Introduction: Navigating the Global Market for how to make a leather wallet

In today’s dynamic global marketplace, sourcing high-quality leather wallets presents a unique challenge for B2B buyers. As businesses seek to meet the diverse preferences of consumers across various regions—particularly in Africa, South America, the Middle East, and Europe—understanding the intricacies of leather wallet production becomes essential. This comprehensive guide on how to make a leather wallet delves into multiple wallet types, their practical applications, and the critical aspects of supplier vetting and cost analysis.

By exploring different styles and functionalities, this guide empowers international buyers to make informed purchasing decisions that align with their market needs. From selecting the right materials to understanding manufacturing processes, each section is designed to address the specific challenges faced by businesses in sourcing leather goods. With insights into regional preferences and trends, B2B buyers can confidently navigate the complexities of the leather wallet market, ensuring they meet customer demands effectively.

Moreover, this guide emphasizes the importance of quality and craftsmanship, providing actionable strategies for identifying reputable suppliers and negotiating favorable terms. In an industry where authenticity and durability are paramount, leveraging this knowledge will not only enhance product offerings but also foster long-term relationships with customers and suppliers alike.

Table Of Contents

- Top 2 How To Make A Leather Wallet Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather wallet

- Understanding how to make a leather wallet Types and Variations

- Key Industrial Applications of how to make a leather wallet

- 3 Common User Pain Points for ‘how to make a leather wallet’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather wallet

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather wallet

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather wallet’

- Comprehensive Cost and Pricing Analysis for how to make a leather wallet Sourcing

- Alternatives Analysis: Comparing how to make a leather wallet With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather wallet

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather wallet Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather wallet

- Strategic Sourcing Conclusion and Outlook for how to make a leather wallet

- Important Disclaimer & Terms of Use

Understanding how to make a leather wallet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bi-Fold Wallet | Classic design, folds in half, multiple card slots | Retail, promotional gifts | Pros: Timeless appeal; Cons: Limited capacity compared to other designs. |

| Tri-Fold Wallet | Folds into thirds, offers more storage | Corporate gifts, branding | Pros: Increased storage; Cons: Bulkier than bi-folds. |

| Cardholder Wallet | Minimalist design, holds cards only | Luxury markets, minimalistic brands | Pros: Sleek and lightweight; Cons: Limited cash storage. |

| Zipper Wallet | Features a zipper for secure closure | Travel accessories, security-focused brands | Pros: Enhanced security; Cons: More complex to manufacture. |

| Customizable Wallet | Personalized designs, various materials available | Gifting, brand promotion | Pros: Unique branding opportunities; Cons: Higher production costs. |

What are the Key Characteristics of Bi-Fold Wallets for B2B Buyers?

Bi-fold wallets are among the most traditional wallet designs, folding in half to provide a compact form factor. Typically featuring multiple card slots and a compartment for cash, they are ideal for everyday use. For B2B buyers, these wallets are suitable for retail environments and promotional gifts, appealing to a wide range of consumers. When purchasing, consider the leather quality and craftsmanship, as these factors significantly influence the product’s longevity and marketability.

How Do Tri-Fold Wallets Enhance Storage for Businesses?

Tri-fold wallets expand on the bi-fold design by incorporating an additional fold, which allows for more card slots and compartments. This design is particularly beneficial for corporate gifting and promotional campaigns where functionality is key. B2B buyers should focus on durability and style, ensuring that the wallets align with their branding efforts. However, the bulkier nature of tri-fold wallets may deter some consumers who prefer slimmer profiles.

Why Choose Cardholder Wallets for Minimalistic Brands?

Cardholder wallets are designed with minimalism in mind, often featuring just a few card slots and no cash compartments. This makes them particularly appealing in luxury markets and for brands emphasizing simplicity. For B2B buyers, these wallets can serve as high-end promotional items that reflect a modern aesthetic. When sourcing, consider the materials used, as premium leather can enhance the perceived value of these products.

What Advantages Do Zipper Wallets Offer for Security-Focused Brands?

Zipper wallets feature a secure closure that protects contents more effectively than traditional designs. This makes them ideal for travel accessories and brands focused on security. B2B buyers should evaluate the quality of the zipper and stitching, as these elements contribute to the wallet’s overall durability. While they offer enhanced security, the complexity of production may lead to higher costs.

How Can Customizable Wallets Drive Brand Promotion?

Customizable wallets allow for personalization in design and materials, making them an excellent choice for gifting and brand promotion. Businesses can leverage these wallets to create unique items that resonate with their target audience. B2B buyers should consider the potential for higher production costs but also recognize the value of offering a distinctive product that stands out in a competitive market.

