Introduction: Navigating the Global Market for leather machine company cobra class 4

In today’s competitive landscape, sourcing reliable leather machinery like the Cobra Class 4 presents unique challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, understanding the capabilities and specifications of the Cobra Class 4 can significantly impact your production efficiency and quality. This comprehensive guide delves into the various types of leather machines available, their applications in industries such as fashion, automotive, and crafting, and essential factors for supplier vetting.

By addressing critical aspects such as cost considerations, warranty options, and maintenance requirements, this guide empowers buyers to make informed purchasing decisions. The Cobra Class 4, with its robust design and capacity to handle thick materials, is ideal for crafting high-quality products, from saddles to handbags. We will explore how to assess potential suppliers effectively, ensuring they meet your specific operational needs and standards.

Additionally, we will cover shipping logistics, compliance with international standards, and after-sales support, all vital for seamless integration into your supply chain. This guide is tailored to equip B2B buyers with actionable insights, allowing you to navigate the global market with confidence and make choices that enhance your business operations.

Table Of Contents

- Top 3 Leather Machine Company Cobra Class 4 Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather machine company cobra class 4

- Understanding leather machine company cobra class 4 Types and Variations

- Key Industrial Applications of leather machine company cobra class 4

- 3 Common User Pain Points for ‘leather machine company cobra class 4’ & Their Solutions

- Strategic Material Selection Guide for leather machine company cobra class 4

- In-depth Look: Manufacturing Processes and Quality Assurance for leather machine company cobra class 4

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather machine company cobra class 4’

- Comprehensive Cost and Pricing Analysis for leather machine company cobra class 4 Sourcing

- Alternatives Analysis: Comparing leather machine company cobra class 4 With Other Solutions

- Essential Technical Properties and Trade Terminology for leather machine company cobra class 4

- Navigating Market Dynamics and Sourcing Trends in the leather machine company cobra class 4 Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather machine company cobra class 4

- Strategic Sourcing Conclusion and Outlook for leather machine company cobra class 4

- Important Disclaimer & Terms of Use

Understanding leather machine company cobra class 4 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cobra Class 4 Dream Machine | 16.5” throat space, sews leather up to 7/8” thick, variable speed motor | Saddlery, holsters, belts, custom leather goods | Pros: High power, versatile; Cons: Higher cost, heavy weight. |

| Cobra Class 4 Pro | Enhanced motor efficiency, larger work area, and robust design | Industrial leather production, heavy-duty projects | Pros: Durable, efficient; Cons: Requires skilled operation. |

| Cobra Class 4 Compact | Smaller footprint, suitable for tight workspaces | Small batch leather crafting, repairs | Pros: Space-saving, easy to transport; Cons: Limited sewing capacity. |

| Cobra Class 4 Deluxe | Premium features, advanced stitch settings, and additional accessories | High-end leather goods, bespoke items | Pros: Comprehensive features, user-friendly; Cons: Premium pricing. |

| Cobra Class 4 Heavy-Duty | Designed for extreme thicknesses, rugged construction | Upholstery, heavy industrial applications | Pros: Handles thick materials, reliable; Cons: Heavier and bulkier. |

