Catalog

Material Insight: Custom Made Leather Garments

Custom-Made Leather Garments: The Premium Choice for Modern Fashion Brands

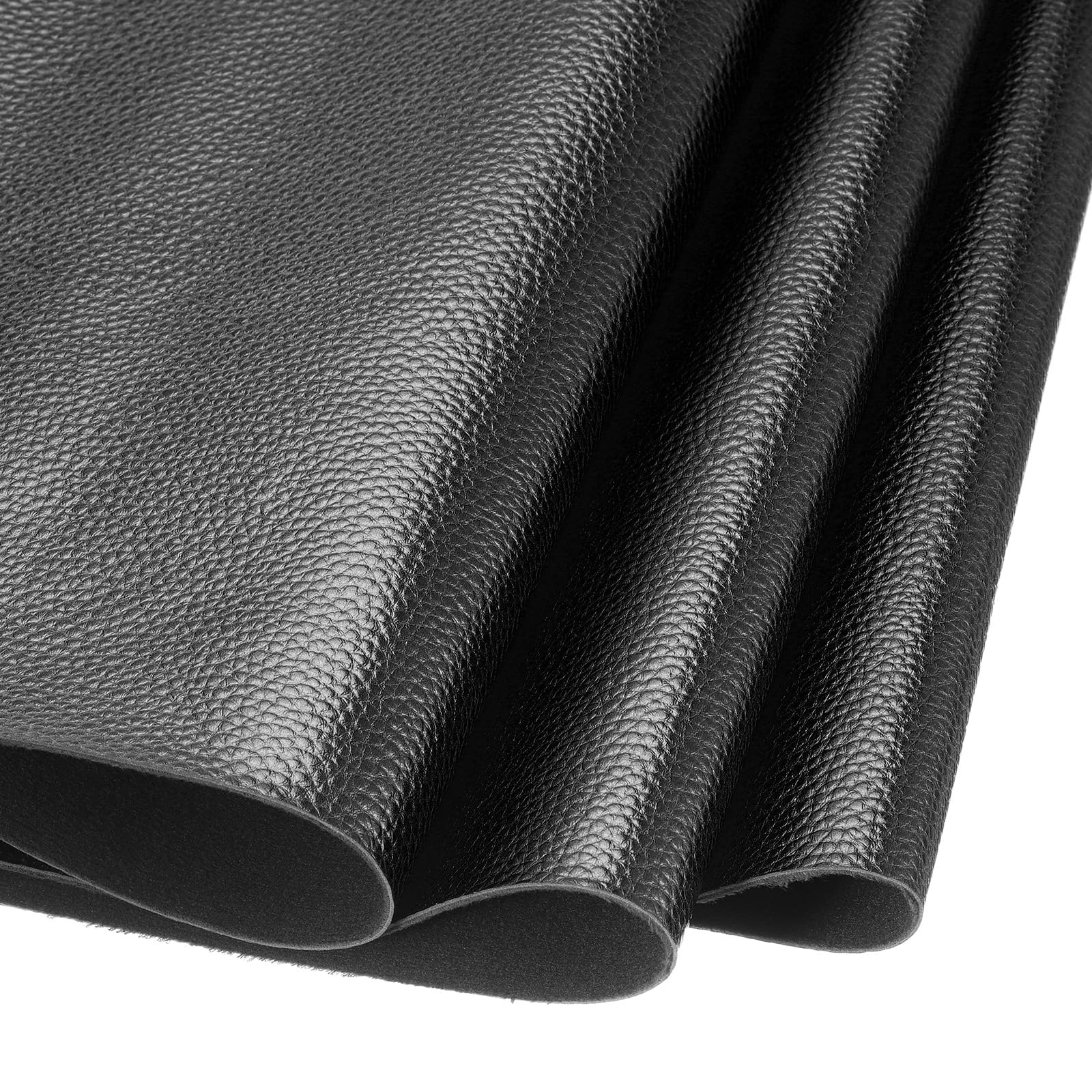

Creating distinctive, high-value leather garments requires materials that deliver exceptional performance, design versatility, and responsible sourcing. While traditional leather has long been the industry standard, its limitations—significant environmental impact, inconsistent quality, ethical concerns, and restricted design flexibility—pose growing challenges for forward-thinking fashion brands. For custom garment production, premium synthetic leather (faux leather) is the optimal solution, enabling unmatched creative freedom without compromising on durability, aesthetics, or sustainability.

