Introduction: Navigating the Global Market for whats faux leather

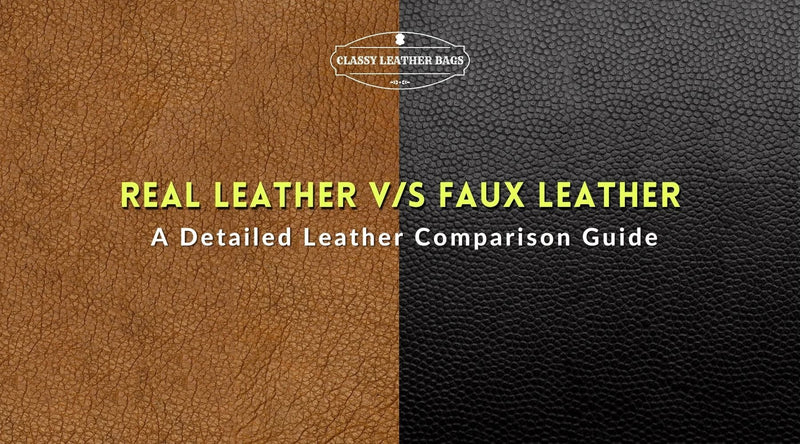

In an increasingly competitive global market, sourcing high-quality faux leather can present significant challenges for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. Faux leather, also known as synthetic or vegan leather, offers a versatile and cost-effective alternative to genuine leather, making it an appealing choice for various applications, from fashion to upholstery. This guide aims to equip international buyers with essential insights into the different types of faux leather available, their applications, and considerations for supplier vetting and cost analysis.

As the demand for sustainable and cruelty-free materials rises, understanding the properties and production processes of faux leather is crucial for making informed purchasing decisions. In this comprehensive resource, we delve into the characteristics of various faux leather types, explore their suitability for specific uses, and provide strategies for identifying reputable suppliers. Additionally, we address the implications of sourcing faux leather in terms of environmental impact and market trends, ensuring buyers are well-informed about their choices.

By leveraging the knowledge and insights contained within this guide, B2B buyers can navigate the complexities of the faux leather market with confidence, ensuring they select the best products that align with their business objectives while appealing to the growing consumer demand for ethical and sustainable materials.

Table Of Contents

- Top 2 Whats Faux Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for whats faux leather

- Understanding whats faux leather Types and Variations

- Key Industrial Applications of whats faux leather

- 3 Common User Pain Points for ‘whats faux leather’ & Their Solutions

- Strategic Material Selection Guide for whats faux leather

- In-depth Look: Manufacturing Processes and Quality Assurance for whats faux leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘whats faux leather’

- Comprehensive Cost and Pricing Analysis for whats faux leather Sourcing

- Alternatives Analysis: Comparing whats faux leather With Other Solutions

- Essential Technical Properties and Trade Terminology for whats faux leather

- Navigating Market Dynamics and Sourcing Trends in the whats faux leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of whats faux leather

- Strategic Sourcing Conclusion and Outlook for whats faux leather

- Important Disclaimer & Terms of Use

Understanding whats faux leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyurethane (PU) | Softer texture, more flexible, and breathable than PVC. | Apparel, upholstery, accessories, automotive interiors | Pros: High-quality feel, environmentally friendlier options. Cons: Higher cost compared to PVC. |

| Polyvinyl Chloride (PVC) | Durable, water-resistant, and often less expensive. | Furniture upholstery, bags, and rainwear | Pros: Cost-effective, good durability. Cons: Less breathable, may feel less premium. |

| Vegan Leather | Made from various plant-based materials, eco-friendly options available. | Fashion, eco-conscious products, furniture | Pros: Sustainable, animal-friendly. Cons: Variable quality, potential higher prices. |

| Naugahyde | A specific brand of synthetic leather known for its durability. | Commercial upholstery, automotive seating | Pros: Proven track record, strong performance. Cons: Brand-specific limitations on variety. |

| Microfiber Leather | Made from tightly woven synthetic fibers, resembling genuine leather. | Luxury goods, fashion, and upholstery | Pros: Soft texture, highly durable. Cons: Can be costlier, less known in some markets. |

What are the Characteristics of Polyurethane (PU) Faux Leather?

Polyurethane (PU) faux leather is recognized for its soft texture and flexibility, making it a popular choice for high-end applications. It is more breathable than other synthetic options, which enhances comfort in clothing and upholstery. B2B buyers should consider the environmental impact, as some PU products are now available with lower ecological footprints. However, PU tends to be more expensive than PVC, which can affect bulk purchasing decisions.

How Does Polyvinyl Chloride (PVC) Compare to Other Faux Leathers?

Polyvinyl Chloride (PVC) faux leather is characterized by its durability and resistance to water, making it suitable for a wide range of applications, including furniture and bags. While it is generally less expensive than PU, it lacks breathability, which can be a drawback for apparel. B2B buyers may find PVC appealing for budget-sensitive projects but should weigh the potential trade-offs in comfort and texture against cost.

Why Should Buyers Consider Vegan Leather?

Vegan leather, crafted from plant-based materials, offers an eco-friendly alternative to traditional faux leather. This type appeals to businesses targeting environmentally conscious consumers. While vegan leather can vary significantly in quality and price, its sustainability is a compelling selling point. Buyers should ensure they are sourcing from reputable manufacturers to guarantee product integrity and performance.

