Introduction: Navigating the Global Market for leather machine company cobra class 4

The leather industry faces a myriad of challenges, particularly when it comes to sourcing reliable machinery like the COBRA Class 4 leather sewing machine. For international B2B buyers, especially those in emerging markets such as Africa and South America, navigating the complexities of machine specifications, supplier credibility, and cost-effectiveness can be daunting. This guide is designed to demystify the sourcing process for the COBRA Class 4, providing a comprehensive overview of its various models, applications, and essential features that cater to diverse leatherworking needs.

In the following sections, we will explore the different configurations of the COBRA Class 4, including the Premium and Standard Packages, and their suitability for tasks ranging from boot making to upholstery. Additionally, we will cover critical factors for vetting suppliers, understanding pricing structures, and assessing the total cost of ownership. This information is especially vital for businesses in regions like Europe and the Middle East, where competition is fierce and quality demands are high.

By equipping B2B buyers with the insights needed to make informed purchasing decisions, this guide aims to streamline the acquisition process, ensuring that companies can confidently invest in the COBRA Class 4 sewing machine. Whether you are looking to enhance production capabilities or improve operational efficiency, understanding the nuances of this powerful tool will position your business for success in the global leather market.

Table Of Contents

- Top 4 Leather Machine Company Cobra Class 4 Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather machine company cobra class 4

- Understanding leather machine company cobra class 4 Types and Variations

- Key Industrial Applications of leather machine company cobra class 4

- 3 Common User Pain Points for ‘leather machine company cobra class 4’ & Their Solutions

- Strategic Material Selection Guide for leather machine company cobra class 4

- In-depth Look: Manufacturing Processes and Quality Assurance for leather machine company cobra class 4

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather machine company cobra class 4’

- Comprehensive Cost and Pricing Analysis for leather machine company cobra class 4 Sourcing

- Alternatives Analysis: Comparing leather machine company cobra class 4 With Other Solutions

- Essential Technical Properties and Trade Terminology for leather machine company cobra class 4

- Navigating Market Dynamics and Sourcing Trends in the leather machine company cobra class 4 Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather machine company cobra class 4

- Strategic Sourcing Conclusion and Outlook for leather machine company cobra class 4

- Important Disclaimer & Terms of Use

Understanding leather machine company cobra class 4 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| COBRA Class 4 Leather Sewing Machine | Heavy-duty, multi-purpose presser feet; variable speed DC motor | Boot making, tack production, upholstery | Pros: Versatile, robust, lifetime warranty. Cons: Higher initial investment. |

| COBRA Class 4 S Heavy Duty Stitcher | Enhanced with standard accessory package; strong cylinder arm | Leather goods manufacturing, crafting custom items | Pros: Comprehensive package, efficient operation. Cons: Limited to standard features. |

| KING COBRA Class 4-25 | Electronic positioning system; premium package available | Industrial leatherwork, precision sewing | Pros: Increased accuracy, advanced features. Cons: More complex setup. |

| COBRA Class 4 P Heavy Duty Stitcher | Includes electronic positioning; optimized for precision work | High-end leather crafting, specialized applications | Pros: Precision stitching, ideal for detailed work. Cons: Requires training for optimal use. |

| COBRA Class 4 S Heavy Duty Stitcher with EPS | Electronic positioning with standard package; robust build | Versatile applications in leather production | Pros: Enhanced control, versatile. Cons: Higher cost due to advanced features. |

What are the Key Characteristics of COBRA Class 4 Leather Sewing Machines?

The COBRA Class 4 Leather Sewing Machine is renowned for its heavy-duty capabilities, making it ideal for a wide range of leatherworking tasks. It features a robust construction, allowing it to sew materials ranging from 6 oz. to 7/8″ leather. This machine is particularly suited for industries such as boot making and tack production, where durability and reliability are paramount. Buyers should consider its versatility and the lifetime warranty, which underscores the manufacturer’s confidence in the product.

Illustrative image related to leather machine company cobra class 4

How Does the COBRA Class 4 S Heavy Duty Stitcher Stand Out?

The COBRA Class 4 S Heavy Duty Stitcher is an enhanced version of the standard Class 4, equipped with a comprehensive accessory package. Its strong cylinder arm and reliable operation make it a preferred choice for leather goods manufacturing. Businesses looking to produce custom items or engage in crafting will find this machine particularly beneficial. While it offers excellent value, buyers should note that it is limited to standard features compared to its electronic counterparts.

What Advantages Does the KING COBRA Class 4-25 Offer?

The KING COBRA Class 4-25 introduces an electronic positioning system, elevating its precision and control during sewing tasks. This machine is designed for industrial leatherwork, where accuracy is essential. It is ideal for businesses focused on high-quality production and complex designs. However, its advanced features may require a more complex setup and training, which could be a consideration for potential buyers.

Why Choose the COBRA Class 4 P Heavy Duty Stitcher?

The COBRA Class 4 P Heavy Duty Stitcher includes an electronic positioning system, making it perfect for high-end leather crafting and specialized applications. This machine excels in precision stitching, which is crucial for detailed work such as custom leather goods. Buyers should weigh the benefits of its precision against the requirement for training to maximize its capabilities, as it may not be as user-friendly for those new to leather sewing.

Illustrative image related to leather machine company cobra class 4

What Makes the COBRA Class 4 S Heavy Duty Stitcher with EPS a Versatile Choice?

