Introduction: Navigating the Global Market for tandy leather factory fresno

In the dynamic world of leathercraft, sourcing high-quality materials from reputable suppliers like the Tandy Leather Factory in Fresno presents a significant challenge for international B2B buyers. Navigating the complexities of global supply chains, varying quality standards, and cost considerations can overwhelm even seasoned procurement professionals. This guide aims to demystify the process, offering a comprehensive exploration of Tandy Leather’s offerings—from premium hides and specialized tools to innovative machines and educational resources.

We will delve into the diverse applications of Tandy Leather products, catering to artisans and manufacturers alike, ensuring that buyers understand how to leverage these materials for maximum impact in their markets. Additionally, the guide will cover critical aspects of supplier vetting, helping you assess quality, reliability, and responsiveness, crucial factors for successful international transactions.

By empowering B2B buyers from Africa, South America, the Middle East, and Europe—such as those in Vietnam and Nigeria—with actionable insights and strategies, this guide facilitates informed purchasing decisions. From understanding pricing structures to identifying the best product fits for specific needs, our aim is to equip you with the knowledge necessary to thrive in the global leather market. With Tandy Leather Factory as a cornerstone of your supply chain, you can enhance your product offerings and elevate your business to new heights.

Table Of Contents

- Top 3 Tandy Leather Factory Fresno Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for tandy leather factory fresno

- Understanding tandy leather factory fresno Types and Variations

- Key Industrial Applications of tandy leather factory fresno

- 3 Common User Pain Points for ‘tandy leather factory fresno’ & Their Solutions

- Strategic Material Selection Guide for tandy leather factory fresno

- In-depth Look: Manufacturing Processes and Quality Assurance for tandy leather factory fresno

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘tandy leather factory fresno’

- Comprehensive Cost and Pricing Analysis for tandy leather factory fresno Sourcing

- Alternatives Analysis: Comparing tandy leather factory fresno With Other Solutions

- Essential Technical Properties and Trade Terminology for tandy leather factory fresno

- Navigating Market Dynamics and Sourcing Trends in the tandy leather factory fresno Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tandy leather factory fresno

- Strategic Sourcing Conclusion and Outlook for tandy leather factory fresno

- Important Disclaimer & Terms of Use

Understanding tandy leather factory fresno Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Veg-Tan Leather | Natural tanning process, high durability, and versatility | High-end leather goods, tooling, and crafts | Pros: Eco-friendly; accepts dyes well. Cons: Can be more expensive than chrome-tanned leather. |

| Chrome-Tan Leather | Soft, supple, and often more affordable; vibrant color retention | Fashion accessories, upholstery, and garments | Pros: Cost-effective; quick to produce. Cons: May not be as durable as veg-tan leather. |

| Leather Crafting Tools | Comprehensive range including cutting, stamping, and sewing tools | Leather crafting, DIY projects, and education | Pros: High quality; designed for durability. Cons: Initial investment can be high for beginners. |

| Leather Kits | Pre-packaged kits that include all necessary materials and tools | Education, workshops, and beginner projects | Pros: Convenient; ideal for beginners. Cons: Limited customization options. |

| Specialty Hides | Unique textures and finishes such as exotic leathers | Luxury goods, custom projects, and art pieces | Pros: Distinctive appearance; high value. Cons: Higher cost and may require special care. |

What are the Characteristics of Veg-Tan Leather and Its B2B Suitability?

Veg-tan leather is known for its natural tanning process, which enhances its durability and versatility. It is ideal for crafting high-end leather goods such as belts, wallets, and custom tooling projects. B2B buyers should consider its eco-friendly properties and the ability to accept dyes and finishes well, allowing for a range of creative applications. However, the higher cost compared to chrome-tanned leather may be a consideration for budget-conscious buyers.

How Does Chrome-Tan Leather Compare for B2B Applications?

Chrome-tan leather is characterized by its softness and vibrant color retention, making it a popular choice for fashion accessories, upholstery, and garments. Its affordability and quicker production time appeal to B2B buyers looking for cost-effective solutions. Despite its benefits, buyers should note that it may not offer the same level of durability as veg-tan leather, which could affect long-term value in certain applications.

Why Invest in Quality Leather Crafting Tools?

Tandy Leather provides a comprehensive range of leather crafting tools designed for both novice and expert leathercrafters. These tools, including cutting, stamping, and sewing implements, are crafted for durability and precision, making them suitable for various leather projects. While the initial investment may be significant, the long-lasting quality of these tools can lead to cost savings over time for B2B buyers engaged in extensive leatherwork.

What Are the Benefits of Leather Kits for Beginners?

Leather kits from Tandy Leather come pre-packaged with all necessary materials and tools, making them an excellent choice for educational purposes, workshops, and beginner projects. These kits offer convenience and a structured approach to learning leathercraft. However, buyers should consider that while kits are great for starting out, they may limit customization options for more experienced crafters looking for unique projects.

How Do Specialty Hides Enhance B2B Offerings?

Specialty hides, such as exotic leathers, provide unique textures and finishes that are highly sought after for luxury goods and custom projects. These hides can significantly enhance the aesthetic value of products, making them appealing to high-end markets. However, buyers should be prepared for higher costs and the need for special care, which may not suit every business model focused on mass production.

