Introduction: Navigating the Global Market for washing a chamois

In the dynamic landscape of global trade, sourcing effective solutions for washing a chamois can present unique challenges, especially for international B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe. The right maintenance practices not only enhance the longevity of chamois products but also ensure optimal performance across various applications, from automotive detailing to household cleaning. This comprehensive guide delves into the essential aspects of chamois washing, including the types available, their specific applications, supplier vetting criteria, and cost considerations.

As buyers navigate the complexities of sourcing high-quality chamois, understanding the nuances of proper care and maintenance becomes crucial. This guide empowers decision-makers by offering insights into the best practices for washing chamois, ensuring they make informed purchasing choices that align with their operational needs. By highlighting industry standards and supplier recommendations, we equip B2B buyers with the knowledge necessary to select reliable partners and products that enhance their service offerings.

Whether you’re managing a car detailing business in Saudi Arabia or a cleaning service in Vietnam, this guide serves as a valuable resource to optimize your chamois care strategy, ultimately driving efficiency and customer satisfaction.

Table Of Contents

- Top 7 Washing A Chamois Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for washing a chamois

- Understanding washing a chamois Types and Variations

- Key Industrial Applications of washing a chamois

- 3 Common User Pain Points for ‘washing a chamois’ & Their Solutions

- Strategic Material Selection Guide for washing a chamois

- In-depth Look: Manufacturing Processes and Quality Assurance for washing a chamois

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘washing a chamois’

- Comprehensive Cost and Pricing Analysis for washing a chamois Sourcing

- Alternatives Analysis: Comparing washing a chamois With Other Solutions

- Essential Technical Properties and Trade Terminology for washing a chamois

- Navigating Market Dynamics and Sourcing Trends in the washing a chamois Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of washing a chamois

- Strategic Sourcing Conclusion and Outlook for washing a chamois

- Important Disclaimer & Terms of Use

Understanding washing a chamois Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mild Soap Wash | Uses gentle detergents suitable for leather | Automotive detailing, luxury vehicle care | Pros: Preserves leather quality; Cons: May require multiple rinses for thorough cleaning. |

| Warm Water Soak | Soaking in lukewarm water before washing | General cleaning, multi-purpose usage | Pros: Effective for removing embedded dirt; Cons: Time-consuming process. |

| Hand Washing | Manual cleaning with soap applied directly | Specialized detailing services | Pros: High control over cleaning; Cons: Labor-intensive, may not be scalable. |

| Machine Washing (not recommended) | Use of washing machines (with caution) | Low-cost cleaning solutions | Pros: Quick cleaning; Cons: Risk of damaging chamois, not recommended for leather. |

| Synthetic Chamois Wash | Specific cleaners for synthetic chamois materials | Industrial applications, automotive sectors | Pros: Tailored for synthetic materials; Cons: Limited to non-leather options. |

What are the characteristics of using mild soap for washing chamois?

Mild soap washing is characterized by the use of gentle detergents that are specifically designed for leather cleaning. This method is widely used in automotive detailing and luxury vehicle care, where preserving the quality of the chamois is crucial. While it effectively maintains the leather’s integrity, buyers should be aware that multiple rinses may be necessary to remove all soap residues, which can extend the cleaning process.

How does a warm water soak benefit chamois cleaning?

A warm water soak involves immersing the chamois in lukewarm water before applying soap. This technique is particularly effective for removing embedded dirt and grime, making it suitable for general cleaning purposes. However, it can be time-consuming, which may not align with the fast-paced needs of businesses that require quick turnaround times in cleaning operations.

Illustrative image related to washing a chamois

Why is hand washing considered a meticulous approach?

Hand washing allows for precise control over the cleaning process, with soap applied directly to the chamois fibers. This method is often favored by specialized detailing services that prioritize quality over speed. However, the labor-intensive nature of hand washing may limit scalability, making it less ideal for larger operations that handle multiple vehicles or items regularly.

What are the risks of machine washing chamois?

While some users may opt for machine washing as a quick cleaning solution, this method is not recommended for leather chamois due to the risk of damage. The agitation and heat from the washing machine can compromise the chamois’ integrity, leading to brittleness and reduced effectiveness. Buyers should consider this risk, especially in professional settings where the quality of materials is paramount.