The COBRA Class 4 S Heavy Duty Stitcher with EPS combines the robustness of the standard Class 4 with the advantages of electronic positioning. This versatility makes it suitable for various applications in leather production, from general sewing to more intricate tasks. While it offers enhanced control and flexibility, potential buyers should consider the higher cost associated with its advanced features, which may impact budget constraints for smaller businesses.

Key Industrial Applications of leather machine company cobra class 4

| Industry/Sector | Specific Application of leather machine company cobra class 4 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Sewing leather components for shoes and boots | Enhances product durability and aesthetic appeal | Ensure compatibility with various leather thicknesses |

| Leather Goods Production | Creating high-quality bags, wallets, and accessories | Provides precision stitching for intricate designs | Evaluate machine adaptability for different leather types |

| Automotive Upholstery | Stitching leather for car interiors and seat covers | Improves luxury feel and comfort in vehicles | Consider machine’s ability to handle multiple fabric layers |

| Equestrian Equipment | Manufacturing saddles, bridles, and other tack items | Delivers strength and reliability in high-stress areas | Assess the machine’s suitability for heavy-duty applications |

| Industrial Textile Production | Sewing heavy canvas and upholstery materials | Increases production efficiency and reduces downtime | Look for machines with strong feed mechanisms for thick fabrics |

How is the COBRA Class 4 Leather Sewing Machine Used in Footwear Manufacturing?

In the footwear manufacturing sector, the COBRA Class 4 is instrumental in sewing leather components for shoes and boots. Its ability to handle leather thicknesses ranging from 6 oz. to 7/8” makes it versatile for various styles. This machine addresses common challenges such as inconsistent stitching quality and difficulty in sewing curved edges. International buyers should consider sourcing machines that can adapt to different leather types, ensuring they meet local market demands and quality standards.

What Role Does the COBRA Class 4 Play in Leather Goods Production?

For businesses involved in leather goods production, the COBRA Class 4 provides a solution for crafting high-quality bags, wallets, and accessories. The machine’s precision stitching capabilities allow for intricate designs that enhance product appeal. It solves issues related to the durability of seams, which is crucial in maintaining the integrity of luxury items. Buyers should focus on the machine’s adaptability to various leather types and thicknesses to ensure they can produce a diverse product range.

How is the COBRA Class 4 Beneficial for Automotive Upholstery?

In the automotive industry, the COBRA Class 4 is used to stitch leather for car interiors and seat covers. The machine’s heavy-duty construction ensures that it can handle the rigors of automotive upholstery, providing a luxurious feel and extended durability. This addresses the need for high-quality finishes in vehicles, essential for customer satisfaction. Buyers should evaluate the machine’s ability to handle multiple layers of fabric and its compatibility with different upholstery materials.

What is the Importance of the COBRA Class 4 in Equestrian Equipment?

The COBRA Class 4 is a vital tool in the production of equestrian equipment, such as saddles and bridles. Its robust stitching capabilities ensure that these high-stress items can withstand the rigors of equestrian use. This machine effectively resolves issues related to seam strength and durability, which are critical in this sector. Buyers should assess the machine’s suitability for heavy-duty applications and its ability to handle various types of leather commonly used in equestrian gear.

How Does the COBRA Class 4 Enhance Industrial Textile Production?

In the industrial textile sector, the COBRA Class 4 is utilized for sewing heavy canvas and upholstery materials. Its strong feed mechanism and variable speed control facilitate efficient production, reducing downtime and enhancing overall productivity. This machine addresses the challenge of sewing thick materials, ensuring consistent quality in finished products. Buyers need to consider the machine’s specifications to ensure it meets the demands of heavy-duty textile applications, particularly in diverse international markets.

3 Common User Pain Points for ‘leather machine company cobra class 4’ & Their Solutions

Scenario 1: Difficulty with Machine Setup and Calibration

The Problem: Many B2B buyers encounter challenges during the initial setup and calibration of the COBRA Class 4 Leather Sewing Machine. These machines are robust and feature-rich, which can lead to confusion about how to properly assemble and adjust them for optimal performance. New users may struggle with understanding the settings for thread tension, stitch length, and feed mechanisms, potentially leading to inefficient operation and subpar stitching quality. This issue can be particularly frustrating for businesses that rely on timely production schedules, as delays in setup can impact overall output.

The Solution: To overcome setup challenges, buyers should prioritize thorough training and resource utilization. Upon receiving the COBRA Class 4, it’s advisable to refer to the comprehensive instructional DVD and owner’s manual included in the package. These materials provide step-by-step guidance on assembly and calibration. Additionally, B2B buyers should consider investing in a brief training session with a certified technician or attending workshops offered by the manufacturer. Engaging with experienced users in forums or online communities can also yield valuable tips and best practices for machine setup. By leveraging these resources, businesses can ensure their machines are optimally calibrated, leading to improved efficiency and stitching quality from day one.

Scenario 2: Challenges with Material Compatibility

The Problem: Another common pain point arises when buyers are unsure about the types of leather and materials compatible with the COBRA Class 4. Given that this machine can sew a range of materials from 6 oz. to 7/8″ leather, buyers might mistakenly use inappropriate materials, leading to machine jams or poor stitching outcomes. This is especially problematic for businesses that deal with diverse leather types or are expanding into new product lines, as they may lack the expertise to determine material suitability.

