Introduction: Navigating the Global Market for crush customs leather seats

Navigating the complexities of sourcing crush customs leather seats can be a daunting task for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. With a growing demand for personalized automotive interiors that reflect unique brand identities and customer preferences, understanding the nuances of this market is crucial. This guide offers a comprehensive exploration of various types of leather seating, their applications in different vehicle categories, and the intricacies of supplier vetting processes.

Buyers will gain insights into the cost factors associated with custom leather installations, including quality variations and installation services, ensuring they make informed decisions that align with their budget and expectations. Additionally, the guide highlights key considerations for selecting reliable suppliers, including quality assurance, warranty offerings, and customer service experiences.

By empowering B2B buyers with essential knowledge and actionable strategies, this guide aims to facilitate smarter purchasing decisions in the competitive landscape of crush customs leather seats. Whether you are in Nigeria looking to elevate your automotive offerings or in Brazil seeking to enhance customer satisfaction with premium interiors, this resource is designed to support your business goals and drive success in the global market.

Table Of Contents

- Top 4 Crush Customs Leather Seats Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for crush customs leather seats

- Understanding crush customs leather seats Types and Variations

- Key Industrial Applications of crush customs leather seats

- 3 Common User Pain Points for ‘crush customs leather seats’ & Their Solutions

- Strategic Material Selection Guide for crush customs leather seats

- In-depth Look: Manufacturing Processes and Quality Assurance for crush customs leather seats

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘crush customs leather seats’

- Comprehensive Cost and Pricing Analysis for crush customs leather seats Sourcing

- Alternatives Analysis: Comparing crush customs leather seats With Other Solutions

- Essential Technical Properties and Trade Terminology for crush customs leather seats

- Navigating Market Dynamics and Sourcing Trends in the crush customs leather seats Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of crush customs leather seats

- Strategic Sourcing Conclusion and Outlook for crush customs leather seats

- Important Disclaimer & Terms of Use

Understanding crush customs leather seats Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Custom Leather | Basic customization options, standard colors, and textures | Fleet vehicles, rental services | Pros: Cost-effective, quick installation. Cons: Limited personalization. |

| Premium Leather Seats | High-quality leather, extensive color and texture choices | Luxury car dealerships, high-end rentals | Pros: Superior comfort, enhanced aesthetics. Cons: Higher cost, longer lead times. |

| Performance Leather | Sports-oriented designs, enhanced durability and grip | Sports car manufacturers, automotive performance shops | Pros: Improved driving experience, enhanced performance. Cons: May not suit all vehicle types. |

| Eco-Friendly Leather | Sustainable materials, environmentally friendly production | Green automotive brands, eco-conscious consumers | Pros: Appeals to eco-friendly markets, unique selling point. Cons: Potentially higher costs. |

| Heated & Cooled Seats | Integrated heating and cooling technology | Luxury vehicles, fleet services | Pros: Increased comfort, year-round usability. Cons: More complex installation, higher maintenance. |

What Are the Key Characteristics of Standard Custom Leather Seats?

Standard custom leather seats offer essential customization with a focus on functionality rather than luxury. These seats typically come in a limited range of colors and textures, making them suitable for fleet vehicles or rental services where budget constraints are a priority. B2B buyers should consider the balance between cost-effectiveness and the need for a cohesive look across multiple vehicles, ensuring that the customization meets the brand’s identity without overspending.

How Do Premium Leather Seats Stand Out in the Market?

Premium leather seats are characterized by their high-quality materials and a wide variety of customization options. They cater to luxury car dealerships and high-end rental services aiming to provide an upscale experience. Buyers must weigh the benefits of enhanced comfort and aesthetic appeal against the higher costs and longer installation times, as these factors can significantly impact customer satisfaction and resale value.

What Makes Performance Leather Seats Ideal for Sports Vehicles?

Performance leather seats are designed for sports cars, offering enhanced durability and grip. These seats often feature sporty designs that appeal to automotive performance enthusiasts. B2B buyers in the sports car manufacturing sector should consider how these seats can improve the overall driving experience and attract a niche market, while also being mindful of their compatibility with various vehicle models.

Why Should Eco-Friendly Leather Be Considered by B2B Buyers?

Eco-friendly leather seats are made from sustainable materials, appealing to environmentally conscious brands and consumers. These seats can be a unique selling point for green automotive brands looking to differentiate themselves in a competitive market. While the initial costs may be higher, the long-term benefits of attracting eco-aware customers and enhancing brand reputation can outweigh the downsides.

What Are the Advantages of Heated and Cooled Seats for B2B Buyers?

Heated and cooled seats provide integrated comfort technology, making them highly desirable for luxury vehicles and fleet services. These seats enhance user experience across various climates, appealing to a wide range of consumers. Buyers should consider the complexity of installation and potential maintenance issues, but the added comfort can justify the investment, especially in markets where climate varies significantly.

