Introduction: Navigating the Global Market for leather patches for hats wholesale

In an increasingly competitive landscape, sourcing leather patches for hats wholesale presents unique challenges for international B2B buyers. As brands strive to differentiate themselves, the demand for high-quality, custom leather patches that enhance product appeal is on the rise. This guide is designed to navigate the complexities of the global market, providing valuable insights into the various types of leather patches available, their applications, and effective supplier vetting strategies.

From understanding the nuances of patch materials and finishes to exploring pricing structures and bulk order discounts, this comprehensive resource empowers businesses to make informed purchasing decisions. Buyers will learn how to identify reputable suppliers, assess product quality, and evaluate cost-effectiveness, ensuring that they procure leather patches that not only meet their needs but also resonate with their target markets.

Particularly for B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Germany—this guide aims to facilitate smoother transactions and foster strong supplier relationships. By equipping buyers with the knowledge they need, we aim to streamline the sourcing process, ultimately contributing to the growth and success of their businesses in the vibrant apparel market.

Table Of Contents

- Top 6 Leather Patches For Hats Wholesale Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather patches for hats wholesale

- Understanding leather patches for hats wholesale Types and Variations

- Key Industrial Applications of leather patches for hats wholesale

- 3 Common User Pain Points for ‘leather patches for hats wholesale’ & Their Solutions

- Strategic Material Selection Guide for leather patches for hats wholesale

- In-depth Look: Manufacturing Processes and Quality Assurance for leather patches for hats wholesale

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather patches for hats wholesale’

- Comprehensive Cost and Pricing Analysis for leather patches for hats wholesale Sourcing

- Alternatives Analysis: Comparing leather patches for hats wholesale With Other Solutions

- Essential Technical Properties and Trade Terminology for leather patches for hats wholesale

- Navigating Market Dynamics and Sourcing Trends in the leather patches for hats wholesale Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather patches for hats wholesale

- Strategic Sourcing Conclusion and Outlook for leather patches for hats wholesale

- Important Disclaimer & Terms of Use

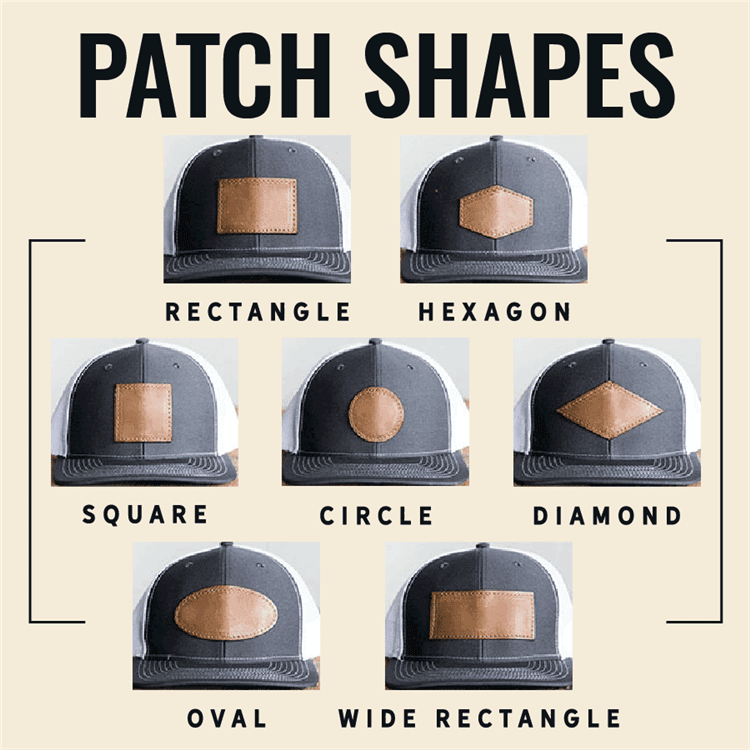

Understanding leather patches for hats wholesale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather Patches | Made from high-quality, natural leather; customizable designs | Apparel, hats, bags, hard goods | Pros: Durable, premium feel; Cons: Higher cost, limited washability |

| Suede Leather Patches | Soft texture with a luxurious appearance; available in various colors | Fashion apparel, promotional items | Pros: Unique aesthetic; Cons: Less durable than genuine leather |

| Laser-Etched Patches | Detailed logos and designs; precise engraving for intricate details | Branding, corporate giveaways | Pros: High detail; Cons: May require specific application methods |

| PVC Leather Patches | Synthetic alternative; water-resistant and easy to clean | Outdoor gear, sports apparel | Pros: Cost-effective, versatile; Cons: Less authentic look compared to real leather |

| Heat-Transfer Leather Patches | Easy application with heat; available in various finishes | Custom apparel production | Pros: Quick to apply; Cons: May not adhere well to all fabrics |

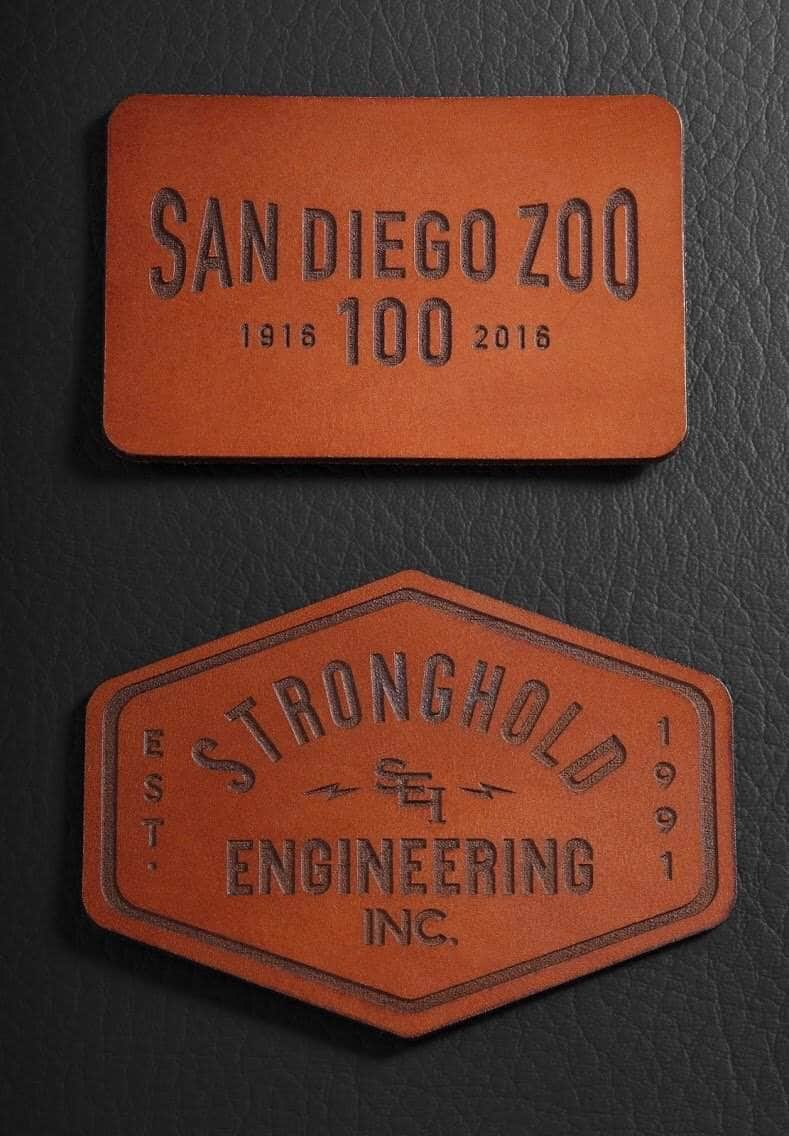

What are the Characteristics of Genuine Leather Patches?

