Catalog

Material Insight: Custom Leather Labels

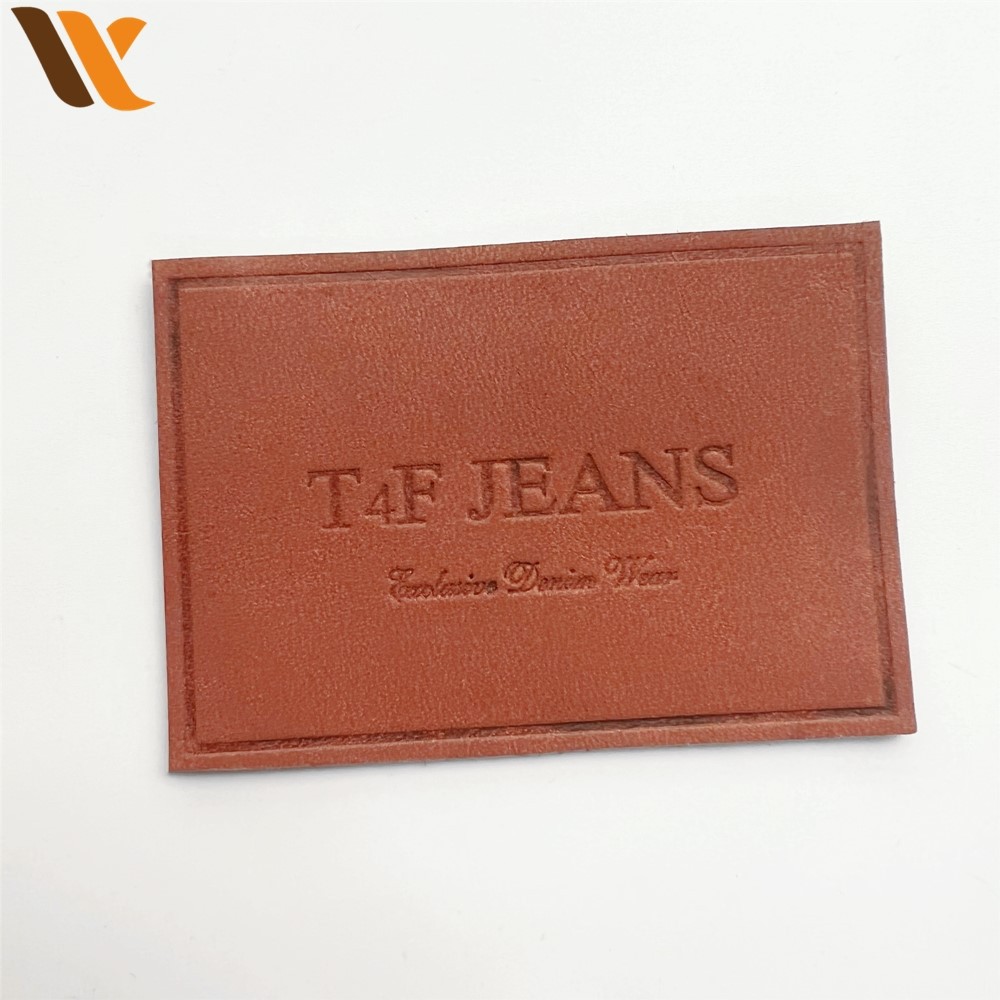

B2B Product Guide: Custom Leather Labels

Custom leather labels serve as a critical touchpoint for brand identity, conveying quality, heritage, and values directly to the end consumer. In today’s market, where sustainability and ethical sourcing are non-negotiable for discerning brands, the material choice for these labels significantly impacts both brand perception and operational efficiency. Traditional genuine leather, while historically popular, presents challenges including inconsistent texture, ethical concerns, higher costs, and vulnerability to cracking or fading—especially when subjected to garment care processes.

Why Faux Leather is the Optimal Choice for Custom Labels:

– Consistent Quality & Precision: Engineered for uniform texture and thickness, faux leather ensures sharp, durable embossing, debossing, and printing—critical for maintaining brand clarity across high-volume production runs.

– Enhanced Durability: Resists cracking, water damage, and UV fading better than genuine leather, ensuring labels retain integrity through washing, wear, and extended shelf life.

– Ethical & Sustainable Compliance: Eliminates animal-derived materials, aligning with vegan certifications and global ESG (Environmental, Social, Governance) standards increasingly mandated by retailers and consumers.

– Cost Efficiency: Offers predictable pricing without the volatility of rawhide markets, reducing total cost of ownership while enabling complex designs at scale.

– Eco-Performance: Modern synthetics (like WINIW’s formulations) use water-based PU, recycled content, and OEKO-TEX® certified processes—minimizing water waste, chemical runoff, and carbon footprint versus tanned leather.

Introducing WINIW: Your Trusted Partner in Precision Synthetic Leather

With over 20 years of specialized R&D in high-performance synthetic materials, WINIW has empowered global apparel, footwear, and accessories brands to elevate their branding sustainably. We combine deep material science expertise with a commitment to circular innovation—delivering custom label solutions that meet stringent eco-certifications (including GRS, ISO 14001) without compromising aesthetics or function. Our vertically integrated production ensures end-to-end supply chain transparency, rapid prototyping, and batch-to-batch consistency tailored to your brand’s exact specifications. When you choose WINIW, you partner with an industry pioneer focused on turning sustainability commitments into tangible, market-ready excellence.