Illustrative image related to leather machine company cobra class 4

The Solution: To address material compatibility issues, buyers should conduct thorough research on the types of leather and other materials the COBRA Class 4 can handle. The machine’s specifications highlight its versatility, making it suitable for sewing not just leather but also canvas, upholstery, and bio-plastics. Buyers should obtain samples of different materials and test them on the machine to understand how each behaves. Additionally, consulting with suppliers about the best leather types for their specific applications can provide insight. Establishing a standard operating procedure that includes testing new materials before full-scale production can minimize risks and enhance product quality.

Scenario 3: Maintenance and Longevity Concerns

The Problem: B2B buyers often worry about the long-term maintenance and durability of their COBRA Class 4 machines. Regular maintenance is crucial for ensuring the machine operates effectively over time, but many users may not know how to properly care for these machines. Neglecting maintenance can lead to mechanical failures, costly repairs, and extended downtime, which is detrimental to businesses operating on tight schedules.

The Solution: To mitigate maintenance concerns, buyers should implement a proactive maintenance schedule that includes regular cleaning, lubrication, and inspections of key components. The COBRA Class 4 comes with an oil and tool package, which should be utilized according to the maintenance guidelines provided in the manual. Users should also consider setting reminders for routine maintenance tasks, such as changing needles and checking thread tension. Additionally, joining user groups or forums can provide access to shared experiences and maintenance tips from seasoned operators. By adopting a diligent maintenance routine and seeking out community knowledge, businesses can significantly enhance the longevity and performance of their COBRA Class 4 machines.

Strategic Material Selection Guide for leather machine company cobra class 4

What Are the Key Materials for the COBRA Class 4 Leather Sewing Machine?

When selecting materials for the COBRA Class 4 leather sewing machine, it is essential to consider their properties, advantages, and limitations. The following analysis focuses on four common materials: aluminum, steel, plastic, and leather. Each material plays a crucial role in the machine’s performance, durability, and suitability for various applications.

Illustrative image related to leather machine company cobra class 4

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is known for its lightweight nature and excellent corrosion resistance. It can withstand temperatures up to 400°F (204°C) without losing integrity, making it suitable for various industrial applications.

Pros & Cons: The primary advantage of aluminum is its low weight, which facilitates easier handling and operation of the sewing machine. However, it may not be as durable as steel, leading to potential wear and tear over time. The cost of aluminum is generally moderate, but its manufacturing complexity can be higher due to the need for specialized machining processes.

Impact on Application: Aluminum components can significantly enhance the portability of the COBRA Class 4, making it ideal for mobile workshops or smaller production facilities. However, buyers should ensure that the aluminum used meets international standards for industrial machinery.

Considerations for International Buyers: Compliance with ASTM standards for aluminum alloys is crucial. Buyers from regions like Europe and the Middle East may prefer aluminum that meets DIN standards for better quality assurance.

Steel: Strength and Durability

Key Properties: Steel offers high tensile strength and can withstand significant pressure and temperature variations, making it a preferred choice for heavy-duty machinery.

Pros & Cons: The durability of steel is unmatched, providing longevity and reliability in high-stress applications. However, it is heavier than aluminum, which may affect portability. The cost of steel is generally lower than aluminum, but the manufacturing process can be more complex due to the need for welding and machining.

Impact on Application: Steel components in the COBRA Class 4 enhance its capability to sew through thicker materials, such as heavy leather or multiple layers of fabric. This makes it suitable for industries like leather goods production and upholstery.

Considerations for International Buyers: Buyers should look for steel that complies with JIS or ASTM standards, ensuring quality and performance consistency across different markets.

Plastic: Versatility and Cost-Effectiveness

Key Properties: Plastics used in the COBRA Class 4 are typically engineered for durability and resistance to wear and tear, withstanding temperatures up to 200°F (93°C).

Pros & Cons: The primary advantage of plastic components is their cost-effectiveness and versatility in design. However, they may lack the strength of metal components, making them less suitable for high-stress applications.

Illustrative image related to leather machine company cobra class 4

Impact on Application: Plastic parts can be used for non-load-bearing components, such as covers or guides, allowing for easier maintenance and replacement. This can be particularly beneficial for small businesses looking to minimize operational costs.

Considerations for International Buyers: Ensuring that plastics meet specific safety and environmental regulations is vital, particularly in regions with stringent compliance standards like Europe.

Leather: The Core Material

Key Properties: Leather is characterized by its flexibility, strength, and ability to withstand wear. It can handle varying temperatures and pressures, making it ideal for sewing applications.

Pros & Cons: Leather’s natural properties make it an excellent choice for applications requiring durability and aesthetics. However, it can be more expensive than synthetic alternatives and requires careful handling to maintain quality.

Impact on Application: The COBRA Class 4 is designed to work seamlessly with leather, enabling the production of high-quality leather goods. Its ability to sew through multiple layers of leather makes it indispensable for industries focused on fashion and accessories.

Considerations for International Buyers: Buyers should ensure that the leather used complies with local regulations regarding sourcing and environmental impact, particularly in regions like Africa and South America, where sustainable practices are increasingly prioritized.