Genuine leather patches are crafted from high-quality natural leather, providing a rugged yet sophisticated look. They are highly customizable, allowing businesses to engrave intricate designs and logos. This type of patch is ideal for premium apparel brands looking to enhance their products with a touch of luxury. Buyers should consider the cost, as genuine leather tends to be more expensive, but its durability and aesthetic appeal can justify the investment.

Why Choose Suede Leather Patches for Fashion Apparel?

Suede leather patches offer a soft, luxurious texture that can elevate the aesthetic of fashion apparel. Available in a variety of colors, these patches are perfect for adding a unique touch to hats and other clothing. While they provide a distinct look, businesses should be aware that suede is generally less durable than genuine leather, making it more suitable for fashion-forward items rather than heavy-duty applications.

How Do Laser-Etched Patches Enhance Branding?

Laser-etched patches are known for their precision and ability to capture intricate designs. This feature makes them particularly appealing for branding purposes, as companies can effectively showcase their logos. These patches are commonly used in corporate giveaways and promotional items. However, buyers should consider the specific application methods required, as proper heat settings and tools are necessary for optimal results.

Illustrative image related to leather patches for hats wholesale

What are the Benefits of PVC Leather Patches?

PVC leather patches are a synthetic alternative that offers several advantages, including water resistance and ease of cleaning. They are particularly well-suited for outdoor gear and sports apparel, where durability and functionality are paramount. While PVC patches are more cost-effective, buyers should note that they may lack the authentic look and feel of genuine leather, which could affect brand perception.

Why Opt for Heat-Transfer Leather Patches?

Heat-transfer leather patches provide a quick and efficient application method, making them ideal for businesses that require high-volume production. These patches come in various finishes and can be applied to a range of fabrics. However, it is essential for buyers to ensure compatibility with their materials, as some fabrics may not hold the adhesive well, potentially leading to issues with longevity.

Key Industrial Applications of leather patches for hats wholesale

| Industry/Sector | Specific Application of leather patches for hats wholesale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion/Apparel | Custom branding for retail hats | Enhances brand recognition and customer loyalty | Quality of leather, customization options, and MOQ |

| Outdoor Recreation | Durable patches for outdoor hats used in hiking and camping | Provides a rugged aesthetic while ensuring product longevity | Weather resistance, attachment methods, and bulk pricing |

| Corporate Branding | Employee gifts and promotional items featuring leather patches | Offers a unique, high-quality branding opportunity | Design flexibility, order volume discounts, and lead times |

| Sports Merchandise | Team-branded hats with custom leather patches | Fosters team spirit and fan engagement | Licensing requirements, color matching, and shipping logistics |

| Artisanal Crafts | Handcrafted hats with unique leather patches | Supports local artisans and promotes sustainable practices | Sourcing local materials, customization potential, and fair trade practices |

How Are Leather Patches Used in the Fashion/Apparel Industry?

In the fashion and apparel sector, leather patches are increasingly used to enhance the branding of hats sold in retail environments. These patches can be custom-designed with logos or unique artwork, allowing retailers to offer distinctive products that stand out in a crowded market. This application not only elevates the aesthetic appeal of the hats but also strengthens brand recognition, fostering customer loyalty. International buyers should consider the quality of leather and the available customization options, as these factors directly impact the perceived value of the product.

Illustrative image related to leather patches for hats wholesale

What Role Do Leather Patches Play in Outdoor Recreation?

For businesses in the outdoor recreation industry, leather patches are applied to hats designed for activities like hiking and camping. These patches provide a rugged, stylish look while ensuring the hats can withstand the elements. They are often made from durable materials that resist wear and tear, appealing to customers who value longevity in their outdoor gear. Buyers must assess the weather resistance of the patches and the methods for attaching them to ensure they meet performance standards in harsh environments.

How Are Leather Patches Utilized in Corporate Branding?

Corporate branding efforts often utilize leather patches on hats as part of employee gifts or promotional items. These patches can be customized to feature company logos or slogans, providing a high-quality branding opportunity that resonates with clients and employees alike. The unique texture and appearance of leather convey a sense of professionalism and quality. When sourcing these products, businesses should focus on design flexibility, minimum order quantities (MOQs), and the availability of volume discounts to optimize their branding budget.

Why Are Leather Patches Important for Sports Merchandise?

In the realm of sports merchandise, leather patches are used to create team-branded hats that foster a sense of community among fans and players alike. These patches can be customized to reflect team logos and colors, enhancing team spirit and engagement. For international buyers, it is essential to understand licensing requirements and ensure the patches are color-matched to the team’s official palette. Additionally, efficient shipping logistics are crucial to meet game-day deadlines and maximize sales opportunities.

Illustrative image related to leather patches for hats wholesale

How Do Artisanal Crafts Benefit from Leather Patches?

Artisanal crafts often incorporate leather patches into handcrafted hats, creating unique pieces that highlight individual artistry. This application supports local artisans and promotes sustainable practices, appealing to consumers looking for ethically produced goods. Buyers in this sector should prioritize sourcing local materials, exploring customization potential, and ensuring fair trade practices to align with the values of their target market. This not only enhances product appeal but also builds a story around the craftsmanship involved.

3 Common User Pain Points for ‘leather patches for hats wholesale’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: B2B buyers often face the challenge of inconsistent quality when sourcing leather patches for hats. Different suppliers may use varying grades of leather, leading to discrepancies in durability, appearance, and overall product satisfaction. This inconsistency can harm a buyer’s brand reputation, especially if customers receive products that do not match their expectations or the images presented during the purchasing process. Furthermore, buyers may find it difficult to establish a reliable supplier who consistently delivers high-quality patches.

The Solution: To mitigate the risk of inconsistent quality, B2B buyers should conduct thorough due diligence on potential suppliers. Start by requesting samples of leather patches before placing bulk orders. This allows buyers to evaluate the material, craftsmanship, and finish firsthand. Additionally, establishing clear specifications and standards for the desired quality can help ensure that all orders meet a consistent benchmark. Communicating these standards to suppliers and discussing their manufacturing processes will further help in establishing reliability. Implementing a quality assurance protocol, such as conducting regular audits of suppliers, can also help maintain high standards over time.

