Introduction: Navigating the Global Market for custom leather bands

In the fast-evolving world of custom leather bands, international B2B buyers face the significant challenge of sourcing high-quality, durable products that align with their brand’s identity and consumer expectations. Whether you are seeking bespoke leather watch straps for luxury timepieces or custom bands for fashion accessories, navigating the complexities of material selection, craftsmanship, and supplier reliability is essential for successful procurement. This guide serves as a comprehensive resource for buyers hailing from diverse markets, including Africa, South America, the Middle East, and Europe, such as Brazil and Nigeria.

Within this guide, we explore a variety of custom leather band types, including popular materials like Horween leather, exotic skins, and vegetable-tanned options. We delve into various applications, from high-end watch straps to everyday fashion accessories, ensuring that your selection meets both aesthetic and functional requirements. Additionally, we provide actionable insights on vetting suppliers, understanding pricing structures, and assessing quality standards.

By leveraging the information presented here, international B2B buyers will be empowered to make informed purchasing decisions, ensuring that their investments not only enhance their product offerings but also resonate with their target markets. With a focus on quality, customization, and supplier transparency, this guide is designed to facilitate your journey in the competitive landscape of custom leather bands.

Table Of Contents

- Top 7 Custom Leather Bands Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather bands

- Understanding custom leather bands Types and Variations

- Key Industrial Applications of custom leather bands

- 3 Common User Pain Points for ‘custom leather bands’ & Their Solutions

- Strategic Material Selection Guide for custom leather bands

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather bands

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather bands’

- Comprehensive Cost and Pricing Analysis for custom leather bands Sourcing

- Alternatives Analysis: Comparing custom leather bands With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather bands

- Navigating Market Dynamics and Sourcing Trends in the custom leather bands Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather bands

- Strategic Sourcing Conclusion and Outlook for custom leather bands

- Important Disclaimer & Terms of Use

Understanding custom leather bands Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather Straps | Made from the top layer of the hide, retains natural grain. | Luxury watch brands, high-end fashion retail | Pros: Durable, develops a unique patina. Cons: Higher cost, requires maintenance. |

| Suede Leather Straps | Soft texture with a napped finish, available in vibrant colors. | Casual and trendy watch collections | Pros: Comfortable, lightweight. Cons: Less durable, can stain easily. |

| Exotic Leather Straps | Crafted from materials like alligator, ostrich, or lizard. | High-end bespoke watchmakers, luxury gifts | Pros: Unique aesthetics, premium appeal. Cons: Expensive, ethical sourcing concerns. |

| Vegetable Tanned Leather Straps | Eco-friendly, retains natural characteristics, develops character. | Sustainable brands, eco-conscious consumers | Pros: Biodegradable, unique aging process. Cons: Can be stiff initially, longer production time. |

| Nylon and Canvas Hybrid Straps | Durable fabric with leather accents, lightweight and versatile. | Sports watches, outdoor gear manufacturers | Pros: Affordable, easy to clean. Cons: Less luxurious appearance, may not suit formal settings. |

What Are the Characteristics of Full Grain Leather Straps?

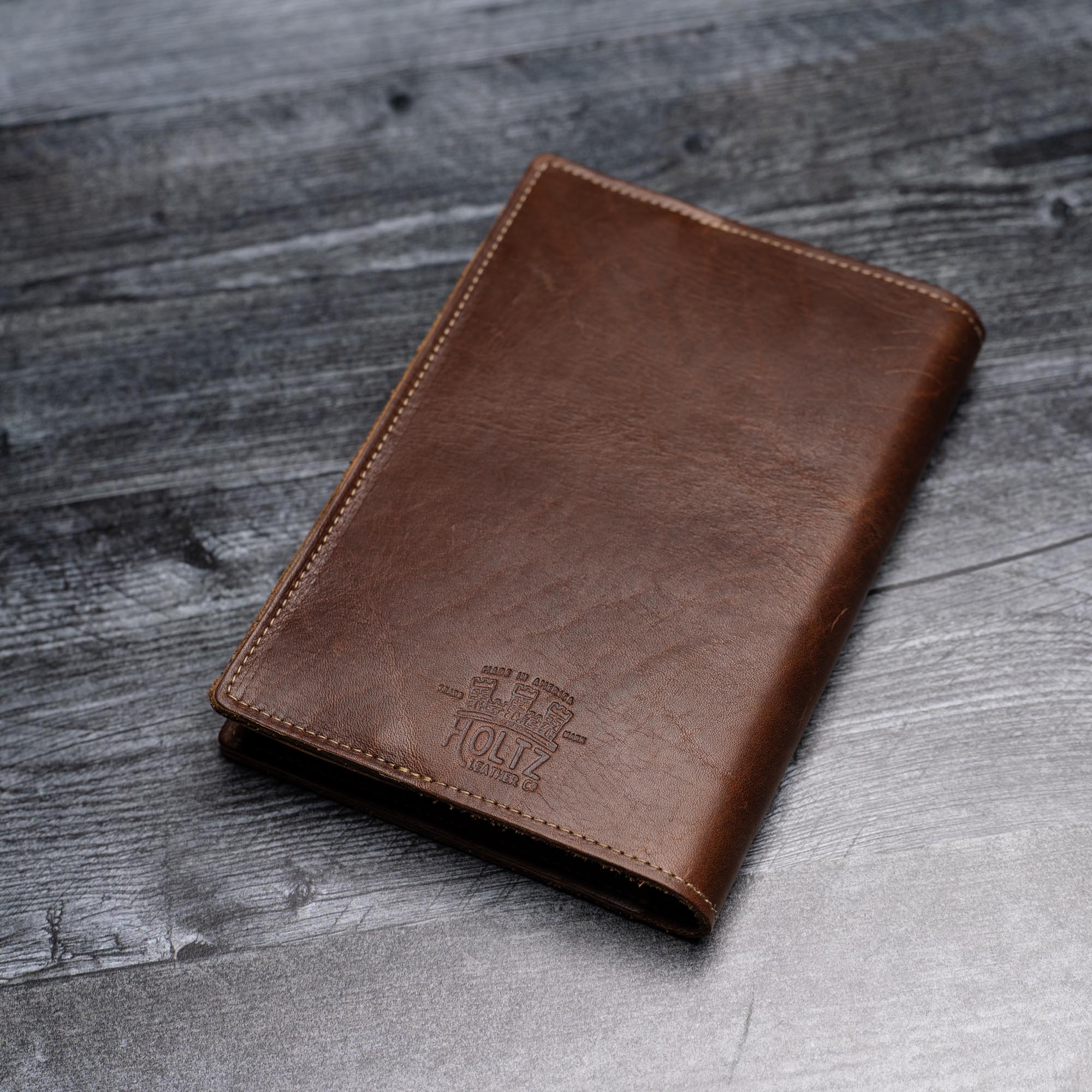

Full grain leather straps are renowned for their durability and natural beauty. They are crafted from the top layer of the hide, preserving its natural grain and imperfections, which contribute to their unique character. Ideal for luxury watch brands and high-end fashion retailers, these straps develop a rich patina over time, enhancing their visual appeal. B2B buyers should consider the higher cost and maintenance requirements associated with full grain leather, as well as its long-lasting nature, making it a worthwhile investment for premium products.