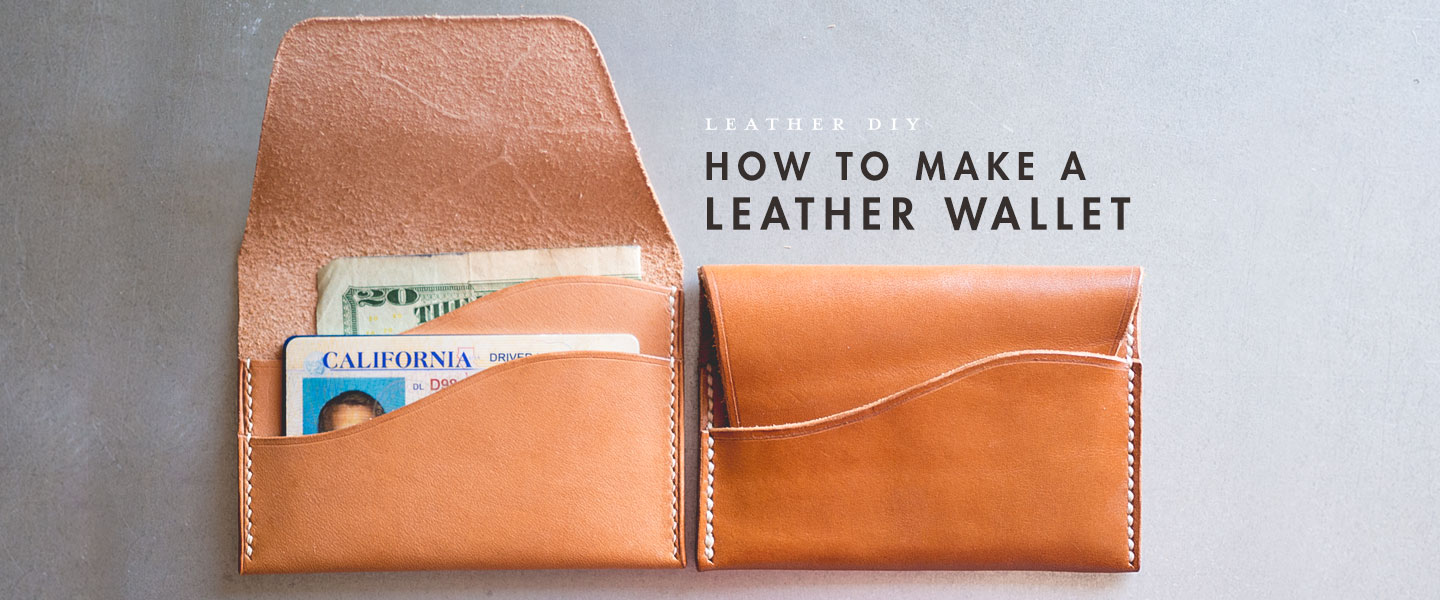

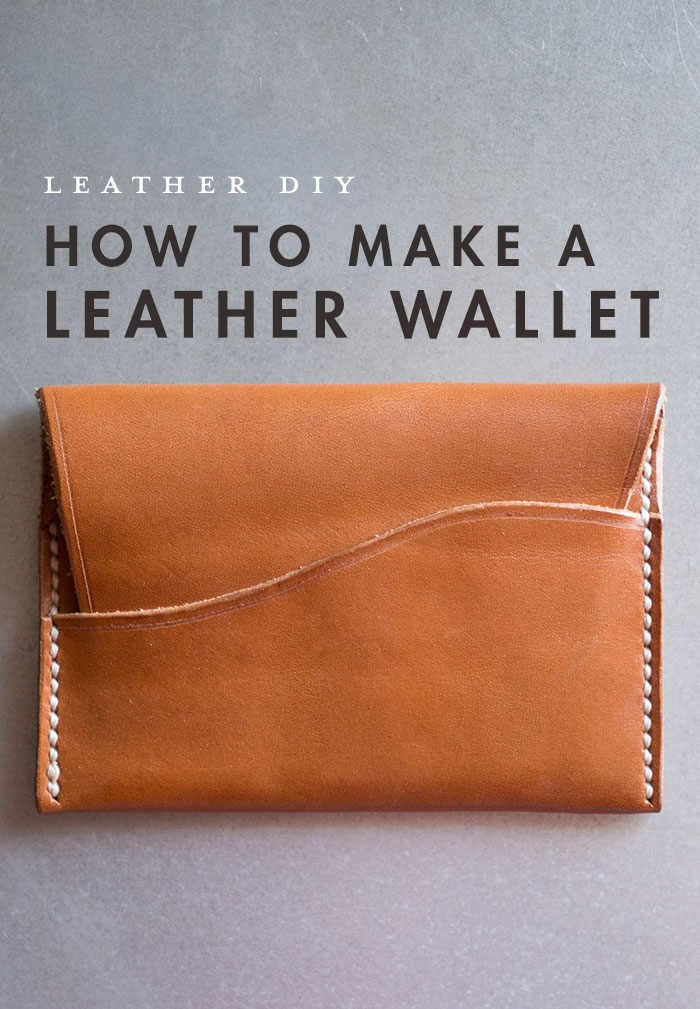

Illustrative image related to how to make a leather wallet

Key Industrial Applications of how to make a leather wallet

| Industry/Sector | Specific Application of how to make a leather wallet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom leather wallets for branded merchandise | Enhances brand identity and customer loyalty | Quality of leather, customization options, pricing |

| Corporate Gifting | Executive leather wallets as corporate gifts | Promotes company image and strengthens relationships | Bulk purchasing capabilities, personalization options |

| E-commerce | DIY leather wallet kits for online sales | Appeals to DIY enthusiasts and fosters customer engagement | Packaging, shipping logistics, and instructional support |

| Luxury Goods | High-end leather wallets for exclusive collections | Attracts affluent customers and increases margins | Sourcing premium materials, craftsmanship standards |

| Craftsmanship Workshops | Leather wallet making classes for skill development | Engages community and promotes craftsmanship | Availability of quality tools, expert instructors |

How Can Fashion Retailers Utilize Leather Wallets for Brand Identity?

Fashion retailers can leverage custom leather wallets as a means to enhance brand identity and customer loyalty. By offering wallets that feature unique designs or logos, brands can create a tangible connection with their customers. This application is particularly relevant in regions such as Europe and South America, where consumers often seek products that reflect their personal style and values. Buyers in this sector should consider the quality of leather used, as it directly impacts the product’s perceived value, alongside customization options to meet specific branding needs.

What Role Do Leather Wallets Play in Corporate Gifting?

In the corporate gifting sector, executive leather wallets serve as a sophisticated gift choice that promotes a company’s image while strengthening relationships with clients and employees. These wallets can be personalized with company logos or messages, making them a thoughtful and memorable gift. For businesses in the Middle East and Africa, where corporate relationships are paramount, sourcing high-quality leather that aligns with cultural expectations and aesthetics is essential. Buyers should also look for suppliers that can meet bulk purchasing requirements without compromising on quality.

How Can E-Commerce Platforms Benefit from DIY Leather Wallet Kits?

E-commerce platforms can attract a niche market by offering DIY leather wallet kits, appealing to consumers who enjoy crafting and personalization. This application not only fosters customer engagement but also allows for higher profit margins through the sale of kits that include all necessary materials and instructions. International buyers, particularly from regions like Brazil and Africa, should consider the logistics of packaging and shipping, ensuring that the kits arrive in good condition and are easy to assemble.

Why Are High-End Leather Wallets Important in Luxury Goods?

Luxury goods retailers can capitalize on high-end leather wallets as part of their exclusive collections to attract affluent customers. These wallets often feature superior craftsmanship and premium materials, which are key selling points in the luxury market. Buyers must be diligent in sourcing top-quality leathers and ensuring that the production process meets high craftsmanship standards. This attention to detail not only enhances the product’s appeal but also justifies its premium pricing, particularly in competitive markets across Europe and the Middle East.

