade under these conditions, leading to cracking, fading, mold growth, and costly replacements. Faux leather (synthetic marine vinyl) has emerged as the superior, purpose-engineered solution for marine upholstery, seating, decking, and interior applications. Its inherent properties deliver unmatched performance where natural materials fail.

Why Synthetic Leather is the Optimal Marine Choice:

– Superior resistance to UV degradation, preventing fading and surface hardening even after years of sun exposure

– Complete waterproof and non-porous structure, eliminating saltwater absorption, corrosion risks, and mold/mildew retention

– Exceptional abrasion and tear strength withstands constant use, foot traffic, and harsh cleaning protocols

– Easy maintenance with simple soap-and-water cleaning; no conditioning required unlike natural leather

– Consistent performance across extreme temperatures (-30°C to +70°C) without stiffening or softening

– Eco-conscious formulations available with PVC-free chemistry, recycled content, and low-VOC emissions

WINIW: Your Trusted Marine Synthetic Leather Partner

With over 20 years of specialized expertise in high-performance synthetic materials, WINIW has pioneered advanced marine vinyl technologies trusted by leading boat manufacturers, yacht refit specialists, and marine upholstery suppliers worldwide. We combine deep technical knowledge of nautical demands with an unwavering commitment to sustainable innovation. Our R&D focuses on creating marine-grade faux leather that exceeds ISO 105-B02 (lightfastness) and ASTM D412 (tensile strength) standards while reducing environmental impact. When you specify WINIW Marine Vinyl, you gain a partner dedicated to delivering durability, compliance, and eco-responsible performance – ensuring your vessels maintain premium aesthetics and operational resilience season after season.

Technical Performance & Standards

WINIW Marine Vinyl Fabric: B2B Product Technical Guide

WINIW Marine Vinyl Fabric is engineered for commercial and industrial applications requiring high performance in demanding marine and outdoor environments. Designed with a focus on durability, cost-efficiency, and regulatory compliance, our marine-grade vinyl fabric delivers long-term value for manufacturers, marine outfitters, and outdoor furniture producers.

The fabric is constructed using high-tenacity polyester yarns as a base scrim, coated with specially formulated PVC to resist water, UV radiation, mildew, and abrasion. This robust construction ensures extended service life, even under continuous exposure to saltwater, intense sunlight, and fluctuating temperatures.

Key Technical Advantages

-

Cost-Effective Performance

WINIW Marine Vinyl offers a superior price-to-performance ratio by minimizing maintenance, replacement, and downtime costs. Its extended lifespan reduces total cost of ownership in commercial marine applications such as boat covers, seating, decking, and enclosures. -

Exceptional Durability

The fabric exhibits high tensile and tear strength, with reinforced scrim layers providing resistance to punctures and mechanical stress. It maintains structural integrity after prolonged exposure to harsh weather conditions, including UV, rain, and temperature extremes from -30°C to +70°C. -