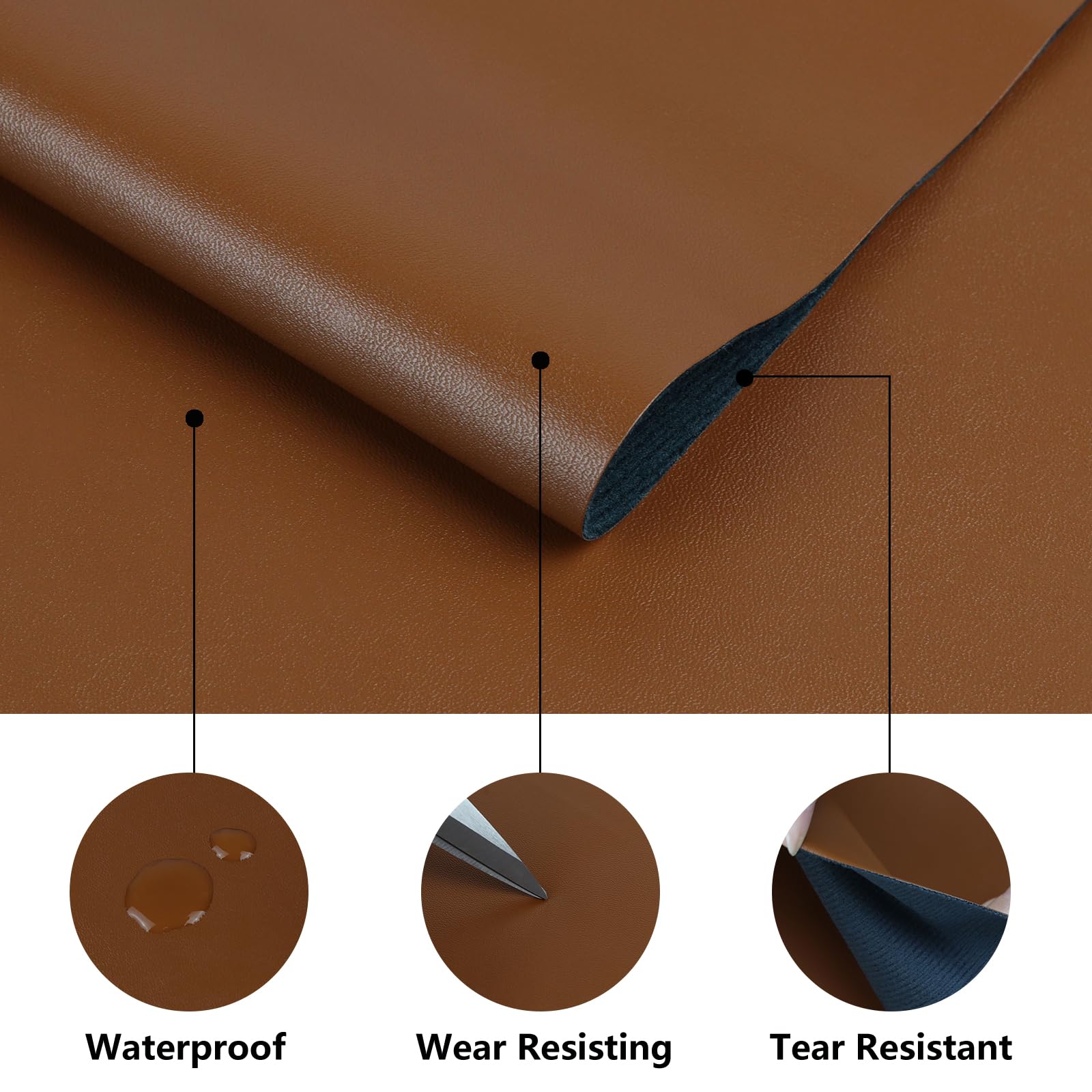

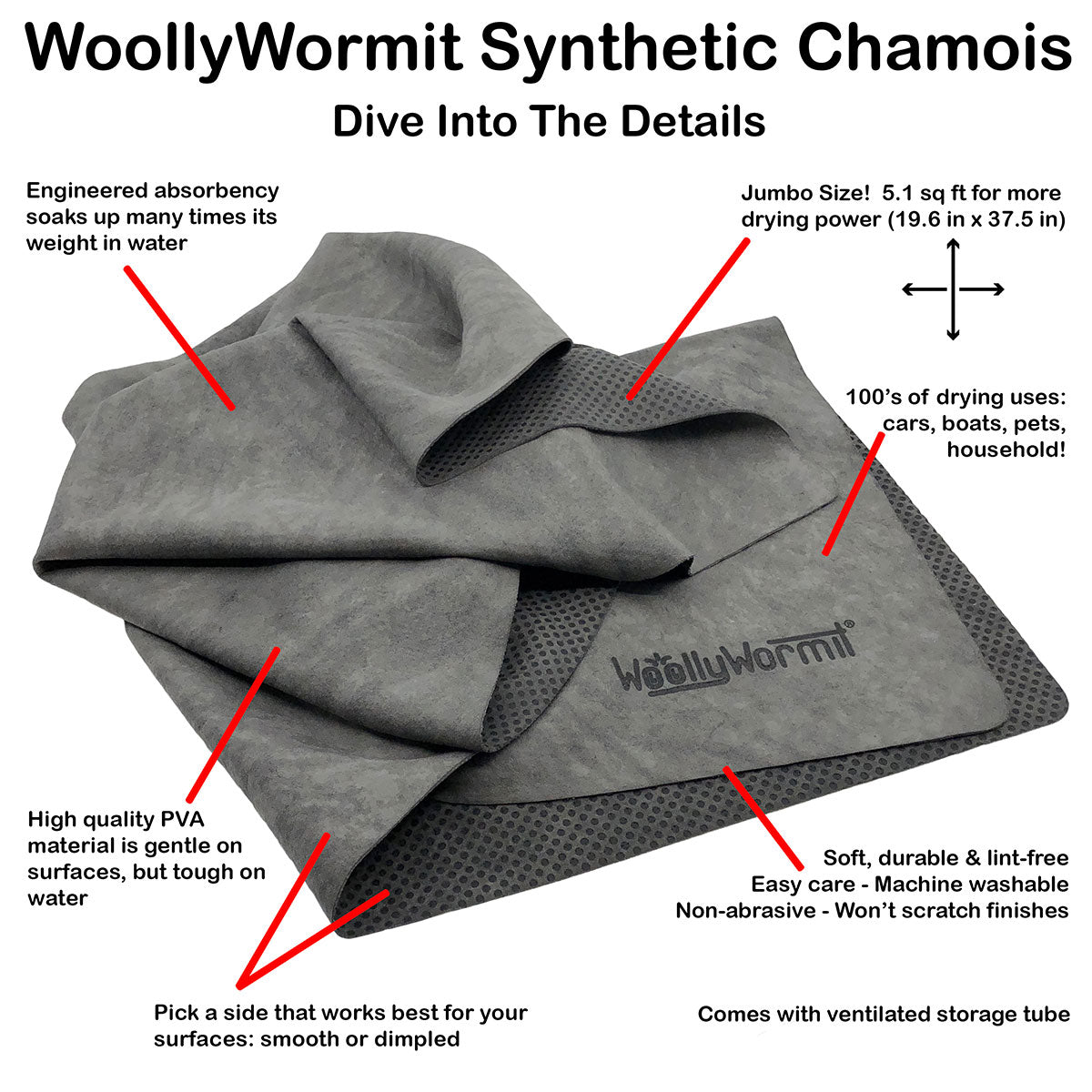

What should buyers know about synthetic chamois washing?

For synthetic chamois materials, specific cleaners tailored to their properties are essential. This approach is common in industrial applications and the automotive sector, where synthetic options are often preferred for their durability. However, buyers should note that these products are limited to non-leather options, and understanding the material composition is crucial for effective cleaning and maintenance strategies.