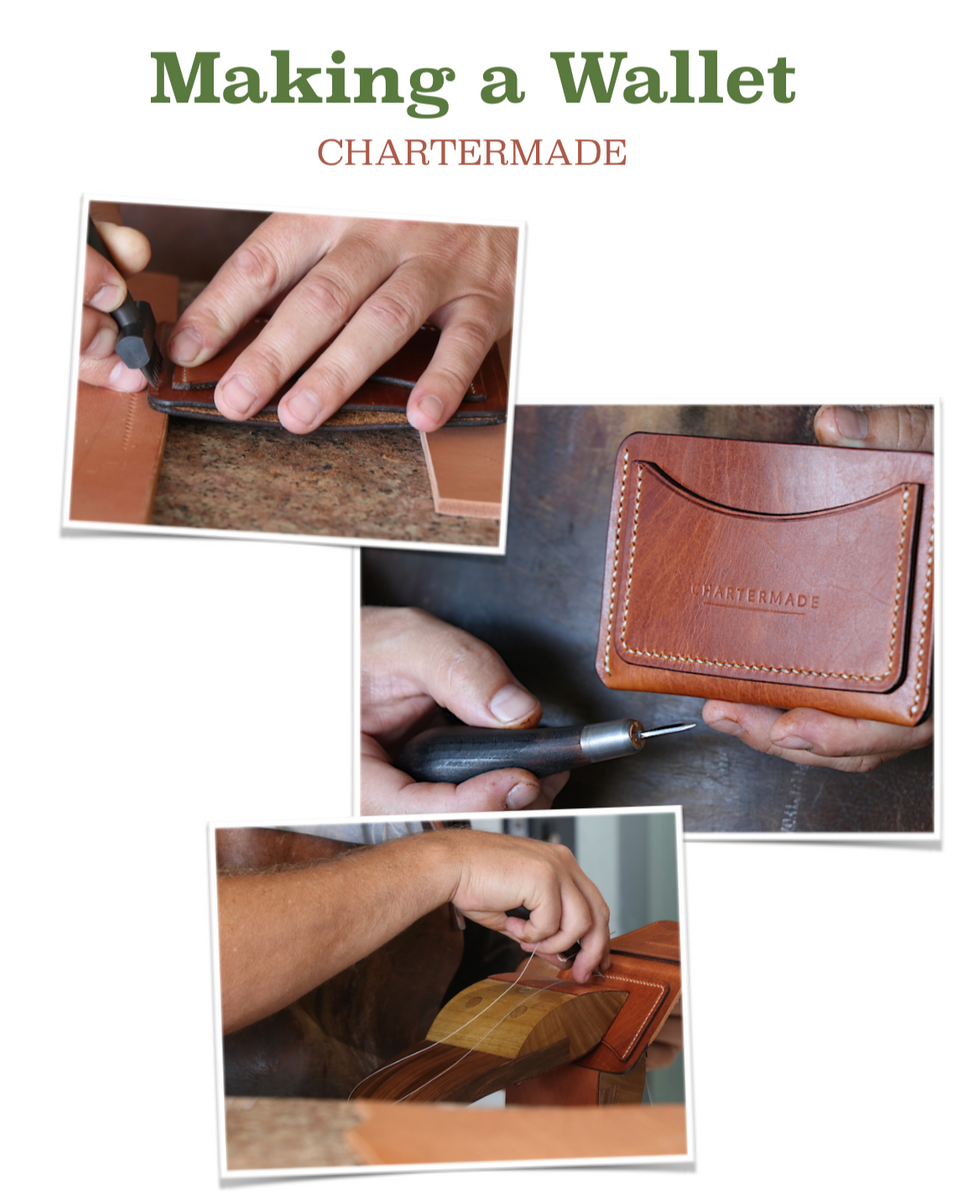

Illustrative image related to how to make a leather wallet

How Do Craftsmanship Workshops Utilize Leather Wallet Making?

Craftsmanship workshops can incorporate leather wallet making into their curriculum to engage the community and promote skills development. This application not only teaches valuable craftsmanship but also fosters a deeper appreciation for handmade goods. Buyers looking to establish such workshops should focus on sourcing quality tools and materials, as well as securing expert instructors who can impart essential techniques. This initiative can particularly resonate in regions like South America, where there is a growing interest in sustainable and artisanal products.

3 Common User Pain Points for ‘how to make a leather wallet’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Wallet Production

The Problem: B2B buyers, particularly those based in regions like Africa and South America, often face significant challenges in sourcing quality leather for wallet production. This issue stems from a lack of reliable suppliers and varying standards in leather quality, which can lead to inconsistencies in the final product. Additionally, buyers may struggle with understanding the types of leather that best suit their wallet designs and customer preferences, risking both product quality and brand reputation.

The Solution: To overcome this challenge, B2B buyers should establish relationships with reputable leather suppliers who offer a range of options, including vegetable-tanned and chrome-tanned leather. Conducting thorough market research to identify suppliers with good reviews and reliable delivery records is essential. Buyers should also request samples before committing to bulk orders, allowing them to evaluate the leather’s texture, durability, and color. Furthermore, it’s beneficial to engage in conversations with suppliers about the properties of different leather types, ensuring they align with the intended use of the wallets. This proactive approach will help secure high-quality materials that enhance the final product’s appeal.

Scenario 2: Mastering Leather Crafting Techniques for Wallets

The Problem: Many B2B buyers who venture into leather wallet production often lack the necessary crafting skills and techniques to create high-quality products. This gap can lead to poorly constructed wallets that do not meet customer expectations, resulting in increased returns and a damaged reputation. Buyers may feel overwhelmed by the complexity of leatherworking, from cutting and stitching to finishing and dyeing.