Why Premium Faux Leather Excels in Custom Garment Applications

- Design Precision & Versatility: Achieve exact color matches, unique textures (embossed, matte, metallic), and consistent thickness across large production runs—eliminating the natural variations inherent in animal hides that disrupt custom patterns.

- Sustainable Production: Reduce water consumption by up to 90% and eliminate toxic tanning chemicals versus traditional leather, aligning with global ESG goals and consumer demand for eco-conscious fashion.

- Cost Efficiency & Speed: Streamline sampling and production with reliable material availability, avoiding hide shortages or seasonal price volatility, while accelerating time-to-market by 30–50%.

- Ethical Compliance: Fully traceable, animal-free materials ensure adherence to evolving international regulations (e.g., EU Deforestation Regulation) and resonate with conscious consumers.

WINIW: Your Trusted Partner for 20+ Years

Since 2003, WINIW has pioneered advanced synthetic leather solutions for global fashion leaders, luxury brands, and technical apparel innovators. Our R&D-driven approach combines cutting-edge polymer science with deep textile expertise to deliver materials that exceed the performance and aesthetic expectations of traditional leather. Every WINIW substrate is engineered for:

– Garment-Specific Performance: Optimal drape, breathability, and abrasion resistance for jackets, pants, skirts, and accessories.

– Eco-Certified Innovation: OEKO-TEX® STANDARD 100, ISO 14001, and GRS-certified materials with recycled content options.

– End-to-End Customization: From concept to cuttable roll, we collaborate closely with your design and production teams to solve technical challenges and elevate your collections.

Choose WINIW to transform your custom leather garment vision into a sustainable, market-ready reality—where uncompromising quality meets responsible innovation.

Next: Explore WINIW’s Custom Garment Material Portfolio (Performance Specs, Lead Times, MOQs)

Technical Performance & Standards

WINIW Custom Made Leather Garments – B2B Product Guide

WINIW specializes in high-performance synthetic leather solutions designed for fashion, automotive, and lifestyle industries. Our custom made leather garments combine advanced material engineering with sustainable manufacturing practices, delivering exceptional value to B2B partners globally. Engineered for durability and aesthetic versatility, WINIW’s synthetic leather garments offer a cost-effective alternative to natural leather without compromising on quality or compliance.

Key Technical Advantages

-

Cost-Effective Production: WINIW’s synthetic leather reduces raw material and processing costs compared to natural leather. Our streamlined manufacturing process minimizes waste and lowers production lead times, enabling competitive pricing without sacrificing performance.

-

Superior Durability: Our garments are constructed with high-tenacity polyurethane (PU) and reinforced backings, offering excellent abrasion resistance, tear strength, and long-term wear performance. Ideal for high-use applications in fashion and industrial apparel.

-

Customizable Colors & Finishes: WINIW provides full color customization with precise color matching (Pantone, RAL, or client-specific standards). We support matte, glossy, embossed, and soft-touch finishes, enabling brand differentiation and design flexibility.

-

REACH Compliant: All materials are rigorously tested and certified in accordance with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals), ensuring the absence of harmful substances and safe handling throughout the product lifecycle.

-

ISO 9001 Certified Quality Management: WINIW operates under ISO 9001 standards, guaranteeing consistent product quality, traceability, and process efficiency across all production batches.