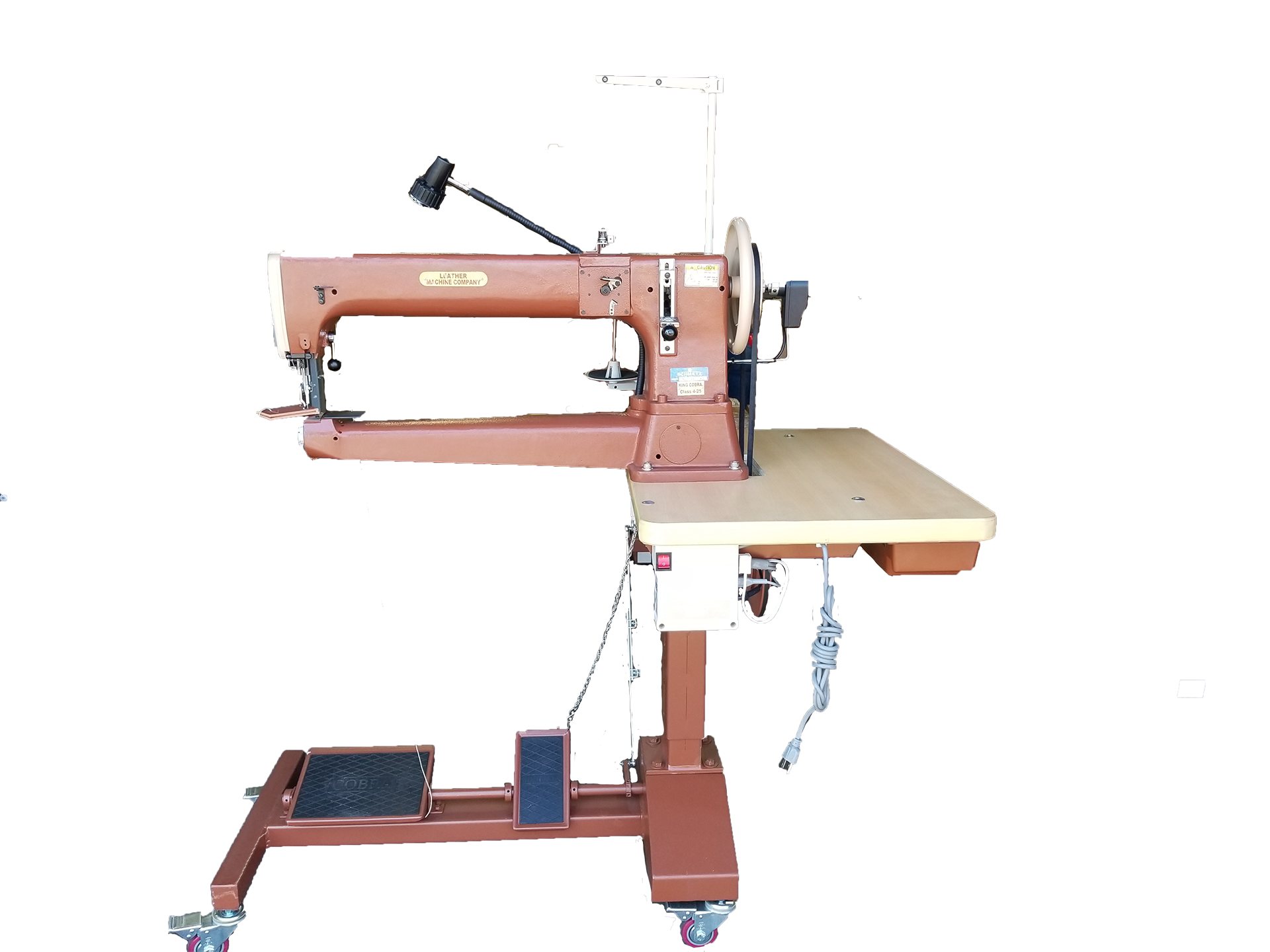

What are the Key Characteristics of the Cobra Class 4 Dream Machine?

The Cobra Class 4 Dream Machine stands out with its impressive 16.5” throat space and the ability to sew leather up to 7/8” thick. This machine is particularly suitable for businesses focused on saddlery, holsters, and custom leather goods. B2B buyers should consider its smooth operation and variable speed motor, which enhance productivity. However, the higher price point and significant weight may be a consideration for smaller operations or those with limited shipping capabilities.

How Does the Cobra Class 4 Pro Enhance Industrial Leather Production?

The Cobra Class 4 Pro is designed for industrial applications with enhanced motor efficiency and a larger work area. It is ideal for businesses engaged in heavy-duty projects and mass production. Buyers looking for durability and efficiency will find this model appealing, although it requires skilled operation to maximize its potential. Businesses should weigh the investment against the potential for increased output and reliability in demanding environments.

Why Choose the Cobra Class 4 Compact for Small Batch Production?

The Cobra Class 4 Compact is tailored for those with limited workspace, making it perfect for small batch leather crafting or repairs. Its smaller footprint allows for easy transport and setup, appealing to startups or smaller workshops. However, buyers should note its limited sewing capacity compared to larger models, which may restrict the types of projects it can handle effectively.

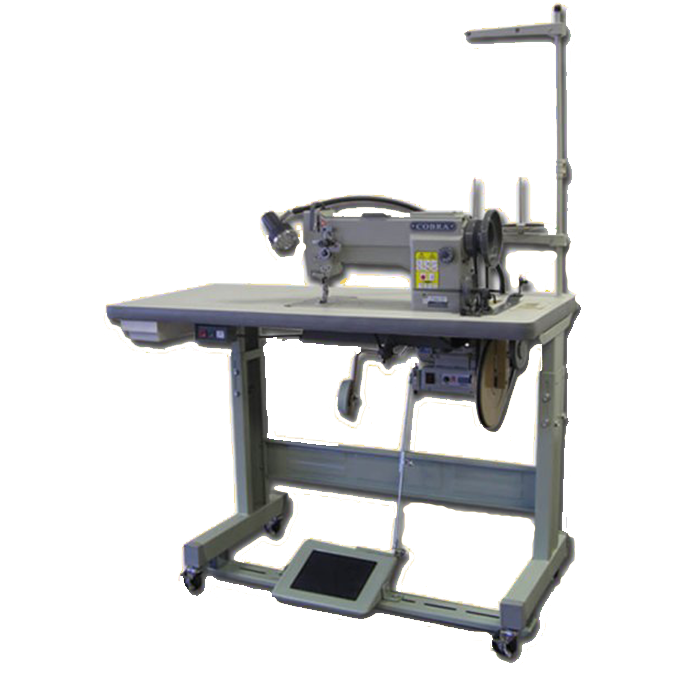

Illustrative image related to leather machine company cobra class 4

What Premium Features Does the Cobra Class 4 Deluxe Offer?

The Cobra Class 4 Deluxe includes advanced stitch settings and additional accessories that cater to high-end leather goods production. This model is particularly suited for bespoke items where precision and versatility are crucial. While it offers comprehensive features and user-friendliness, the premium pricing may be a barrier for smaller businesses or those just entering the leather market.

What Makes the Cobra Class 4 Heavy-Duty Ideal for Rugged Applications?

Designed for extreme thicknesses, the Cobra Class 4 Heavy-Duty machine is built for reliability in upholstery and heavy industrial applications. Its rugged construction allows it to handle thick materials with ease, making it suitable for businesses that require robust machinery. However, its heavier and bulkier design may pose challenges in terms of mobility and workspace requirements. Buyers should consider their operational needs when evaluating this model.

