Introduction: Navigating the Global Market for how to make leather bracelets

In the competitive landscape of the global market, sourcing high-quality materials for crafting leather bracelets poses a significant challenge for B2B buyers. As the demand for unique, handcrafted leather accessories continues to rise, it becomes essential for international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, to understand the nuances of making leather bracelets. This guide offers a comprehensive overview, covering various types of leather bracelets, innovative applications, and essential considerations for supplier vetting.

By delving into the intricacies of leather bracelet production, this resource equips businesses with the knowledge needed to make informed purchasing decisions. From understanding the cost implications of different materials and techniques to exploring design trends that resonate with target markets, readers will gain valuable insights that can enhance their product offerings.

Furthermore, this guide emphasizes the importance of quality craftsmanship and sustainable sourcing, which are critical in today’s eco-conscious marketplace. By empowering B2B buyers with actionable information and strategic approaches, this resource aims to facilitate successful partnerships and foster growth in the leather accessory sector. Whether you are a retailer, wholesaler, or manufacturer, understanding how to make leather bracelets will not only elevate your product line but also position your business as a leader in a flourishing industry.

Table Of Contents

- Top 1 How To Make Leather Bracelets Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make leather bracelets

- Understanding how to make leather bracelets Types and Variations

- Key Industrial Applications of how to make leather bracelets

- 3 Common User Pain Points for ‘how to make leather bracelets’ & Their Solutions

- Strategic Material Selection Guide for how to make leather bracelets

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather bracelets

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather bracelets’

- Comprehensive Cost and Pricing Analysis for how to make leather bracelets Sourcing

- Alternatives Analysis: Comparing how to make leather bracelets With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make leather bracelets

- Navigating Market Dynamics and Sourcing Trends in the how to make leather bracelets Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather bracelets

- Strategic Sourcing Conclusion and Outlook for how to make leather bracelets

- Important Disclaimer & Terms of Use

Understanding how to make leather bracelets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Beaded Leather Bracelet | Incorporates beads for decorative flair | Fashion accessories, custom orders | Pros: Customizable, trendy; Cons: Requires more skill for assembly. |

| Braided Leather Bracelet | Features interwoven strips of leather | Casual wear, promotional items | Pros: Strong and durable; Cons: Limited design options. |

| Leather Cuff | Wider leather bands often with embellishments | Statement pieces, gift items | Pros: High visibility, versatile; Cons: Bulkier, may not suit all styles. |

| Friendship Leather Bracelet | Simple design, often made with multiple strands | Youth markets, friendship gifts | Pros: Low-cost, easy to produce; Cons: Less durable compared to thicker designs. |

| Studded Leather Bracelet | Adorned with studs or spikes for an edgy look | Fashion-forward retailers, niche markets | Pros: Eye-catching, appeals to trendsetters; Cons: Can be uncomfortable if not crafted well. |

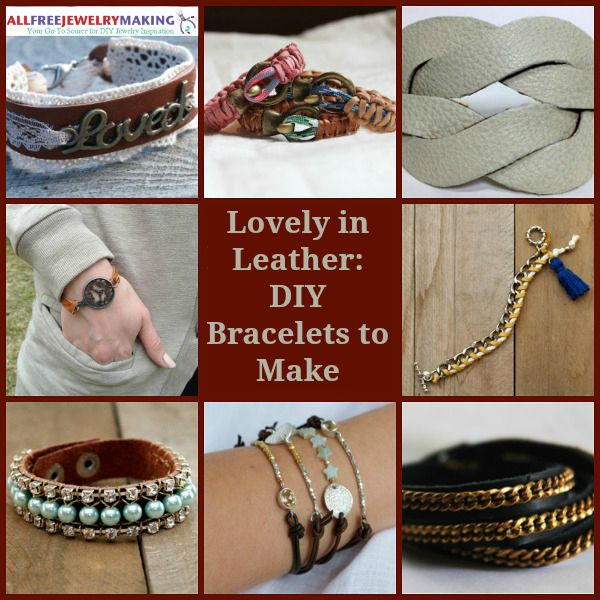

What Are the Characteristics of Beaded Leather Bracelets?

Beaded leather bracelets combine leather cords with decorative beads, creating a unique and personalized accessory. This type is particularly suitable for artisans looking to offer customizable products, allowing customers to choose colors and bead types. B2B buyers should consider sourcing high-quality leather and a variety of beads to cater to diverse consumer preferences. The assembly process requires some skill but can lead to high-margin products, especially in fashion-forward markets.

How Do Braided Leather Bracelets Stand Out?

Braided leather bracelets are made by intertwining three or more strips of leather, resulting in a textured and robust design. They are ideal for casual wear and can be marketed as unisex accessories. B2B buyers should focus on sourcing durable leather to ensure product longevity. While the braiding technique is relatively straightforward, it allows for a variety of styles, making it a versatile option for bulk orders in promotional campaigns.

