Introduction: Navigating the Global Market for automotive leather material

Navigating the global market for automotive leather material presents a significant challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality automotive leather that meets both aesthetic and functional demands can be daunting, especially as buyers strive to balance cost, durability, and compliance with local regulations. This comprehensive guide aims to demystify the complexities of the automotive leather supply chain by covering essential topics such as various types of leather, their applications in different vehicle interiors, and effective supplier vetting strategies.

In this guide, you will discover an array of leather options tailored for automotive use, from premium top-grain hides to eco-friendly alternatives. Each section is designed to equip you with the knowledge needed to make informed purchasing decisions, ensuring you select materials that not only enhance the vehicle’s interior but also withstand the rigors of daily use.

Additionally, we will delve into pricing structures, helping you understand how to negotiate and secure the best deals without compromising quality. By addressing these critical aspects, this guide empowers international B2B buyers to navigate the automotive leather market with confidence, enabling them to forge successful partnerships and ultimately enhance their product offerings.

Table Of Contents

- Top 7 Automotive Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automotive leather material

- Understanding automotive leather material Types and Variations

- Key Industrial Applications of automotive leather material

- 3 Common User Pain Points for ‘automotive leather material’ & Their Solutions

- Strategic Material Selection Guide for automotive leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for automotive leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive leather material’

- Comprehensive Cost and Pricing Analysis for automotive leather material Sourcing

- Alternatives Analysis: Comparing automotive leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for automotive leather material

- Navigating Market Dynamics and Sourcing Trends in the automotive leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automotive leather material

- Strategic Sourcing Conclusion and Outlook for automotive leather material

- Important Disclaimer & Terms of Use

Understanding automotive leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Top-Grain Leather | Made from the uppermost layer of cowhide, retains natural grain. | Luxury automotive interiors | Pros: Durable, UV resistant, aesthetically pleasing. Cons: Higher cost than other types. |

| Split Leather | Derived from the lower layers of hide, often sanded for a smooth finish. | Budget-friendly automotive options | Pros: More affordable, lightweight. Cons: Less durable, can show wear quicker. |

| Nubuck Leather | Sanded or buffed to create a soft, velvety surface. | High-end custom vehicles | Pros: Luxurious feel, unique texture. Cons: Prone to staining, requires special care. |

| Perforated Leather | Features small holes for breathability and style. | Sports cars and performance vehicles | Pros: Enhanced ventilation, sporty aesthetic. Cons: May be less durable in high-wear areas. |

| Bonded Leather | Made from leather scraps bonded together with latex or polyurethane. | Entry-level automotive interiors | Pros: Cost-effective, can mimic leather appearance. Cons: Less durable, may not withstand UV exposure. |

What Are the Characteristics and Suitability of Top-Grain Leather for Automotive Use?

Top-grain leather is considered the premium choice for automotive interiors due to its balance of durability and aesthetic appeal. It is made from the outermost layer of cowhide, which retains the natural grain and texture, giving it a luxurious look. This type is treated to resist UV damage, making it suitable for vehicles exposed to sunlight. Buyers should consider its higher price point but recognize the long-term investment it offers in terms of durability and resale value.

How Does Split Leather Compare to Other Types in Terms of Cost and Durability?

Split leather is derived from the lower layers of animal hides and is often sanded to achieve a smoother finish. While it is more budget-friendly than top-grain leather, it lacks the same level of durability and can wear out more quickly. This type is commonly used in entry-level vehicles or as a cost-effective option for fleet vehicles. Buyers should weigh the lower initial costs against potential long-term replacements or repairs.

What Unique Benefits Does Nubuck Leather Offer for Automotive Interiors?

Nubuck leather is renowned for its soft, velvety texture, created by sanding the outer layer of hide. This luxurious material is often chosen for high-end custom vehicles, providing a unique tactile experience. However, it is more susceptible to staining and requires specific care to maintain its appearance. B2B buyers should consider the target market and vehicle type when opting for nubuck, balancing luxury with maintenance requirements.

Illustrative image related to automotive leather material

How Does Perforated Leather Enhance the Performance and Aesthetics of Automotive Interiors?

Perforated leather features small holes that provide enhanced breathability, making it ideal for sports cars and performance vehicles. This design not only adds a sporty aesthetic but also helps to keep occupants cool during hot weather. While it is often more durable than other leather types, the perforations can be prone to wear in high-traffic areas. Buyers should consider the intended use of the vehicle and the importance of ventilation when selecting this type of leather.

Why Might Buyers Consider Bonded Leather for Entry-Level Automotive Applications?

Bonded leather is made from leftover leather scraps that are bonded together with synthetic materials, making it a cost-effective alternative for entry-level automotive interiors. While it can mimic the appearance of real leather, its durability is significantly lower, and it may not withstand UV exposure as well as genuine leather types. Buyers should assess the trade-off between cost and quality, especially for vehicles that may require frequent replacements or repairs.

Key Industrial Applications of automotive leather material

| Industry/Sector | Specific Application of automotive leather material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Interior Upholstery for Vehicles | Enhances vehicle aesthetics and resale value | Require UV-resistant, durable leather; consider color and texture options. |

| Luxury Vehicle Design | Custom Leather Seats and Accessories | Provides a premium feel and comfort for high-end clients | Source top-grain leather; ensure compliance with automotive standards. |

| Automotive Restoration | Replacement Upholstery for Classic Cars | Restores original look and feel, increasing vehicle value | Need authentic, high-quality leather; consider historical accuracy in color and grain. |

| Commercial Vehicle Production | Functional Upholstery for Fleet Vehicles | Offers durability and ease of maintenance; enhances driver comfort | Require materials that withstand heavy use and are easy to clean. |

| Specialty Vehicle Customization | Unique Leather Applications (e.g., dashboards) | Customization options attract niche markets | Focus on bespoke solutions; ensure leather meets specific design requirements. |

How is Automotive Leather Material Used in Automotive Manufacturing?