Summary Table

| Material | Typical Use Case for leather machine company cobra class 4 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight components for ease of use | Corrosion-resistant and lightweight | Less durable than steel | Medium |

| Steel | Structural components for heavy-duty applications | High strength and durability | Heavier, affecting portability | Low |

| Plastic | Non-load-bearing parts like covers and guides | Cost-effective and versatile | Lacks strength for high-stress applications | Low |

| Leather | Core material for sewing applications | Durable and aesthetically pleasing | Higher cost and requires careful handling | High |

This comprehensive analysis provides B2B buyers with valuable insights into material selection for the COBRA Class 4 leather sewing machine, aiding in informed purchasing decisions tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for leather machine company cobra class 4

What are the Main Stages of Manufacturing the COBRA Class 4 Leather Machine?

The manufacturing process for the COBRA Class 4 leather sewing machine is meticulously designed to ensure quality, durability, and high performance. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The journey begins with the selection of high-quality raw materials, including durable metals and components that are essential for the machine’s longevity. The materials undergo rigorous inspection to meet predetermined specifications, ensuring that only the best inputs enter the production line. This stage involves cutting and shaping raw materials into parts that are ready for further processing.

Forming Techniques

Once the materials are prepared, advanced forming techniques come into play. CNC (Computer Numerical Control) machining is often employed to achieve precision in the manufacturing of critical components like the cylinder arm and presser feet. This technology allows for complex shapes and tight tolerances, which are vital for the machine’s operational efficiency. Additional techniques such as stamping and welding may also be used to construct subassemblies that will later be integrated into the final product.

Assembly Process

The assembly of the COBRA Class 4 involves a systematic approach where individual components are carefully brought together. Skilled technicians follow detailed assembly instructions, ensuring that each part fits seamlessly. The use of jigs and fixtures aids in maintaining consistency and precision during this stage. Quality checks are integrated into the assembly process, with each machine undergoing preliminary testing to confirm basic functionality before proceeding to the next phase.

Illustrative image related to leather machine company cobra class 4

Finishing Touches

In the final stage, the assembled machine is subjected to finishing processes, which may include painting, coating, and polishing. These not only enhance aesthetic appeal but also protect the machine from wear and corrosion. A thorough inspection is performed to ensure that all components meet quality standards. The machine is then prepared for packaging, ensuring that it is securely stored for transport to global markets.

How is Quality Assurance Implemented in the Production of COBRA Class 4?

Quality assurance (QA) is integral to the manufacturing process of the COBRA Class 4 leather machine, ensuring that every unit meets international and industry-specific standards.

What International Standards Guide the Quality Assurance Process?

The COBRA Class 4 is manufactured in compliance with international standards such as ISO 9001, which focuses on quality management systems, ensuring a consistent level of quality in products and services. Additionally, CE marking is often sought, indicating compliance with health, safety, and environmental protection standards within the European Economic Area. This is especially significant for B2B buyers in Europe, who prioritize compliance with such regulations.

What are the Key Quality Control Checkpoints?

To maintain high-quality standards, several checkpoints are established throughout the production process:

Illustrative image related to leather machine company cobra class 4

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter production. Every batch is tested against specifications to prevent defective materials from affecting the final product.

-

In-Process Quality Control (IPQC): During assembly, IPQC measures are implemented to ensure each component is correctly assembled and functions as intended. This includes monitoring critical parameters such as torque and alignment.

-

Final Quality Control (FQC): After assembly and finishing, the machine undergoes FQC, where it is tested under operational conditions. This stage assesses the machine’s performance, ensuring it operates smoothly and meets the specified stitch quality.

What Testing Methods are Commonly Used?

Various testing methods are employed to guarantee the performance and durability of the COBRA Class 4 leather machine. These may include:

- Functional Testing: Evaluating the machine’s operational capabilities, including stitch quality and speed adjustments.

- Durability Testing: Subjecting the machine to prolonged use scenarios to assess wear and tear over time.

- Safety Testing: Ensuring that all safety features function correctly, minimizing risk during operation.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is crucial. Here are some effective strategies:

What Auditing Processes are Available?

Buyers can conduct audits to evaluate the supplier’s manufacturing processes and quality assurance protocols. These audits can be performed by third-party organizations specializing in manufacturing and quality assessments. They provide an objective review of the supplier’s adherence to international standards.

How Can Buyers Access Quality Reports?

Many manufacturers provide quality assurance reports that detail the results of inspections and tests performed on their machines. Buyers should request these reports to gain insights into the product’s quality and the manufacturer’s commitment to maintaining high standards.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further assure buyers of the product’s quality. These services can perform random checks during production and before shipment, ensuring that the machines meet the agreed specifications and standards.

What are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is vital for international buyers. Different regions may have specific requirements that impact the buying decision.

-

Regulatory Compliance: Buyers from the European market need to ensure that products comply with CE marking requirements, while those in the Middle East may prioritize compliance with local standards.

-

Documentation: Ensure that all necessary certifications and quality control documentation accompany the product. This includes compliance certificates, testing reports, and warranty information, which are often critical in international trade.

-

Cultural Considerations: Buyers should be aware of cultural differences that may affect business practices and expectations regarding quality assurance and communication. Establishing clear lines of communication regarding quality requirements can mitigate misunderstandings.