Key Industrial Applications of tandy leather factory fresno

| Industry/Sector | Specific Application of Tandy Leather Fresno | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather garments and accessories | High-quality materials enhance brand value and appeal | Availability of various leather types and finishes |

| Automobilindustrie | Upholstery for vehicles | Durable and aesthetic leather enhances vehicle interiors | Compliance with regional regulations and standards |

| Craftsmanship & Hobby | DIY leathercraft supplies and tools | Enables businesses to offer unique, handmade products | Bulk purchasing options and educational resources |

| Footwear | Production of custom leather shoes | Quality leather improves product longevity and comfort | Sourcing leather that meets specific weight and texture needs |

| Furniture & Interior Design | Leather furnishings and decor | Luxurious appeal increases market competitiveness | Customization options for large orders and color matching |

How Can Fashion and Apparel Businesses Leverage Tandy Leather Fresno for Custom Leather Garments?

In the fashion and apparel sector, Tandy Leather Fresno serves as a vital source for high-quality leather, enabling designers to create custom garments and accessories. Businesses can benefit from the diverse range of leather types and finishes available, which enhances the aesthetic appeal and durability of their products. International buyers should consider the sourcing of specific leather grades and the ability to meet minimum order quantities to ensure a consistent supply for their collections.

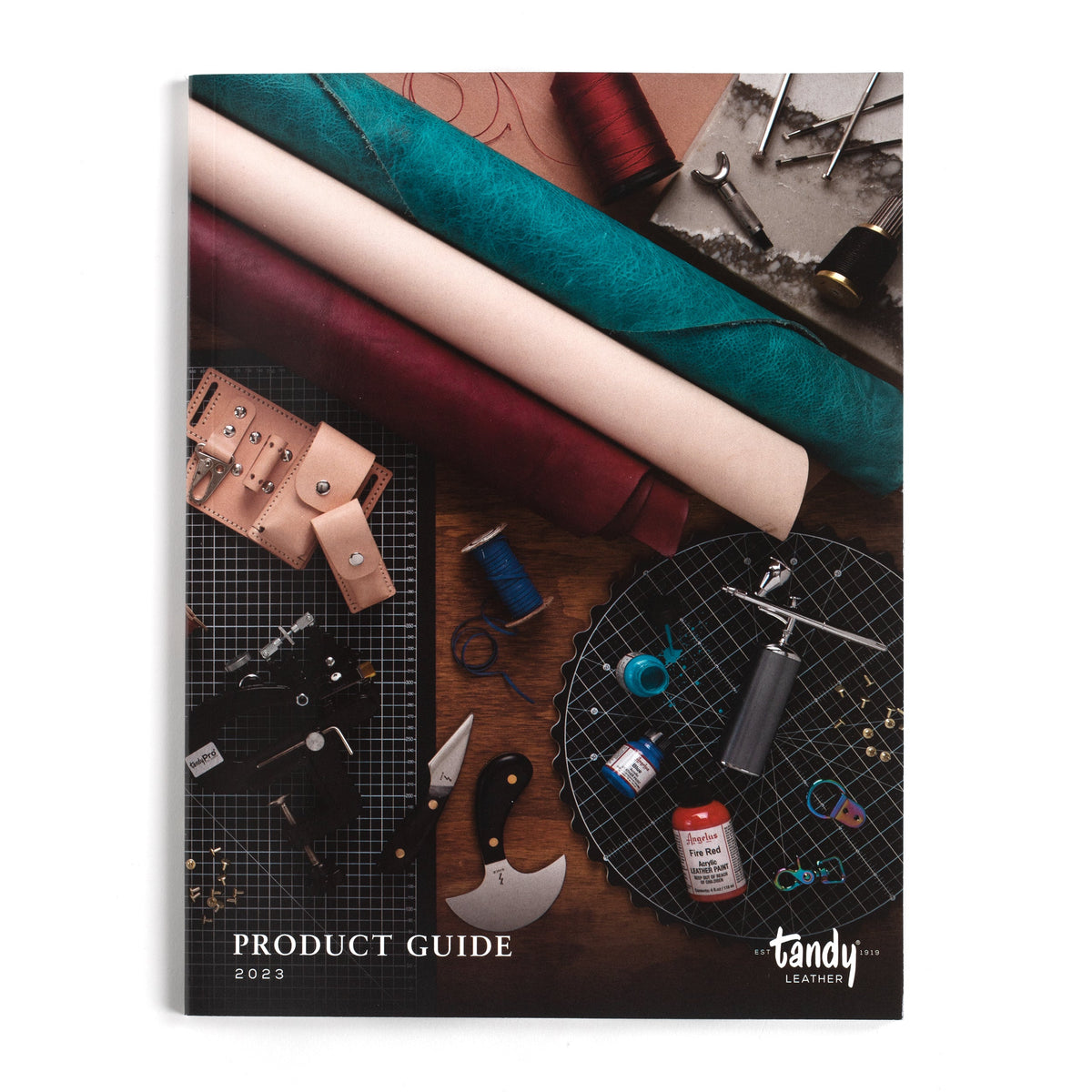

Illustrative image related to tandy leather factory fresno

What Role Does Tandy Leather Fresno Play in Automotive Upholstery?

Automotive manufacturers and custom shops can utilize Tandy Leather Fresno for sourcing premium upholstery materials that enhance vehicle interiors. The durability and visual appeal of leather significantly contribute to customer satisfaction and vehicle value. For international buyers, understanding local regulations regarding automotive materials and ensuring compliance with safety standards is crucial when sourcing leather for automotive applications.

How Can Craftsmanship and Hobbyists Benefit from Tandy Leather Fresno’s Offerings?

For businesses focused on craftsmanship and DIY projects, Tandy Leather Fresno provides a comprehensive range of leathercraft supplies and tools. This enables companies to offer unique, handmade products that cater to niche markets. Buyers should consider bulk purchasing options for cost efficiency and access to educational resources that can help them improve their crafting skills, which is particularly valuable for emerging markets.