Key Industrial Applications of crush customs leather seats

| Industry/Sector | Specific Application of crush customs leather seats | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom interior upgrades for luxury vehicles | Enhances brand image and customer satisfaction | Quality of leather, customization options, and warranty |

| Hospitality | High-end seating solutions for hotels and restaurants | Provides a luxurious experience, increasing guest retention | Durability, maintenance requirements, and aesthetic appeal |

| Transportation | Fleet vehicle upgrades for comfort and branding | Improves driver and passenger comfort, enhancing company image | Compliance with safety standards and ease of cleaning |

| Marine Industry | Custom seating for yachts and luxury boats | Elevates onboard experience, attracting affluent clients | Resistance to moisture, customization capabilities |

| Event Management | VIP seating solutions for conferences and exhibitions | Creates a sophisticated atmosphere, enhancing attendee experience | Portability, ease of maintenance, and design flexibility |

How Are Crush Customs Leather Seats Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, crush customs leather seats are employed to upgrade the interiors of luxury vehicles. This application enhances the overall aesthetic and comfort of the vehicle, addressing consumer demand for high-quality interiors. Buyers in this sector often require specific customization options to align with brand standards and consumer expectations. Key considerations include the quality of leather, the range of colors and textures available, and warranty offerings to ensure long-lasting satisfaction.

What Benefits Do Crush Customs Leather Seats Offer to the Hospitality Industry?

In the hospitality industry, crush customs leather seats are utilized in hotels and restaurants to create a luxurious ambiance. These seats not only enhance the aesthetic appeal of the establishment but also provide comfort, which is crucial for guest satisfaction and retention. Businesses must consider the durability of the leather, as well as maintenance requirements, to ensure that the seating remains pristine over time. Aesthetic appeal is also vital, as it should match the overall theme and style of the venue.

How Do Crush Customs Leather Seats Improve Transportation Services?

For transportation companies, custom leather seats in fleet vehicles significantly enhance both driver and passenger comfort. This application is essential for businesses aiming to improve their brand image and customer experience. Buyers in this sector should focus on compliance with safety standards, as well as the ease of cleaning and maintaining the leather upholstery, ensuring that the fleet remains presentable and functional over time.

Why Are Crush Customs Leather Seats Important in the Marine Industry?

In the marine industry, crush customs leather seats are tailored for use in yachts and luxury boats, elevating the onboard experience for passengers. This application addresses the need for high-quality, comfortable seating that can withstand the marine environment. Buyers must consider the resistance of the leather to moisture and UV damage, as well as the customization capabilities that allow for unique designs that reflect the owner’s style.

How Can Event Management Benefit from Crush Customs Leather Seats?

Event management companies utilize crush customs leather seats for VIP areas at conferences and exhibitions, creating a sophisticated atmosphere that enhances the attendee experience. This application is critical for attracting high-profile clients and sponsors. Key sourcing considerations include the portability of the seating, ease of maintenance, and design flexibility to fit various event themes and layouts.

3 Common User Pain Points for ‘crush customs leather seats’ & Their Solutions

Scenario 1: Difficulty in Customization Alignment with Brand Identity

The Problem: B2B buyers often struggle to find custom leather seat solutions that align with their brand identity and vision. For instance, a luxury car dealership might seek to enhance their vehicles’ interiors with high-end materials that reflect their branding. However, they may face challenges in sourcing leather seats that not only match the aesthetic of their vehicles but also resonate with their target market’s preferences. This misalignment can lead to dissatisfaction among customers who expect a cohesive luxury experience.

The Solution: To ensure that the custom leather seats meet both aesthetic and brand alignment, B2B buyers should engage in a detailed consultation process with Crush Customs. During this consultation, buyers should provide comprehensive insights into their brand identity, including color palettes, textures, and overall design themes. By leveraging Crush Customs’ expertise in personalized design, buyers can collaborate on selecting the right materials and finishes that enhance their vehicles’ interiors while remaining true to their brand. Additionally, requesting sample swatches or prototypes can help visualize the final product and confirm that it aligns perfectly with the desired brand experience.

Scenario 2: Concerns About Installation Quality and Longevity

The Problem: Many B2B buyers worry about the installation quality of custom leather seats, fearing that poor craftsmanship could lead to premature wear and tear or even safety issues. For example, a fleet manager responsible for outfitting company vehicles may be anxious about how well the seats will withstand daily use by multiple drivers. If the installation is not up to standard, it could result in costly repairs or replacements, which can affect the fleet’s operational efficiency and budget.

The Solution: To alleviate concerns about installation quality, B2B buyers should prioritize working with a reputable provider like Crush Customs, known for its skilled craftsmanship and attention to detail. It’s advisable for buyers to inquire about the company’s warranty and service guarantees, such as the three-year, 36,000-mile warranty offered by Crush Customs. This assurance indicates a commitment to quality and durability. Additionally, buyers should request detailed information on the installation process, including the types of adhesives and techniques used, to ensure that they meet industry standards. Conducting site visits or reviewing case studies of previous installations can also provide confidence in the provider’s capabilities.