Illustrative image related to how to make leather bracelets

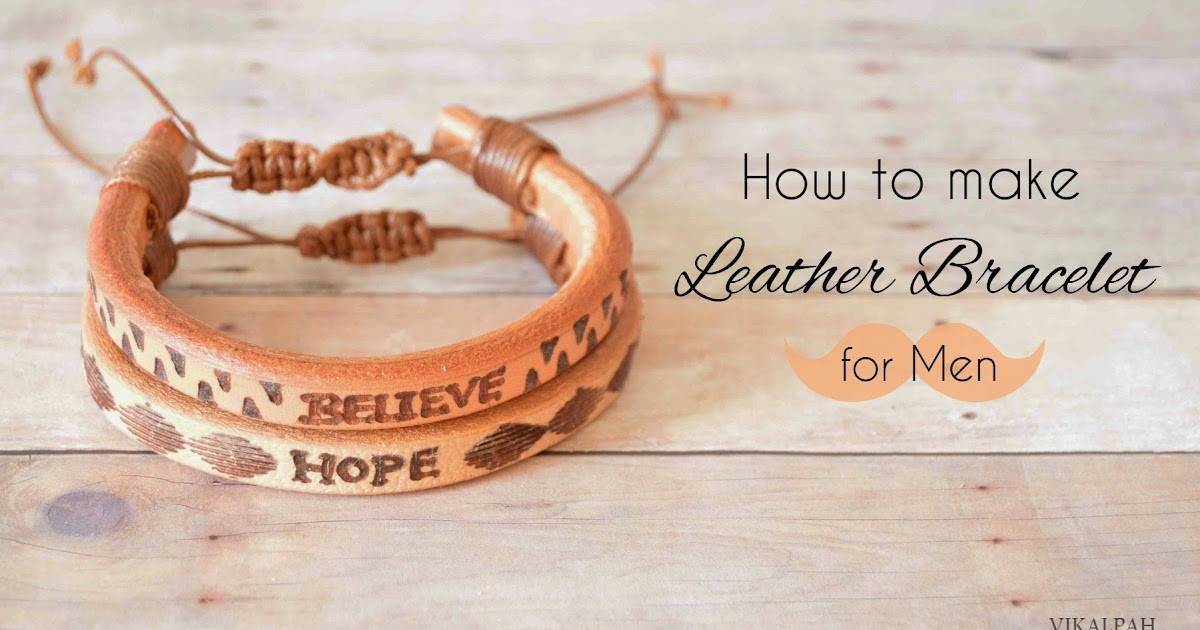

What Makes Leather Cuffs a Popular Choice?

Leather cuffs are characterized by their wider bands, often embellished with tooling, stamps, or additional materials. They serve as statement pieces and are suitable for both casual and formal occasions. For B2B buyers, the potential for customization makes leather cuffs an attractive option for gift shops and boutiques. However, the bulkiness may limit their appeal to some consumers, so ensuring a balance between style and comfort is essential when sourcing these products.

Why Are Friendship Leather Bracelets Ideal for Youth Markets?

Friendship leather bracelets are typically simple, using multiple strands to symbolize connection and camaraderie. This design appeals especially to younger demographics, making them popular items for schools and youth organizations. B2B buyers can capitalize on their low production costs and ease of assembly, allowing for quick turnarounds on orders. However, their simplicity may limit their market reach compared to more elaborate designs.

What Are the Benefits of Studded Leather Bracelets?

Studded leather bracelets feature metallic studs or spikes, offering an edgy aesthetic that attracts fashion-forward consumers. They are often marketed toward niche audiences looking for bold accessories. B2B buyers should prioritize sourcing both high-quality leather and durable metal components to ensure product appeal. While they can be striking, comfort must be considered in the design phase, as poorly crafted studded bracelets may deter potential customers.

Illustrative image related to how to make leather bracelets

Key Industrial Applications of how to make leather bracelets

| Industry/Sector | Specific Application of how to make leather bracelets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Custom Leather Jewelry Production | Enhances product differentiation and brand identity | Quality of leather, design capabilities, and production capacity |

| Corporate Gifting | Personalized Leather Bracelets for Employees | Strengthens employee morale and promotes company culture | Customization options, pricing for bulk orders, and lead times |

| Craft and Hobby Supplies | DIY Leather Bracelet Kits | Attracts creative consumers seeking unique projects | Variety of materials, ease of assembly, and instructional content |

| Tourism & Souvenir Shops | Local Artisan Leather Bracelets | Supports local artisans and enhances cultural experiences | Authenticity of materials, production sustainability, and design uniqueness |

| Event Planning & Promotions | Branded Leather Bracelets for Events | Effective promotional items to enhance brand visibility | Custom branding options, durability, and cost-effectiveness |

How is ‘how to make leather bracelets’ used in the Fashion & Accessories Industry?

In the fashion and accessories sector, making leather bracelets allows brands to offer custom jewelry that reflects current trends and consumer preferences. By incorporating unique designs and high-quality materials, businesses can differentiate their products in a competitive market. International buyers, especially from regions like Africa and Europe, should focus on sourcing leather that meets both aesthetic and durability standards, ensuring that the final product aligns with their brand ethos.

What are the benefits of personalized leather bracelets in Corporate Gifting?

Personalized leather bracelets are increasingly popular in corporate gifting as they provide a unique way to acknowledge employees and foster a sense of belonging. Companies can customize these bracelets with logos or messages, reinforcing their brand identity. When sourcing for this application, international buyers must consider customization capabilities, pricing for bulk orders, and reliable delivery timelines to ensure timely gifting during corporate events.

How do DIY Leather Bracelet Kits appeal to Craft and Hobby Suppliers?

DIY leather bracelet kits cater to the growing market of craft enthusiasts seeking hands-on projects. These kits typically include all necessary materials and instructions, making them accessible for consumers of all skill levels. For B2B buyers in South America and the Middle East, sourcing kits that offer a variety of leather types and styles can enhance product offerings in craft stores and online platforms, driving sales through customer engagement.