Key Industrial Applications of washing a chamois

| Industry/Sector | Specific Application of washing a chamois | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Detailing | Cleaning and maintaining vehicle chamois | Extends lifespan of chamois, ensuring high-quality finish | Quality of cleaning agents, compatibility with chamois material |

| Manufacturing | Use in machinery and equipment maintenance | Prevents damage to sensitive surfaces, improves equipment longevity | Availability of specialized soaps, adherence to safety standards |

| Hospitality | Cleaning and drying tableware and glassware | Ensures streak-free surfaces, enhances customer experience | Eco-friendly cleaning solutions, durability of chamois |

| Aviation | Maintenance of aircraft exteriors | Maintains aesthetics and prevents surface damage | Compliance with aviation cleaning protocols, lightweight materials |

| Marine Industry | Drying and polishing boats and yachts | Prevents water spots and enhances appearance | Resistance to saltwater damage, ease of maintenance |

How is washing a chamois used in automotive detailing?

In the automotive detailing sector, washing a chamois is crucial for maintaining the quality of the chamois used to dry vehicles after washing. Proper cleaning removes residual dirt and oils that can lead to streaking or surface damage. For international B2B buyers, sourcing high-quality chamois and mild soaps that are specifically formulated for automotive use is essential. This ensures that the chamois remains soft and effective, enhancing the overall detailing process and customer satisfaction.

What are the applications of washing a chamois in manufacturing?

In manufacturing, particularly in industries involving precision machinery, washing a chamois is employed to clean and maintain equipment. A clean chamois prevents abrasive particles from damaging sensitive surfaces, thus prolonging the life of machinery. Buyers should consider sourcing specialized cleaning agents that are compatible with the materials of their equipment and adhere to safety regulations. This practice minimizes downtime and maintenance costs, providing significant operational benefits.

How does washing a chamois benefit the hospitality sector?

In the hospitality sector, chamois are used for drying and polishing tableware and glassware to ensure a spotless finish. Washing these chamois is essential to remove any food residues or cleaning agents that could leave streaks. B2B buyers in this industry must prioritize eco-friendly cleaning solutions that align with sustainable practices, ensuring that the chamois remains durable and effective. This attention to detail enhances the guest experience and reflects the establishment’s commitment to quality.

What role does washing a chamois play in aviation maintenance?

The aviation industry utilizes chamois for the cleaning and maintenance of aircraft exteriors. Washing the chamois is vital to prevent the transfer of dirt and contaminants that could damage the aircraft’s surface. Buyers should ensure that the cleaning products used comply with aviation standards and do not compromise the integrity of the materials. Proper maintenance of chamois contributes to the aesthetic appeal and safety of aircraft, which is critical in this highly regulated industry.

Why is washing a chamois important in the marine industry?

In the marine industry, washing a chamois is essential for drying and polishing boats and yachts to prevent water spots and maintain their appearance. A well-maintained chamois can significantly enhance the visual appeal of marine vessels. Buyers should focus on sourcing chamois that are resistant to saltwater damage and easy to clean, ensuring longevity and effectiveness. This practice not only preserves the investment in the vessel but also enhances customer satisfaction and loyalty in a competitive market.

3 Common User Pain Points for ‘washing a chamois’ & Their Solutions

Scenario 1: Ensuring Longevity of Chamois in High-Volume Operations

The Problem: B2B buyers in industries such as automotive detailing or manufacturing often rely on chamois for their superior absorbency and gentle touch. However, frequent washing with incorrect methods can lead to premature wear, causing chamois to crack, split, or lose their absorbency. This not only leads to additional costs from having to replace chamois more often but also affects the quality of service provided to customers, as a damaged chamois may leave streaks on vehicles.

The Solution: To extend the lifespan of chamois, it’s crucial to implement a standardized washing protocol. Begin by educating staff on the importance of using only mild, pH-balanced soaps specifically designed for automotive use. Set up a washing station equipped with lukewarm water and designated soap. Instruct employees to soak the chamois for a few minutes, gently agitating to release dirt, and thoroughly rinse until the water runs clear. Establish a drying area that avoids direct sunlight or heat sources to prevent the leather from becoming brittle. By creating a systematic approach to chamois care, companies can maintain high-quality performance and reduce costs associated with replacements.

Scenario 2: Addressing Stains and Residue Buildup

The Problem: In regions with varying climates, chamois can accumulate stains and residue, particularly in areas with high dust or humidity. This can lead to unsightly marks on vehicles and negatively impact customer perceptions of quality. B2B buyers often struggle to find effective methods for removing stubborn stains without damaging the chamois material itself, leading to frustration and potential loss of business.

The Solution: For effective stain removal, it’s essential to employ a two-step cleaning process. First, for typical stains, soak the chamois in warm water mixed with a small amount of mild soap for about 10 minutes. For tougher stains, a direct application of the soap onto the affected area and gentle rubbing with fingers can help. After rinsing thoroughly, ensure that the chamois is completely free of soap residue, as leftover soap can attract dirt and cause further staining. Additionally, consider using a quality leather conditioner post-washing to restore moisture and flexibility, which will also help in preventing future stains from setting. Implementing this method ensures that your chamois remains effective and visually appealing.

Scenario 3: Managing Inventory and Supply Chain Issues

The Problem: Companies that rely heavily on chamois for cleaning and detailing often face challenges in managing inventory levels. Fluctuations in demand, especially during peak seasons, can lead to stockouts or excessive stock. This not only disrupts operations but also affects service delivery and customer satisfaction. Additionally, sourcing high-quality chamois that meet specific performance criteria can be a challenge in various international markets.

The Solution: To effectively manage chamois inventory, businesses should adopt a data-driven approach by analyzing usage patterns over time. This can be achieved by tracking the frequency of chamois use in relation to business cycles and customer demand. Establish relationships with multiple suppliers to ensure a steady supply of high-quality chamois, and negotiate bulk purchasing agreements that can reduce costs. Furthermore, consider implementing a just-in-time inventory system that allows for more flexibility in stock levels without compromising on quality. By streamlining procurement processes and leveraging data analytics, businesses can ensure they always have the right amount of chamois on hand, thus enhancing operational efficiency and customer satisfaction.