Why is Tandy Leather Fresno Essential for Custom Leather Footwear Production?

In the footwear industry, Tandy Leather Fresno supplies quality leather that enhances the comfort and longevity of custom shoes. Leather sourced from Tandy can meet specific requirements for weight and texture, allowing businesses to tailor their products to consumer preferences. International buyers should focus on the consistency of leather quality and the ability to handle large orders to ensure timely production cycles.

How Can Furniture and Interior Design Companies Enhance Their Products with Tandy Leather Fresno?

Tandy Leather Fresno plays a critical role in the furniture and interior design sectors by providing luxurious leather options for furnishings and decor. The use of high-quality leather not only elevates the aesthetic appeal but also increases the market competitiveness of products. Buyers should explore customization options for large orders and consider the range of colors and textures available to meet specific design requirements.

Illustrative image related to tandy leather factory fresno

3 Common User Pain Points for ‘tandy leather factory fresno’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Leather for Large Orders

The Problem: B2B buyers often face challenges when sourcing quality leather for large-scale projects. This is particularly true for businesses that rely on consistent leather quality and specific leather types, such as veg-tan or chrome-tan leather. Inconsistent quality can lead to production delays, increased costs, and ultimately, a negative impact on customer satisfaction. Additionally, international buyers from regions like Africa or South America may encounter complications with shipping and customs, adding another layer of complexity to the procurement process.

The Solution: To address this pain point, B2B buyers should establish a direct relationship with Tandy Leather Factory Fresno. This can be achieved by contacting the store manager to discuss specific needs and available stock. Buyers should inquire about bulk purchasing options and any available manager specials that can provide cost benefits. Moreover, working closely with the knowledgeable staff can help ensure that the quality and specifications of the leather meet project requirements. For international transactions, Tandy Leather can provide guidance on the best shipping options and necessary documentation to streamline the customs process, ensuring timely delivery.

Scenario 2: Limited Knowledge of Leatherworking Tools and Techniques

The Problem: Many B2B buyers may not have extensive knowledge about the tools and techniques necessary for effective leather crafting, which can lead to underutilization of the materials purchased. This lack of expertise can result in wasted resources and time, affecting overall productivity and profitability. For instance, businesses looking to create bespoke leather goods may struggle to find the right tools or techniques to achieve the desired quality in their products, ultimately hindering their competitiveness in the market.

The Solution: Tandy Leather Factory Fresno offers a range of educational resources, including leathercraft classes and an open table for tool demonstrations. Buyers should take advantage of these offerings to enhance their understanding of leatherworking techniques. By participating in workshops or classes, they can learn about the proper use of tools, such as stitching chisels, dyes, and finishing products. Additionally, accessing Tandy’s online resources, such as tutorials and guides, can empower buyers to improve their crafting skills. Investing in training can lead to better product quality and efficiency, ultimately benefiting the bottom line.

Scenario 3: Challenges in Product Customization and Design

The Problem: B2B buyers often require customized leather products tailored to specific client needs. However, navigating the design and customization process can be overwhelming, particularly for those who are new to leather crafting. Buyers may struggle with understanding the types of leather that are best suited for specific applications or how to incorporate unique design elements that will appeal to their target market. This challenge can lead to dissatisfaction with the final product and potential loss of business opportunities.

The Solution: To effectively tackle customization challenges, B2B buyers should leverage the expertise available at Tandy Leather Factory Fresno. Engaging with the knowledgeable staff can provide insights into the best materials and techniques for achieving desired customizations. Buyers can also request samples of different leather types to better understand their properties and suitability for various applications. Moreover, utilizing Tandy’s resources, such as design templates and project kits, can simplify the customization process. Collaborating with Tandy’s team to brainstorm ideas can inspire innovative designs that will differentiate products in the market, enhancing the business’s competitive edge.

Strategic Material Selection Guide for tandy leather factory fresno

What Are the Key Materials Available at Tandy Leather Factory Fresno?

Tandy Leather Factory Fresno offers a variety of materials essential for leather crafting. Understanding the properties, advantages, and limitations of these materials can help B2B buyers make informed decisions. Here, we analyze four common materials: Vegetable-Tanned Leather, Chrome-Tanned Leather, Synthetic Leather, and Leather Dye.

Illustrative image related to tandy leather factory fresno

What Are the Key Properties of Vegetable-Tanned Leather?

Vegetable-tanned leather is a traditional leather type processed using natural tannins from plant sources. Its key properties include excellent breathability, a natural finish that ages beautifully, and a high degree of moldability. It can withstand moderate temperatures but should be kept away from excessive moisture to prevent damage.

Pros: This material is highly durable and environmentally friendly, making it suitable for high-quality products such as belts, wallets, and bags. Its ability to accept dyes and finishes allows for customization.

Cons: The manufacturing process can be time-consuming and labor-intensive, leading to a higher cost compared to other leather types. Additionally, it may not be as resistant to water and stains as chrome-tanned leather.

Impact on Application: Vegetable-tanned leather is ideal for products requiring a natural look and feel, such as handmade goods. However, it is not recommended for items exposed to harsh conditions.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local environmental regulations, as the tanning process can vary in sustainability. Familiarity with standards like ASTM D-2000 can also enhance product quality assurance.

How Does Chrome-Tanned Leather Compare?

Chrome-tanned leather is treated with chromium salts, resulting in a softer and more pliable product. Its key properties include high resistance to water, heat, and wear, making it suitable for various applications.

Pros: This leather type is durable and easy to maintain, making it ideal for items like upholstery and fashion accessories. Its vibrant colors and finishes are also appealing for commercial products.