In automotive manufacturing, leather is primarily utilized for interior upholstery, including seats, door panels, and dashboards. The use of high-quality leather enhances the aesthetic appeal of vehicles while providing durability and comfort. For international buyers, especially in regions like Africa and the Middle East, sourcing leather that meets UV resistance and automotive-grade specifications is crucial to ensure longevity in diverse climates. Buyers must also consider color and texture options to match their vehicle design requirements, as these factors significantly influence consumer preferences.

What Role Does Leather Play in Luxury Vehicle Design?

Luxury vehicle design heavily relies on automotive leather for custom seats and accessories. Premium leather elevates the overall feel of the vehicle, offering comfort and an upscale experience for discerning customers. Buyers in markets such as Europe and South America should focus on sourcing top-grain leather that adheres to stringent automotive standards, ensuring both quality and compliance. Additionally, understanding the specific needs of luxury consumers—such as customization and exclusivity—can enhance product offerings and market positioning.

How is Automotive Leather Material Important for Automotive Restoration?

In the realm of automotive restoration, leather is vital for replacing upholstery in classic cars. High-quality leather not only restores the original look and feel of vintage vehicles but also increases their market value. For buyers, particularly those in regions with a rich automotive heritage like Europe, sourcing authentic leather that matches historical specifications is essential. Buyers must also pay attention to the unique characteristics of leather, such as natural variations and defects, to ensure authenticity in restoration projects.

Illustrative image related to automotive leather material

Why is Automotive Leather Material Essential for Commercial Vehicle Production?

For commercial vehicle production, automotive leather is used in functional upholstery designed to withstand heavy use. This application prioritizes durability and ease of maintenance, which are crucial for fleet vehicles that experience constant wear and tear. Buyers should look for leather materials that are specifically treated for stain resistance and easy cleaning, accommodating the practical needs of businesses. Understanding the balance between cost and quality is vital for international buyers, especially in emerging markets where budget constraints may be a concern.

How Can Automotive Leather Material Enhance Specialty Vehicle Customization?

In specialty vehicle customization, automotive leather serves as a unique application for enhancing aesthetics, such as custom dashboards and trim. This allows manufacturers to attract niche markets seeking bespoke solutions. International buyers should focus on sourcing leather that not only meets design requirements but also aligns with specific performance attributes, such as weather resistance and durability. Additionally, establishing relationships with suppliers who can provide customization options will be critical for success in this competitive sector.

3 Common User Pain Points for ‘automotive leather material’ & Their Solutions

Scenario 1: Sourcing High-Quality Automotive Leather Materials

The Problem:

B2B buyers often struggle with sourcing high-quality automotive leather materials that meet industry standards. Many suppliers offer inferior products labeled as “genuine leather,” which can lead to durability issues and customer dissatisfaction. This is particularly concerning in regions like Africa and South America, where buyers may be tempted by lower prices but end up compromising on quality. The lack of clear information about the grading and types of leather can further complicate the decision-making process, leading to mismatched expectations and potentially costly mistakes.

The Solution:

To ensure you are sourcing the best automotive leather materials, prioritize suppliers who explicitly state that they offer top-grain or full-grain leather, as these types are known for their durability and aesthetic appeal. Look for suppliers that provide detailed information about their leather’s specifications, including UV resistance, grain type, and dyeing processes. Engaging directly with manufacturers can help clarify any uncertainties; ask for samples before making large orders. Additionally, consider leveraging trade shows or industry expos, particularly in Europe and the Middle East, where you can inspect the leather firsthand and build relationships with reputable suppliers.

Scenario 2: Managing Variability in Leather Hides

The Problem:

A common pain point for automotive upholstery manufacturers is the natural variability in leather hides. Each hide can differ significantly in size, texture, and appearance due to the nature of animal hides. This variability can lead to challenges in production planning, as manufacturers may find that they do not have enough usable material to complete their projects, resulting in delays and additional costs. In regions with fluctuating demand, such as the Middle East, this can be particularly problematic, as manufacturers need to maintain both quality and efficiency.

Illustrative image related to automotive leather material

The Solution:

To manage variability effectively, B2B buyers should adopt a proactive approach in planning and inventory management. First, establish a clear understanding of your project requirements, including the specific dimensions and finishes needed. When ordering, consider purchasing additional hides to account for natural defects and variability. Collaborating with suppliers who offer hides in various sizes can also be beneficial; for example, sourcing a mix of quarter, half, and full hides can provide flexibility in usage. Additionally, training your team on how to assess and grade hides can lead to better utilization of available materials, ensuring that you maximize your investment.

Scenario 3: Ensuring Compliance with Automotive Standards

The Problem:

Compliance with automotive industry standards is a critical concern for B2B buyers dealing with automotive leather materials. Different regions may have varying regulations regarding the types of materials that can be used in vehicle interiors, particularly concerning fire safety, emissions, and durability. Buyers, especially those operating in Europe and the Middle East, face the challenge of ensuring that their suppliers adhere to these standards, as non-compliance can lead to costly recalls or legal issues.

The Solution:

To navigate compliance challenges, buyers should thoroughly research the regulations applicable to their target markets. Engage with suppliers who can provide certification and documentation that demonstrates their leather materials meet relevant automotive standards. Additionally, consider forming partnerships with third-party testing organizations that can independently verify the compliance of the materials you intend to use. It is also advisable to stay informed about evolving regulations through industry associations and trade bodies, which can provide updates and resources that help ensure your sourcing strategies align with compliance requirements.