Scenario 2: Complicated Application Processes for Leather Patches

The Problem: Another common pain point for buyers is the complexity involved in applying leather patches to hats. Many B2B buyers may lack the necessary equipment or expertise to apply patches correctly, leading to potential product damage or subpar finishes. This challenge can result in wasted materials, increased labor costs, and delays in product delivery, ultimately affecting customer satisfaction and sales.

The Solution: Buyers should invest in training and resources to streamline the application process. This could include purchasing specialized equipment such as heat presses designed for leather applications, which can ensure consistent and professional results. Additionally, suppliers often provide detailed application instructions and best practices; leveraging these resources can significantly reduce application errors. Buyers should also consider developing partnerships with local embroidery or patch application businesses that have the necessary expertise. This collaborative approach can help ensure that the patches are applied correctly and efficiently, ultimately enhancing the quality of the final product.

Illustrative image related to leather patches for hats wholesale

Scenario 3: Navigating International Shipping and Customs Challenges

The Problem: For international B2B buyers, shipping leather patches across borders can present significant challenges. Issues such as customs delays, unexpected tariffs, and varying regulations can lead to prolonged delivery times, increased costs, and potential disruptions in the supply chain. These complications can be particularly detrimental for businesses that rely on timely inventory to meet customer demands.

The Solution: To navigate these shipping complexities, B2B buyers should work closely with their suppliers to understand the logistics involved in international shipping. It is crucial to clarify shipping terms and responsibilities at the outset, ideally opting for suppliers who have experience in exporting goods to the buyer’s region. Additionally, buyers can consult with freight forwarders or logistics experts who specialize in international shipping. They can provide insights into customs regulations, duty rates, and necessary documentation. Establishing a clear timeline for delivery and maintaining open communication with suppliers during the shipping process can help mitigate risks and ensure timely delivery, ultimately leading to better customer satisfaction.

Strategic Material Selection Guide for leather patches for hats wholesale

When selecting materials for leather patches used in hats, it is essential to consider the specific properties, advantages, and limitations of each material. This analysis focuses on four common materials: genuine leather, synthetic leather, suede, and eco-leather. Each material has unique characteristics that can affect the final product’s performance, durability, and appeal to international markets.

Illustrative image related to leather patches for hats wholesale

What Are the Key Properties of Genuine Leather for Patches?

Genuine leather is prized for its durability and aesthetic appeal. It can withstand high temperatures and pressure during the application process, making it suitable for heat pressing. Genuine leather exhibits natural breathability and flexibility, which allows it to conform well to the contours of various hat styles. However, it may require special care to maintain its appearance and longevity.

Pros: Genuine leather patches offer a premium look and feel, enhancing the overall quality of the hat. They are highly durable and can withstand wear and tear, making them ideal for outdoor and rugged use.

Cons: The cost of genuine leather can be relatively high, which may affect pricing strategies for wholesale buyers. Additionally, genuine leather is not waterproof and can be susceptible to staining if not treated properly.

How Does Synthetic Leather Compare for Hat Patches?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), provides a cost-effective alternative to genuine leather. It can mimic the look and feel of real leather while offering enhanced resistance to moisture and stains. Synthetic leather can also be produced in a variety of colors and finishes, allowing for greater customization.

Illustrative image related to leather patches for hats wholesale

Pros: The lower cost of synthetic leather makes it an attractive option for bulk orders. It is also easier to clean and maintain compared to genuine leather, which can be a selling point for customers.

Cons: While synthetic leather is durable, it may not match the longevity and aesthetic appeal of genuine leather. Additionally, it may not perform as well under high temperatures during the application process.

What Are the Benefits of Using Suede for Leather Patches?

Suede, a type of leather with a soft, napped finish, offers a unique texture that can enhance the visual appeal of hats. Suede is typically made from the underside of animal hides, providing a different aesthetic compared to traditional leather. It is lightweight and can be easily cut into various shapes and sizes.

Pros: Suede patches provide a distinctive look that can set a brand apart. They are often perceived as luxurious and can attract a specific customer demographic.

Cons: Suede is more susceptible to staining and damage from moisture than other leather types. It may also require additional care and treatment to maintain its appearance, which could be a drawback for wholesale buyers.

Illustrative image related to leather patches for hats wholesale

How Does Eco-Leather Fit into the Market for Hat Patches?

Eco-leather, made from recycled materials or produced through environmentally friendly processes, is becoming increasingly popular among consumers who prioritize sustainability. This material can provide a similar look and feel to traditional leather while reducing environmental impact.

Pros: Eco-leather appeals to a growing market segment focused on sustainability. It often comes at a competitive price point and can be produced in various colors and textures.

Cons: The durability of eco-leather may vary depending on the manufacturing process. Additionally, some eco-leather products may not meet the same performance standards as genuine leather, which could affect their suitability for certain applications.

Illustrative image related to leather patches for hats wholesale

Summary Table of Material Selection for Leather Patches

| Material | Typical Use Case for leather patches for hats wholesale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Echtes Leder | Premium hats and outdoor apparel | High durability and aesthetic appeal | Higher cost and care requirements | Hoch |

| Synthetic Leather | Budget-friendly hats and promotional items | Cost-effective and easy to maintain | May lack longevity and authenticity | Medium |

| Wildleder | Luxury hats and fashion-forward designs | Unique texture and luxurious appearance | Susceptible to stains and moisture | Medium |

| Eco-Leather | Sustainable fashion and eco-conscious brands | Environmentally friendly and appealing | Variable durability and performance | Medium |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions when sourcing leather patches for hats. Understanding the properties and implications of each material can lead to better product offerings and customer satisfaction.

In-depth Look: Manufacturing Processes and Quality Assurance for leather patches for hats wholesale

When engaging in the wholesale trade of leather patches for hats, understanding the manufacturing processes and quality assurance protocols is essential for B2B buyers. This knowledge not only helps in assessing the quality of products but also in building reliable partnerships with suppliers across different regions.

What Are the Main Stages in the Manufacturing Process of Leather Patches?

The manufacturing process for leather patches typically involves several key stages, each crucial for ensuring the final product meets quality standards.

1. Material Preparation

The initial stage involves selecting high-quality leather, which can vary in type (genuine, top grain, or synthetic) depending on the desired outcome. For wholesale orders, suppliers often source leather from reputable tanneries that adhere to environmental and ethical standards. The leather is then treated and dyed, ensuring it retains its natural properties while achieving the desired aesthetic.

During this stage, suppliers will often conduct tests to check for durability and colorfastness, ensuring that the material can withstand wear and maintain its appearance over time.