Strategic Material Selection Guide for washing a chamois

What Materials Are Best for Washing a Chamois?

When it comes to washing a chamois, the choice of cleaning materials is critical to ensure the longevity and performance of the chamois. Below, we analyze four common materials used in the washing process, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Mild Liquid Soap

Key Properties: Mild liquid soaps are formulated to be gentle on materials while effectively removing dirt and oils. They typically have a neutral pH, which helps maintain the integrity of the chamois leather.

Pros & Cons: These soaps are widely available and cost-effective, making them an attractive option for businesses. However, they may not be as effective against heavy stains or grime, potentially requiring more frequent applications.

Impact on Application: Mild soaps are compatible with the delicate fibers of chamois, ensuring that the leather does not dry out or become brittle. However, they may not be suitable for industrial-scale operations where heavy-duty cleaning is necessary.

International Considerations: Buyers from regions like Africa and South America should ensure that the mild soaps comply with local regulations regarding chemical safety and environmental impact. Familiarity with ASTM or JIS standards can also guide selection.

2. Car Wash Soap

Key Properties: Specifically designed for automotive surfaces, car wash soaps often contain surfactants that lift dirt without harming wax or sealants. They usually perform well in various water temperatures.

Pros & Cons: Car wash soaps are effective for cleaning chamois and are designed to rinse easily, leaving no residue. However, they can be more expensive than generic soaps and may not be as readily available in some regions.

Impact on Application: These soaps are ideal for businesses focused on vehicle detailing, as they enhance the cleaning process without damaging the chamois. Their formulation ensures compatibility with automotive finishes.

Illustrative image related to washing a chamois

International Considerations: B2B buyers should verify that car wash soaps meet local standards and regulations, particularly in the Middle East and Europe, where environmental compliance is increasingly scrutinized.

3. Leather Cleaner

Key Properties: Leather cleaners are formulated to penetrate and clean leather fibers while maintaining moisture balance. They often contain conditioning agents that help preserve the leather’s suppleness.

Pros & Cons: While leather cleaners are excellent for maintaining the quality of chamois, they can be more expensive and may require specialized knowledge for proper use. Some formulations may not be suitable for all types of chamois.

Illustrative image related to washing a chamois

Impact on Application: Using a leather cleaner can enhance the lifespan of the chamois, making it a worthwhile investment for businesses prioritizing quality. However, improper use can lead to damage.

International Considerations: Buyers should ensure that leather cleaners comply with local regulations and standards, particularly in regions with strict chemical regulations, such as Europe and parts of the Middle East.

4. Soft Cloths and Sponges

Key Properties: Soft cloths and sponges are designed to be non-abrasive and highly absorbent, making them suitable for cleaning delicate surfaces like chamois.

Pros & Cons: These materials are inexpensive and readily available, providing a cost-effective solution for many businesses. However, they may need frequent replacement, which can increase long-term costs.

Illustrative image related to washing a chamois

Impact on Application: Soft cloths and sponges can effectively remove dirt and moisture from chamois without causing damage. However, they must be regularly cleaned to prevent cross-contamination.

International Considerations: Businesses in regions with varying access to quality cleaning materials should consider sourcing soft cloths and sponges that meet local standards for durability and performance.

Summary Table of Material Selection

| Material | Typical Use Case for washing a chamois | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Liquid Soap | General cleaning of chamois | Gentle on leather | May require multiple applications | Low |

| Car Wash Soap | Vehicle detailing | Effective and residue-free | Higher cost and availability issues | Medium |

| Leather Cleaner | Maintaining chamois quality | Preserves leather suppleness | More expensive and requires expertise | High |

| Soft Cloths/Sponges | Cleaning and drying chamois | Cost-effective and widely available | Frequent replacement needed | Low |

This strategic material selection guide provides B2B buyers with crucial insights into the best practices for washing a chamois, ensuring optimal performance and longevity while considering regional factors and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for washing a chamois

What Are the Key Manufacturing Processes for Chamois?

The manufacturing of chamois involves several critical stages that ensure the end product meets quality and performance standards. Understanding these processes is essential for B2B buyers looking to source high-quality chamois for their operations.

How Is Material Prepared for Chamois Production?

The first step in the manufacturing process is the preparation of the raw material, typically sheepskin or lambskin. The hides undergo a rigorous selection process to ensure only the best quality is used. This involves cleaning, soaking, and liming the hides to remove hair and prepare them for tanning.

Once cleaned, the hides are treated with tanning agents, which can be either vegetable-based or synthetic, depending on the desired characteristics of the final product. This tanning process is crucial, as it not only preserves the leather but also enhances its flexibility, softness, and durability.

What Techniques Are Used in Forming Chamois?

After the tanning process, the hides are cut into specific shapes and sizes to form chamois. This cutting is typically done using precision machinery to ensure uniformity and reduce waste.

The forming stage may also involve additional treatments, such as dyeing or conditioning, to enhance the color and texture of the leather. Some manufacturers may employ techniques like embossing to create a unique finish that adds aesthetic value while maintaining functionality.

How Is the Chamois Assembled and Finished?

Once the chamois pieces are cut, they are sewn or bonded together, depending on the design requirements. For high-quality chamois, hand-stitching is often preferred to ensure durability and performance.

After assembly, the chamois undergoes a finishing process that may include softening treatments and final quality checks. This stage is critical for ensuring that the chamois has the desired absorbency and softness, which are essential for its use in various applications, such as vehicle detailing or household cleaning.

What Quality Assurance Measures Are Essential for Chamois?

Quality assurance is a vital aspect of the manufacturing process that guarantees the chamois meets international standards. B2B buyers should be aware of the quality control protocols that suppliers implement to ensure product reliability.

What International Standards Should B2B Buyers Consider?

For chamois production, adherence to international standards such as ISO 9001 is crucial. This standard focuses on quality management systems and ensures that manufacturers consistently produce products that meet customer and regulatory requirements.