In summary, the manufacturing processes and quality assurance measures for the COBRA Class 4 leather sewing machine are designed to ensure reliability and performance for B2B buyers across various international markets. By understanding these processes, buyers can make informed decisions that align with their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather machine company cobra class 4’

This guide aims to provide international B2B buyers with a comprehensive checklist for sourcing the COBRA Class 4 leather sewing machine. This machine is recognized for its heavy-duty capabilities and is essential for businesses engaged in leather production, such as saddlery, upholstery, and custom leather goods. By following this step-by-step guide, you can ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical specifications you require from the COBRA Class 4 machine. Consider factors such as the thickness of leather you will be working with, desired stitch length, and thread size compatibility. Knowing your requirements helps streamline the selection process and avoids unnecessary inquiries.

Illustrative image related to leather machine company cobra class 4

Step 2: Research Reputable Suppliers

Identify and research suppliers who offer the COBRA Class 4 machine. Look for companies with a solid reputation in the leather machinery market and positive reviews from existing customers. Pay attention to their experience, customer service, and after-sales support, as these aspects are critical for long-term satisfaction.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify the certifications of potential suppliers. Look for industry-standard certifications that indicate compliance with safety and quality regulations. This step is crucial to ensure that you are purchasing a machine that meets international quality standards, which can impact your operational efficiency.

Step 4: Request Detailed Product Information

Once you have shortlisted suppliers, request detailed product specifications and documentation for the COBRA Class 4. This should include user manuals, warranty information, and maintenance guides. Understanding the machine’s features, such as the heavy-duty presser feet and digital servo motor, allows you to assess its suitability for your specific needs.

Step 5: Analyze Pricing and Financing Options

Compare pricing among different suppliers while considering the value of included accessories and warranty terms. Inquire about financing options, especially if you are making a significant investment. Understanding total costs, including shipping and potential import duties, is vital for accurate budgeting.

Illustrative image related to leather machine company cobra class 4

Step 6: Check for After-Sales Support and Warranty

Before finalizing your purchase, confirm the after-sales support and warranty terms offered by the supplier. A limited lifetime warranty, as provided by COBRA, indicates confidence in the product’s durability. Additionally, responsive customer service can be invaluable for troubleshooting and maintenance needs.

Step 7: Final Decision and Purchase

After evaluating all the gathered information, make your final decision based on a combination of product quality, supplier reliability, and cost-effectiveness. Ensure that you have all necessary documentation in place before finalizing the purchase. This includes order confirmations and shipping details to avoid any misunderstandings.

By following these steps, you can ensure a well-informed and efficient sourcing process for the COBRA Class 4 leather sewing machine, ultimately enhancing your production capabilities and business success.

Comprehensive Cost and Pricing Analysis for leather machine company cobra class 4 Sourcing

What are the Key Cost Components in the COBRA Class 4 Leather Machine Pricing Structure?

When evaluating the pricing of the COBRA Class 4 leather sewing machines, several cost components come into play. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

Materials: The primary materials for the COBRA Class 4 machines are high-grade metals and durable plastics, which are essential for ensuring longevity and performance. The choice of materials directly influences the machine’s durability and, subsequently, its cost. For instance, premium components such as heavy-duty presser feet add to the machine’s robustness but also increase the overall price.

-

Labor: Skilled labor is required for the assembly and quality testing of these machines. As labor costs can vary significantly depending on the region, this factor may influence the final pricing, especially for international buyers.

-

Manufacturing Overhead: This includes the costs associated with the factory operations, utilities, and equipment maintenance. A well-optimized production process can lead to lower overhead costs, allowing manufacturers to offer more competitive pricing.

-

Tooling: The tooling costs involved in producing the machines are significant, particularly for custom features. Specific configurations or adaptations can increase tooling expenses, which are typically reflected in the pricing.

-

Quality Control (QC): Rigorous QC processes ensure that each machine meets the high standards expected by professional users. The costs associated with these QC measures can contribute to the pricing structure but ultimately enhance the value for the buyer.

-

Logistics: Shipping costs, which can vary based on destination, mode of transport, and Incoterms, also play a critical role. For international buyers, understanding these logistics costs is essential for calculating the total expenditure.

-

Margin: Finally, the profit margin incorporated by the manufacturer affects the final pricing. This margin can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect the Cost of COBRA Class 4 Machines?

Several factors can influence the pricing of the COBRA Class 4 machines, particularly for international buyers.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts, making it financially advantageous for buyers who can commit to purchasing multiple units.

-

Specifications and Customization: Custom specifications, such as unique attachments or features, can significantly impact pricing. Buyers should weigh the benefits of customization against the additional costs.

-

Materials and Quality Certifications: Machines made from higher-quality materials with certifications (like ISO standards) may come at a premium but often provide better reliability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established manufacturers with a track record of quality may charge more but offer better after-sales support.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) affect the total cost and risk associated with shipping.

What Tips Can Buyers Follow to Ensure Cost-Efficiency in Their COBRA Class 4 Machine Purchases?

For B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engaging in negotiations can yield discounts, especially for bulk orders or long-term contracts. Building a relationship with the supplier can facilitate better terms.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes not just the purchase price but also maintenance, operational costs, and potential downtime. Investing in higher-quality machines may reduce long-term costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import duties, which can impact the final cost. Obtaining quotes in local currency may help in better budget management.

-

Market Research: Conduct thorough research on pricing trends and competitor offerings to ensure you’re making an informed purchasing decision. This can also help in identifying the best time to buy based on market conditions.