Scenario 3: Navigating Compliance and Regulatory Standards

The Problem: B2B buyers, particularly in regions with strict automotive regulations, often find it challenging to navigate compliance when selecting custom leather seats. For instance, a car manufacturer in Europe might face stringent environmental and safety regulations regarding the materials used in their vehicles. They may be unsure whether aftermarket customizations will meet these regulations, potentially leading to legal complications or additional costs.

The Solution: To effectively navigate compliance and regulatory standards, B2B buyers should proactively engage in discussions with Crush Customs about their specific regional requirements. Buyers should inquire about the materials used in the leather seats and ensure that they are sourced from sustainable and compliant suppliers. Additionally, it is beneficial to request documentation that certifies the materials meet local regulations. Buyers can also consult with legal experts or industry associations to gain clarity on compliance issues specific to their market. By taking these proactive steps, buyers can confidently invest in custom leather seats that enhance their vehicles while adhering to all necessary regulations.

Strategic Material Selection Guide for crush customs leather seats

What Are the Key Properties of Common Materials for Crush Customs Leather Seats?

When selecting materials for crush customs leather seats, it is essential to consider various factors that influence performance, durability, and overall suitability for specific applications. Below, we analyze four common materials used in the production of leather seats, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Genuine Leather: The Classic Choice

Key Properties: Genuine leather is known for its natural grain, breathability, and ability to age gracefully. It typically withstands a temperature range of -30°C to 50°C and has good resistance to wear and tear.

Pros & Cons: The primary advantage of genuine leather is its luxurious appearance and feel, which can significantly enhance the aesthetic value of any vehicle. However, it is relatively expensive and requires regular maintenance to prevent cracking and fading. The manufacturing process can be complex, involving tanning and finishing, which may lead to longer lead times.

Impact on Application: Genuine leather is compatible with a wide range of automotive interiors, providing a premium feel. However, it may not be suitable for high-humidity environments unless treated for moisture resistance.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider climate conditions that may affect leather durability. Compliance with international standards such as ASTM and JIS for leather quality is also crucial.

Synthetic Leather (PU Leather): The Economical Alternative

Key Properties: Synthetic leather, particularly polyurethane (PU) leather, offers a temperature tolerance of -20°C to 60°C and is resistant to abrasion and fading.

Pros & Cons: The key advantage of synthetic leather is its cost-effectiveness and ease of maintenance. It is easier to clean and does not require conditioning like genuine leather. However, it may lack the luxurious feel and breathability of natural leather, which can affect comfort over time.

Impact on Application: Synthetic leather is suitable for various applications, including budget-friendly vehicles and fleet cars. Its resistance to moisture makes it a good choice for humid climates.

Considerations for International Buyers: Buyers should ensure that the synthetic leather complies with local environmental regulations, particularly regarding VOC emissions. Preferences for sustainable materials are rising in Europe, which may influence purchasing decisions.

Alcantara: The Premium Synthetic Option

Key Properties: Alcantara is a high-end synthetic material that mimics the look and feel of suede. It has excellent temperature resistance, typically ranging from -30°C to 70°C, and is known for its durability and stain resistance.

Pros & Cons: The primary advantage of Alcantara is its luxurious appearance and soft texture, making it a popular choice for high-end vehicles. However, it is more expensive than standard synthetic leather and may require special cleaning products to maintain its appearance.

Impact on Application: Alcantara is often used in luxury vehicles and sports cars, providing a unique aesthetic appeal. Its breathability and moisture-wicking properties make it suitable for various climates.

Considerations for International Buyers: Buyers should verify that Alcantara meets the necessary safety and quality standards in their region. The material’s higher cost may also require justification in budget-sensitive markets like Nigeria and Brazil.

Vinyl: The Durable, Low-Cost Material

Key Properties: Vinyl is a synthetic material known for its durability and resistance to moisture, with a temperature tolerance of -30°C to 70°C.

Pros & Cons: Vinyl is highly resistant to stains and easy to clean, making it a practical choice for family vehicles and commercial applications. However, it can feel less luxurious compared to leather options and may not provide the same level of comfort over long periods.

Impact on Application: Vinyl is commonly used in budget vehicles and fleet applications where durability is prioritized over aesthetics. Its resistance to moisture makes it suitable for humid and wet environments.

Considerations for International Buyers: Buyers should consider the environmental impact of vinyl production and ensure compliance with local regulations. In regions like the Middle East, where high temperatures are common, vinyl’s heat resistance can be a significant advantage.