Why are Local Artisan Leather Bracelets important for Tourism & Souvenir Shops?

Tourism and souvenir shops benefit from offering locally made leather bracelets, which serve as tangible reminders of a destination. These products not only support local artisans but also provide tourists with authentic cultural experiences. International buyers should prioritize sourcing from local producers who use sustainable practices and authentic materials, as this can enhance the appeal of their offerings and resonate with eco-conscious consumers.

How can branded leather bracelets be effective promotional items in Event Planning?

Branded leather bracelets are effective promotional items for events, providing attendees with a functional keepsake that promotes brand visibility. These bracelets can be customized to reflect event themes or corporate branding, making them memorable. When sourcing for event planning, businesses should consider the durability of the materials and the cost-effectiveness of bulk orders to maximize their marketing investment while ensuring quality.

3 Common User Pain Points for ‘how to make leather bracelets’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Bracelet Making

The Problem: B2B buyers often face challenges in sourcing high-quality leather that meets their specific needs for bracelet making. Many suppliers may provide leather of varying grades, thickness, and texture, leading to inconsistencies in the final product. In addition, buyers may struggle with understanding the characteristics of different leather types, such as vegetable-tanned versus chrome-tanned leather, which can significantly affect the durability and aesthetic of the bracelets.

The Solution: To overcome these sourcing challenges, buyers should establish strong relationships with reputable suppliers who specialize in leather products. Conduct thorough research to identify suppliers with a proven track record of quality and reliability. Request samples of various leather types to evaluate their suitability for your bracelet designs. When specifying leather, clearly communicate your requirements regarding thickness, finish, and treatment processes. Additionally, consider leveraging online platforms that aggregate supplier ratings and reviews, allowing you to make informed purchasing decisions. Engaging in direct communication with suppliers can also help clarify any uncertainties regarding leather characteristics and ensure that the materials align with your design vision.

Scenario 2: Mastering the Techniques for Leather Bracelet Construction

The Problem: Many B2B buyers may lack the necessary skills and knowledge to effectively construct leather bracelets, leading to frustration and wasted materials. This is particularly true for buyers who are new to leatherworking or those transitioning from other crafting mediums. Common issues include improper cutting, stitching, or finishing techniques that can compromise the bracelet’s quality and aesthetic appeal.

The Solution: To enhance crafting skills, buyers should invest in training resources such as workshops, online courses, or instructional videos that focus on leatherworking techniques. Collaborating with experienced leather artisans can provide invaluable hands-on guidance and mentorship. Furthermore, consider creating a standardized process for bracelet production that includes detailed step-by-step guides and templates for cutting and stitching. This not only streamlines the production process but also ensures consistency across all products. Incorporating feedback mechanisms within your team can also help identify common errors and facilitate continuous improvement in craftsmanship.

Illustrative image related to how to make leather bracelets

Scenario 3: Meeting Market Trends and Customer Preferences in Leather Jewelry

The Problem: The leather jewelry market is dynamic, with trends and customer preferences changing rapidly. B2B buyers may find it challenging to keep up with these shifts, leading to inventory that does not resonate with their target audience. For instance, certain styles or colors may fall out of favor, resulting in unsold stock and financial losses.

The Solution: To stay ahead of market trends, B2B buyers should conduct regular market research and analysis to identify emerging styles and consumer preferences. Utilize tools such as social media analytics and trend forecasting platforms to gain insights into popular designs and materials. Engaging with customers through surveys or feedback sessions can also provide direct input on their preferences. Additionally, consider developing a flexible product line that allows for quick adaptations to new trends, such as limited-edition collections or customizable options. By fostering a culture of innovation and responsiveness, buyers can ensure that their leather bracelet offerings remain relevant and appealing to their clientele.

Strategic Material Selection Guide for how to make leather bracelets

What are the Key Materials for Making Leather Bracelets?

When selecting materials for leather bracelets, it’s essential to consider the properties and suitability of various types of leather. This analysis focuses on four common materials: vegetable-tanned leather, chrome-tanned leather, suede, and synthetic leather. Each material has unique characteristics that impact durability, cost, and manufacturing complexity, making them suitable for different applications in the leather bracelet market.

How Does Vegetable-Tanned Leather Perform for Bracelets?

Vegetable-tanned leather is derived from natural plant sources, making it a popular choice among artisans. Its key properties include excellent breathability and the ability to develop a rich patina over time, which enhances its aesthetic appeal. This type of leather is also biodegradable, aligning with sustainability trends.

Illustrative image related to how to make leather bracelets

Pros: It is durable and ages beautifully, making it suitable for high-end products. It can be easily dyed and stamped, allowing for customization.

Cons: The tanning process can be time-consuming and labor-intensive, leading to higher production costs. Additionally, it is less resistant to water and may require regular conditioning to maintain its appearance.

Impact on Application: Vegetable-tanned leather is ideal for bracelets that are marketed as luxury or artisanal products. However, it may not be suitable for environments with high moisture exposure.

Considerations for International Buyers: Buyers from regions like Africa and South America may prefer this leather due to its eco-friendly properties. Compliance with local environmental regulations is crucial, as is adherence to international standards like ASTM for leather quality.

What Advantages Does Chrome-Tanned Leather Offer?

Chrome-tanned leather is processed using chromium salts, resulting in a more flexible and water-resistant material. Its key properties include high durability and resistance to wear, making it suitable for everyday use.