Illustrative image related to leather patches for hats wholesale

2. Forming the Leather Patches

Once the leather is prepared, the next step is forming the patches. This involves cutting the leather into the desired shapes and sizes, which may be based on custom designs provided by the buyer. Advanced techniques such as laser engraving are commonly employed at this stage, allowing for intricate designs and logos to be etched into the leather.

Additionally, the forming process may include the application of backing materials if specified by the buyer, although many suppliers offer patches without backing for a more natural look.

3. Assembly

In this stage, the leather patches are assembled. If the patches include additional elements such as embroidery or embellishments, these are added during assembly. Quality assurance checks are often integrated into this process to ensure that each patch meets design specifications and quality standards before moving to the next stage.

4. Finishing

The final stage in manufacturing leather patches involves finishing touches that enhance both the aesthetics and durability of the product. This includes sealing the edges to prevent fraying, applying protective coatings, and ensuring that the surface is smooth and free from defects.

Illustrative image related to leather patches for hats wholesale

At this stage, patches may also undergo additional treatments, such as water resistance, depending on the intended use of the product.

How Is Quality Assurance Implemented in Leather Patch Production?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final products meet international standards and customer expectations. Various quality control (QC) checkpoints are employed throughout the production process.

International Standards for Quality Assurance

For B2B buyers, understanding the relevant international quality standards is essential. Many suppliers comply with ISO 9001, which outlines criteria for a quality management system. This certification indicates that a supplier maintains consistent quality in their products and services.

Additionally, industry-specific standards such as CE (European Conformity) for safety and environmental compliance may apply, especially for buyers in Europe. In regions like Africa and South America, local regulations may also influence quality standards.

Illustrative image related to leather patches for hats wholesale

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control is usually segmented into several checkpoints:

-

Incoming Quality Control (IQC): This is the first line of defense, where incoming materials, including leather and other components, are inspected for quality and compliance with specifications before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are performed to ensure that production methods adhere to established standards and specifications. This includes monitoring the cutting, forming, and assembly stages.

-

Final Quality Control (FQC): After production, finished patches undergo a thorough inspection to ensure they meet quality standards. This may include checking dimensions, design accuracy, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several proactive steps to verify the quality assurance processes of their suppliers:

-

Supplier Audits: Conducting audits can provide insights into the supplier’s manufacturing processes and quality control measures. Buyers can assess compliance with international standards and identify any areas for improvement.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the QC measures a supplier employs. These reports often include statistics on defect rates and compliance with quality standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality processes. These inspections can occur at various stages of production, offering a comprehensive overview of quality assurance.

What Are the Common Testing Methods Used in Quality Assurance?

Quality assurance testing methods for leather patches may include:

-

Durability Testing: Evaluating the wear and tear of patches under various conditions to ensure longevity.

-

Adhesion Testing: For patches with adhesive backing, tests are conducted to ensure that they adhere properly to hats and other materials.

-

Colorfastness Testing: This involves exposing patches to various elements, such as water and UV light, to assess how well colors hold up over time.

-

Dimensional Accuracy Testing: Ensuring that the patches meet specified dimensions and tolerances.

How Do Quality Control Nuances Affect International B2B Buyers?

For international buyers, understanding the nuances of quality control across different regions is crucial. Factors such as local regulations, cultural expectations, and environmental standards can vary significantly.

For instance, buyers from Europe may prioritize compliance with stringent environmental regulations, while buyers in Africa may focus more on durability and cost-effectiveness. Therefore, establishing clear communication regarding quality expectations and standards at the outset of any partnership is vital.

Illustrative image related to leather patches for hats wholesale

In conclusion, a thorough understanding of manufacturing processes and quality assurance in leather patches for hats can significantly enhance the purchasing experience for B2B buyers. By engaging with suppliers who adhere to international quality standards and employing robust QC measures, buyers can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather patches for hats wholesale’

The following guide serves as a comprehensive checklist for B2B buyers looking to procure leather patches for hats wholesale. By following these steps, you can ensure a smooth sourcing process that meets your business needs and standards.