Additionally, specific certifications like CE (Conformité Européenne) may be relevant for products sold in Europe, while API (American Petroleum Institute) standards could apply to chamois used in industrial settings. Buyers should verify that their suppliers hold these certifications to ensure compliance with regional regulations.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral throughout the manufacturing process to identify and rectify defects early. Common checkpoints include:

Illustrative image related to washing a chamois

-

Incoming Quality Control (IQC): This stage verifies the quality of raw materials before they enter the production line. It ensures that only materials that meet specified standards are used.

-

In-Process Quality Control (IPQC): During production, IPQC monitors various parameters, such as dimensions and tanning quality, to ensure they meet predefined specifications.

-

Final Quality Control (FQC): This final stage assesses the finished chamois for performance characteristics like softness, absorbency, and absence of defects.

B2B buyers should inquire about the specific QC measures in place at their suppliers’ facilities to ensure that they receive a high-quality product.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure confidence in supplier quality, B2B buyers should take proactive steps to verify the effectiveness of quality control measures.

What Audit Processes Should Be Conducted?

Conducting regular audits of suppliers is an effective way to assess their manufacturing and quality assurance processes. Buyers can implement both scheduled and unscheduled audits to gain insight into the supplier’s operations.

During these audits, buyers should focus on evaluating the supplier’s adherence to international standards, their QC checkpoints, and the effectiveness of their quality management systems.

Illustrative image related to washing a chamois

What Documentation and Reporting Should Be Requested?

Buyers should request detailed documentation regarding quality control practices, including:

- Quality assurance reports

- Certificates of compliance with international standards

- Records of QC testing and inspection results

This documentation provides transparency and helps buyers make informed decisions about their suppliers.

What Testing Methods Are Commonly Used in Chamois Quality Control?

Various testing methods are employed to ensure that chamois meet performance standards. These may include:

-

Absorbency Tests: Assessing how much water the chamois can absorb, which is critical for its intended use.

-

Durability Tests: Evaluating the wear and tear of the chamois under various conditions to ensure longevity.

-

Chemical Resistance Tests: Ensuring that the chamois can withstand exposure to cleaning agents without degrading.

How Do QC Nuances Affect International B2B Buyers?

For B2B buyers operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control can significantly impact purchasing decisions.

What Regional Considerations Should Be Taken into Account?

Different regions may have varying standards and regulations for quality control. Buyers should familiarize themselves with local requirements to ensure compliance.

Additionally, cultural differences may affect expectations around quality and communication. Establishing clear communication channels and understanding regional nuances can enhance supplier relationships and ensure a smoother procurement process.

How Can Buyers Navigate Compliance Challenges?

To navigate compliance challenges effectively, B2B buyers should consider working with local consultants or industry experts who can provide insights into regional standards and regulations. This approach can help mitigate risks and ensure that all products meet the necessary quality benchmarks.

By understanding the manufacturing processes and quality assurance measures associated with chamois production, B2B buyers can make informed decisions that contribute to their operational success and enhance their product offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘washing a chamois’

To ensure the longevity and performance of a chamois, proper washing and maintenance are essential. This step-by-step guide serves as a practical checklist for B2B buyers who are looking to procure the best practices for washing a chamois effectively. Following these steps will help preserve the quality of the chamois, ensuring it meets operational needs while maximizing its lifespan.

Step 1: Understand the Material Composition

Before washing a chamois, it is crucial to understand its material—typically natural leather or synthetic. Knowing the type will dictate the appropriate cleaning methods.

- Natural Leather Chamois: Requires mild soap and careful handling to avoid damage.

- Synthetic Chamois: Generally more forgiving, but still requires specific detergents to maintain performance.

Step 2: Select Appropriate Cleaning Agents

Choosing the right cleaning agents is vital for maintaining the integrity of the chamois.

- Mild Car Wash Soap: Ideal for natural chamois to remove oils without stripping the leather.

- Avoid Harsh Chemicals: Steer clear of bleach, ammonia, or degreasers, as these can cause irreversible damage.

Step 3: Prepare Washing Equipment

Gather the necessary tools before beginning the washing process to streamline your efforts.

- Bucket: For mixing the soap and water solution.

- Soft Sponge or Cloth: To aid in gentle cleaning without causing abrasions.

- Clean Water Source: Ensure you have access to clean water for rinsing.

Step 4: Execute the Initial Soaking

Soaking the chamois is an essential first step to loosen dirt and grime.

- Warm Water: Use lukewarm water to effectively dissolve residues.

- Soaking Time: Allow the chamois to soak for 5-10 minutes to ensure thorough cleaning.

Step 5: Wash with Care

When washing the chamois, handle it gently to avoid damaging the fibers.

- Gentle Scrubbing: Use a soft sponge to work soap into the chamois without excessive force.

- Thorough Rinsing: Rinse multiple times until the water runs clear, indicating all soap has been removed.

Step 6: Drying Techniques

Proper drying is crucial to prevent mold and maintain the chamois’ texture.

- Air Dry Only: Hang the chamois in a shaded area to dry completely, avoiding direct sunlight which can cause brittleness.

- Avoid Mechanical Drying: Do not use a washing machine or tumble dryer, as this can damage the leather.

Step 7: Store Properly for Longevity

After washing and drying, how you store the chamois can significantly impact its lifespan.

- Cool, Dry Place: Store in an area free from moisture and heat to prevent deterioration.

- Avoid Plastic Bags: Never seal the chamois in airtight containers while damp, as this can lead to mold growth.

By following these steps, B2B buyers can ensure their chamois remains in optimal condition, contributing to effective cleaning and detailing processes across various applications. Proper care not only extends the life of the chamois but also enhances its performance, ultimately leading to better operational efficiency.

Comprehensive Cost and Pricing Analysis for washing a chamois Sourcing

What Are the Key Cost Components for Washing a Chamois?

Understanding the cost structure for washing a chamois involves several components that can significantly impact the overall pricing. The primary cost elements include:

-

Materials: The type of soap used for washing chamois is crucial. Mild soaps that maintain the leather’s integrity are preferred, avoiding harsh chemicals that can damage the material. The cost of these specialized soaps may vary based on local availability and quality.