Illustrative image related to custom leather bands

How Do Suede Leather Straps Differ from Other Types?

Suede leather straps are characterized by their soft texture and vibrant color options, making them a popular choice for casual and trendy watch collections. These straps offer a lightweight and comfortable fit, appealing to consumers seeking a laid-back style. However, buyers should be aware of their susceptibility to stains and wear, which may necessitate more frequent replacements. For B2B buyers, understanding the balance between aesthetics and durability is crucial when considering suede for their product offerings.

What Makes Exotic Leather Straps a Premium Choice?

Exotic leather straps, crafted from materials such as alligator, ostrich, and lizard, are synonymous with luxury and exclusivity. These straps are often used by high-end bespoke watchmakers and as luxury gifts, appealing to affluent consumers. Their unique textures and patterns set them apart, but B2B buyers must also consider the ethical sourcing of these materials and their higher price points. While exotic leather can elevate a product’s prestige, careful consideration of market demand and ethical implications is essential.

Why Choose Vegetable Tanned Leather Straps?

Vegetable tanned leather straps are an eco-friendly option that retains the natural characteristics of the hide. This type of leather is biodegradable and develops a unique aging process, appealing to sustainable brands and eco-conscious consumers. While vegetable tanned leather may be stiffer initially and require a longer production time, its distinctiveness and environmental benefits can attract a niche market. B2B buyers should assess the growing demand for sustainable products when considering this option.

What Are the Benefits of Nylon and Canvas Hybrid Straps?

Nylon and canvas hybrid straps combine the durability of fabric with leather accents, offering a lightweight and versatile solution for sports watches and outdoor gear. These straps are typically more affordable and easy to clean, making them attractive for manufacturers targeting budget-conscious consumers. However, they may lack the luxurious appearance of leather options, which could limit their appeal in formal settings. B2B buyers should evaluate their target market’s preferences when integrating hybrid straps into their product lines.

Illustrative image related to custom leather bands

Key Industrial Applications of custom leather bands

| Industry/Sector | Specific Application of custom leather bands | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Custom leather watch straps for luxury timepieces | Enhances product appeal and personalization | Quality of leather, craftsmanship, and customization options |

| Automotive | Leather straps for automotive interior design | Adds luxury and durability to vehicle interiors | Material resilience, color matching, and design flexibility |

| Sporting Goods | Custom leather bands for sports watches | Provides comfort and style for active lifestyles | Breathability, moisture resistance, and durability |

| Corporate Gifts & Branding | Personalized leather bands for corporate gifts | Strengthens brand identity and customer loyalty | Branding options, customization capabilities, and lead times |

| E-commerce & Retail | Customizable leather bands for online retail | Increases customer engagement and satisfaction | Production scalability, shipping logistics, and inventory management |

How Are Custom Leather Bands Used in the Fashion & Accessories Industry?

In the fashion and accessories sector, custom leather bands are primarily utilized for luxury watch straps. These bands not only enhance the aesthetic appeal of high-end timepieces but also allow brands to offer personalized options that cater to individual customer preferences. The challenge for international buyers lies in sourcing high-quality leather that meets sustainability standards while ensuring craftsmanship that aligns with their brand identity. Buyers should consider the types of leather available, such as Horween or vegetable-tanned options, and the potential for custom stitching and colors to elevate their product offerings.

What Role Do Custom Leather Bands Play in Automotive Design?

In the automotive industry, custom leather bands are essential for enhancing interior designs, especially in luxury vehicles. These bands are often used in seat belts, steering wheels, and gear shifts, providing both comfort and a touch of elegance. For buyers in regions like Africa and the Middle East, where luxury automotive markets are growing, the sourcing of durable and aesthetically pleasing leather is critical. Buyers should focus on the leather’s resilience to wear and tear, color coordination with vehicle interiors, and the ability to withstand various climatic conditions.

How Are Custom Leather Bands Integrated into Sporting Goods?

Custom leather bands are increasingly popular in the sporting goods sector, particularly for sports watches. These bands offer a combination of style and functionality, appealing to athletes and fitness enthusiasts. The primary challenges for buyers include ensuring breathability and moisture resistance, which are crucial for comfort during physical activity. Buyers should seek suppliers who can provide leather options that are both lightweight and durable, as well as customizable features that enhance the user experience.

Why Are Custom Leather Bands Important for Corporate Gifts?

In the realm of corporate gifts and branding, custom leather bands serve as unique, personalized items that strengthen brand loyalty. Businesses often opt for engraved or embossed leather bands as gifts for clients or employees, making a lasting impression. For international buyers, the key considerations include the ability to scale production for large orders and the potential for quick turnaround times. Additionally, sourcing high-quality leather that reflects the company’s values—such as sustainability—can enhance the perceived value of the gift.

How Do E-commerce and Retail Benefit from Custom Leather Bands?

E-commerce and retail sectors leverage custom leather bands to create unique products that stand out in a crowded market. By offering customizable options, retailers can significantly enhance customer engagement and satisfaction. International buyers should focus on sourcing partners that can handle scalable production while maintaining quality and consistency. Logistics, including shipping and inventory management, are also critical aspects to consider, as they impact lead times and overall customer experience.