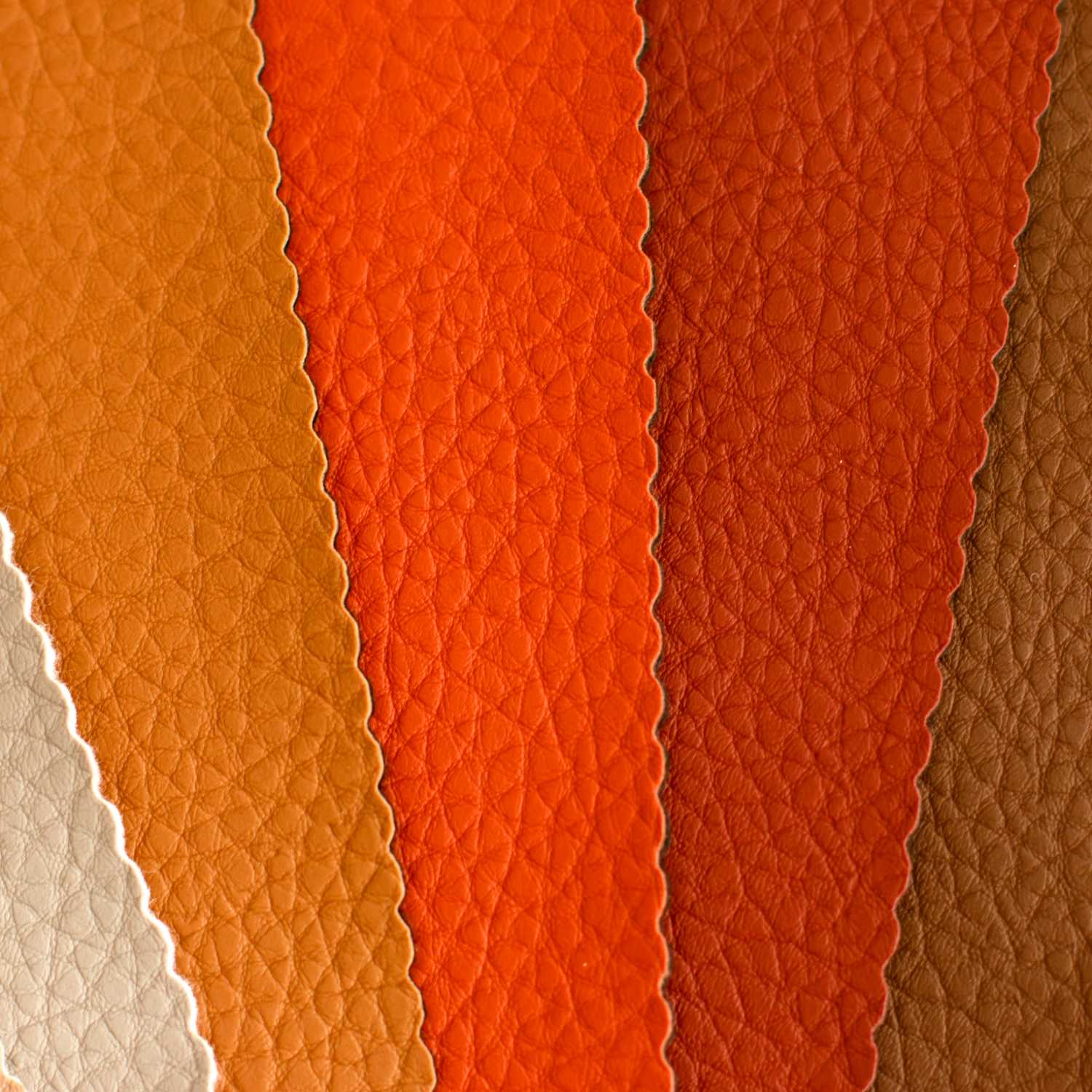

Illustrative image related to whats faux leather

What Makes Naugahyde a Reliable Choice for Commercial Applications?

Naugahyde is a well-established brand in the faux leather market, known for its durability and performance, especially in commercial settings like automotive and upholstery. Its long-standing reputation provides buyers with confidence in its quality. However, as a brand-specific option, it may limit variety compared to other faux leather types. B2B buyers should evaluate their specific needs against the available Naugahyde offerings.

What Are the Benefits of Microfiber Leather?

Microfiber leather is made from finely woven synthetic fibers, closely mimicking the look and feel of genuine leather. Its soft texture and high durability make it suitable for luxury goods and high-end upholstery. While it may come at a higher price point, the quality and performance can justify the investment for businesses looking to position themselves in premium markets. Buyers should consider their target demographic and the perceived value of microfiber products.

Key Industrial Applications of whats faux leather

| Industry/Sector | Specific Application of whats faux leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Handbags and Footwear | Cost-effective alternative to leather, appealing to eco-conscious consumers | Durability, color variety, and sourcing of eco-friendly materials |

| Automotive | Upholstery for Car Interiors | Enhances aesthetics while being easier to maintain than leather | Resistance to wear and tear, compliance with safety standards |

| Furniture and Upholstery | Sofas and Chairs | Provides a stylish look at a lower cost, easy to clean and maintain | Quality of finish, resistance to stains, availability of colors |

| Sports Equipment | Athletic Gear and Accessories | Lightweight, water-resistant, and easy to clean, ideal for outdoor use | Breathability, flexibility, and durability against abrasions |

| Home Décor | Wall Hangings and Decorative Items | Offers a luxurious appearance at a fraction of the cost of genuine leather | Sourcing options for custom designs and textures, environmental impact |

How is Faux Leather Used in the Fashion and Apparel Industry?

In the fashion sector, faux leather is predominantly utilized for handbags and footwear. This material offers a cost-effective alternative to genuine leather, making it attractive for brands targeting eco-conscious consumers. Faux leather can be produced in various colors and textures, allowing designers to create unique pieces without the ethical concerns associated with animal-derived materials. For international buyers, sourcing considerations should include durability and the availability of eco-friendly options, especially in markets where sustainability is increasingly valued.

What Role Does Faux Leather Play in the Automotive Industry?

Faux leather is widely used for car upholstery, providing an aesthetic appeal while being easier to clean and maintain compared to genuine leather. It enhances the overall look of vehicle interiors and is often more affordable, which can significantly lower manufacturing costs for automotive companies. Buyers should focus on sourcing materials that comply with safety standards and are resistant to wear and tear, especially in regions like Africa and the Middle East, where climate conditions can affect material longevity.

Illustrative image related to whats faux leather

Why is Faux Leather Popular in Furniture and Upholstery?