Technical Specifications

| Property | Spezifikation |

|---|---|

| Material Type | High-performance synthetic leather (PU-based) |

| Thickness Range | 0.6 mm – 1.8 mm (customizable) |

| Weight | 200 – 450 g/m² (varies by backing fabric) |

| Tensile Strength | ≥ 45 N/cm (warp & weft) |

| Elongation at Break | ≤ 35% |

| Color Fastness (ISO 105-B02) | ≥ Grade 4 |

| Martindale Abrasion Resistance | ≥ 30,000 cycles (dry) |

| Cold Crack Resistance | Passes at -20°C |

| REACH Compliance | Full compliance (SVHC < 0.1%) |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Color, thickness, texture, roll length, backing fabric |

Why Partner with WINIW?

- Scalable production for large-volume B2B orders

- Short lead times with reliable global logistics

- Eco-conscious manufacturing with low-VOC emissions

- Dedicated R&D support for custom material development

WINIW’s custom made leather garments deliver a balanced combination of performance, compliance, and cost-efficiency—making them the preferred choice for forward-thinking brands in sustainable and high-quality textile solutions.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Synthetic Leather Garments vs. Real Leather for Fashion Brands

For fashion brands pursuing sustainable innovation and design flexibility, selecting the right material for custom garment production is critical. WINIW specializes in high-performance synthetic leather engineered specifically for B2B applications, offering a compelling alternative to traditional real leather. Below, we objectively compare key considerations for custom-made garment production.

Key Comparison: Custom Synthetic Leather Garments vs. Real Leather

| Factor | Custom Synthetic Leather (WINIW) | Real Leather |

|---|---|---|

| Cost | – Predictable pricing with no hide variation costs – Lower waste in cutting (consistent grain) – Reduced R&D costs for complex customizations (colors, textures) |

– High variability due to hide grading (30-40% waste) – Premium pricing for consistent quality hides – Costly customization (limited dye/finish options) |

| Dauerhaftigkeit | – Consistent strength across batches – Superior resistance to stains, UV fading & moisture – No cracking or water damage in high-stress areas |

– Natural aging (patina) but prone to cracking/drying – Vulnerable to water stains & chemical damage – Durability varies significantly by hide quality |

| Eco-Friendliness | – WINIW Standard: 30-50% recycled content (GRS-certified) – Water-based PU process (0% DMF, low VOC) – 60% lower carbon footprint vs. bovine leather (Higg MSI data) |

– Tanning uses chromium/hazardous chemicals (1.2M tons wastewater/year industry-wide) – High land/water use (17k L water per kg leather) – Non-recyclable at end-of-life |

Why Synthetic Leather is Strategic for Custom Garment Production

- Design Freedom: Achieve exact color matches (Pantone®), embossed textures, or technical properties (stretch, breathability) impossible with real leather.

- Supply Chain Resilience: Avoid hide scarcity and price volatility; WINIW delivers consistent rolls within 30 days globally.

- Waste Reduction: Uniform material structure minimizes cutting waste by 25%+ compared to irregular hides.

- Certification Ready: WINIW’s water-based PU meets OEKO-TEX® STANDARD 100 and REACH, accelerating your sustainability claims.

WINIW’s Sustainable Advantage for Custom Runs

Our custom synthetic leather solutions are engineered for brands committed to circularity:

– Material Innovation: Bio-based PU options (20% plant content) and 100% recycled backing fabrics.

– Traceability: Blockchain-enabled batch tracking from recycled PET bottles to finished roll.

– Low-Impact Production: Solar-powered manufacturing with closed-loop water systems.

For fashion brands scaling custom collections without compromising ethics or design intent, WINIW synthetic leather delivers superior control, consistency, and environmental stewardship. Request our Technical Dossier (TDS-2024) for full specs on custom color/texture development.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, sustainable, and premium-quality materials. Our vertically integrated production capabilities and commitment to excellence position us as a trusted partner in the synthetic leather industry.