Illustrative image related to custom leather bands

3 Common User Pain Points for ‘custom leather bands’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Custom Leather Bands

The Problem: B2B buyers often struggle with sourcing high-quality leather materials for custom bands. With a plethora of suppliers available globally, it can be overwhelming to assess the quality of leather, especially when considering factors like durability, texture, and appearance. This challenge is compounded for buyers in regions such as Africa and South America, where access to premium materials may be limited, and the risk of counterfeit products is higher. Inconsistent quality can lead to customer dissatisfaction, damaging a company’s reputation and leading to potential financial losses.

The Solution: To overcome this sourcing challenge, buyers should establish relationships with reputable suppliers who provide transparent sourcing information and product samples. It’s advisable to request detailed specifications on leather types, such as full-grain or top-grain, and inquire about the tanning processes used. Additionally, utilizing quality certifications and customer testimonials can help validate a supplier’s claims. Consider collaborating with suppliers who offer customization options, enabling you to choose specific characteristics that align with your brand identity. Finally, engage in small initial orders to test the materials before committing to larger quantities, ensuring that the quality meets your standards.

Scenario 2: Customization Limitations in Design and Size

The Problem: Many B2B buyers encounter limitations when it comes to customizing leather bands to fit specific design requirements or sizes. This issue can be particularly frustrating for businesses that target niche markets or require bands for unique watch models. Standardized options may not cater to the aesthetic preferences or functional needs of all customers, leading to missed sales opportunities and dissatisfaction among end users.

The Solution: To effectively tackle customization limitations, buyers should seek out manufacturers that specialize in bespoke solutions. Look for suppliers who offer a comprehensive configurator tool, allowing for detailed customization options such as size, color, stitching, and material. It’s essential to communicate specific design requirements upfront to ensure that suppliers can accommodate your needs. Establishing a collaborative relationship with your supplier can also facilitate quicker iterations and prototypes, allowing for adjustments based on feedback. Moreover, consider utilizing local artisans who can offer handcrafted solutions tailored to your unique specifications, thus enhancing the product’s exclusivity and appeal.

Illustrative image related to custom leather bands

Scenario 3: Ensuring Timely Delivery and Managing Supply Chain Disruptions

The Problem: Timely delivery is a critical concern for B2B buyers of custom leather bands, especially when operating in fast-paced markets or during seasonal peaks. Delays in production or shipping can lead to inventory shortages, affecting sales and customer satisfaction. Buyers often find it challenging to manage supply chain disruptions, particularly when dealing with international suppliers who may face their own logistical issues, such as customs delays or transport strikes.

The Solution: To mitigate risks associated with delivery timelines, buyers should diversify their supplier base, including both local and international manufacturers. This approach can provide flexibility in case one supplier encounters delays. It’s also prudent to implement inventory management systems that allow for real-time tracking of orders and shipments. Establish clear communication channels with suppliers to receive updates on production status and potential delays. Additionally, consider placing orders well in advance of peak seasons to buffer against unforeseen disruptions. Establishing contracts with clear terms regarding delivery expectations can further protect against delays and ensure accountability from suppliers.

Strategic Material Selection Guide for custom leather bands

What Are the Key Properties of Common Materials Used in Custom Leather Bands?

When selecting materials for custom leather bands, several options stand out based on their unique properties and suitability for various applications. Understanding these materials can help B2B buyers make informed decisions that align with their specific needs and market preferences.

How Does Full Grain Leather Perform in Custom Leather Bands?

Full grain leather is renowned for its durability and natural beauty. It retains the original grain of the hide, which enhances its aesthetic appeal and allows it to develop a rich patina over time. This material is highly resistant to wear and tear, making it ideal for products that require longevity. However, it can be more expensive due to the quality of the hide and the extensive tanning process involved.

From a manufacturing perspective, full grain leather is relatively easy to work with, but it may require specialized tools for cutting and stitching. For international buyers, particularly in regions like Africa and South America, it’s essential to ensure compliance with local tanning regulations and standards, as some countries have strict guidelines regarding leather processing.

What Advantages Does Horween Leather Offer for Custom Leather Bands?

Horween leather, particularly the Chromexcel variant, is known for its unique pull-up effect, which adds character as it ages. This leather is treated with oils and waxes, providing a soft texture that enhances comfort. Its ability to resist moisture and dirt makes it suitable for various climates, including humid environments found in parts of the Middle East and Africa.

However, Horween leather can be on the pricier side, making it less accessible for budget-conscious buyers. Additionally, the tanning process can be complex, requiring skilled artisans. Buyers should also consider the environmental impact of sourcing and processing this leather, as sustainability is becoming increasingly important in global markets.

How Does Suede Compare for Custom Leather Bands?

Suede, made from the underside of the animal hide, offers a soft and luxurious feel that appeals to many consumers. It is lightweight and can be dyed in a wide range of colors, making it a versatile choice for fashion-forward designs. However, suede is less durable than full grain leather and can be more susceptible to stains and water damage.

For B2B buyers in Europe and South America, understanding the care and maintenance requirements of suede is crucial, as it may not withstand extreme conditions as well as other leather types. Compliance with local environmental regulations regarding animal sourcing and processing is also a consideration that cannot be overlooked.

What Role Does Vegetable-Tanned Leather Play in Custom Leather Bands?

Vegetable-tanned leather is celebrated for its eco-friendly properties, as it uses natural tannins from plant sources rather than synthetic chemicals. This type of leather is robust and develops a beautiful patina over time, making it a popular choice for custom leather bands. However, it can be less water-resistant than other leathers, which may limit its use in certain applications.

Illustrative image related to custom leather bands

Manufacturing with vegetable-tanned leather requires specific expertise, particularly in the tanning process, which can be time-consuming. For international buyers, especially in regions like Africa and the Middle East, ensuring that the leather complies with local environmental standards is critical to avoid potential legal issues.

Summary Table of Material Selection for Custom Leather Bands

| Material | Typical Use Case for custom leather bands | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end watch bands, luxury accessories | Exceptional durability and aesthetics | Higher cost, requires skilled artisans | High |

| Horween Leather | Premium watch straps, fashion accessories | Unique aging characteristics, comfort | Expensive, complex tanning process | High |

| Suede | Casual and fashion-oriented straps | Soft texture, wide color range | Less durable, susceptible to stains | Medium |

| Vegetable-Tanned Leather | Eco-friendly products, artisanal straps | Environmentally friendly, beautiful patina | Less water-resistant, time-consuming tanning | Medium |

This guide provides a comprehensive overview of the key materials used in custom leather bands, enabling B2B buyers to make informed decisions that align with their market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather bands

What Are the Main Stages of Manufacturing Custom Leather Bands?