In the furniture industry, faux leather is favored for sofas and chairs due to its stylish appearance and lower cost compared to real leather. It is also easy to clean, making it suitable for homes with children or pets. B2B buyers in this sector need to consider the quality of the finish and the material’s resistance to stains, particularly in markets where consumers prioritize durability and maintenance ease.

How is Faux Leather Beneficial in Sports Equipment?

Faux leather is increasingly being utilized in athletic gear and accessories, offering lightweight and water-resistant properties ideal for outdoor sports. This material is easier to clean and maintain, making it a practical choice for athletes and outdoor enthusiasts. Buyers should prioritize sourcing faux leather that provides both breathability and flexibility, ensuring it meets the demands of active users, particularly in regions with diverse climates.

In What Ways is Faux Leather Used in Home Décor?

In home décor, faux leather is often used for wall hangings and decorative items, providing a luxurious look at a fraction of the cost of genuine leather. It allows for creative design options, appealing to consumers looking to enhance their living spaces. For international buyers, sourcing considerations include options for custom designs and textures, as well as the environmental impact of the materials used, which is becoming increasingly important in markets across Europe and South America.

3 Common User Pain Points for ‘whats faux leather’ & Their Solutions

Scenario 1: Understanding the Durability and Maintenance of Faux Leather Products

The Problem: B2B buyers often face uncertainty regarding the durability and maintenance of faux leather products. Many are concerned about whether synthetic leather will withstand wear and tear, particularly in high-use environments such as hospitality or automotive industries. Additionally, the varying quality of faux leather can lead to confusion about maintenance requirements, resulting in potential product damage or dissatisfaction from end users.

The Solution: To address these concerns, buyers should prioritize sourcing high-quality faux leather made from polyurethane (PU) rather than polyvinyl chloride (PVC), as PU tends to offer better durability and breathability. When selecting faux leather, request samples to assess the material’s texture and resilience. Additionally, establish clear maintenance guidelines with your suppliers. For instance, recommend regular spot cleaning with mild soap and water, avoiding harsh chemicals that can degrade the material. Providing end users with a care guide that includes cleaning tips and recommended cleaning products can help preserve the appearance and lifespan of faux leather items.

Illustrative image related to whats faux leather

Scenario 2: Navigating Ethical and Environmental Concerns in Faux Leather Sourcing

The Problem: B2B buyers are increasingly pressured to consider the ethical and environmental implications of their sourcing decisions. With rising consumer awareness about sustainability, buyers need to ensure that the faux leather products they choose do not contribute to environmental degradation or animal cruelty. This concern is particularly relevant in regions where consumers prioritize ethical sourcing, such as Europe.

The Solution: Buyers should actively seek suppliers who offer eco-friendly faux leather options, such as those made from vegetable-based materials or recycled plastics. When evaluating suppliers, inquire about their production processes, certifications, and sustainability practices. Establishing partnerships with manufacturers committed to ethical practices not only mitigates environmental concerns but also positions your brand as a responsible market player. Additionally, consider incorporating transparency in your marketing materials, highlighting the sustainable attributes of your products to appeal to eco-conscious consumers.