-

Labor: Labor costs can fluctuate based on the geographical region and the expertise required for proper chamois care. Regions with higher labor costs may see a significant impact on the overall expense, while automated processes could reduce these costs but may require upfront investment.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses linked to the washing process. Efficient operations and economies of scale can help reduce these overhead costs.

-

Tooling and Equipment: Proper washing and drying equipment are necessary to ensure the longevity and performance of the chamois. This includes washing machines designed for delicate fabrics and drying racks that protect the material from sunlight damage.

-

Quality Control (QC): Implementing a robust QC process ensures that each chamois meets quality standards before and after washing. This process incurs additional costs but is essential for maintaining customer satisfaction.

-

Logistics: Transportation costs for sourcing materials and distributing washed chamois can vary widely, especially for international buyers. Factors such as distance, shipping method, and customs duties can influence these logistics costs.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. Understanding the supplier’s margin structure can provide insight into pricing flexibility during negotiations.

What Influences Pricing in the Chamois Washing Industry?

Several factors can influence the pricing of chamois washing services and products:

-

Volume/MOQ: Bulk orders generally lead to lower per-unit costs. Establishing a Minimum Order Quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom requests for specific cleaning processes or materials can lead to higher costs. Buyers should clearly communicate their needs to avoid unexpected pricing.

-

Quality and Certifications: Higher quality chamois or those with specific certifications may command a premium price. Buyers should consider the long-term benefits of investing in higher-quality products versus cheaper alternatives.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the shipping terms and responsibilities (Incoterms) is critical for international buyers. These terms can affect the total cost, including shipping, insurance, and tariffs.

What Tips Can Help Buyers Negotiate Better Prices for Chamois Washing?

-

Leverage Total Cost of Ownership (TCO): Buyers should evaluate the long-term value of purchasing higher-quality chamois, considering factors such as lifespan, maintenance costs, and performance. This analysis can justify higher upfront costs.

-

Negotiate with Clarity: Clearly outline expectations regarding quality, delivery timelines, and pricing to avoid misunderstandings. A well-defined scope of work can facilitate smoother negotiations.

-

Explore Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers can reduce logistics costs and lead times, creating a more favorable pricing structure.

-

Stay Informed About Market Trends: Keeping abreast of industry developments can provide insights into pricing fluctuations and help buyers time their purchases effectively.

-

Request Samples: Before committing to a large order, requesting samples can help assess quality and suitability, ensuring that the chosen supplier meets expectations.

Conclusion

While the costs associated with washing a chamois can vary widely based on multiple factors, understanding the cost components and pricing influencers can empower B2B buyers to make informed decisions. By leveraging effective negotiation strategies and focusing on the total cost of ownership, buyers can secure the best value for their investments.

Alternatives Analysis: Comparing washing a chamois With Other Solutions

When considering the maintenance of chamois cloths, it is crucial to evaluate alternative cleaning methods and solutions. This analysis provides insights into the effectiveness, costs, and practicality of washing a chamois compared to other cleaning approaches. The goal is to help B2B buyers make informed decisions that align with their operational needs.

| Comparison Aspect | Washing A Chamois | Microfiber Towels | Synthetic Chamois |

|---|---|---|---|

| Performance | High absorbency and gentleness on surfaces | Excellent cleaning power and versatility | Good absorbency but may leave lint |

| Cost | Moderate (initial purchase + soap) | Low (affordable and reusable) | Moderate (initial purchase) |

| Ease of Implementation | Requires specific washing instructions | Easy to wash and dry; machine washable | Easy to maintain, requires no special care |

| Maintenance | Regular washing needed to avoid deterioration | Minimal maintenance, machine wash | Low maintenance, no special care required |

| Best Use Case | Ideal for delicate finishes | Versatile for various applications | Suitable for quick drying tasks |

What are the advantages and disadvantages of using microfiber towels as an alternative?

Microfiber towels are an increasingly popular alternative due to their exceptional cleaning capabilities and ease of use. They excel in picking up dust and dirt without scratching surfaces, making them suitable for both automotive and household cleaning tasks. Additionally, microfiber towels are machine washable, which simplifies maintenance. However, they may not offer the same level of absorbency as a traditional chamois, particularly on delicate surfaces. Over time, they can also wear out and lose their effectiveness if not cared for properly.

How does a synthetic chamois compare to washing a traditional chamois?

Synthetic chamois provide a practical alternative, especially for those seeking a low-maintenance solution. They generally offer good absorbency and are designed to dry quickly, making them convenient for rapid drying tasks. Unlike natural chamois, synthetic options do not require special care, allowing users to wash them with regular laundry. However, they may not achieve the same level of softness and gentleness on surfaces as natural chamois, and they can leave behind lint or particles, which may affect the finish on high-end vehicles or delicate surfaces.

Conclusion: How can a B2B buyer choose the right cleaning solution for their needs?

When selecting the appropriate cleaning solution for chamois maintenance, B2B buyers should consider their specific use cases and operational requirements. If maintaining delicate finishes is a priority, traditional chamois washed correctly may be the best choice due to its superior absorbency and gentleness. On the other hand, if versatility and low maintenance are more critical, microfiber towels or synthetic chamois could be more suitable options. Ultimately, the decision should be based on balancing performance, cost, and ease of implementation to align with the buyer’s cleaning operations and objectives.

Illustrative image related to washing a chamois

Essential Technical Properties and Trade Terminology for washing a chamois

When engaging in the procurement and maintenance of chamois for automotive and household applications, understanding the essential technical properties and terminology is crucial for ensuring product quality and longevity. Below are key specifications and trade terms relevant to the washing of chamois, which can aid international B2B buyers in making informed decisions.

What Are the Key Technical Properties of Chamois Washing?

1. Material Grade

Chamois are typically made from natural sheepskin or synthetic alternatives. The material grade indicates the quality of the hide and its tanning process. High-grade chamois will exhibit superior absorbency and softness, making them effective for drying surfaces without scratching. For B2B buyers, investing in higher-grade chamois can result in longer-lasting products that require less frequent replacement.