Key Industrial Applications of leather machine company cobra class 4

| Industry/Sector | Specific Application of leather machine company cobra class 4 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Leather Goods Manufacturing | Production of high-quality leather bags and accessories | Enhances product durability and aesthetic appeal | Evaluate machine specifications for thickness and stitch options |

| Equestrian Equipment | Crafting saddles, bridles, and other tack items | Ensures safety and performance in high-stress situations | Consider materials compatibility and after-sales support |

| Fashion and Apparel | Designing custom leather garments, including jackets and pants | Allows for unique designs and customization options | Assess sourcing of compatible threads and needles |

| Automotive Upholstery | Creating leather seat covers and interior trim | Improves vehicle aesthetics and resale value | Check for machine’s ability to handle various leather thicknesses |

| Sporting Goods | Manufacturing protective gear, like gloves and pads | Increases safety and performance for athletes | Ensure compliance with safety standards and durability requirements |

How is the Cobra Class 4 Used in Leather Goods Manufacturing?

The Cobra Class 4 excels in the production of high-quality leather bags and accessories. Its ability to sew leather up to 7/8” thick allows manufacturers to create durable products that withstand daily use. International buyers should look for machines that accommodate various leather types and thicknesses, ensuring versatility in production. Additionally, the machine’s triple feed mechanism provides consistent stitching, which is crucial for maintaining the aesthetic integrity of luxury items.

What Role Does the Cobra Class 4 Play in Equestrian Equipment?

In the equestrian sector, the Cobra Class 4 is instrumental in crafting saddles, bridles, and other tack items. The machine’s robust design enables it to handle heavy-duty materials, ensuring that products are not only functional but also safe for both horse and rider. Buyers from regions with a strong equestrian culture should prioritize machines that offer reliability and durability, as these features are paramount in high-stress environments.

How is the Cobra Class 4 Beneficial for Fashion and Apparel?

Fashion designers utilize the Cobra Class 4 for creating custom leather garments, including jackets and pants. The machine’s variable speed digital servo motor allows for intricate designs and detailed stitching, catering to the unique requirements of fashion industry professionals. When sourcing this machine, buyers should consider compatibility with diverse leather types and the availability of additional accessories that enhance design capabilities.

Illustrative image related to leather machine company cobra class 4

Why is the Cobra Class 4 Important for Automotive Upholstery?

The automotive industry benefits significantly from the Cobra Class 4 when creating leather seat covers and interior trim. This machine not only enhances the aesthetic appeal of vehicles but also adds to their resale value. International buyers should ensure that the machine can handle various leather thicknesses and has features that support the intricate detailing required in automotive upholstery.

How Does the Cobra Class 4 Support the Manufacturing of Sporting Goods?

In the sporting goods sector, the Cobra Class 4 is used to manufacture protective gear such as gloves and pads. The machine’s capacity to sew thick leather ensures that the products are durable and provide the necessary protection for athletes. Buyers should focus on machines that meet safety standards and can adapt to various materials, allowing for a wide range of sporting applications.

3 Common User Pain Points for ‘leather machine company cobra class 4’ & Their Solutions

Scenario 1: Challenges with Heavy Leather Thickness

The Problem: B2B buyers often face difficulties when trying to sew heavy leather, especially when dealing with thicknesses up to 7/8″ (22.2 mm). Many industrial sewing machines struggle with this task, leading to skipped stitches, uneven feeding, and potential damage to both the machine and the material. This can result in wasted time and resources, particularly for businesses focused on producing high-quality leather goods like saddles, holsters, or bags.

Illustrative image related to leather machine company cobra class 4

The Solution: To effectively tackle this issue, buyers should ensure they are using the Cobra Class 4, which is specifically designed to handle heavy leather. It features a powerful motor capable of delivering consistent speed and torque, allowing for smooth operation even with the thickest materials. Additionally, understanding the machine’s settings, such as stitch length and tension, is crucial. For optimal results, use the recommended needle sizes (like #25 leather point needles) and thread sizes (69-415) to achieve the best stitch quality. Regular maintenance, including cleaning and oiling, will also help maintain performance and prolong the life of the machine.

Scenario 2: Inconsistent Stitch Quality

The Problem: Another common pain point for B2B buyers is inconsistent stitch quality, which can lead to a negative perception of their products. This issue often arises from improper machine setup, including incorrect tension settings, poor needle choice, or inadequate threading techniques. In the leather industry, where precision is paramount, such inconsistencies can compromise the integrity of the final product.

The Solution: To ensure consistent stitch quality, buyers should take advantage of the Cobra Class 4’s advanced features, such as its triple feed mechanism and reverse stitching capability. First, it’s essential to correctly set the machine’s tension according to the leather weight being used. Buyers should experiment with different settings to find the optimal balance. Furthermore, utilizing the built-in bobbin winder and ensuring the bobbin is properly threaded can prevent thread bunching and misalignment. For those new to the machine, accessing training resources or instructional videos can provide valuable insights into effective threading and setup techniques.

Scenario 3: Difficulty in Machine Operation and Maintenance

The Problem: Many B2B buyers encounter challenges related to the operation and maintenance of the Cobra Class 4 machine, particularly if they are new to industrial sewing. These challenges can lead to frustration, reduced productivity, and even safety hazards if the machine is not used correctly. Users may struggle with understanding machine controls, performing regular maintenance, or troubleshooting common issues.

The Solution: To mitigate these operational challenges, buyers should invest time in comprehensive training for their staff. The Cobra Class 4 comes with an instruction manual that outlines basic operations, but additional resources such as online tutorials, workshops, or demonstrations can enhance user competence. Establishing a routine maintenance schedule is also crucial; this includes cleaning the machine after use, checking for wear and tear on parts, and regularly oiling moving components. For troubleshooting, maintaining an open line of communication with the supplier can provide access to expert advice and support when issues arise. By ensuring that operators are well-trained and informed, businesses can maximize the efficiency and safety of their leather sewing processes.