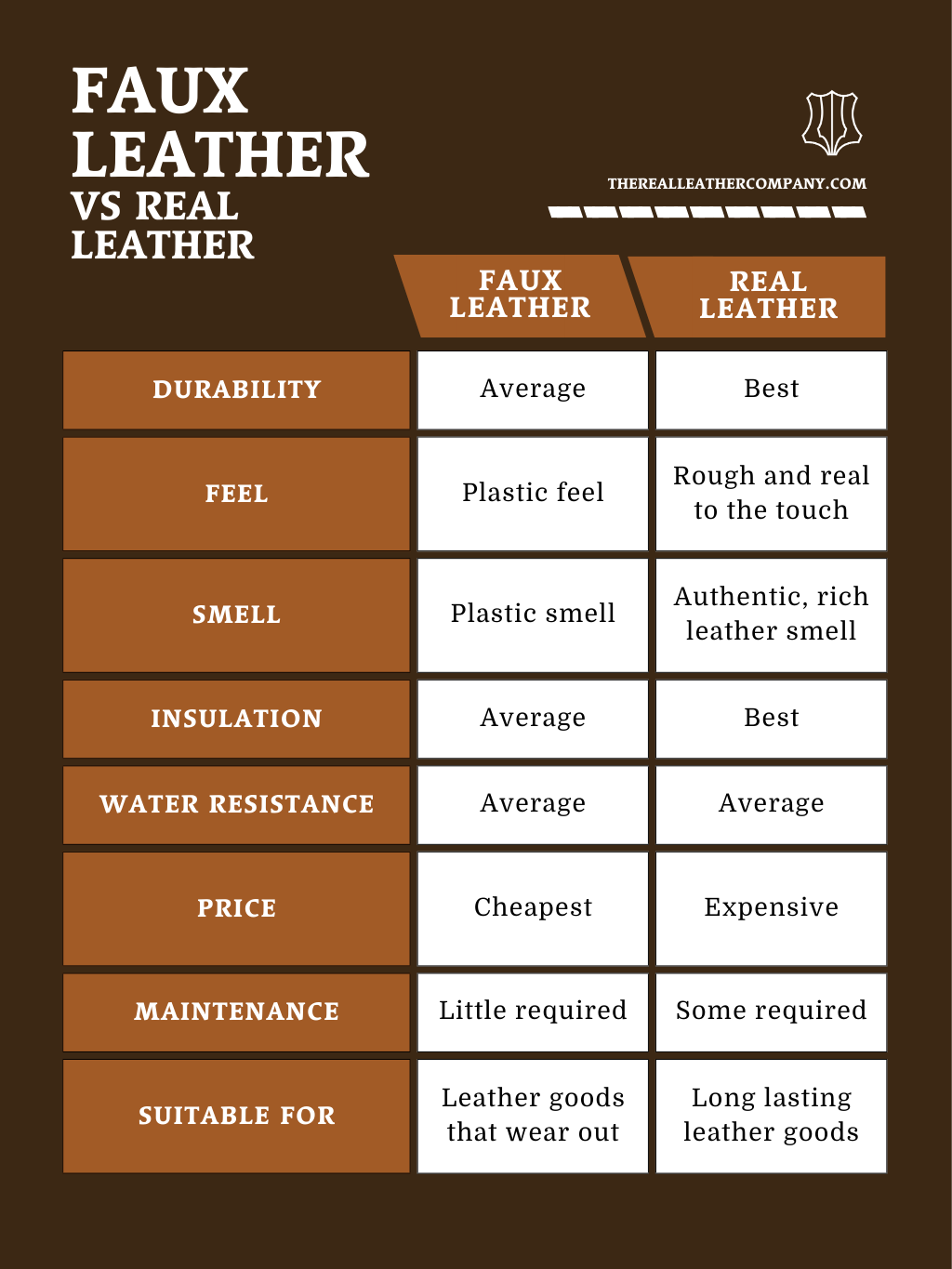

Scenario 3: Differentiating Faux Leather from Genuine Leather in the Market

The Problem: In competitive markets, B2B buyers struggle to effectively communicate the benefits of faux leather over genuine leather, especially when customers have strong brand loyalties to traditional leather products. This challenge is compounded by the misconception that faux leather is of inferior quality, which can hinder sales and market penetration.

Illustrative image related to whats faux leather

The Solution: To overcome this barrier, B2B buyers should invest in comprehensive product education and marketing strategies that highlight the unique advantages of faux leather. This includes emphasizing its affordability, versatility, and ease of maintenance. Develop marketing materials that showcase faux leather’s ability to mimic the look and feel of genuine leather while offering a wider range of colors and designs. Create case studies or testimonials from satisfied customers who have successfully used faux leather in their applications. Additionally, consider hosting workshops or webinars to educate potential customers about the benefits and applications of faux leather, thereby building trust and credibility in your product offerings.

Strategic Material Selection Guide for whats faux leather

What Are the Key Materials Used in Faux Leather Production?

When selecting faux leather for various applications, understanding the materials involved is crucial for B2B buyers. Here, we analyze the most common materials used in faux leather production: Polyvinyl Chloride (PVC), Polyurethane (PU), and Vegetable-based synthetics. Each material has unique properties, advantages, and limitations that can significantly impact product performance and suitability for specific applications.

What Are the Properties and Performance of PVC in Faux Leather?

Polyvinyl Chloride (PVC) is one of the most widely used materials in faux leather production. It is known for its durability and resistance to moisture, making it suitable for various applications, including upholstery and fashion accessories. PVC has a temperature tolerance ranging from -10°C to 60°C, which can be beneficial in warmer climates. However, it has low breathability and can feel stiff compared to other materials.

Pros: PVC is cost-effective and offers good abrasion resistance, making it a popular choice for budget-conscious buyers. Its water-resistant properties also make it ideal for items like bags and upholstery in humid environments.

Cons: The rigidity of PVC can limit its use in applications requiring flexibility. Additionally, environmental concerns regarding its production and disposal may deter some buyers, particularly in regions with stringent regulations.

How Does Polyurethane (PU) Compare as a Faux Leather Material?

Polyurethane (PU) is another prevalent material in faux leather, known for its soft texture and flexibility. It mimics the feel of genuine leather more closely than PVC, making it a popular choice for high-end fashion items and upholstery. PU can withstand temperatures between -20°C and 50°C, which makes it suitable for various climates.

Illustrative image related to whats faux leather

Pros: PU is more environmentally friendly than PVC, as it can be produced without harmful chemicals. It also offers better breathability, making it suitable for clothing and accessories that require comfort.

Cons: PU is generally more expensive than PVC, which can be a consideration for budget-sensitive projects. Additionally, its durability may not match that of PVC in high-wear applications, leading to a shorter lifespan.

What Are the Advantages of Vegetable-Based Faux Leather?

Vegetable-based synthetics are an emerging alternative to traditional faux leather materials. These products are made from plant-based sources, offering a more sustainable option for environmentally conscious buyers. They can be suitable for a variety of applications, including fashion and upholstery, and typically exhibit good temperature resistance.

Pros: The primary advantage of vegetable-based faux leather is its biodegradability, which aligns with growing consumer demand for sustainable products. Additionally, it can be produced in various textures and colors, appealing to diverse market segments.

Cons: The manufacturing process for vegetable-based synthetics can be more complex and costly, which may limit their adoption in price-sensitive markets. Furthermore, their performance characteristics can vary widely depending on the specific formulation used.

Illustrative image related to whats faux leather

What Should International Buyers Consider When Selecting Faux Leather Materials?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must consider several factors when selecting faux leather materials. Compliance with local regulations and standards, such as ASTM, DIN, or JIS, is critical to ensure product safety and quality. Additionally, buyers should be aware of regional preferences for sustainability and animal welfare, which may influence their choice of materials. Understanding the local market dynamics, including pricing and availability, will also aid in making informed purchasing decisions.

Summary Table of Faux Leather Materials

| Material | Typical Use Case for whats faux leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Upholstery, bags, and fashion accessories | Cost-effective and water-resistant | Low breathability and rigidity | Low |

| Polyurethane (PU) | Clothing, high-end fashion, and upholstery | Soft texture and better breathability | Higher cost and potentially lower durability | Med |

| Vegetable-based synthetics | Eco-friendly fashion and upholstery | Biodegradable and sustainable | Higher manufacturing complexity and cost | High |

This analysis provides a comprehensive overview of the materials used in faux leather production, equipping B2B buyers with the insights needed to make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for whats faux leather

What Are the Main Stages in the Manufacturing Process of Faux Leather?

Faux leather manufacturing involves a series of well-defined stages, each critical to ensuring the final product meets quality and performance standards. Understanding these stages helps B2B buyers identify reliable suppliers and assess their production capabilities.

How Is Material Prepared for Faux Leather Production?