Pros: It is less expensive than vegetable-tanned leather and can be produced in various colors and finishes. The quick tanning process allows for faster production cycles.

Cons: The use of chemicals in the tanning process raises environmental concerns. Additionally, chrome-tanned leather may not age as gracefully as vegetable-tanned leather.

Impact on Application: This leather is ideal for mass-produced bracelets targeting a broader market. Its water resistance makes it suitable for outdoor wear, but it may not appeal to eco-conscious consumers.

Considerations for International Buyers: Buyers in Europe may face stricter regulations regarding chemical use in leather production. Compliance with EU REACH regulations is essential to ensure market access.

Illustrative image related to how to make leather bracelets

How Does Suede Compare as a Material for Leather Bracelets?

Suede, made from the underside of animal hides, offers a unique texture and appearance. Its key properties include softness and a luxurious feel, making it appealing for fashion-oriented products.

Pros: Suede is lightweight and comfortable to wear, making it suitable for casual bracelets. It can be easily dyed and offers a variety of color options.

Cons: Suede is less durable than other types of leather and is more susceptible to staining and damage from moisture. This limits its longevity in daily wear.

Impact on Application: Suede is best for fashion bracelets that prioritize aesthetics over durability. It may not be suitable for high-wear applications.

Illustrative image related to how to make leather bracelets

Considerations for International Buyers: Buyers from the Middle East may prefer suede for its luxury appeal. However, they should consider local climate conditions that may affect the material’s longevity.

What Role Does Synthetic Leather Play in Bracelet Manufacturing?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers an alternative to traditional leather. Its key properties include water resistance and ease of maintenance.

Pros: Synthetic leather is typically less expensive and can be produced in a wide range of colors and patterns. It is also cruelty-free, appealing to vegan consumers.

Cons: While durable, synthetic leather may not offer the same aesthetic appeal or longevity as genuine leather. It can also be less breathable, leading to discomfort in warmer climates.

Impact on Application: This material is suitable for budget-friendly bracelets and those targeting environmentally conscious consumers. However, it may not be suitable for high-end markets.

Considerations for International Buyers: Buyers from regions with a strong vegan movement may favor synthetic leather. Compliance with international standards for synthetic materials is essential to ensure product quality.

Summary of Material Selection for Leather Bracelets

| Material | Typical Use Case for how to make leather bracelets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Luxury and artisanal bracelets | Eco-friendly and develops a rich patina | Higher production costs and moisture sensitivity | High |

| Chrome-Tanned Leather | Mass-produced bracelets | Durable and water-resistant | Environmental concerns and less graceful aging | Medium |

| Suede | Fashion-oriented casual bracelets | Soft texture and luxurious feel | Less durable and moisture-sensitive | Medium |

| Synthetic Leather | Budget-friendly and vegan bracelets | Cost-effective and cruelty-free | Less aesthetic appeal and breathability | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather bracelets

What Are the Main Stages of Manufacturing Leather Bracelets?

The manufacturing process for leather bracelets is a meticulous journey that encompasses several key stages, ensuring the final product meets high standards of quality and craftsmanship. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Leather Bracelet Production?

Material preparation is the first step in the manufacturing process. Quality leather is sourced from reliable suppliers, typically vegetable-tanned or chrome-tanned varieties depending on the desired look and feel of the bracelet. B2B buyers should prioritize suppliers who can provide detailed information about their leather sourcing practices, including traceability and sustainability.

Illustrative image related to how to make leather bracelets

Once the leather is acquired, it undergoes inspection to ensure it meets specific quality standards. This includes checking for consistency in color, thickness, and absence of defects such as scars or tears. A common practice is to categorize leather into grades, allowing manufacturers to utilize higher-quality pieces for premium products.

What Techniques Are Used in Forming Leather Bracelets?

After material preparation, the forming stage begins. This involves cutting the leather into predetermined shapes and sizes. Techniques can vary, but die-cutting is often employed for precision and efficiency, especially in larger production runs. For smaller batches or custom designs, manual cutting with templates or scissors may be used.

Stamping and tooling are additional techniques that enhance the aesthetic appeal of leather bracelets. Custom designs or logos can be embossed or debossed onto the leather, providing a unique touch that can attract B2B buyers looking for distinct branding opportunities. Buyers should inquire about the capabilities of suppliers in terms of customization, as this can significantly affect marketability.

How Are Leather Bracelets Assembled?

The assembly stage involves bringing together all components of the leather bracelet. This may include attaching clasps, buttons, or additional decorative elements. For example, in cuff-style bracelets, stitching is often used to secure layers of leather together, while beaded or braided designs may require knotting techniques.

Quality assurance during assembly is critical. Manufacturers should implement systematic checks to ensure all components are securely attached and that the bracelet meets design specifications. Buyers should look for suppliers who have standardized assembly protocols to minimize defects and maintain consistency across product lines.

What Finishing Techniques Are Applied to Leather Bracelets?

Finishing techniques are crucial for enhancing the durability and aesthetic appeal of leather bracelets. This stage may include edge finishing, where the raw edges of the leather are smoothed and sealed to prevent fraying. Dyes and finishes are applied to achieve the desired color and sheen, while conditioners may be used to maintain the leather’s suppleness.

In some cases, water-resistant or protective coatings are applied to enhance the bracelet’s longevity. Buyers should inquire about the types of finishes used, as these can affect not only the appearance but also the functionality and care requirements of the product.