Disclaimer

The prices mentioned in this analysis are indicative and may fluctuate based on market conditions, supplier policies, and additional costs incurred during international shipping. Always request a formal quote to confirm current pricing and terms.

Alternatives Analysis: Comparing leather machine company cobra class 4 With Other Solutions

Understanding Alternative Solutions for Leather Sewing Machines

When considering the purchase of a leather sewing machine, especially for heavy-duty applications, it’s essential to evaluate various options available in the market. The COBRA Class 4 Leather Sewing Machine is a strong contender, but several alternatives may also meet the needs of international B2B buyers across regions like Africa, South America, the Middle East, and Europe. This analysis compares the COBRA Class 4 with two notable alternatives: the JUKI TSC-441 and the CONSEW 206RB-5.

Comparison Table

| Comparison Aspect | Leather Machine Company COBRA Class 4 | JUKI TSC-441 | CONSEW 206RB-5 |

|---|---|---|---|

| Performance | Sews from 6 oz. to 7/8″ leather; triple feed mechanism for smooth operation | Handles heavy materials; offers a walking foot for consistent feeding | Good for multiple layers; walking foot mechanism for stability |

| Cost | Approximately $3,922 (Premium Package) | Approximately $3,500 | Approximately $1,800 |

| Ease of Implementation | Requires minimal setup; includes instructional DVD | Requires more initial setup and calibration | Easy to set up; user-friendly interface |

| Maintenance | Limited lifetime warranty; generally low maintenance | Requires regular oiling and upkeep | Moderate maintenance; user manual available |

| Best Use Case | Ideal for holsters, tack, and intricate leatherwork | Best for upholstery and heavy-duty applications | Suitable for general leather work and light upholstery |

Detailed Breakdown of Alternatives

JUKI TSC-441

The JUKI TSC-441 is renowned for its exceptional performance with heavy materials, making it a popular choice among manufacturers in upholstery and leather goods. The walking foot feature ensures that multiple layers of material are fed smoothly and evenly, reducing the risk of fabric shifting during sewing. However, it requires more initial setup and calibration compared to the COBRA Class 4. Additionally, while it offers robust performance, its maintenance can be more demanding, requiring regular oiling and care to keep it operating optimally.

CONSEW 206RB-5

The CONSEW 206RB-5 is an excellent option for businesses looking for a cost-effective solution without compromising on quality. Priced lower than the COBRA Class 4, it is versatile enough for general leather work and light upholstery tasks. Its walking foot mechanism provides stability when sewing multiple layers, making it suitable for various applications. The downside is that while it is user-friendly, it may not handle the same range of leather thicknesses as the COBRA Class 4, potentially limiting its use in more specialized projects.

Conclusion: How to Choose the Right Leather Sewing Machine

Selecting the right leather sewing machine depends on specific business needs and application requirements. The COBRA Class 4 stands out for its versatility and ease of use, especially for intricate leatherwork. However, if your operations lean towards upholstery or require a more cost-effective solution, the JUKI TSC-441 and CONSEW 206RB-5 are viable alternatives. Evaluate factors such as performance, cost, ease of implementation, and maintenance to ensure that the chosen machine aligns with your production goals and operational capacities. By carefully assessing these aspects, B2B buyers can make informed decisions that enhance their manufacturing capabilities.

Essential Technical Properties and Trade Terminology for leather machine company cobra class 4

What Are the Key Technical Properties of the COBRA Class 4 Leather Sewing Machine?

-

Sewing Capacity (Material Thickness)

The COBRA Class 4 can handle materials ranging from 6 oz. to 7/8 inch thick leather. This versatility is crucial for businesses involved in leather goods production, as it allows for a wide range of applications from simple leather goods to more complex items like saddles and holsters. Understanding the sewing capacity helps buyers assess if the machine meets their specific production needs. -

Stitch Length Adjustment

The machine features an adjustable stitch length ranging from 3 to 22 stitches per inch. This capability is significant for achieving different sewing styles and finishes, which can affect both the durability and aesthetic quality of the final product. For B2B buyers, this adaptability can enhance their product offering and meet diverse customer demands. -

Thread Size Compatibility

The COBRA Class 4 accommodates thread sizes from 69 to 415. This range is important as it allows for the use of different thread thicknesses depending on the application, which can influence the strength and appearance of the seams. Buyers should consider thread compatibility to ensure that they can source appropriate materials for their projects. -

Triple Feed Mechanism

This machine is equipped with a triple feed mechanism that ensures consistent material feeding during sewing. This feature minimizes the risk of fabric slippage, which can lead to uneven stitching. For manufacturers, this reliability translates into higher quality production and less material waste, making it a critical specification. -

Heavy-Duty Construction

With a robust design and heavy-duty components, the COBRA Class 4 is built to withstand rigorous industrial use. This durability is essential for businesses that require reliable machinery for high-volume production. Understanding the construction quality helps buyers evaluate long-term investment and maintenance costs. -

Variable Speed Digital DC Servo Motor

The inclusion of a variable speed digital DC servo motor allows for precise control over sewing speed. This feature is vital for intricate work that requires careful handling, enabling operators to adjust the pace according to the complexity of the task. Buyers benefit from this flexibility, as it can enhance productivity and reduce the likelihood of errors.