The first stage in faux leather production is material preparation, which involves sourcing and processing the base fabrics. Typically, manufacturers use cotton or polyester, chosen for their porous nature, which allows for better adhesion of the plastic coating. Buyers should inquire about the origin of these base materials, as their quality can directly impact the performance of the final product.

Once the base fabric is selected, it undergoes a treatment process to enhance its properties. This may include chemical treatments to improve durability, moisture resistance, and flexibility. Buyers should consider suppliers who provide transparency regarding their material sourcing and treatment processes, as these factors are crucial for overall product integrity.

What Techniques Are Used for Forming Faux Leather?

The forming stage is where the plastic components are applied to the base fabric. The two most common materials used are Polyvinyl Chloride (PVC) and Polyurethane (PU). Each has its unique formulation and processing method. PVC, for example, is created through a complex chemical reaction involving salt and petroleum derivatives, while PU requires a more intricate process involving isocyanates and polyols.

During the forming stage, the plastic is typically melted and then bonded to the base fabric using techniques such as heat lamination or coating. This process can significantly affect the texture and appearance of the faux leather, so B2B buyers should request samples to evaluate the tactile qualities and visual appeal.

How Is Assembly and Finishing Conducted in Faux Leather Production?

Once the faux leather is formed, it moves to the assembly stage, where it is cut and shaped into the desired products. This could include garments, upholstery, or accessories. Precision in cutting and assembly is crucial, especially for products that require specific dimensions or designs.

The finishing stage includes adding protective coatings, dyes, or textures that enhance the aesthetic qualities of the faux leather. Finishing techniques can vary widely, and the choice of techniques can significantly impact the durability and overall look of the final product. B2B buyers should inquire about the finishing processes employed by suppliers to ensure they align with their specific product requirements.

What Quality Assurance Measures Are Critical for Faux Leather Manufacturing?

Quality assurance (QA) is essential in the faux leather manufacturing process, ensuring that products meet both international standards and customer expectations. B2B buyers need to understand the key QA measures in place to make informed purchasing decisions.

Which International Standards Should Faux Leather Manufacturers Comply With?

Faux leather manufacturers should adhere to international quality management standards such as ISO 9001, which focuses on consistent quality and customer satisfaction. Other relevant certifications may include CE marking for products sold in the European market and API standards for specific applications.

These certifications indicate that the manufacturer has implemented a robust quality management system, which can give B2B buyers confidence in the products they are sourcing. It is advisable for buyers to request documentation of these certifications to verify compliance.

Illustrative image related to whats faux leather

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predefined standards.

- In-Process Quality Control (IPQC): This ongoing inspection occurs during production, where samples may be taken at various stages to assess quality.

- Final Quality Control (FQC): At this stage, the finished products are thoroughly inspected for defects and compliance with specifications before they are packaged and shipped.

B2B buyers should inquire about the specific QC checkpoints their potential suppliers implement to ensure rigorous quality standards throughout production.

What Common Testing Methods Are Used to Ensure Faux Leather Quality?

Testing methods for faux leather can include:

- Physical Testing: Assessing properties such as tensile strength, abrasion resistance, and flexibility to determine durability.

- Chemical Testing: Evaluating the material for harmful substances and ensuring compliance with safety regulations.

- Environmental Testing: Simulating conditions like exposure to moisture, UV light, and temperature variations to assess performance under real-world conditions.

Buyers should ask suppliers for detailed testing reports to verify that the products meet necessary quality and safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure the integrity of the faux leather products they are sourcing, B2B buyers should take proactive steps in verifying supplier quality control processes.

What Steps Can Buyers Take for Supplier Audits and Assessments?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control practices. This can include on-site visits to evaluate production facilities, review quality assurance practices, and inspect inventory management systems. Buyers can also request third-party audits from accredited organizations to gain an objective assessment of the supplier’s capabilities.

How Can Buyers Utilize Reports and Documentation for Quality Assurance?

Buyers should request comprehensive reports and documentation related to quality control processes, including testing results, compliance certificates, and inspection records. These documents provide insight into the supplier’s commitment to quality and can help identify any potential risks in the supply chain.

Illustrative image related to whats faux leather

What Are the QC and Certification Nuances for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional regulations and standards is crucial. Different markets may have unique requirements regarding product safety, environmental impact, and material sourcing.

Buyers should be aware of any regional certifications that may be necessary for their specific market and ensure that suppliers can provide evidence of compliance. This not only protects the buyer but also enhances the brand’s reputation in the market.

Conclusion

Understanding the manufacturing processes and quality assurance measures in faux leather production is vital for B2B buyers aiming to source reliable and high-quality materials. By engaging with suppliers on these topics, buyers can ensure they are making informed decisions that align with their product standards and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘whats faux leather’

To assist B2B buyers in successfully sourcing faux leather, this practical guide outlines essential steps to ensure a smooth procurement process. As demand for faux leather continues to rise globally, especially in regions like Africa, South America, the Middle East, and Europe, understanding how to navigate this market is crucial for making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the faux leather you need. Consider factors such as composition (PVC vs. PU), intended use (apparel, upholstery, etc.), and desired properties (breathability, durability, and aesthetics). This clarity will guide your supplier search and ensure that the materials meet your quality requirements.

Illustrative image related to whats faux leather

Step 2: Identify Reputable Suppliers

Conduct thorough research to identify reputable suppliers of faux leather. Look for manufacturers with a strong track record and positive reviews from other B2B buyers. Utilize online platforms, industry directories, and trade shows to compile a list of potential suppliers who specialize in faux leather.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to their production capabilities, quality control processes, and response times to inquiries.

- Sub-bullets:

- Ask about their experience with faux leather and any specific certifications they hold.

- Verify their ability to meet your volume needs and delivery schedules.

Step 4: Request Samples

Always request samples of the faux leather products you are considering. This step is vital to assess the quality, texture, and color accuracy of the material. Evaluating samples helps you ensure that the product aligns with your defined specifications and intended application.

- Sub-bullets:

- Examine samples for consistency in texture and color.

- Consider testing samples under actual use conditions to evaluate durability.