Illustrative image related to leather machine company cobra class 4

Strategic Material Selection Guide for leather machine company cobra class 4

What Are the Key Materials for the Cobra Class 4 Leather Sewing Machine?

The Cobra Class 4 leather sewing machine is designed for heavy-duty applications, making the selection of materials critical for optimal performance. Below are analyses of four common materials used in conjunction with this machine, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Leather Perform as a Material?

Key Properties: Leather is a natural material known for its flexibility, durability, and resistance to wear. It can withstand high temperatures and pressures, making it suitable for heavy-duty sewing tasks.

Pros & Cons: Leather is highly durable and provides a premium feel, which is often desired in high-end products. However, it can be expensive and may require specialized handling and care during the manufacturing process. Additionally, variations in quality can affect the end product’s consistency.

Impact on Application: Leather is compatible with various sewing techniques and patterns, allowing for intricate designs. However, it may not perform well in extreme moisture conditions unless treated.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with environmental regulations regarding leather sourcing and treatment. Standards such as REACH in Europe may apply.

Illustrative image related to leather machine company cobra class 4

What Role Does Synthetic Leather Play in Production?

Key Properties: Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a water-resistant surface and is easier to clean compared to natural leather.

Pros & Cons: The primary advantage of synthetic leather is its lower cost and wide availability. It can mimic the appearance of real leather while being more resistant to stains and moisture. However, it may not provide the same level of durability or breathability as genuine leather.

Impact on Application: Synthetic leather is suitable for various applications, including upholstery and fashion items. It can be less forgiving in terms of sewing, requiring precise adjustments to avoid damage during the stitching process.

Considerations for International Buyers: Buyers in Africa and South America may prefer synthetic options due to cost-effectiveness. Compliance with local regulations regarding synthetic materials is essential, as some regions have restrictions on specific chemicals used in production.

How Do Threads Impact the Performance of the Cobra Class 4?

Key Properties: Threads used in the Cobra Class 4 machine must be strong enough to withstand tension and friction during sewing. Common thread materials include polyester and nylon, both known for their tensile strength.

Pros & Cons: Polyester threads are resistant to UV rays and moisture, making them ideal for outdoor applications. Nylon threads, while slightly more elastic, can be more susceptible to UV degradation. The choice of thread can significantly affect the durability of the final product.

Impact on Application: The right thread enhances the overall quality of the leather product, ensuring seams remain intact under stress. However, using incompatible thread types can lead to issues like fraying or breaking.

Considerations for International Buyers: Compliance with international thread standards, such as ASTM and ISO, is crucial. Buyers should also consider the availability of specific thread types in their local markets.

What Are the Benefits of Using Heavy-Duty Needles?

Key Properties: Heavy-duty needles are designed to penetrate thick materials like leather, featuring a robust shaft and a sharp point.

Pros & Cons: These needles provide the necessary strength for sewing thick layers, ensuring clean and precise stitches. However, they can be more expensive than standard needles and may require specific adjustments to the sewing machine.

Impact on Application: Using the right needle is essential for maintaining the integrity of the leather and ensuring a professional finish. Incorrect needle selection can lead to damage to both the material and the sewing machine.

Considerations for International Buyers: Buyers should ensure that the needle types they choose comply with local standards and are readily available in their regions. For instance, European buyers might prefer needles that meet DIN standards.

Summary Table of Material Selection

| Material | Typical Use Case for leather machine company cobra class 4 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | High-end fashion items, saddles, and accessories | Exceptional durability and quality | High cost and variable quality | Hoch |

| Synthetic Leather | Upholstery, fashion items, and accessories | Cost-effective and water-resistant | Less durable than genuine leather | Medium |

| Threads | Essential for all leather sewing applications | Strong and UV resistant | Compatibility issues with some materials | Medium |

| Heavy-Duty Needles | Sewing thick leather layers | Ensures clean, precise stitches | Higher cost and specific adjustments needed | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers, ensuring they make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for leather machine company cobra class 4

What Are the Key Stages of the Manufacturing Process for Cobra Class 4 Leather Machines?

The manufacturing process of the Cobra Class 4 leather machine involves several critical stages that ensure high-quality output and durability. Understanding these stages can help B2B buyers gauge the reliability and efficiency of their suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The foundation of any high-quality leather machine lies in its materials. The Cobra Class 4 utilizes premium-grade steel and aluminum for structural components, ensuring strength and longevity. Raw materials undergo rigorous selection criteria based on mechanical properties and resistance to wear.

Once selected, materials are cut to size and prepped for forming. This may involve processes such as surface treatment or heat treatment to enhance durability and performance. These initial steps are crucial for minimizing defects in the final product.

Forming: What Techniques Are Used to Shape Components?

In the forming stage, components are shaped using advanced manufacturing techniques such as CNC machining and stamping. CNC machining allows for precise cuts and shapes, ensuring that each component meets stringent design specifications.

Stamping processes are employed for high-volume production of parts like presser feet and needle plates, where consistency is vital. The incorporation of robotics in this phase can enhance precision and reduce human error, further improving the overall quality of the machine.

Assembly: How Are Components Integrated into the Final Product?

The assembly stage involves integrating various components, such as motors, feed mechanisms, and electronic controls. Skilled technicians typically carry out this process, following strict assembly protocols to ensure that each machine operates seamlessly.