What Are the Common Trade Terminologies Used in the Leather Machinery Industry?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are used in another company’s end product. In the leather machine industry, understanding OEM relationships can help buyers identify trusted suppliers for parts and machinery, ensuring quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers looking to optimize their inventory levels while minimizing costs. Knowing the MOQ can help companies plan their purchasing strategy effectively. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products or services. For B2B buyers, submitting an RFQ for the COBRA Class 4 can lead to competitive pricing and better negotiation leverage. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping responsibilities, risks, and costs, which is crucial for smooth international procurement. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the goods. For machinery like the COBRA Class 4, understanding lead times is essential for production planning and managing customer expectations. Buyers should consider lead times when coordinating their supply chain logistics. -

Warranty

A warranty is a promise from the manufacturer regarding the condition of the product and the terms under which repairs or replacements will be made. The COBRA Class 4 comes with a limited lifetime warranty, which is a significant consideration for B2B buyers as it reflects the manufacturer’s confidence in their product and can mitigate long-term costs.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions, optimizing their procurement processes and enhancing their operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the leather machine company cobra class 4 Sector

What Are the Key Trends and Dynamics in the COBRA Class 4 Leather Machine Market?

The global leather industry is experiencing a notable shift driven by technological advancements and evolving consumer preferences. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The COBRA Class 4 leather sewing machine stands out due to its versatility, capable of sewing various materials including leather, canvas, and bio-plastics. This adaptability is increasingly sought after as businesses diversify their product offerings to meet changing market demands.

Moreover, the rise of automation and digitalization in manufacturing processes is redefining sourcing strategies. Features such as electronic positioning systems and variable speed digital DC servo motors, which are available in the COBRA Class 4 models, enhance precision and efficiency. International buyers are focusing on these tech-driven solutions to optimize their production capabilities and reduce operational costs.

Illustrative image related to leather machine company cobra class 4

Additionally, the market is witnessing a growing preference for heavy-duty, reliable machinery that can withstand rigorous usage, particularly in regions with burgeoning leather goods industries like Brazil and Germany. Buyers are not only looking for quality but also for machines that provide long-term value, evidenced by warranties and robust support services. As the leather industry continues to evolve, understanding these trends will help businesses make informed sourcing decisions.

How Does Sustainability Impact Sourcing Decisions for COBRA Class 4 Leather Machines?

Sustainability has emerged as a pivotal concern in the global leather industry. The environmental impact of leather production is significant, prompting B2B buyers to prioritize ethical sourcing and sustainable practices. For those considering the COBRA Class 4, it is vital to evaluate the sourcing of materials and the machinery’s energy efficiency. The demand for ‘green’ certifications and sustainable materials is on the rise, with businesses seeking to align their operations with global sustainability goals.

The COBRA Class 4 machines are designed with durability and efficiency in mind, minimizing waste during the manufacturing process. Buyers should assess the environmental policies of suppliers, including the sourcing of components and adherence to sustainable manufacturing practices. Incorporating sustainable machinery into their operations not only enhances a company’s reputation but also meets the expectations of environmentally conscious consumers.

Illustrative image related to leather machine company cobra class 4

Additionally, establishing an ethical supply chain is crucial for fostering long-term relationships with customers and partners. Companies that prioritize transparency in their sourcing practices are more likely to gain trust and loyalty, particularly in regions like Europe and the Middle East, where regulatory pressures for sustainability are intensifying.

What Is the Historical Context of the COBRA Class 4 Leather Machine?

The COBRA Class 4 leather sewing machine has a rich history rooted in craftsmanship and innovation. Originally designed to meet the demanding needs of professional leather workers, it has evolved significantly to incorporate advanced technologies. The machine has garnered a reputation for reliability and precision, often referred to as the “Dream Machine” by industry leaders.

Over the years, the COBRA Class 4 has adapted to the changing landscape of the leather industry, embracing new materials and production techniques. Its evolution reflects broader trends in manufacturing, where efficiency, versatility, and sustainability are increasingly prioritized. This historical context is essential for B2B buyers as it illustrates the machine’s proven track record and its ability to meet contemporary demands in the leather sector.

Frequently Asked Questions (FAQs) for B2B Buyers of leather machine company cobra class 4

-

How do I ensure the COBRA Class 4 machine meets my production needs?

To ensure the COBRA Class 4 machine is suitable for your production requirements, assess the types of materials you will be sewing and their thickness. The COBRA Class 4 is capable of sewing leather from 6 oz. to 7/8″ thick, making it ideal for various applications such as tack, holsters, and upholstery. Additionally, consider the machine’s stitch length and speed capabilities, as well as the available presser feet that can accommodate different sewing tasks. -

What are the shipping options for the COBRA Class 4 machine?

Shipping for the COBRA Class 4 machine is typically offered as curbside delivery, which can take 3-4 weeks to arrange. It is essential to discuss shipping logistics with your supplier to confirm the delivery timeframe and any additional costs associated with international shipping. Ensure you also understand any customs duties or taxes that may apply in your country upon arrival. -

What customization options are available for the COBRA Class 4 machine?

The COBRA Class 4 machine can be customized with various presser feet and accessories to suit specific sewing tasks. Buyers can choose from premium packages that include additional tools such as left and right toe presser feet, slotted plates, and heavy-duty roller edge guides. For unique requirements, it’s advisable to communicate with the supplier regarding any specific modifications or additional features you may need. -

What is the minimum order quantity (MOQ) for purchasing the COBRA Class 4 machine?