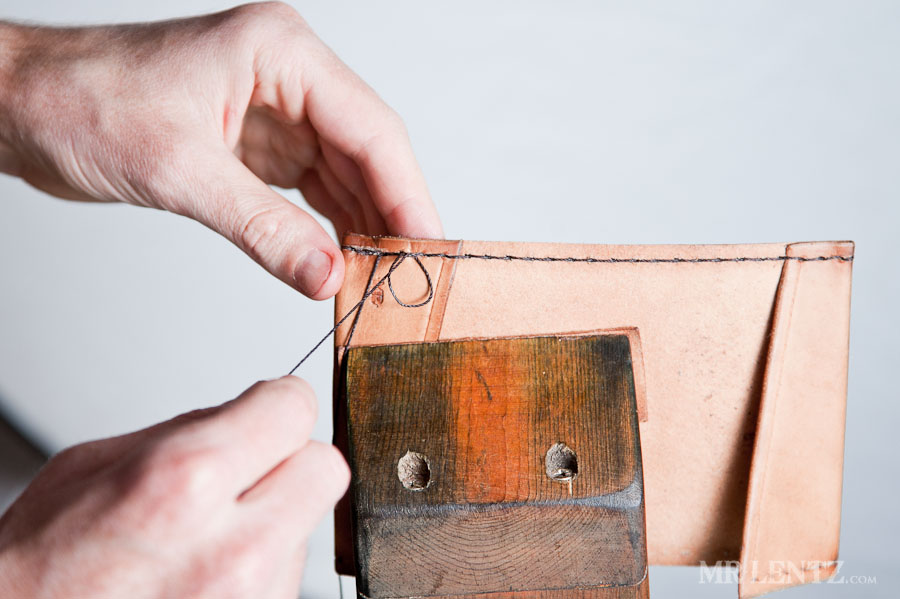

Illustrative image related to how to make a leather wallet

The Solution: Investing in training and resources is crucial for buyers looking to improve their leather crafting skills. They can seek out workshops or online courses that focus specifically on leather wallet production. Additionally, leveraging detailed tutorials and guides can provide step-by-step insights into essential techniques such as saddle stitching, edge burnishing, and proper dye application. Collaborating with skilled artisans or hiring consultants can also facilitate knowledge transfer and elevate craftsmanship within the business. By prioritizing skill development, buyers can ensure their wallets are not only aesthetically pleasing but also durable and functional.

Scenario 3: Managing Production Costs Effectively

The Problem: In the competitive landscape of leather goods, managing production costs while maintaining quality is a common pain point for B2B buyers. Fluctuating material prices, labor costs, and overhead can severely impact profit margins. This challenge is particularly pronounced for businesses operating in emerging markets, where cost efficiency is critical for sustainability and growth.

The Solution: To tackle this issue, B2B buyers should adopt a strategic approach to cost management. This includes optimizing the supply chain by negotiating better terms with suppliers, exploring bulk purchasing options, and considering local sourcing to reduce shipping costs. Implementing lean manufacturing principles can also help streamline production processes, minimize waste, and improve overall efficiency. Additionally, buyers should analyze their pricing strategies to ensure they reflect the quality and craftsmanship of their products while remaining competitive in the market. By focusing on cost-effective practices, buyers can enhance their profitability without compromising on the quality of their leather wallets.

Strategic Material Selection Guide for how to make a leather wallet

What Are the Key Materials for Making a Leather Wallet?

When selecting materials for crafting leather wallets, several options are available, each with distinct properties and implications for production and marketability. Below, we analyze four common materials used in leather wallet production: vegetable-tanned leather, chrome-tanned leather, synthetic leather, and suede leather. This analysis will focus on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Vegetable-Tanned Leather Perform in Wallet Manufacturing?

Vegetable-tanned leather is a traditional material known for its durability and eco-friendliness. Made from natural tannins found in plant matter, this leather is biodegradable and can be dyed in various colors. Its key properties include excellent breathability and a natural patina that develops over time, enhancing its aesthetic appeal.

Pros: Vegetable-tanned leather is highly durable and resistant to wear, making it suitable for long-lasting products. It is also relatively easy to work with, allowing for intricate designs and stitching.

Cons: The primary disadvantage is its higher cost compared to other tanning methods, which may not be suitable for budget-sensitive markets. Additionally, it can be sensitive to moisture and requires regular maintenance to prevent drying and cracking.

International Considerations: Buyers from regions like Europe may prefer this material due to its eco-friendly attributes, aligning with increasing sustainability demands. Compliance with standards such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is essential for market acceptance.

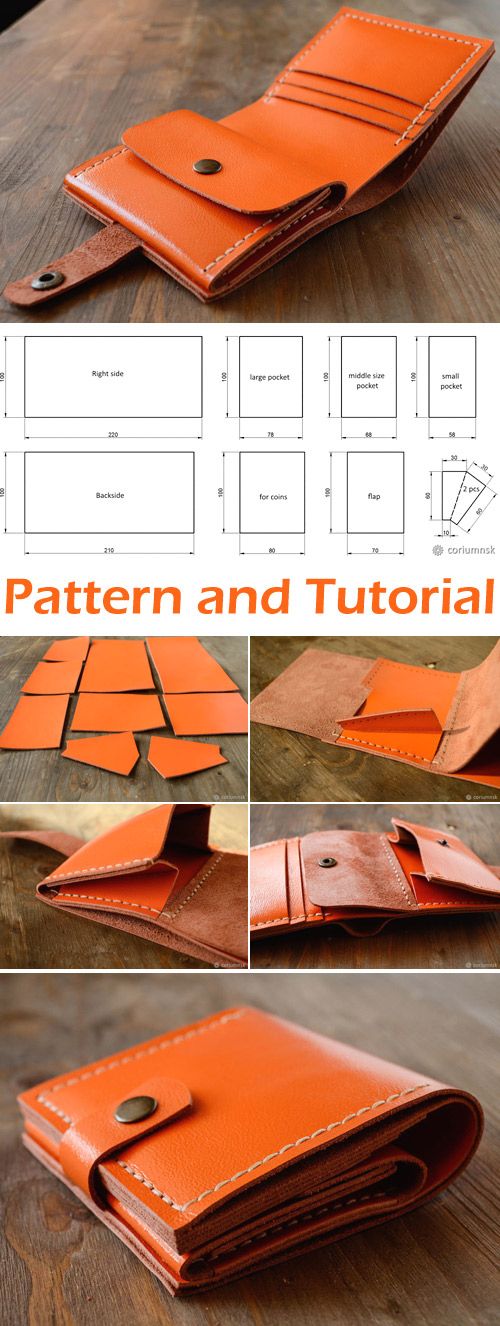

Illustrative image related to how to make a leather wallet

What Are the Benefits of Chrome-Tanned Leather for Wallets?

Chrome-tanned leather is produced using chromium salts, resulting in a softer and more pliable material. This tanning method allows for faster production times and a wide range of colors.

Pros: Chrome-tanned leather is highly resistant to water and stains, making it ideal for everyday use. Its softness enhances comfort, which is a significant selling point for consumers.

Cons: However, chrome tanning involves chemicals that may raise environmental concerns. Additionally, this leather may not develop the same character over time as vegetable-tanned leather.

International Considerations: In regions like Brazil and Saudi Arabia, where climate conditions can be humid, chrome-tanned leather’s water resistance is a considerable advantage. Nevertheless, compliance with environmental regulations is vital, particularly in markets with stringent chemical usage laws.

How Does Synthetic Leather Compare for Wallet Production?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to traditional leather. It mimics the look and feel of genuine leather while being cruelty-free.

Pros: The primary advantage of synthetic leather is its affordability and easy maintenance. It is also available in various colors and textures, appealing to a broader consumer base.