Cons: The chrome tanning process can be harmful to the environment, raising concerns about sustainability. Additionally, the leather may not develop the same character over time as vegetable-tanned leather.

Impact on Application: Chrome-tanned leather is suitable for applications requiring durability and color retention, such as automotive interiors and fashion items.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of compliance with environmental standards, such as REACH, which regulates chemical use in leather production.

Illustrative image related to tandy leather factory fresno

What Are the Advantages of Synthetic Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers an animal-friendly alternative. Its key properties include water resistance, ease of cleaning, and a wide range of textures and colors.

Pros: It is generally more affordable than natural leather and can mimic the look and feel of genuine leather. Its versatility makes it suitable for various applications, including fashion and automotive.

Cons: Synthetic leather may not have the same durability or breathability as natural leather. It can also degrade over time, particularly when exposed to UV light.

Impact on Application: Synthetic leather is ideal for products requiring low maintenance and cost-effectiveness, such as promotional items and budget-friendly fashion.

Illustrative image related to tandy leather factory fresno

Considerations for International Buyers: Buyers should ensure that synthetic materials meet relevant safety and quality standards, such as ISO 14001 for environmental management.

How Do Leather Dyes Impact the Crafting Process?

Leather dyes are essential for finishing leather products, offering a range of colors and finishes. Key properties include water resistance and the ability to penetrate various leather types.

Pros: Dyes enhance the aesthetic appeal of leather goods and can be used to create unique designs. They are available in various formulations, including eco-friendly options.

Cons: Some dyes may require specific application techniques, and improper use can lead to uneven coloring. Additionally, certain dyes may not be suitable for all leather types.

Impact on Application: Dyes are crucial for branding and personalization, making them suitable for promotional products and custom orders.

Illustrative image related to tandy leather factory fresno

Considerations for International Buyers: Buyers should verify compliance with local regulations regarding chemical use, especially in regions with strict environmental laws.

Summary Table of Material Selection

| Material | Typical Use Case for Tandy Leather Factory Fresno | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Belts, wallets, handmade goods | Environmentally friendly, customizable | Higher cost, less water-resistant | Hoch |

| Chrome-Tanned Leather | Upholstery, fashion accessories | Durable, vibrant colors | Environmental concerns, less character | Medium |

| Synthetic Leather | Fashion items, automotive interiors | Affordable, low maintenance | Less durable, may degrade over time | Low |

| Leather Dye | Customization of leather goods | Enhances aesthetic appeal | Requires specific application techniques | Medium |

This guide serves as a valuable resource for B2B buyers seeking to understand the materials available at Tandy Leather Factory Fresno and their implications for product development and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for tandy leather factory fresno

What Are the Key Stages in the Manufacturing Process at Tandy Leather Factory Fresno?

The manufacturing process at Tandy Leather Factory Fresno is designed to ensure high-quality leather products suitable for both hobbyists and professionals. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation

– The journey begins with the selection of premium leather hides. Tandy sources various types of leather, including vegetable-tanned and chrome-tanned options, ensuring a diverse range of textures and qualities.

– The hides undergo rigorous inspection for defects and inconsistencies before being cut to size. This quality control step is crucial as it affects the final product’s durability and aesthetics. -

Forming

– In this stage, the prepared leather is shaped into desired forms using a combination of traditional handcraft techniques and modern machinery. Techniques such as stamping, carving, and dyeing are employed to add unique features and finishes.

– Tools and machinery are chosen based on the specific requirements of the product being manufactured. Tandy Leather Factory offers a range of machines that facilitate efficient and precise crafting, which is vital for meeting the diverse needs of B2B customers. -

Assembly

– After forming, the various components are assembled. This may involve stitching, riveting, or gluing, depending on the product specifications. Skilled artisans oversee this process to ensure that all elements fit together seamlessly.

– Quality checks are performed at this stage to confirm that each piece meets design specifications and quality standards before moving on to the next step. -

Finishing

– The final stage involves applying finishing touches such as edge finishing, polishing, and applying protective coatings. These processes not only enhance the appearance of the leather but also increase its longevity and resistance to wear and tear.

– Products are then labeled and packaged for distribution, ready to meet the needs of international markets.

How Does Tandy Leather Factory Fresno Ensure Quality Assurance?

Quality assurance (QA) is a critical aspect of Tandy Leather Factory’s operations, particularly given the international clientele that includes buyers from Africa, South America, the Middle East, and Europe.

-

Adherence to International Standards

– Tandy Leather Factory complies with recognized international quality standards, such as ISO 9001, which establishes a framework for effective quality management systems. This compliance assures B2B buyers of consistent quality across all products.

– In addition, industry-specific standards, such as CE marking for safety and API standards for leather goods, are also adhered to, ensuring that products meet specific regulatory requirements. -

Quality Control Checkpoints

– The factory implements several quality control checkpoints throughout the manufacturing process:- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Ongoing assessments are conducted during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Completed products undergo a final inspection to ensure they meet all quality standards before shipment.

-

Common Testing Methods

– Various testing methods are utilized to assess the quality and durability of leather products. These may include tensile strength tests, colorfastness tests, and abrasion resistance tests, ensuring that the products can withstand the rigors of use.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from diverse regions such as Vietnam and Nigeria, verifying supplier quality control is essential to ensure product reliability and compliance with local regulations.

-

Audits and Reports

– Conducting regular audits of the manufacturing facilities can provide insights into the quality control processes in place. Buyers can request audit reports that detail compliance with quality standards and any corrective actions taken.