Strategic Material Selection Guide for automotive leather material

What Are the Key Materials Used in Automotive Leather and Their Properties?

When selecting automotive leather materials, it’s crucial for B2B buyers to understand the various options available, their properties, and how they align with specific applications. Here, we analyze four common materials used in automotive leather, focusing on their key properties, advantages, disadvantages, and considerations for international buyers.

1. Top-Grain Leather

Key Properties:

Top-grain leather is made from the uppermost layer of the hide, retaining the natural grain. It is known for its durability and resistance to wear and tear, making it suitable for high-traffic areas in vehicles. It typically offers good UV resistance, which is vital in regions with intense sunlight.

Illustrative image related to automotive leather material

Pros & Cons:

The primary advantage of top-grain leather is its luxurious appearance and feel, which enhances the overall aesthetic of automotive interiors. However, it is more expensive than other leather types and requires specialized care to maintain its appearance. Manufacturing complexity can also be higher due to the need for precise finishing.

Impact on Application:

Top-grain leather is ideal for premium car interiors and luxury vehicles, where aesthetics and comfort are paramount. Its durability ensures it can withstand daily use without significant wear.

Considerations for International Buyers:

Buyers from regions like the Middle East and Africa should ensure compliance with local standards for leather quality and environmental regulations. Understanding local preferences for color and texture can also influence purchasing decisions.

2. Split Leather

Key Properties:

Split leather is derived from the lower layers of the hide after the top-grain layer has been removed. While it is less durable than top-grain leather, it can still offer decent abrasion resistance.

Pros & Cons:

The main advantage of split leather is its lower cost, making it an attractive option for budget-conscious manufacturers. However, it is less resistant to moisture and UV damage, which can lead to quicker degradation. Its appearance is also less refined compared to top-grain leather.

Impact on Application:

Split leather is often used in entry-level vehicles or as an alternative for non-visible areas of the interior, such as under seats or in less trafficked spaces.

Considerations for International Buyers:

Buyers should be aware of the varying quality standards across regions. For instance, European buyers may prioritize higher-grade materials, while buyers in South America might focus on cost-effectiveness.

Illustrative image related to automotive leather material

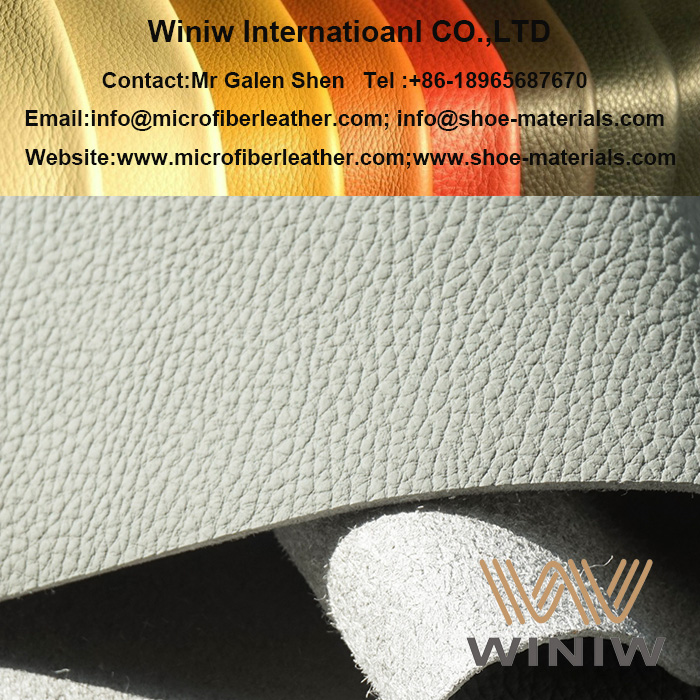

3. Synthetic Leather (Vinyl)

Key Properties:

Synthetic leather, often made from polyvinyl chloride (PVC) or polyurethane (PU), is designed to mimic the appearance and feel of natural leather while being more resistant to moisture and stains.

Pros & Cons:

A significant advantage of synthetic leather is its affordability and ease of maintenance. However, it lacks the breathability and luxurious feel of natural leather, which can affect overall comfort. Additionally, synthetic materials may not have the same longevity as genuine leather.

Impact on Application:

Synthetic leather is commonly used in mass-market vehicles and for upholstery in commercial applications due to its cost-effectiveness and durability.

Considerations for International Buyers:

Compliance with environmental regulations regarding synthetic materials is critical, especially in Europe, where sustainability is a key concern. Buyers should also consider the local market’s acceptance of synthetic versus natural materials.

Illustrative image related to automotive leather material

4. Nubuck Leather

Key Properties:

Nubuck leather is a type of top-grain leather that has been sanded or buffed to create a soft, velvety surface. It offers a unique aesthetic appeal and is generally more resistant to wear than split leather.

Pros & Cons:

The luxurious look and feel of nubuck make it appealing for high-end applications. However, it is more susceptible to stains and requires more maintenance to keep it looking pristine. Its cost is typically higher than that of split leather but lower than top-grain leather.

Impact on Application:

Nubuck is often used in luxury vehicles and high-end interiors where aesthetics are prioritized. Its softness enhances comfort but may not be suitable for all applications due to its maintenance requirements.

Considerations for International Buyers:

Buyers should consider climate factors, as nubuck can be less durable in humid environments. Understanding regional preferences for texture and finish can also guide purchasing decisions.