Summary Table of Material Selection for Crush Customs Leather Seats

| Material | Typical Use Case for crush customs leather seats | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Luxury vehicles, high-end custom interiors | Luxurious feel and appearance | Expensive, requires maintenance | High |

| Synthetic Leather (PU) | Budget-friendly vehicles, fleet cars | Cost-effective, easy to clean | Less luxurious feel | Medium |

| Alcantara | Luxury vehicles, sports cars | Soft texture, high-end appearance | Higher cost, requires special care | High |

| Vinyl | Family vehicles, commercial applications | Highly durable, moisture-resistant | Less luxurious, can be uncomfortable | Low |

This guide provides a comprehensive overview of material options for crush customs leather seats, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for crush customs leather seats

What Are the Main Stages of Manufacturing Crush Customs Leather Seats?

The manufacturing process for Crush Customs leather seats involves several critical stages that ensure the final product meets high standards of quality and durability. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation: How Is Quality Leather Selected?

The first step in the manufacturing process is the selection and preparation of high-quality leather. Crush Customs sources leather from reputable suppliers, emphasizing the importance of full-grain or top-grain leather, which offers superior durability and aesthetic appeal. Each hide undergoes thorough inspection to identify any imperfections or inconsistencies.

Once selected, the leather is treated using eco-friendly tanning processes to enhance its longevity and resistance to wear. This step is vital, as the quality of the leather directly impacts the performance and look of the finished seats.

Forming: What Techniques Are Used to Shape the Leather?

After the leather is prepared, it moves to the forming stage. This involves cutting the leather into specific patterns designed for each vehicle model. Advanced cutting techniques, such as laser cutting, are employed to achieve precision and minimize waste.

In addition to cutting, the leather is often pre-treated to improve its flexibility and workability during the assembly phase. This ensures that the final product will fit snugly and securely in the vehicle, enhancing both comfort and aesthetics.

Assembly: How Are Crush Customs Leather Seats Constructed?

The assembly process is where the real craftsmanship comes into play. Skilled artisans at Crush Customs meticulously stitch the leather components together, often using heavy-duty threads that resist fraying and wear. This stage may also involve the integration of foam padding for added comfort, which is cut and shaped to fit the contours of the seat.

Quality control is integrated into the assembly process, with workers checking for consistency in stitching and alignment. This attention to detail is crucial in maintaining the luxurious look and feel that Crush Customs is known for.

Finishing: What Final Touches Are Applied to Ensure Quality?

Finishing is the last stage in the manufacturing process, where the seats receive their final touches. This may include dyeing, polishing, or applying protective coatings to enhance durability and maintain the leather’s natural luster.

At this stage, additional features such as custom embroidery or piping can be added based on customer specifications. The finishing process is crucial for ensuring that the seats not only look appealing but also withstand daily use and environmental factors.

What Quality Assurance Standards Are Followed in Leather Seat Manufacturing?

Quality assurance is a cornerstone of the manufacturing process at Crush Customs, ensuring that each product meets international standards and customer expectations.

Which International Standards Are Relevant for Quality Control?

Crush Customs adheres to several international quality standards, including ISO 9001, which emphasizes a systematic approach to managing quality. This standard requires regular audits and continuous improvement practices, ensuring that the manufacturing processes remain effective and efficient.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are also considered, particularly when it comes to the materials used in production and their environmental impact.

What Are the Key Quality Control Checkpoints?

Quality control at Crush Customs is integrated into every stage of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): Before production begins, all materials, including leather and foam, undergo rigorous inspection to ensure they meet predefined quality criteria.

-

In-Process Quality Control (IPQC): Throughout the assembly phase, quality checks are performed to monitor stitching accuracy, material alignment, and overall workmanship.

-

Final Quality Control (FQC): Once the seats are fully assembled, a comprehensive quality assessment is conducted. This includes visual inspections, functionality tests, and stress tests to evaluate durability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality assurance practices of their suppliers.

What Methods Are Available for Supplier Verification?

-

Audits: Conducting supplier audits is an effective way to assess quality control practices firsthand. Buyers can schedule regular visits to manufacturing facilities to observe processes and check compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s performance metrics, including defect rates, customer feedback, and compliance with industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and product quality. This is particularly useful for buyers unfamiliar with the local manufacturing landscape.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers should be aware of several nuances when dealing with quality control in leather seat manufacturing.

Are There Regional Variations in Quality Standards?

Different regions may have varying expectations regarding quality standards. For instance, buyers from Europe may prioritize stringent environmental regulations, while those from Africa may focus more on cost-effectiveness. It’s essential for buyers to communicate their specific requirements and understand how suppliers can meet these expectations.

How Do Import Regulations Affect Quality Assurance?

Import regulations can also impact quality assurance practices. Buyers should familiarize themselves with import standards in their home countries, as non-compliance can lead to delays or additional costs. Ensuring that suppliers are aware of and comply with these regulations is vital for a smooth procurement process.