– Engaging third-party auditing firms can add an additional layer of assurance, providing unbiased evaluations of the supplier’s quality management practices. -

Third-Party Inspections

– Buyers should consider employing third-party inspection services to verify the quality of products before shipment. These inspections can assess various factors, including material quality, workmanship, and adherence to specifications.

– Third-party inspectors can also provide certificates that confirm compliance with relevant standards, which can be crucial for customs clearance and market acceptance. -

Quality Certifications

– Buyers should look for suppliers who possess relevant quality certifications. These certifications not only indicate adherence to international standards but also reflect a commitment to maintaining high-quality manufacturing practices.

– Understanding the nuances of these certifications and how they apply to specific markets is vital for B2B buyers looking to establish long-term partnerships.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers face unique challenges when sourcing leather products, and understanding these nuances is critical for successful procurement.

-

Cultural and Regulatory Differences

– Different regions may have varying standards and regulations regarding leather goods. For instance, some countries have strict regulations concerning animal welfare and environmental impact, which can affect sourcing decisions.

– It’s essential for buyers to familiarize themselves with these regulations to ensure compliance and avoid potential legal issues. -

Logistical Challenges

– Shipping leather products internationally can pose logistical challenges, including potential damage during transit. Quality control measures should extend to packaging and transportation to minimize risks.

– Buyers should discuss with suppliers the steps taken to protect products during shipping, including the use of appropriate packing materials and handling procedures. -

Long-Term Partnerships

– Establishing long-term relationships with suppliers who demonstrate a commitment to quality can lead to better pricing, improved service, and more reliable supply chains. Regular communication and feedback can help reinforce quality standards and address any concerns promptly.

By understanding the manufacturing processes and quality assurance measures in place at Tandy Leather Factory Fresno, B2B buyers can make informed decisions and build successful partnerships that meet their specific needs in the leather industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tandy leather factory fresno’

Einführung

This practical sourcing guide is designed to assist B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, in procuring quality leather supplies from the Tandy Leather Factory in Fresno. By following this step-by-step checklist, you will ensure a streamlined procurement process that aligns with your business needs and enhances your leathercraft projects.

Step 1: Identify Your Leather Needs

Before reaching out to suppliers, clearly define the types of leather and supplies required for your projects. This includes the specific grades, colors, and types (e.g., veg-tan, chrome-tan) you need. Understanding your requirements helps in communicating effectively with suppliers and ensures that you receive the appropriate products.

Step 2: Research Tandy Leather Factory Offerings

Familiarize yourself with the range of products available at the Tandy Leather Factory. Review their website and product catalog to identify items that meet your specifications. Pay particular attention to their tools, kits, and machine options, as these can significantly enhance your leather crafting capabilities.

Step 3: Evaluate Pricing Structures

Once you have identified your needs, request a detailed pricing list from Tandy Leather Factory. Compare these prices with other suppliers to ensure you are getting competitive rates. Look for volume discounts or special offers that may be available for bulk orders, which can significantly reduce your overall costs.

Step 4: Verify Quality Assurance Standards

Quality is paramount in leather sourcing. Inquire about Tandy Leather’s quality control processes and certifications. Understand the grading system for their leather products to ensure that the materials meet your business’s quality standards. Ask for samples if possible to assess the quality before making a large purchase.

Step 5: Check Shipping and Delivery Options

Understanding the logistics involved in your order is crucial. Confirm the shipping options available for international deliveries and the expected lead times. Inquire about any additional fees for shipping and customs clearance, particularly if you are ordering from regions outside the United States.

Step 6: Request References and Case Studies

To gauge the reliability of Tandy Leather Factory as a supplier, request references from other B2B customers, particularly those in your industry. This can provide insights into their customer service, delivery times, and overall satisfaction. Additionally, reviewing case studies can illustrate how other businesses have successfully used Tandy Leather products.

Illustrative image related to tandy leather factory fresno

Step 7: Establish Clear Communication Channels

Finally, set up effective communication channels with Tandy Leather Factory. Designate a point of contact for your orders and inquiries to streamline the process. Regular communication will help in addressing any issues that may arise and ensure that your procurement process runs smoothly.

By following these steps, you can effectively source high-quality leather supplies from Tandy Leather Factory in Fresno, ensuring that your projects meet the necessary standards and timelines.

Comprehensive Cost and Pricing Analysis for tandy leather factory fresno Sourcing

The cost structure and pricing analysis for sourcing from Tandy Leather Factory in Fresno involves several key components and influencers that international B2B buyers must consider. Understanding these elements will help buyers make informed decisions and optimize their procurement strategies.

What Are the Key Cost Components in Tandy Leather Pricing?

Materials: The primary cost driver in leather sourcing is the quality of the leather itself. Tandy offers a range of leather types, including vegetable-tanned and chrome-tanned options, which vary significantly in price. Premium leathers typically command higher prices due to their durability and aesthetic appeal, making them suitable for high-end applications.

Labor: Labor costs encompass the expenses associated with skilled craftsmanship in leather processing. Tandy Leather employs experienced artisans who ensure quality control and craftsmanship, which can be reflected in the pricing. Buyers should factor in these costs, especially when considering customized products.

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Tandy’s established presence since 1919 indicates a robust operational framework that ensures consistent quality. These overheads are indirectly passed on to the buyer through pricing.

Tooling: Custom tooling can significantly influence pricing, particularly for specialized designs. If buyers require unique shapes or patterns, the initial investment in tooling should be considered as part of the total cost.

Quality Control (QC): Tandy’s commitment to quality involves thorough QC processes that ensure products meet specified standards. Buyers can expect a premium for this level of assurance, which is crucial for maintaining brand reputation.