Summary Table of Automotive Leather Materials

| Material | Typical Use Case for automotive leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Top-Grain Leather | Luxury car interiors | Durable and luxurious appearance | Higher cost and maintenance needs | High |

| Split Leather | Budget vehicles or non-visible areas | Cost-effective | Less durable and refined | Low |

| Synthetic Leather | Mass-market vehicles and commercial upholstery | Affordable and easy to maintain | Lacks breathability and luxury feel | Med |

| Nubuck Leather | High-end interiors in luxury vehicles | Unique soft texture and aesthetic | Requires maintenance and is prone to stains | Med |

This guide provides a comprehensive overview for B2B buyers looking to make informed decisions when selecting automotive leather materials, considering both performance and regional preferences.

Illustrative image related to automotive leather material

In-depth Look: Manufacturing Processes and Quality Assurance for automotive leather material

What Are the Key Stages in the Manufacturing Process of Automotive Leather?

The manufacturing of automotive leather involves several critical stages that ensure the final product meets the high standards required for vehicle interiors. Understanding these stages is vital for B2B buyers to assess quality and suitability for their specific applications.

-

Material Preparation

The initial stage involves sourcing high-quality raw hides, typically cowhide, which are selected based on their grade and characteristics. The hides undergo a rigorous cleaning process to remove any contaminants. This is followed by soaking and liming, which prepares the hides for tanning by removing hair and flesh. The choice of tanning method—vegetable tanning or chrome tanning—affects the leather’s properties. Chrome tanning, for instance, is popular for automotive leather due to its efficiency and the durability it imparts. -

Forming and Treatment

Once tanned, the leather is dyed, often using vat dyeing techniques to ensure deep and uniform color penetration. This process is critical for maintaining the leather’s appearance over time, particularly under UV exposure. After dyeing, the leather undergoes a conditioning process to enhance its flexibility and softness. It is then treated with protective coatings to improve resistance to stains, scratches, and fading, which are crucial for automotive applications. -

Assembly and Cutting

After treatment, the leather is cut into specific patterns based on the design requirements of automotive interiors. Precision cutting is essential to minimize waste and ensure consistency in size and shape. The cut pieces are then assembled, often using advanced stitching techniques that enhance durability and aesthetic appeal. This stage may involve the integration of perforated leather for breathability, especially in seating applications. -

Finishing Touches

The final stage includes applying additional finishes that provide texture and enhance visual appeal. This may involve embossing patterns or applying surface treatments to achieve specific tactile qualities. The leather is then inspected for any defects before being prepared for shipment.

How Is Quality Assurance Implemented in Automotive Leather Production?

Quality assurance (QA) in automotive leather manufacturing is critical to ensure that the final product meets international standards and customer expectations. For B2B buyers, understanding the QA processes can help mitigate risks and assure the quality of the materials purchased.

-

International Standards Compliance

Many manufacturers adhere to international quality standards such as ISO 9001, which establishes a framework for quality management systems. Compliance with ISO standards ensures that processes are documented, monitored, and continuously improved. Additionally, specific automotive standards, such as those set by the Automotive Industry Action Group (AIAG) and the European Committee for Standardization (CEN), may also apply, particularly for suppliers serving markets in Europe and the Middle East. -

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. The quality of hides is assessed for defects, thickness, and overall suitability.

– In-Process Quality Control (IPQC): During production, ongoing inspections ensure adherence to specifications. This includes monitoring dyeing processes, treatment application, and cutting accuracy.

– Final Quality Control (FQC): Before shipment, the finished leather is subjected to rigorous testing for colorfastness, durability, and surface defects. This final inspection is crucial to ensure that the product meets the required standards. -

Common Testing Methods Employed

Various testing methods are employed to validate the quality of automotive leather, including:

– Physical Tests: Assessing tensile strength, abrasion resistance, and tear strength.

– Chemical Tests: Evaluating resistance to UV light, water, and staining agents.

– Aesthetic Tests: Ensuring color consistency and the absence of defects like scars or discoloration.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is crucial to ensure that the materials meet their specifications and standards.

-

Supplier Audits

Conducting supplier audits is one of the most effective ways to evaluate a potential partner’s quality assurance practices. Audits should focus on the supplier’s adherence to established quality management systems, production processes, and compliance with relevant standards. This can be done through on-site visits or by hiring third-party auditing firms. -

Requesting Quality Reports

B2B buyers should request detailed quality assurance reports from suppliers. These reports should outline testing results, compliance certifications, and any corrective actions taken in response to quality issues. Such documentation provides transparency and helps buyers assess the reliability of the supplier. -

Third-Party Inspections

Engaging third-party inspection services can further validate the quality of automotive leather before it is shipped. Independent inspectors can verify that the leather meets the specified standards and report any discrepancies. This additional layer of scrutiny is particularly valuable for buyers who may be unfamiliar with local suppliers.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers must be aware of certain nuances in quality control that can affect their procurement processes:

-

Understanding Regional Standards

Different regions may have varying standards for automotive leather. For example, European buyers may prioritize compliance with stricter environmental regulations compared to those in other regions. Understanding these nuances can guide buyers in selecting suppliers who meet their specific market requirements. -

Navigating Cultural Differences

Cultural differences can also impact communication and expectations regarding quality. B2B buyers should establish clear lines of communication with suppliers and ensure that quality expectations are well understood on both sides. -

Logistical Considerations

The logistics of international shipping can introduce risks that affect quality, such as temperature fluctuations or improper handling. B2B buyers should ensure that suppliers have robust logistics protocols to mitigate these risks and maintain the integrity of the leather during transit.