By understanding the manufacturing processes and quality assurance measures in place at Crush Customs, international B2B buyers can make informed decisions, ensuring they choose a supplier capable of delivering high-quality leather seats that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘crush customs leather seats’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure Crush Customs leather seats. Whether you are a car dealership, an automotive restoration company, or an individual looking to enhance your vehicle’s interior, following these steps will ensure you make informed decisions and secure quality products that align with your business goals.

Step 1: Define Your Technical Specifications

Clearly outlining your requirements is essential before engaging with suppliers. Determine the type of leather, color, design, and custom features you desire, as well as the specific vehicle models these seats will be installed in. This clarity will not only streamline the procurement process but also ensure that the supplier can meet your exact needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in custom leather seats. Look for companies with a proven track record, positive client reviews, and robust portfolios showcasing their work. Prioritize suppliers who have experience with your specific vehicle types, as they will better understand the nuances of different models.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their industry certifications and standards. Certifications can indicate a commitment to quality and safety, which is particularly important in automotive upholstery. Additionally, check for warranties offered on their products, such as the three-year, 36,000-mile warranty that reputable suppliers provide.

Step 4: Request Samples and Product Information

Always ask for samples of the leather materials and detailed product specifications. This will allow you to assess the quality, texture, and durability of the leather before making a bulk purchase. Pay attention to the weight and feel of the leather, as well as any additional features like stain resistance or easy maintenance.

Step 5: Inquire About Customization Options

Discuss customization options with potential suppliers. Understanding their capabilities in terms of color matching, stitching patterns, and additional features such as heated seats or lumbar support is crucial. Customization can significantly enhance the appeal of your offerings, so ensure that the supplier can accommodate your unique requests.

Step 6: Assess Lead Times and Logistics

Inquire about the lead times for production and delivery. Timely delivery is critical for maintaining your business schedule and fulfilling customer orders. Additionally, discuss logistics, including shipping options and costs, to avoid unexpected expenses that could affect your bottom line.

Step 7: Establish Communication Channels

Effective communication is key to a successful partnership. Establish clear lines of communication with your supplier to ensure you can address any issues or questions that may arise during the procurement process. Regular updates on production status and delivery timelines can help you manage your inventory and customer expectations effectively.

By following these steps, you will be better positioned to source high-quality Crush Customs leather seats that meet your specifications and enhance your product offerings.

Comprehensive Cost and Pricing Analysis for crush customs leather seats Sourcing

What Are the Key Cost Components in Sourcing Crush Customs Leather Seats?

Understanding the cost structure of sourcing custom leather seats is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

-

Materials: The quality of leather used significantly impacts the price. Top-grain and full-grain leathers are more expensive due to their durability and luxurious feel. Additionally, sourcing locally produced leather versus imported leather can affect costs, particularly for buyers in regions like Africa and South America.

-

Labor: Skilled labor is crucial for the installation and customization of leather seats. The expertise of the workforce can vary by region, influencing labor costs. Countries with a robust vocational training system may offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. A well-established manufacturer may have lower overhead costs due to economies of scale, which can translate into more competitive pricing for buyers.

-

Tooling: Customization often requires specific tools and equipment, especially for unique designs. Initial tooling costs can be significant but are amortized over larger production runs.

-

Quality Control (QC): Ensuring that the leather seats meet high-quality standards incurs additional costs. Investments in QC processes enhance product reliability and can reduce returns, making them worthwhile for both manufacturers and buyers.

-

Logistics: Shipping costs vary significantly based on distance, mode of transport, and Incoterms. International buyers must consider customs duties and taxes, which can inflate the final price.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainability. Understanding the average margin in the industry can help buyers gauge the fairness of quoted prices.

What Price Influencers Should Buyers Consider When Sourcing Leather Seats?

Several factors can influence pricing in the custom leather seat market:

-

Volume/MOQ: Larger orders often lead to discounted pricing due to economies of scale. Buyers should negotiate minimum order quantities to secure better rates.

-

Specifications/Customization: Unique designs or specialized features (such as heated seats) can increase costs. Buyers should prioritize essential features to manage expenses effectively.

-

Materials: The choice between synthetic and genuine leather can dramatically alter costs. Buyers should assess their budget against the desired quality and aesthetics.

-

Quality and Certifications: Certifications for sustainability or environmental impact may add to the cost. Buyers should weigh the long-term benefits of certified products against upfront costs.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can impact pricing and lead times. Establishing a relationship with trusted suppliers can mitigate risks associated with quality and delivery.

-

Incoterms: Understanding shipping terms can affect the total cost. Buyers should clarify who is responsible for transportation, insurance, and duties to avoid unexpected expenses.

What Are Some Buyer Tips for Cost-Efficiency in Leather Seats Procurement?

-

Negotiation: Engage in open discussions with suppliers to negotiate terms, especially for larger orders. Highlighting long-term partnership potential can often yield better pricing.