Logistics: Transportation and handling costs are essential factors in the overall pricing structure. International buyers should be aware that shipping costs may vary based on destination, shipping method, and current market conditions.

Margin: Tandy Leather maintains a margin that reflects its brand value and the quality of its products. Understanding the margin structure can help buyers negotiate effectively and gauge the fairness of the pricing.

Illustrative image related to tandy leather factory fresno

What Factors Influence Pricing for International Buyers?

Volume/MOQ: Tandy may offer tiered pricing based on order volume. Buyers looking to maximize cost efficiency should inquire about Minimum Order Quantities (MOQ) to leverage better pricing.

Specifications/Customization: Custom specifications can lead to additional costs, particularly if specialized tooling is required. Buyers should balance their need for unique products against the potential increase in costs.

Materials Quality/Certifications: The type of leather and its certifications (e.g., eco-friendly, cruelty-free) can influence pricing. International buyers are encouraged to assess whether these factors align with their market demands.

Supplier Factors: The reputation and reliability of Tandy Leather as a supplier are critical. Buyers should evaluate past performance, customer reviews, and delivery timelines when establishing a partnership.

Incoterms: Understanding Incoterms is crucial for international buyers. They define the responsibilities of buyers and sellers in shipping and handling, impacting total costs. Familiarity with these terms can prevent unexpected expenses.

How Can Buyers Negotiate and Optimize Costs?

Negotiation Strategies: Establishing a solid relationship with Tandy’s sales representatives can lead to better pricing and terms. Buyers should be prepared to discuss their needs, including volume and delivery schedules, to negotiate favorable conditions.

Cost-Efficiency and Total Cost of Ownership (TCO): When evaluating pricing, buyers should consider the TCO, which includes not just the purchase price but also maintenance, shipping, and potential waste costs. Investing in higher-quality materials may reduce long-term expenses related to replacements and repairs.

Pricing Nuances for Specific Regions: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of regional market conditions that may affect pricing. Currency fluctuations, import tariffs, and local demand can all impact the final cost of goods.

Disclaimer

Prices mentioned are indicative and may vary based on market conditions, specific requirements, and negotiations. It is recommended that buyers reach out directly to Tandy Leather for the most accurate and current pricing information.

Alternatives Analysis: Comparing tandy leather factory fresno With Other Solutions

In the competitive landscape of leathercraft supplies, Tandy Leather Factory Fresno stands as a prominent option for both hobbyists and professionals. However, B2B buyers exploring their options may find it valuable to compare Tandy Leather with other suppliers and methods. Understanding the strengths and weaknesses of various alternatives can aid in making an informed purchasing decision tailored to specific business needs.

| Comparison Aspect | Tandy Leather Factory Fresno | Alternative 1: Leathercraft Supply Co. | Alternative 2: The Leather Guy |

|---|---|---|---|

| Performance | High-quality leather and tools; extensive range of products. | Comparable quality; specialized in custom orders. | Offers competitive quality; focuses on bulk supplies. |

| Cost | Moderate; competitive pricing on most items. | Generally lower prices, especially on bulk orders. | Cost-effective for larger quantities; discounts available. |

| Ease of Implementation | User-friendly store experience with knowledgeable staff; classes available. | Online ordering can be complicated; limited in-store support. | Easy online ordering; lacks personalized customer service. |

| Wartung | Ongoing support and classes for users; encourages skill development. | Limited ongoing support post-purchase. | Minimal maintenance; primarily a supply provider. |

| Best Use Case | Ideal for beginners and small businesses needing a variety of supplies. | Best for custom projects and bulk orders. | Suitable for large-scale operations and bulk purchasing. |

What Are the Advantages and Disadvantages of Leathercraft Supply Co.?

Leathercraft Supply Co. offers a strong alternative for businesses focusing on custom leather goods. Their competitive pricing structure is especially attractive for bulk orders, making them a go-to choice for larger projects. However, their online ordering system may not be as intuitive as Tandy’s in-store experience, and the lack of in-person support can be a disadvantage for those seeking hands-on guidance. For businesses that prioritize customization and price over immediate support, Leathercraft Supply Co. is a viable option.

What Makes The Leather Guy a Competitive Option?

The Leather Guy stands out with its emphasis on bulk supplies, which can be a significant advantage for larger manufacturers. Their pricing strategy is designed to cater to high-volume buyers, offering discounts that can lead to substantial savings. However, the trade-off is a diminished level of customer service, as they primarily operate online and may not provide the same personalized support that Tandy offers. For businesses focused on cost-efficiency and volume, The Leather Guy represents a practical choice.

How Can B2B Buyers Choose the Right Leathercraft Solution?

When selecting a leathercraft supplier, B2B buyers should assess their specific needs, including budget constraints, the scale of their operations, and the level of support required. Tandy Leather Factory Fresno excels in providing a comprehensive, supportive environment ideal for beginners and small businesses. In contrast, alternatives like Leathercraft Supply Co. and The Leather Guy may better serve those focused on customization or large-scale production. Ultimately, understanding the nuances of each option will empower businesses to make decisions that align with their operational goals and customer demands.

Essential Technical Properties and Trade Terminology for tandy leather factory fresno

What Are the Key Technical Properties of Leather from Tandy Leather Factory Fresno?