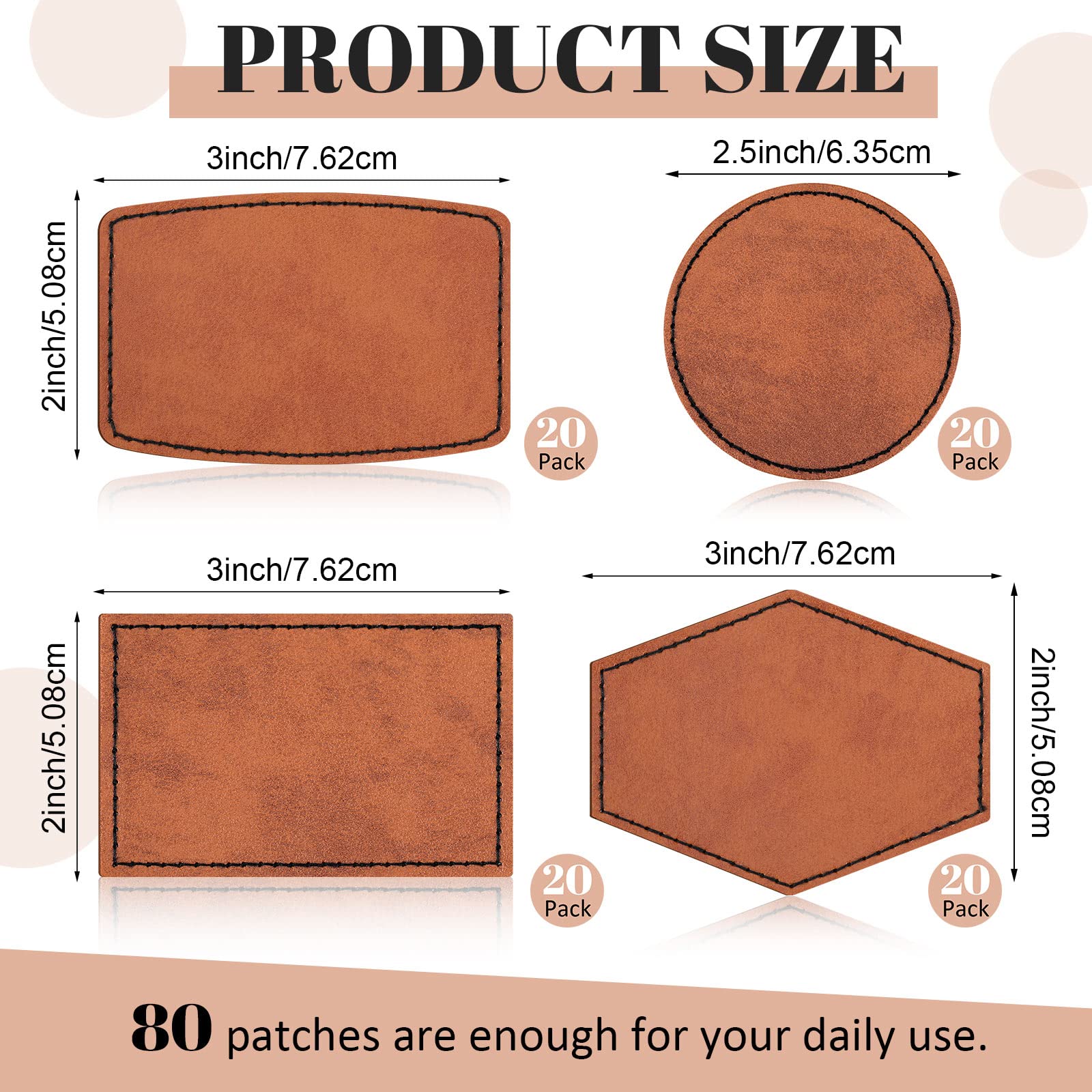

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the leather patches you require. This includes the type of leather (genuine, top grain, etc.), size, thickness, and finishing options. Having a detailed specification helps in getting accurate quotes and ensures that the final product aligns with your brand’s aesthetic.

- Considerations:

- Determine if you want pre-engraved designs or if you will provide your own artwork.

- Specify color preferences and texture types (smooth, distressed, etc.).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in leather patches. Look for manufacturers that have a solid reputation and experience in the industry. This step is crucial to avoid future complications with quality and delivery.

Illustrative image related to leather patches for hats wholesale

- Action Items:

- Review supplier websites and product offerings.

- Check online reviews and ratings on platforms relevant to your industry.

Step 3: Evaluate Supplier Certifications

Verify that your potential suppliers have the necessary certifications and quality assurance processes in place. Certifications may include ISO standards or ethical sourcing certifications, which can give you confidence in their practices.

- What to Look For:

- Request documentation to confirm certifications.

- Understand their quality control measures to ensure consistent product quality.

Step 4: Request Samples

Before placing a bulk order, always request samples of the leather patches. This allows you to assess the quality, craftsmanship, and adherence to your specifications. Samples can also help in making informed decisions about the final design.

- Benefits:

- Evaluate the texture, color, and finish of the leather.

- Test the application methods to see how they perform on hats.

Step 5: Discuss Minimum Order Quantities and Pricing

Engage in discussions about minimum order quantities (MOQs) and pricing structures. Many suppliers offer discounts on larger orders, which can significantly affect your budget. Understanding these terms upfront helps in planning your inventory.

- Negotiation Tips:

- Inquire about bulk order discounts and payment terms.

- Be clear about your estimated order volume to negotiate better rates.

Step 6: Understand Shipping and Delivery Times

Clarify shipping options and expected delivery times with your suppliers. Reliable shipping is vital to ensure that your inventory arrives on time, especially if you have a specific launch date for your products.

Illustrative image related to leather patches for hats wholesale

- Key Questions:

- What shipping methods do you offer, and what are the associated costs?

- Are there any guarantees or tracking options available for shipments?

Step 7: Establish a Communication Plan

Set up a clear communication plan with your supplier. Effective communication is essential for addressing any concerns or adjustments needed during the production process. Regular updates can help prevent misunderstandings and delays.

- Best Practices:

- Agree on a preferred method of communication (email, phone, etc.).

- Schedule regular check-ins during the production phase for updates.

By following these steps, B2B buyers can effectively source leather patches for hats, ensuring that they meet both quality standards and business needs.

Comprehensive Cost and Pricing Analysis for leather patches for hats wholesale Sourcing

Analyzing the cost structure and pricing for leather patches intended for wholesale hat sourcing involves a comprehensive look at various components and influencing factors. Understanding these elements can help international buyers make informed decisions, especially when considering unique market dynamics across Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Leather Patches?

-

Materials: The primary cost driver is the type of leather used. Genuine top-grain leather typically commands higher prices due to its durability and aesthetic appeal. Additional materials, such as adhesives or backing, may also influence costs. Suppliers often offer different grades of leather, which can affect both quality and price.

-

Labor: Labor costs vary significantly depending on the region where the patches are produced. In countries with lower labor costs, such as certain South American nations, manufacturers can provide competitive pricing. Conversely, labor in regions like Germany or parts of the Middle East may be higher, impacting overall costs.

-

Manufacturing Overhead: This includes the costs of facilities, utilities, and equipment. Efficient manufacturing processes and modern machinery can reduce these overheads, leading to more competitive pricing for buyers.

-

Tooling: Customization of patches often requires specific tooling or dies. The initial setup costs can be substantial, especially for unique designs, but these costs can be amortized over larger orders, making bulk purchases more economical.

-

Quality Control (QC): Ensuring the quality of leather patches involves inspections and testing, which add to the overall cost. Buyers should consider suppliers with robust QC processes to avoid costly returns or rework.

-

Logistics: Shipping costs can vary significantly based on the Incoterms negotiated. Buyers should be aware that shipping from regions with higher freight costs, such as Europe, may impact the total landed cost of patches.

-

Margin: Suppliers will factor in their profit margins, which can vary based on market competition and demand. Understanding typical margins in different regions can aid buyers in negotiation.

How Do Price Influencers Affect Leather Patch Costs?

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce the per-unit cost due to economies of scale. Many suppliers offer tiered pricing based on volume, encouraging bulk purchases.

-

Specifications and Customization: Custom designs, colors, and finishes can increase costs. Buyers should clarify their requirements upfront to receive accurate quotes.

-

Quality and Certifications: Patches that meet specific industry standards or certifications may come at a premium. Buyers should assess whether these certifications are necessary for their target markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but can offer better quality and service.

-

Incoterms: Understanding the agreed terms of shipping and responsibility for costs can significantly affect the total price. Common terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks.

What Buyer Tips Can Enhance Cost Efficiency?

-

Negotiation Strategies: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes from multiple suppliers to negotiate better terms.

-

Total Cost of Ownership (TCO): Consider not only the upfront cost but also long-term factors like quality and durability, which can impact future expenses related to returns or replacements.

-

Pricing Nuances for International Buyers: Be mindful of currency fluctuations and their potential impact on pricing. Understanding local market conditions and supplier relationships can also provide leverage during negotiations.

-

Sample Orders: Before committing to large orders, request samples to evaluate quality and ensure it meets your specifications. This step can prevent costly mistakes down the line.

-

Stay Informed: Regularly monitor market trends and pricing changes to anticipate fluctuations that may affect sourcing decisions.

In conclusion, a thorough understanding of the cost structure, pricing influencers, and strategic negotiation techniques can empower B2B buyers to make informed decisions in the competitive market for leather patches for hats.