Attention to detail is paramount during assembly. Each unit is calibrated for optimal performance, ensuring that features like the triple feed mechanism and variable speed motor function as intended. This attention to detail can significantly impact the machine’s operational efficiency, making it essential for B2B buyers to understand the assembly practices of their suppliers.

Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage encompasses several processes, including surface finishing, painting, and quality checks. A protective coating may be applied to prevent corrosion and wear, which is particularly important in humid environments often found in regions like Africa and South America.

Final inspections are conducted to verify that each machine meets the required specifications before packaging. This stage ensures that the Cobra Class 4 not only looks aesthetically pleasing but also adheres to functional standards.

What Quality Assurance Measures Are in Place for Cobra Class 4 Machines?

Quality assurance (QA) is a critical component in the manufacturing of the Cobra Class 4 leather machine, ensuring that every unit meets international and industry-specific standards. B2B buyers should be aware of these measures to ensure they are sourcing high-quality machinery.

Which International Standards Govern Quality Assurance?

The Cobra Class 4 is manufactured in compliance with international standards such as ISO 9001, which focuses on quality management systems. This certification indicates that the company has established a robust framework for maintaining quality throughout the manufacturing process.

In addition, compliance with CE marking and other relevant certifications (such as API for certain components) ensures that the machines meet European safety and environmental requirements. B2B buyers should inquire about these certifications when assessing potential suppliers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is implemented at various stages of the manufacturing process, typically divided into three main checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Any materials that do not meet specified standards are rejected, ensuring that only high-quality components are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to monitor the quality of components and assemblies. This might include checking tolerances, dimensions, and operational functionality.

-

Final Quality Control (FQC): Before shipment, each machine undergoes a comprehensive final inspection. This includes functional testing to ensure that all features operate correctly and that the machine meets design specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the QC measures of suppliers:

-

Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems directly. This hands-on approach can provide valuable insights into the supplier’s commitment to quality.

-

Quality Reports: Requesting quality assurance reports can help buyers understand how the supplier tracks and manages quality throughout the manufacturing process. These reports often include metrics related to defect rates, compliance with standards, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process. These services can perform random inspections and provide detailed reports on compliance and quality metrics.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding local standards and ensuring that the supplier complies with them is crucial for avoiding legal issues.

-

Cultural Considerations: Communication styles and business practices can vary widely. Building strong relationships with suppliers and understanding their quality assurance processes can enhance collaboration and ensure that expectations are met.

-

Logistics and Supply Chain: The logistics involved in shipping heavy machinery like the Cobra Class 4 can introduce additional risks. Buyers should ensure that quality controls extend to packaging and shipping to prevent damage during transit.

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for the Cobra Class 4 leather machine is essential for B2B buyers. By assessing these factors, buyers can make informed decisions and establish long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather machine company cobra class 4’

Einführung

This practical sourcing guide is designed to assist B2B buyers in the procurement of the Cobra Class 4 leather sewing machine. By following this step-by-step checklist, you can ensure a well-informed purchase that meets your production needs and aligns with your business goals.

Illustrative image related to leather machine company cobra class 4

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for selecting the right machine. Consider factors such as the maximum leather thickness (up to 7/8″), sewing speed (3 to 22 stitches per inch), and throat size (16.5 inches). These specifications will help you identify machines that can handle your specific projects, whether they involve saddles, belts, or other heavy leather goods.

Step 2: Research Suppliers and Manufacturers

A thorough research of potential suppliers is essential for a successful purchase. Look for manufacturers with a strong reputation in the leather industry, particularly those that specialize in heavy-duty sewing machines. Verify their history, production capabilities, and customer feedback to gauge their reliability and service quality.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet your suppliers rigorously. Request detailed company profiles, case studies, and references from other businesses in your sector. Additionally, consider visiting their facilities or requesting virtual demonstrations to assess their production quality and customer service.

Illustrative image related to leather machine company cobra class 4

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers meet industry standards and certifications. Compliance with safety and quality regulations, such as ISO certifications, can be a good indicator of a supplier’s commitment to quality. This step mitigates risks related to equipment malfunction or substandard performance in your production environment.

Step 5: Assess Warranty and After-Sales Support

Understanding the warranty terms and after-sales support options is crucial for long-term operational efficiency. Look for suppliers that offer comprehensive warranties, ideally covering parts and labor. Inquire about their customer service policies, including response times and support for technical issues that may arise post-purchase.

Step 6: Compare Pricing and Payment Terms

Price comparison should go beyond the initial cost of the machine. Analyze the total cost of ownership, including shipping fees, potential import duties, and maintenance costs. Additionally, negotiate payment terms that align with your cash flow, such as installment payments or financing options.

Step 7: Finalize Your Purchase and Arrange Logistics

Once you have selected a supplier, finalize the purchase agreement by confirming all terms and conditions. Coordinate the logistics for delivery, including shipping timelines and any necessary customs documentation, especially if importing from international suppliers. This ensures a smooth transition from procurement to production.

By following these steps, B2B buyers can confidently navigate the sourcing process for the Cobra Class 4 leather sewing machine, ensuring they make an informed and strategic investment for their business.

Comprehensive Cost and Pricing Analysis for leather machine company cobra class 4 Sourcing

What Are the Key Cost Components for the Cobra Class 4 Leather Sewing Machine?

When sourcing the Cobra Class 4 leather sewing machine, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in the manufacturing of the Cobra Class 4 is a significant cost factor. High-grade metals for the machine’s body, durable plastic components, and specialized sewing mechanisms add to the overall cost. The choice of materials also influences the machine’s longevity and performance.