Understanding the technical specifications of leather products is crucial for B2B buyers, especially when sourcing materials for manufacturing or crafting. Here are essential properties associated with leather available at Tandy Leather Factory Fresno:

-

Material Grade

Leather is classified into various grades, typically including full-grain, top-grain, and genuine leather. Full-grain leather is the highest quality, retaining the natural grain and imperfections, making it durable and aesthetically pleasing. For B2B buyers, selecting the appropriate material grade is vital for ensuring the quality and longevity of the final product. -

Thickness

Leather thickness is measured in ounces or millimeters. For example, a 4-5 oz leather is approximately 1.6 to 2 mm thick. Different applications require specific thickness levels; for instance, thicker leather is ideal for belts and bags, while thinner leather works well for garments and linings. Buyers should consider the intended use to make informed decisions. -

Tannage Type

Tannage refers to the method used to preserve leather. Common types include chrome tanning and vegetable tanning. Chrome-tanned leather is more supple and water-resistant, suitable for various applications, while vegetable-tanned leather is more environmentally friendly and is preferred for tooling and crafting. Understanding the tanning process helps buyers align with sustainability goals and product requirements. -

Finish and Treatment

Leather can undergo various finishing processes, such as dyeing, coating, or oiling, which affect its appearance and functionality. For instance, Eco-Flo Leather Dye is a water-based option offered at Tandy, which provides vibrant colors while maintaining the leather’s natural characteristics. Buyers must evaluate finishes based on desired aesthetics and performance attributes. -

Weight and Load-Bearing Capacity

The weight of leather affects its strength and suitability for different uses. Heavyweight leathers are ideal for items that require durability, such as saddles or work gear, while lightweight leathers are preferable for fashion items. Understanding the load-bearing capacity ensures that the chosen leather meets performance expectations.

What Are the Common Trade Terms in the Leather Industry?

Familiarizing oneself with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms relevant to the leather industry:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, this could mean that a business provides leather components for other brands. Knowing about OEM partnerships can help buyers understand sourcing options and potential collaborations. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In leather sourcing, MOQs can vary widely depending on the type of leather and the supplier. Understanding MOQs is crucial for buyers to assess inventory needs and cost-effectiveness, especially when dealing with international suppliers. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request quotes from suppliers for specific products or services. By issuing an RFQ, buyers can compare prices, terms, and conditions, facilitating better decision-making. This is especially important in the leather industry, where prices can fluctuate based on material quality and market demand. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Understanding these terms helps buyers navigate shipping logistics and costs, ensuring clarity in agreements. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). -

Dyeing and Finishing Techniques

These terms refer to the processes applied to leather to achieve desired color and texture. Dyeing involves coloring the leather, while finishing includes applying protective coatings or treatments. Knowledge of these techniques allows buyers to select leathers that meet aesthetic and functional requirements for their products.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing leather from Tandy Leather Factory Fresno, ultimately enhancing their product offerings and business success.

Navigating Market Dynamics and Sourcing Trends in the tandy leather factory fresno Sector

What Are the Current Market Dynamics in the Tandy Leather Factory Fresno Sector?

The Tandy Leather Factory in Fresno represents a vital hub in the global leather supply chain, catering to diverse international B2B buyers, including those from Africa, South America, the Middle East, and Europe. The leather industry is witnessing several key trends that are reshaping sourcing strategies. Firstly, the rise of e-commerce has made it easier for international buyers to access quality leather products and tools from Tandy, allowing for more streamlined purchasing processes. Furthermore, advancements in technology, such as digital inventory management and online marketplaces, have enhanced transparency and efficiency in sourcing operations.

As sustainability becomes a focal point in global supply chains, buyers are increasingly seeking suppliers who prioritize environmentally-friendly practices. The Tandy Leather Factory, with its long-standing reputation since 1919, is adapting to these demands by offering a range of eco-friendly materials and processes. Another emerging trend is the demand for customization and personalization in leather products, driven by consumer preferences for unique items. This shift encourages B2B buyers to engage with suppliers like Tandy that can provide tailored solutions.

Additionally, geopolitical factors, such as trade agreements and tariffs, can influence sourcing decisions. Buyers from regions such as Nigeria and Vietnam should stay informed about these dynamics to navigate potential challenges effectively. Overall, the Tandy Leather Factory in Fresno is positioned to meet the evolving needs of international buyers through its extensive product range and commitment to quality.

How Is Sustainability and Ethical Sourcing Addressed in the Tandy Leather Factory Fresno Sector?

Sustainability and ethical sourcing are increasingly critical considerations for B2B buyers in the leather sector. The environmental impact of leather production has prompted a shift towards more responsible practices, making it essential for suppliers to adopt sustainable methodologies. Tandy Leather Factory is responding to these demands by sourcing leather from suppliers who adhere to ethical practices, ensuring that the leather used is processed with minimal environmental harm.

Buyers are encouraged to look for certifications that indicate a commitment to sustainability, such as the Leather Working Group (LWG) certification, which assesses the environmental performance of tanneries. Tandy offers a selection of eco-friendly dyes and materials that align with the growing trend towards sustainable crafting. In addition, the factory emphasizes the importance of waste reduction through recycling initiatives and the use of biodegradable materials in packaging.

As international buyers increasingly prioritize sustainability in their procurement processes, aligning with suppliers like Tandy who demonstrate a commitment to ethical sourcing can enhance brand reputation and consumer trust. By investing in sustainable practices, Tandy not only meets the expectations of modern buyers but also contributes to the overall improvement of the leather industry’s environmental footprint.

What Is the Historical Context of Tandy Leather Factory in Fresno Relevant to B2B Buyers?

Since its establishment in 1919, Tandy Leather has evolved from a small leather supply store into a prominent global distributor of leathercraft materials. This rich history is significant for B2B buyers, as it reflects a deep-rooted expertise in the leather industry. Tandy’s longevity indicates a consistent commitment to quality and innovation in leather products, making it a reliable partner for international buyers.