The minimum order quantity for the COBRA Class 4 machine may vary depending on the supplier’s policies. Typically, suppliers are flexible for B2B buyers, especially for bulk orders. It is advisable to directly contact the supplier to discuss your purchasing needs, as they may offer discounts or favorable terms for larger orders. -

What payment terms should I expect when purchasing the COBRA Class 4 machine?

Payment terms can vary by supplier but often include options such as upfront payment, partial payment upon order confirmation, and the balance before shipping. Some suppliers may also offer financing or payment plans, especially for larger orders. Always clarify payment options before finalizing your purchase to ensure smooth transactions. -

How does the warranty work for the COBRA Class 4 machine?

The COBRA Class 4 machine comes with a limited lifetime warranty on all COBRA products, covering defects in materials and workmanship. This warranty ensures that any issues with the machine under normal usage conditions will be addressed by the manufacturer. For peace of mind, review the warranty terms carefully and ensure you keep all purchase documentation for any potential claims. -

What quality assurance measures are in place for the COBRA Class 4 machine?

Quality assurance for the COBRA Class 4 machine includes rigorous testing during production to ensure it meets high standards of performance and durability. Additionally, reputable suppliers often provide manuals and instructional DVDs to assist users in proper machine operation and maintenance, which can enhance the longevity of the equipment. -

How can I vet suppliers when purchasing the COBRA Class 4 machine internationally?

When vetting suppliers for the COBRA Class 4 machine, consider their reputation in the industry, customer reviews, and their experience with international shipping. Request references from other B2B buyers, and check if they have certifications or affiliations with recognized industry organizations. Engaging with suppliers through initial conversations can also provide insight into their professionalism and responsiveness.

Top 4 Leather Machine Company Cobra Class 4 Manufacturers & Suppliers List

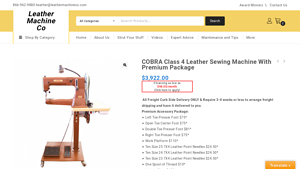

1. COBRA – Class 4 Leather Sewing Machine

Domain: leathermachineco.com

Registered: 2009 (16 years)

Introduction: COBRA Class 4 Leather Sewing Machine with Premium Package

– Price: $3,922.00

– Delivery: All Freight Curb Side Delivery ONLY, requires 3-4 weeks for shipping

– Premium Accessory Package includes:

– Left Toe Presser Foot: $75

– Open Toe Center Foot: $75

– Double Toe Presser Foot: $81

– Right Toe Presser Foot: $75

– Work Platform: $110

– Ten Size 25 7X4 Leather Point Needles: $24.50

– …

2. Cobra – Class 4 Premium Leather Sewing Machine

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Cobra Class 4 Premium leather sewing machine; suitable for heavy leather projects; recommended thread size: 277 for top thread, 138 for lighter projects; machine weight: approximately 120 lbs; requires at least two people for assembly; recommended accessories include good needles, good thread, good bobbins, and oil; users suggest purchasing extra bobbins and a narrow plate for better functionality…

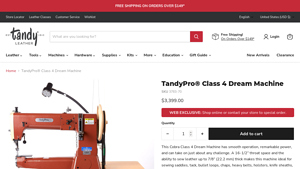

3. Tandy Leather – Cobra Class 4 Dream Machine

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: Cobra Class 4 Dream Machine, heavy-duty sewing machine, designed for leather and heavy materials, features walking foot mechanism, adjustable stitch length, includes a variety of presser feet, suitable for upholstery, bags, and other leather projects, durable construction, easy to use, ideal for both beginners and experienced sewers.

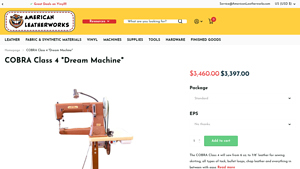

4. American Leatherworks – COBRA Class 4 Leather Sewing Machine

Domain: americanleatherworks.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “COBRA Class 4 Leather Sewing Machine”, “description”: “The COBRA Class 4 is perfect for skirting, tack, bullet loops, chap leather and more. Its heavy-duty presser feet and strong, compact design make it easy to sew in tight spaces.”, “premium_accessory_package”: [“left/right toe presser feet”, “open toe center foot”, “double toe presser foot”, “work platform”, “10x size 25/24/23…

Strategic Sourcing Conclusion and Outlook for leather machine company cobra class 4

In conclusion, the COBRA Class 4 leather sewing machine stands out as an exceptional choice for businesses seeking reliability and efficiency in leather production. With capabilities to handle materials ranging from 6 oz. to 7/8″ leather and a robust design that includes a heavy-duty pedestal stand and variable speed digital servo motor, it meets the diverse needs of manufacturers across various sectors. The inclusion of premium packages and a limited lifetime warranty further underscores the value proposition for international buyers.

Strategic sourcing of the COBRA Class 4 can significantly enhance operational efficiency, reduce downtime, and improve product quality. For B2B buyers in Africa, South America, the Middle East, and Europe, investing in this machine not only equips businesses with advanced technology but also aligns with global standards of craftsmanship and durability.

As you consider your sourcing options, we encourage you to explore the full range of COBRA products. By leveraging these high-quality machines, you can position your business for growth in an increasingly competitive market. Don’t miss the opportunity to elevate your production capabilities and meet the demands of discerning customers worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.