Cons: Synthetic leather is generally less durable than genuine leather and may not age as gracefully. It can also be less breathable, leading to discomfort in warmer climates.

Illustrative image related to how to make a leather wallet

International Considerations: In markets like South America, where cost is a significant factor, synthetic leather can attract budget-conscious consumers. However, buyers should be aware of varying quality standards and consumer preferences for natural materials.

What Are the Unique Characteristics of Suede Leather for Wallets?

Suede leather, made from the underside of animal hides, provides a soft, luxurious texture. It is often used for high-end wallets due to its aesthetic appeal.

Pros: Suede offers a unique tactile experience and is visually appealing, making it suitable for luxury products. It can also be dyed easily, allowing for customization.

Illustrative image related to how to make a leather wallet

Cons: On the downside, suede is more susceptible to stains and water damage, requiring careful handling and maintenance. Its durability is also lower compared to other leather types.

International Considerations: In Europe, where fashion trends often dictate consumer choices, suede can be a popular option for premium wallets. However, buyers must consider the implications of sourcing animal products and adhere to animal welfare standards.

Summary Table of Material Selection for Leather Wallets

| Material | Typical Use Case for how to make a leather wallet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end wallets, eco-friendly products | Durability and natural patina | Higher cost, moisture sensitivity | Hoch |

| Chrome-Tanned Leather | Everyday wallets, fashion accessories | Water resistance, softness | Environmental concerns | Medium |

| Synthetic Leather | Budget wallets, cruelty-free options | Affordability, easy maintenance | Less durability, less breathable | Low |

| Suede Leather | Luxury wallets, fashion-forward designs | Luxurious texture | Stain susceptibility, lower durability | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather wallet

What Are the Key Stages in the Manufacturing Process of Leather Wallets?

The manufacturing process for leather wallets is a complex series of stages, each critical for ensuring the final product meets quality standards and consumer expectations. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to how to make a leather wallet

Material Preparation: How Is Leather Selected and Prepared?

The first step in manufacturing leather wallets involves selecting high-quality leather, often vegetable-tanned, which is preferred for its durability and aesthetic appeal. Suppliers typically evaluate the leather based on its thickness, grain, and texture. Once selected, the leather undergoes various treatments to enhance its properties. This may include conditioning with oils or waxes to improve flexibility and resistance to wear.

Cutting is the next crucial step, where the leather is precisely cut according to patterns. Automated cutting machines may be employed for efficiency and accuracy, especially in high-volume production. It is vital to minimize waste during this process, as leather can be a significant cost component.

What Techniques Are Used During the Forming Stage?

Once the leather is cut, the forming stage begins. This involves shaping the leather into the desired wallet form. Techniques such as folding, stitching, and edge finishing are employed.

Folding and Stitching: The edges of the leather are often burnished to create a smooth finish. Stitching can be done by hand or machine, depending on the production scale. Saddle stitching is a common technique that ensures durability, as it employs two needles and a single thread, creating a robust seam.

Edge Finishing: The edges of the wallet are not only cut but also treated to prevent fraying and enhance aesthetics. This can include dyeing, sanding, or sealing with edge paints.

How Is the Assembly Process Managed for Leather Wallets?

The assembly stage is where all components come together. After forming, the different parts of the wallet, such as pockets and linings, are assembled.

Gluing and Clamping: A high-quality leather cement is often used to bond layers before sewing. Clamps are utilized to hold components in place while the adhesive sets, ensuring that the final product is stable and aligned correctly.

Quality Control During Assembly: At this stage, manufacturers should implement in-process quality control (IPQC) measures. This includes regular checks for alignment, stitching quality, and the overall finish of each wallet. Ensuring consistency at this stage is crucial for maintaining brand reputation.

What Finishing Techniques Are Applied to Leather Wallets?

Finishing is the final stage of wallet manufacturing. It involves several processes designed to enhance the wallet’s appearance and durability.

Illustrative image related to how to make a leather wallet

Oiling and Dyeing: Leather may be dyed to achieve the desired color. After dyeing, wallets are often oiled to enrich the leather’s natural texture and provide protection against moisture and wear.

Final Inspection: This is a critical checkpoint where the finished product is thoroughly inspected for defects. Any inconsistencies in stitching, alignment, or finish are addressed before the product is packaged for distribution.

Which International Standards Are Relevant for Quality Assurance in Leather Wallet Manufacturing?

Quality assurance (QA) is paramount in the leather wallet manufacturing process, especially for B2B buyers looking to ensure their suppliers meet international standards. Relevant standards include:

Illustrative image related to how to make a leather wallet

-

ISO 9001: This quality management standard focuses on ensuring consistent quality in products and services. Manufacturers adhering to ISO 9001 demonstrate their commitment to quality and customer satisfaction.

-

CE Marking: Particularly relevant for products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For businesses concerned with the environmental impact of their products, API (American Petroleum Institute) standards may apply, particularly regarding the sustainability of the materials used.

What Are the Common QC Checkpoints in Leather Wallet Manufacturing?

Quality control checkpoints are vital for ensuring that every wallet meets the established standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specifications before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections help catch defects early. This includes checking stitching quality and alignment during assembly.

-

Final Quality Control (FQC): The last line of defense, FQC involves a comprehensive inspection of finished wallets to ensure they are free from defects and meet all quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify their suppliers’ quality control practices. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing processes, quality assurance protocols, and adherence to international standards.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, including any certifications they hold and results from recent inspections.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of product quality before shipment, ensuring that buyers receive goods that meet their specifications.

What Nuances Should International B2B Buyers Consider Regarding QC Standards?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different markets may have varying expectations for quality and compliance, influenced by regional standards and consumer preferences.

-

Cultural Considerations: Buyers should be aware of regional differences in quality expectations and standards. For instance, European buyers may prioritize eco-friendly practices more than other regions.

-

Customs and Import Regulations: Understanding the regulations and standards in the destination country can prevent delays and additional costs. Ensuring that suppliers comply with these regulations is crucial for seamless market entry.

By focusing on these manufacturing processes and quality assurance protocols, B2B buyers can ensure they partner with reliable suppliers who deliver high-quality leather wallets that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather wallet’

Einführung

This sourcing guide is designed to provide B2B buyers with a clear and actionable checklist for procuring the necessary materials and tools to create high-quality leather wallets. Whether you are a manufacturer, retailer, or a designer looking to expand your product line, understanding the sourcing process is crucial for ensuring quality, efficiency, and profitability.