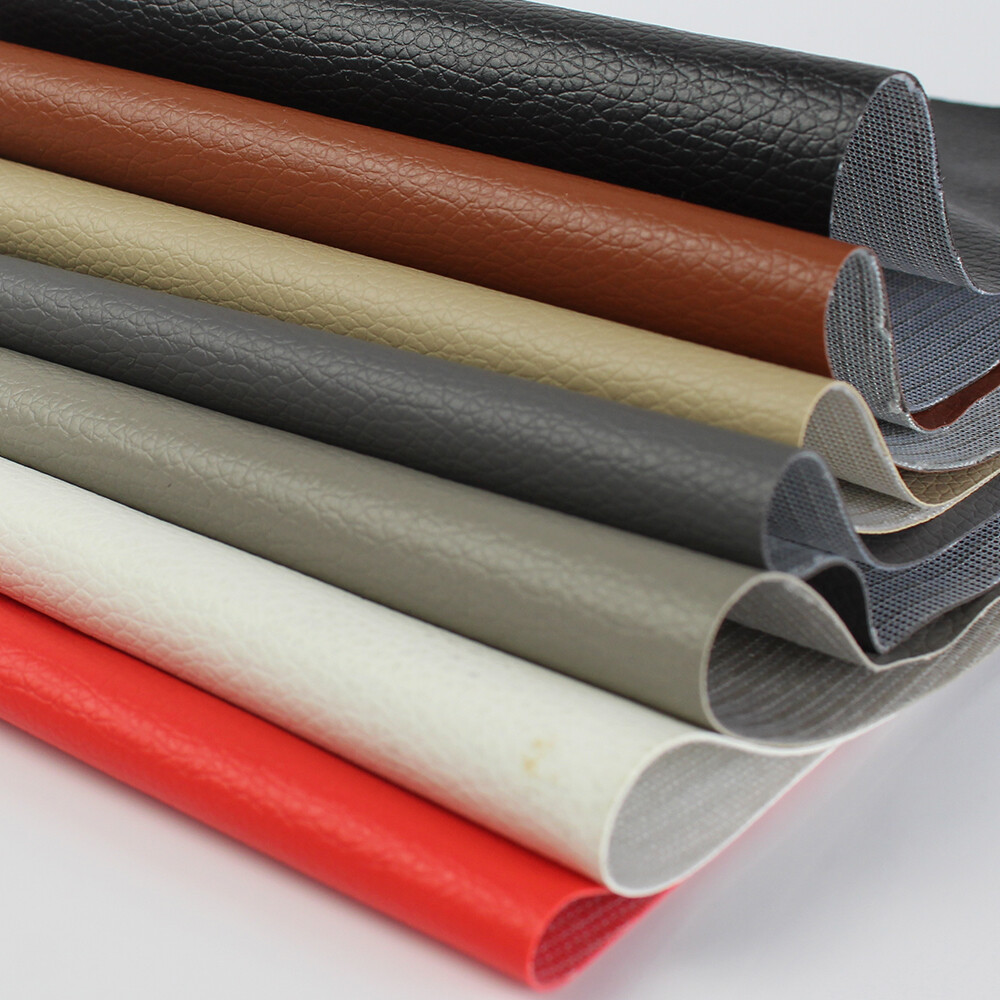

Customizable Color Options

WINIW offers full color customization to meet brand-specific or design requirements. Our pigmentation process ensures consistent dye dispersion and superior colorfastness (rated up to 1,000+ hours in QUV testing), minimizing fading over time. -

REACH Compliant

All formulations comply with EU REACH regulations (EC 1907/2006), ensuring the absence of restricted hazardous substances. This certification supports environmentally responsible manufacturing and facilitates market access across Europe and regulated regions. -

ISO 9001 Certified Production

Manufactured under an ISO 9001-certified quality management system, WINIW ensures consistent product quality, traceability, and process control across all production batches. This certification reflects our commitment to reliability and continuous improvement.

Technical Specifications

| Property | Spezifikation |

|---|---|

| Base Material | High-tenacity polyester scrim (1000D) |

| Coating | PVC with UV stabilizers and anti-fungal agents |

| Weight | 600 – 900 g/m² (customizable) |

| Thickness | 0.45 – 0.75 mm |

| Tensile Strength (warp) | ≥ 2,200 N/5cm |

| Tensile Strength (weft) | ≥ 1,800 N/5cm |

| Tear Strength (Elmendorf) | ≥ 120 N (warp & weft) |

| Colorfastness to UV (1000h) | Grade 7–8 (ISO 105-B02) |

| Temperature Range | -30°C to +70°C |

| Water Resistance | > 2,000 mm H₂O (hydrostatic head) |

| REACH Status | Compliant (SVHC-free) |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Width: 1.3m – 2.0m; Color: RAL/Pantone match |

WINIW Marine Vinyl Fabric is ideal for B2B clients seeking a reliable, compliant, and scalable material solution for marine upholstery, awnings, inflatable boats, and transportation interiors. With in-house R&D and flexible production capacity, WINIW supports bulk orders with fast turnaround and consistent quality assurance.

Why Choose Synthetic over Real Leather

B2B Product Guide: Marine-Grade Synthetic Leather vs. Real Leather for Marine Applications

Selecting the optimal upholstery material for marine environments requires rigorous evaluation of performance, lifecycle costs, and sustainability. Many businesses encounter generic terms like “marine vinyl fabric com,” which typically refers to low-cost PVC-based vinyls. At WINIW, we specialize in high-performance, eco-conscious synthetic leather engineered specifically for demanding marine use. Below, we objectively compare standard PVC “marine vinyl” (commonly marketed under such terms) against genuine leather, highlighting critical factors for commercial marine outfitters, yacht builders, and marine furniture manufacturers.