-

Labor: Labor costs vary based on the region of production. Skilled labor is essential for assembling complex machines like the Cobra Class 4, which involves precision engineering. Countries with higher labor costs may reflect this in the pricing of the machine.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation associated with the production facility. Efficient manufacturing processes can mitigate these costs, making it important for buyers to inquire about the supplier’s production efficiency.

-

Tooling: Tooling costs are related to the specific equipment needed to produce the Cobra Class 4. Custom tooling for unique specifications may increase the overall price, particularly if a buyer requires modifications or additional features.

-

Quality Control (QC): Stringent QC processes ensure that each machine meets safety and performance standards. While this adds to the cost, it is crucial for maintaining the brand’s reputation and ensuring customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the machine’s weight (approximately 325 lbs) and destination. International shipping, tariffs, and customs duties can significantly affect the final price.

-

Margin: The manufacturer’s margin will depend on their pricing strategy and market positioning. Understanding this aspect can help buyers negotiate more effectively.

How Do Price Influencers Affect the Cost of the Cobra Class 4?

Several factors influence the pricing of the Cobra Class 4, including:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating for better rates when placing bulk orders.

-

Specifications and Customization: Custom features or specifications can increase the machine’s price. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Machines made with higher-quality materials and those that meet international certifications may command a premium price. Buyers should evaluate whether the additional cost aligns with their needs.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can influence pricing. Established suppliers may offer better support, which can justify a higher price.

-

Incoterms: Understanding Incoterms is essential for buyers to clarify who is responsible for shipping costs, insurance, and tariffs. This knowledge can help in budgeting the total cost of acquisition effectively.

What Are Effective Buyer Tips for Sourcing the Cobra Class 4?

-

Negotiation Strategies: Engage in discussions about pricing and terms early in the sourcing process. Leverage your purchasing power, especially if you represent a larger organization or are placing a bulk order.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes maintenance, operational costs, and potential downtime. A higher upfront investment in a reliable machine could yield savings over its lifespan.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and shipping times. These factors can affect the final cost and should be factored into your budget.

-

Research Market Prices: Before finalizing your purchase, conduct market research to compare prices from different suppliers. This can provide leverage during negotiations and help ensure you are getting a competitive rate.

-

Request Detailed Quotations: Ensure that any quotes received include a breakdown of costs. This transparency will help you identify areas where you may be able to negotiate or find cost savings.

Understanding these components and strategies will empower international B2B buyers to make informed decisions when sourcing the Cobra Class 4 leather sewing machine. Always remember that prices are indicative and can vary based on specific requirements and market conditions.

Alternatives Analysis: Comparing leather machine company cobra class 4 With Other Solutions

Introduction: Evaluating Alternatives for Leather Sewing Machines

In the competitive landscape of leather sewing machines, B2B buyers often face a myriad of choices. The Cobra Class 4, renowned for its robust performance and versatility, is a popular option among leather craftsmen. However, understanding alternative solutions can empower buyers to make informed decisions tailored to their specific needs. This analysis compares the Cobra Class 4 with two viable alternatives, helping businesses assess their options based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Leather Machine Company Cobra Class 4 | TandyPro® Class 4 Dream Machine | Techsew 2700 Heavy-Duty Sewing Machine |

|---|---|---|---|

| Performance | Sews leather up to 7/8″ thick; 3-22 stitches per inch | Similar capabilities; 16.5″ throat space | Sews leather up to 1/2″; 5-20 stitches per inch |

| Cost | Approx. $3,399 | Approx. $3,399 | Approx. $1,200 |

| Ease of Implementation | Requires some setup; user manual provided | User-friendly; includes instructional materials | Straightforward setup; good for beginners |

| Wartung | Regular oiling and occasional servicing | Similar maintenance requirements | Generally low maintenance needs |

| Best Use Case | Ideal for heavy-duty leatherwork (saddles, holsters) | Versatile for various leather goods | Best for lighter projects and smaller businesses |

Detailed Breakdown of Alternatives

TandyPro® Class 4 Dream Machine

The TandyPro® Class 4 Dream Machine stands as a strong competitor to the Cobra Class 4. With a similar price point and performance capabilities, it also features a 16.5″ throat space, allowing for the sewing of various leather goods. Its triple feed mechanism and built-in bobbin winder enhance usability. However, like the Cobra, it requires regular maintenance to ensure optimal performance. This machine is particularly well-suited for businesses that require a versatile sewing solution, from crafting saddles to smaller leather items.

Techsew 2700 Heavy-Duty Sewing Machine

The Techsew 2700 offers a more budget-friendly alternative, priced significantly lower than both the Cobra and TandyPro machines. While it can handle leather up to 1/2″ thick, it is less powerful than the Cobra Class 4. This machine is ideal for smaller operations or businesses just starting in leatherworking. Its ease of setup and low maintenance requirements make it accessible for beginners. However, for those looking to tackle heavier projects, it may fall short in performance compared to the Cobra Class 4.

Illustrative image related to leather machine company cobra class 4

Conclusion: Choosing the Right Leather Sewing Machine for Your Business Needs

When selecting a leather sewing machine, it’s crucial for B2B buyers to assess their specific requirements, including the types of projects they plan to undertake and their budget constraints. The Cobra Class 4 excels in heavy-duty applications and offers robust features, making it a prime choice for established leather businesses. On the other hand, the TandyPro® Class 4 Dream Machine provides comparable performance with a focus on versatility, while the Techsew 2700 serves as an economical option for smaller businesses or those new to leatherworking. By weighing these factors, buyers can make a well-informed decision that aligns with their operational goals and project demands.