Step 1: Identify Your Target Market

Understanding your target market is essential for tailoring your leather wallet offerings. Research demographics, preferences, and purchasing behavior in regions such as Africa, South America, the Middle East, and Europe. This knowledge will guide your choices in design, material, and pricing.

- Consider regional styles: Different markets may prefer specific wallet designs or functionalities.

- Analyze competitors: Look at what similar businesses are offering and identify gaps in the market.

Step 2: Define Your Technical Specifications

Clearly outline the specifications for your leather wallets, including size, capacity, and material type. This step is vital for ensuring that suppliers can meet your quality standards and design requirements.

- Material quality: Specify the type of leather (e.g., vegetable-tanned, chrome-tanned) that aligns with your brand’s values.

- Functional features: Decide on elements like RFID protection or multiple card slots based on market demand.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request detailed company profiles, product samples, and customer references to ensure they can meet your needs.

- Check for certifications: Look for suppliers with industry certifications that demonstrate quality control and ethical practices.

- Assess manufacturing capabilities: Ensure they have the necessary technology and workforce to produce your designs efficiently.

Step 4: Source Quality Materials

Quality materials are the backbone of any leather wallet. Establish relationships with reputable tanneries and suppliers to procure leather and other components like thread and hardware.

- Sustainability: Consider sourcing leather from suppliers who prioritize environmentally-friendly practices.

- Cost vs. quality: Balance your budget with the need for high-quality materials to maintain brand integrity.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers, enter negotiations to secure favorable pricing and terms. This step is critical for maintaining profitability while ensuring quality.

- Volume discounts: Leverage potential bulk orders to negotiate lower prices.

- Payment terms: Discuss payment options that align with your cash flow needs.

Step 6: Establish Quality Control Protocols

Quality control is essential to ensure that the final product meets your standards. Develop a comprehensive quality assurance plan that includes inspections at various stages of production.

- Sampling: Request samples before full production to verify quality.

- Ongoing assessments: Implement regular checks to maintain standards throughout the production process.

Step 7: Plan for Logistics and Distribution

Finally, outline your logistics and distribution strategies to ensure timely delivery of your leather wallets to market.

- Shipping options: Evaluate different shipping methods to find the most cost-effective and reliable options.

- Inventory management: Develop a system for tracking inventory levels to meet market demand without overstocking.

By following these steps, you can streamline your sourcing process for leather wallets, ensuring high-quality products that meet market demands while maintaining efficiency and profitability.

Illustrative image related to how to make a leather wallet

Comprehensive Cost and Pricing Analysis for how to make a leather wallet Sourcing

What Are the Key Cost Components for Sourcing Leather Wallets?

When sourcing leather wallets, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margins.

-

Materials: The choice of leather significantly impacts costs. Vegetable-tanned leather, commonly used for wallets, typically ranges from $4 to $10 per square foot, depending on thickness and quality. Additional materials, such as thread, glue, and edge finishing products, can add another $1 to $3 per wallet.

-

Labor: Labor costs will vary based on the region and the skill level required. For example, skilled artisans in Europe may demand higher wages compared to those in South America or Africa. Labor costs can range from $2 to $10 per wallet depending on the complexity of the design and the artisan’s expertise.

-

Manufacturing Overhead: This includes expenses such as utilities, rent, and indirect labor. A reasonable estimate for overhead can be around 20-30% of the total labor costs.

-

Tooling: Initial tooling costs for molds, cutting dies, and other machinery can be significant but are usually amortized over large production runs. Tooling costs can range from $500 to several thousand dollars, depending on the complexity and scale of production.

-

Quality Control (QC): Ensuring that each wallet meets quality standards can add costs. A typical QC process may add $1 to $2 per unit, especially if thorough inspections are conducted.

-

Logistics: Shipping and handling costs should also be factored in, particularly for international buyers. These costs can vary widely based on the origin and destination, potentially adding $2 to $5 per wallet.

-

Margin: Suppliers typically seek a profit margin of 20-50%, which will influence the final pricing.

How Do Price Influencers Affect Leather Wallet Sourcing?

Several factors can influence the price of leather wallets, and understanding these can help buyers negotiate better deals.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may provide discounts for bulk purchases, making it crucial to assess your purchasing capacity.

-

Specs/Customization: Customized designs, colors, or additional features (like RFID protection) can significantly increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials: Higher-quality leather or sustainable sourcing methods will elevate costs. Buyers need to balance quality requirements with budget limitations.

-

Quality/Certifications: Certifications for eco-friendly materials or ethical labor practices can raise costs. Buyers should consider these factors based on their target market’s preferences.

-

Supplier Factors: The supplier’s location, reputation, and reliability can influence pricing. Established suppliers with a track record of quality may charge more but could save costs in the long run through reduced defects and returns.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) will dictate who bears shipping costs and risks, impacting the total cost of ownership.

What Negotiation and Cost-Efficiency Tips Should Buyers Consider?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, adopting strategic negotiation tactics can enhance cost efficiency.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Trust fosters open communication, which can facilitate negotiations.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also logistics, duties, and potential quality issues. A slightly higher initial cost may yield savings in the long run if it results in lower returns or higher customer satisfaction.

-

Stay Informed on Pricing Nuances: Be aware of currency fluctuations and local economic conditions, as these can impact pricing. Understanding regional market trends allows for more informed negotiations.

-

Request Samples: Before committing to large orders, request samples to assess quality and ensure it meets your specifications. This can prevent costly mistakes down the line.

By understanding these cost components, price influencers, and negotiation strategies, B2B buyers can effectively navigate the sourcing process for leather wallets, ensuring they achieve a balance between quality and cost-efficiency.

Alternatives Analysis: Comparing how to make a leather wallet With Other Solutions

Understanding Alternatives to Making a Leather Wallet

In the realm of wallet production, traditional leather crafting offers a unique blend of craftsmanship and quality. However, there are alternative methods and technologies that can achieve similar results, catering to different business needs, budgets, and production capacities. This analysis will compare the traditional method of making a leather wallet with two viable alternatives: mass-produced synthetic wallets and digital wallet applications.