In summary, the manufacturing processes and quality assurance measures for automotive leather are complex but crucial for ensuring high-quality products. B2B buyers must be diligent in their assessment of suppliers, understand the relevant standards, and engage in proactive quality verification to ensure that their automotive leather needs are met effectively.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive leather material’

To successfully procure automotive leather materials, B2B buyers must navigate a multifaceted process that ensures quality, compliance, and suitability for their specific needs. This step-by-step checklist serves as a practical guide to streamline your sourcing efforts and make informed decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, establish clear technical specifications for the leather materials needed. This includes factors such as the type of leather (e.g., top-grain vs. split leather), desired finish, and specific applications (seats, dashboards, etc.). Understanding these requirements helps in identifying suitable suppliers who can meet your quality and performance standards.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Utilize online directories, industry trade shows, and recommendations from industry peers to identify reputable manufacturers. Focus on suppliers that specialize in automotive leather, as they will be more familiar with the stringent standards required for vehicle interiors.

Step 3: Verify Supplier Certifications

It’s essential to ensure that your selected suppliers possess the necessary certifications and adhere to industry standards. Look for certifications related to environmental sustainability, such as ISO 14001, and quality assurance standards like ISO 9001. These certifications indicate a supplier’s commitment to quality and responsible sourcing practices.

Illustrative image related to automotive leather material

Step 4: Request Product Samples

Always request samples of the leather before finalizing any orders. Evaluating physical samples allows you to assess the texture, color, and overall quality of the leather. Pay attention to how the leather feels, its durability, and how it responds to light exposure, especially if UV resistance is a requirement for your application.

Step 5: Evaluate Pricing and Payment Terms

Once you have identified potential suppliers and received samples, compare pricing structures and payment terms. Ensure that the pricing aligns with your budget while considering the quality of the materials offered. Look for transparency in pricing, including any additional costs for shipping or handling, and negotiate favorable payment terms that suit your cash flow needs.

Step 6: Review Customer Feedback and References

Before making a final decision, gather feedback from other businesses that have sourced from the suppliers you’re considering. Request references and read customer reviews to gauge the supplier’s reliability, product quality, and customer service. This information can provide valuable insights into potential challenges and the overall experience of working with a supplier.

Illustrative image related to automotive leather material

Step 7: Finalize Contracts and Logistics

After selecting a supplier, ensure that all terms are clearly outlined in a formal contract. This should include specifications, pricing, delivery timelines, and any warranties or guarantees. Additionally, coordinate logistics for the delivery of materials, considering factors such as shipping times and potential customs regulations if sourcing internationally.

By following this checklist, B2B buyers can navigate the complexities of sourcing automotive leather materials, ensuring that they procure high-quality products that meet their specific needs while minimizing risks associated with the procurement process.

Comprehensive Cost and Pricing Analysis for automotive leather material Sourcing

What Are the Key Cost Components in Automotive Leather Material Sourcing?

When sourcing automotive leather, understanding the cost structure is essential for B2B buyers. The primary components include:

-

Materials: The quality of leather significantly affects pricing. Top-grain leather, which is vat-dyed and treated for durability and UV resistance, typically commands higher prices than lower-quality options like split leather or synthetic alternatives. Prices for standard hides can range from $120 for a quarter hide to over $300 for premium options, depending on the size and finish.

-

Labor: Labor costs encompass the processing and finishing of the leather. Skilled artisans may be required for tasks such as tanning, dyeing, and finishing, which can vary by region. For instance, labor costs may be lower in countries with abundant leather production, impacting overall pricing.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, equipment, and utilities. Manufacturers with advanced technology may achieve higher efficiency, potentially lowering costs, while traditional methods might increase overhead due to longer processing times.

-

Tooling: Custom tooling for specific designs or finishes can add to the cost. Buyers should consider whether they need unique specifications, as these can lead to additional upfront expenses.

-

Quality Control (QC): Ensuring that the leather meets automotive-grade standards involves rigorous QC processes, which can increase costs. Buyers should inquire about a supplier’s QC practices to ensure consistent quality.

-

Logistics: Shipping costs vary widely depending on the supplier’s location and the buyer’s destination. Factors such as shipping method, packaging, and customs duties play a significant role in overall logistics costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can be influenced by market demand, competition, and the supplier’s positioning in the industry.

How Do Price Influencers Impact Automotive Leather Costs?

Several factors influence the pricing of automotive leather:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to lower per-unit costs due to economies of scale. Suppliers often have MOQs, which can impact pricing flexibility for smaller buyers.

-

Specifications and Customization: Customized leather, whether in terms of color, texture, or finish, can lead to higher costs. Buyers should evaluate whether standard options meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality leathers often come with certifications that may add to the cost but also provide assurance of durability and compliance with automotive standards.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality may charge more, while less-known suppliers might offer lower prices but at higher risk.

-

Incoterms: The terms of trade (e.g., FOB, CIF) can affect total costs significantly. Understanding the implications of these terms is crucial for international buyers to avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better Prices?

B2B buyers can adopt several strategies to optimize costs:

-

Negotiation: Always negotiate terms and prices with suppliers. Building a relationship can lead to better deals, especially for repeat orders.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also long-term maintenance, durability, and potential resale value. High-quality leather may have a higher upfront cost but could save money over time through reduced replacement needs.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and tariffs that can affect final costs. Understanding local market conditions and supplier pricing strategies can provide leverage during negotiations.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can help gauge the market rate and identify competitive pricing.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and can vary significantly based on factors such as supplier, market demand, and regional economic conditions. Buyers are encouraged to conduct thorough research and obtain current pricing directly from suppliers before making purchasing decisions.