Step 5: Understand Pricing and Payment Terms

Clarify pricing structures and payment terms with your chosen suppliers. Ensure that you comprehend the cost per unit, any minimum order quantities, and potential shipping fees. Understanding these financial aspects upfront will help you budget effectively and avoid unexpected costs.

- Sub-bullets:

- Inquire about bulk pricing discounts and payment options (e.g., letters of credit, net 30 terms).

- Discuss any potential for price fluctuations due to raw material costs.

Step 6: Assess Environmental and Ethical Standards

Given the growing concern over sustainability, evaluate suppliers’ environmental practices and ethical standards. Inquire about their production processes, waste management, and use of eco-friendly materials. This assessment will not only align with your corporate social responsibility goals but also enhance your brand’s image.

- Sub-bullets:

- Look for certifications related to sustainability (e.g., OEKO-TEX, GRS).

- Consider suppliers that offer vegetable-based or biodegradable faux leather options.

Step 7: Negotiate and Finalize Contracts

Once you have selected a supplier, negotiate the terms of your contract carefully. Ensure all specifications, pricing, delivery timelines, and quality assurances are documented. A well-structured contract protects both parties and lays the foundation for a successful long-term partnership.

- Sub-bullets:

- Include clauses for quality assurance and penalties for non-compliance.

- Establish clear communication channels for ongoing support and issue resolution.

By following these steps, B2B buyers can effectively navigate the faux leather sourcing process, ensuring they obtain high-quality materials that meet their specific needs while fostering sustainable and ethical business practices.

Comprehensive Cost and Pricing Analysis for whats faux leather Sourcing

What Are the Key Cost Components in Faux Leather Sourcing?

When sourcing faux leather, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to whats faux leather

-

Materials: Faux leather is predominantly made from PVC or PU, with costs varying based on the type of plastic and any additional treatments or finishes applied. Vegetable-based alternatives may carry a premium due to their sustainable attributes.

-

Labor: Labor costs can fluctuate significantly depending on the region of production. Countries with lower labor costs may offer more competitive pricing, but this could impact quality and consistency.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. In regions with higher operational costs, such as Europe, these expenses can add significantly to the final price of faux leather.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should factor these costs into their overall budget, particularly for unique specifications.

-

Quality Control (QC): Ensuring that the faux leather meets international quality standards involves additional costs. Effective QC processes can prevent defects that lead to costly returns.

-

Logistics: Transportation and shipping costs can vary based on the destination and Incoterms used. For international buyers, understanding freight charges and potential tariffs is critical.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary widely based on the supplier’s market positioning, reputation, and the demand for faux leather.

How Do Price Influencers Affect Faux Leather Costs?

Several factors influence the pricing of faux leather, which can impact your sourcing strategy:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to lower per-unit costs. Establishing a long-term relationship with suppliers may also yield better pricing structures.

-

Specifications and Customization: Custom designs or specific colors can increase costs. Buyers should clarify their needs upfront to avoid unexpected price increases.

-

Material Quality and Certifications: Higher quality materials or certifications (e.g., eco-friendly) generally come at a premium. Buyers should weigh the benefits of these attributes against their budget.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can affect pricing. Established suppliers may charge more due to their reliability and product quality.

-

Incoterms: Understanding the terms of shipping can have a significant impact on total costs. Different Incoterms dictate who is responsible for shipping costs, insurance, and customs duties.

What Are the Best Negotiation and Cost-Efficiency Tips for B2B Buyers?

To optimize sourcing costs for faux leather, consider the following strategies:

-

Negotiate Terms: Engage in open discussions with suppliers about pricing, payment terms, and delivery schedules. Flexibility on both sides can lead to mutually beneficial agreements.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider shipping, storage, and potential wastage to get a complete picture of costs.

-

Understand Pricing Nuances for International Sourcing: Different regions may have varying pricing structures based on local demand, production capabilities, and economic factors. For buyers from Africa, South America, the Middle East, and Europe, it’s essential to research local market conditions and adjust strategies accordingly.

-

Build Long-Term Relationships: Establishing a partnership with suppliers can lead to better pricing, reliability, and quality assurance over time.

Disclaimer on Pricing

Prices for faux leather are subject to fluctuations based on market conditions, material costs, and supplier pricing strategies. Always conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing whats faux leather With Other Solutions

Exploring Alternatives to Faux Leather: What Are the Options?

In the quest for sustainable and cost-effective materials, faux leather has emerged as a popular choice among manufacturers and consumers alike. However, several alternatives exist that also cater to the demand for leather-like products. This section will compare faux leather against two significant alternatives: genuine leather and plant-based leather. Understanding these options will help B2B buyers make informed decisions that align with their business needs and values.

| Comparison Aspect | Whats Faux Leather | Genuine Leather | Plant-Based Leather |

|---|---|---|---|

| Performance | Water-resistant, less durable than real leather | Highly durable, ages well | Moderate durability, varies by type |

| Cost | Generally lower than genuine leather | Higher due to sourcing and processing | Competitive, often slightly higher than faux leather |

| Ease of Implementation | Easy to source and process | Requires skilled labor for tanning | Growing market, but may have sourcing challenges |

| Maintenance | Low maintenance, easy to clean | Requires regular conditioning | Varies by type, generally low maintenance |

| Best Use Case | Upholstery, fashion accessories | High-end goods, luxury items | Eco-friendly products, casual wear |

What Are the Advantages and Disadvantages of Genuine Leather?

Genuine leather is renowned for its durability and aesthetic appeal, often sought for high-end products such as luxury handbags and furniture. One of the primary advantages is its longevity; with proper care, genuine leather can last decades. However, it comes with a higher cost due to the ethical concerns surrounding animal sourcing and the environmental impact of the tanning process. For B2B buyers in regions with a strong demand for premium products, genuine leather may be a worthwhile investment, provided they can justify the cost.

Illustrative image related to whats faux leather

How Does Plant-Based Leather Compare to Faux Leather?