Key Differentiators: PVC “Marine Vinyl” vs. Real Leather

While both materials are used in marine settings, they present significant operational and sustainability challenges:

- PVC “Marine Vinyl” (e.g., products under “marine vinyl fabric com”):

- Typically contains phthalates and heavy metal stabilizers, posing environmental and health risks during production and disposal.

- Prone to UV degradation, leading to cracking, fading, and loss of flexibility within 2–3 years in direct sun exposure.

- Non-breathable structure traps moisture, accelerating mold/mildew growth in humid marine environments.

- Limited repairability; damaged sections often require full replacement.

-

Low upfront cost but high long-term replacement frequency increases total cost of ownership (TCO).

-

Real Leather:

- Naturally porous but requires intensive chemical treatments (chromium tanning) to resist water, compromising biodegradability.

- Susceptible to saltwater corrosion, staining, and permanent deformation when wet; demands constant conditioning.

- High maintenance costs: regular cleaning, conditioning, and professional repairs are mandatory to prevent deterioration.

- Ethical and ecological concerns regarding resource intensity (land, water, feed) and tannery pollution.

- Premium initial cost, but unpredictable lifespan in marine settings often results in premature replacement.

Comparative Analysis: Critical Metrics for Marine Use

The table below quantifies core performance and sustainability variables:

| Metric | PVC “Marine Vinyl” (Generic) | Real Leather | WINIW Marine-Grade Synthetic Leather |

|---|---|---|---|

| Cost (TCO Focus) | Low initial cost ($8–$12/yd²) but high replacement frequency (2–3 yr lifespan). TCO over 10 years: ★★☆☆☆ (High) | Very high initial cost ($30–$50+/yd²) + ongoing maintenance. Unpredictable lifespan in marine use. TCO over 10 years: ★★★☆☆ (Moderate-High) | Competitive initial cost ($18–$25/yd²) + minimal maintenance + 5–7+ yr lifespan. TCO over 10 years: ★★★★★ (Lowest) |

| Dauerhaftigkeit | Poor UV resistance (cracks/fades in <500 hrs); low abrasion resistance; fails saltwater immersion tests. | Moderate UV resistance but degrades rapidly with salt/moisture; requires constant care to prevent hardening/cracking. | Excellent UV resistance (>2,000 hrs per ISO 4892); superior saltwater/mold resistance; high abrasion strength (Martindale >50,000 cycles). |

| Eco-Friendliness | High environmental burden: chlorine-based production, phthalates, non-recyclable, releases dioxins when incinerated. ★★☆☆☆ | High water/land use; toxic chromium tanning effluents; slow biodegradation only if untreated (rare). ★★★☆☆ | PVC-free; water-based PU production; 30%+ recycled content; OEKO-TEX® certified; fully recyclable via closed-loop systems. ★★★★★ |

Why WINIW Synthetic Leather Outperforms in Marine Environments

WINIW’s engineered marine-grade synthetics address the critical gaps in both generic PVC vinyl and real leather:

- Engineered for Resilience: Our proprietary PU matrix resists UV, salt spray, and mold without plasticizers, ensuring dimensional stability and colorfastness for 5+ years.

- True Sustainability: Eliminating PVC and phthalates reduces marine ecosystem toxicity. Our closed-loop manufacturing cuts water use by 70% versus leather tanning.

- Operational Efficiency: 60% lower maintenance vs. leather; easily cleaned with mild soap, no conditioning required. Repairable with standard marine adhesives.

- Compliance Ready: Meets IMO A.652(16) flammability standards and REACH/EPA regulations—critical for commercial vessel certification.

For marine industry partners prioritizing durability, lifecycle economics, and environmental stewardship, WINIW synthetic leather delivers a future-proof alternative. Request our technical datasheet for ISO test reports, marine application case studies, and TCO modeling specific to your production volume.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong commitment to sustainability and quality, WINIW serves industries ranging from automotive and furniture to fashion and sports.