Alternatives Analysis: Comparing automotive leather material With Other Solutions

Understanding Alternatives to Automotive Leather Material

In the automotive industry, selecting the right upholstery material is crucial for both aesthetic appeal and functional performance. While automotive leather is a popular choice for its luxurious look and durability, several alternatives exist that may offer different advantages depending on the specific needs of manufacturers and consumers. This section explores how automotive leather compares with synthetic leather and high-performance textiles, providing B2B buyers with the insights needed to make informed decisions.

| Comparison Aspect | Automotive Leather Material | Synthetic Leather (e.g., PU Leather) | High-Performance Textiles (e.g., Alcantara) |

|---|---|---|---|

| Performance | Highly durable, UV-resistant, luxurious feel | Good durability, less UV resistance | Excellent durability, breathable, premium feel |

| Cost | Higher initial investment | More affordable than leather | Moderate to high, depending on the type |

| Ease of Implementation | Requires skilled labor for installation | Easier to work with, less specialized knowledge needed | Specialized installation may be required |

| Maintenance | Requires regular conditioning and cleaning | Low maintenance, easy to clean | Requires specific cleaning methods, but resistant to stains |

| Best Use Case | Luxury vehicles, high-end models | Budget-friendly vehicles, mass production | Sports cars, premium interiors, high-end applications |

What Are the Advantages and Disadvantages of Synthetic Leather?

Synthetic leather, often made from polyurethane (PU), serves as a practical alternative to automotive leather. One of its main advantages is cost-effectiveness; it is generally more affordable, making it appealing for budget-conscious manufacturers. Additionally, synthetic leather is easier to maintain, as it requires simple cleaning and does not need conditioning. However, it may lack the luxurious feel and durability of genuine leather, and its UV resistance can be inferior, leading to potential color fading over time.

How Does High-Performance Textile Compare to Automotive Leather?

High-performance textiles, such as Alcantara, offer a unique blend of durability and aesthetics. These materials are often used in high-end sports cars due to their breathability and premium feel. They resist stains and are easy to clean, providing a practical solution for performance vehicles. However, the cost can be higher than synthetic leather, and installation may require specialized techniques. While they provide a luxurious look, they may not match the traditional appeal of automotive leather for some consumers.

How Should B2B Buyers Choose the Right Upholstery Material?

When selecting the right upholstery material, B2B buyers should consider their target market and the intended use of the vehicles. For luxury models that prioritize aesthetics and durability, automotive leather remains a strong contender. Conversely, for budget-friendly or mass-produced vehicles, synthetic leather may be more appropriate due to its lower cost and easier maintenance. High-performance textiles serve as an excellent choice for sports and luxury vehicles where a unique, premium feel is desired. Ultimately, understanding the specific requirements of the vehicle and the preferences of the end consumer will guide buyers in making the best decision for their automotive upholstery needs.

Illustrative image related to automotive leather material

Essential Technical Properties and Trade Terminology for automotive leather material

What Are the Key Technical Properties of Automotive Leather Material?

When sourcing automotive leather, understanding its technical properties is crucial for ensuring quality and longevity. Here are several key specifications that B2B buyers should consider:

1. Material Grade

The grade of leather is fundamental in determining its quality. Automotive leather is typically categorized into grades like top-grain or full-grain. Top-grain leather is durable and retains a natural appearance, while full-grain leather is the highest quality, showcasing the hide’s natural texture. Opting for higher-grade leather ensures better wear resistance and aesthetic appeal, critical for automotive applications.

2. Tolerance

Tolerance refers to the acceptable variations in the leather’s thickness, size, and color. For automotive interiors, a standard tolerance of ±0.5 mm in thickness is often required to maintain uniformity in upholstery. Understanding tolerance is vital for manufacturers to ensure that the leather fits precisely in automotive interiors, avoiding costly rework and ensuring a seamless finish.

3. UV Resistance

Due to prolonged exposure to sunlight, automotive leather must possess UV resistance properties to prevent fading and degradation. This property is particularly important for regions with high sun exposure, such as parts of Africa and the Middle East. High UV resistance prolongs the life of the leather, ensuring that it maintains its color and integrity over time, which is a significant selling point for luxury vehicles.

4. Water Resistance

Water resistance is another critical property, particularly in climates prone to rain or humidity. Leather with enhanced water resistance can repel moisture, preventing mold and mildew growth. This characteristic is especially beneficial for automotive manufacturers targeting consumers in rainy regions, as it enhances customer satisfaction by maintaining the leather’s appearance and performance.

Illustrative image related to automotive leather material

5. Natural Variation

Natural leather, particularly cowhide, exhibits unique characteristics such as scars and brands, which add to its beauty. Understanding the implications of these natural variations helps buyers appreciate the uniqueness of each hide and plan accordingly for design and aesthetic consistency in vehicle interiors.

What Are Common Trade Terms in the Automotive Leather Industry?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of automotive leather, an OEM may source leather from a supplier to use in vehicle production. Understanding OEM relationships can help buyers identify reliable suppliers and maintain quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to ensure that their orders meet supplier requirements while balancing inventory needs. This term is particularly relevant in negotiations, as lower MOQs can facilitate smaller businesses entering the market.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific quantities of leather. It is a critical step in the procurement process, allowing buyers to compare offers and select the best supplier based on price and quality.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for smooth cross-border transactions, particularly for buyers in Africa and South America who may deal with various shipping and customs regulations.

5. Cut and Sew

This term refers to the process of cutting the leather hides into specific shapes and sewing them into finished products. Understanding this terminology helps buyers gauge the complexity and labor involved in leather production, impacting lead times and costs.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing automotive leather, ensuring that they select materials that meet their specifications and market demands.