Plant-based leather, made from materials such as pineapple leaves, apple peels, or other agricultural waste, has gained traction as a sustainable alternative. Its eco-friendly attributes appeal to consumers looking for ethical choices. The performance of plant-based leather can vary, but it generally offers moderate durability and is suitable for casual wear and accessories. While it may be slightly more expensive than faux leather, its unique marketing angle can justify the price for brands targeting environmentally conscious consumers. However, sourcing challenges may arise, particularly in regions where these materials are not readily available.

Conclusion: How Should B2B Buyers Choose the Right Leather Alternative?

When selecting the right material, B2B buyers should evaluate their specific needs, including performance requirements, budget constraints, and the target market’s preferences. For businesses focused on eco-friendly practices, plant-based leather presents a compelling option, while those aiming for luxury may lean towards genuine leather despite its higher cost. Faux leather remains an excellent choice for cost-conscious manufacturers seeking versatility and ease of use. By carefully analyzing these alternatives, buyers can align their material choices with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for whats faux leather

What Are the Key Technical Properties of Faux Leather for B2B Buyers?

Understanding the essential technical properties of faux leather is critical for B2B buyers looking to make informed procurement decisions. Here are some key specifications to consider:

1. Material Composition

Faux leather is primarily made from two types of plastics: Polyvinyl Chloride (PVC) and Polyurethane (PU). PVC is often less expensive but less breathable, while PU offers a more leather-like feel and better breathability. For buyers, knowing the composition helps in determining the suitability of faux leather for specific applications, such as upholstery or fashion accessories.

2. Breathability

Breathability refers to the fabric’s ability to allow air and moisture to pass through. Faux leather typically has low breathability, which can impact comfort in clothing and accessories. For buyers in warmer climates or those producing items like footwear, this property is vital for ensuring consumer satisfaction.

3. Durability and Resistance

Faux leather is generally resistant to abrasions and cuts, making it suitable for various applications. However, it is less durable than genuine leather, which is a critical consideration for long-term use products like furniture or automotive interiors. Buyers should assess the expected lifespan and performance requirements of their products to choose the right type of faux leather.

4. Maintenance Requirements

Faux leather is easy to clean and maintain, often requiring only spot cleaning or professional cleaning services. This low-maintenance characteristic is attractive for buyers in industries like hospitality or automotive, where cleanliness and upkeep are crucial for customer experience.

5. Thermal Properties

Faux leather exhibits high heat retention, making it an excellent choice for outerwear and winter clothing. This property is particularly relevant for buyers in colder regions, as it can influence the performance and comfort of their products.

What Are Common Trade Terminology and Jargon in the Faux Leather Industry?

Navigating the faux leather market requires familiarity with specific trade terms that can significantly impact procurement processes and negotiations. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. For faux leather, this could mean manufacturers who supply to brands that create handbags or furniture. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better terms.

Illustrative image related to whats faux leather

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the faux leather industry, MOQs can vary widely based on the supplier and material. Buyers should clarify MOQs to ensure they can meet their inventory needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. For faux leather, an RFQ can help buyers compare different suppliers and negotiate better prices, ensuring they get the best value for their investment.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade. They specify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to manage costs and logistics effectively when importing faux leather products.

Illustrative image related to whats faux leather

5. Customization

Customization refers to the ability to tailor products to specific requirements, such as color, texture, or thickness of faux leather. This is particularly important for buyers in fashion or upholstery who want to differentiate their products in the market.

6. Sustainability Certifications

As environmental concerns rise, sustainability certifications indicate that a product meets certain ecological standards. Buyers increasingly seek faux leather products with certifications to align with consumer preferences for eco-friendly options, especially in regions sensitive to sustainability issues.

By grasping these properties and terminologies, B2B buyers can make strategic decisions that enhance their product offerings and ensure competitive advantage in the market.

Navigating Market Dynamics and Sourcing Trends in the whats faux leather Sector

What Are the Key Market Trends Impacting the Faux Leather Sector?

The faux leather market is experiencing significant growth, driven by a combination of ethical consumerism, technological advancements, and changing fashion trends. Globally, the demand for sustainable and cruelty-free alternatives to genuine leather is on the rise, particularly in regions like Africa, South America, the Middle East, and Europe. This is evident in countries such as Nigeria and Saudi Arabia, where consumers are increasingly prioritizing eco-friendly products.

Emerging technologies, such as digital printing and innovative manufacturing processes, are enhancing the quality and aesthetic appeal of faux leather. B2B buyers can leverage these advancements to offer products that not only meet current consumer preferences but also set trends in their respective markets. Additionally, the rise of e-commerce platforms facilitates easier access to a broader range of suppliers, allowing international buyers to source unique faux leather products that cater to local tastes.

Illustrative image related to whats faux leather

Market dynamics are also influenced by the competitive pricing of faux leather compared to genuine leather, making it an attractive option for manufacturers and retailers. As the global market continues to expand, particularly in developing economies, B2B buyers should stay informed about regional trends and consumer preferences to effectively position their offerings.

How Can Sustainability and Ethical Sourcing Impact Your B2B Strategies?

Sustainability has become a pivotal concern in the faux leather industry, prompting a shift towards more environmentally friendly practices. The production of traditional synthetic leather often involves harmful chemicals and non-biodegradable materials, raising ethical questions among consumers and stakeholders. B2B buyers must prioritize suppliers that demonstrate commitment to sustainable practices, such as using vegetable-based materials or adopting eco-friendly production processes.

Ethical sourcing is not just a trend; it has become essential for businesses looking to enhance their brand reputation and meet regulatory requirements. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By partnering with certified suppliers, B2B buyers can ensure that their product offerings align with consumer expectations for transparency and responsibility.

Moreover, as regulations around environmental impact become more stringent worldwide, companies that proactively adopt sustainable practices will likely enjoy a competitive advantage. Buyers should assess the supply chain thoroughly, focusing on sourcing materials that minimize environmental impact while still delivering high-quality faux leather products.

What Is the Historical Context of Faux Leather and Its Relevance Today?