2. Absorbency Rate

This property measures how much liquid the chamois can absorb relative to its weight. A higher absorbency rate means that the chamois can effectively dry surfaces more quickly. For businesses in car detailing or cleaning services, selecting chamois with optimal absorbency can enhance operational efficiency, reducing the time and effort required to complete tasks.

Illustrative image related to washing a chamois

3. Durability Specification

Durability refers to the lifespan of a chamois when subjected to regular use and cleaning. A durable chamois will resist cracking, splitting, or developing holes even after repeated wash cycles. Understanding durability specifications is vital for B2B buyers, as it impacts the total cost of ownership and maintenance schedules.

4. Chemical Resistance

Chamois are sensitive to harsh chemicals and detergents. Knowing the chemical resistance of a chamois helps businesses choose appropriate cleaning agents that will not degrade the material. This knowledge is critical to maintaining the integrity of the chamois, ensuring that it remains effective over time.

5. Tanning Process

The tanning process affects the softness, flexibility, and overall quality of the chamois. Vegetable tanning is commonly preferred for its eco-friendliness and ability to retain natural oils. Buyers should consider the tanning process when sourcing chamois, as it can influence both performance and environmental sustainability.

What Are Common Trade Terms Related to Chamois Washing?

1. OEM (Original Equipment Manufacturer)

In the context of chamois, OEM refers to products made by the original manufacturer of the chamois materials. Sourcing OEM products ensures that businesses receive high-quality goods that meet specific standards, which is essential for maintaining brand reputation in the market.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of chamois that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory costs and ensure that they are not overcommitting to stock that may not sell quickly.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products, such as chamois. By issuing an RFQ, businesses can compare prices and terms from multiple suppliers, helping them to secure the best deal for their procurement needs.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. For chamois procurement, understanding these terms is essential for determining shipping costs, risk management, and delivery timelines, ensuring that parties are clear on their obligations.

5. Lifespan

This term refers to the expected duration that a chamois can be effectively used before it needs replacement. B2B buyers should evaluate the lifespan of chamois when assessing cost-effectiveness and sustainability in their purchasing strategies.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their operational efficiency and product quality in the washing and maintenance of chamois.

Navigating Market Dynamics and Sourcing Trends in the washing a chamois Sector

What Are the Current Market Dynamics and Key Trends in the Washing a Chamois Sector?

The washing chamois sector is witnessing notable growth driven by increased consumer awareness regarding vehicle maintenance and care, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The global demand for quality cleaning products is on the rise, propelled by an expanding automotive industry and a growing emphasis on vehicle aesthetics. International B2B buyers are increasingly seeking high-performance, durable chamois materials that can withstand rigorous use while providing excellent absorbency and ease of maintenance.

Emerging technologies are reshaping the chamois sector, with innovations in synthetic materials and production processes enhancing product longevity and performance. For instance, the development of microfiber chamois is gaining traction due to their superior cleaning capabilities and reduced environmental footprint. Additionally, automation in manufacturing is streamlining supply chains, making it easier for international buyers to source high-quality products efficiently.

Moreover, the trend towards online purchasing is reshaping the sourcing landscape. B2B buyers are leveraging e-commerce platforms to connect with suppliers globally, allowing for increased competition and a broader selection of products. As buyers from regions like Saudi Arabia and Vietnam seek to optimize their procurement processes, understanding these market dynamics is crucial for making informed sourcing decisions.

Illustrative image related to washing a chamois

How Important Is Sustainability and Ethical Sourcing in the Washing a Chamois Sector?

Sustainability and ethical sourcing have become paramount considerations for B2B buyers in the washing chamois sector. The environmental impact of traditional chamois production, particularly those derived from animal hides, necessitates a shift towards more sustainable practices. This includes the use of eco-friendly tanning processes and sourcing materials from suppliers that adhere to ethical animal welfare standards.

The importance of ‘green’ certifications cannot be overstated, as they serve as a mark of quality and responsibility for international buyers. Certifications such as OEKO-TEX and GOTS (Global Organic Textile Standard) assure purchasers that the products meet stringent environmental and social criteria. B2B buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainability, which not only aligns with global environmental goals but also enhances brand reputation and consumer loyalty.

Furthermore, the demand for synthetic alternatives, such as microfiber chamois, is rising due to their lower environmental impact and superior performance characteristics. These materials are often more durable and require less frequent replacement, contributing to reduced waste. By investing in sustainable products, buyers can mitigate their environmental footprint while meeting the growing consumer demand for responsible sourcing.

What Is the Historical Context of the Washing Chamois Sector?

The washing chamois sector has evolved significantly over the past century. Initially crafted from animal hides, particularly from the chamois goat, these products were prized for their absorbency and softness. The traditional method of tanning leather was labor-intensive and often involved the use of harsh chemicals, raising concerns about environmental and ethical implications.

Illustrative image related to washing a chamois

The late 20th century saw a shift towards synthetic materials, driven by advancements in textile technology. Microfiber chamois emerged as a popular alternative, offering enhanced cleaning efficiency and ease of care. This shift not only transformed the product offerings but also addressed many of the environmental concerns associated with traditional leather chamois.

Today, the sector is marked by a blend of traditional craftsmanship and modern innovation, with an increasing focus on sustainability and ethical sourcing. As global markets continue to expand, the washing chamois sector is poised for further growth, reflecting changing consumer preferences and industry standards. International B2B buyers must stay informed about these historical trends to navigate the evolving landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of washing a chamois

-

1. How do I properly clean and maintain a chamois for optimal performance?

To maintain a chamois effectively, wash it in lukewarm water with a mild soap designed for vehicle care, avoiding harsh chemicals like bleach or ammonia. After washing, rinse thoroughly until the water runs clear, wring out excess moisture, and hang it to dry away from direct sunlight. This process not only extends the life of the chamois but also ensures it retains its absorbency and softness, crucial for maintaining quality finishes on vehicles. -

2. What is the best soap to use for washing a chamois?

The best soap for washing a chamois is a mild car wash soap. Avoid using laundry detergents or degreasing soaps, as these can strip essential oils from the leather, leading to brittleness and damage. Using a soap specifically designed for automotive care ensures that the chamois remains in optimal condition, allowing it to perform its drying and cleaning functions effectively. -