Our manufacturing strength is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive campus enables large-scale production while maintaining operational efficiency and flexibility to meet diverse client demands—from custom formulations to high-volume orders.

Key strengths of WINIW’s factory include:

- Advanced R&D team with over 15 years of specialized expertise in synthetic leather innovation, continuously developing eco-friendly materials that meet evolving market needs.

- In-house research and testing laboratories to accelerate product development and ensure performance consistency across applications.

- Strict quality control (QC) protocols implemented at every stage of production, from raw material inspection to final product validation, ensuring compliance with international standards.

- Automated production lines integrated with real-time monitoring systems to enhance precision, reduce waste, and improve batch-to-batch uniformity.

- Environmental stewardship through low-emission processes, solvent recycling systems, and compliance with REACH, RoHS, and other global regulatory frameworks.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products are trusted by leading brands in automotive, furniture, apparel, and accessories industries for their durability, aesthetic refinement, and sustainable profile.

Through continuous innovation and a robust manufacturing foundation, WINIW delivers synthetic leather solutions that combine performance, responsibility, and scalability for global B2B partners.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Solutions for Fashion & Apparel Manufacturing

WINIW delivers high-performance, eco-conscious microfiber leather engineered specifically for B2B fashion and garment production. Our materials combine luxury aesthetics with sustainable manufacturing integrity, meeting the rigorous demands of global apparel brands committed to ethical sourcing and circular design principles.

Core Advantages for Garment Manufacturers

- Superior Performance: Exceptional softness, drape, and breathability rivaling premium genuine leather, with consistent thickness and color fastness for streamlined cutting and sewing.

- Eco-Certified Production: OEKO-TEX® STANDARD 100 Class I certified, REACH compliant, and manufactured using 30% less water vs. conventional leather tanning. Full traceability from raw material to finished roll.

- Design Flexibility: Available in 0.6mm–1.2mm thicknesses, 1,370mm–1,500mm widths, and customizable textures (suede, grain, embossed) to match seasonal collections.

- Durability & Care: Resistant to cracking, fading, and abrasion; compatible with standard garment finishing processes and low-impact cleaning protocols.

- Supply Chain Resilience: Stable pricing, no seasonal raw material shortages, and 30-day lead times for stocked collections.

Key Product Lines for Apparel Applications

| Product Series | Primary Application | Key Features | Sustainability Credentials |

|---|---|---|---|

| WINIW ECO-TEX™ | Lightweight jackets, skirts | 0.6–0.8mm thickness, 4-way stretch, water-repellent finish | 100% recycled polyester backing; GRS certified |

| WINIW LUXE™ | Luxury outerwear, handbags | Deep grain texture, matte finish, 1.0–1.2mm weight | Low-carbon footprint; ISO 14064 verified |

| WINIW ACTIVE™ | Performance wear, accessories | Moisture-wicking, antimicrobial treatment, seamless bonding | Bluesign® approved; OEKO-TEX® ECO PASSPORT |

Custom Solutions for Your Brand Identity

WINIW specializes in end-to-end custom development for private-label leather garments. Our technical team collaborates with your designers to:

– Match exact color, texture, and performance specifications (e.g., vegan leather with recycled content >70%).

– Optimize material weight and flexibility for specific garment types (tailored blazers, fluid dresses, structured bags).

– Integrate functional properties: wind resistance, thermal regulation, or biodegradable coatings.

– Provide full lifecycle analysis (LCA) reports to support your ESG commitments.

Request Custom Samples for Your Next Collection

Accelerate your sustainable design pipeline with complimentary 30cm x 30cm samples of any WINIW microfiber leather. Our material scientists will tailor recommendations to your production requirements, compliance goals, and aesthetic vision.

→ Contact WINIW’s B2B Solutions Team: MKT88@MicrofiberLeather.com

Free samples • Technical datasheets • MOQs from 500m per SKU

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.