What Are the Quality Control Procedures for Leather Bracelets?

Implementing stringent quality control (QC) procedures is essential in the leather bracelet manufacturing process. This helps ensure that each product meets international standards and customer expectations.

Which International Standards Should B2B Buyers Consider?

B2B buyers should be familiar with relevant international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with such standards ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Illustrative image related to how to make leather bracelets

In addition to ISO standards, industry-specific certifications like CE marking or API (American Petroleum Institute) standards may be applicable, depending on the intended market and use of the leather bracelets. Buyers should verify that suppliers hold necessary certifications, as this can enhance product credibility and acceptance in various markets.

What Are the Key QC Checkpoints in Leather Bracelet Production?

Quality control checkpoints should be established at various stages of production. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified quality standards.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, this stage involves regular checks to identify defects early, minimizing waste and rework.

-

Final Quality Control (FQC): This involves a thorough inspection of finished products before shipment. Each bracelet is checked for defects in craftsmanship, functionality, and overall appearance.

B2B buyers should inquire about the specific QC processes employed by suppliers, as this can vary significantly between manufacturers.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can conduct audits and request quality assurance reports. Regular audits can provide insights into a supplier’s manufacturing processes and adherence to quality standards.

Additionally, third-party inspections can serve as an unbiased assessment of product quality. Buyers can engage independent quality control firms to conduct inspections, ensuring compliance with specified standards.

What Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control and manufacturing practices. Variations in regulations and market expectations can impact product quality and acceptance.

It is advisable for buyers to establish clear communication channels with suppliers, ensuring that all specifications and expectations are documented and agreed upon. Understanding local manufacturing practices and compliance requirements can also aid in avoiding potential pitfalls in the supply chain.

In conclusion, the manufacturing processes and quality assurance practices for leather bracelets are critical to ensuring high-quality products that meet market demands. By understanding these processes and verifying supplier practices, B2B buyers can make informed decisions that support their business objectives.

Illustrative image related to how to make leather bracelets

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather bracelets’

Introduction

Creating leather bracelets can be a lucrative opportunity for B2B buyers in the fashion and accessories industry. This step-by-step checklist is designed to guide you through the sourcing process, ensuring you procure the right materials and establish partnerships with reliable suppliers. By following this checklist, you will enhance your product offerings while maintaining quality and cost-effectiveness.

Step 1: Identify Your Target Market

Understanding your target market is essential for tailoring your leather bracelet offerings. Research demographic data and trends in regions such as Africa, South America, the Middle East, and Europe. This knowledge will guide your design choices, material selections, and marketing strategies to align with local preferences.

Step 2: Define Your Technical Specifications

Establish clear technical specifications for the leather bracelets you intend to produce. Consider the type of leather (e.g., genuine, vegan), thickness, color, and finish. Providing detailed specifications will help suppliers understand your requirements and ensure consistency in quality across your products.

Step 3: Source Quality Leather Materials

The quality of leather is paramount in bracelet production. Look for suppliers that offer high-grade leather, as this will impact the durability and aesthetic appeal of your products. Verify the sourcing practices of your suppliers to ensure they adhere to ethical and sustainable standards, particularly in regions where environmental regulations may vary.

- Tip: Request samples to assess the leather’s texture, flexibility, and overall quality before making bulk purchases.

Step 4: Evaluate Additional Components

In addition to leather, consider other components that may enhance your bracelets, such as buttons, clasps, and decorative elements. Make a list of all required materials and identify suppliers for each component. This approach ensures you can maintain a cohesive style while also providing variety in your offerings.

Step 5: Assess Supplier Capabilities

Evaluate potential suppliers for their ability to meet your production needs. Look for manufacturers with experience in leather goods, and request case studies or references from clients in similar industries. Ensure that suppliers can handle your order volume and meet delivery timelines without compromising quality.

Step 6: Verify Compliance and Certifications

Before finalizing any agreements, verify that your suppliers comply with industry standards and certifications. This includes checking for ISO certifications, ethical labor practices, and environmental compliance. Ensuring that your suppliers uphold these standards will protect your brand’s reputation and mitigate potential risks.

Step 7: Establish Clear Communication Channels

Effective communication with your suppliers is critical for a successful partnership. Establish preferred channels of communication and set expectations for updates on production timelines, shipping, and any issues that may arise. Regular check-ins will help you stay informed and address concerns promptly, fostering a strong working relationship.

By following this sourcing checklist, you can confidently navigate the process of procuring materials for leather bracelets, ensuring a successful and sustainable business venture in the accessories market.

Comprehensive Cost and Pricing Analysis for how to make leather bracelets Sourcing

What Are the Key Cost Components for Sourcing Leather Bracelets?

When sourcing materials for leather bracelets, several cost components come into play. The primary elements include:

-

Materials: The choice of leather significantly impacts costs. Full-grain leather is more expensive than bonded leather due to its durability and aesthetic appeal. Additionally, components like buttons, beads, and thread also add to the overall material costs. Bulk purchasing of these materials can yield cost savings.

-

Labor: Labor costs vary depending on the complexity of the bracelet design. Simple designs may require less time and skilled labor, whereas intricate designs, such as those featuring embossing or multi-layering, will necessitate more skilled artisans, thereby increasing labor costs.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment maintenance associated with the production facility. Efficient overhead management can lead to significant savings, particularly for larger-scale operations.

-

Tooling Costs: Initial setup costs for specialized tools or molds can be substantial, particularly for custom designs. However, once amortized over a larger production run, these costs can decrease per unit.