Manufacturing custom leather bands involves several key stages that ensure the final product meets quality and aesthetic standards. Each stage is critical to the overall craftsmanship and durability of the leather bands, making it essential for B2B buyers to understand the process.

Illustrative image related to custom leather bands

1. Material Preparation: How Is Leather Processed for Bands?

The first step in the manufacturing process is the selection and preparation of high-quality leather. This typically involves sourcing leather from reputable tanneries known for their sustainable practices. Leather types such as full-grain, top-grain, and specialty leathers like Horween Chromexcel or Shell Cordovan are often used due to their durability and aesthetic qualities.

Once the leather is sourced, it undergoes various treatments, including tanning, dyeing, and conditioning. Tanning can be vegetable-based or chrome-based, affecting the leather’s texture, color retention, and longevity. For instance, vegetable-tanned leather is known for its eco-friendliness and ability to develop a rich patina over time, while chrome-tanned leather offers vibrant colors and a supple feel.

2. Forming: What Techniques Are Used to Shape Leather Bands?

In the forming stage, the leather is cut to the required dimensions using precision tools or die-cutting machines. Manufacturers often create templates to ensure consistency across multiple bands. Techniques such as embossing or laser engraving may be applied at this stage to add branding or decorative elements.

Illustrative image related to custom leather bands

After cutting, the leather pieces are shaped through techniques like folding, stitching, or molding. This is where artisans apply their skills to create unique designs that cater to specific customer preferences. For example, custom stitching patterns and colors can enhance the overall look of the leather band, making it more appealing to end-users.

3. Assembly: How Are Leather Bands Constructed?

During assembly, the cut and shaped leather pieces are sewn together using durable thread. High-quality bonded nylon or linen threads are commonly used, with options for various colors to match or contrast the leather. The stitching process is crucial; it not only holds the pieces together but also adds to the aesthetic appeal of the band.

Assembly may also involve additional components such as buckles, clasps, or lining materials. Quality manufacturers pay close attention to the alignment and finishing of each piece to ensure a snug fit for various watch models, thus enhancing the user experience.

4. Finishing: What Final Touches Are Applied to Custom Leather Bands?

The finishing stage includes applying protective coatings, polishing, and inspecting the leather bands for any defects. A finish may involve applying oils, waxes, or sealants to enhance water resistance and durability. Artisans may also hand-polish the edges to provide a smooth, refined look.

Quality assurance checks are performed at this stage to ensure that each band meets the desired specifications before packaging. This may include checking for color consistency, stitching integrity, and overall craftsmanship.

What International Standards Guide Quality Assurance for Leather Bands?

Quality assurance in the leather band manufacturing process is critical for maintaining product consistency and meeting customer expectations. B2B buyers should be familiar with international standards that govern quality control.

1. What Are the Relevant International Standards for Leather Bands?

ISO 9001 is a widely recognized standard for quality management systems, applicable to various industries, including leather goods. It emphasizes customer satisfaction, process improvement, and compliance with regulatory requirements. Manufacturers adhering to ISO 9001 demonstrate a commitment to quality and continuous improvement.

Illustrative image related to custom leather bands

In addition to ISO standards, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) certifications may be relevant for certain leather products, particularly if they are used in specialized applications.

2. What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are essential to identify defects and ensure that the final product meets quality standards. Key checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials like leather and components are inspected for quality before production begins. This includes checking for defects, color consistency, and material specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted to ensure that each stage meets quality standards. This can involve checking stitching, alignment, and finishing.

-

Final Quality Control (FQC): After assembly and finishing, a final inspection is performed to ensure that the leather bands meet all specifications and quality standards before shipping.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is crucial to ensure they receive high-quality products that meet their specifications. Here are some actionable steps:

1. What Audits and Reports Should Buyers Request from Suppliers?

Buyers should request copies of quality assurance reports, including results from IQC, IPQC, and FQC inspections. Regular audits conducted by third-party quality assurance firms can also provide insight into a supplier’s compliance with international standards.

Illustrative image related to custom leather bands

Additionally, buyers can ask for documentation regarding the supplier’s adherence to ISO 9001 or other relevant certifications. This information can help assess the supplier’s commitment to quality management.

2. How Do Third-Party Inspections Work in the Leather Band Industry?

Third-party inspections involve hiring an independent organization to evaluate the manufacturing process and final products. This can include on-site inspections during production and testing of finished goods to ensure compliance with specified standards.

Buyers should consider using third-party inspection services, especially when sourcing from international suppliers. This can help mitigate risks associated with quality inconsistencies, particularly in regions where quality control practices may vary.

What Nuances Should International Buyers Consider for Quality Control?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control practices that may vary by region. For instance:

Illustrative image related to custom leather bands

-

Cultural Differences: Understanding the cultural context of the manufacturing country can influence quality expectations and communication styles. Building relationships with suppliers can enhance transparency in quality assurance practices.

-

Regulatory Compliance: Different regions may have varying regulations regarding leather goods. Buyers should familiarize themselves with local laws and international trade agreements that may affect product quality and compliance.

-

Logistical Considerations: Shipping and handling can impact the quality of leather bands. Buyers should ensure that suppliers implement proper packaging and handling procedures to prevent damage during transit.

By understanding the manufacturing processes and quality assurance measures involved in producing custom leather bands, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather bands’

In this guide, we present a step-by-step checklist designed to help B2B buyers effectively source custom leather bands. These bands are essential components in various industries, from watchmaking to fashion accessories. By following this checklist, you will ensure that your procurement process is efficient, cost-effective, and aligned with your quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing custom leather bands that meet your exact needs. Consider factors such as leather type (e.g., full-grain, top-grain, or suede), thickness, color, and any specific design features. This clarity will help potential suppliers understand your requirements and deliver products that align with your brand.

- Leather Type: Research the benefits of various leather types, such as durability and aesthetics.

- Design Features: Specify any unique stitching, embossing, or customization options.

Step 2: Conduct Market Research

Before engaging suppliers, conduct thorough market research to understand current trends and pricing. This information will help you set realistic budgets and identify potential suppliers who can deliver high-quality products at competitive prices.

- Trend Analysis: Look into popular styles and materials used in your industry.

- Price Benchmarking: Compare prices from various suppliers to gauge the market average.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in quality and reliability.