3. How can I ensure the quality of chamois suppliers in international trade?

When sourcing chamois from international suppliers, conduct thorough vetting by reviewing certifications, customer testimonials, and samples of their products. Request detailed product specifications and inquire about their manufacturing processes to ensure compliance with quality standards. Additionally, consider suppliers who provide a clear return policy and warranties, as these factors can indicate their commitment to quality. -

4. What are the common minimum order quantities (MOQs) for chamois products?

Minimum order quantities for chamois can vary widely depending on the supplier and the type of chamois. Typically, MOQs range from 100 to 1,000 units for bulk orders. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are testing a new market or product line. -

5. What payment terms are standard in B2B transactions for chamois?

Standard payment terms in B2B transactions for chamois often include options such as net 30, 60, or 90 days, depending on the supplier’s policies and the buyer’s creditworthiness. Some suppliers may require a deposit upfront, especially for large orders. It’s crucial to clarify payment terms before finalizing any agreements to ensure smooth financial transactions. -

6. How do I handle logistics and shipping when importing chamois?

When importing chamois, collaborate with a reliable logistics provider who understands international shipping regulations and can manage customs clearance efficiently. Ensure that you have a clear shipping plan, including choosing between air or sea freight, based on your budget and urgency. Always factor in lead times and potential delays to maintain inventory levels. -

7. What quality assurance measures should I consider when sourcing chamois?

Implement quality assurance measures by requesting product samples before placing bulk orders. Establish clear quality standards and inspection processes with your supplier, including criteria for texture, absorbency, and durability. Regularly audit suppliers and consider third-party inspections to maintain high product quality and ensure compliance with international standards. -

8. Can I customize chamois products to fit specific market needs?

Yes, many suppliers offer customization options for chamois products, including size, color, and packaging. Discuss your specific market requirements with potential suppliers to explore available customization options. Customization can enhance your product’s appeal in local markets, allowing for better alignment with consumer preferences and brand positioning.

Top 7 Washing A Chamois Manufacturers & Suppliers List

1. Tanner’s Select – Chamois Care Instructions

Domain: tannersselect.com

Registered: 2017 (8 years)

Introduction: Proper care and maintenance of a chamois extends its life and performance. Instructions are included on product packaging. Before first use, wash the chamois in lukewarm water with mild car soap to remove residual tanning oils. Avoid degreasing soaps, harsh chemicals, or laundry detergents. Rinse until water is clear, then use or dry in the shade. To use, rinse and wring out the chamois before dry…

2. Chamois Leather Shammy – Cleaning Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Chamois Leather Shammy, used for bowling, has a distinct factory/chemical smell when new. Cleaning suggestions include using Dawn dish soap and hot water, working the shammy thoroughly, and air drying. Some users recommend using a microfiber cloth as an alternative. Others suggest washing it in a washing machine and air drying. A few users humorously mention using Febreeze or cologne to mask the s…

3. PeachParts – Leather Chamois Care

Domain: peachparts.com

Registered: 2009 (16 years)

Introduction: Leather chamois should be cleaned with mild soap or liquid dish soap. For stubborn stains, work soap directly into the chamois fibers. Rinse thoroughly after cleaning. It is recommended to wash the chamois in warm water and mild soap for 3 to 4 minutes. The chamois should be used only after the car has been washed thoroughly to avoid scratching the paint. New leather chamois should be washed to re…

4. Meguiar’s – Natural & Synthetic Chamois Care

Domain: meguiarsonline.com

Registered: 2003 (22 years)

Introduction: Natural leather chamois requires storage in airtight containers to prevent it from turning hard and smelling bad. It should be rinsed and hung to dry completely before storage. Synthetic chamois are easier to care for and can be hung to dry, regaining softness after soaking. Some users recommend microfiber drying towels as a superior alternative to chamois, citing ease of care and better results.

5. AutoGeek – Synthetic Chamois & Microfiber Drying Towel

Domain: autogeekonline.net

Registered: 2006 (19 years)

Introduction: 1. Synthetic Chamois: Mentioned as a type of chamois used for drying cars, specifically a ‘black magic chamois’ similar to the Absorber. 2. Microfiber Waffle Weave Drying Towel: Recommended as a safer alternative to chamois, machine washable, does not trap debris, and can be washed with anti-bacterial wash. 3. The Ultimate Guzzler Waffle Weave Microfiber Drying Towel: Described as pricey but worth…

6. BikeForums – Shower Gear Tips

Domain: bikeforums.net

Registered: 2001 (24 years)

Introduction: This company, BikeForums – Shower Gear Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Pistonheads – Chamois Leather Care Guide

Domain: pistonheads.com

Registered: 1999 (26 years)

Introduction: Chamois leather cleaning methods discussed include: 1. Using washing up liquid with plenty of rinses and drying. 2. Avoiding detergents as they can wash out oils and shorten the chamois’ useful life. 3. Using a cleaner/conditioner specifically for leather seats, such as Autoglym. 4. Some users prefer to buy a new chamois instead of cleaning it. 5. A method involving laying the chamois on a pre-cle…

Strategic Sourcing Conclusion and Outlook for washing a chamois

In summary, effective chamois maintenance is essential for maximizing the lifespan and performance of this versatile tool, particularly in sectors such as automotive detailing and cleaning services. Key takeaways include the importance of using mild, vehicle-specific soaps for washing, avoiding harsh chemicals, and implementing proper drying and storage techniques. By adhering to these practices, businesses can ensure that their chamois remains soft, durable, and free from streaks or damage, ultimately enhancing the quality of service provided to customers.

Strategic sourcing of high-quality chamois products, aligned with best practices in care and maintenance, can lead to significant cost savings and improved operational efficiency. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe evaluate their suppliers, prioritizing partnerships with manufacturers who emphasize quality and sustainability will be paramount.

Looking ahead, as the demand for eco-friendly and effective cleaning solutions continues to grow, now is the time for businesses to invest in premium chamois products. By doing so, they can not only elevate their service offerings but also position themselves as leaders in sustainable practices within the industry. Engage with trusted suppliers today to secure your competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.