Illustrative image related to leather patches for hats wholesale

Alternatives Analysis: Comparing leather patches for hats wholesale With Other Solutions

When evaluating options for enhancing hat designs, leather patches for hats wholesale are a popular choice among B2B buyers. However, it’s essential to consider alternative solutions that may fit specific needs or budget constraints. Below, we analyze leather patches against two viable alternatives: embroidered patches and PVC rubber patches.

| Comparison Aspect | Leather Patches For Hats Wholesale | Embroidered Patches | PVC Rubber Patches |

|---|---|---|---|

| Performance | Durable and rugged appearance; adds a premium feel | Highly customizable; good for intricate designs | Weather-resistant; flexible and durable |

| Cost | Moderate to high; varies by order size | Generally lower; bulk discounts available | Low to moderate; cost-effective for larger orders |

| Ease of Implementation | Requires specific heat application or adhesive | Easy to sew or iron on | Simple to attach with adhesive backing |

| Wartung | Not suitable for washing; care needed | Can be machine washed (depending on materials) | Easy to clean and maintain |

| Best Use Case | High-end or outdoor hats; brands seeking a premium look | Casual hats, promotional items | Outdoor and casual hats; brands needing a versatile solution |

What Are the Advantages and Disadvantages of Embroidered Patches?

Embroidered patches are a popular alternative to leather patches, known for their versatility and cost-effectiveness. They can be produced in various sizes and shapes, making them ideal for intricate designs. The manufacturing process is generally less expensive, particularly when ordered in bulk, which can significantly reduce costs for B2B buyers. Additionally, embroidered patches can be easily sewn or ironed onto hats, facilitating straightforward implementation. However, they may not provide the same premium, rugged aesthetic that leather patches offer, making them less suitable for brands focusing on high-end market segments. Furthermore, depending on the fabric used, embroidered patches may not withstand outdoor conditions as effectively as leather.

How Do PVC Rubber Patches Compare to Leather Patches?

PVC rubber patches present another viable option, particularly for outdoor and casual hats. These patches are highly weather-resistant, making them ideal for brands targeting an active lifestyle market. They are also flexible and can maintain their shape well over time, which is an essential factor for hats that may be exposed to the elements. PVC patches typically come with an adhesive backing, allowing for easy application without specialized equipment. However, while they offer durability, they may lack the premium feel and aesthetic appeal that leather patches provide, potentially affecting brand perception. Additionally, the design limitations may restrict the level of detail achievable compared to leather or embroidered patches.

Illustrative image related to leather patches for hats wholesale

How Can B2B Buyers Choose the Right Solution for Their Needs?

In conclusion, selecting the right patch solution depends on various factors, including brand identity, target market, and budget. Leather patches may be the best option for brands aiming for a rugged and premium look, particularly in the outdoor or high-end fashion sectors. Conversely, embroidered patches may be more suitable for those looking for cost-effective, customizable solutions without a premium branding focus. Lastly, PVC rubber patches can serve well for brands targeting a functional, casual audience, offering durability and ease of application. B2B buyers should carefully assess their specific needs and consider the unique advantages and disadvantages of each option before making a decision.

Essential Technical Properties and Trade Terminology for leather patches for hats wholesale

What Are the Key Technical Properties of Leather Patches for Hats Wholesale?

When sourcing leather patches for hats, it is essential to understand the technical specifications that influence quality and usability. Here are some critical properties to consider:

-

Material Grade

Leather patches are typically made from various grades of leather, including full-grain, top-grain, and genuine leather. Full-grain leather is the highest quality, retaining the natural grain and imperfections, which provides durability and a unique aesthetic. Top-grain leather is sanded and treated for a more uniform appearance but is slightly less durable. Understanding the material grade helps buyers select patches that align with their product quality standards and branding. -

Thickness

The thickness of the leather patch affects its durability, appearance, and how it adheres to the hat. Common thicknesses range from 0.5mm to 2mm. Thicker patches are generally more robust and suitable for rugged use, while thinner patches can provide a sleek, lightweight option. Buyers should consider the intended use of the hats and customer preferences when choosing thickness. -

Finish Type

Leather patches can be finished in various ways, including matte, glossy, or distressed. The finish impacts both the aesthetic and the tactile feel of the patch. A matte finish offers a more understated look, while a glossy finish can enhance visibility and vibrancy. Understanding the finish type helps buyers match patches with their brand’s image and the desired hat style. -

Adhesion Method

Leather patches can be applied using heat transfer, adhesive, or stitching. Heat-applied patches offer a clean look and are often quicker to apply, while stitched patches provide a more permanent solution and can withstand washing. Buyers should evaluate the adhesion method based on their production capabilities and the end user’s expectations for durability. -

Customizability

The ability to customize leather patches with branding, logos, or unique designs is crucial for B2B buyers. Customization options can include laser engraving, embossing, or printing. Understanding the level of customizability available allows businesses to create unique products that resonate with their target market, enhancing brand recognition. -

Color Variability

Natural leather can exhibit variations in color and texture, which can affect the final appearance of the patches. Buyers should account for potential differences when placing orders, as these variations can add character but may also impact brand consistency. It’s advisable to request samples to ensure the colors meet expectations.

What Common Trade Terms Should B2B Buyers Know When Sourcing Leather Patches?

Navigating the wholesale landscape requires familiarity with specific industry jargon. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or products that are used in another company’s product. In the context of leather patches, an OEM might produce patches that are then branded and sold by another business. Understanding OEM relationships can help buyers secure reliable sources for high-quality patches. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers as it helps them understand the scale at which they can order patches. Knowing the MOQ allows businesses to plan their inventory and cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific goods or services. For buyers sourcing leather patches, an RFQ can clarify costs associated with different materials, customizations, and shipping options, enabling better budgeting and decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is crucial for international buyers to clarify who is responsible for shipping costs, insurance, and risk during transit, ensuring smooth logistics. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For leather patches, lead times can vary based on customization and production capacity. Buyers should consider lead times when planning product launches or inventory replenishment to avoid stockouts. -

Sample Approval

This process involves reviewing a prototype or sample of the product before full-scale production begins. For leather patches, sample approval is vital to ensure that the quality, design, and specifications meet expectations. It allows buyers to make necessary adjustments before committing to a larger order.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing leather patches for hats, ensuring they meet both quality and market demands.