The faux leather industry has evolved significantly since its inception in the early 20th century. Initially developed as a substitute for genuine leather during wartime, faux leather gained popularity with the introduction of Naugahyde in the 1920s. Over the decades, advancements in production techniques have led to the creation of more durable and aesthetically pleasing alternatives.

Illustrative image related to whats faux leather

Today, the history of faux leather is not just about its origins but also its adaptation to modern consumer demands. The recent shift towards sustainability has led to the development of innovative materials that are both eco-friendly and functional. This historical context provides valuable insights for B2B buyers, as understanding the evolution of faux leather can help them anticipate future trends and consumer preferences.

As the market continues to grow, international buyers can leverage this historical knowledge to make informed sourcing decisions that align with current and emerging trends, ensuring they remain competitive in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of whats faux leather

-

How do I determine the quality of faux leather for my business needs?

To assess the quality of faux leather, consider factors such as the material composition (PU vs. PVC), texture, durability, and resistance to wear and tear. Request samples from suppliers to evaluate their products first-hand. Additionally, check for certifications that indicate compliance with international standards for safety and environmental impact. Engaging with suppliers who can provide detailed specifications and have positive reviews from other B2B clients can further ensure you are sourcing high-quality faux leather. -

What is the best faux leather type for upholstery applications?

For upholstery, polyurethane (PU) faux leather is often preferred due to its superior softness, breathability, and durability compared to PVC. PU faux leather provides a more luxurious feel and is less prone to cracking, making it ideal for items like sofas, chairs, and automotive interiors. Ensure that the chosen material is treated for stain resistance and easy cleaning, which are essential for maintaining upholstery in high-traffic areas. -

What are the common customization options available for faux leather products?

Most suppliers offer various customization options, including color, texture, thickness, and even patterns for faux leather. Depending on your specific needs, you can request unique prints or finishes that align with your brand identity. Discuss minimum order quantities (MOQs) with suppliers, as these can vary significantly based on the level of customization. Additionally, inquire about lead times for custom orders to plan your inventory accordingly. -

What should I consider when vetting faux leather suppliers for international trade?

When vetting suppliers, prioritize their reputation, production capabilities, and compliance with international quality standards. Check for certifications, such as ISO or Oeko-Tex, which indicate adherence to safety and environmental regulations. Request references from previous clients, especially those in your region, to understand their reliability. Furthermore, assess their communication responsiveness and willingness to provide samples, as these factors can indicate their commitment to quality service. -

What are typical payment terms when sourcing faux leather internationally?

Payment terms can vary widely by supplier and region, but common practices include a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services for larger orders to secure both parties’ interests. Ensure that you clarify these terms before finalizing agreements to avoid misunderstandings. Additionally, consider the currency exchange rates and any potential transaction fees when budgeting your costs. -

How can I ensure quality assurance for faux leather products?

To ensure quality assurance, implement a comprehensive inspection process both pre-production and post-production. Request quality control reports from suppliers and consider third-party inspections to verify product specifications. Establish clear quality metrics, such as color consistency, texture, and durability tests, to be met before shipment. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations and any potential issues during production. -

What logistics considerations should I keep in mind when importing faux leather?

Logistics considerations include shipping methods, customs regulations, and lead times. Determine the most cost-effective shipping method based on your delivery timeline—air freight is faster but more expensive, while sea freight is economical for larger volumes. Be aware of import duties and tariffs that may apply in your country, which can affect total costs. Collaborating with a freight forwarder can streamline the logistics process, ensuring compliance with all regulations and timely delivery. -

How does the global market demand for faux leather affect pricing?

The global demand for faux leather is influenced by various factors, including consumer preferences for sustainable materials and the price competitiveness of genuine leather. As regions like Africa and South America industrialize, the demand for faux leather is expected to rise, potentially driving prices up due to increased competition among suppliers. Staying informed about market trends, including shifts towards eco-friendly alternatives, can help you make strategic sourcing decisions and negotiate better pricing with suppliers.

Top 2 Whats Faux Leather Manufacturers & Suppliers List

1. Sewport – Faux Leather Solutions

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: Faux leather, also known as synthetic leather, is a petroleum-based alternative to genuine leather. It is soft to the touch, water-resistant, and highly resistant to stains, making it easy to clean. While less durable than real leather, it is resistant to abrasions and cuts, ideal for upholstery in homes with children or pets. Faux leather can be produced in various colors, including unconventiona…

2. LeatherCult – Faux Leather Essentials

Domain: leathercult.com

Registered: 2010 (15 years)

Introduction: Faux leather, also known as PU leather, is a synthetic material made to look and feel like real leather. It is constructed primarily from two types: Polyvinyl Chloride (PVC) and Polyurethane (PU). Faux leather is cheaper than genuine leather, easier to maintain, and available in various styles and colors. It is commonly used in clothing, upholstery, and accessories. Pros of faux leather include af…

Strategic Sourcing Conclusion and Outlook for whats faux leather

What Key Insights Should International Buyers Consider About Faux Leather?

In today’s competitive marketplace, understanding the dynamics of faux leather sourcing is essential for international B2B buyers, particularly in emerging regions like Africa, South America, the Middle East, and Europe. Faux leather, with its diverse applications ranging from fashion to upholstery, presents a cost-effective alternative to genuine leather without the ethical concerns associated with animal products. Buyers should prioritize sourcing from manufacturers that utilize innovative, environmentally-friendly materials, as the demand for sustainable options continues to rise.

Strategic sourcing of faux leather not only offers significant cost savings but also allows companies to meet consumer preferences for eco-conscious products. As the global market for synthetic leather expands, particularly in rapidly industrializing nations, establishing strong partnerships with reputable suppliers can enhance product offerings and market presence.

As we look to the future, it is imperative for international buyers to remain proactive in their sourcing strategies. Engaging with suppliers who prioritize quality, sustainability, and compliance will position businesses for success in a market increasingly driven by ethical consumerism. Explore your options today, and leverage the advantages of faux leather to meet the evolving demands of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.