-

Quality Control (QC): Implementing robust QC processes is essential to ensure product quality and compliance with buyer specifications. This can increase labor and overhead costs but is necessary to maintain a good market reputation.

-

Logistics: Transportation costs, including shipping and customs duties, are critical, especially for international buyers. Understanding local regulations and potential tariffs can aid in cost management.

-

Margin: The desired profit margin will ultimately influence the pricing strategy. A common practice is to set a margin that reflects the market value while ensuring competitiveness.

How Do Price Influencers Affect Leather Bracelet Sourcing?

Several factors can influence the pricing of leather bracelets:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes can lead to reduced per-unit costs. Suppliers often provide better pricing for bulk orders, which is crucial for B2B buyers aiming to maximize profit margins.

-

Specifications and Customization: Custom designs or specific material requirements can drive up costs. Buyers should be clear about their specifications to receive accurate quotes.

-

Material Quality and Certifications: The quality of the leather and any certifications (e.g., eco-friendly or cruelty-free) can impact pricing. High-quality materials typically command higher prices.

-

Supplier Factors: The reliability, reputation, and location of the supplier can also influence costs. Local suppliers may reduce logistics costs but may not always offer the best material quality compared to international suppliers.

-

Incoterms: Understanding Incoterms is vital for pricing clarity in international transactions. They define responsibilities for shipping, insurance, and tariffs, which can affect the total landed cost of goods.

What Tips Can Help Buyers Negotiate Better Prices for Leather Bracelets?

When negotiating prices for leather bracelets, B2B buyers can employ several strategies:

-

Bulk Purchasing: Leverage larger order volumes to negotiate better pricing with suppliers. Discuss potential discounts for long-term contracts or repeat orders.

-

Total Cost of Ownership (TCO): Focus on the TCO rather than just the initial purchase price. This includes considering logistics, quality, and durability, which can impact overall profitability.

-

Research Market Trends: Stay informed about market trends and competitor pricing to strengthen negotiation positions. Understanding the demand for specific styles can also provide leverage.

-

Build Strong Supplier Relationships: Cultivating good relationships with suppliers can lead to better pricing and service. Regular communication and feedback can foster trust and collaboration.

-

Consider Alternative Suppliers: Don’t hesitate to explore multiple suppliers. Obtaining quotes from various sources can provide insights into fair pricing and ensure competitive offers.

Disclaimer on Pricing

Prices for leather bracelets can vary significantly based on the aforementioned factors. The information provided serves as a guideline and should be verified through direct communication with suppliers. Always request detailed quotes that consider all aspects of the sourcing process.

Alternatives Analysis: Comparing how to make leather bracelets With Other Solutions

Exploring Alternatives to Making Leather Bracelets

In the realm of crafting leather bracelets, various methods and materials can achieve similar aesthetics and functionality. Understanding these alternatives can help businesses and artisans make informed decisions based on performance, cost, and ease of implementation. Below is a comparative analysis of traditional leather bracelet making against two viable alternatives: using synthetic materials and employing 3D printing technology.

| Comparison Aspect | How To Make Leather Bracelets | Synthetic Bracelet Making | 3D Printing Bracelets |

|---|---|---|---|

| Performance | High durability and classic appeal. | Moderate durability; can mimic leather but may not have the same feel. | Excellent precision; can create complex designs but material strength varies. |

| Cost | Moderate; depends on leather quality. | Generally lower; synthetic materials are cheaper. | High initial investment for 3D printers; material costs can add up. |

| Ease of Implementation | Requires crafting skills and tools. | Simple; often involves cutting and gluing without specialized tools. | Requires technical skills in design and operation of 3D printers. |

| Maintenance | Low; leather requires conditioning but is durable. | Moderate; synthetics can wear out and require replacement. | Low; printed designs are generally easy to clean and maintain. |

| Best Use Case | Ideal for high-end, custom, or artisanal products. | Suitable for mass production or budget-friendly options. | Best for unique, complex designs or prototyping. |

What Are the Pros and Cons of Using Synthetic Materials for Bracelet Making?

Synthetic materials, such as faux leather or plastics, provide a cost-effective alternative to traditional leather. These materials can replicate the look and feel of leather while being lighter and easier to work with. However, they may lack the durability and luxury appeal of genuine leather. For businesses focusing on affordability or mass production, synthetic options are attractive, but they may not resonate with consumers seeking high-quality, artisanal products.

How Does 3D Printing Compare to Traditional Leather Bracelet Making?

3D printing technology represents a cutting-edge alternative for creating intricate bracelet designs. This method allows for customization and rapid prototyping, enabling businesses to respond quickly to market trends. However, it requires a significant investment in both equipment and training. The material strength of 3D printed bracelets can vary based on the filament used, which may not always match the durability of leather. For businesses aiming for innovation and uniqueness, 3D printing can be a game changer, provided they are willing to invest in the necessary resources.

Conclusion: Which Bracelet Making Method Should B2B Buyers Choose?

When selecting the best method for bracelet production, B2B buyers should consider their target market, budget constraints, and desired product quality. Traditional leather bracelet making is ideal for those seeking luxury and durability, while synthetic materials offer an economical option for mass production. On the other hand, 3D printing caters to businesses wanting to explore innovative designs and customization. Ultimately, the right choice will depend on aligning the production method with the business’s overall strategy and customer preferences.