Navigating Market Dynamics and Sourcing Trends in the automotive leather material Sector

What Are the Key Trends Driving the Automotive Leather Material Market?

The automotive leather material market is currently experiencing significant growth, driven by several global factors. One of the primary drivers is the increasing demand for premium vehicle interiors, as consumers prioritize luxury and comfort in their automotive choices. This trend is particularly pronounced in emerging markets such as Africa and South America, where rising disposable incomes are leading to a greater emphasis on high-quality materials. Additionally, advancements in manufacturing technology are enabling suppliers to produce automotive leather that is not only more durable but also available in a wider range of colors and textures, catering to diverse consumer preferences.

Illustrative image related to automotive leather material

In terms of sourcing trends, B2B buyers are increasingly leveraging digital platforms to streamline their procurement processes. Online marketplaces are becoming a vital tool for sourcing automotive leather, allowing buyers to compare prices, quality, and supplier credentials from the comfort of their offices. Furthermore, the rise of data analytics is empowering buyers to make informed decisions based on market trends and consumer behavior, enhancing their negotiation capabilities. As international trade regulations evolve, particularly in regions like the Middle East and Europe, understanding compliance and import/export requirements has become essential for B2B buyers looking to source leather materials efficiently.

How Is Sustainability Shaping the Sourcing of Automotive Leather?

Sustainability has emerged as a critical factor in the sourcing of automotive leather materials, driven by increasing consumer awareness and regulatory pressures. The environmental impact of leather production, particularly in terms of water usage and chemical processing, necessitates a shift toward more sustainable practices. B2B buyers are now prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable production methods.

Ethical supply chains are gaining traction, with buyers seeking partners who can provide transparency regarding their sourcing processes. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential for suppliers aiming to distinguish themselves in a competitive market. These certifications not only verify sustainable practices but also enhance brand reputation among environmentally conscious consumers.

Moreover, the adoption of alternative materials, such as plant-based leathers, is on the rise. These innovations not only reduce the environmental footprint of automotive leather but also cater to a growing segment of consumers who prefer cruelty-free options. B2B buyers must stay informed about these trends to align their sourcing strategies with consumer preferences and regulatory standards.

What Is the Evolution of Automotive Leather Materials in the B2B Context?

The history of automotive leather materials dates back to the early 20th century when leather was predominantly used for luxury vehicles. Initially, the focus was on aesthetics and comfort, with leather being a symbol of prestige. Over the decades, advancements in tanning and finishing processes have improved the durability and functionality of automotive leather, making it suitable for a wider range of vehicles.

Illustrative image related to automotive leather material

As consumer preferences evolved, so did the production methods. The introduction of synthetic leathers and various treatments to enhance UV resistance and stain repellency has expanded the options available to manufacturers and consumers alike. Today, automotive leather is not just about luxury; it also encompasses functionality, sustainability, and ethical considerations, reflecting a comprehensive shift in the industry that B2B buyers must navigate when sourcing materials.

By understanding these dynamics, B2B buyers can make informed decisions that align with market trends, consumer expectations, and sustainability goals, ultimately enhancing their competitive edge in the automotive sector.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive leather material

-

How do I ensure the quality of automotive leather before purchasing?

To ensure the quality of automotive leather, request samples from potential suppliers. Look for top-grain or full-grain leather, as these are more durable and suitable for automotive applications. Verify that the leather is vat-dyed, offering better UV resistance and color retention. Additionally, check for certifications that align with industry standards, and inquire about the supplier’s quality assurance processes. A reputable supplier should also provide detailed information about the leather’s source and any treatments applied. -

What is the best type of leather for automotive interiors?

The best type of leather for automotive interiors is typically top-grain or full-grain leather, which provides a balance of durability, aesthetics, and comfort. These grades offer superior resistance to wear and tear, UV damage, and staining, making them ideal for vehicles exposed to varying climates. Additionally, selecting leather that has been treated for water and stain resistance can further enhance longevity. Always consider the specific requirements of your vehicle model to ensure a perfect fit and finish. -

What are the minimum order quantities (MOQs) for automotive leather?

Minimum order quantities for automotive leather can vary significantly among suppliers. Generally, MOQs can range from a quarter hide (approximately 10 square feet) to a full hide (40-45 square feet). It’s essential to confirm these details with your supplier, as larger orders may qualify for discounts. If your project requires a smaller quantity, inquire about possible options for sampling or combining orders with other buyers to meet MOQ requirements. -

What payment terms should I expect when sourcing automotive leather internationally?

Payment terms for international orders can vary widely based on the supplier and the nature of the transaction. Common arrangements include advance payments, letters of credit, or payment upon delivery. It’s advisable to discuss terms upfront, ensuring clarity on payment schedules, currency, and any potential fees. Additionally, consider using secure payment methods that offer buyer protection to mitigate risks associated with international transactions. -

How can I vet suppliers of automotive leather materials?

To vet suppliers effectively, begin by researching their reputation through online reviews and industry forums. Request references from previous clients and check their response times and customer service quality. Evaluate their product offerings, certifications, and compliance with international quality standards. If possible, arrange a factory visit or request third-party inspections to verify production capabilities. Building a strong relationship with reliable suppliers can lead to better pricing and service in the long run. -

What are common logistics challenges when importing automotive leather?

Common logistics challenges when importing automotive leather include customs clearance delays, shipping damage, and compliance with import regulations. It’s crucial to understand the specific import requirements of your destination country, including tariffs and documentation. Partnering with a logistics provider experienced in handling automotive materials can help navigate these challenges. Additionally, consider purchasing insurance for your shipment to protect against potential losses during transit. -

Can I customize the color and texture of automotive leather?