Technical Performance & Standards

B2B Product Guide: WINIW Custom Leather Labels

WINIW’s custom leather labels are engineered for brands seeking a premium, sustainable, and cost-effective branding solution for apparel, accessories, and footwear. Crafted from high-performance synthetic leather, these labels combine durability with design flexibility, meeting the rigorous demands of modern manufacturing and global compliance standards.

Designed specifically for B2B clients, WINIW’s custom leather labels deliver consistent quality, long-term value, and full customization—without compromising on environmental responsibility or regulatory compliance.

Technical Advantages

-

Cost-Effective Production

WINIW uses an optimized manufacturing process that reduces material waste and energy consumption, enabling competitive pricing without sacrificing quality. The synthetic base eliminates the variability and high costs associated with genuine leather sourcing. -

Exceptional Durability

Resistant to abrasion, tearing, and fading, WINIW’s labels maintain integrity through repeated washing, exposure to UV light, and mechanical stress. Ideal for high-use garments and outdoor gear. -

Fully Customizable Colors

Offers unlimited color matching using eco-friendly, non-toxic dyes. Clients can specify Pantone codes or develop proprietary shades for brand consistency across product lines. -

REACH Compliant

All materials and dyes used in WINIW’s custom leather labels comply with EU REACH regulations, ensuring the absence of harmful substances such as phthalates, heavy metals, and carcinogenic amines. -

ISO9001-Certified Manufacturing

Produced in facilities certified under ISO9001 for quality management systems, guaranteeing consistent product performance, traceability, and continuous improvement in production processes.

Application Versatility

WINIW’s custom leather labels are suitable for sew-on, heat-transfer, and woven integration methods. Commonly used in denim, sportswear, luxury bags, and eco-conscious fashion lines.

Product Specifications

| Property | Spezifikation |

|---|---|

| Material Base | Synthetic leather (PU-based, eco-friendly) |

| Thickness | 0.6 mm – 1.0 mm (customizable) |

| Standard Size Range | 20 mm x 30 mm to 50 mm x 80 mm (custom shapes) |

| Color Options | Full Pantone matching; matte, gloss, or textured finishes |

| Durability (Tear Strength) | ≥ 25 N (ASTM D1424) |

| Wash Resistance | Withstands 50+ wash cycles at 40°C |

| UV Resistance | Grade 4–5 (ISO 105-B02) |

| Compliance Standards | REACH, ISO9001, RoHS (on request) |

| Customization Lead Time | 7–10 business days (after artwork approval) |

| MOQ (Minimum Order Qty) | 1,000 units per design |

WINIW’s custom leather labels offer a sustainable, high-performance alternative to traditional leather branding—delivering brand distinction, operational efficiency, and global regulatory alignment for forward-thinking manufacturers and designers.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Synthetic Leather Labels vs. Genuine Leather Labels

For brands prioritizing ethical sourcing, supply chain resilience, and brand integrity, selecting the right label material is a strategic decision. “Custom leather labels” in modern manufacturing contextually refer to synthetic leather labels (typically PU or advanced microfiber-based), engineered to replicate leather aesthetics without animal-derived materials. This guide compares them directly against genuine leather labels for informed procurement decisions.

Key Considerations for Brand Partners

- Brand Alignment: Synthetic labels offer full traceability and alignment with cruelty-free, vegan, and circular economy commitments demanded by conscious consumers.

- Design Flexibility: Achieve precise color matching, intricate embossing, and consistent textures impossible with variable genuine leather hides.

- Supply Chain Security: Eliminate volatility from livestock markets and tannery shortages; synthetic production is scalable and region-agnostic.

- Regulatory Compliance: Avoid REACH/EPA concerns tied to chrome-tanning chemicals (e.g., Cr(VI)) prevalent in conventional leather processing.

Performance & Sustainability Comparison

| Kriterien | Custom Synthetic Leather Labels (WINIW®) | Genuine Leather Labels |

|---|---|---|

| Cost | – Material: 30-50% lower raw material cost – Produktion: Streamlined cutting (no hide grading); 20% faster turnaround – Long-term: Reduced waste (up to 95% yield) lowers unit cost at scale |

– Material: High hide variability inflates cost (premium grades only) – Produktion: Labor-intensive grading/cutting; 15-30% material waste – Long-term: Price volatility from livestock/tannery markets |

| Dauerhaftigkeit | – Tragen Sie: Resists cracking, fading, and moisture (ideal for washable apparel) – Elements: Non-porous; unaffected by humidity/salt exposure – Consistency: Uniform thickness and performance batch-to-batch |

– Tragen Sie: Prone to drying, cracking in low-humidity environments – Elements: Absorbs moisture; susceptible to mold/staining – Consistency: Natural grain variations cause quality discrepancies |

| Eco-Friendliness | – Resources: 70% lower water use vs. tanning; uses recycled PET or plant-based polymers – Chemicals: PFC-free, metal-free; OEKO-TEX® certified production – End-of-Life: Recyclable via WINIW® Reclaim Program; bio-based options commercially compostable |

– Resources: 17,000L+ water per kg of leather; high land/feed footprint – Chemicals: Chrome-tanning generates toxic sludge (30% of global Cr(VI) pollution) – End-of-Life: Non-biodegradable due to tanning agents; landfill-bound |

Strategic Recommendation

For B2B partners committed to scalable sustainability without compromising aesthetics, WINIW® synthetic leather labels are the unequivocal choice. They deliver:

– Cost predictability through stable input pricing and near-zero production waste.