Essential Technical Properties and Trade Terminology for how to make leather bracelets

What Are the Key Technical Properties for Making Leather Bracelets?

When engaging in the production of leather bracelets, understanding the technical properties of the materials involved is crucial for ensuring product quality and consumer satisfaction. Here are some essential specifications to consider:

Illustrative image related to how to make leather bracelets

1. Material Grade

Material grade refers to the quality and type of leather used in bracelet production, such as full-grain, top-grain, or genuine leather. Full-grain leather, for instance, is the highest quality and retains the natural grain of the hide, providing durability and a unique appearance. Choosing the right grade is important for B2B buyers, as it affects the product’s longevity and overall marketability.

2. Thickness

The thickness of leather is typically measured in ounces or millimeters. A thicker leather (usually 4-8 ounces) is more robust and suitable for cuffs and heavy-duty bracelets, while thinner leather (1-3 ounces) is more flexible and ideal for braided or beaded designs. Specifying the right thickness is essential for meeting customer expectations regarding comfort and durability.

3. Tolerance

Tolerance in leather production refers to the allowable variation in dimensions and quality of the leather pieces. For instance, a tolerance of ±1 mm in width or length ensures that each bracelet fits consistently. Maintaining strict tolerances is vital in B2B settings to ensure that products meet specifications and minimize returns or customer dissatisfaction.

4. Finish and Treatment

The finish of leather can vary significantly, including options like aniline, semi-aniline, or pigmented. Each finish affects the leather’s appearance, texture, and resistance to wear and tear. Understanding the different treatments can help B2B buyers choose the right leather for their target market, balancing aesthetics with functionality.

Illustrative image related to how to make leather bracelets

5. Colorfastness

Colorfastness refers to the leather’s ability to retain its color when exposed to light, washing, or abrasion. This property is especially important for fashion accessories like bracelets that may undergo frequent handling and exposure to the elements. Ensuring high colorfastness can enhance product longevity and consumer satisfaction.

What Are Common Trade Terms Used in the Leather Bracelet Industry?

Familiarity with industry jargon can greatly facilitate communication and negotiation between buyers and suppliers. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on another company’s specifications. In the context of leather bracelets, an OEM might produce bracelets designed by a fashion brand. Understanding OEM relationships is vital for B2B buyers looking to develop custom products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to produce or sell. For leather bracelets, MOQs can vary based on the complexity of the design and materials used. Knowing the MOQ helps buyers plan their inventory and manage production costs effectively.

Illustrative image related to how to make leather bracelets

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price offers from suppliers for specific products. In the leather bracelet industry, an RFQ would detail the desired materials, designs, and quantities. B2B buyers use RFQs to compare pricing and select suppliers that meet their budgetary needs.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. For leather bracelets, understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for managing shipping costs and responsibilities, ensuring clarity in contracts.

5. Lead Time

Lead time refers to the time taken from placing an order until its delivery. For leather bracelet production, this can include manufacturing, quality control, and shipping times. Knowing the lead time is essential for B2B buyers to synchronize their inventory and marketing strategies effectively.

Incorporating this knowledge of technical properties and trade terminology can empower B2B buyers to make informed decisions, enhance product offerings, and foster successful supplier relationships in the leather bracelet market.

Illustrative image related to how to make leather bracelets

Navigating Market Dynamics and Sourcing Trends in the how to make leather bracelets Sector

What Are the Current Market Dynamics and Key Trends for Leather Bracelets?

The leather bracelet market is witnessing a surge in demand driven by a combination of fashion trends and consumer preferences for personalized, handmade items. Global drivers include the rise of e-commerce platforms that facilitate direct access to artisans and small-scale manufacturers, particularly in emerging markets such as Africa, South America, and Southeast Asia. B2B buyers from these regions are increasingly looking for unique, artisanal products to differentiate themselves in the marketplace.

Emerging B2B tech trends such as digital sourcing platforms and collaborative marketplaces are reshaping how businesses procure leather materials and finished products. These platforms allow buyers to connect with suppliers worldwide, streamlining the sourcing process and enhancing transparency in the supply chain. Additionally, the integration of 3D printing technologies is enabling companies to create custom leather bracelet designs with minimal waste, catering to the growing demand for bespoke items.

Market dynamics are also influenced by shifting consumer values, with a growing emphasis on sustainability and ethical production practices. This shift is prompting international buyers to seek suppliers who prioritize environmentally friendly practices and ethical labor standards. As a result, businesses that adapt to these trends will be better positioned to capture market share and build lasting relationships with their customers.

How Is Sustainability and Ethical Sourcing Impacting the Leather Bracelet Sector?

Sustainability has become a key concern for businesses in the leather bracelet sector. The environmental impact of traditional leather production methods, which often involve toxic chemicals and water-intensive processes, has led to an increased demand for ethically sourced materials. B2B buyers are now prioritizing suppliers who utilize vegetable-tanned leather or alternative materials such as cork or synthetic leathers that reduce environmental harm.

Ethical sourcing is also crucial in maintaining a positive brand image. Companies that can demonstrate a commitment to fair labor practices and sustainable sourcing are likely to gain a competitive edge in the marketplace. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming increasingly important for buyers seeking to ensure that their products meet ethical and environmental standards.

Moreover, the trend toward transparency in supply chains is gaining traction. B2B buyers are increasingly demanding information about the sourcing and production processes of the products they purchase. This transparency not only builds trust with consumers but also reinforces the importance of sustainable practices in the leather bracelet industry.