-

Total Cost of Ownership (TCO): Consider not only the upfront costs but also the long-term benefits of leather seats, such as durability and resale value. High-quality leather can provide a better TCO compared to cheaper alternatives.

-

Pricing Nuances for International Buyers: For buyers in regions like Nigeria or Brazil, consider currency fluctuations and local economic conditions that might affect pricing. Understanding these factors can help in timing purchases strategically.

-

Market Research: Conduct thorough market research to compare pricing and quality from multiple suppliers. This knowledge empowers buyers to make informed decisions and negotiate effectively.

-

Trial Orders: For new suppliers, consider placing smaller trial orders to assess quality and service before committing to larger purchases. This approach minimizes risk while evaluating supplier capabilities.

Disclaimer on Indicative Prices

Prices for custom leather seats can vary widely based on the aforementioned factors. It is advisable for buyers to request detailed quotes from multiple suppliers to obtain a comprehensive understanding of pricing structures specific to their needs and market conditions.

Alternatives Analysis: Comparing crush customs leather seats With Other Solutions

Introduction to Alternatives in Custom Automotive Seating

When considering upgrades to automotive interiors, particularly for leather seating, it’s essential to evaluate various options available in the market. While Crush Customs leather seats are a premium choice, other solutions exist that may cater to different needs, budgets, and preferences. This section will compare Crush Customs leather seats against viable alternatives, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table of Custom Leather Seating Solutions

| Comparison Aspect | Crush Customs Leather Seats | Synthetic Leather Seats | Cloth Upholstery |

|---|---|---|---|

| Performance | High durability and comfort | Moderate durability, less luxurious feel | Good comfort but less durable |

| Cost | Higher price point due to customization | Generally lower cost | Lowest initial cost |

| Ease of Implementation | Requires professional installation | Easier to install, often DIY-friendly | Simple installation, widely available |

| Maintenance | Requires occasional conditioning | Easy to clean, less maintenance | Requires regular cleaning, prone to stains |

| Best Use Case | Luxury vehicles, custom builds | Budget-conscious buyers, family vehicles | Fleet vehicles, budget constraints |

Detailed Breakdown of Alternatives

Synthetic Leather Seats

Synthetic leather, often referred to as “vegan leather” or “faux leather,” offers a cost-effective alternative to Crush Customs leather seats. These materials provide a similar aesthetic appeal, are easier to clean, and require minimal maintenance. However, they generally lack the luxurious feel and durability of genuine leather, making them less suitable for high-end vehicles. Synthetic leather can be a great option for budget-conscious buyers or family vehicles where practicality is prioritized over luxury.

Cloth Upholstery

Cloth upholstery is a traditional choice that remains popular due to its affordability and comfort. It is widely available and can be installed relatively easily, even by DIY enthusiasts. However, cloth seats tend to absorb stains and odors more readily than leather or synthetic options, requiring more frequent cleaning. While ideal for fleet vehicles or budget-sensitive projects, cloth upholstery may not convey the same level of sophistication or long-term durability that buyers expect from high-end or custom vehicles.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right seating solution for automotive interiors depends on various factors, including budget, intended use, and desired aesthetics. For buyers looking for a luxurious, durable option, Crush Customs leather seats stand out despite their higher price point and professional installation requirement. Conversely, synthetic leather and cloth upholstery may offer viable solutions for those prioritizing cost and ease of installation. Ultimately, B2B buyers should assess their specific needs and preferences to make an informed decision that aligns with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for crush customs leather seats

What Are the Key Technical Properties of Crush Customs Leather Seats?

Understanding the essential specifications of crush customs leather seats is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical technical properties that define the quality and performance of these custom leather seats:

-

Material Grade

Leather is categorized by its grade, which refers to the quality and type of hide used. Common grades include full-grain, top-grain, and corrected grain. Full-grain leather, for instance, is the highest quality, retaining the natural texture and imperfections of the hide, making it more durable and aesthetically appealing. For buyers, understanding material grade is vital as it directly influences the longevity, appearance, and resale value of the vehicle. -

Thickness

The thickness of leather is typically measured in millimeters. Standard automotive leather ranges from 0.9mm to 1.4mm. Thicker leather tends to be more durable and resistant to wear, making it an ideal choice for high-traffic areas like car seats. Buyers should consider thickness when assessing durability and comfort, as thicker leather can provide a more luxurious feel but may also affect flexibility. -

Abrasion Resistance

This property measures how well the leather withstands wear and tear from friction. It’s particularly important in automotive applications where seats are subjected to daily use. High abrasion resistance ensures that the leather maintains its aesthetic appeal over time. Buyers should inquire about abrasion testing standards to ensure the product will perform well in real-world conditions. -

UV Resistance

Exposure to sunlight can lead to fading and deterioration of leather materials. UV resistance indicates how well the leather can withstand sun exposure without losing its color or structural integrity. This is especially critical for international buyers in regions with intense sunlight, as it affects both the longevity of the seats and the overall comfort of the vehicle. -

Moisture Resistance

This property defines how well the leather can resist water and humidity. Moisture-resistant leather prevents mold growth and degradation, making it suitable for diverse climates. B2B buyers should prioritize moisture resistance to ensure the longevity and hygiene of their products, particularly in humid regions like parts of Africa and South America.