Illustrative image related to tandy leather factory fresno

Over the decades, Tandy has adapted to changing market dynamics, embracing new technologies and sustainable practices to meet the needs of modern consumers. This evolution not only enhances the value proposition for B2B buyers but also underscores the importance of choosing a supplier with a proven track record. By partnering with Tandy Leather, buyers can leverage decades of industry knowledge, ensuring they receive high-quality products and support tailored to their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of tandy leather factory fresno

-

How can I ensure the quality of leather sourced from Tandy Leather Factory Fresno?

To ensure the quality of leather from Tandy Leather Factory Fresno, start by requesting samples of different leather types before placing a bulk order. Evaluate the samples for texture, durability, and finish. Additionally, engage with the store’s knowledgeable staff who can provide insights into the leather’s origin, tanning process, and suitability for your specific projects. Regular visits or audits can also help maintain quality assurance and consistency in your orders. -

What customization options are available for leather products?

Tandy Leather Factory Fresno offers various customization options, including different leather types, colors, and finishes. B2B buyers can inquire about custom tooling, embossing, or dyeing services to meet specific project requirements. To explore these options, discuss your needs with the store’s representatives, who can guide you through the available customizations and help you achieve your desired product specifications. -

What are the minimum order quantities (MOQs) for bulk purchases?

Minimum order quantities at Tandy Leather Factory Fresno can vary based on the type of leather and products being ordered. Typically, for bulk purchases, you can expect MOQs to range from a few hides to larger quantities, depending on your requirements. It’s advisable to contact the store directly to get precise information on MOQs for specific items, which can help streamline your purchasing process. -

What payment terms does Tandy Leather Factory Fresno offer for international buyers?

Tandy Leather Factory Fresno generally provides flexible payment terms for international buyers, including options for credit card payments, wire transfers, and possibly letters of credit for larger orders. For clarity on specific terms, including deposit requirements and payment schedules, direct communication with the store’s management is essential. This ensures that you have a clear understanding of the financial commitments involved. -

How can I manage logistics for shipping leather products internationally?

Managing logistics for shipping leather products internationally involves selecting a reliable freight forwarder experienced in handling leather goods. Consider factors such as shipping times, customs clearance, and insurance. Tandy Leather Factory Fresno can assist by providing necessary documentation and product specifications required for international shipping. Additionally, keep abreast of import regulations in your country to avoid delays. -

What should I consider when vetting suppliers for leather products?

When vetting suppliers like Tandy Leather Factory Fresno, focus on their reputation, quality of products, and customer service. Look for reviews from other B2B buyers and request references to gauge reliability. It’s also crucial to verify their compliance with international quality standards and ethical sourcing practices. Establishing a clear communication channel will aid in building a trustworthy partnership. -

Are there any educational resources available for leathercrafting techniques?

Yes, Tandy Leather Factory Fresno offers a variety of educational resources, including in-store classes, workshops, and instructional materials. These resources cover various leathercraft techniques, from basic to advanced skills, catering to both beginners and experienced artisans. Engaging with these educational opportunities can enhance your team’s skills and improve product quality. -

What are the typical lead times for orders placed with Tandy Leather Factory Fresno?

Lead times for orders with Tandy Leather Factory Fresno can vary based on the complexity of the order and stock availability. Generally, you can expect lead times to range from a few days to several weeks for larger or customized orders. To better plan your production schedules, it’s recommended to discuss expected timelines with the store’s staff when placing your order, ensuring timely delivery for your projects.

Top 3 Tandy Leather Factory Fresno Manufacturers & Suppliers List

1. Tandy Leather – Quality Leather Goods

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Quality Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Tandy Leather Factory – Leather Goods and Supplies

Domain: nextdoor.com

Registered: 2004 (21 years)

Introduction: Tandy Leather Factory is a manufacturer and leather goods store located at 2750 Clovis Ave, Fresno, CA 93727. They have been a resource for leather and leathercraft supplies since 1919. Contact information includes phone number +15592915533 and email [email protected] Their website is http://www.tandyleatherfactory.com.

3. Tandy Leather – Leatherworking Supplies

Domain: tandyleather.irpass.com

Registered: 2002 (23 years)

Introduction: Tandy Leather Factory, Inc. is a specialty retailer offering a broad product line including leather, leatherworking tools, buckles and adornments for belts, leather dyes and finishes, saddle and tack hardware, and do-it-yourself kits. The company operates over 100 stores in the U.S. and Canada, and one store in Spain.

Strategic Sourcing Conclusion and Outlook for tandy leather factory fresno

In today’s global marketplace, effective strategic sourcing is crucial for B2B buyers, particularly those engaged in leathercraft and related industries. Tandy Leather Factory Fresno stands out as a premier supplier, offering a diverse range of high-quality leather, tools, and educational resources. By leveraging Tandy’s extensive product offerings, international buyers can enhance their crafting capabilities and streamline their supply chains.

The value of strategic sourcing lies in establishing strong partnerships that not only provide access to premium materials but also foster innovation and creativity. Tandy’s commitment to quality and customer service ensures that businesses can rely on consistent supply and expert guidance, which is essential for maintaining competitive advantage in regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to tandy leather factory fresno

As the leathercraft market continues to evolve, international buyers are encouraged to explore the opportunities at Tandy Leather Factory Fresno. Embrace the potential for growth by investing in quality materials and tools that can elevate your craftsmanship. Connect with Tandy Leather today to discover how their offerings can meet your unique business needs and help you thrive in the global leather market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.