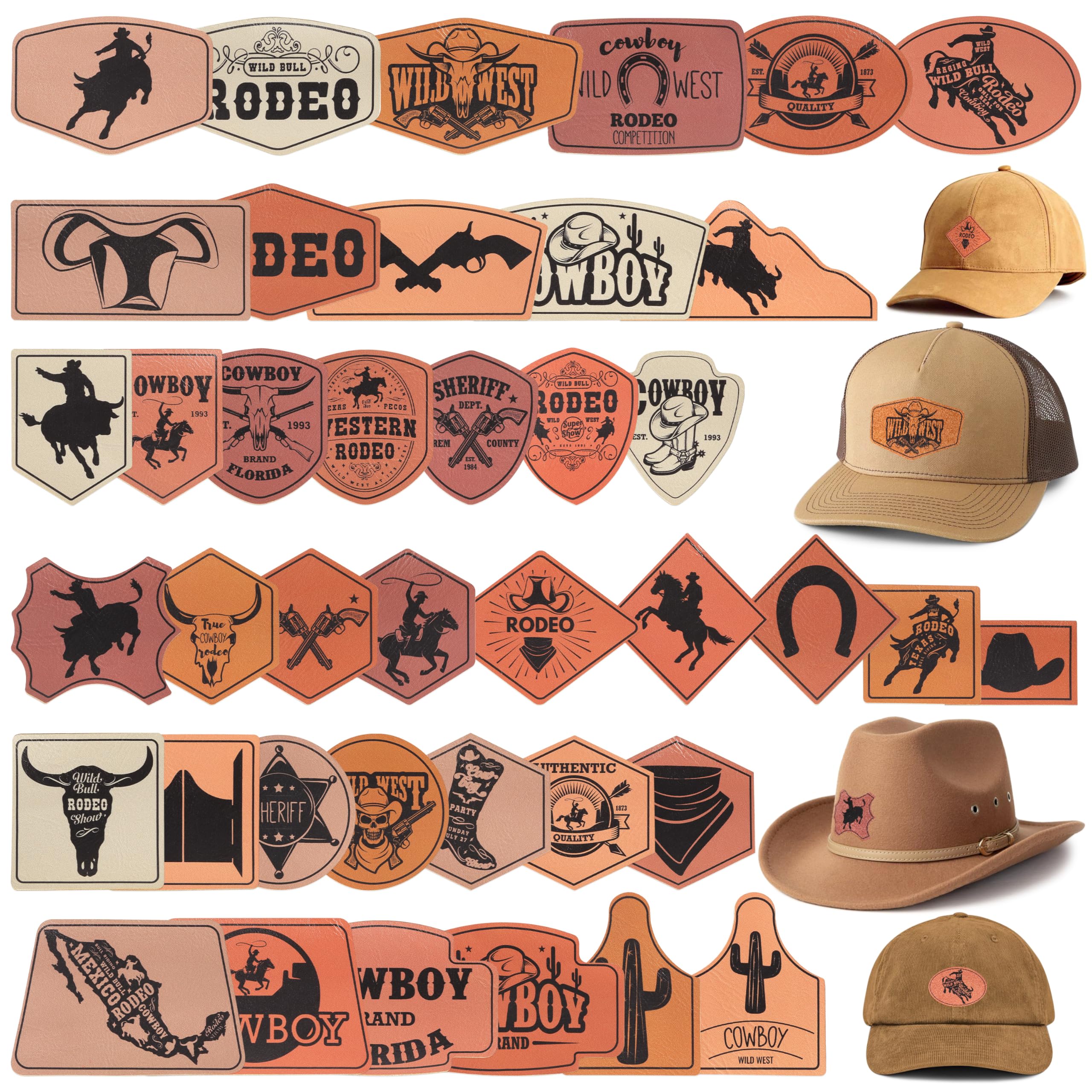

Navigating Market Dynamics and Sourcing Trends in the leather patches for hats wholesale Sector

What Are the Key Market Dynamics in the Leather Patches for Hats Wholesale Sector?

The global leather patches for hats wholesale market is experiencing a surge driven by several factors. First, the growing demand for custom, branded merchandise across various sectors, including fashion and outdoor apparel, is propelling the market forward. This trend is particularly notable in regions like Africa and South America, where local artisans and businesses are increasingly looking to enhance their product offerings with unique branding options. Additionally, the rise of e-commerce and digital marketing has made it easier for B2B buyers to source products from international suppliers, thus expanding market reach.

Illustrative image related to leather patches for hats wholesale

Emerging technologies in manufacturing and design are also influencing sourcing trends. Innovations such as laser engraving allow for detailed custom designs on leather patches, enhancing their appeal to brands seeking to create distinctive products. Buyers are now looking for suppliers who can offer high-quality, customizable options quickly and efficiently, reflecting the fast-paced nature of today’s retail environment.

Furthermore, the importance of aesthetics cannot be overstated. Leather patches provide a rugged yet refined look that resonates with consumers, particularly in Europe and the Middle East, where style and quality are paramount. As a result, buyers are increasingly focusing on sourcing high-grade materials that offer both durability and visual appeal, while also considering the supplier’s ability to deliver consistent quality across large orders.

How Are Sustainability and Ethical Sourcing Shaping the Leather Patches Market?

Sustainability and ethical sourcing have become crucial considerations in the leather patches for hats wholesale sector. As consumers increasingly demand transparency and accountability from brands, B2B buyers are prioritizing suppliers that adhere to ethical practices in their production processes. This includes sourcing leather from tanneries that implement eco-friendly methods and ensure fair labor practices.

Illustrative image related to leather patches for hats wholesale

The environmental impact of leather production is significant, with traditional tanning processes often involving harmful chemicals. Buyers are therefore seeking suppliers that utilize vegetable-tanned leather or other sustainable alternatives that minimize environmental harm. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) rating can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the push for “green” certifications is not just a trend; it is becoming a requirement for many brands that wish to maintain market competitiveness. By aligning with suppliers who emphasize sustainable practices, B2B buyers can enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

What Is the Evolution of Leather Patches in the Apparel Industry?

The history of leather patches in the apparel industry dates back centuries, originating as functional elements in clothing to reinforce areas subject to wear and tear. Over time, these patches evolved into a canvas for branding and personalization, particularly in the hat sector.

Initially, leather patches served a utilitarian purpose, but as fashion trends shifted, they began to be embraced for their aesthetic qualities. The rise of custom and branded merchandise in the late 20th century propelled leather patches into the spotlight, with businesses recognizing their potential to enhance brand identity. Today, they are a staple in the apparel industry, particularly among outdoor and lifestyle brands that seek to convey authenticity and craftsmanship through their products.

This evolution reflects broader changes in consumer preferences, with a growing appreciation for unique, high-quality items that tell a story. As the market continues to mature, the focus is shifting toward customization and sustainability, making leather patches an integral part of modern branding strategies in the wholesale sector.

Illustrative image related to leather patches for hats wholesale

Frequently Asked Questions (FAQs) for B2B Buyers of leather patches for hats wholesale

1. How can I ensure the quality of leather patches when sourcing them wholesale?

To ensure quality, request samples from potential suppliers before placing a bulk order. Evaluate the leather’s texture, durability, and craftsmanship. Look for suppliers that provide detailed product specifications and quality assurance certifications. Additionally, consider suppliers with positive reviews and established reputations in the industry. Establishing clear quality control criteria in your purchase agreement can further safeguard your interests.