Essential Technical Properties and Trade Terminology for leather machine company cobra class 4

When considering the purchase of a leather sewing machine such as the Cobra Class 4, understanding its technical specifications and the relevant trade terminology is crucial for making informed decisions. This knowledge not only helps in selecting the right equipment but also facilitates smoother transactions and better negotiations.

What Are the Key Technical Specifications of the Cobra Class 4?

1. Throat Size: 16.5 inches (41.91 cm)

The throat size determines the maximum width of material that can be sewn, making it essential for accommodating larger projects like saddles and bags. A larger throat size increases versatility, allowing businesses to handle various leather goods without limitation.

2. Leather Thickness Limit: 6 oz. to 7/8 inch (2.4 mm to 22 mm)

This specification defines the range of leather thickness the machine can effectively sew. The ability to handle thick leather is vital for companies focused on heavy-duty applications, ensuring durability and quality in their products.

Illustrative image related to leather machine company cobra class 4

3. Stitches Per Inch (SPI): 3 to 22

The adjustable SPI allows users to customize the stitch density according to their project needs. Higher stitch counts can enhance the strength and appearance of seams, which is particularly important in high-quality leather goods.

4. Motor Type: Servo Motor, 110V, >4/5hp, 600W

The servo motor provides precise control over speed and power, which is essential for intricate sewing tasks. It also offers energy efficiency, a significant consideration for companies aiming to reduce operational costs.

5. Weight: 325 lbs. (147.42 kg)

The weight of the machine impacts its stability during operation. A heavier machine is less likely to vibrate, which can lead to more consistent stitching quality. Understanding the weight is important for logistics and workspace planning.

6. Triple Feed Mechanism

This feature ensures that the leather is moved uniformly through the machine, preventing uneven stitching. For businesses producing leather goods, this translates to higher quality and reduced waste due to misalignment.

What Are Common Trade Terms Related to Leather Machinery?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for businesses looking to source high-quality components or negotiate favorable pricing.

2. MOQ (Minimum Order Quantity)

This term refers to the smallest number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and planning inventory levels, ensuring that they do not overcommit financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. This process is essential for comparing prices and terms from different suppliers, aiding in cost-effective procurement.

Illustrative image related to leather machine company cobra class 4

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms used in international transactions. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which is crucial for smooth cross-border operations.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. Understanding lead times helps businesses plan their production schedules and manage customer expectations effectively.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. Knowing the warranty terms is essential for assessing the long-term value and reliability of the investment in machinery.

By familiarizing yourself with these specifications and trade terms, you can navigate the complexities of purchasing leather machinery more effectively, ensuring that your investments align with your business goals and operational needs.

Navigating Market Dynamics and Sourcing Trends in the leather machine company cobra class 4 Sector

What Are the Current Market Dynamics and Key Trends for the Cobra Class 4 Leather Machine?

The leather machine sector, particularly the Cobra Class 4 model, is experiencing notable growth driven by several global factors. Increasing demand for high-quality leather products in industries such as fashion, automotive, and outdoor gear is fueling this trend. Additionally, the rise of e-commerce platforms has made it easier for international buyers from regions like Africa, South America, the Middle East, and Europe—particularly Germany and Brazil—to access advanced machinery.

Emerging B2B technology trends, such as automation and digitalization, are reshaping the sourcing landscape. Buyers are increasingly looking for machines that not only offer robust performance but also come equipped with smart features like programmable stitching and data analytics capabilities. These features enhance operational efficiency and reduce waste, aligning with the growing emphasis on sustainability in manufacturing processes. Furthermore, the integration of online marketplaces is simplifying the sourcing process, allowing buyers to compare specifications and prices across various vendors efficiently.

How Does Sustainability Influence Sourcing Trends for Leather Machines?

Sustainability and ethical sourcing are becoming paramount in the leather machine industry, particularly for B2B buyers focusing on the Cobra Class 4 model. The environmental impact of leather production—ranging from water usage to chemical runoff—has led many companies to seek out suppliers who prioritize sustainable practices. This includes sourcing leather from tanneries that adhere to strict environmental regulations and use eco-friendly tanning methods.

Buyers are increasingly interested in machines that facilitate sustainable production methods. Features such as energy-efficient motors, reduced waste mechanisms, and compatibility with biodegradable materials are becoming key selling points. Certifications like the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification can enhance a supplier’s credibility and appeal to conscientious buyers. As a result, the demand for Cobra Class 4 machines that align with these sustainable practices is likely to increase, providing a competitive edge for manufacturers who prioritize ethical sourcing.

How Has the Cobra Class 4 Leather Machine Evolved Over Time?

The Cobra Class 4 leather machine has a rich history rooted in the evolution of leather crafting technologies. Originally designed for heavy-duty applications, the model has adapted to the changing needs of the leather industry. Over the years, enhancements in motor technology, such as the introduction of digital servo motors, have significantly improved the machine’s efficiency and user-friendliness.

This evolution reflects broader trends within the leather industry, where there is a growing emphasis on precision and versatility. As the market continues to demand more from leather products, the Cobra Class 4 has positioned itself as a reliable solution for businesses looking to meet high-quality standards while also addressing the operational challenges posed by modern manufacturing environments. Consequently, this machine has become a staple for B2B buyers seeking to invest in durable and capable leather sewing technology.

Frequently Asked Questions (FAQs) for B2B Buyers of leather machine company cobra class 4

-

How do I troubleshoot issues with my Cobra Class 4 machine?