Illustrative image related to how to make a leather wallet

Comparison Table

| Comparison Aspect | How To Make A Leather Wallet | Mass-Produced Synthetic Wallets | Digital Wallet Applications |

|---|---|---|---|

| Performance | High durability and aesthetics; unique designs | Good durability; often lacks unique design | High convenience; dependent on device security |

| Cost | Moderate to high due to material and labor | Low to moderate; economies of scale | Low to zero; often free with app purchases |

| Ease of Implementation | Requires skilled labor and tools | Simple assembly line production | Requires technical setup but easy for end-users |

| Wartung | Needs regular care (oiling, cleaning) | Minimal maintenance; easy to clean | Requires updates and security checks |

| Best Use Case | Luxury markets, bespoke products | Budget-conscious consumers, mass market | Tech-savvy users, contactless transactions |

Detailed Breakdown of Alternatives

Mass-Produced Synthetic Wallets

Mass-produced synthetic wallets are manufactured using various materials such as PVC or polyurethane, allowing for lower production costs and quicker turnaround times. These wallets can appeal to budget-conscious consumers and often come in a variety of styles and colors. However, while they may mimic the appearance of leather, they typically lack the durability and luxury feel of genuine leather. Additionally, synthetic options may not perform well in terms of environmental sustainability, which is increasingly important to consumers.

Digital Wallet Applications

Digital wallets, such as Apple Pay or Google Wallet, represent a growing trend in personal finance management. They offer high convenience, allowing users to store payment information and make transactions from their smartphones. This solution is particularly attractive to tech-savvy consumers who prioritize speed and ease of use. However, digital wallets depend heavily on device security and internet access, which can be a barrier in regions with limited technology infrastructure. Furthermore, they do not replace the physical wallet, limiting their appeal in markets where traditional wallets are still preferred.

Conclusion: Choosing the Right Solution for Your Needs

When considering the best solution for wallet production or procurement, B2B buyers should evaluate their target market and specific needs. If the goal is to create a high-end product that emphasizes craftsmanship and durability, making a leather wallet is the ideal choice. On the other hand, for businesses targeting mass markets or budget-conscious consumers, synthetic wallets may provide a cost-effective alternative. Lastly, for companies looking to innovate in the financial technology space, digital wallet applications can offer a cutting-edge solution. Ultimately, the decision should align with the company’s brand, customer expectations, and market dynamics.

Essential Technical Properties and Trade Terminology for how to make a leather wallet

What Are the Key Technical Properties for Manufacturing Leather Wallets?

When producing leather wallets, understanding the essential technical properties is crucial for ensuring product quality and meeting market demands. Here are some critical specifications:

Illustrative image related to how to make a leather wallet

-

Material Grade

Leather quality significantly impacts the durability and aesthetic of the wallet. Vegetable-tanned leather, typically used for wallets, is favored for its eco-friendly properties and ability to develop a patina over time. For B2B buyers, sourcing leather with a specific grade ensures compliance with customer expectations and regulatory standards, especially in markets that prioritize sustainable practices. -

Thickness (Oz Weight)

The thickness of leather is measured in ounces (oz), with 3-4 oz being common for wallets. Thicker leather offers greater durability but may limit flexibility, while thinner leather provides a softer feel but can be less robust. Understanding the desired thickness is essential for manufacturers to balance quality, functionality, and cost-effectiveness, catering to different consumer preferences. -

Tensile Strength

This property measures the leather’s ability to withstand pulling forces. High tensile strength ensures that the wallet can endure daily use without tearing or deforming. B2B buyers should prioritize suppliers who provide tensile strength specifications, as this can be a differentiating factor in competitive markets. -

Finish Type

The finish of the leather affects both aesthetics and functionality. Common finishes include aniline, semi-aniline, and pigmented, each offering different levels of color saturation and protection against wear. For B2B buyers, knowing the finish type helps in marketing the product effectively, as it influences consumer perceptions regarding luxury and durability. -

Water Resistance

While most leather is not inherently water-resistant, treatments can enhance its ability to repel moisture. This property is critical for wallets, which are often exposed to varying environmental conditions. Buyers should inquire about water resistance treatments when sourcing leather to ensure their products meet consumer needs for practicality and longevity.

What Common Trade Terms Should B2B Buyers Know in Leather Wallet Manufacturing?

Understanding industry jargon is vital for effective communication and negotiation in the leather goods market. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the leather wallet industry, an OEM might create wallet components that are then assembled and branded by a different company. For buyers, working with OEMs can enhance product customization options while reducing manufacturing costs. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is crucial for B2B transactions, as it affects inventory management and initial investment costs. Buyers should negotiate MOQs that align with their market demand to optimize cash flow and minimize excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific goods or services. In the leather wallet sector, an RFQ helps buyers gather competitive pricing and terms from multiple manufacturers, enabling informed decision-making based on cost, quality, and lead time. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in shipping and logistics. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risk transfer, and insurance responsibilities when importing leather goods from other countries. -

Lead Time

Lead time is the duration between the initiation of a purchase order and the delivery of goods. In the leather wallet industry, understanding lead times is critical for inventory planning and meeting customer demand. Buyers should always clarify lead times with suppliers to ensure timely product availability. -

Sustainability Standards

These are benchmarks that assess the environmental impact of leather production, including sourcing and manufacturing practices. As consumers increasingly demand ethically produced goods, B2B buyers should prioritize suppliers who adhere to recognized sustainability standards, enhancing brand reputation and marketability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they source high-quality leather wallets that meet market demands.

Navigating Market Dynamics and Sourcing Trends in the how to make a leather wallet Sector

What Are the Key Market Trends Impacting the Leather Wallet Manufacturing Sector?

The leather wallet market is currently experiencing a resurgence, driven by a combination of consumer preference for durable goods and a growing interest in artisanal craftsmanship. Global demand is particularly strong in regions like Africa, South America, the Middle East, and Europe, where traditional craftsmanship is valued alongside modern design aesthetics. One significant trend is the increasing integration of technology in the sourcing process, with digital platforms streamlining procurement and allowing for greater transparency in supply chains. B2B buyers are increasingly utilizing platforms that offer real-time inventory management and supplier ratings, enhancing decision-making capabilities.

Additionally, customization is becoming a key differentiator in the market. Manufacturers are leveraging advanced production techniques and software to provide bespoke options for consumers, catering to individual preferences while maintaining efficient production processes. This trend aligns with the rise of e-commerce, where personalized items can command premium pricing, thus allowing businesses to explore new revenue streams. Furthermore, the focus on local sourcing is gaining traction, as buyers seek to reduce lead times and transportation costs, while also supporting local economies.

Illustrative image related to how to make a leather wallet

How Is Sustainability Shaping Sourcing Decisions in the Leather Wallet Industry?