What Is the Historical Context of Leather Bracelets in B2B Markets?

Leather bracelets have a rich history that dates back to ancient civilizations, where they were often used as symbols of status, identity, or protection. Traditionally, leather was valued for its durability and versatility, making it a favored material for crafting wearable items. Over time, the craft of leatherworking evolved, with artisans developing unique techniques that led to the diverse styles of leather bracelets seen today.

In recent decades, the resurgence of interest in handmade and artisanal products has transformed the leather bracelet market into a niche yet vibrant segment within the broader fashion industry. B2B buyers are now more inclined to explore partnerships with small-scale producers and artisans who offer distinctive, high-quality products, further cementing the relevance of leather bracelets in contemporary fashion. This evolution reflects a shift towards valuing craftsmanship and sustainability, which continues to influence buyer preferences in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather bracelets

-

How do I choose the right leather for making bracelets?

Selecting the appropriate leather is crucial for creating quality bracelets. For durability and comfort, vegetable-tanned leather is often recommended, as it ages beautifully and maintains its shape. If you are targeting a more fashion-forward market, consider using chrome-tanned leather for its vibrant colors and softness. Always request samples from suppliers to assess the texture, thickness, and color to ensure it meets your design requirements. -

What is the best method for attaching clasps to leather bracelets?

The best method for attaching clasps depends on the bracelet design. For simple leather cuffs, a snap button or magnetic clasp can be easily sewn on. For braided or beaded designs, consider using a loop or hook clasp that allows for flexibility. It’s essential to choose clasps that match the style and weight of the leather; heavier leathers require more robust hardware. Always perform a stress test on your prototypes to ensure durability. -

How can I customize leather bracelets for my brand?

Customization options for leather bracelets include stamping, dyeing, and adding unique embellishments like beads or charms. Work closely with your supplier to explore techniques such as laser engraving for intricate designs or hand-stamping for a more artisanal feel. Additionally, consider offering various sizes and color options to cater to diverse consumer preferences. Establishing a clear branding strategy around your customized products can help differentiate your offerings in the market. -

What are the minimum order quantities (MOQ) for leather bracelets?

MOQs for leather bracelets can vary widely depending on the supplier and the complexity of the designs. Generally, you may find MOQs ranging from 50 to 500 pieces. When negotiating with suppliers, clarify whether the MOQ includes various styles or sizes, as this can impact your ability to test different products in your market. Establishing a relationship with your supplier may also provide flexibility in order quantities. -

What payment terms should I expect when sourcing leather bracelets internationally?

Payment terms can differ by supplier and region. Common terms include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers might offer letter-of-credit options or payment through platforms like PayPal or escrow services for added security. Always negotiate terms that protect your interests while ensuring the supplier feels secure in the transaction. Review international payment methods to minimize transaction fees. -

How can I ensure quality assurance (QA) for my leather bracelets?

Implementing a robust QA process involves several steps. Start by defining clear quality standards for materials and finished products. Request samples before placing large orders and conduct inspections upon receipt to ensure compliance with your specifications. Consider third-party inspection services, especially for international shipments, to verify quality before products reach your warehouse. Establishing a feedback loop with your supplier can also help address any quality issues promptly. -

What logistics considerations should I keep in mind when importing leather bracelets?

Logistics is critical when importing leather bracelets. Ensure you understand the shipping methods available, such as air freight for speed or sea freight for cost-effectiveness. Familiarize yourself with customs regulations in your country to avoid delays or unexpected fees. Working with a reliable freight forwarder can streamline the process and provide guidance on documentation, tariffs, and insurance for your shipments. -

How do I vet suppliers for leather bracelet manufacturing?

Vetting suppliers is essential to ensure quality and reliability. Start by researching their business history, customer reviews, and product samples. Request references from other B2B buyers who have worked with them. If possible, visit their facilities to evaluate their production capabilities and quality control processes. Additionally, check for compliance with international standards and certifications, which can provide assurance of their manufacturing practices.

Top 1 How To Make Leather Bracelets Manufacturers & Suppliers List

1. Instructables – Easy DIY Leather Bracelet

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Easy DIY Leather Bracelet made from leather, a button, thread, scissors, and a stamp. Steps include cutting leather to size, optional stamping, adding a button hole and sewing on a button, and wearing the finished bracelet.

Strategic Sourcing Conclusion and Outlook for how to make leather bracelets

As the leather bracelet market continues to expand, strategic sourcing becomes crucial for B2B buyers aiming to optimize costs and enhance product quality. By understanding the diverse methods of crafting leather bracelets—ranging from simple cuff designs to intricate beaded styles—buyers can align their sourcing strategies with market trends. Investing in quality raw materials and tools not only elevates the craftsmanship but also contributes to the brand’s reputation for excellence.

Furthermore, establishing relationships with reliable suppliers across regions—especially in Africa, South America, the Middle East, and Europe—can lead to innovative designs and unique offerings that cater to local tastes. The ability to source sustainably and ethically will also resonate with increasingly conscious consumers, adding further value to your brand.

Illustrative image related to how to make leather bracelets

Looking ahead, international B2B buyers should prioritize collaboration and knowledge sharing within the leathercraft community to foster innovation. By embracing these practices, you can position your business not only to thrive in the competitive landscape but also to lead in creating beautiful, high-quality leather bracelets that appeal to a global audience. Start exploring your sourcing options today to harness the full potential of this vibrant market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how to make leather bracelets