What Common Trade Terms Should B2B Buyers Know When Purchasing Leather Seats?

Navigating the B2B landscape requires familiarity with industry-specific jargon. Here are some essential trade terms that are relevant when dealing with crush customs leather seats:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures parts or equipment that may be marketed by another manufacturer. In the context of leather seats, OEM products are made to match the specifications of original vehicle designs. Buyers often prefer OEM parts for their reliability and compatibility. -

MOQ (Minimum Order Quantity)

This term signifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and cost efficiency. For instance, a supplier may set an MOQ of 50 units for custom leather seats, influencing bulk purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for specific products. This is a critical step in the procurement process, enabling buyers to compare offers and negotiate terms effectively. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers manage logistics and understand their obligations in cross-border transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For custom leather seats, lead time can vary based on design complexity and material availability. Understanding lead times helps buyers plan effectively and manage customer expectations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right products that meet their operational needs and market demands.

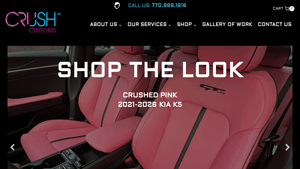

Illustrative image related to crush customs leather seats

Navigating Market Dynamics and Sourcing Trends in the crush customs leather seats Sector

What Are the Key Market Dynamics and Trends Influencing the Crush Customs Leather Seats Sector?

The crush customs leather seats market is experiencing a notable transformation, driven by several global trends that are reshaping the automotive upholstery landscape. The demand for personalized and high-quality interiors is surging, particularly among international B2B buyers in regions like Africa, South America, the Middle East, and Europe. This shift is fueled by a growing preference for luxury and comfort in vehicles, as consumers increasingly seek unique designs that reflect their individual styles.

Technological advancements are also playing a crucial role. Innovations in materials and manufacturing processes are enabling suppliers to offer a wider range of customizable options, such as heated and cooled seats and advanced ergonomic designs. Additionally, the rise of e-commerce platforms is facilitating easier access to these products for international buyers, allowing them to compare options and prices seamlessly.

Emerging trends such as the integration of smart technologies in automotive interiors are further influencing buyer preferences. As features like integrated infotainment systems and smart seat adjustments become standard, the demand for high-quality leather that complements these technologies is expected to grow. For B2B buyers, understanding these dynamics is essential for making informed sourcing decisions that align with market expectations.

How Is Sustainability Shaping Sourcing Trends for Crush Customs Leather Seats?

Sustainability and ethical sourcing are becoming increasingly vital in the crush customs leather seats sector. As environmental concerns gain prominence, B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing leather from tanneries that adhere to eco-friendly processes, minimizing waste, and reducing carbon footprints.

The importance of ethical supply chains cannot be overstated. Buyers are looking for transparency in sourcing, ensuring that the materials used are not only high-quality but also ethically produced. This demand is driving suppliers to seek certifications that validate their sustainability claims, such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) certifications.

Moreover, the shift towards using alternative materials, such as plant-based leathers or recycled materials, is gaining traction. These innovations not only reduce environmental impact but also appeal to eco-conscious consumers. For B2B buyers, aligning with suppliers who prioritize sustainability can enhance brand reputation and cater to the growing market segment that values ethical consumption.

What Is the Historical Context of Crush Customs Leather Seats?

The evolution of crush customs leather seats can be traced back to the early 20th century when leather was primarily used in luxury vehicles. Over the decades, the automotive industry saw significant advancements in upholstery technologies, with leather becoming more accessible and customizable. The rise of aftermarket modifications in the late 20th century paved the way for specialized providers like Crush Customs, which focus on tailoring leather interiors to meet individual customer preferences.

As consumer demand for unique and premium interior finishes has grown, so too has the importance of customization in the leather seating market. Today, suppliers are not only tasked with providing high-quality leather but also with integrating modern design elements and technologies that enhance the overall driving experience. This historical context underscores the dynamic nature of the market and the continuous evolution of consumer preferences, which are critical for B2B buyers to consider when sourcing crush customs leather seats.

Frequently Asked Questions (FAQs) for B2B Buyers of crush customs leather seats

-

How do I ensure the quality of crush customs leather seats before purchasing?

To ensure the quality of crush customs leather seats, request samples of the leather and upholstery materials used. Additionally, ask for information regarding the manufacturing process, including any certifications or quality assurance measures in place. Consider visiting the supplier’s facility if possible or seek third-party quality inspections. Reviews and testimonials from other B2B clients can also provide insights into the durability and craftsmanship of the products. -

What customization options are available for crush customs leather seats?