- Supplier Profiles: Assess their experience and expertise in manufacturing custom leather bands.

- References and Reviews: Reach out to other businesses that have sourced from them to gauge satisfaction levels.

Step 4: Request Samples

Obtaining samples is an essential step in the sourcing process. Samples allow you to assess the quality of materials, craftsmanship, and overall aesthetics before making a bulk order.

- Quality Assessment: Examine the leather’s texture, durability, and finish.

- Fit and Comfort: If applicable, test the sample for comfort and fit on the intended product.

Step 5: Verify Compliance and Certifications

Ensure that your suppliers comply with international standards and regulations, especially if you are sourcing from different regions. Certifications such as ISO or adherence to environmental standards can indicate a supplier’s commitment to quality and sustainability.

Illustrative image related to custom leather bands

- Certification Check: Request documentation that confirms compliance with relevant standards.

- Sustainability Practices: Inquire about the sourcing and tanning processes used in the production of leather.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, it’s time to negotiate the terms of your agreement. This includes pricing, minimum order quantities, lead times, and payment terms. Clear agreements can prevent misunderstandings down the line.

- Pricing Structure: Discuss volume discounts for larger orders.

- Delivery Schedules: Establish realistic timelines for production and delivery.

Step 7: Establish Communication Channels

Effective communication is essential throughout the sourcing process. Establish clear channels for updates, inquiries, and feedback to ensure that both parties are aligned on expectations and timelines.

- Regular Updates: Set up a schedule for progress reports during production.

- Feedback Loop: Create a system for providing and receiving feedback on samples and final products.

By following this comprehensive checklist, you can navigate the complexities of sourcing custom leather bands with confidence, ensuring that your procurement process meets both your quality standards and business objectives.

Illustrative image related to custom leather bands

Comprehensive Cost and Pricing Analysis for custom leather bands Sourcing

What Are the Key Cost Components in Sourcing Custom Leather Bands?

When sourcing custom leather bands, understanding the cost structure is crucial for effective budgeting and pricing strategies. The primary cost components include:

-

Materials: The choice of leather significantly impacts the cost. High-quality options like Horween Chromexcel or Shell Cordovan can range from $58 to over $265 per strap, depending on the type and finish. Other materials, such as suede or synthetic alternatives, may be more cost-effective but could compromise quality.

-

Labor: Skilled craftsmanship is essential in producing high-quality leather bands. Labor costs can vary based on geographic location and the expertise of the artisans involved. Regions with lower labor costs may offer more competitive pricing, but this should be balanced against quality.

-

Manufacturing Overhead: This includes expenses related to facilities, equipment, and utilities necessary for production. Companies must consider how these overheads are distributed across different products, affecting overall pricing.

-

Tooling: Custom tooling for specific designs or sizes can incur additional costs. These costs should be factored into the initial price, particularly for unique or bespoke orders.

-

Quality Control (QC): Ensuring that each product meets quality standards requires investment in QC processes. This step is vital to maintain brand reputation and customer satisfaction.

-

Logistics: Shipping and handling costs can vary significantly based on the destination. International buyers should account for potential tariffs, customs duties, and freight charges, which can add to the total cost.

-

Margin: Suppliers will build in a profit margin to cover their costs and sustain their business. Understanding typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Custom Leather Bands?

Several factors influence the pricing of custom leather bands, and being aware of these can aid in making informed purchasing decisions:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to lower per-unit costs. Suppliers are more inclined to offer discounts for bulk orders, which can significantly reduce total expenses.

-

Specifications and Customization: Custom features, such as specific stitching, colors, or sizing, can raise the price. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher-quality materials may come with certifications that assure buyers of their sustainability and ethical sourcing. While this can increase costs, it may also enhance the product’s marketability.

-

Supplier Factors: Different suppliers may have varying pricing strategies based on their operational efficiencies, market positioning, and brand reputation. Engaging with multiple suppliers can yield comparative insights.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is essential. Different terms can shift the responsibility for shipping costs and risks, impacting the overall price.

What Buyer Tips Can Help Achieve Cost-Efficiency in Custom Leather Bands?

To maximize value in sourcing custom leather bands, buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially when placing large orders. Leverage quotes from multiple vendors to strengthen your negotiation position.

-

Total Cost of Ownership (TCO): Analyze not just the purchase price but all costs associated with acquiring and maintaining the product, including shipping, handling, and potential returns.

-

Pricing Nuances for International Buyers: When sourcing from different regions, consider the impact of currency fluctuations, local economic conditions, and trade agreements. Being informed about these aspects can help avoid unanticipated cost increases.

-

Quality Over Price: While it may be tempting to opt for the lowest cost option, prioritize suppliers who offer the best quality and service. Investing in higher-quality bands can lead to greater customer satisfaction and lower replacement costs over time.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier assessments to obtain the most accurate pricing for your needs.

Illustrative image related to custom leather bands

Alternatives Analysis: Comparing custom leather bands With Other Solutions

Understanding Alternatives to Custom Leather Bands in the B2B Market

When considering custom leather bands, international B2B buyers must evaluate various alternatives that could meet their needs for quality, durability, and aesthetic appeal. This analysis will compare custom leather bands against synthetic materials and metal bands—two popular alternatives that serve similar functions. Each option presents unique advantages and drawbacks that can influence purchasing decisions.

| Comparison Aspect | Custom Leather Bands | Synthetic Bands | Metal Bands |

|---|---|---|---|

| Performance | High durability; develops patina over time | Moderate durability; less luxurious feel | Extremely durable; resistant to wear |

| Cost | Generally higher ($50-$200) | Lower ($15-$100) | Mid-range ($30-$300) |

| Ease of Implementation | Requires customization; longer lead time | Readily available; no customization needed | Requires precise measurements; some customization possible |

| Maintenance | Requires occasional conditioning | Low maintenance; easy to clean | Minimal maintenance; may require polishing |

| Best Use Case | Luxury and personalized branding | Budget-friendly solutions for mass production | Durable and professional settings |

Exploring Synthetic Bands as an Alternative

Synthetic bands, often made from materials like nylon or polyurethane, offer a budget-friendly option for businesses looking to provide a practical yet stylish alternative to leather. These bands are readily available in various colors and styles, making them easy to source and implement. However, while they require minimal maintenance and can withstand various environmental conditions, they may lack the luxury appeal and long-term durability of custom leather bands. For companies focused on cost-effectiveness and immediate availability, synthetic bands may be a viable solution, but they may not convey the same level of prestige or craftsmanship.