Yes, many suppliers offer customization options for color, texture, and finish of automotive leather. When discussing your requirements, provide samples or references to ensure alignment with your vision. Be mindful that custom orders may have higher MOQs and longer lead times. It’s advisable to clarify these details with your supplier and request samples of the customized leather before finalizing your order to ensure it meets your expectations. -

What quality assurance processes should be in place for automotive leather?

Effective quality assurance processes for automotive leather should include thorough inspections at various stages of production. This includes evaluating raw hides for defects, monitoring dyeing and finishing processes, and conducting final inspections before shipment. Suppliers should provide documentation of their quality control measures, such as certifications and test results for durability and UV resistance. Establishing clear quality standards upfront will help ensure that the leather meets your specifications and industry requirements.

Top 7 Automotive Leather Material Manufacturers & Suppliers List

1. LeatherSeats.com – Automotive Leather Hides

Domain: leatherseats.com

Registered: 2000 (25 years)

Introduction: Automotive Leather Hides for interior car upholstery available at LeatherSeats.com. The product includes Standard Leather Hides and Ecstasy Leather Hides. Various matching materials and DIY installation tools are also offered, including upholstery supplies like thread, templates, and adhesive. The site features a wide range of pre-configured interior packages and custom upholstery configurators fo…

2. BuyLeatherOnline – Premium Automotive Leather

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: Leather for Car Seats and Automotive: Premium automotive leather for car upholstery, characterized by durability and aesthetic appeal. Suitable for upgrading car seats, dashboards, and door panels. Key features include enhanced comfort, durability against spills and stains, aesthetic appeal, and ease of maintenance. Types of leather available include full-grain and top-grain. Various colors and te…

3. Leather Hide Store – Premium Auto Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Auto upholstery leather for cars and trucks; meets/exceeds color fastness standards (UV resistance); Essentials Line: durable, soft, and supple; Market Street: smoother leather, buttery feel, rich color with sheen; Urban: heavier weight, lots of grain, lux and rich; Dakota line: high performance distressed leathers; aftermarket automotive leathers (not OEM); darker colors have higher UV resistance…

4. Hydes Leather – Automotive Leather

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather offers a wide range of automotive leather and Alcantara products, including:

1. **Automotive Leather**:

– Astro Bomber

– Distressed Buffalo

– Distressed Leather

– OEM Leather

– Pelle Fresco

– Prima Nappa

– Roser 2 Tone

– Royal Steering Wheel Leather

– Thema Vintage

– Vintage OEM Leather

– Vision Woven Leather

2. **Alcantara**:

– Aut…

5. Moore & Giles – Natural Automotive Leathers

Domain: mooreandgilesleather.com

Registered: 2022 (3 years)

Introduction: Moore & Giles offers a range of natural automotive leathers available in various colors and textures, suitable for customizing or restoring vehicles. The leathers can be filtered by finish types including Aniline Plus, Nubuck, Pigmented, Semi-Aniline, and Suede. There are 13 items listed for comparison, including products named Apollo, Berkshire, Burnham, Carlyle, Castello, Dresden, Eden, Holland,…

6. Apex Leather – Auto Upholstery Supplies

Domain: apexleather.com

Registered: 2005 (20 years)

Introduction: Apex Leather offers a variety of auto upholstery supplies including high performance auto leather, square weave carpet, microsuede, and thread. The types of auto leather available include smooth grain leather, distressed leather, natural grain leather, and heavyweight leather. Additional services include CNC panels, CNC perforation, custom color matching, and standard perforation samples.

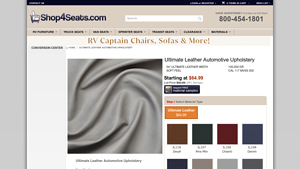

7. Shop4Seats – Ultimate Leather Automotive Upholstery

Domain: shop4seats.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Ultimate Leather Automotive Upholstery”, “Width”: “54 inches”, “Thickness”: “50 ga”, “Weight”: “25 oz per linear yard”, “Abrasion Resistance”: “100,000 DR”, “Flame Resistance”: “CAL 117 SECT E MVSS 302”, “UV Resistance”: “1000 Hours”, “Mildew Resistance”: “Back and face conforms with ASTM G21”, “Material Composition”: “100% premium polyurethane”, “Price”: “$64.99”, “List Price”: …

Strategic Sourcing Conclusion and Outlook for automotive leather material

As the automotive industry continues to evolve, strategic sourcing of high-quality leather materials remains a pivotal factor for manufacturers and upholsterers alike. The demand for premium automotive leather—characterized by its durability, UV resistance, and aesthetic appeal—underscores the necessity for sourcing partners who prioritize quality over lower-grade alternatives. Buyers should focus on suppliers that offer top-grain hides and a range of customizable options to ensure the final product meets consumer expectations for luxury and comfort.

In regions such as Africa, South America, the Middle East, and Europe, the potential for growth in the automotive sector is significant. Buyers in these markets are encouraged to establish relationships with reliable suppliers who can provide not only the materials but also the expertise needed to navigate the complexities of leather sourcing. By leveraging strategic sourcing practices, businesses can enhance their competitive edge, reduce costs, and increase customer satisfaction.

Looking ahead, the integration of sustainable practices within leather sourcing will become increasingly important. B2B buyers should prioritize suppliers committed to ethical sourcing and environmental stewardship. Engaging with forward-thinking partners will not only align with global sustainability goals but also resonate with the evolving values of consumers. Invest in quality and sustainability today to drive your automotive business forward tomorrow.

Illustrative image related to automotive leather material

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.