Sustainability is no longer just a buzzword; it is a driving force in the leather industry, influencing sourcing decisions significantly. The environmental impact of traditional leather production methods has prompted businesses to seek out more sustainable options. B2B buyers are increasingly prioritizing suppliers that adhere to environmentally friendly practices, such as vegetable tanning and the use of recycled materials. Certifications like the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification are becoming essential criteria for supplier selection, as they demonstrate a commitment to ethical sourcing and environmental stewardship.

Moreover, the rise of consumer awareness regarding ethical sourcing is compelling manufacturers to adopt more transparent practices. Buyers are now looking for suppliers who can trace the origins of their materials and demonstrate responsible labor practices. This shift towards sustainability not only mitigates risks associated with regulatory compliance but also enhances brand reputation. As a result, businesses that prioritize sustainable sourcing practices are better positioned to attract eco-conscious consumers and partners, thereby driving long-term growth.

What Is the Historical Context Behind the Leather Wallet Market?

The leather wallet has a rich history, dating back to ancient civilizations when leather was first used for utility items. Initially, wallets served primarily functional purposes, crafted from animal hides to store coins and small valuables. As trade expanded and commerce grew, the design and craftsmanship of leather wallets evolved, transitioning from purely functional items to fashion statements that reflect personal style.

In the 20th century, the leather wallet became a staple accessory, symbolizing status and sophistication. The rise of mass production in the mid-1900s made wallets more accessible, but it also led to a decline in artisanal craftsmanship. However, recent years have seen a revival of interest in handmade products, as consumers increasingly value authenticity and quality. This evolution highlights the ongoing balancing act between tradition and innovation in the leather wallet market, providing B2B buyers with opportunities to capitalize on both heritage and contemporary trends.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather wallet

-

1. How do I source high-quality leather for making wallets?

When sourcing leather for wallet production, prioritize suppliers who offer vegetable-tanned leather, as it is durable and eco-friendly. Look for manufacturers with certifications like ISO or those who adhere to sustainable practices. Request samples to evaluate the leather’s texture, thickness, and finish. Establish relationships with suppliers who have experience in international trade, as they can navigate customs and regulations specific to your region, ensuring a smooth import process. -

2. What is the best stitching method for leather wallets?

The saddle stitch is widely regarded as the best method for stitching leather wallets due to its strength and durability. This technique involves using two needles and a single thread, creating a secure bond that can withstand daily wear. For a professional finish, consider using a diamond chisel to create evenly spaced holes before stitching. Investing in high-quality waxed thread will enhance the overall appearance and longevity of the wallet. -

3. How can I customize leather wallets for my brand?

Customization options for leather wallets include embossing your logo, selecting unique colors, and choosing specific materials. Engage with your supplier early in the design process to discuss possibilities, including custom patterns and features like RFID-blocking technology. Ensure that your supplier has experience with custom projects and can provide samples or prototypes before mass production to confirm that the final product aligns with your brand’s vision. -

4. What are the typical minimum order quantities (MOQs) for leather wallet production?

Minimum order quantities can vary significantly based on the supplier and the complexity of the wallet design. Generally, MOQs for leather wallets range from 50 to 500 units. When negotiating, consider your budget, storage capacity, and sales projections. If you’re starting small, look for suppliers willing to accommodate lower MOQs or consider a partnership with a local manufacturer to reduce initial costs. -

5. What payment terms should I expect when sourcing leather wallets internationally?

Payment terms can vary by supplier, but common practices include a deposit (typically 30-50%) upfront, with the balance due before shipment. Some suppliers may offer flexible terms based on your relationship and order size. Ensure to clarify payment methods accepted, such as bank transfers or letters of credit, and factor in any currency exchange rates. Protect your investment by using secure payment platforms that offer buyer protection. -

6. How can I ensure quality assurance in leather wallet production?

To ensure quality assurance, establish clear quality standards and expectations with your supplier before production begins. Request detailed specifications, including materials, stitching techniques, and finishing processes. Implement regular inspections during production, and consider hiring a third-party quality control service to conduct final inspections before shipment. This proactive approach can help mitigate defects and ensure that the final product meets your quality standards. -

7. What logistics considerations should I keep in mind when importing leather wallets?

Logistics considerations include shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling leather goods to navigate the complexities of international shipping. Familiarize yourself with the import regulations specific to your country, including any documentation required for customs clearance. Additionally, calculate shipping costs and lead times to ensure they align with your delivery expectations to customers. -

8. How can I effectively market leather wallets to international buyers?

To effectively market leather wallets internationally, focus on understanding regional preferences and trends. Leverage digital marketing channels, such as social media and targeted online ads, to reach your audience. Create compelling content that highlights the craftsmanship, sustainability, and unique features of your wallets. Participating in international trade shows can also enhance visibility and allow you to establish direct relationships with potential buyers.

Top 2 How To Make A Leather Wallet Manufacturers & Suppliers List

1. Instructables – Leather Wallet Tutorial

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Make a Leather Wallet tutorial by jessyratfink. The wallet is designed to be small enough to fit in women’s jeans pockets while holding up to eight cards and some folded cash. The project includes three different wallet patterns: one with straight pockets and two with slanted pockets. Key materials include 3-4 oz weight vegetable tanned leather, diamond chisel set, sewing awl, waxed thread, stitch…

2. PopSewing – DIY Leather Wallet Kits

Domain: popsewing.com

Registered: 2021 (4 years)

Introduction: DIY Leather Wallet Kit Purse Kit – Wallet Making Kit, In stock (38), Out of stock (11), Make your own purse or wallet within 2 hours, Price range: $29.99 – $75.99, Various styles available including bifold wallets, card holders, and passport wallets, Free worldwide shipping on all orders, 20% off Halloween sale with no code needed.

Strategic Sourcing Conclusion and Outlook for how to make a leather wallet

In conclusion, the journey to crafting high-quality leather wallets offers significant opportunities for strategic sourcing in the global marketplace. By leveraging locally sourced materials and skilled artisans, businesses can not only enhance product quality but also align with sustainable practices that resonate with today’s conscious consumers. Key takeaways include the importance of selecting the right tools and materials, understanding the craftsmanship involved, and implementing efficient production techniques to maintain competitive pricing.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to diversify their product offerings, investing in leather goods manufacturing can yield substantial returns. The rising demand for unique, handcrafted items presents an opportunity to differentiate in crowded markets.

Looking ahead, now is the time to explore partnerships with established suppliers and artisans who share your vision for quality and sustainability. By doing so, you position your business to not only meet market demands but also to create a lasting impact in the leather goods industry. Embrace this opportunity to elevate your product line and meet the growing consumer appetite for distinctive, ethically made leather wallets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.