Evaluating Metal Bands as Another Option

Metal bands, crafted from stainless steel or titanium, are known for their exceptional durability and resistance to wear and tear. They provide a sleek and modern aesthetic, making them popular in corporate and professional settings. However, the cost can vary significantly based on the material and design complexity, often falling in the mid-range category. While metal bands require little maintenance, they can be heavy and may not offer the same level of comfort as leather or synthetic options. Businesses seeking a robust and professional look may find metal bands appealing, but they may need to consider comfort and weight for long-term wear.

Conclusion: How to Choose the Right Band for Your Business

Selecting the right band for your needs involves weighing the pros and cons of each option against your specific business requirements. Custom leather bands excel in providing a luxurious, personalized touch, ideal for branding and high-end markets. In contrast, synthetic bands serve well for budget-conscious buyers seeking practicality and quick availability, while metal bands offer durability and a modern aesthetic for professional environments. By assessing factors such as performance, cost, and intended use, B2B buyers can make informed decisions that align with their brand image and customer expectations.

Essential Technical Properties and Trade Terminology for custom leather bands

What Are the Essential Technical Properties of Custom Leather Bands?

When sourcing custom leather bands, understanding key technical properties is vital for ensuring quality and compatibility with your products. Here are critical specifications that B2B buyers should consider:

1. Material Grade

The grade of leather directly influences durability, aesthetics, and pricing. Common grades include full-grain, top-grain, and genuine leather. Full-grain leather, for example, is the highest quality, retaining the natural texture and strength, making it ideal for high-end applications. Buyers should assess the grade based on their target market and product positioning.

2. Tolerance

Tolerance refers to the permissible limits of variation in the leather band’s dimensions. This specification is crucial for ensuring that the bands fit the watches or devices they are intended for. A tight tolerance (e.g., ±1mm) is essential for luxury items, while a looser tolerance may be acceptable for more casual products. Understanding tolerance helps prevent costly errors in production and enhances customer satisfaction.

3. Thickness

The thickness of the leather can impact both the look and feel of the band. Standard thicknesses range from 1.2mm to 3.5mm, with thicker bands offering more durability but potentially sacrificing comfort. Buyers should consider the intended use—sporty models may benefit from thicker, more rugged leather, while elegant designs may require a thinner, more supple leather.

4. Finish

The finish of the leather affects its appearance, texture, and water resistance. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather is soft and showcases natural markings but is less resistant to stains, while pigmented leather offers a more uniform appearance and enhanced durability. Choosing the right finish is crucial for aligning with customer expectations and product use cases.

Illustrative image related to custom leather bands

5. Stitching and Thread Quality

The quality of stitching can significantly influence the durability and aesthetic of leather bands. Premium options often utilize bonded nylon or linen threads, which provide strength and flexibility. Custom stitching options, including color and style, can also enhance the personalization aspect of the product, appealing to buyers looking for unique offerings.

6. Patina Development

Patina refers to the natural aging process of leather, which can enhance its character and beauty over time. High-quality leather, such as Horween Chromexcel, develops a rich patina that adds value. Buyers should consider how the leather’s aging properties align with their branding and customer preferences, as a desirable patina can be a selling point.

What Are Common Trade Terms in the Custom Leather Bands Industry?

Understanding industry jargon is essential for effective communication and negotiation. Here are several common terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then sold under another company’s brand. In the context of custom leather bands, an OEM might manufacture the bands for a watch brand, allowing the latter to focus on design and marketing.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of products that a supplier is willing to produce or sell. For custom leather bands, MOQs can vary significantly based on material and complexity. Understanding MOQs helps buyers plan their inventory and manage cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. In the leather band industry, an RFQ allows buyers to obtain detailed pricing and terms from multiple suppliers, facilitating competitive comparisons.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps in negotiating shipping costs and delivery obligations.

Illustrative image related to custom leather bands

5. Lead Time

Lead time refers to the time it takes from placing an order until the goods are delivered. Understanding lead times is crucial for inventory management, especially for businesses that operate on tight schedules or seasonal demand.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather bands, ensuring that they meet market demands and maintain high-quality standards.

Navigating Market Dynamics and Sourcing Trends in the custom leather bands Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Bands?

The custom leather bands sector is witnessing significant growth driven by a surge in demand for personalized accessories across various markets. Key global drivers include the rise of e-commerce platforms, which facilitate direct-to-consumer sales, and the increasing consumer preference for unique, high-quality products. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly drawn to custom leather bands due to their ability to cater to diverse tastes and preferences, reflecting local cultures and fashion trends.

Emerging trends indicate a shift towards customization options, with businesses offering bespoke designs tailored to individual specifications. This trend is supported by advancements in technology, such as 3D printing and digital design tools, enabling manufacturers to create intricate designs efficiently. Additionally, the integration of augmented reality (AR) tools in the shopping experience allows buyers to visualize how a custom strap will look on their timepiece before purchase, enhancing customer engagement and satisfaction.

Illustrative image related to custom leather bands

Market dynamics are also influenced by the competitive landscape, with an influx of small, artisanal producers entering the market alongside established brands. This diversification offers B2B buyers a broader selection of products but necessitates thorough supplier vetting to ensure quality and reliability. In summary, the custom leather bands market presents lucrative opportunities for international buyers, particularly when leveraging technology and personalization to meet evolving consumer demands.

How Is Sustainability and Ethical Sourcing Addressed in the Custom Leather Bands Sector?

Sustainability and ethical sourcing have become paramount in the custom leather bands sector, responding to growing consumer awareness regarding environmental and social impacts. Leather production is often scrutinized for its ecological footprint, prompting manufacturers to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing, which includes using hides from animals raised in humane conditions and minimizing waste throughout the production process.

Incorporating ‘green’ certifications and materials can significantly enhance a brand’s appeal. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for suppliers seeking to establish credibility in the market. Moreover, the use of vegetable-tanned leather, which avoids harmful chemicals, is gaining traction among conscious consumers.

Sourcing from suppliers who embrace eco-friendly practices not only supports environmental sustainability but also aligns with the growing demand for transparency in supply chains. This focus on ethical sourcing can enhance brand loyalty and attract a more discerning clientele, making it a crucial consideration for B2B buyers in the custom leather bands market.