To address common issues with the Cobra Class 4, start by checking the threading and tension settings, as improper threading can lead to skipped stitches or thread breaks. Ensure the needle is compatible and correctly installed, as a dull or wrong needle can affect performance. Regular maintenance, including oiling moving parts and cleaning the feed dogs, is crucial. If problems persist, consult the user manual for specific troubleshooting tips or reach out to the supplier for technical support. -

What types of leather can the Cobra Class 4 sew?

The Cobra Class 4 is versatile, capable of sewing leather ranging from 6 oz. to 7/8 inch (approximately 2.4 mm to 22 mm) thick. This includes various leather types suitable for crafting saddles, belts, holsters, and other heavy-duty items. For optimal performance, ensure you are using the correct needle and thread size for the leather type you are working with. This adaptability makes it an excellent choice for businesses involved in leather goods production across different markets. -

What payment terms should I expect when purchasing the Cobra Class 4?

Payment terms can vary by supplier, but many B2B transactions require a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. International buyers should inquire about payment methods accepted, such as bank transfers or letters of credit, which offer additional security. It’s also essential to clarify currency exchange rates and any potential fees associated with international transactions to avoid unexpected costs. -

What is the minimum order quantity (MOQ) for the Cobra Class 4?

The MOQ for the Cobra Class 4 can differ depending on the supplier’s policies and your specific needs. Some suppliers may allow single-unit purchases, while others may have a minimum of two or more machines to qualify for bulk pricing. When negotiating, consider discussing your long-term procurement plans, as this can lead to more favorable terms, especially if you intend to make recurring orders. -

How can I ensure the quality of the Cobra Class 4 machine?

To ensure the quality of the Cobra Class 4, request detailed specifications and warranty information from your supplier. It’s beneficial to ask for customer testimonials or case studies from other businesses in your region who have used the machine. Additionally, if possible, arrange for a demonstration or visit a local distributor to inspect the machine firsthand. Regular maintenance and using genuine parts can further enhance the longevity and performance of your investment. -

What are the shipping logistics for the Cobra Class 4 to my region?

Shipping logistics depend on the supplier’s location and your destination. Most suppliers provide an estimated shipping time, which typically ranges from 1-3 weeks for the Cobra Class 4. It’s crucial to discuss shipping options, costs, and potential customs duties with your supplier. Ensure you understand the shipping terms, including whether the price includes insurance and if there are any restrictions on shipping heavy machinery to your country. -

Can the Cobra Class 4 be customized for specific production needs?

Yes, many suppliers offer customization options for the Cobra Class 4 to better fit your production requirements. Customizations may include specialized attachments, modified throat sizes, or adjustments in motor specifications. To initiate this process, communicate your specific needs to the supplier early in the negotiation phase. Custom solutions can enhance efficiency and productivity, particularly for businesses with unique manufacturing processes. -

What support is available after purchasing the Cobra Class 4?

After purchasing the Cobra Class 4, most suppliers provide comprehensive support, including installation assistance, user manuals, and access to online resources like troubleshooting guides. It’s advisable to inquire about after-sales service, warranty coverage, and whether the supplier offers training sessions for your staff. Regular maintenance support or access to replacement parts can also be crucial for minimizing downtime and ensuring the machine operates at peak efficiency.

Top 3 Leather Machine Company Cobra Class 4 Manufacturers & Suppliers List

1. Cobra – Class 4 P Premium Package

Domain: leathermachineco.com

Registered: 2009 (16 years)

Introduction: Cobra Class 4 P Premium Package includes a Cobra Class 4 P sewing machine, a heavy-duty walking foot, a 1/4″ guide foot, a 1/8″ guide foot, a zipper foot, a roller foot, a stitch guide foot, a needle set, a bobbin set, a thread stand, and a carrying case. It is designed for leather and heavy materials, featuring a powerful motor and adjustable stitch length. The machine is suitable for various app…

2. Tandy Leather – Cobra Class 4 Dream Machine

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Cobra Class 4 Dream Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. American Leatherworks – COBRA Class 4 Leather Sewing Machine

Domain: americanleatherworks.com

Registered: 2009 (16 years)

Introduction: COBRA Class 4 Leather Sewing Machine

– Description: Perfect for skirting, tack, bullet loops, chap leather, and more. Heavy-duty presser feet and compact design for sewing in tight spaces.

– Premium Accessory Package includes: left/right toe presser feet, open toe center foot, double toe presser foot, work platform, 10x size 25/24/23 needles, thread holster plate, stirrup plate, slotted plate, bla…

Strategic Sourcing Conclusion and Outlook for leather machine company cobra class 4

In the competitive landscape of leather machinery, the Cobra Class 4 stands out as a robust solution for international buyers seeking efficiency and quality. With its impressive capability to sew through materials up to 7/8” thick and a throat space of 16.5 inches, this machine caters to a diverse range of applications—from saddles and holsters to heavy-duty belts. The advanced features, including a triple feed mechanism and variable speed digital DC servo motor, significantly enhance operational efficiency, making it a valuable asset for businesses aiming to streamline their production processes.

Strategic sourcing plays a pivotal role in maximizing the value derived from investments in equipment like the Cobra Class 4. By leveraging supplier relationships and understanding market dynamics, businesses can ensure they are obtaining the best possible pricing, support, and service.

As you consider integrating the Cobra Class 4 into your operations, remember that investing in quality machinery is not just about the upfront cost but the long-term gains in productivity and craftsmanship. Engage with suppliers who understand your market needs and can provide tailored solutions. Moving forward, seize the opportunity to elevate your leather production capabilities and stay ahead in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.