– Enhanced durability for labels exposed to frequent handling or environmental stressors.

– Verified eco-credentials via third-party certifications (GRS, ISO 14001) and closed-loop recycling.

Genuine leather labels carry inherent ethical and environmental liabilities incompatible with modern ESG frameworks. WINIW®’s advanced microfiber technology (e.g., WINIW® EcoLux) achieves leather-like drape and texture while exceeding it in performance consistency and lifecycle responsibility. Partner with us to future-proof your label sourcing—contact our technical team for material samples and lifecycle assessment data.

WINIW: Engineering Sustainable Materials for Responsible Brands Since 1996

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our vertically integrated production ecosystem is built on advanced technology, sustainable practices, and rigorous quality assurance, making us a trusted partner across industries such as automotive, fashion, furniture, and technical textiles.

Our state-of-the-art manufacturing facility spans over 100,000 square meters, one of the largest in the synthetic leather industry. This expansive campus enables us to maintain full control over every stage of production—from raw material processing to final finishing—ensuring efficiency, scalability, and consistency in every batch.

Key factory strengths include:

- A dedicated R&D team of over 100 engineers and material scientists focused on developing next-generation synthetic leather solutions. Our innovations include water-based, solvent-free, and recycled content materials that meet evolving environmental standards.

- Advanced production lines equipped with automated monitoring systems for precision coating, embossing, and laminating, supporting customization in texture, thickness, color, and performance properties.

- Strict quality control protocols implemented throughout the production cycle. Each product undergoes comprehensive testing for abrasion resistance, color fastness, tensile strength, and environmental compliance (including REACH, RoHS, and OEKO-TEX® standards).

- In-house testing laboratory accredited to international standards, ensuring consistent product reliability and traceability.

- Sustainable manufacturing practices, including closed-loop water systems, energy-efficient machinery, and low-emission processes, aligning with global ESG goals.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products are trusted by leading brands for their durability, aesthetic quality, and compliance with stringent regulatory requirements. With a logistics network designed for timely delivery and a customer-centric approach to technical support, WINIW delivers scalable, high-quality synthetic leather solutions that meet the demands of modern industries.

Contact Us for Samples

WINIW Microfiber Leather: Premium Sustainable Solutions for Discerning Brands

WINIW delivers high-performance synthetic leather engineered for durability, aesthetics, and environmental responsibility. Our PU/PVC-free microfiber substrates, crafted with up to 40% recycled content, meet rigorous global compliance standards (REACH, OEKO-TEX® STANDARD 100) while offering exceptional breathability and tear resistance. Ideal for automotive, furniture, and luxury accessories, WINIW materials reduce carbon footprint without compromising on quality or design flexibility.

Key Advantages for Your Production Line

- Eco-Certified Performance: Water-based finishing processes eliminate DMF and VOC emissions; 100% recyclable backing options available

- Superior Physical Properties: 30% higher abrasion resistance vs. conventional synthetics; consistent thickness tolerance (±0.1mm) for precision cutting

- Design Versatility: 500+ stock colors/finishes; custom embossing and texture development within 15 business days

- Supply Chain Security: ISO 9001-certified manufacturing; 99.5% on-time delivery rate with global warehousing

Technical Specification Comparison

| Property | WINIW Standard Line | WINIW EcoPro™ Premium | Industry Average |

|---|---|---|---|

| Basis Weight (g/m²) | 380-420 | 350-400 | 400-450 |

| Tensile Strength (MPa) | 28-32 | 35-40 | 22-26 |

| Martindale Rubs (min) | 50,000 | 100,000+ | 30,000 |

| Recycelter Inhalt | 25% | 40% | 0-10% |

| Water Absorption (%) | <8 | <5 | 15-20 |

Elevate Your Brand Identity with Custom Leather Labels

Differentiate your products with bespoke WINIW leather labels featuring:

– Zero-waste laser-cut shapes (logos, tags, hang tags)

– Deep embossing or metallic foil stamping

– Biodegradable adhesive options

– Minimum order: 500 units

Request custom leather labels today

Contact our Material Innovation Team at MKT88@MicrofiberLeather.com to discuss specifications. Mention code LABEL24 for complimentary sample swatches of our label substrates. Free production samples available for qualified B2B partners.

WINIW: Where sustainable innovation meets uncompromising performance. Partner with us to transform your material vision into reality.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.