What Is the Historical Context of Custom Leather Bands in the B2B Market?

The history of custom leather bands dates back centuries, with leather serving as a durable material for various applications, including horology. Initially, leather bands were primarily functional, designed for utility rather than aesthetics. However, as timepieces became symbols of status and style, the demand for personalized and luxurious leather bands grew.

In the modern era, the rise of fashion and individual expression has transformed custom leather bands into coveted accessories. The introduction of advanced manufacturing techniques and the digital revolution have further accelerated this evolution, allowing artisans and manufacturers to cater to niche markets with bespoke offerings. Today, the custom leather bands sector stands at the intersection of tradition and innovation, providing B2B buyers with unique opportunities to tap into the growing market for personalized luxury.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather bands

-

How do I ensure the quality of custom leather bands from suppliers?

To ensure quality, request samples from potential suppliers to evaluate the leather’s texture, durability, and craftsmanship. Look for suppliers who provide detailed information about their materials, such as full-grain or vegetable-tanned leather. Additionally, inquire about their production processes and quality assurance practices. Certifications from recognized organizations can also serve as indicators of quality. Establishing clear quality control standards in your contract will help maintain consistency in your orders. -

What customization options are available for leather bands?

Customization options typically include leather type, color, stitching style, and length. Many suppliers also offer unique features such as embossed logos or personalized engravings. When discussing customization with potential suppliers, specify your design preferences and ask for a configurator tool if available. This ensures that the final product aligns with your brand identity and meets your customers’ expectations. -

What are the typical minimum order quantities (MOQs) for custom leather bands?

Minimum order quantities can vary significantly based on the supplier and the complexity of the customization. Generally, MOQs range from 50 to 500 units. Some suppliers may be flexible with MOQs for first-time buyers or sample orders. It’s essential to discuss MOQs upfront to ensure they align with your business needs and budget. Consider negotiating terms if you plan to establish a long-term relationship with the supplier. -

What payment terms should I expect when sourcing leather bands internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit (usually 30-50%) before production and the balance upon delivery or before shipping. Some suppliers may accept letters of credit or payment through secure platforms. Always clarify payment methods and terms in your contract to avoid misunderstandings. Additionally, consider the impact of currency fluctuations on pricing if you are dealing with international suppliers. -

How can I verify the legitimacy of a supplier before placing an order?

To verify a supplier’s legitimacy, conduct thorough research by checking their business registration, online reviews, and industry reputation. Request references from other clients, and consider visiting their facility if feasible. Utilize platforms like Alibaba or trade shows to find reputable suppliers with a proven track record. Engaging with third-party verification services can also provide additional assurance about the supplier’s credibility. -

What logistics considerations should I be aware of when importing leather bands?

Logistics considerations include shipping methods, customs regulations, and import duties. Choose a reliable shipping partner familiar with international trade, especially if you are importing from regions with stringent regulations. Understand the tariffs and taxes that may apply to your order, and factor these costs into your budget. Clear communication with your supplier about shipping timelines and documentation is essential to avoid delays. -

How do I handle quality assurance for bulk orders of leather bands?

Implementing a quality assurance protocol is crucial for bulk orders. Define quality standards and inspection criteria in your contract with the supplier. Consider conducting inspections at different stages of production, or hire third-party inspection services for unbiased assessments. Request detailed reports and photographs before shipment to confirm that the products meet your specifications. Establishing a clear return policy for defective items is also important for protecting your investment. -

What trends should I consider in the custom leather band market?

Stay updated on trends such as sustainable and eco-friendly materials, which are increasingly important to consumers. Personalization and customization are also rising in demand, as customers seek unique products. Additionally, consider the impact of technology, such as smartwatches, on traditional leather bands. Understanding these trends can help you position your offerings effectively and meet the evolving preferences of your target market.

Top 7 Custom Leather Bands Manufacturers & Suppliers List

1. Delugs – Custom Watch Straps

Domain: delugs.com

Registered: 2018 (7 years)