The company operates from a state-of-the-art manufacturing facility spanning 100,000 square meters, one of the largest in the synthetic leather industry. This expansive production base enables high-volume output while maintaining precision, consistency, and operational efficiency to meet the demands of international markets.

Key strengths of WINIW’s factory include:

- Advanced production lines integrated with automation and green manufacturing technologies to reduce environmental impact.

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and sustainable development.

- Strict quality control (QC) protocols implemented at every stage—from raw material selection to final product inspection—ensuring compliance with international standards such as REACH, RoHS, and OEKO-TEX®.

- In-house testing laboratory capable of conducting abrasion resistance, colorfastness, tensile strength, and eco-compliance tests to guarantee product reliability.

WINIW exports to key markets worldwide, with established distribution and partnerships across Europe and the USA. Our products are trusted by global brands for their consistent quality, sustainable composition, and competitive lead times.

Through continuous innovation and a vertically integrated supply chain, WINIW delivers synthetic leather solutions that combine performance, aesthetics, and environmental responsibility—making us a preferred B2B partner in the global materials industry.

Contact Us for Samples

WINIW Marine-Grade Synthetic Leather: Engineered for Excellence on the Water

WINIW delivers premium, sustainable synthetic leather solutions purpose-built for the rigorous demands of marine environments. Our advanced microfiber technology combines exceptional durability with eco-conscious manufacturing, ensuring your marine upholstery withstands saltwater, UV exposure, and heavy use while aligning with modern sustainability standards. Ideal for boat manufacturers, yacht outfitters, and marine upholstery suppliers seeking reliable, high-performance materials.

Key Advantages for Marine Applications

- Extreme Weather Resistance: Engineered to withstand 5,000+ hours of UV exposure (ASTM G154) without fading or cracking, and stable from -30°C to +80°C.

- 100% Waterproof & Stain-Proof: Non-porous structure repels saltwater, oils, and common marine contaminants; easy-clean surface maintains appearance with minimal maintenance.

- Superior Abrasion Resistance: Passes 50,000+ double-rub tests (Martindale), outperforming standard vinyl in high-traffic seating and deck applications.

- Eco-Responsible Composition: Contains 30%+ recycled content; manufactured with water-based, low-VOC processes (OEKO-TEX® STANDARD 100 certified).

- Marine-Grade Safety: Meets IMO FTP Code, SOLAS, and ISO 17012 flammability standards for vessel interiors.

Performance Comparison: WINIW vs. Standard Marine Vinyl

| Merkmal | WINIW Marine Microfiber | Conventional PVC Marine Vinyl |

|---|---|---|

| UV Resistance | 5,000+ hours (no fade) | 1,000–2,000 hours (fading/cracking) |

| Eco-Certifications | OEKO-TEX®, Recycled Content | Limited/None |

| Breathability | High (reduces condensation) | Non-breathable (traps moisture) |

| Weight | 20% lighter (reduces vessel load) | Heavy |

| Lifespan | 10–15 years (marine use) | 5–8 years (frequent replacement) |

| Recyclability | Fully recyclable at end-of-life | Landfill-bound (non-recyclable) |

Why Marine Industry Leaders Choose WINIW

- Total Cost of Ownership: Reduced replacement frequency and maintenance costs vs. traditional vinyl.

- Design Flexibility: Wide range of textures (suede, leather-grain), colors, and custom embossing for premium aesthetics.

- Sustainability Compliance: Supports ESG goals with traceable supply chains and Cradle-to-Cradle® principles.

- Global Readiness: Shipped worldwide with ISO 9001-certified quality control; compliant with EU REACH and US CPSIA.

Request Free Samples for Your Marine Project

Evaluate WINIW’s performance firsthand. Contact our Marine Solutions Team for complimentary 30cm x 30cm samples, full technical datasheets, and custom swatch books:

MKT88@MicrofiberLeather.com

Specify “Marine Vinyl Fabric Inquiry” in your subject line. Samples dispatched within 48 hours.

WINIW: Where uncompromising marine durability meets responsible innovation. Partner with us to elevate your vessel interiors with future-proof, planet-positive materials.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.