Crush Customs offers a variety of customization options, including leather type, color, stitching patterns, and additional features like heating or cooling systems. You can also request unique designs that reflect your brand or personal style. It’s advisable to discuss your specific requirements during the consultation phase to ensure that the final product meets your expectations. -

What is the typical minimum order quantity (MOQ) for crush customs leather seats?

The minimum order quantity (MOQ) for crush customs leather seats can vary depending on the specific product and customization options. Generally, for bespoke items, the MOQ might be higher to justify production costs. It’s best to directly contact the supplier to understand their MOQ policies and discuss your needs, especially if you are considering bulk orders. -

What payment terms are available for international B2B transactions?

Payment terms can vary by supplier, but common options include upfront payments, partial payments during production, and final payments upon delivery. For international transactions, it’s advisable to use secure payment methods such as letters of credit or escrow services. Always clarify the payment schedule and any potential fees related to currency exchange or international transactions before finalizing the order. -

How is shipping and logistics managed for international orders of crush customs leather seats?

Shipping and logistics for international orders are typically coordinated by the supplier. They should provide information on shipping methods, estimated delivery times, and any additional costs such as tariffs or customs fees. It’s important to discuss logistics in advance, including tracking options and insurance coverage during transit, to ensure a smooth delivery process. -

What steps should I take to vet a supplier of crush customs leather seats?

To vet a supplier, research their reputation in the industry by checking reviews and testimonials from previous clients. Request references and inquire about their experience with similar projects. Additionally, assess their certifications and compliance with international quality standards. A visit to their facility or a virtual tour can also provide insights into their operations and capabilities. -

What quality assurance measures should I expect with crush customs leather seats?

Expect a comprehensive quality assurance process that includes material inspections, craftsmanship evaluations, and post-installation checks. Suppliers should have a warranty policy that covers defects and ensures customer satisfaction. Request details on their QA procedures and any third-party inspections to confirm that the leather seats meet industry standards. -

How do I handle post-purchase support and maintenance for leather seats?

Post-purchase support typically includes guidance on care and maintenance of the leather seats to ensure longevity. Request information on cleaning products suitable for leather and recommended maintenance schedules. Many suppliers also offer warranties or service agreements, so clarify these options at the time of purchase to ensure ongoing support for any issues that may arise after installation.

Top 4 Crush Customs Leather Seats Manufacturers & Suppliers List

1. Crush Customs – Automotive Interior Customization

Domain: crushcustoms.com

Registered: 2013 (12 years)

Introduction: Crush Customs specializes in automotive interior customization and offers a variety of services including: Collision Avoidance Systems, Custom Audio Builds, Custom Car Lighting, Custom Upholstery, Headliners + Carpet Restoration, Keyless Entry + Power Lift Gates, Leather Seating, Interior Navigation + Apple Car Play, Rear Entertainment Systems, Seat Heating + Cooling Systems, Sunroofs, and Vinyl G…

2. Facebook – After-Market Automotive Services

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – After-Market Automotive Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Yelp – Auto Customization Services

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: Auto customization, Auto electronics repair, Auto interior customization, Auto upholstery customization, Auto electronics installation, Grille customization, Auto security, Leather interiors, Sunroofs, DVD players, Navigation systems, Remote starts, Alarm systems, Vinyl graphics, Bluetooth.

4. Crush Customs – Custom Leather Seats

Domain: crush-customs-leather-seats.wheree.com

Registered: 2023 (2 years)

Introduction: Crush Customs Leather Seats specializes in custom leather seat installations, reupholstering, and various interior modifications for vehicles. The shop is located at 1092 West Atlanta St SE Ste 700, Marietta, GA 30060, United States. They are known for exceptional craftsmanship and quality, delivering custom leather interiors that resemble factory installations. Unique features include heated seat…

Strategic Sourcing Conclusion and Outlook for crush customs leather seats

In the competitive landscape of automotive customization, strategic sourcing of Crush Customs leather seats offers a unique opportunity for international B2B buyers. By investing in high-quality, custom leather upholstery, businesses can enhance their product offerings, improve customer satisfaction, and ultimately drive higher resale values. The benefits of these premium leather seats extend beyond aesthetics; they are easy to maintain, provide unparalleled comfort, and reduce allergens, making them an attractive choice for diverse markets, from Africa to Europe.

As a boutique, family-owned company, Crush Customs prioritizes personalized service and quality craftsmanship, ensuring that every client’s specific needs are met. This commitment to excellence not only enhances the customer experience but also builds long-term relationships that can lead to repeat business and referrals.

Looking ahead, the demand for customized automotive interiors is set to rise, driven by consumer preferences for individuality and luxury. Now is the time for B2B buyers to seize this opportunity by partnering with Crush Customs. Engage with us today to explore how our bespoke leather seating solutions can elevate your offerings and position your business for success in the evolving automotive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.