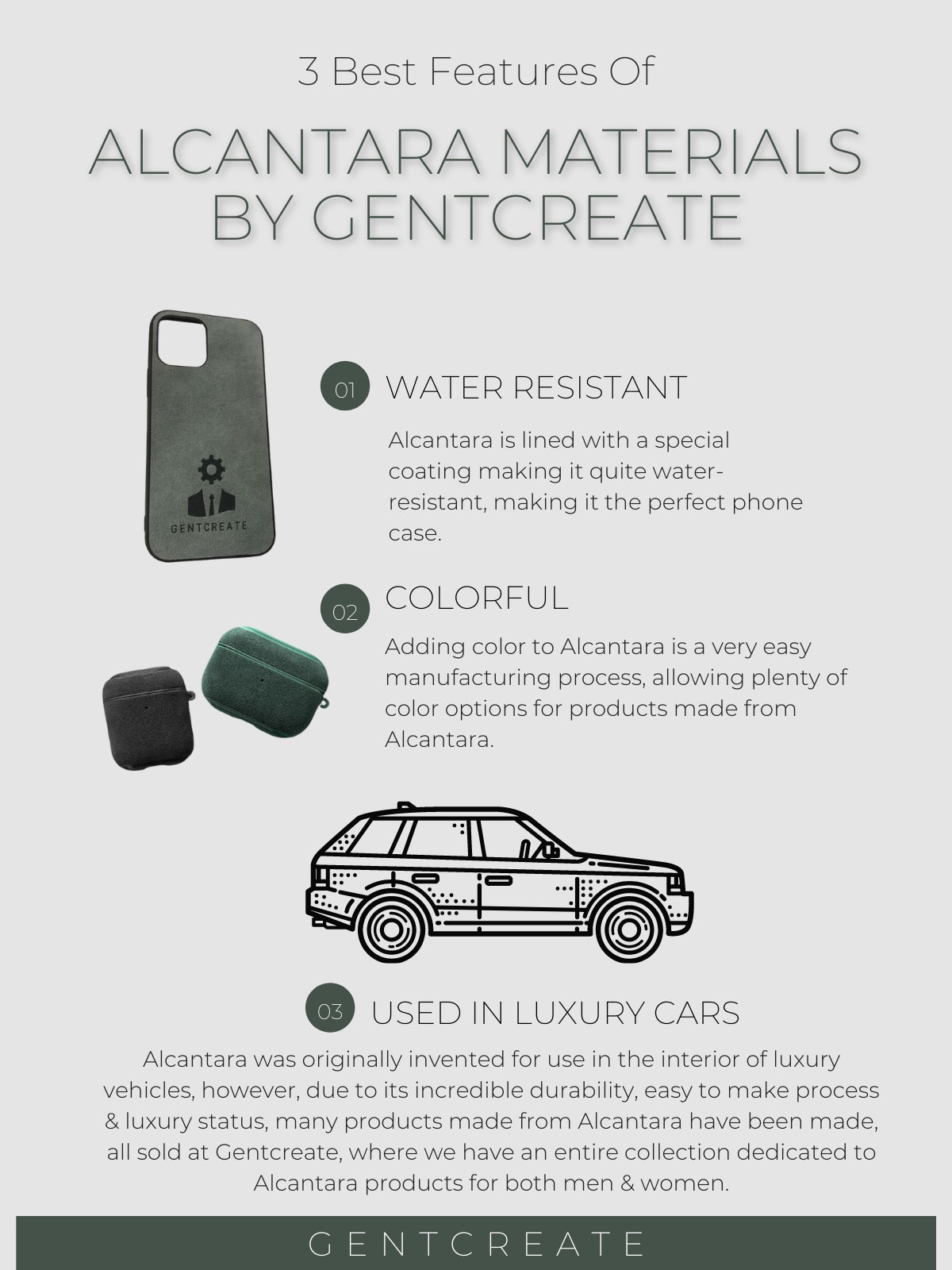

Introduction: Custom Watch Strap by Delugs

– Price: Starting at USD 150.00

– Free shipping on first order with code FREE-FIRST-SHIPPING (minimum spend of US$100)

– Materials available: Alcantara, Alligator/Crocodile, Babele, Baranil, Buttero, Chevre, Crazy Horse, Epsom, Lizard, Nubuck, Ostrich (Body and Leg), Pueblo, Rubberised Leather (Smooth and Togo), Saffiano, Sailcloth, Salmon, Shell Cordovan, Stingray, Wa…

2. Jack Foster – Custom Leather Watch Straps

Domain: jack-foster.com

Registered: 2013 (12 years)

Introduction: This company, Jack Foster – Custom Leather Watch Straps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. The House Of Straps – Hand-Made Leather Watch Straps

Domain: thehouseofstraps.com

Registered: 2018 (7 years)

Introduction: The House Of Straps offers a variety of hand-made leather watch straps crafted from high-quality materials. Key product details include: 1. Horween Shell Cordovan: Extremely resilient, non-creasing, rich color, and subtle luster. 2. Horween Chromexcel Leather: Features a rich pull-up effect, comfortable fit, and develops a great patina over time. 3. Wickett & Craig Bridle Leather: Full grain, vege…

4. Veblenist – Custom Watch Straps

Domain: veblenist.com

Registered: 2013 (12 years)

Introduction: Custom watch straps available in leather and canvas, including luxury bespoke handmade bands. Categories include: Two-Piece Leather, Canvas, Alligator, Cordovan, Calfskin, Suede, Rubber, and NATO straps. Specific types include: Leather NATO, Cordovan NATO, Suede NATO, Nylon NATO, and straps built for Panerai and Apple Watch. New arrivals and bestsellers are highlighted, with prices ranging from $1…

5. Camille Fournet – Custom Leather Watch Straps

Domain: camillefournet.com

Registered: 1999 (26 years)

Introduction: Custom-made leather watch straps available in various colors, sizes, and precious leathers including alligator, ostrich, calfskin, and lizard. Four models offered with customizable options. Prices range from $143 to $195. Available widths: 15/14 mm, 16/14 mm, 17/16 mm, 18/16 mm, 19/16 mm, 20/16 mm, 20/18 mm, 21/18 mm, 22/18 mm. Length options include 105-70 mm and 115-75 mm.

6. Finwatch Straps – Exotic Leather & Premium Watch Straps

Domain: finwatchstraps.com

Registered: 2017 (8 years)

Introduction: Free shipping on orders over €250 with DHL and UPS (applies on EU, USA and Canada shipping destinations). Product categories include: Alligator watch straps (Artisan, Prestige Collection, Luxe Edition, Exquisite Collection), Premium Bison Leather Watch Straps, Exotic leather watch straps (Camel, Shark, Stingray, Lizard, Ostrich, Python, African kudu, Kangaroo), Ammo Vintage watch straps (1930-1980…

7. The StrapSmith – Custom Handcrafted Watch Straps

Domain: thestrapsmith.com

Registered: 2007 (18 years)

Introduction: The StrapSmith offers handcrafted custom watch straps made to order, including textured leather, vintage ammo, classic series, Alcantara, Bell & Ross, pilot style, canvas & denim, baseball glove, football, ostrich, shark, project straps, gator, and limited edition leathers. They also provide pre-made straps ready to ship, such as pilot style, leather, gator, pilot gator embossed, ballistic nylon, …

Strategic Sourcing Conclusion and Outlook for custom leather bands

What Are the Key Takeaways for Sourcing Custom Leather Bands?

In the evolving landscape of custom leather bands, strategic sourcing emerges as a pivotal factor for international B2B buyers. Prioritizing quality materials such as Horween leather and bridle leather not only enhances product durability but also aligns with consumer preferences for luxury and sustainability. Understanding regional market demands, particularly in Africa, South America, the Middle East, and Europe, can drive tailored product offerings that resonate with diverse customer bases.

How Can Buyers Leverage Customization for Competitive Advantage?

Customization is no longer a luxury; it is a necessity. As buyers seek unique selling propositions, collaborating with manufacturers that offer bespoke solutions—such as varied lengths, colors, and stitching options—can significantly elevate brand differentiation. This adaptability in design not only meets individual customer needs but also fosters brand loyalty, a critical asset in competitive markets.

Illustrative image related to custom leather bands

What Lies Ahead for the Custom Leather Band Market?

Looking forward, the demand for custom leather bands is set to grow, fueled by rising consumer interest in personalized fashion accessories. B2B buyers should actively engage with suppliers who demonstrate craftsmanship and innovation, ensuring they stay ahead of trends. Embrace the opportunity to collaborate with skilled artisans and leverage local materials, which not only supports regional economies but also enhances the authenticity of your products.

Take the next step in your sourcing journey and explore the wealth of options available in the custom leather band market today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather bands