2. What are the typical minimum order quantities (MOQs) for leather patches?

Minimum order quantities for leather patches can vary significantly among suppliers. Generally, MOQs range from 12 to 100 pieces, depending on the supplier’s production capabilities and the complexity of the designs. It’s advisable to negotiate MOQs when placing larger orders, as many suppliers offer tiered pricing discounts that reduce costs per unit at higher quantities.

3. What customization options are available for leather patches?

Most suppliers offer various customization options, including size, shape, color, and engraving methods. You can typically choose between laser etching or embossing for your logo or design. Some suppliers also allow you to select specific leather types or finishes to match your brand’s aesthetic. Always inquire about the design process and whether there are any additional costs associated with custom designs.

4. How do payment terms work when buying leather patches wholesale?

Payment terms can vary by supplier, but common practices include a deposit upfront (usually 30-50%) with the balance due upon shipment. Some suppliers may offer net terms (e.g., net 30 days) for established buyers. Always clarify payment methods accepted (bank transfer, credit card, etc.) and any potential fees associated with international transactions.

5. What should I consider regarding logistics when sourcing leather patches internationally?

Logistics considerations include shipping costs, delivery times, and customs regulations specific to your country. Verify if the supplier handles shipping or if you need to arrange it yourself. It’s also crucial to factor in lead times for production, which can vary based on order size and complexity. Ensure you understand your country’s import duties and taxes to avoid unexpected expenses.

6. How can I vet suppliers for leather patches effectively?

Vetting suppliers involves checking their business credentials, customer reviews, and manufacturing capabilities. Request references from previous clients and ask about their experience with quality control and delivery times. Utilize platforms that specialize in connecting B2B buyers with verified suppliers. Visiting the supplier’s facility, if feasible, can provide deeper insights into their operations.

7. Are there specific care instructions for leather patches on hats?

Leather patches typically require special care to maintain their appearance. They are generally not intended for machine washing or dry cleaning. Instead, recommend spot cleaning with a damp cloth and avoiding exposure to excessive moisture. Inform your customers that the longevity of the leather patch can be extended by storing the hats in a cool, dry place when not in use.

8. What are the trends in leather patch designs for hats in the global market?

Current trends include the use of eco-friendly leather, intricate laser-etched designs, and contrasting colors that make patches stand out. Minimalist designs and vintage aesthetics are also gaining popularity, appealing to a broad range of consumers. Keeping an eye on fashion trends in your target markets can help you select designs that resonate with local customers, enhancing your sales potential.

Illustrative image related to leather patches for hats wholesale

Top 6 Leather Patches For Hats Wholesale Manufacturers & Suppliers List

1. Stahls – Custom Leather Patches

Domain: stahls.com

Registered: 1996 (29 years)

Introduction: Custom Leather Patches for Apparel

– Material: Genuine leather

– Custom designs available

– Colors: Taupe, Caramel, Natural

– Ideal for: Hats, bags, heavy apparel (like outerwear not regularly laundered), and hard goods

– Application: Can be heat applied or stickered to any hard good

– Minimum order: 12 pieces

– Pre-production physical sample available for a fee (Limit QTY 1)

– Note: Etching depth…

2. Odin Leather Goods – Custom Bulk Hats

Domain: odinleathergoods.com

Registered: 2012 (13 years)

Introduction: Custom Hat Order (Bulk)\nSale price: $50.00\nOrder Sizes: 1, 12, 24, 36, 48, 60, 72\nHat Styles and Colors: \n- No. 815 – Snapback – Curved Bill / Mesh Back (Most Popular)\n- No. 815 – Snapback – Curved Bill / Hydro Mesh\n- No. 301 – 5-Panel Classic Trucker\n- No. 301 – 6-Panel Flat Bill / Mesh Back\n- No. 301 – 6-Panel – Flat Bill / Solid Back\n- No. 301 – 6-Panel – Flat Bill / Hydro Mesh\n- Clas…

3. Leathering – Custom Leather Patch Hats

Domain: leathering.co

Registered: 2023 (2 years)

Introduction: Custom Leather Patch Hats made with Full Grain Italian Leather. Sale price: $16.50 (Regular price: $29.00). 4.96 rating from 354 reviews. Features include: customization options for logos, mix and match quantities for volume discounts, handcrafted leather patches, and a commitment to quality. Care instructions advise against washing and recommend spot cleaning. Customization process involves desig…

4. Faire – Wholesale Leather Patches

Domain: faire.com

Registered: 1998 (27 years)

Introduction: Wholesale leather patches available for retail stores, featuring a variety of products including:

– Iron-On Genuine Vegetable Tanned Leather Patch (6 colors) – KW Custom Creations, Rating: 4.7 (14 reviews)

– Custom Business Logo Leatherette Patch – Adhesive, Rating: 5.0 (245 reviews)

– Leather Hat Bar Patch – Self Adhesive, Rating: 4.9 (146 reviews)

– Square Leather Patches – The Tinkerbox LLC

– E…

5. Ninja Patches – Custom Embroidered Patches

Domain: ninjapatches.com

Registered: 2022 (3 years)

Introduction: Custom Patches for Hats & Apparel, Shipped Fast! Patches ship as fast as 5 business days with free shipping. No setup, art fees, or minimums required. Various patch types available:

– Embroidered Patches: As low as $1.42 each, made with premium thread on durable fabric.

– 3D Embroidered Patches: As low as $2.31 each, providing a raised effect.

– Full Color Printed Patches: As low as $1.09 each, u…

6. Star Hats – Etched Leather Patches

Domain: starhatsandembroidery.com

Registered: 2018 (7 years)

Introduction: Etched Leather Patches are customizable patches made from high-quality leather. They feature intricate designs that are etched into the leather surface, providing a unique and durable product. These patches can be used for branding, personalizing items, or as decorative elements on clothing and accessories. They are available in various sizes and can be tailored to meet specific design requirement…

Strategic Sourcing Conclusion and Outlook for leather patches for hats wholesale

In the competitive landscape of wholesale leather patches for hats, strategic sourcing emerges as a pivotal factor for success. By partnering with reliable manufacturers, buyers can ensure a consistent supply of high-quality patches that not only enhance product offerings but also elevate brand identity. Understanding the nuances of materials, customization options, and application methods is essential for crafting unique hats that resonate with consumers across diverse markets.

International buyers, especially from Africa, South America, the Middle East, and Europe, should leverage the growing trend towards personalized and sustainable fashion. The demand for genuine leather patches is on the rise, driven by consumers’ preferences for authenticity and craftsmanship. By tapping into this trend, businesses can differentiate themselves and cater to the evolving tastes of their clientele.

As you consider your next sourcing decisions, remember that quality and flexibility are paramount. Engage with suppliers who offer customization and scalability to meet your business needs effectively. The future of leather patches is bright, and now is the time to invest in strategic partnerships that will propel your brand forward. Embrace this opportunity to innovate and captivate your customers with unique, high-quality products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to leather patches for hats wholesale

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.